Testing and measurement method for hardening curve of metal bar under large strain range

A hardening curve and measurement method technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of cumbersome measurement links, high calculation costs, hardening, etc., and achieve simple and feasible operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

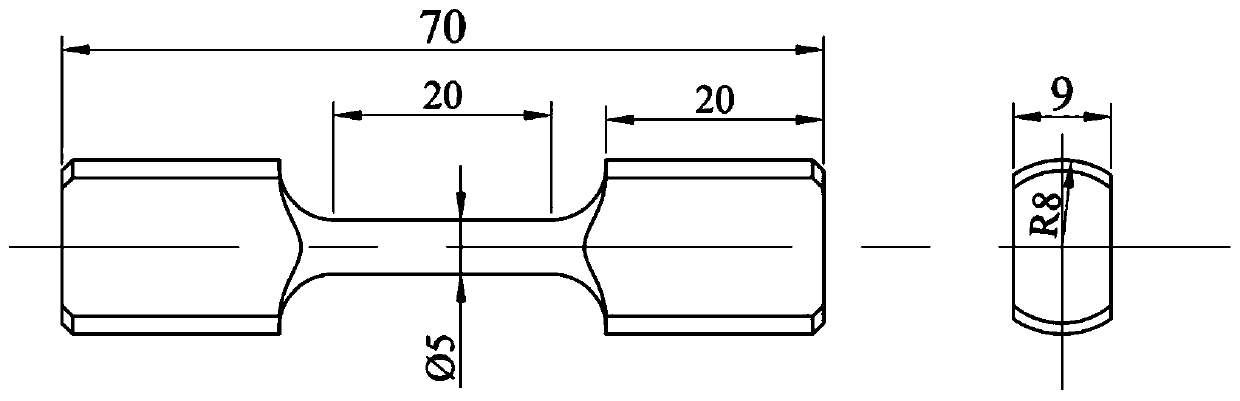

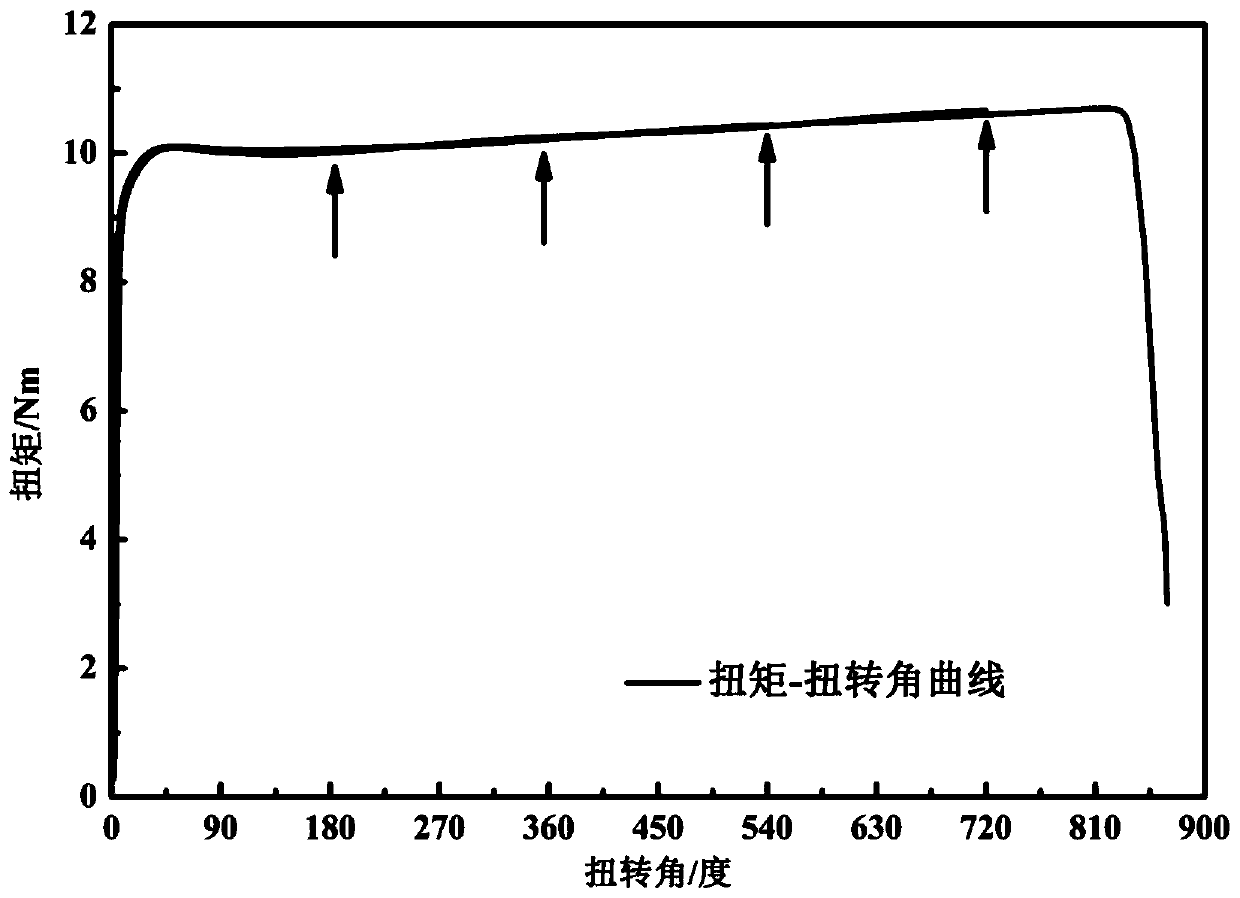

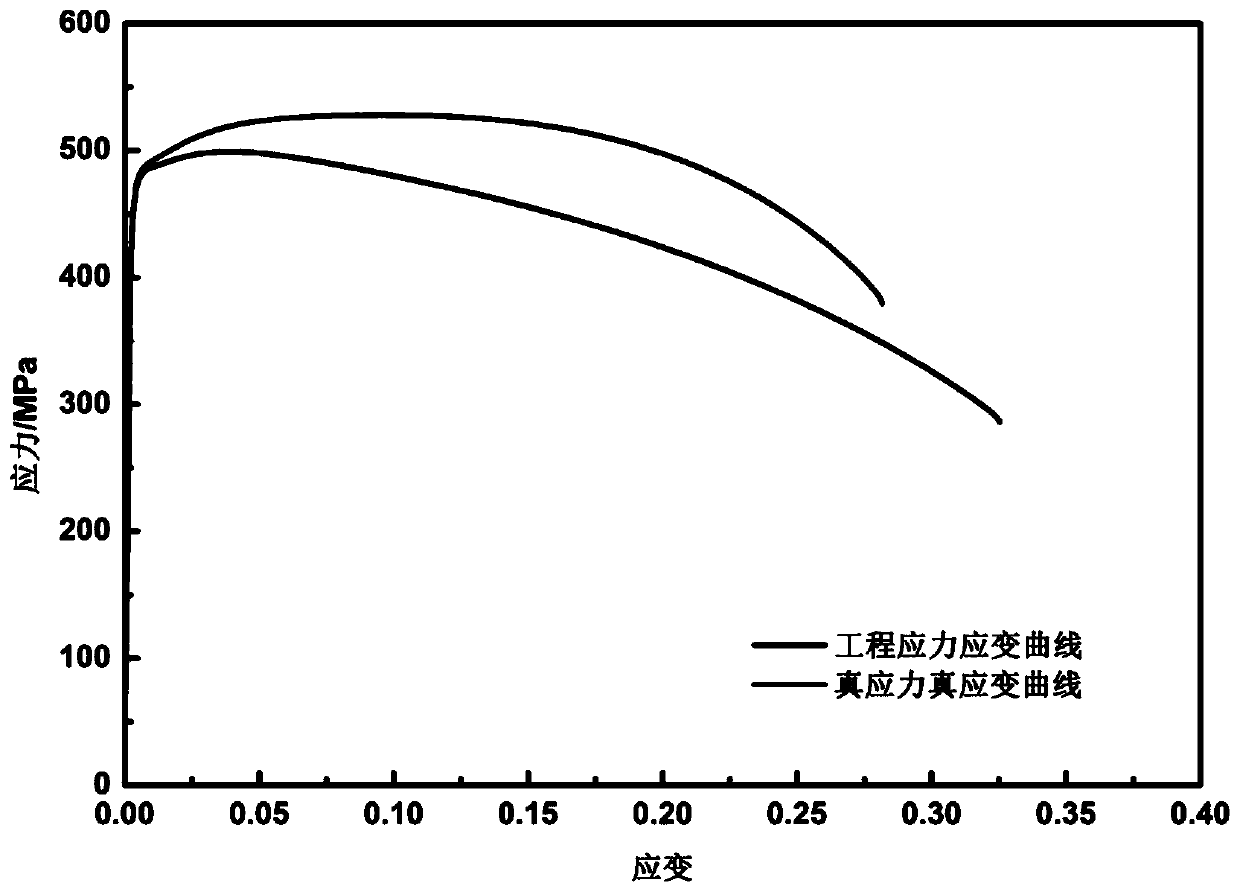

[0032] (1) The present invention takes the low-carbon steel Q345 round bar sample as an example to specifically illustrate the implementation process of the present invention's scheme. The round bar sample parallel section cross-sectional diameter is 5mm, and the gauge length section is 20mm. The specific details are as follows: figure 1 shown. Firstly, the torsional pre-strain test of the round bar sample is carried out. The sample needs to be torsion until it breaks. The torque torsion angle recorded in the torsion experiment is as follows: figure 2 As shown, it is finally determined that the maximum torsion angle before the material fractures is 840 degrees (4.66πrad). Since the tensile test is required after the sample is twisted, the pre-torsion angle must be an integer multiple of πrad in order to clamp the sample on the tensile machine, so the subsequent round bar samples are twisted to πrad, 2πrad, 3πrad respectively , 4πrad, the corresponding prestrain ε pre Calcul...

Embodiment 2

[0050] (1) The present invention takes the brass alloy H62 round bar sample as an example to specifically explain the implementation process of the present invention's scheme. The diameter of the cross-section of the parallel section of the round bar sample is 5mm, and the gauge length section is 20mm. The specific details are as follows: figure 1 shown. Firstly, the torsional pre-strain test of the round bar sample is carried out. The sample needs to be torsion until it breaks. The torque torsion angle recorded in the torsion experiment is as follows: Figure 8 As shown, it is finally determined that the maximum twist angle before the material fractures is 600 degrees (3.33πrad). Since the tensile test is required after the sample is twisted, the pre-torsion angle must be an integer multiple of πrad in order to clamp the sample on the tensile machine, so the subsequent round bar samples are twisted to πrad, 2πrad, 3πrad respectively , the corresponding prestrain ε pre Calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com