Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72 results about "Test coupon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coupon or test coupon is a printed circuit board (PCB) used to test the quality of a printed wiring board (PWB) fabrication process. Test coupons are fabricated on the same panel as the PWBs, typically at the edges.

Corrosion monitoring

InactiveUS6077418AEasy monitoring (observation)Accurate monitoringWeather/light/corrosion resistanceResistance/reactance/impedenceTest couponMaterials science

Corrosion of a metal member under heat transfer condition is monitored by using a test coupon made of the same material as that of the metal member. The test coupon may have a welded portion and a crevice. One substantial surface of the test coupon is heated by a sheet shaped heating element, and at least one portion of the other surface of the test coupon is contacted with the corrosive fluid. After detecting a status of corrosion of the test coupon, the corrosion of the metal member is monitored based on the results of the detection. In case a counter electrode or reference electrode is used, the electrode is immersed in the corrosive fluid, and electrical signals between the test coupon and the electrode are measured. Then, the corrosion of the metal member is monitored.

Owner:KURITA WATER INDUSTRIES LTD

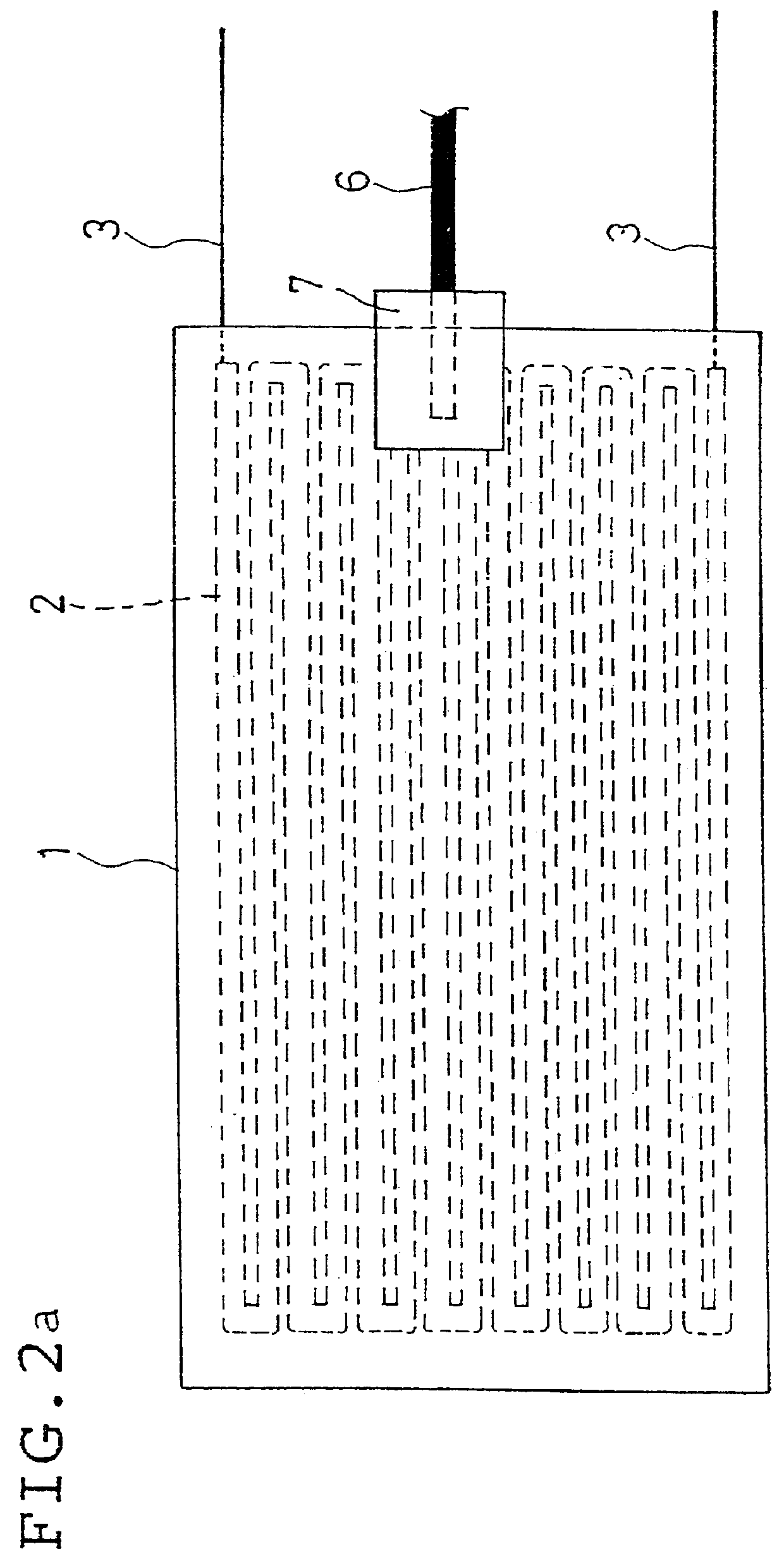

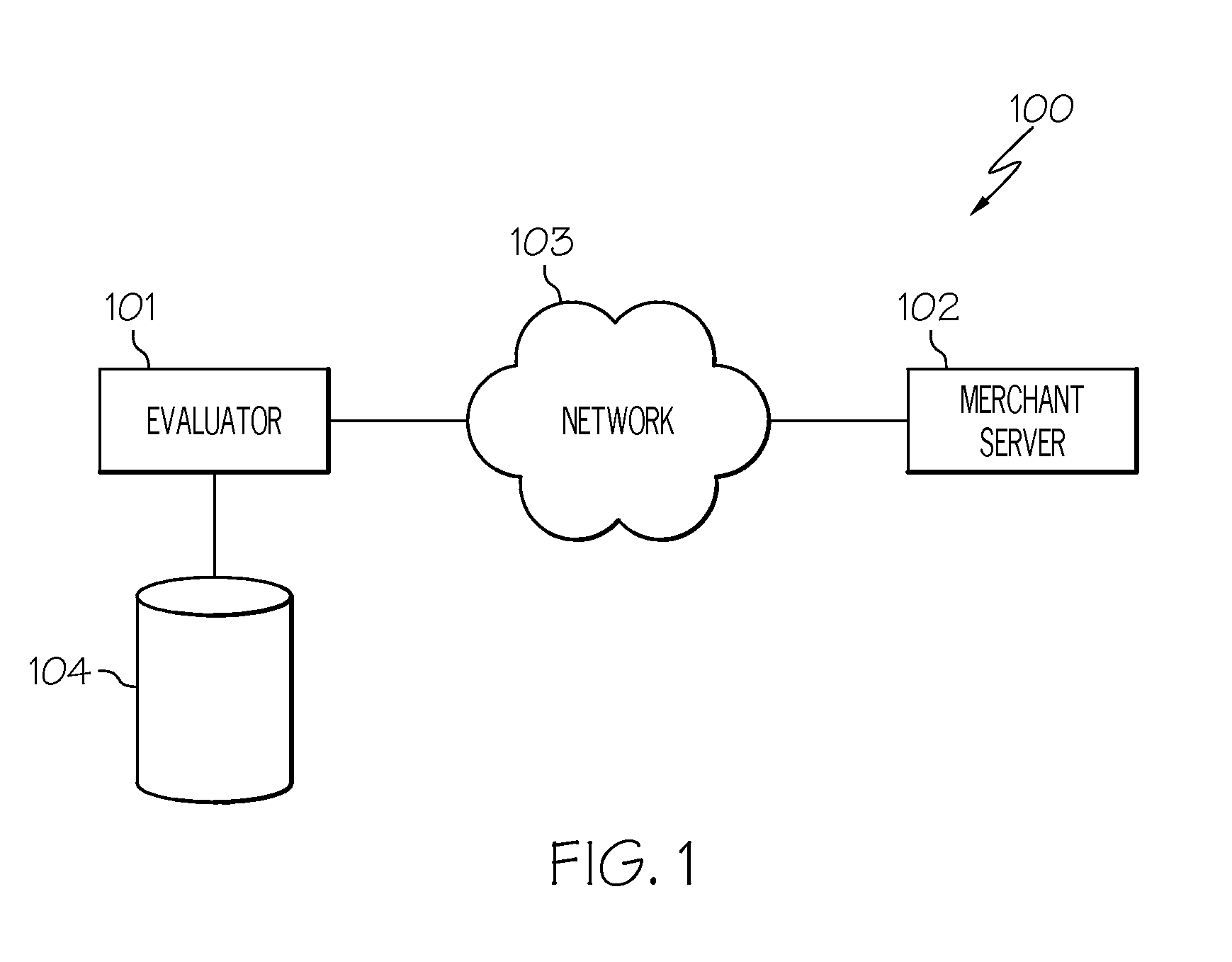

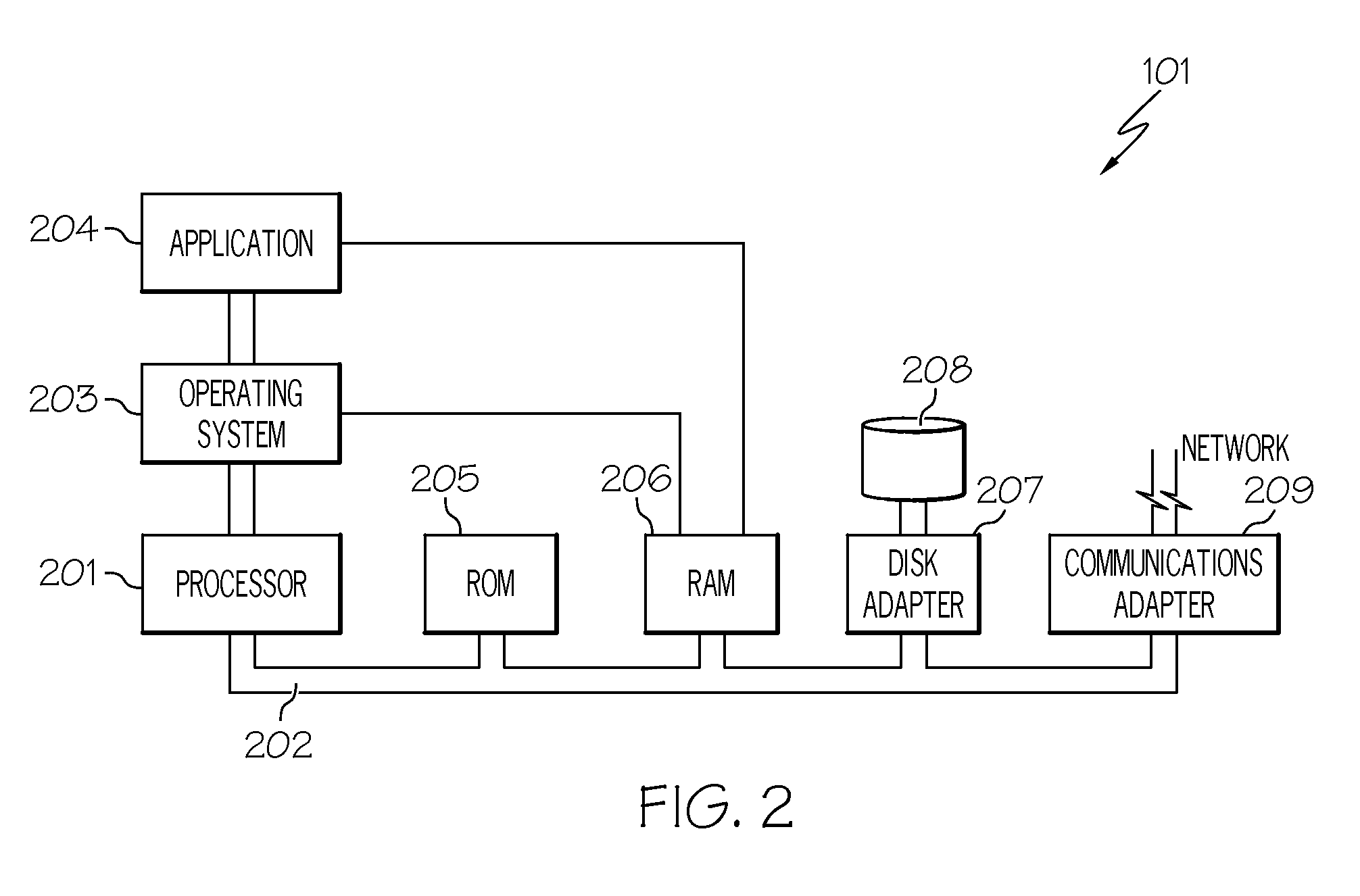

Testing the validity of electronic coupon codes

A system and computer program product for testing the validity of coupon codes. Coupon codes can be automatically tested, instead of manually testing them, by having a program select one or more products on a merchant's website and then add them to the shopping cart on the merchant's website. Upon entering the checkout stage on the merchant's website, the program can submit the coupon code to be tested at the checkout stage. The validity of the coupon code is determined based on the status of the coupon code (e.g., expired, approved advertised benefit) returned by the merchant's website. By having a program automatically test coupon codes instead of having a user manually test each coupon code, the validity of coupons code can be more accurately determined in a more efficient manner.

Owner:INTERNET BRANDS

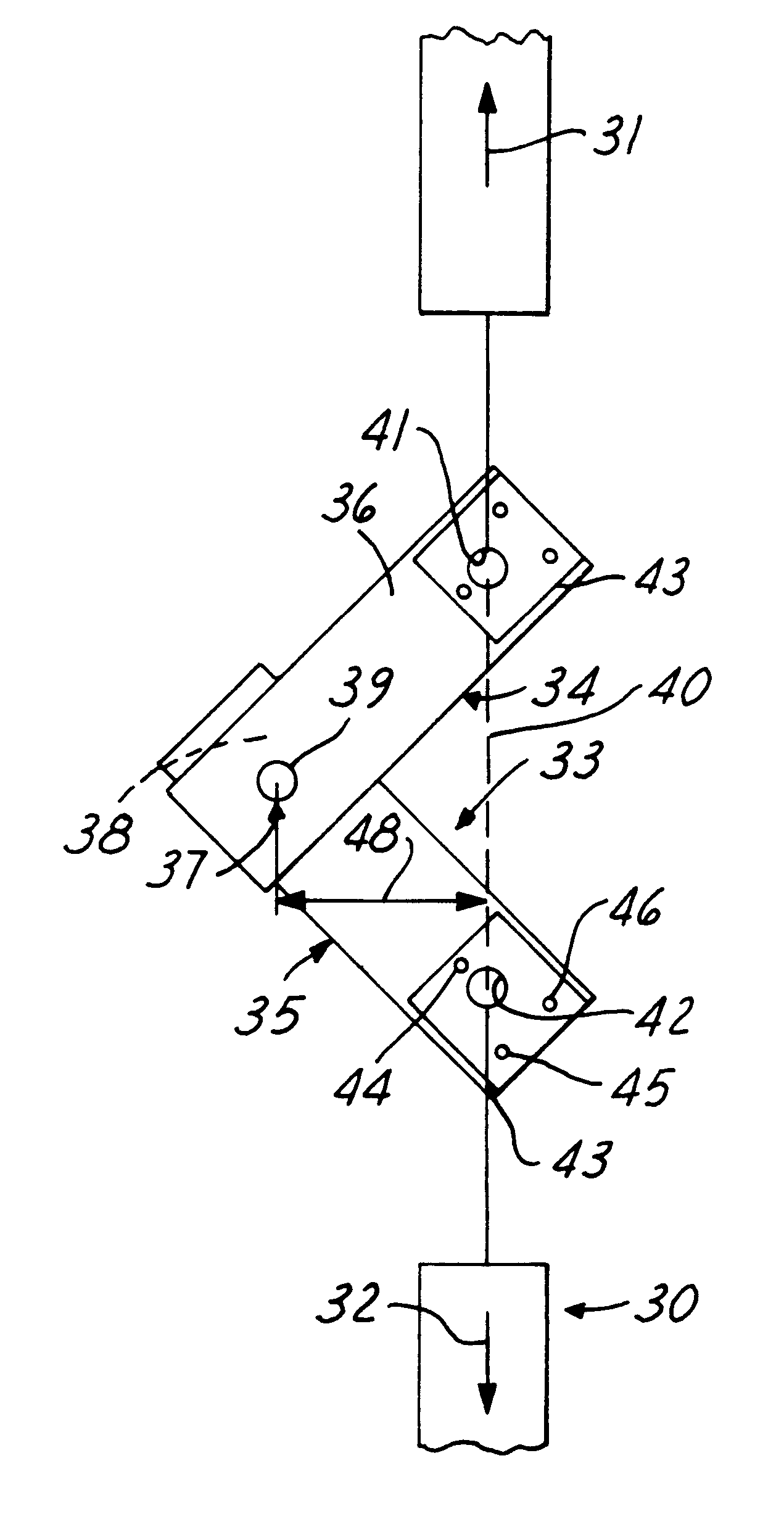

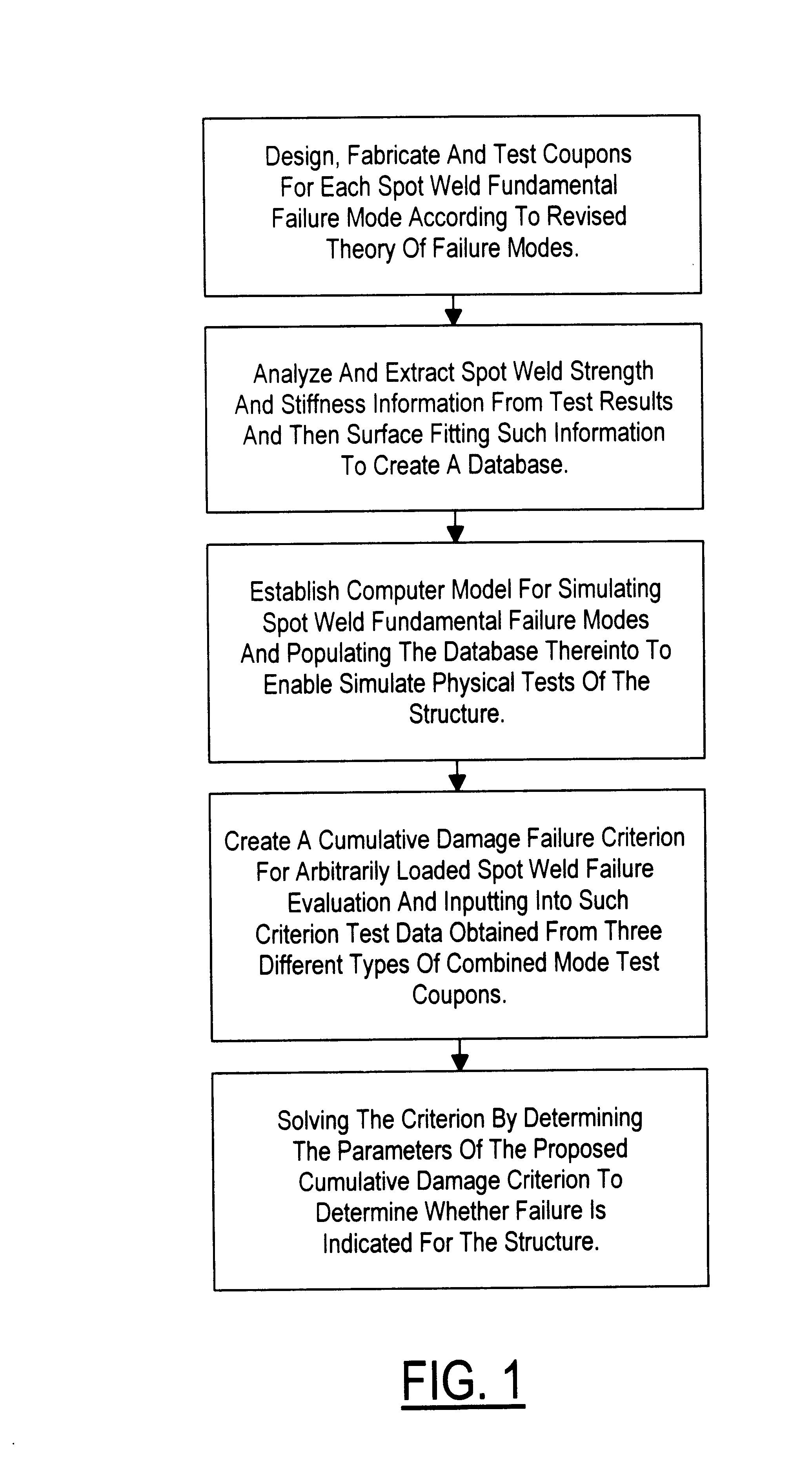

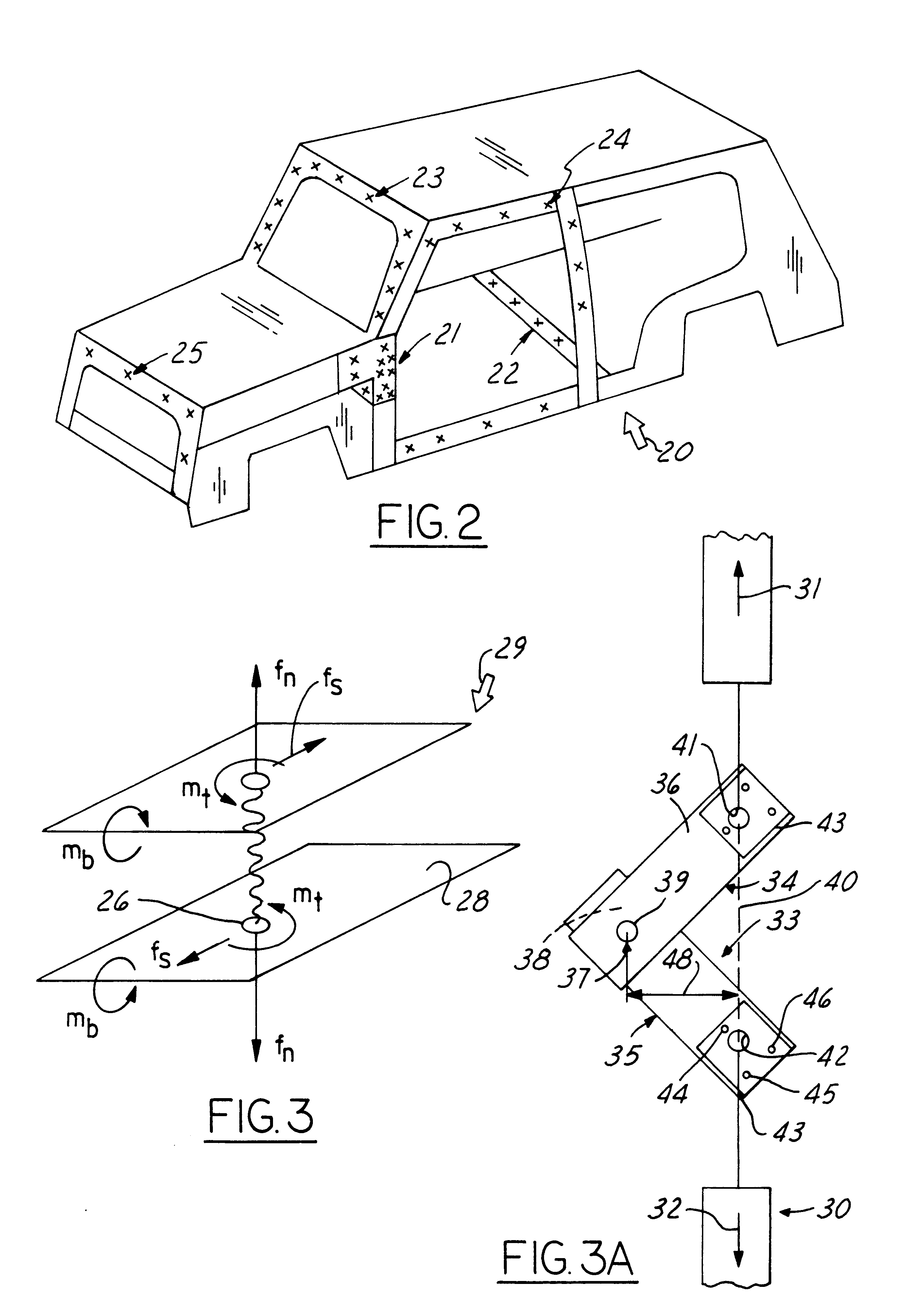

Method of analyzing spot welded structures

InactiveUS6186011B1Improve accuracyMaterial strength using steady bending forcesResistance welding apparatusIn planeMathematical model

Method of analyzing spot welded sheet metal structures subjected to forces that promote one or more basic failure modes of either shear tension, in-plane rotation, coach peel, normal tension, or any combination of such basic modes, the method comprising: (i) providing spot welded sheet metal test coupons for analysis of the selected failure mode for the structure to be analyzed and subjecting such test coupons to progressively increasing forces that eventually achieve failure in the selected failure mode to thereby generate measured load and displacement test data; (ii) analyzing the data from the basic modes to derive and extract spot weld strength and stiffness information and then surface fitting such extracted data to create a database; (iii) establishing a computer math model for simulating the spot weld failure modes of the structure and populating the database thereinto to enable simulated physical tests of the structure; (iv) creating a cumulative-damage failure criterion for the spot welded structure that ratios (a) the resultant strength information from the populated math model for selected combinations of load and selected combinations of time and structure thickness, and (b) the measured strength information derived for such combinations of load derived from the test data; and (v) solving the criterion to determine whether it indicates failure for the combination of resultant strength and other values selected.

Owner:FORD GLOBAL TECH LLC

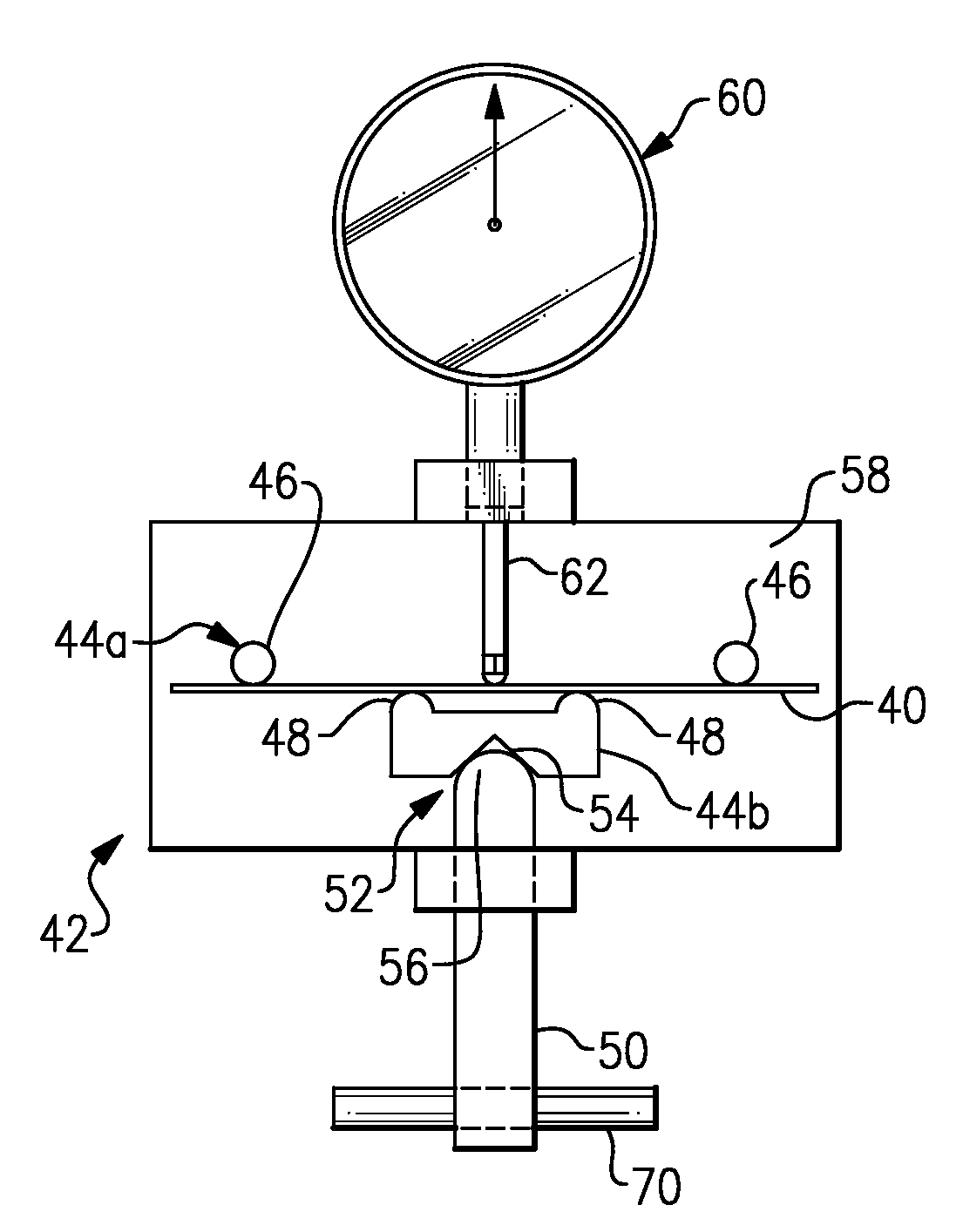

Corrosion monitoring station

A corrosion monitoring station for a water-based fire protection system which allows for test coupons to be removed without having to drain the system. The corrosion monitoring station also generally provides for mimicking of the conditions present in at least a portion of the water-based fire protection system and can provide for a portion of the system which can be easily removed for more extensive testing.

Owner:NAT CITY BANK CO

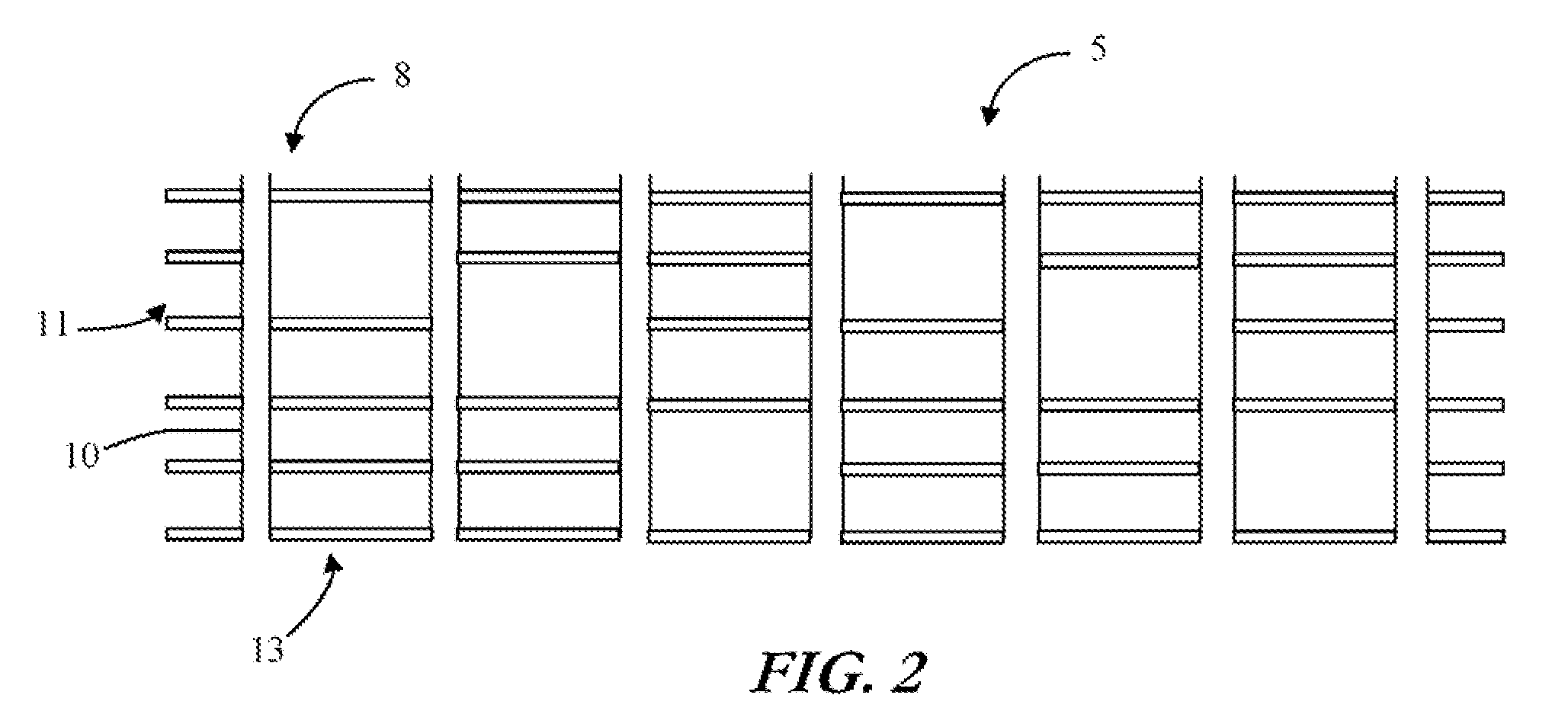

Combination Impedance/Back Drill Coupon

ActiveUS20080087461A1Printed circuit assemblingPrinted electric component incorporationTest couponEngineering

A test coupon on a printed circuit board used for verifying that vias in the printed circuit board are back drilled to a proper predetermined depth. Use of the coupon involves correlating a via on the board to a via of a test coupon drilling the board via and the test coupon via to substantially the same depth, where the depth is predetermined based on the board via. Then measuring the impedance of the test coupon to reveal the actual depth of the back drilling of the coupon via. Knowing the actual back drill depth of the coupon via is used to verify the back drill depth of the board via.

Owner:DELL PROD LP

Method of processing a circuit board

ActiveUS7676920B2Printed circuit assemblingElectrical measurement instrument detailsTest couponPrinted circuit board

A test coupon on a printed circuit board used for verifying that vias in the printed circuit board are back drilled to a proper predetermined depth. Use of the coupon involves correlating a via on the board to a via of a test coupon drilling the board via and the test coupon via to substantially the same depth, where the depth is predetermined based on the board via. Then measuring the impedance of the test coupon to reveal the actual depth of the back drilling of the coupon via. Knowing the actual back drill depth of the coupon via is used to verify the back drill depth of the board via.

Owner:DELL PROD LP

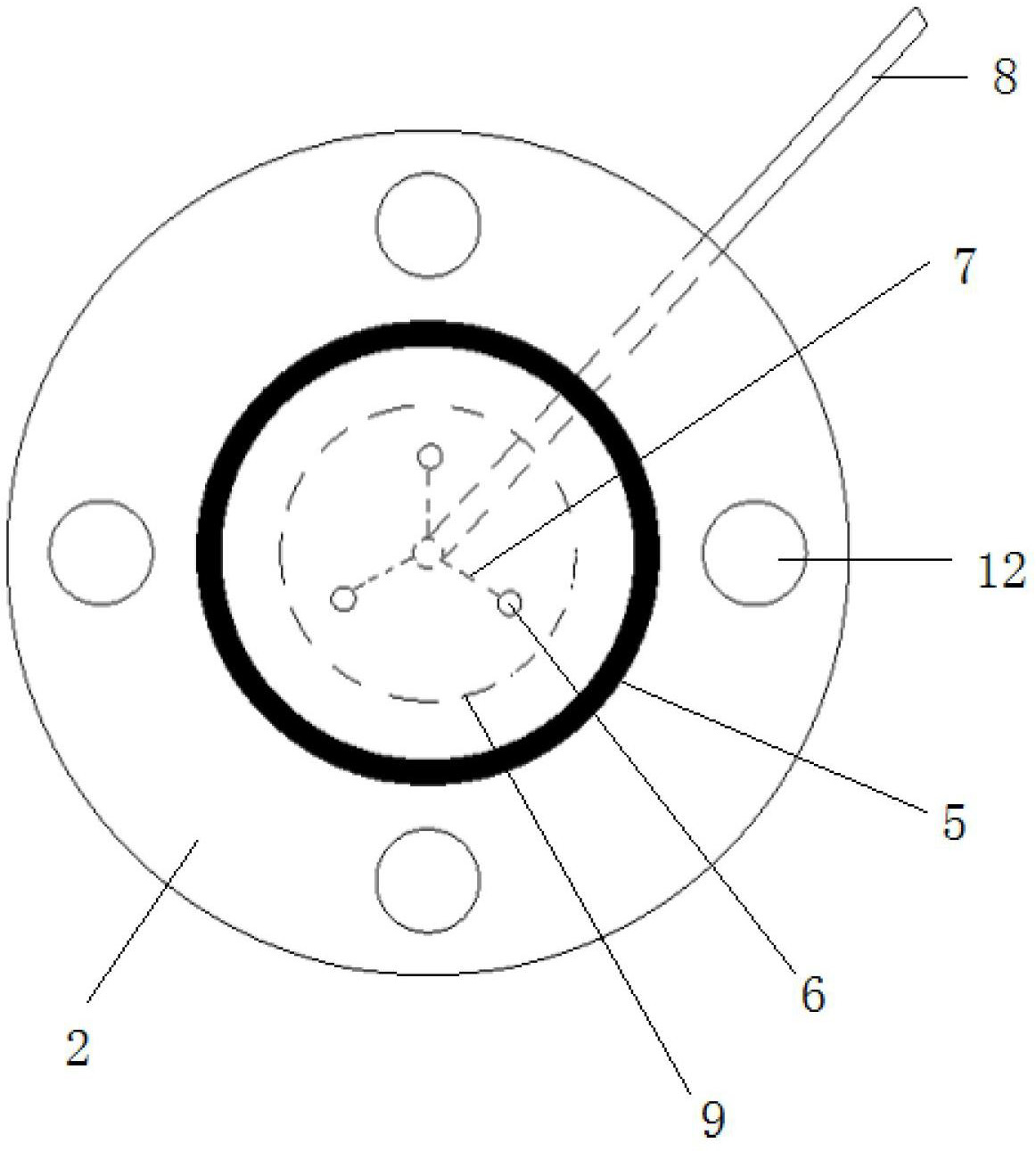

Under-deposit corrosion experiment bracket and method for experimenting by using same

ActiveCN102680382ASolve the problem of poor reliability of research resultsReliable experimental methodWeather/light/corrosion resistanceElectricityTest coupon

The invention relates to an under-deposit corrosion experiment bracket and a method for experimenting by using the same, relating to the technical field of corrosion testing. The under-deposit corrosion experiment bracket comprises a bracket panel and a bracket base, wherein outer edges of the bracket panel and the bracket base are provided with fixing holes which are opposite in position, the bracket panel and the bracket base are connected and fixed through fixing members arranged in the fixing holes, the bracket panel is provided with a working electrode hole the diameter of which is equal to that of a working electrode, a panel groove is arranged around the working electrode hole and is internally provided with an O-shaped panel ring, a base groove is arranged in the bracket base, an O-shaped base ring is arranged in the base groove, three electric contacts are arranged on positions on the bracket base, which are positioned in the circumference of the inner diameter of the O-shaped base ring; lower ends of the electric contacts are inserted to the tops of electric contact supports; and a lead groove is arranged in the bracket base, and electric leads are arranged on the electric contact supports. The method can be used for carrying out electrochemical corrosion testing, corrosion weight loss measurement and surface appearance observation on the same corrosion test coupon, and is suitable for simulation study on electrochemical corrosion and under-deposit corrosion.

Owner:CHINA PETROLEUM & CHEM CORP +1

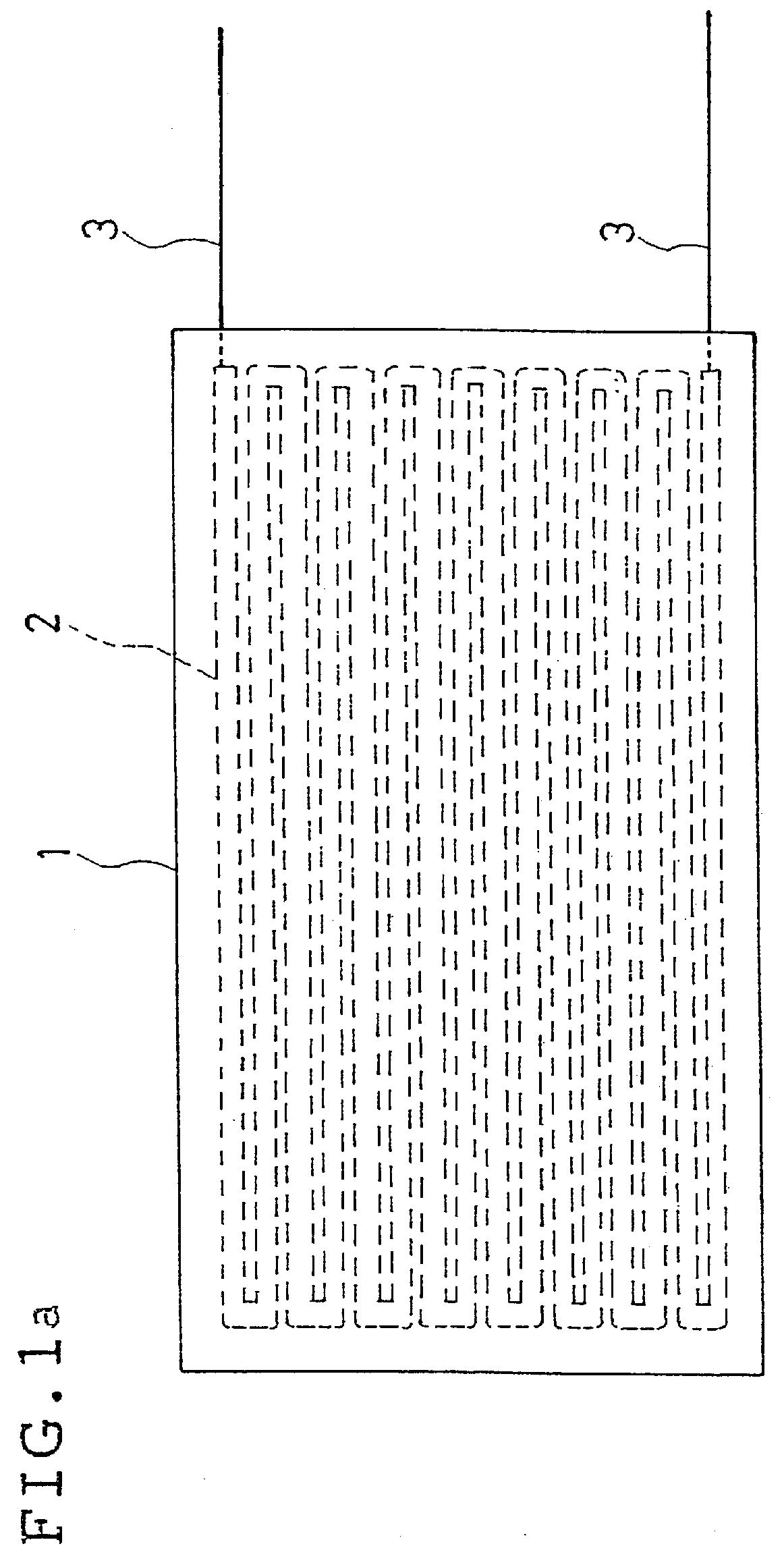

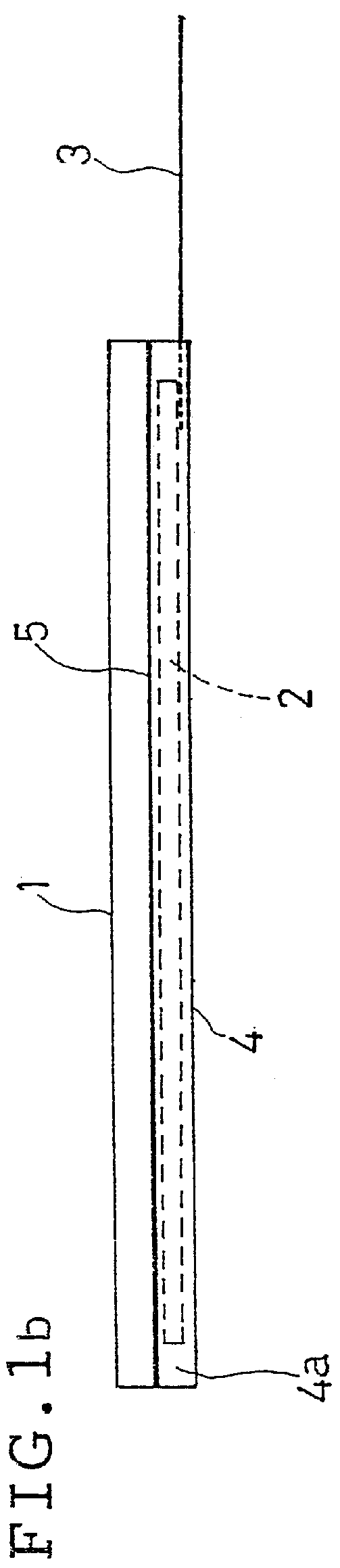

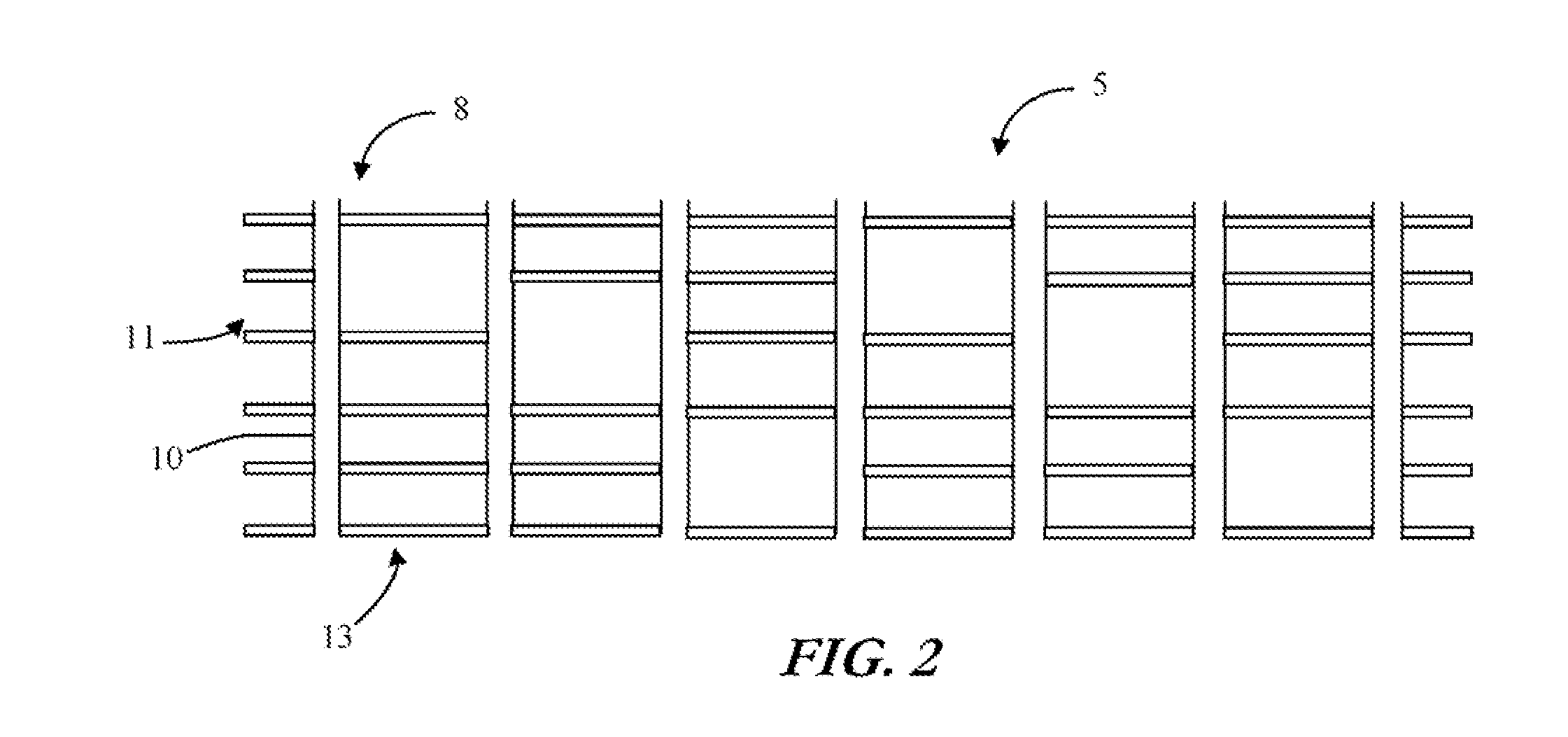

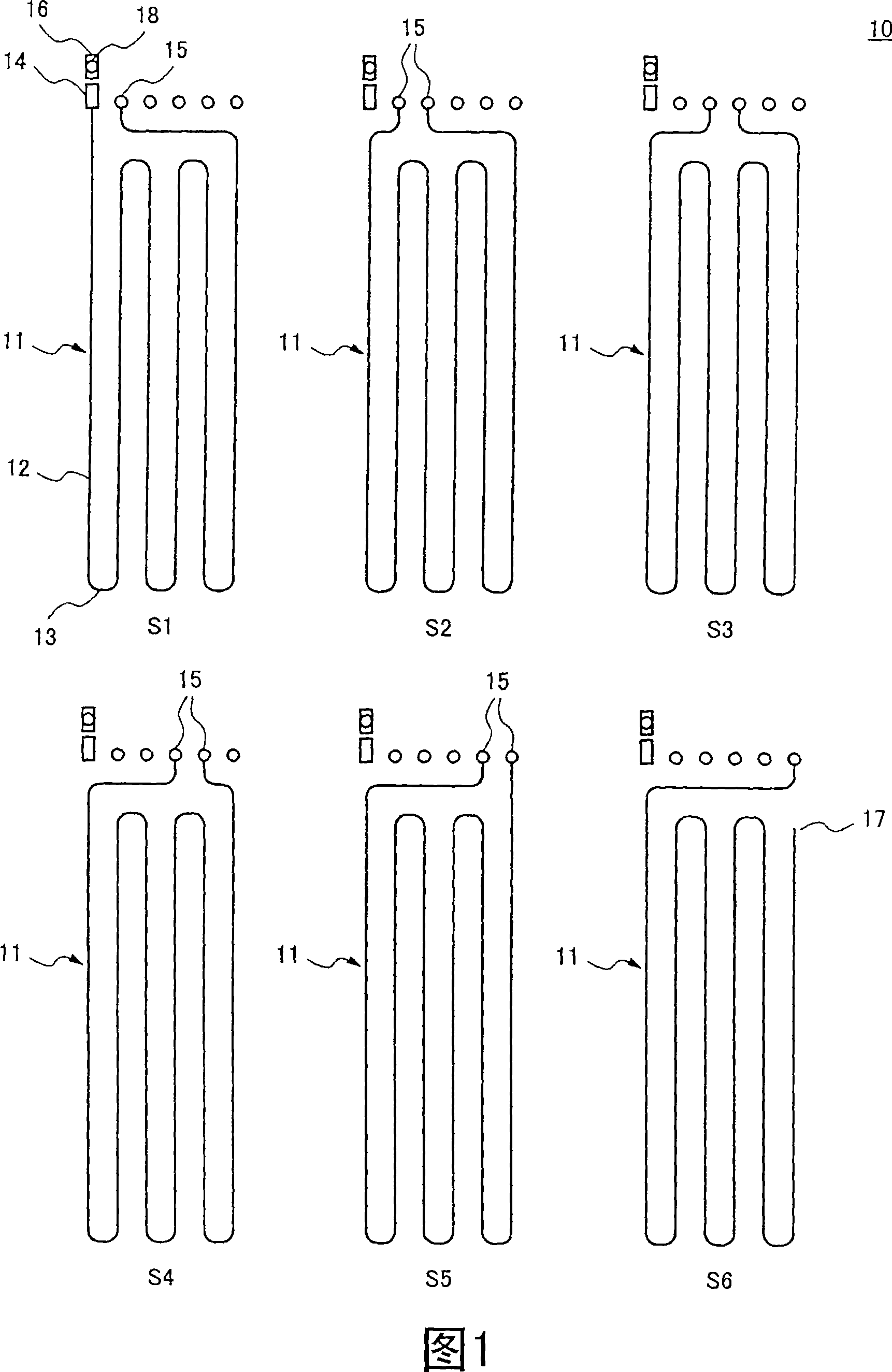

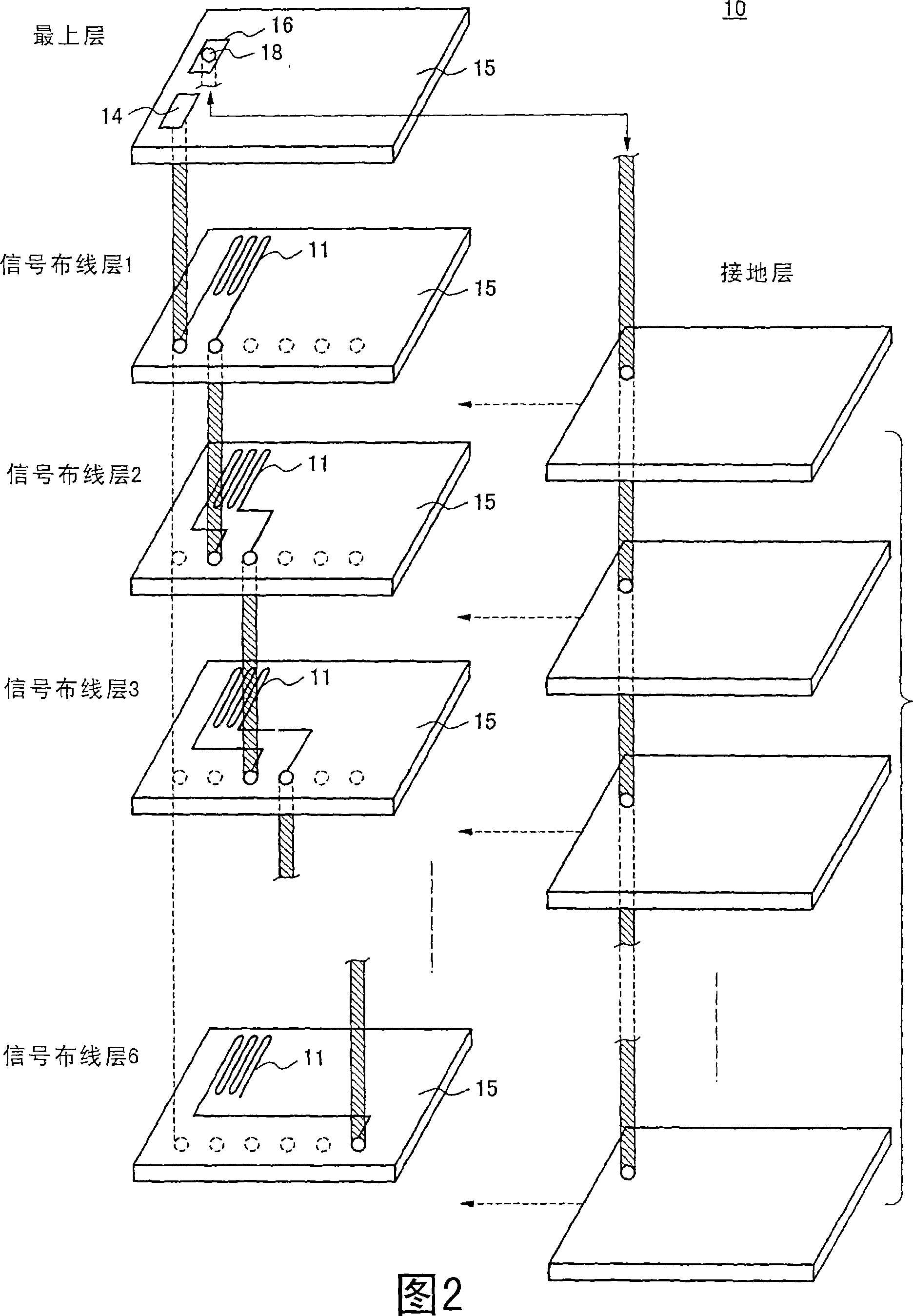

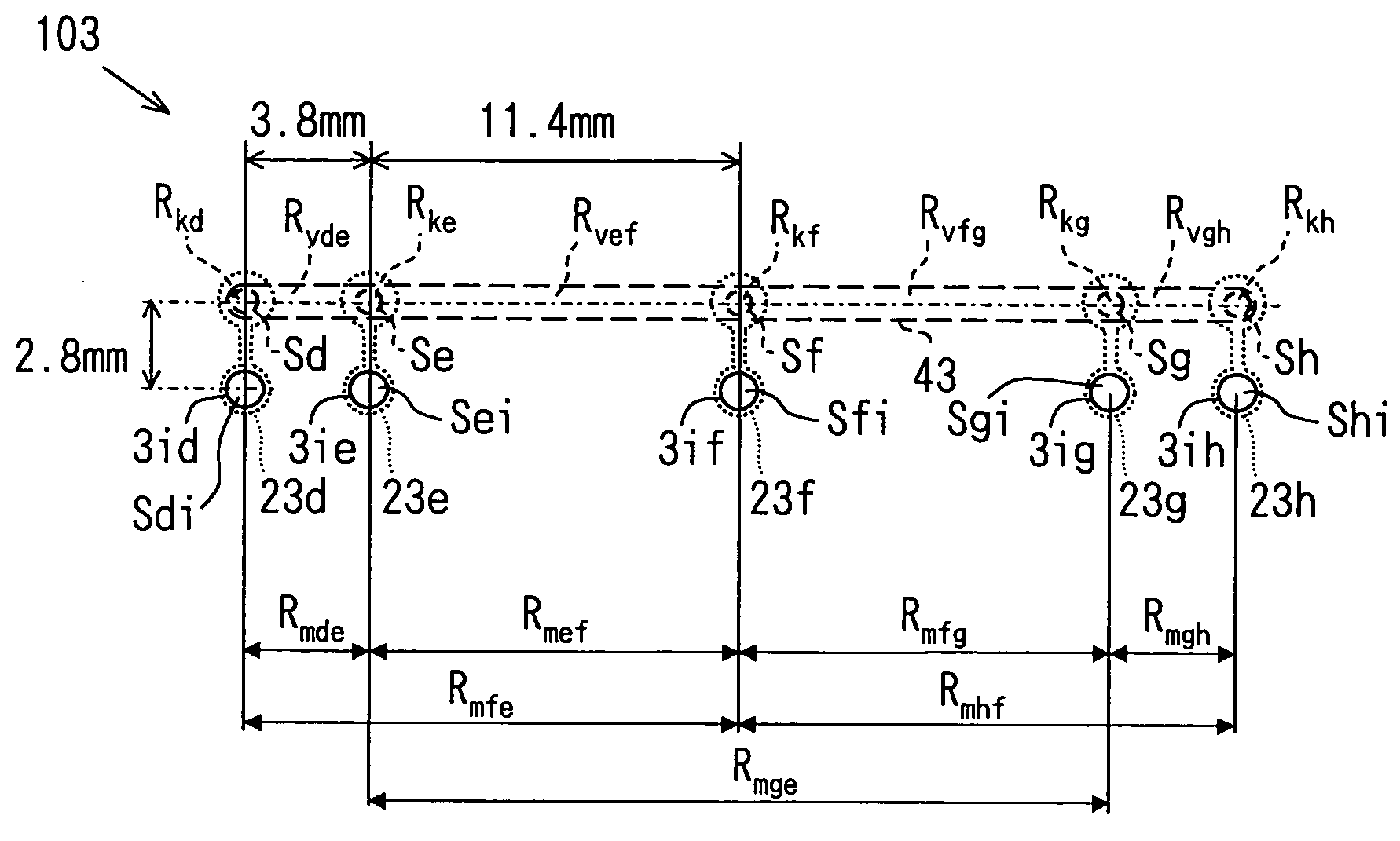

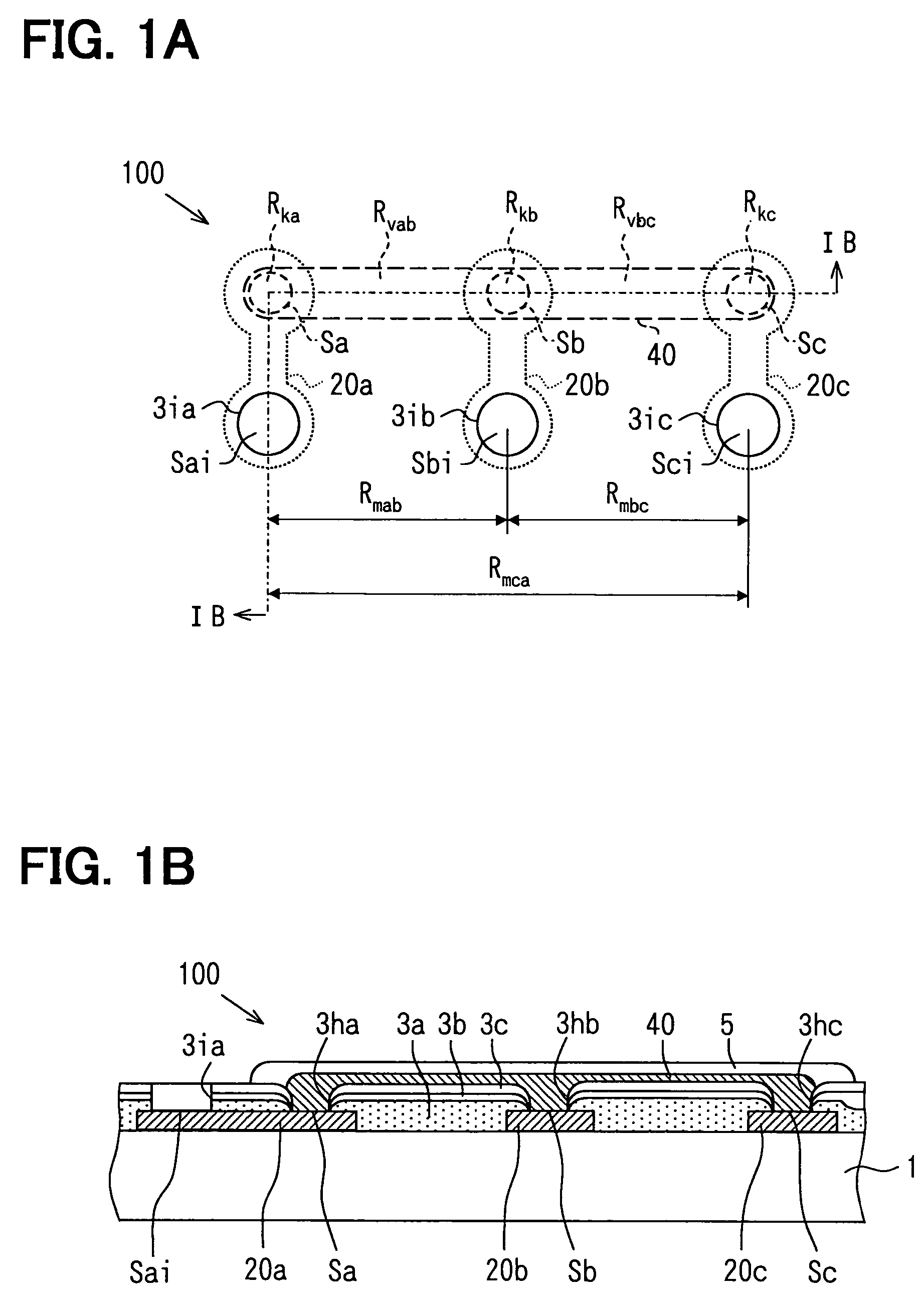

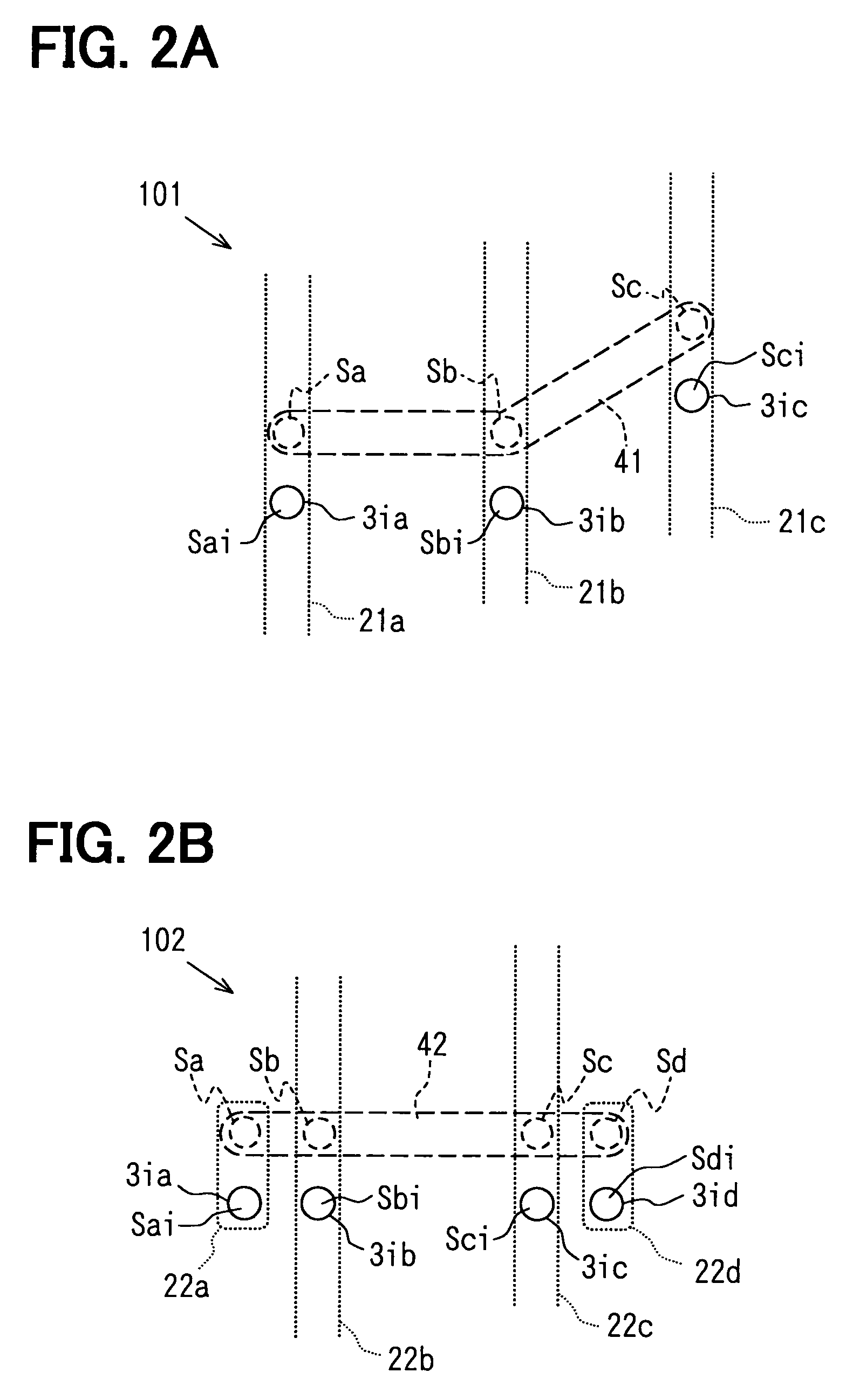

Multilayer printed wiring board and method of measuring characteristic impedance

ActiveCN101043790AEfficient measurementSmall footprintResistance/reactance/impedencePrinted electric component incorporationMethod of characteristicsTest coupon

A multilayer printed wiring board having a compact test coupon formed on each of the signal wiring layers is provided, and accurate and efficient method of characteristic impedance measurement for each signal wiring layer is realized. The test coupon is constituted by a plurality of linear parts extending parallel to each other and folded-back parts mutually connecting the linear parts. A through hole is provided for serially connecting the respective test coupons of the signal wiring layers adjoining each other. Two measuring pads, one is connected to one end of the serially connected test coupons and another is connected to the ground layer, are also provided. The measurement is performed by applying a step pulse between two measuring pads and measuring voltages of reflection waves from the serially connected test coupons.

Owner:NEC CORP

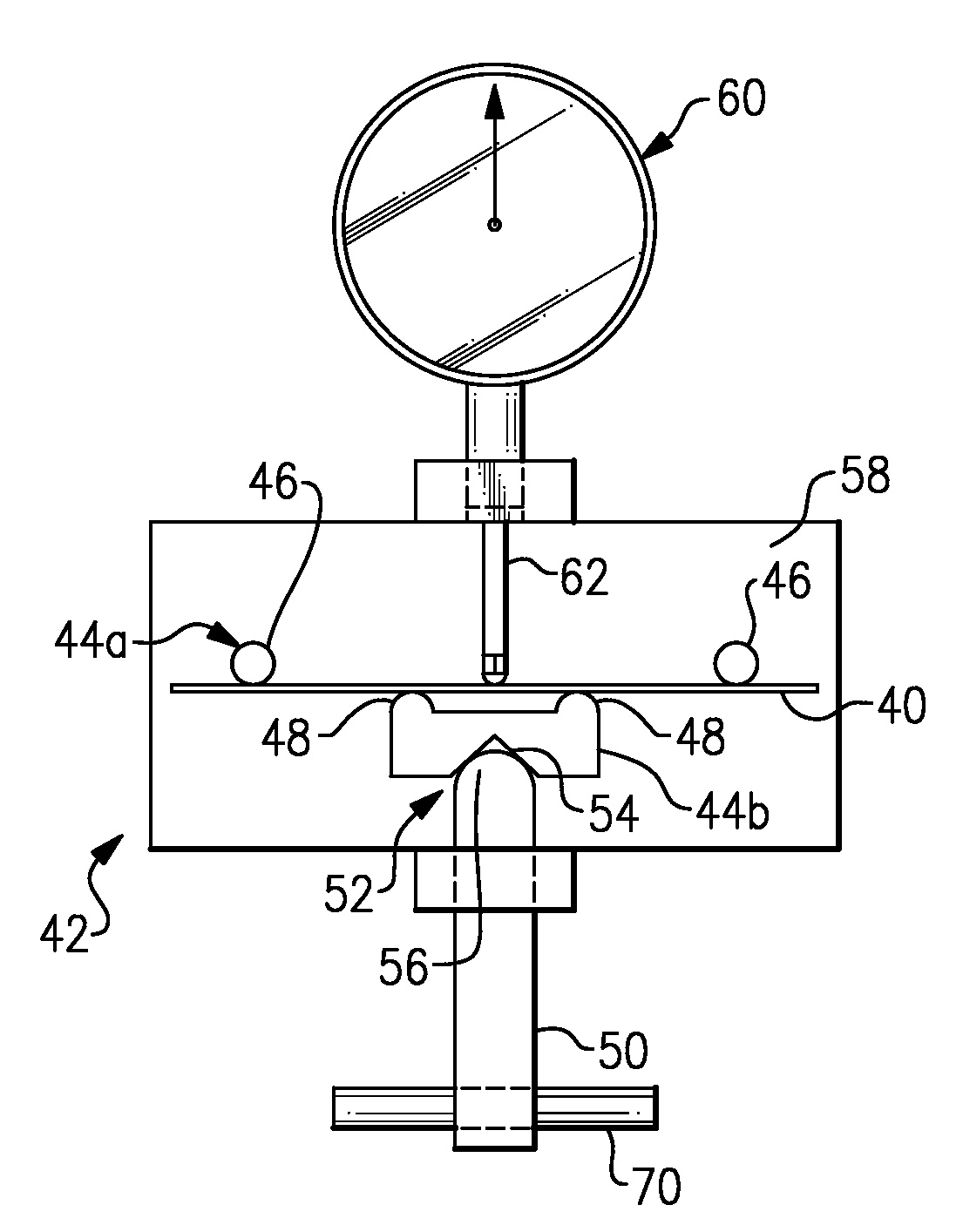

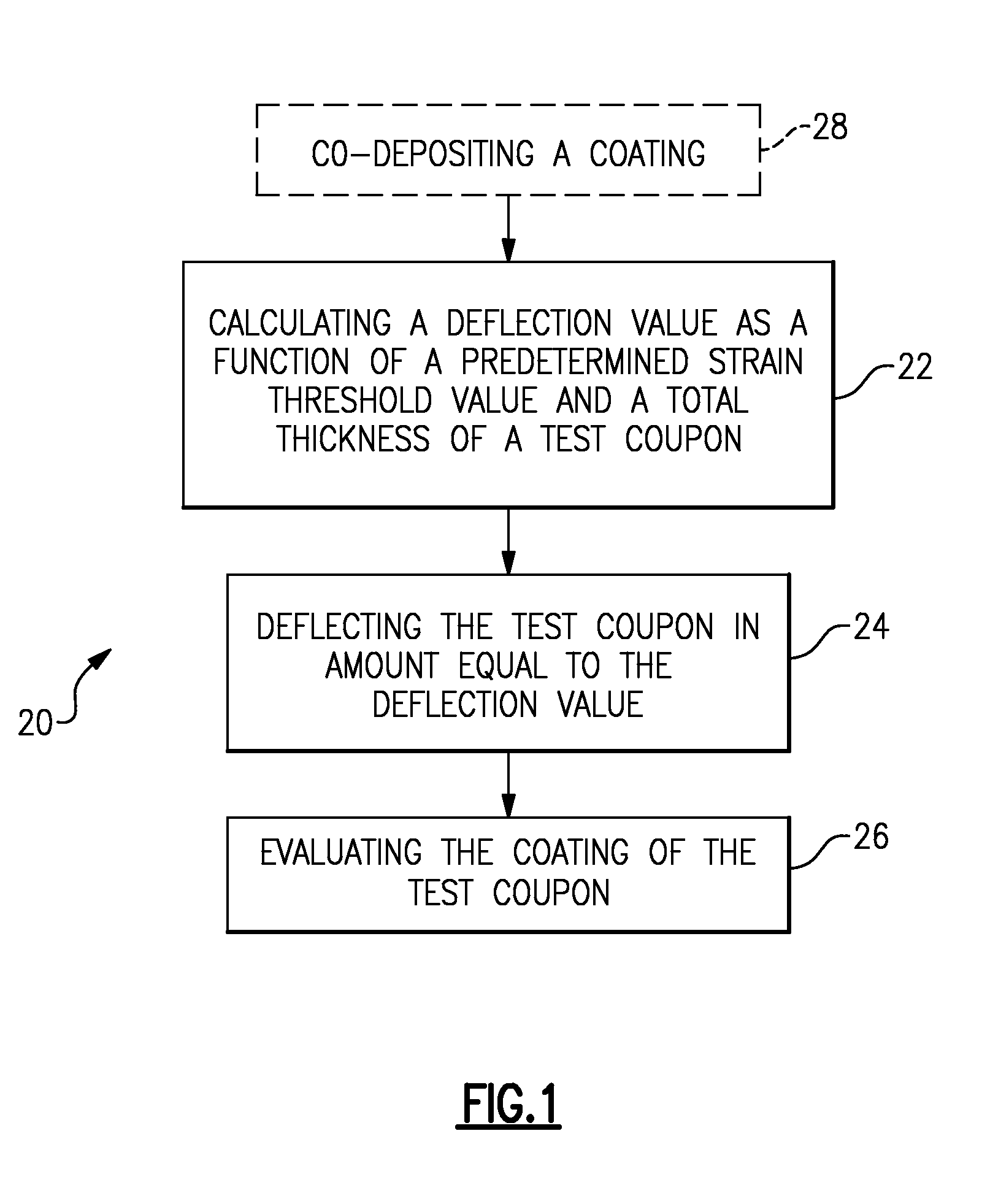

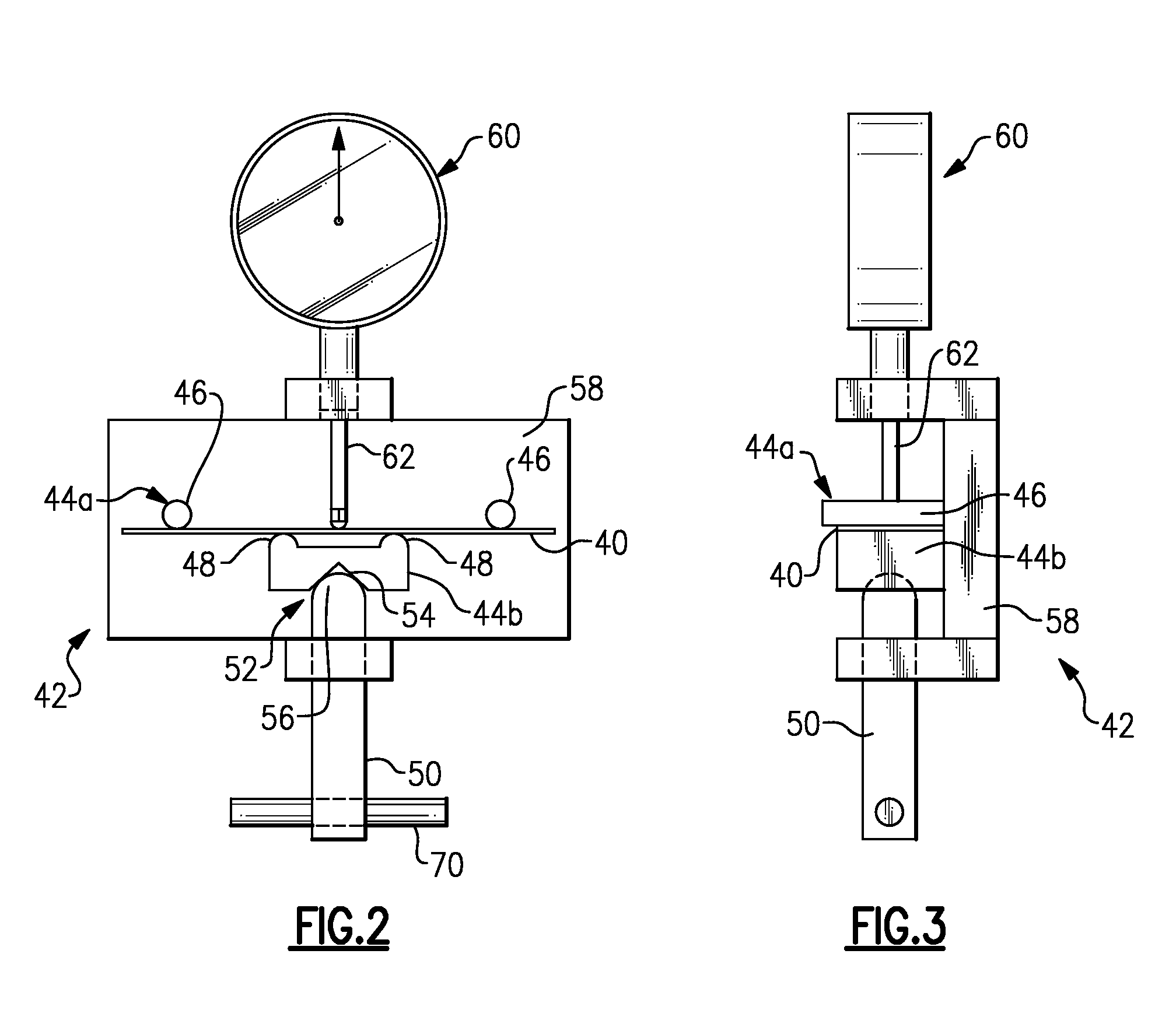

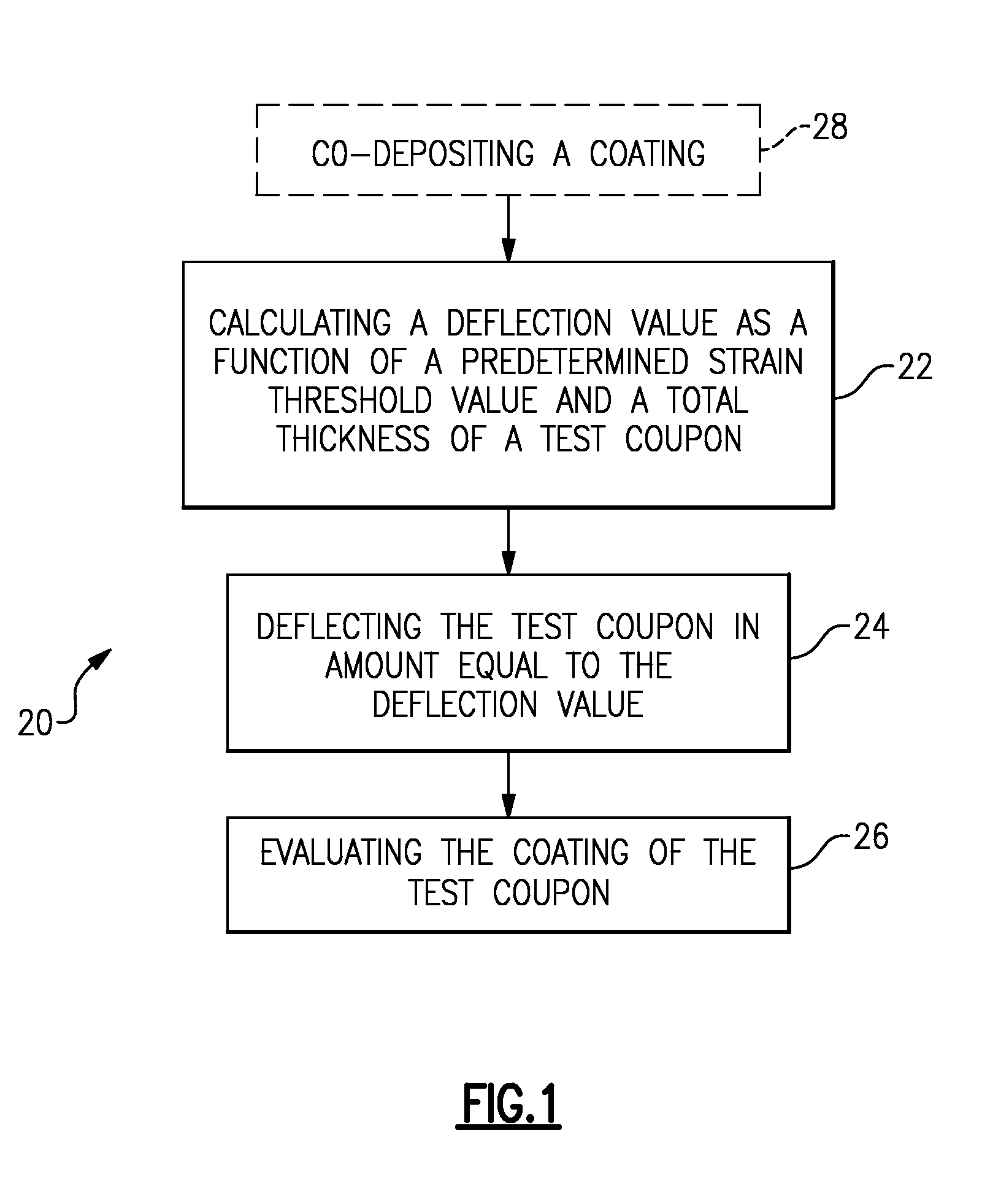

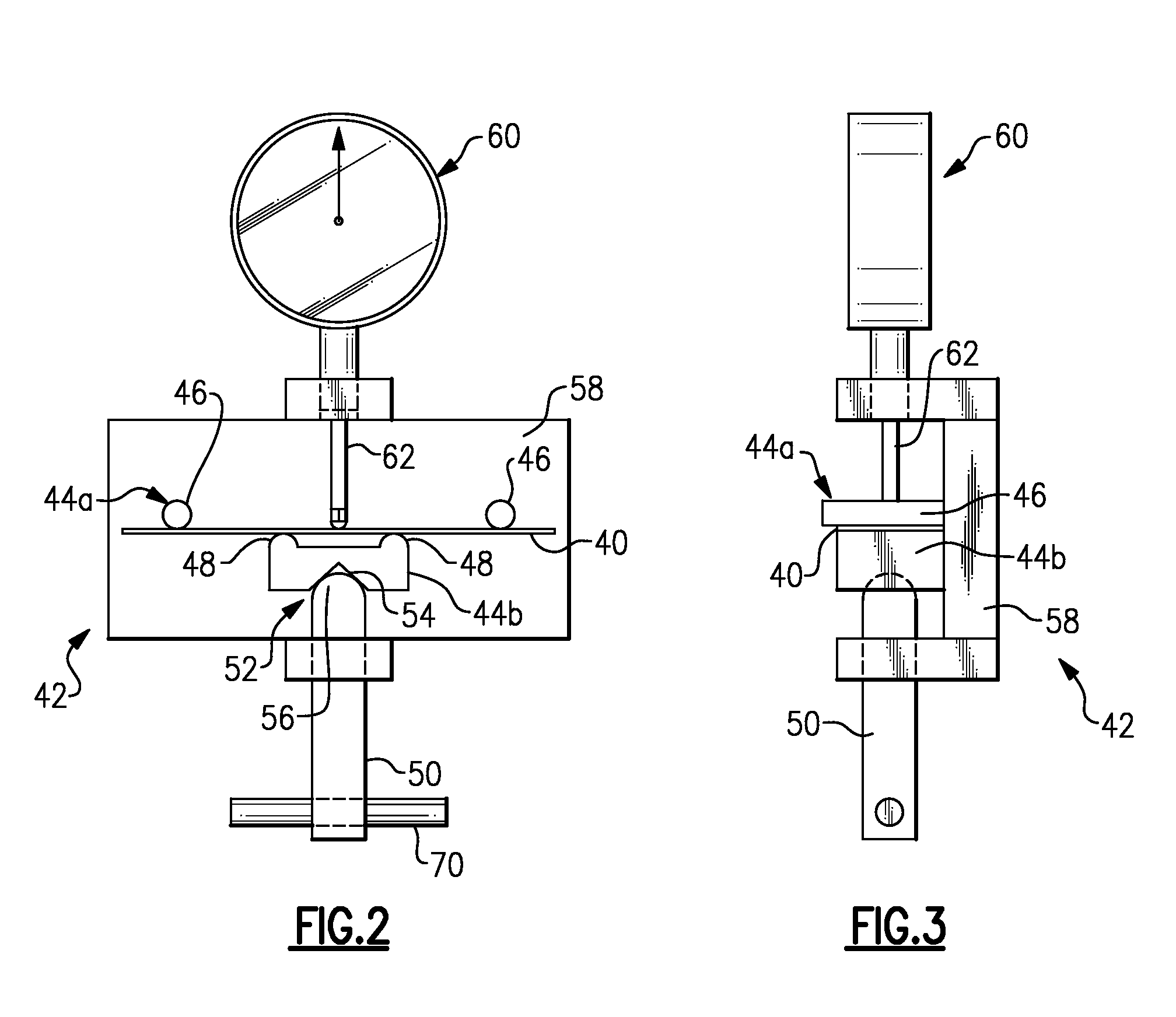

Method and apparatus for evaluation of coated parts

A method of verifying performance of a coated part includes calculating a deflection value as a function of a predetermined strain threshold value and a total thickness of a test coupon that comprises a coating on a substrate. The coating of the test coupon is co-deposited in a deposition process for producing a coated part. The test coupon is bent in an amount equal to the calculated deflection value and then evaluated as an indication of whether a mechanical characteristic of the coated part meets a specified level.

Owner:HAMILTON SUNDSTRAND CORP

Circuit board having test coupon and method for evaluating the circuit board

InactiveUS7333346B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical conductorInsulation layer

A circuit board includes: a substrate; a conductive pattern disposed on a surface of the substrate; a lower insulation layer disposed on the conductive pattern to cover the conductive pattern except for an opening, through which the conductive pattern is partially exposed from the lower insulation layer; a conductor disposed on the lower insulation layer and connecting to the conductive pattern through the opening; an upper insulation layer disposed on the conductor for covering the conductor and the lower insulation layer; and a test coupon disposed on the substrate for evaluating the conductor.

Owner:DENSO CORP

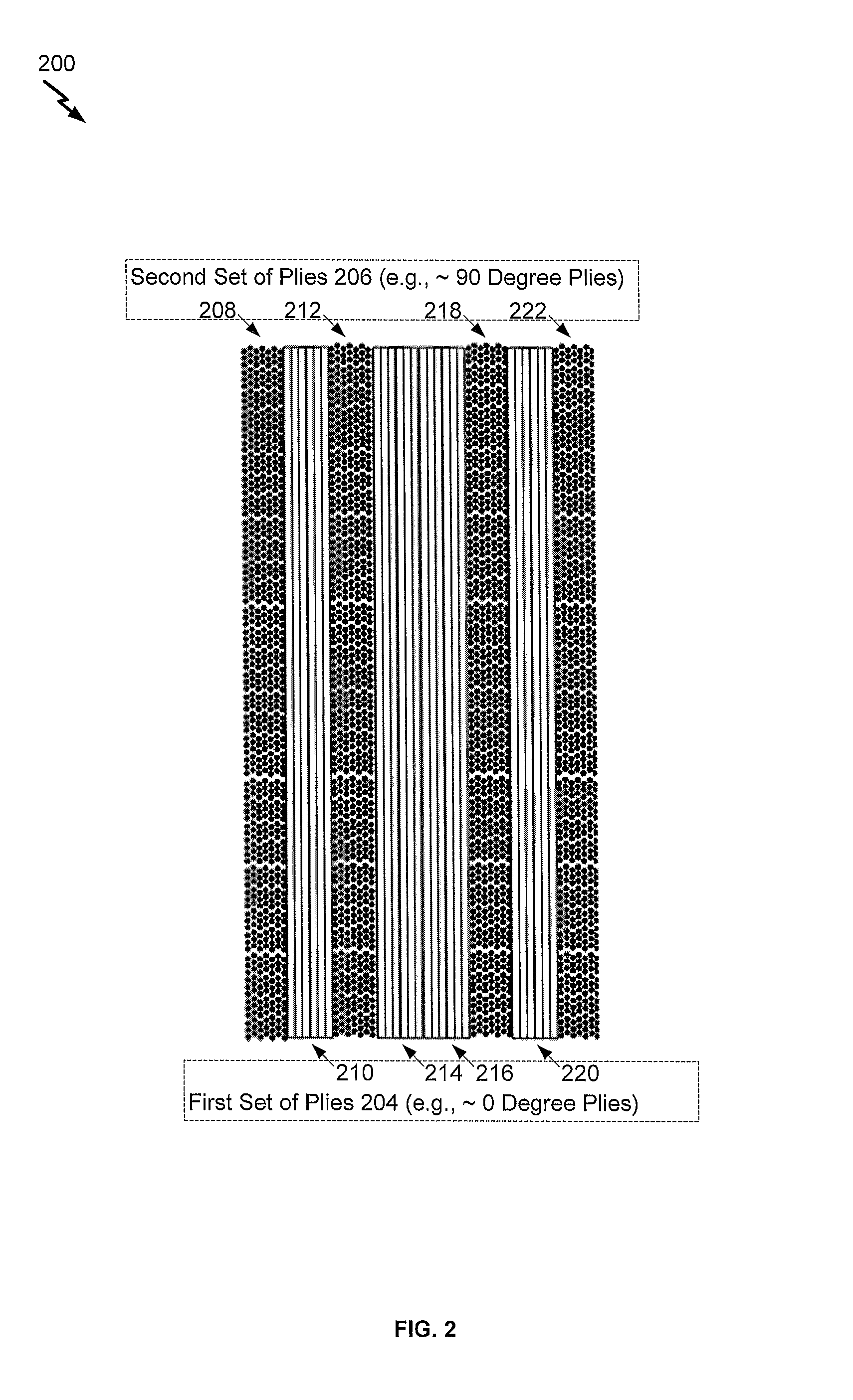

Method and apparatus for testing composite materials

InactiveUS7798014B2Material strength using tensile/compressive forcesTest couponMechanical engineering

Owner:AIRBUS OPERATIONS LTD

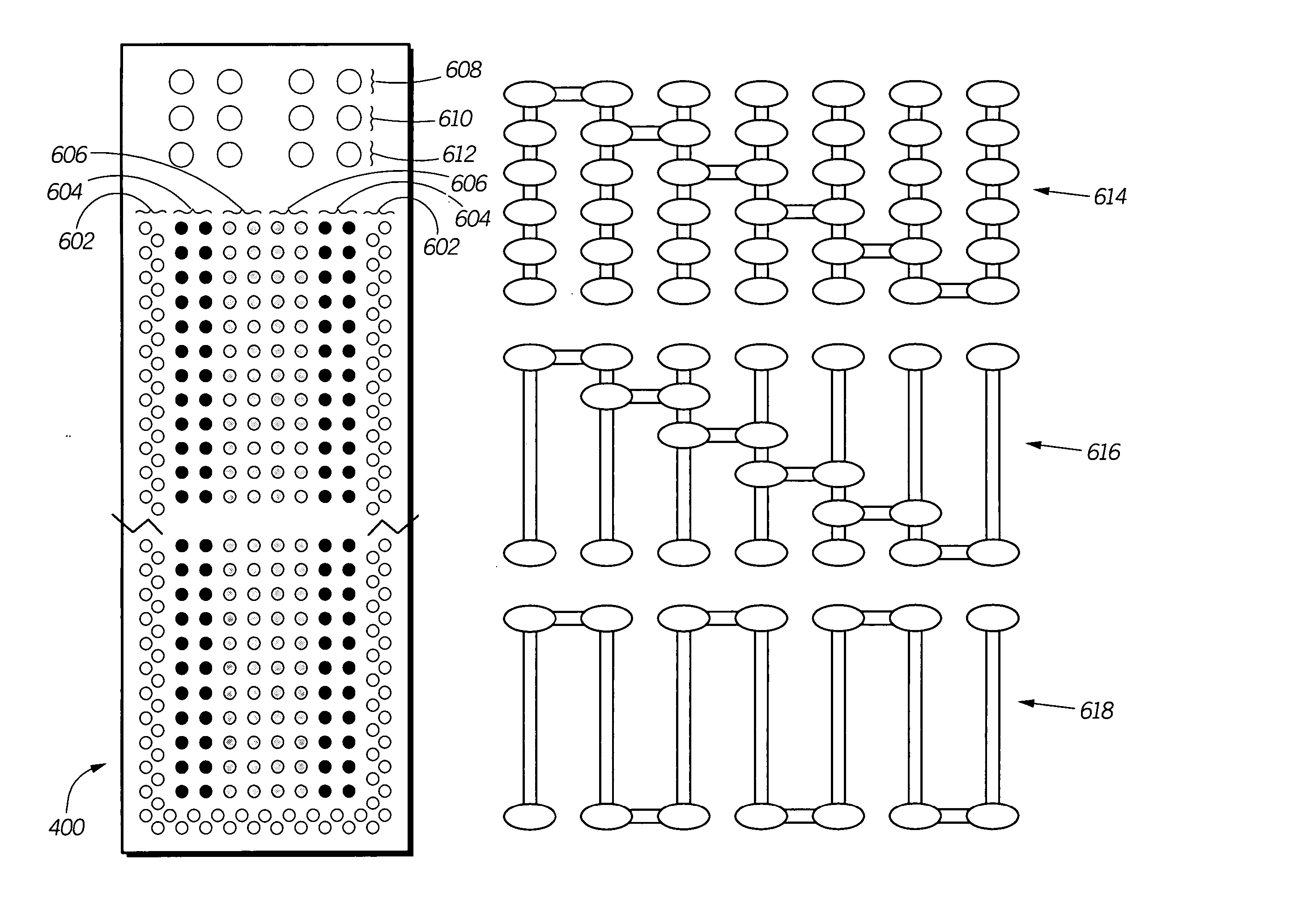

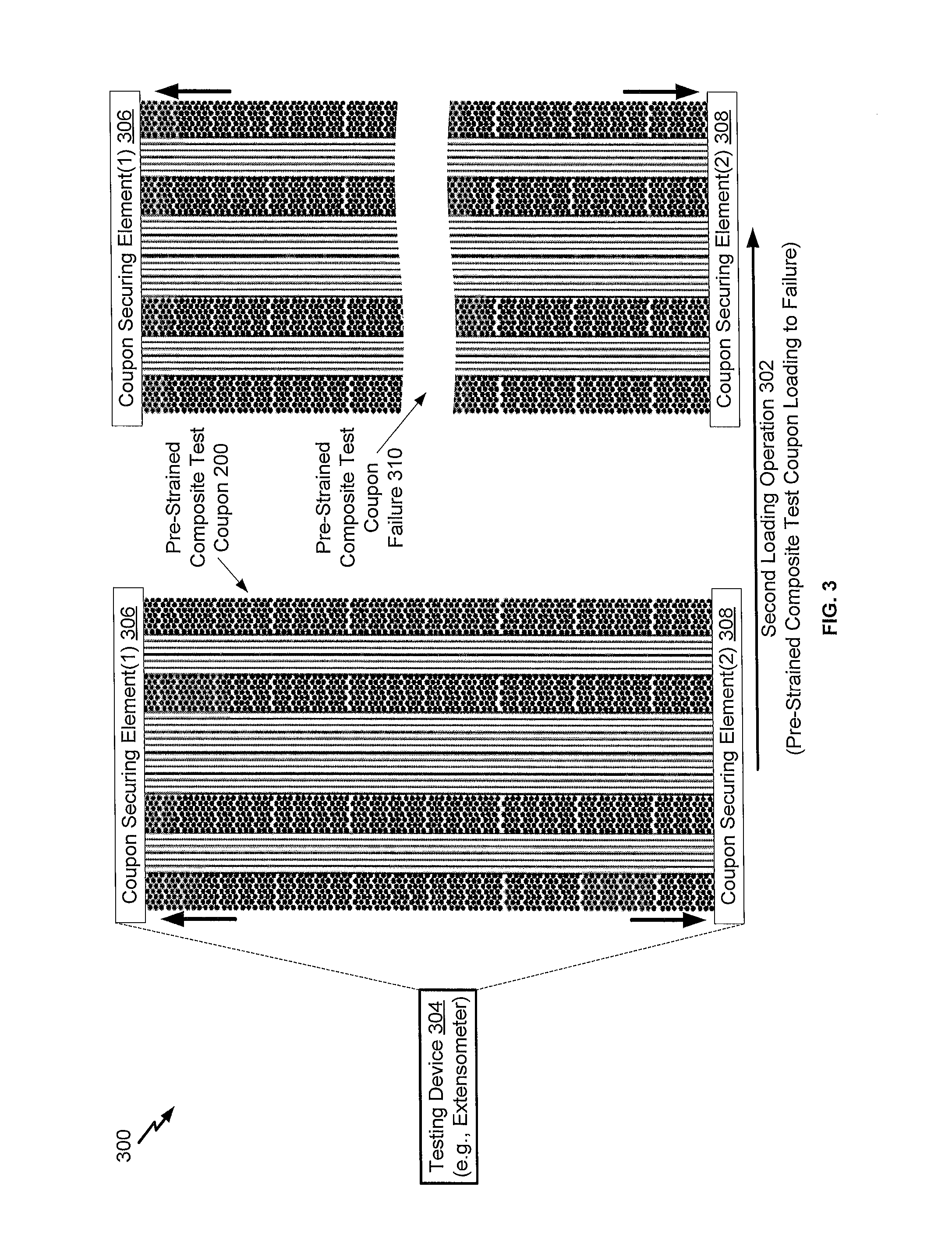

System and method for testing dynamic resistance during thermal shock cycling

InactiveUS20060103404A1Fast and Accurate TestingReliable dataInspection/indentification of circuitsPrinted circuit manufactureOhmmeterTest coupon

A system includes a temperature chamber (100), a text fixture (402), a test coupon (400), a data acquisition unit (404), an ohmmeter (406) and a computer (410). The temperature chamber (100) provides temperature extremes to the test coupon (400). The test coupon (400) includes a substrate (314), one or more vias (418-429) and traces (402-412) connecting the vias. The data acquisition unit (404) continuously measures a resistance value of the circuit formed by the vias (418-429) and traces (402-412) during temperature cycling of the test coupon (400) held by the test fixture (402). The ohmmeter (406) measures the temperature of the test coupon (400) with a thermocouple. The data is used to detect failures of the materials in the test coupon (400) during the temperature cycling.

Owner:MOTOROLA INC

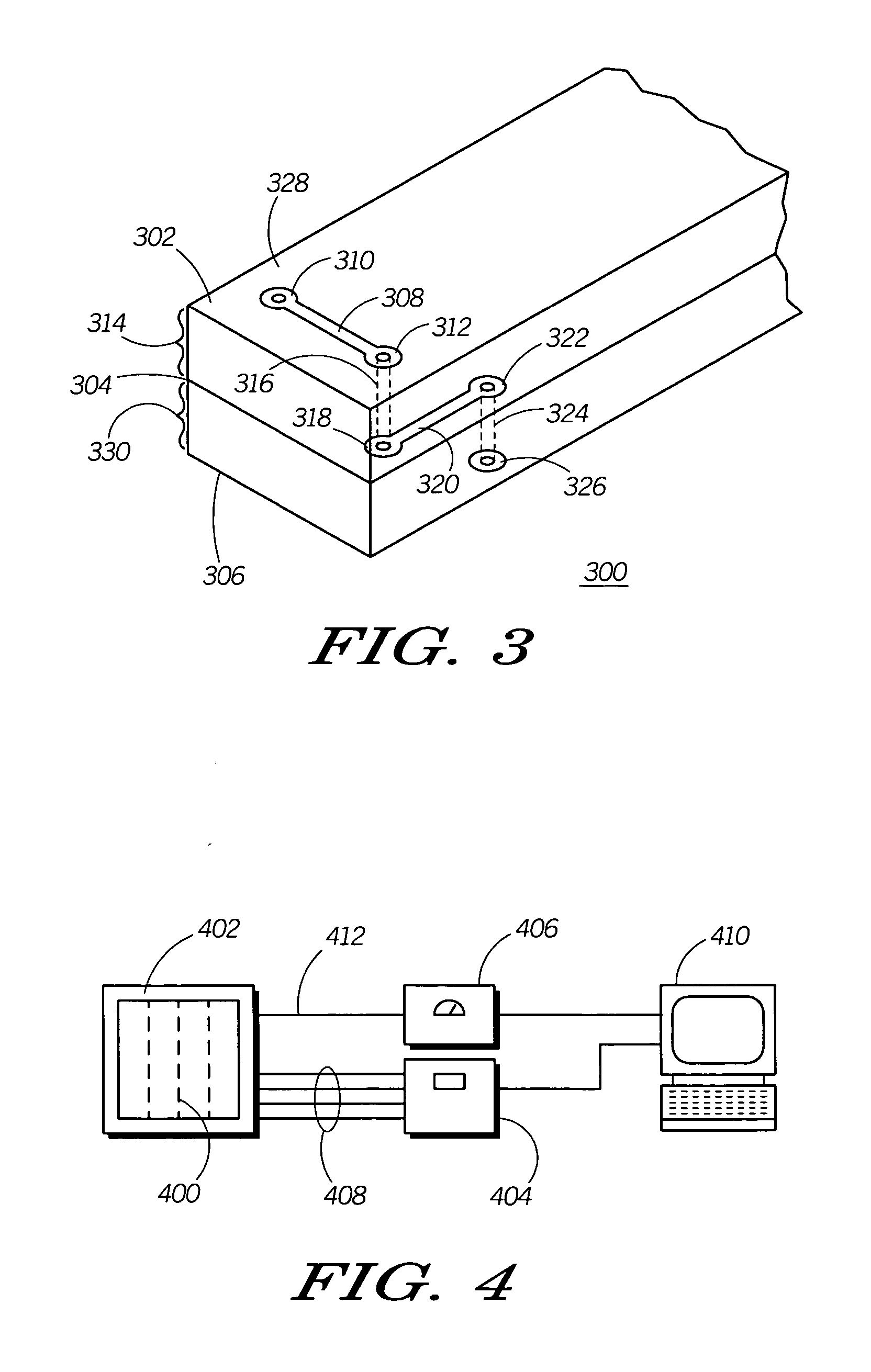

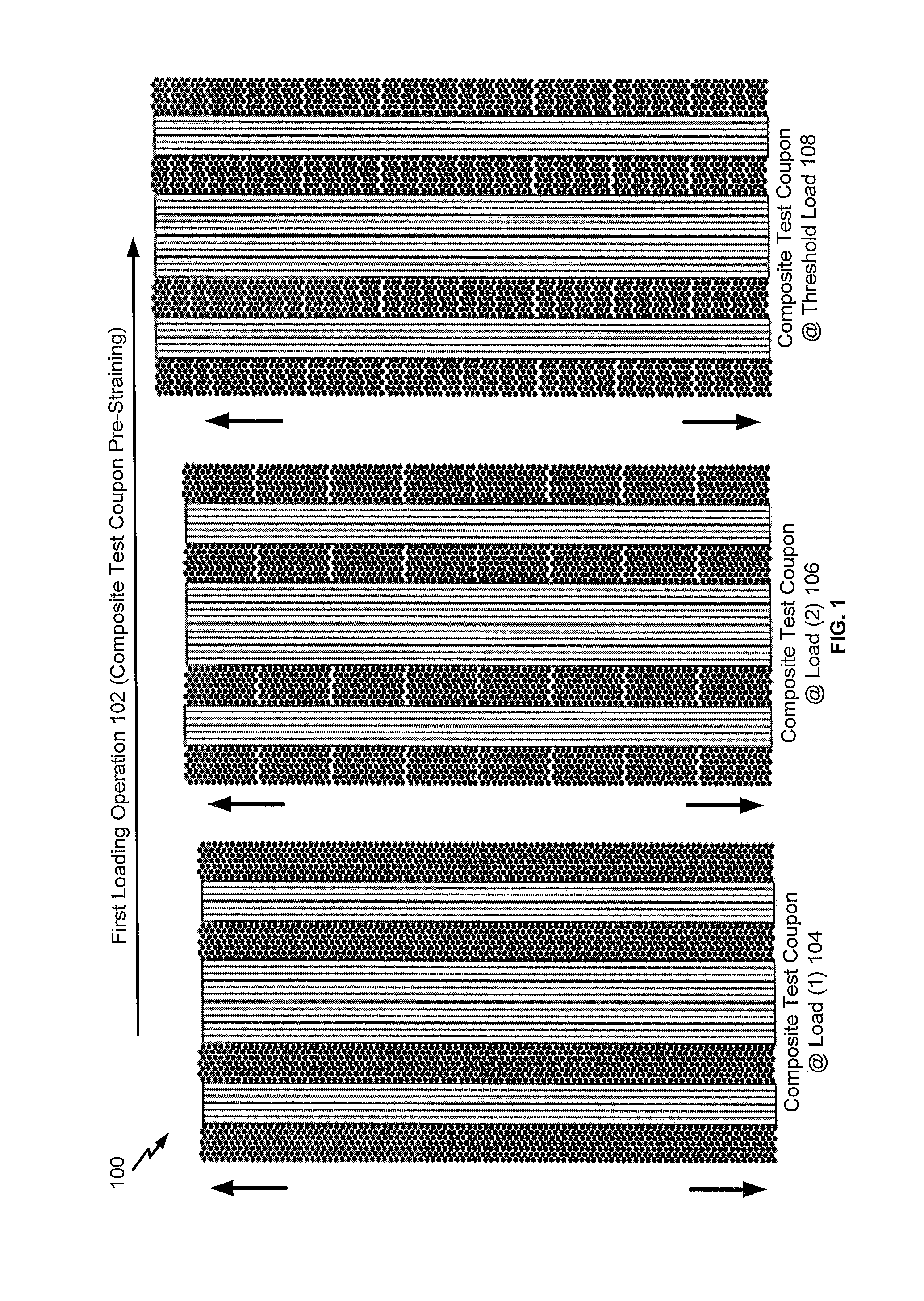

Pre-strained composite test coupons

A composite test coupon includes a plurality of plies. The plurality of plies include first ply layers and second ply layers. The first ply layers have first fibers and a substantially uniform matrix material associated with the first fibers. The second ply layers have second fibers and a pre-stressed matrix material associated with the second fibers. The first fibers are oriented in a first direction, and the second fibers are oriented in a second direction that is different from the first direction. The pre-stressed matrix material includes stress induced cracks between the second fibers of each of the second ply layers.

Owner:THE BOEING CO

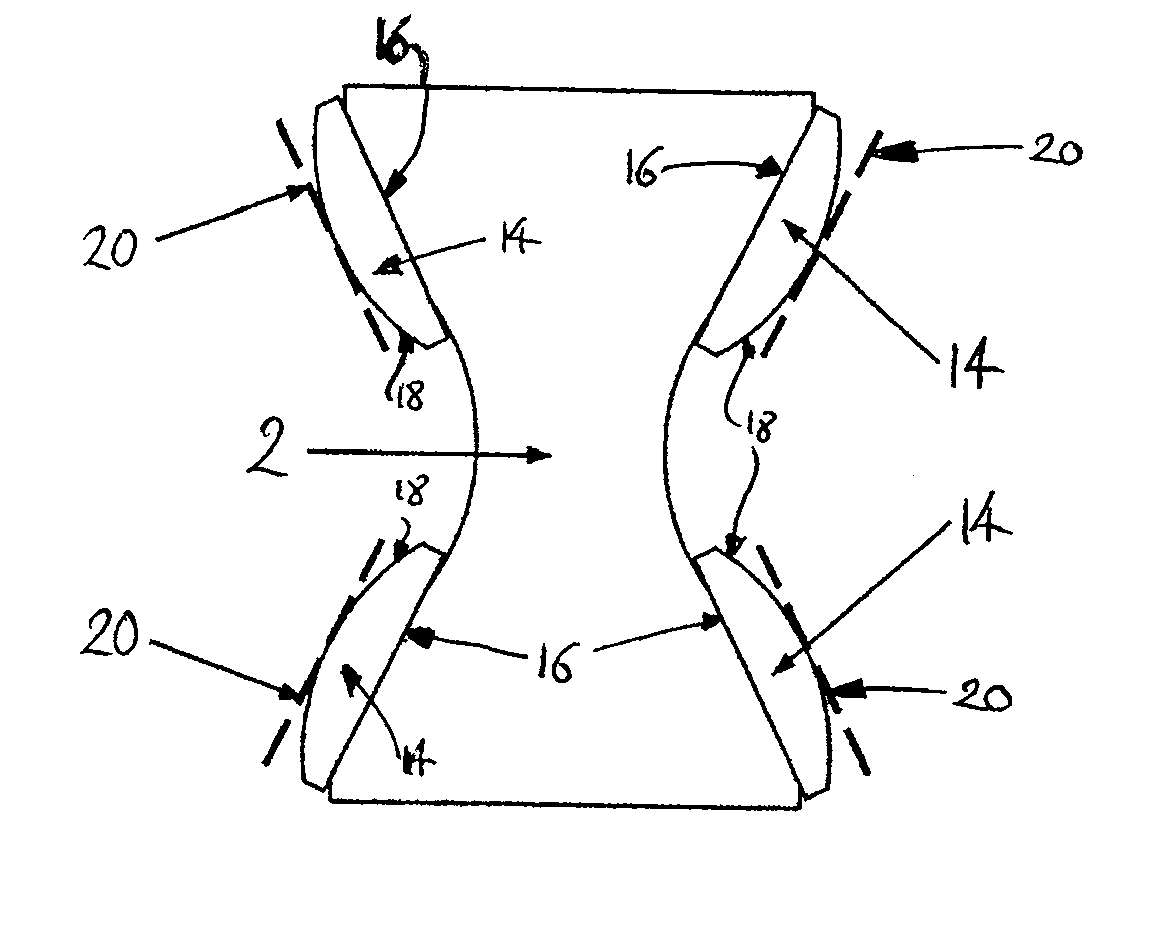

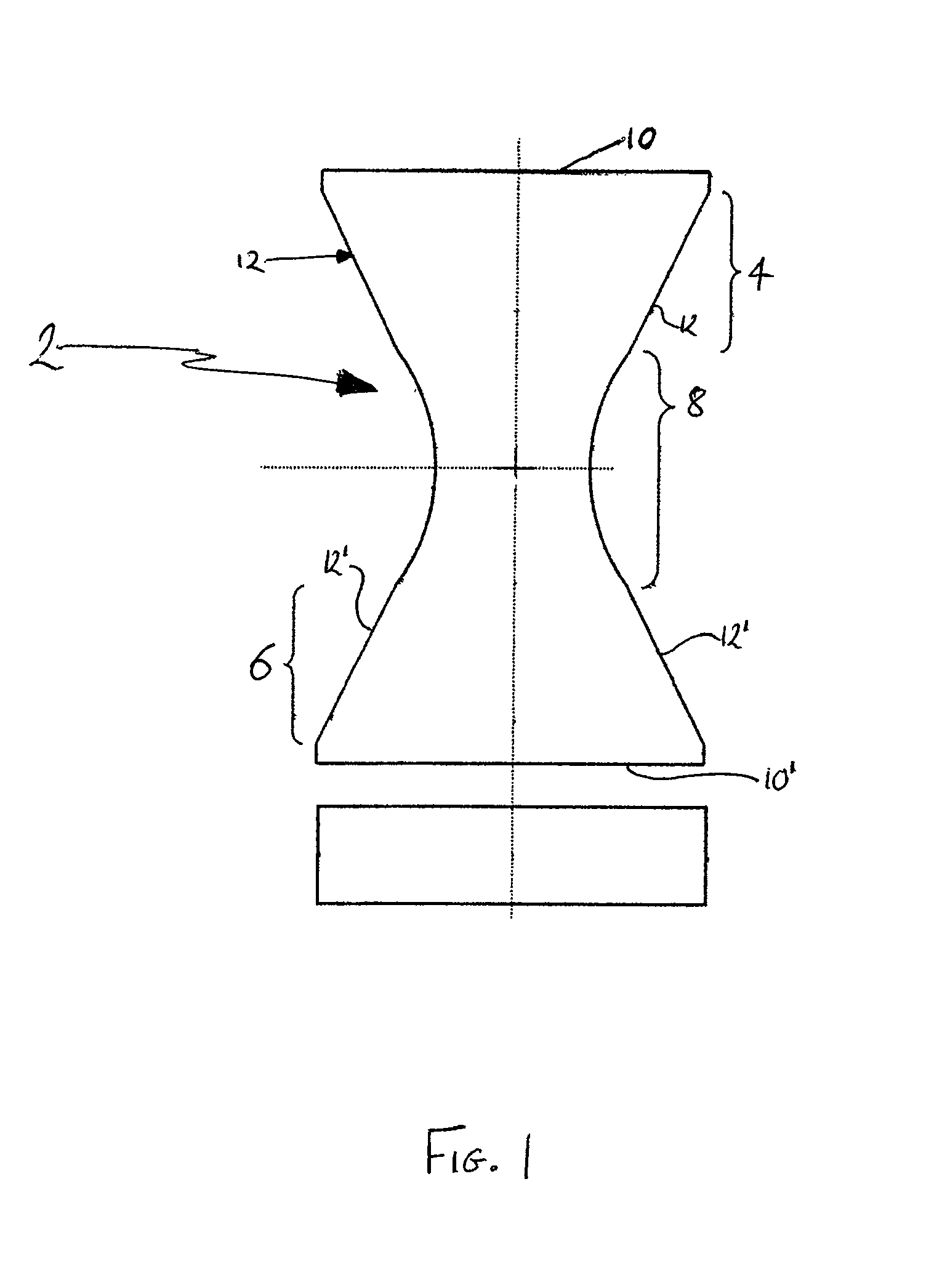

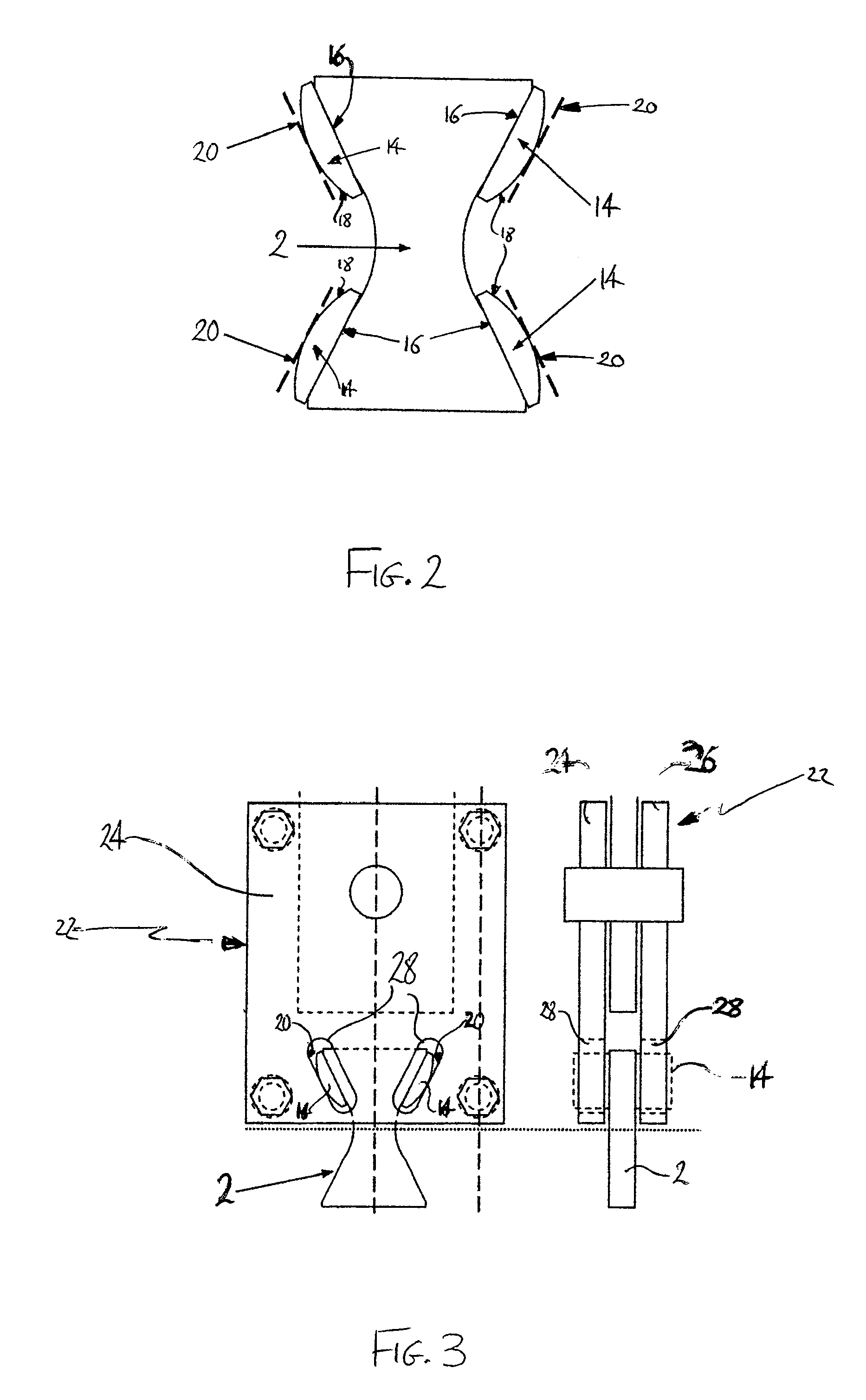

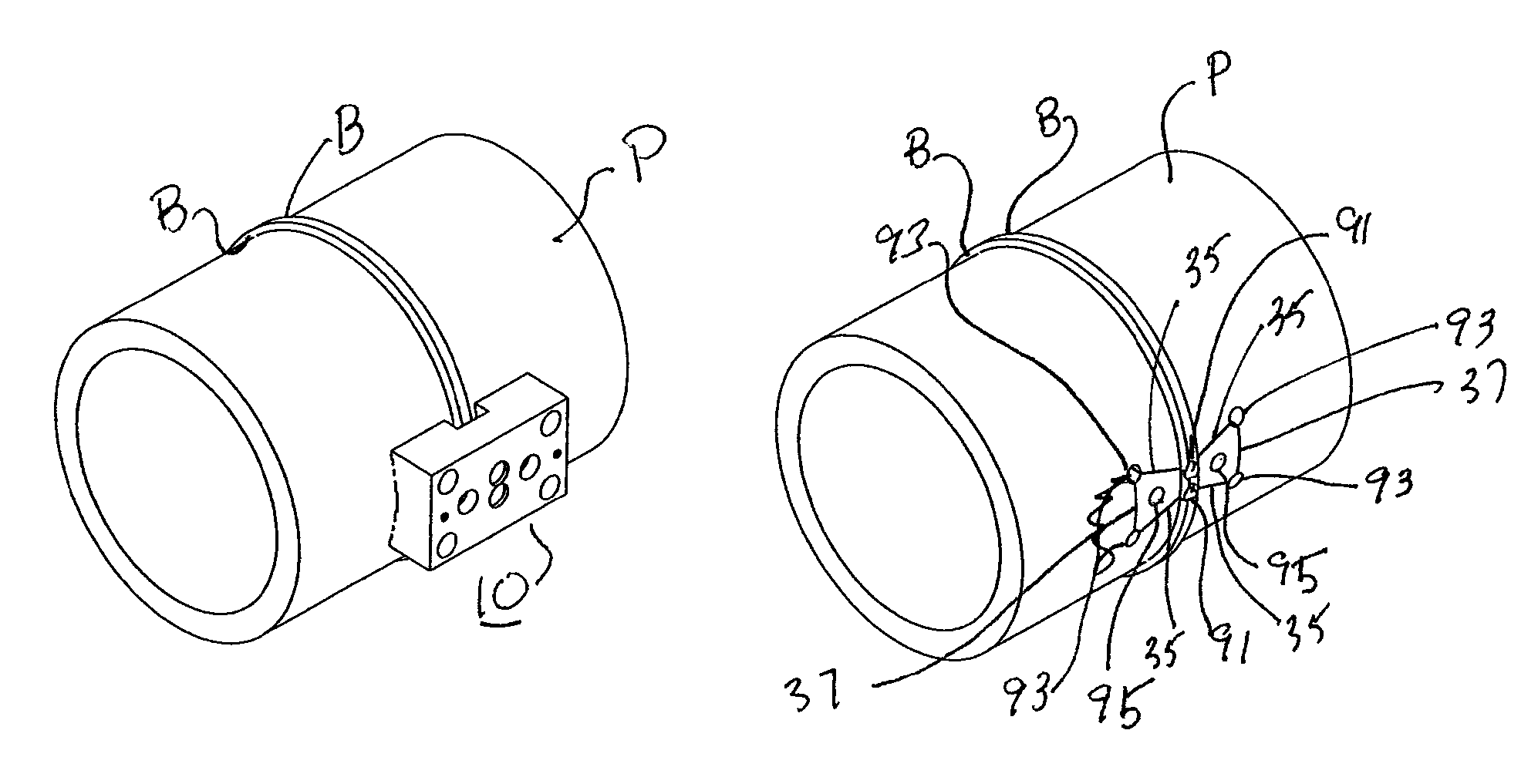

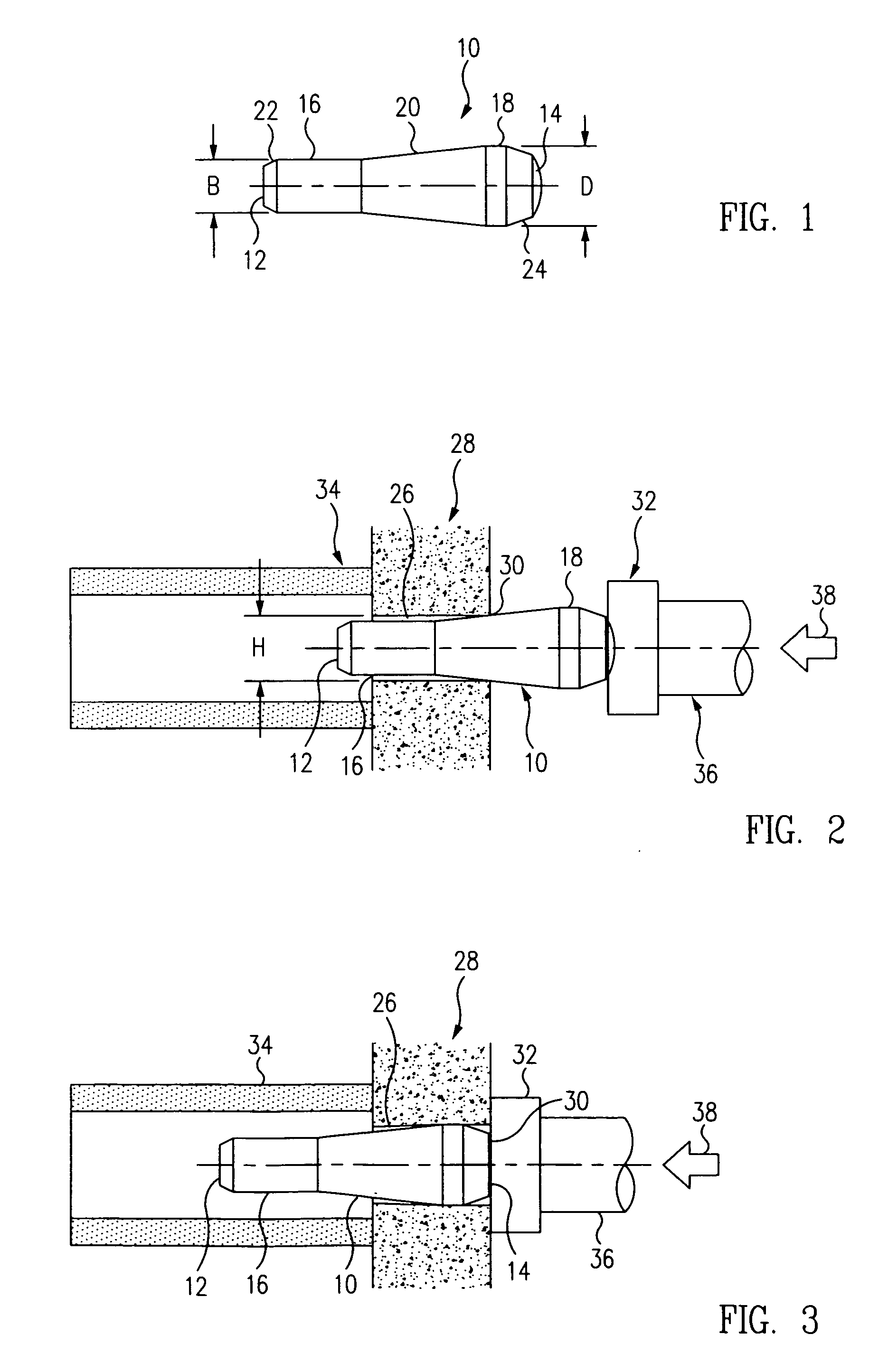

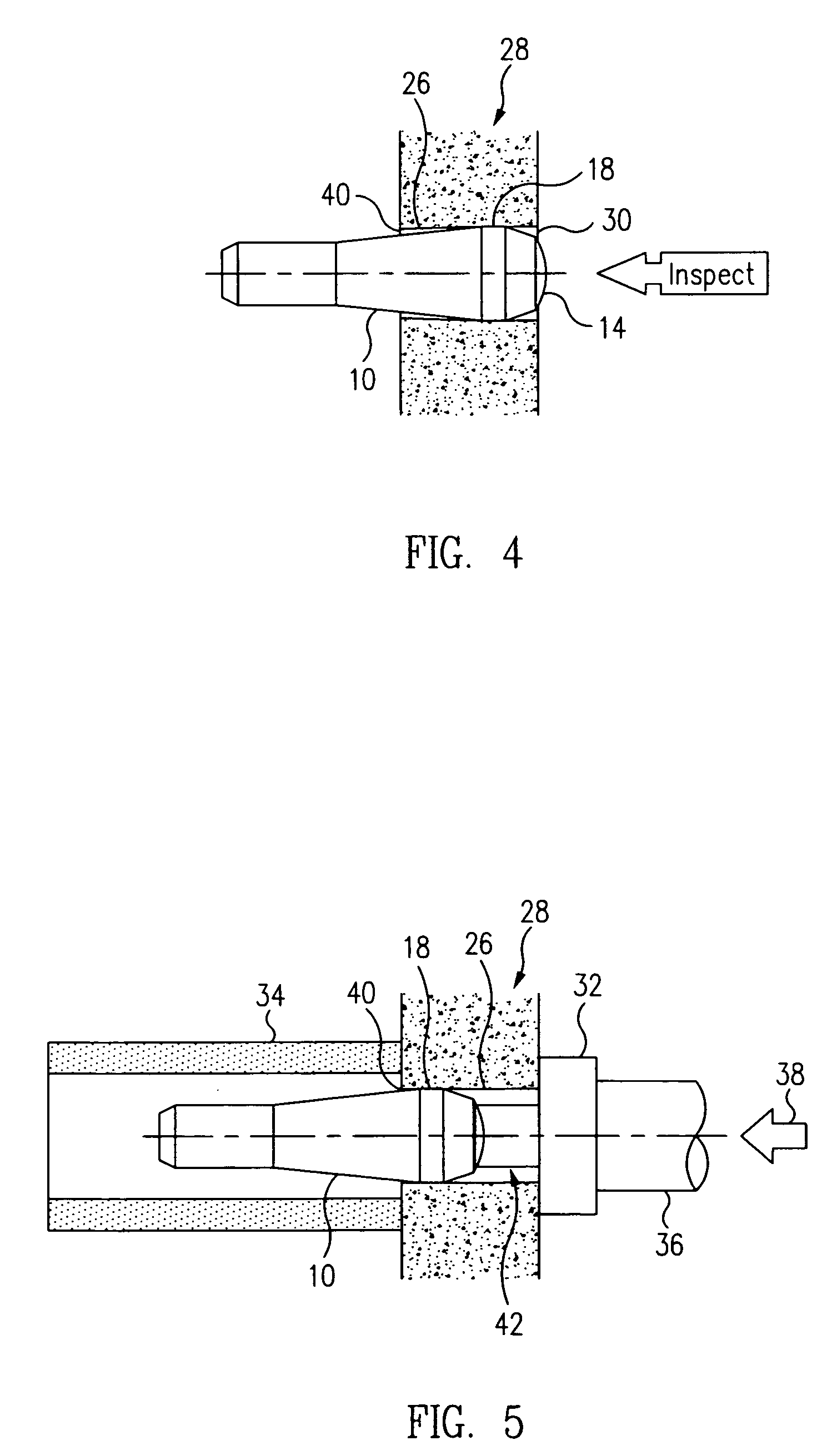

Method and template for producing a tensile test coupon

ActiveUS8365429B2Material strength using tensile/compressive forcesUsing mechanical meansFusion jointsTest coupon

A method and template enable the testing of fusion joints of plastic pipes to be conducted by a single operator in the field at the welding site by the efficient and precise extraction from the joints to be tested of a number of high quality tensile coupons. The coupons are tested to failure in a field-suitable, well controlled, self contained, tensile testing apparatus. A narrowing bow-tie-like pattern of the coupon ensures that the failure of the coupon in the tensile test will occur at the narrowest section of the coupon. The template can be visually aligned with the joint to ensure that it is the joint that will be tested.

Owner:MCELROY MFG

Method and apparatus for evaluation of coated parts

Owner:HAMILTON SUNDSTRAND CORP

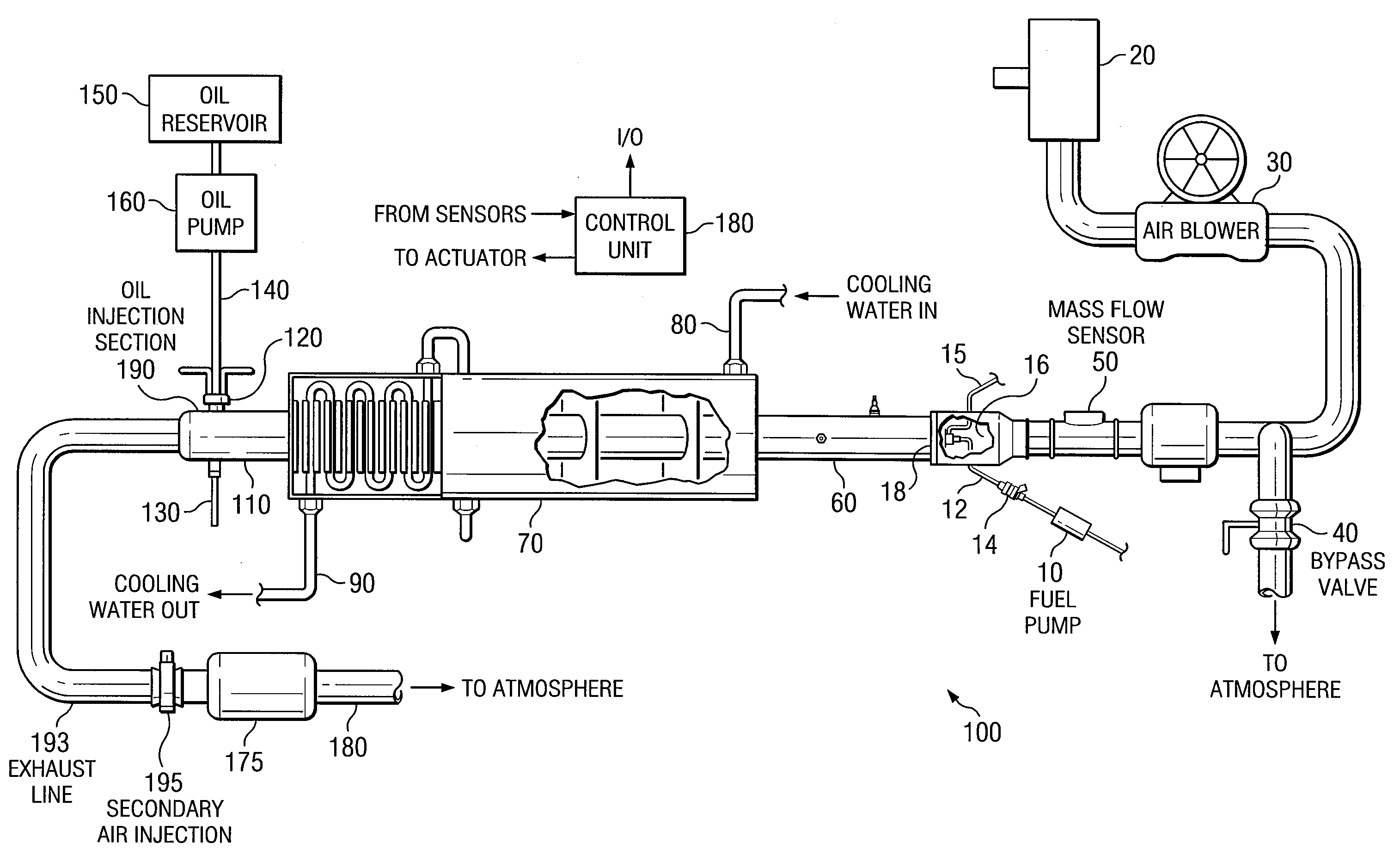

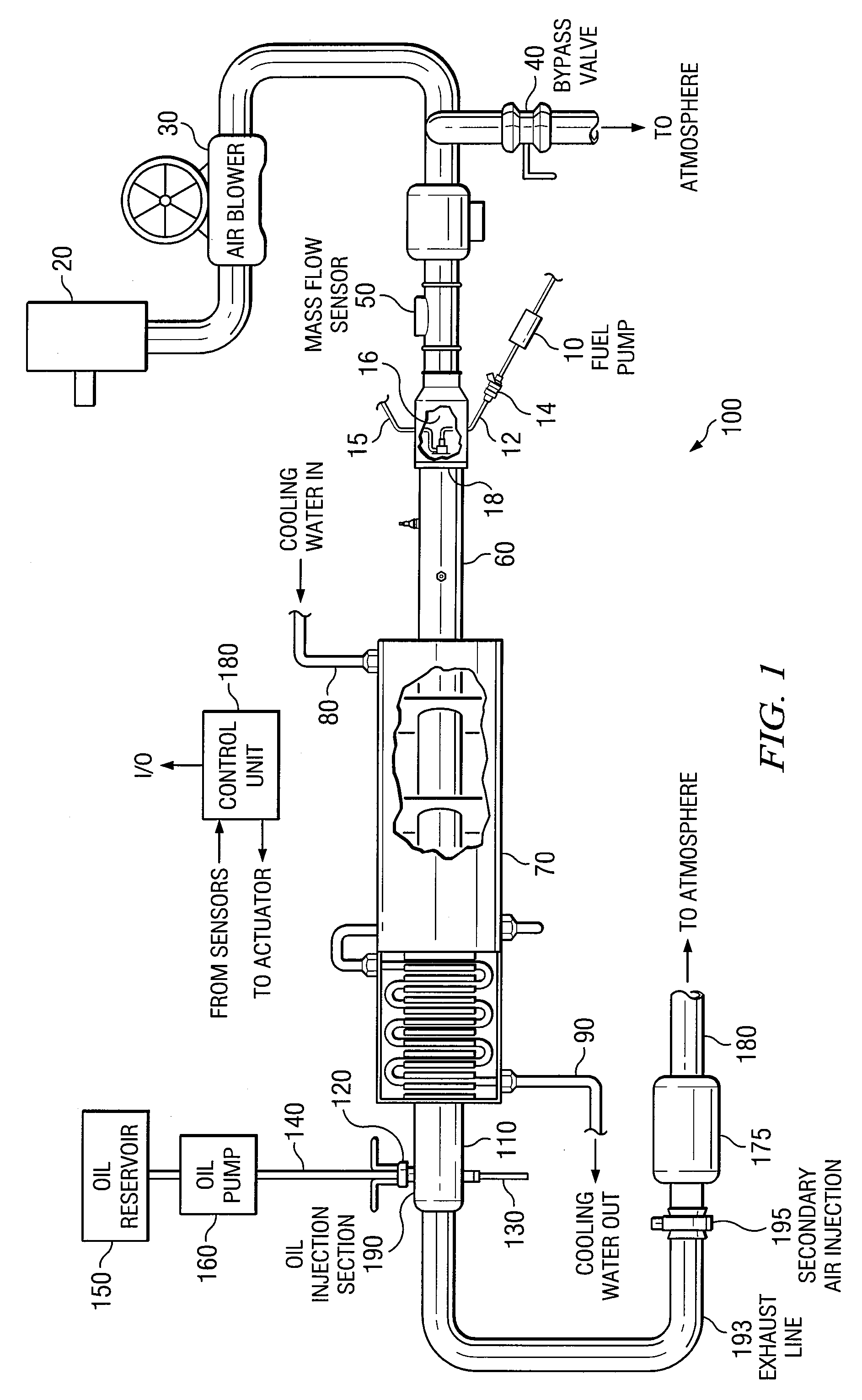

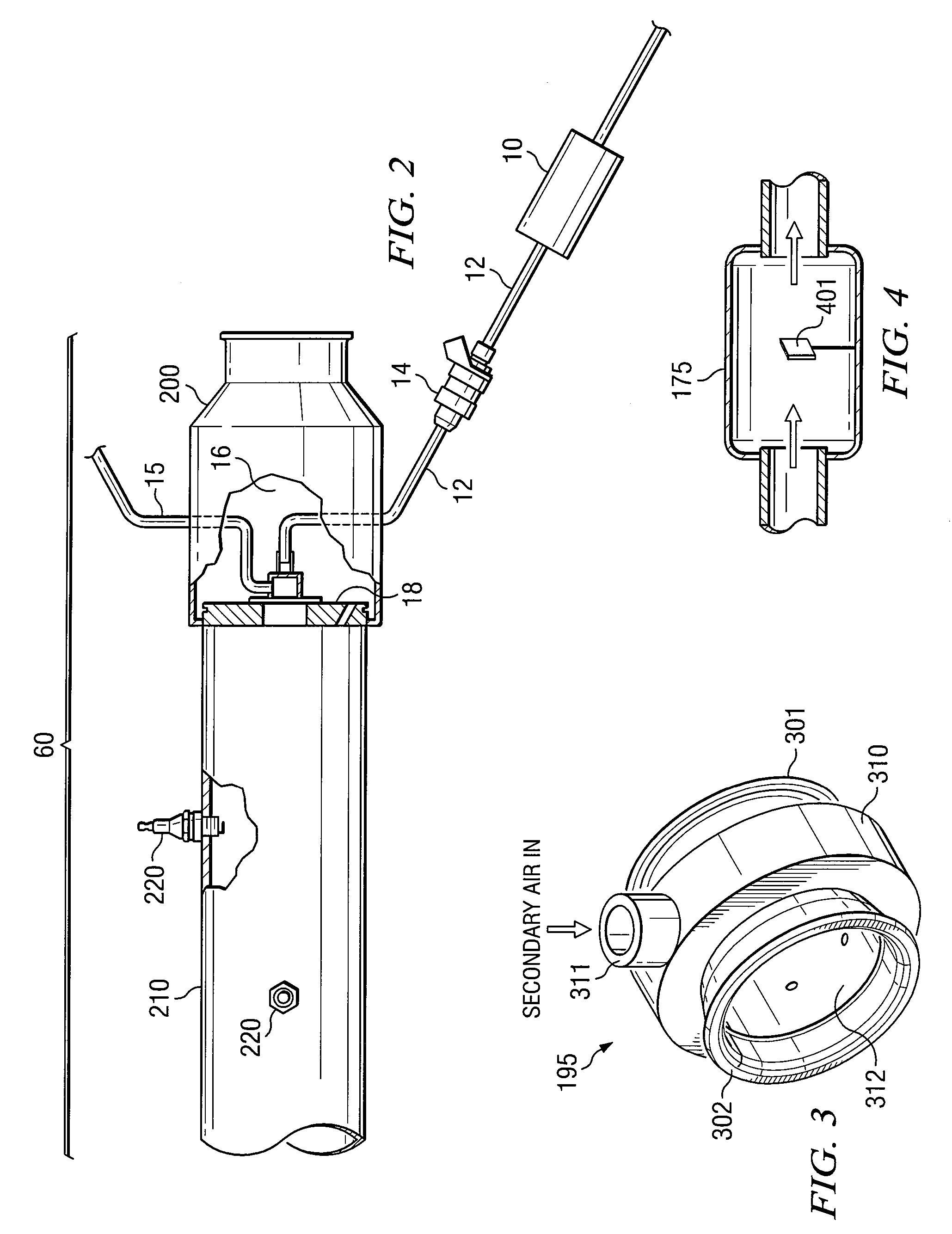

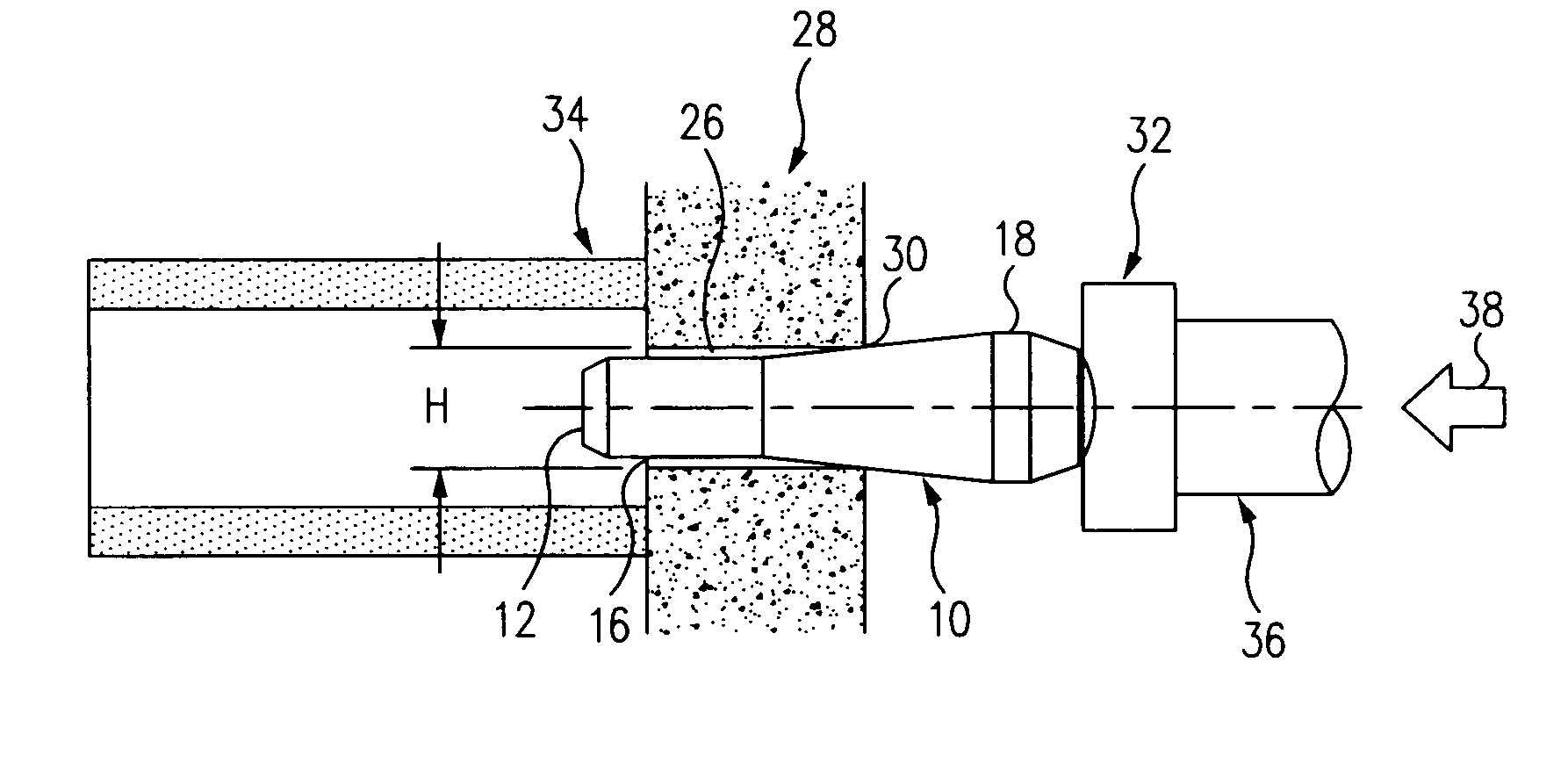

Fuel deposit testing using burner-based exhaust flow simulation system

ActiveUS7597016B2Chemical analysis using combustionWeather/light/corrosion resistanceLine tubingCombustor

A method of using an exhaust flow simulation system to test the effects of exhaust system conditions on various materials. A typical exhaust flow simulator is a burner-based system, in which exhaust from burner combustion is exhausted through an exhaust line. A “test coupon” of the material may be placed at an appropriate location in the flow line, and tested to determine how it is affected by the exhaust resulting from various fuels and additives.

Owner:SOUTHWEST RES INST

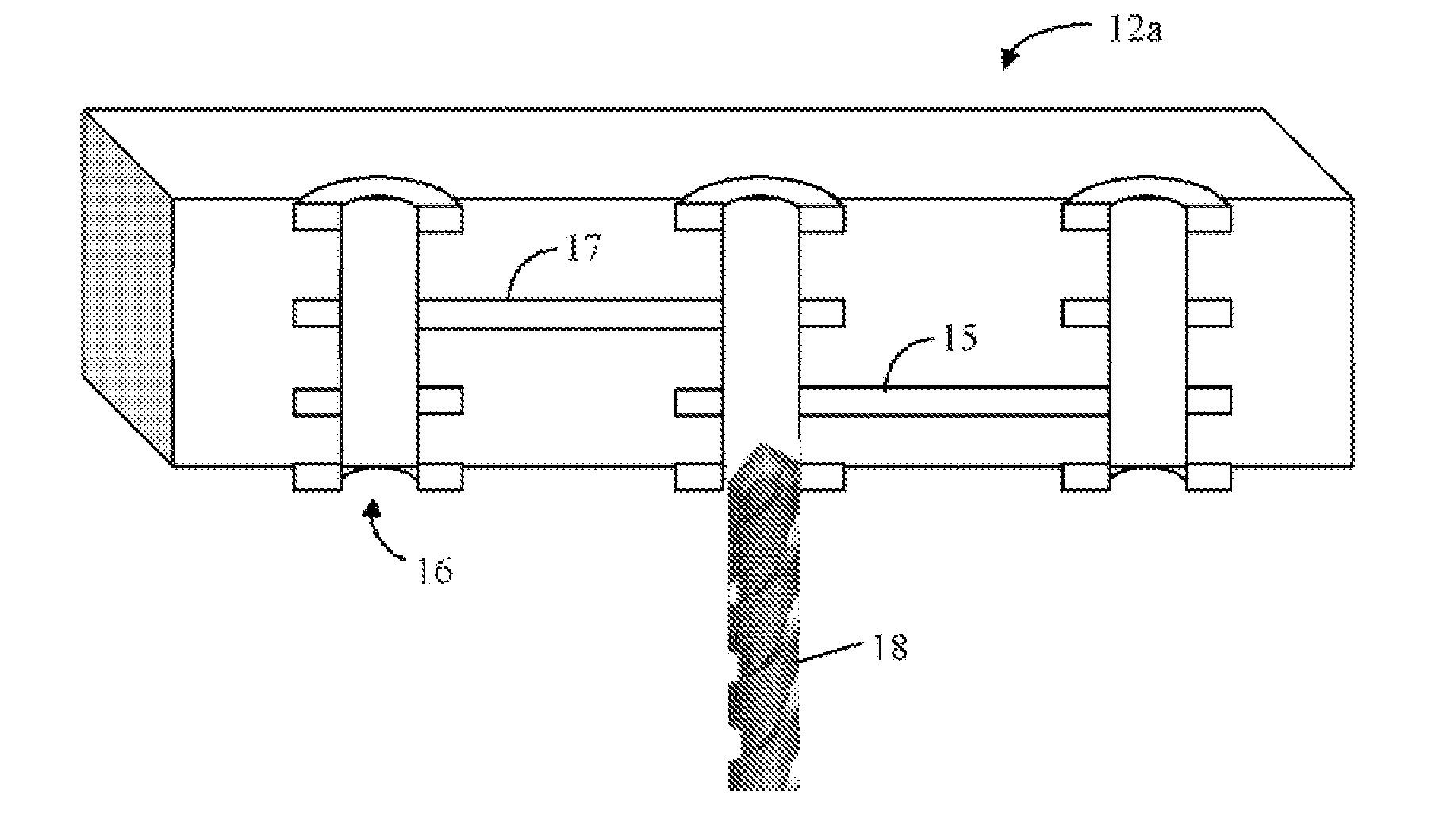

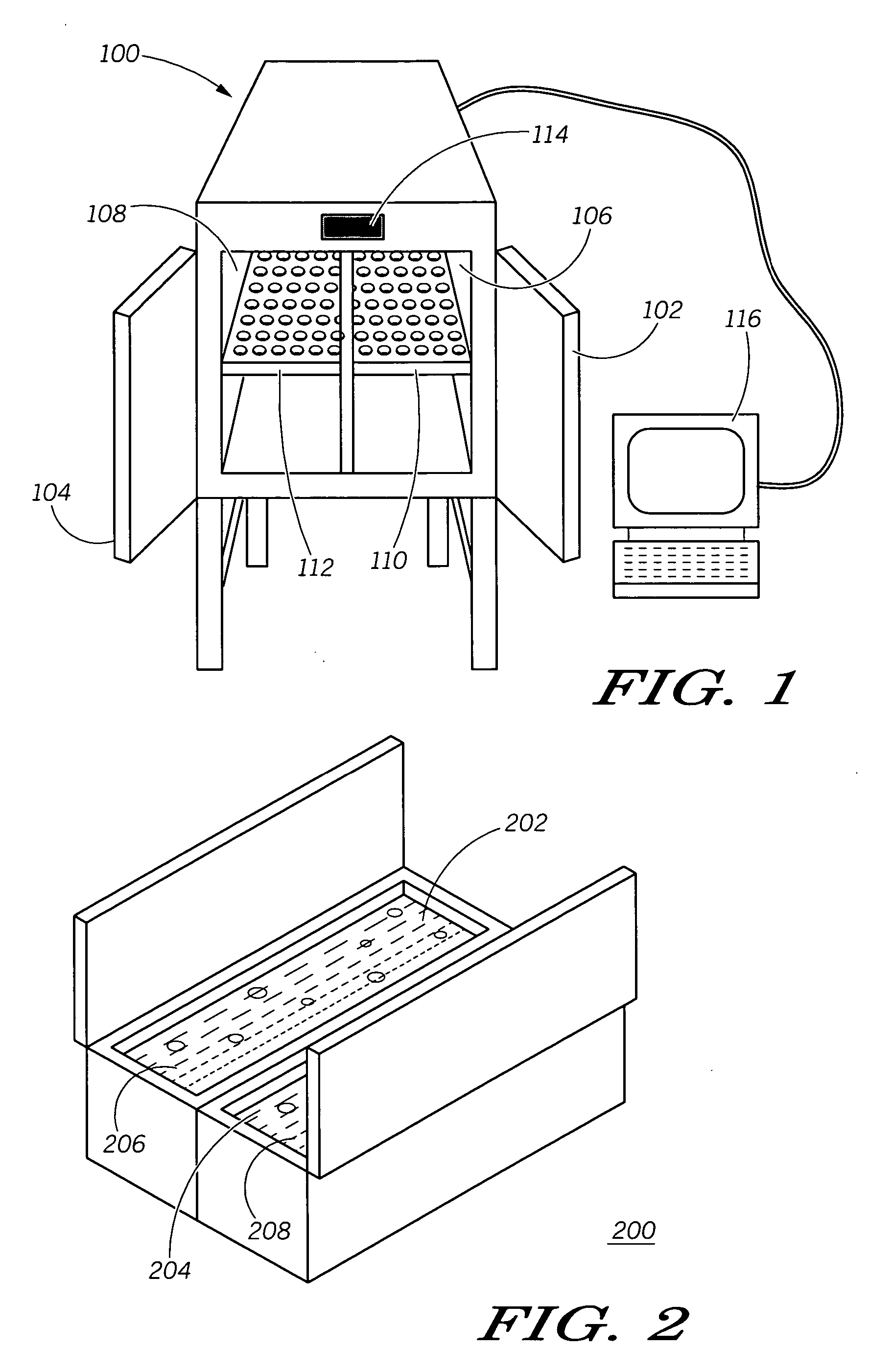

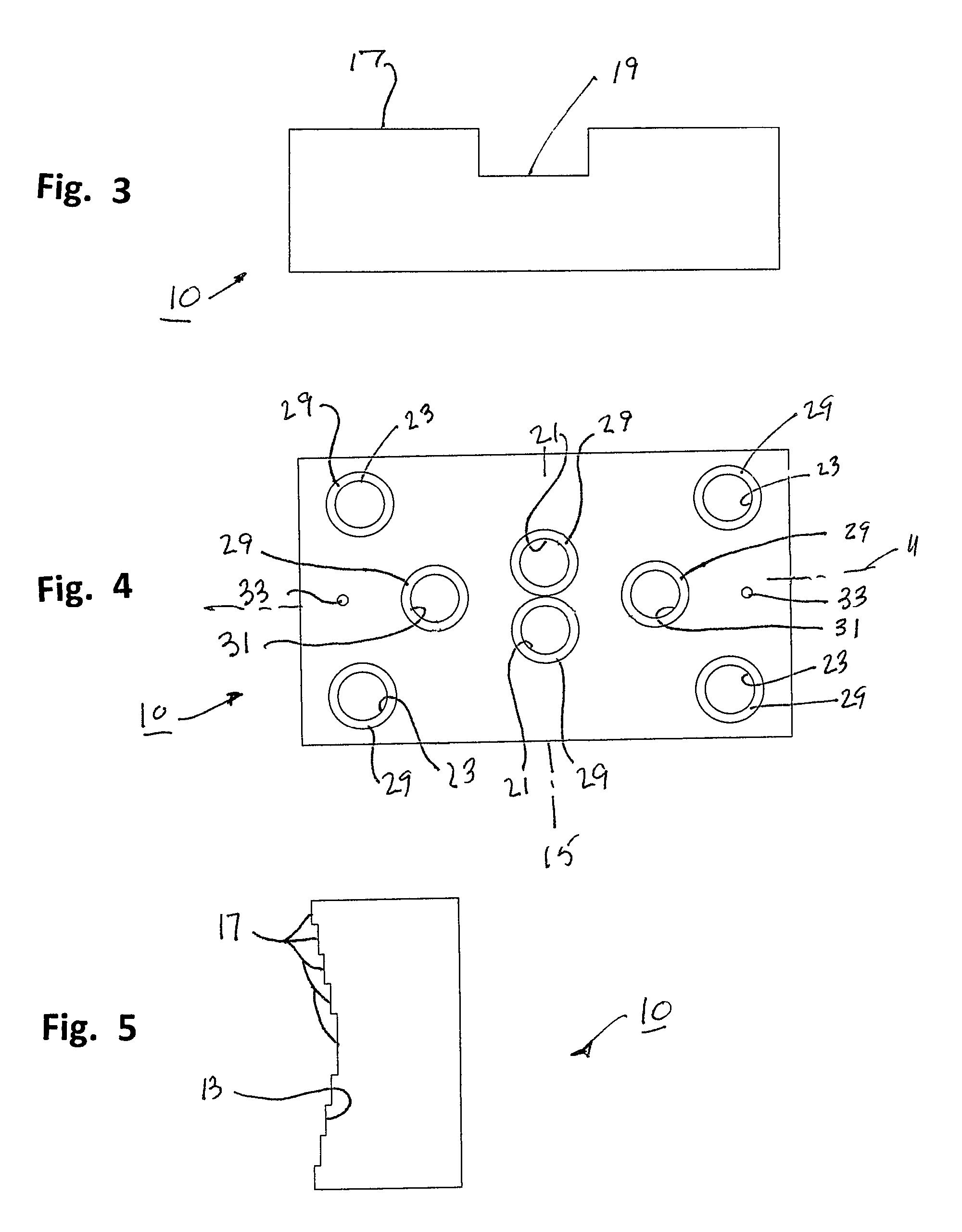

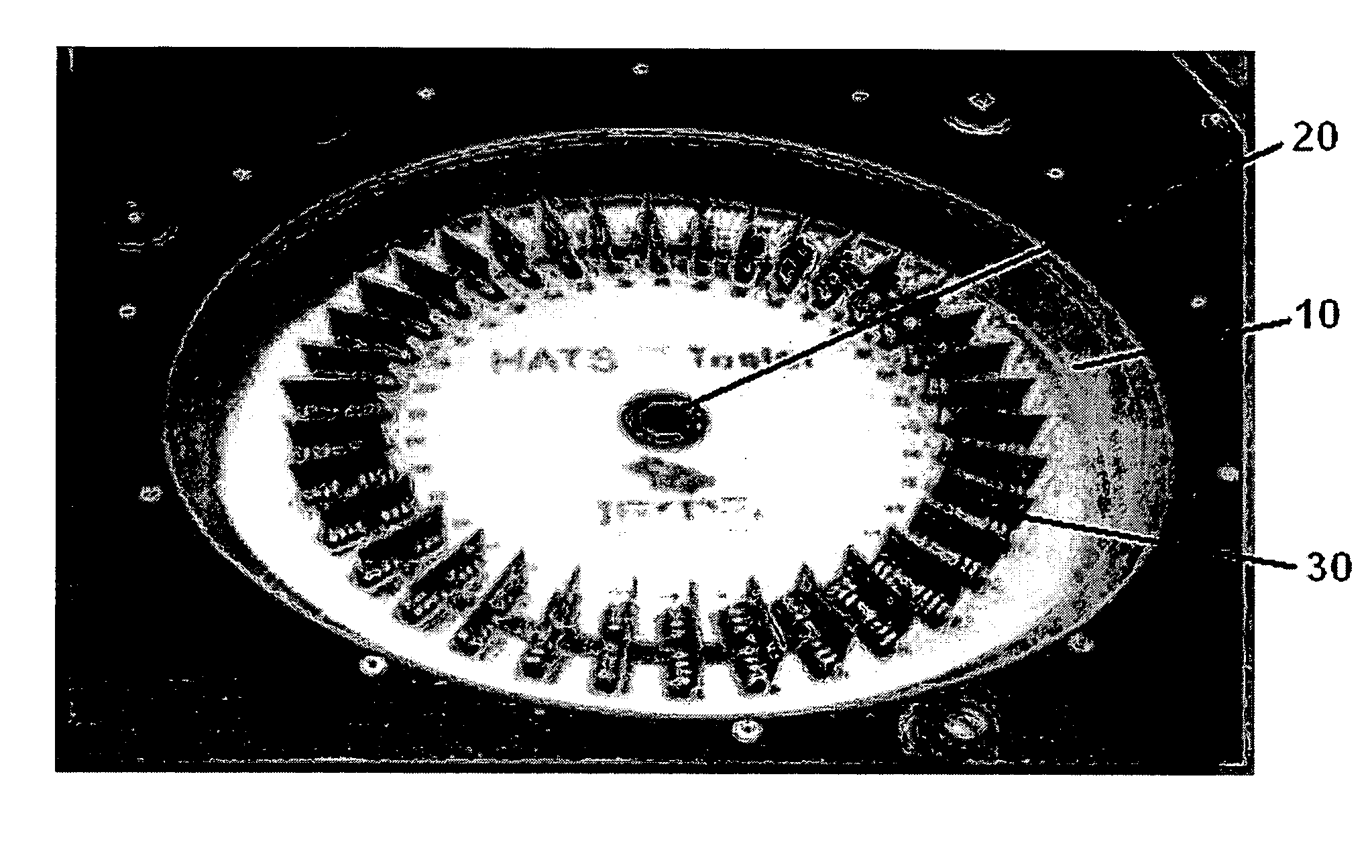

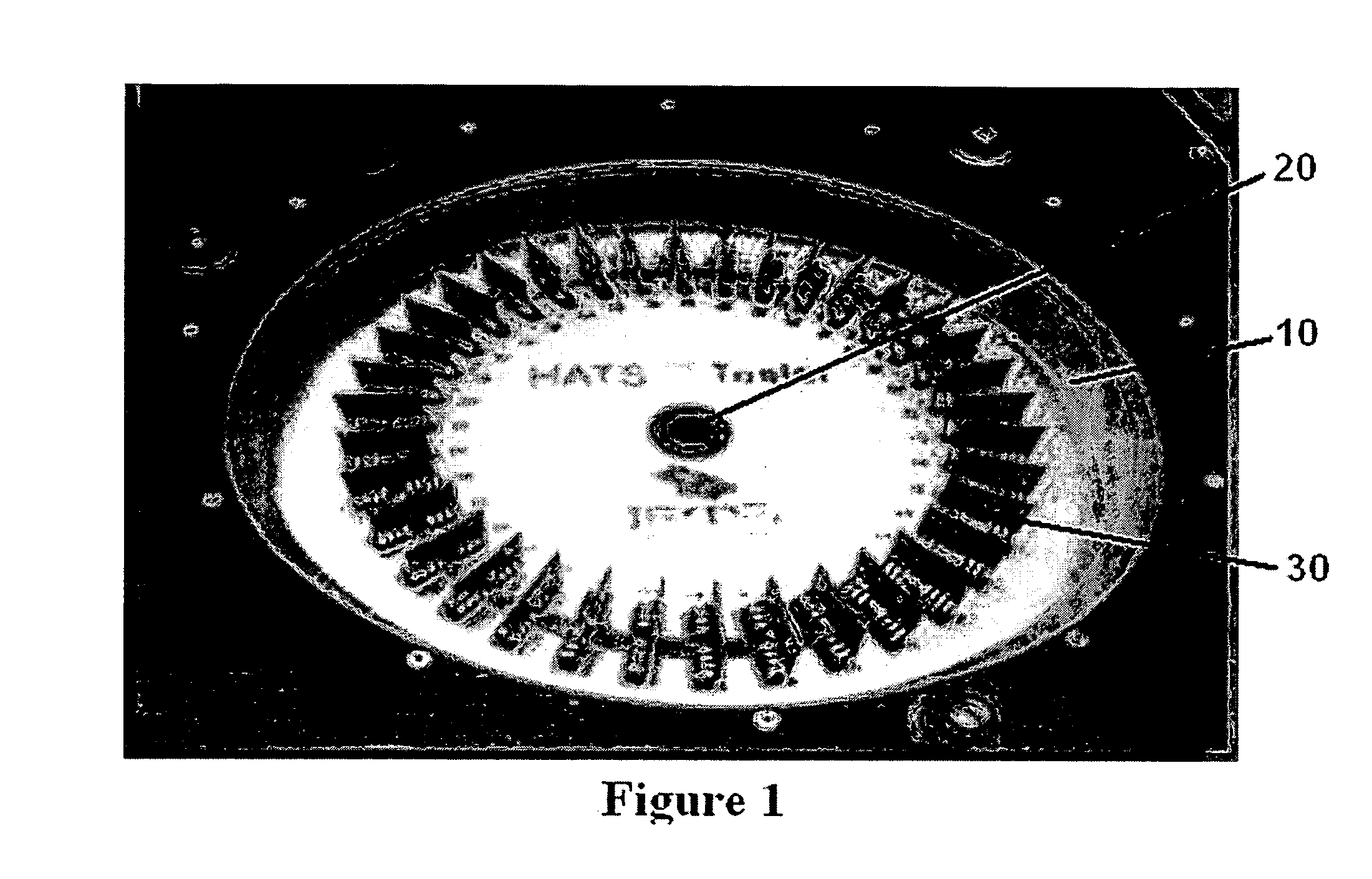

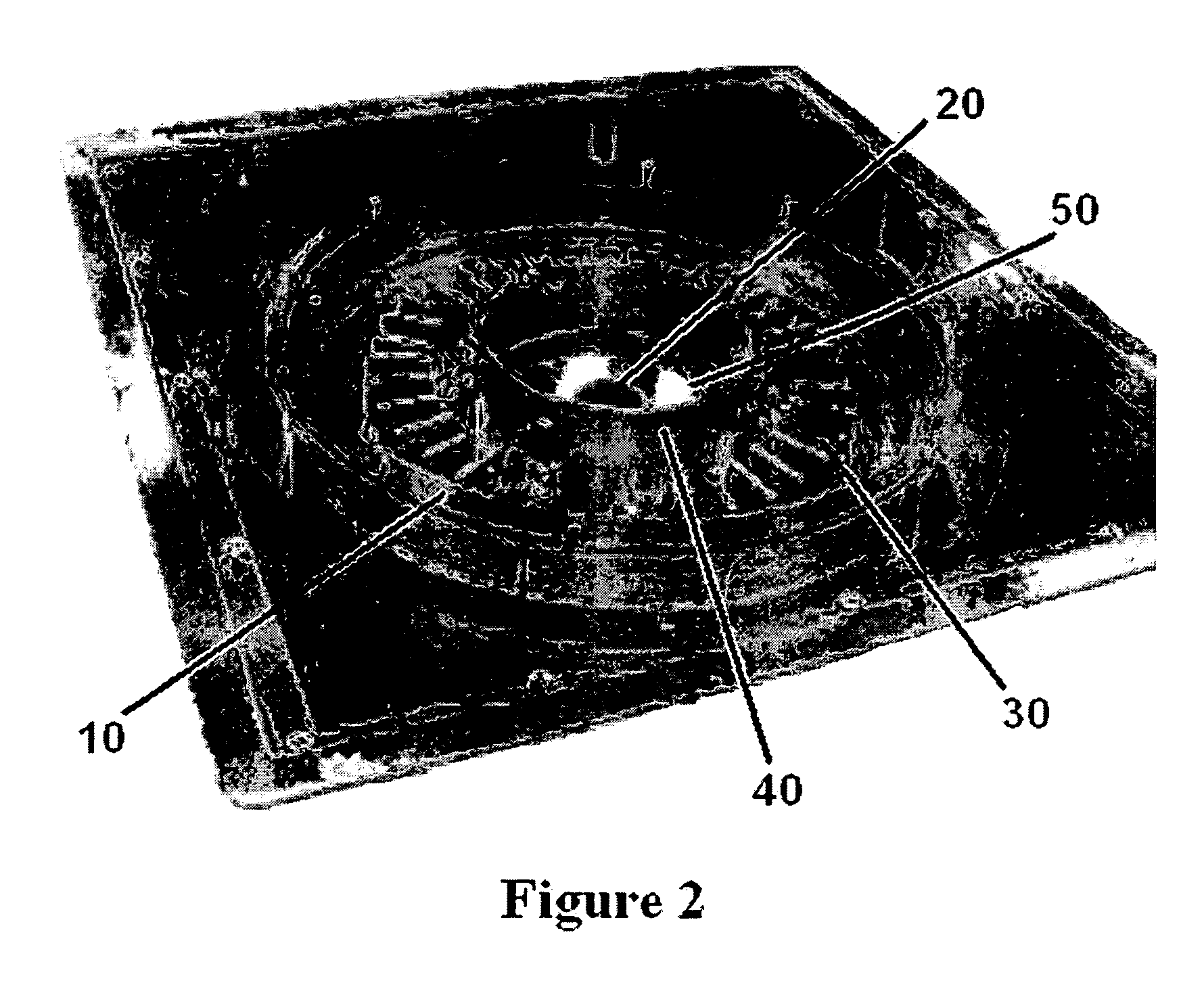

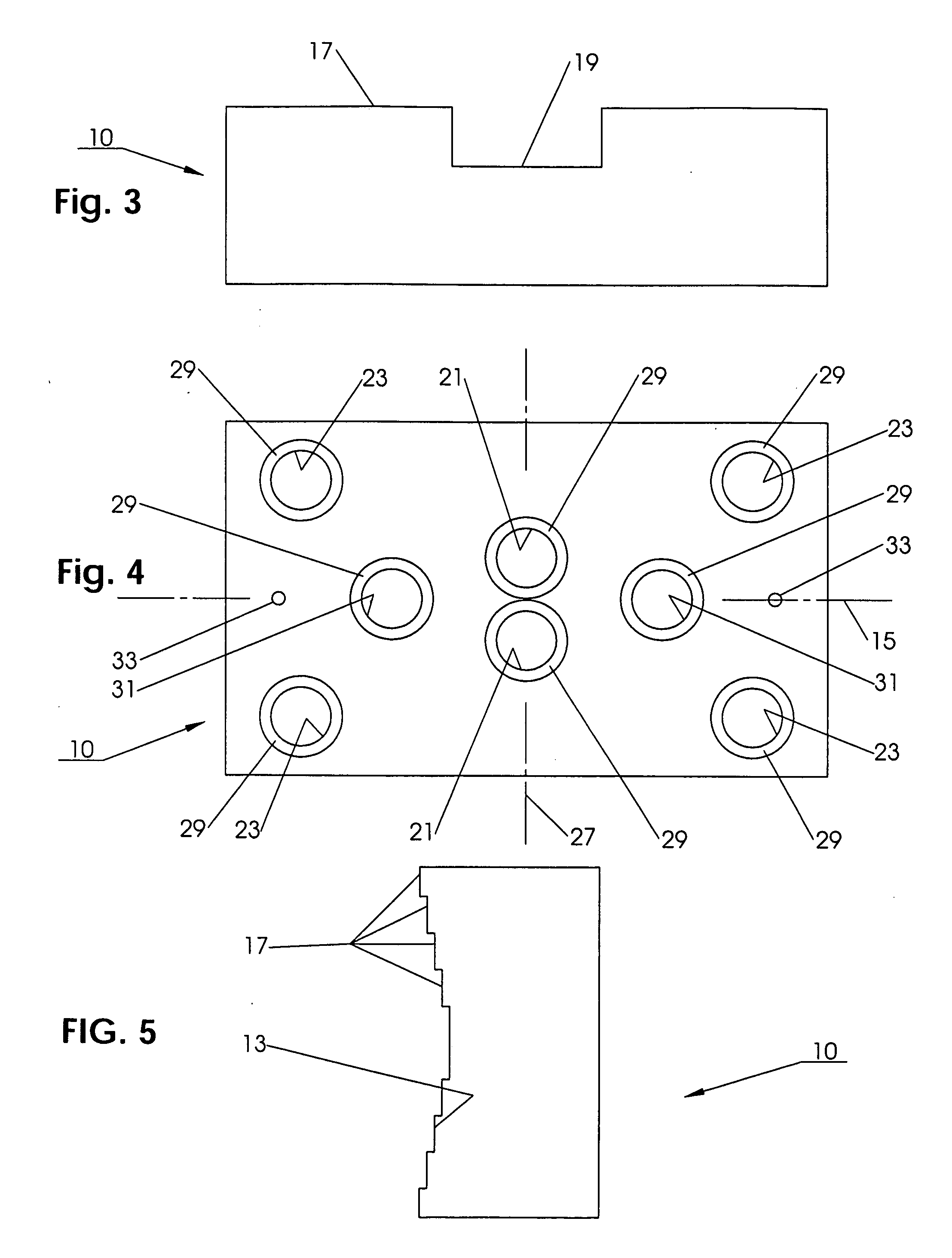

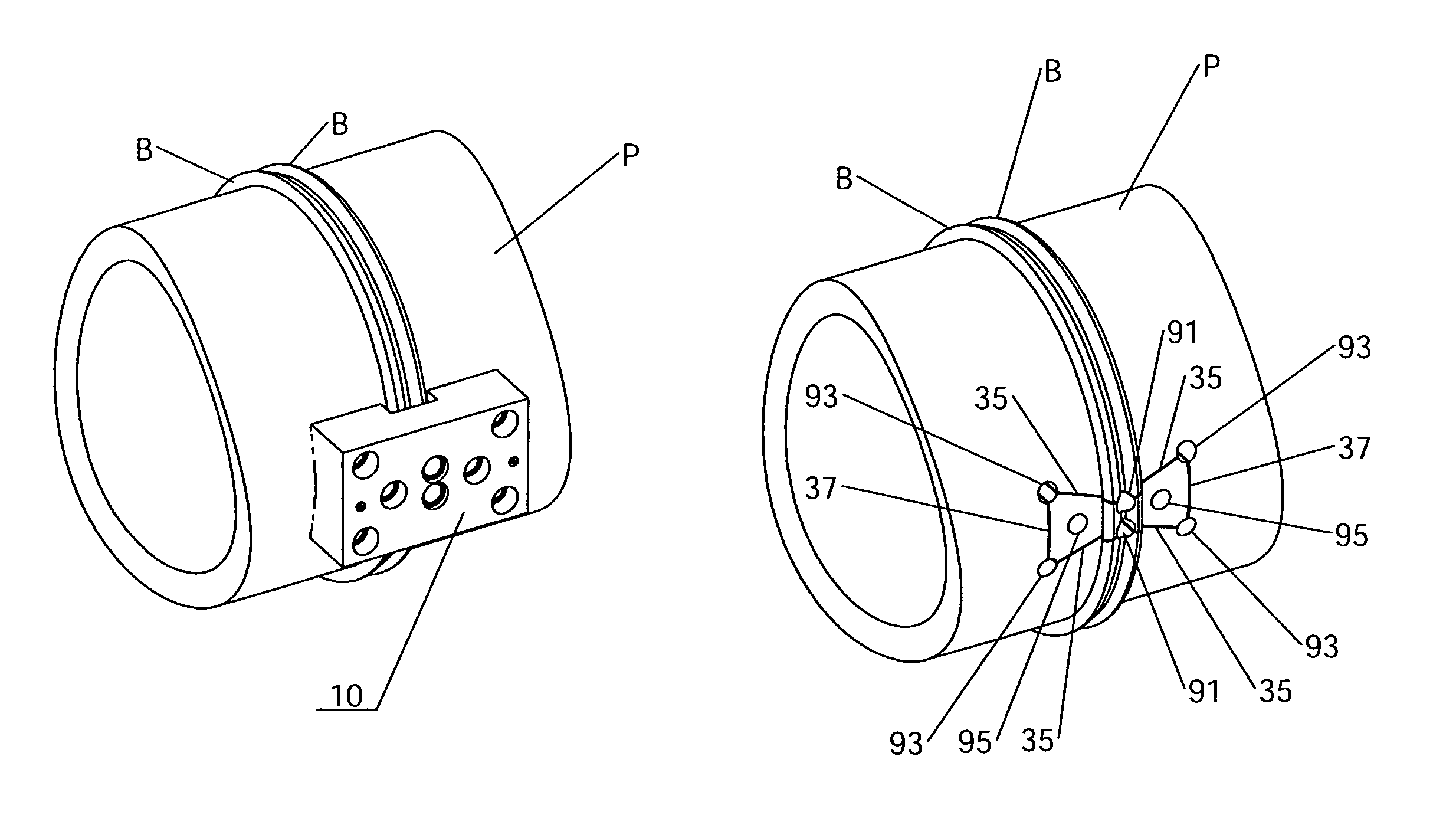

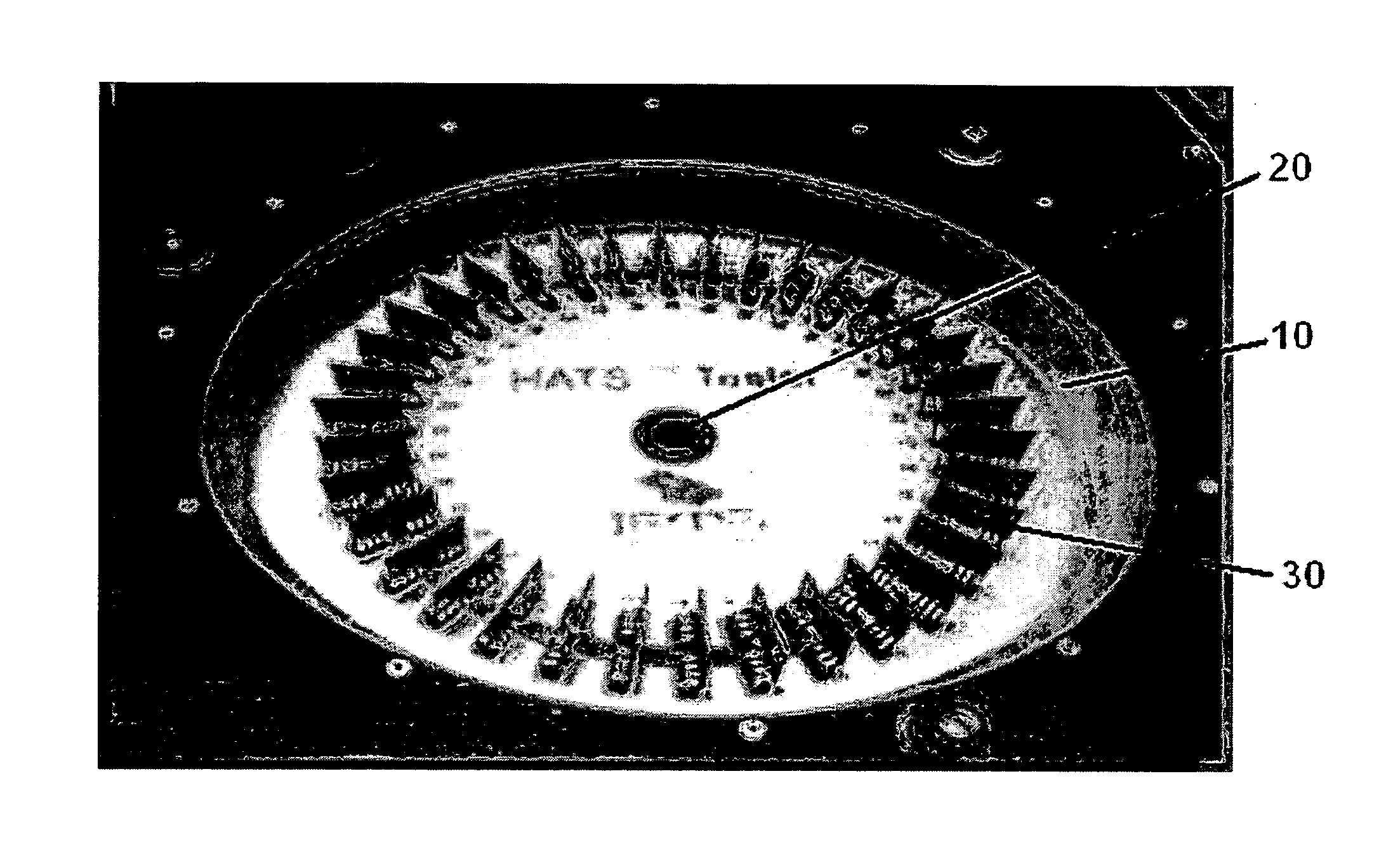

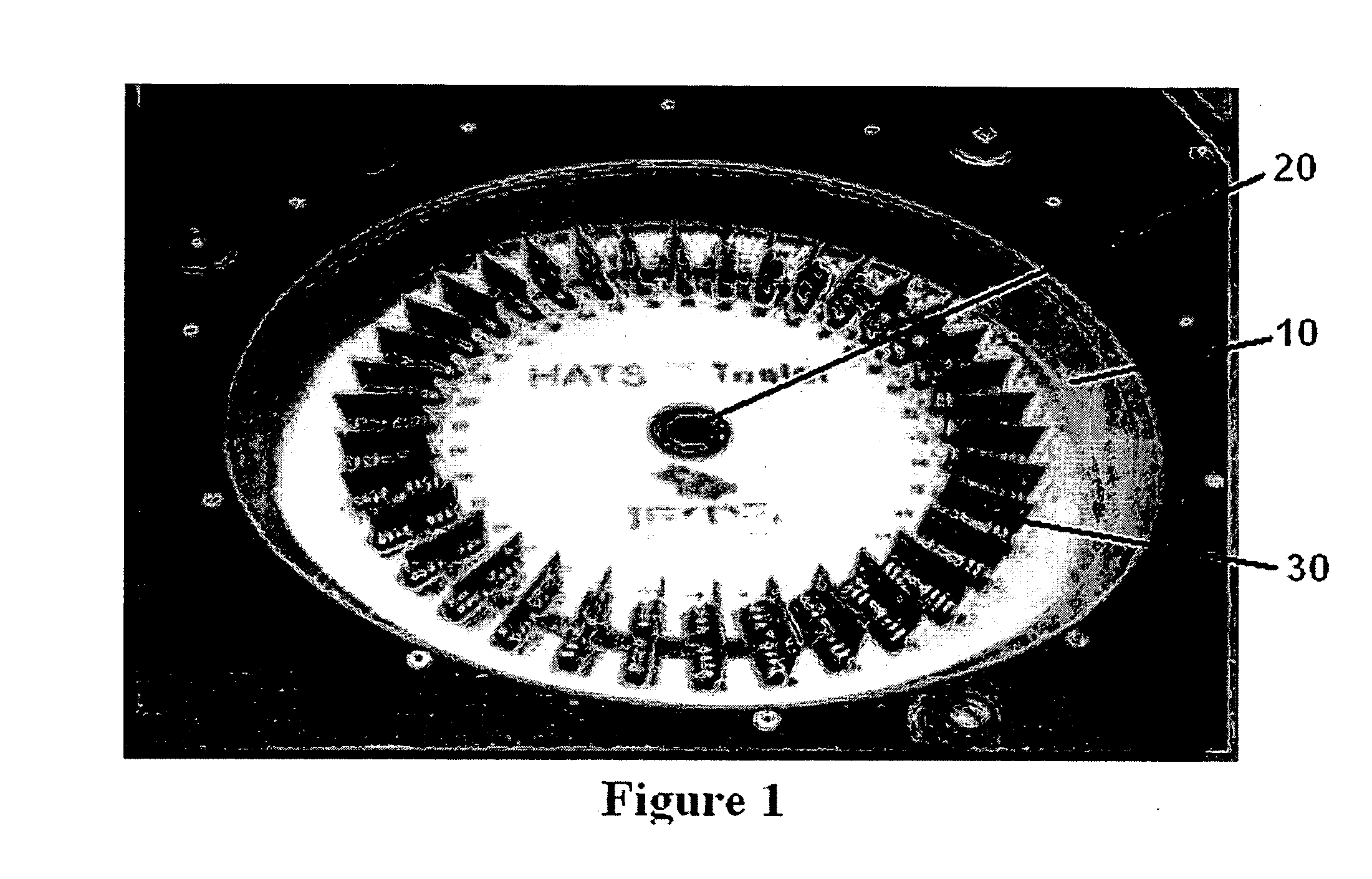

Method and apparatus for rapid thermal testing

InactiveUS7287903B2Weather/light/corrosion resistanceResistance/reactance/impedenceSingle sampleElectrical resistance and conductance

An apparatus for rapid thermal testing of samples consisting of a single sample chamber in which the samples are preferably arranged circularly around the opening through which a fluid of varying temperature, preferably air, is introduced to provide for rapid, uniform cooling and heating of the samples. The samples are preferably uniformly spaced to allow for uniform air flow. The samples are mounted in slots which are preferably oriented radially outward from the opening. The sample mounts comprise electrical connectors which form a network connected to at least one ohmmeter for measuring the resistance of the samples. The samples preferably comprise test coupons, each with multiple daisy-chained nets of vias or other components to be tested. Also a method for thermal testing of samples consisting of steps to characterize the samples before the test is run. First, the resistance of the samples which correlates to each target temperature is determined, and the time required for the samples to reach that resistance when they are heated or cooled is measured. Then, for reliability testing, the temperature of the samples is cycled between the target temperatures, where the cycle segment durations are given by the times measured in the characterization steps.

Owner:CONDUCTOR ANALYSIS TECH

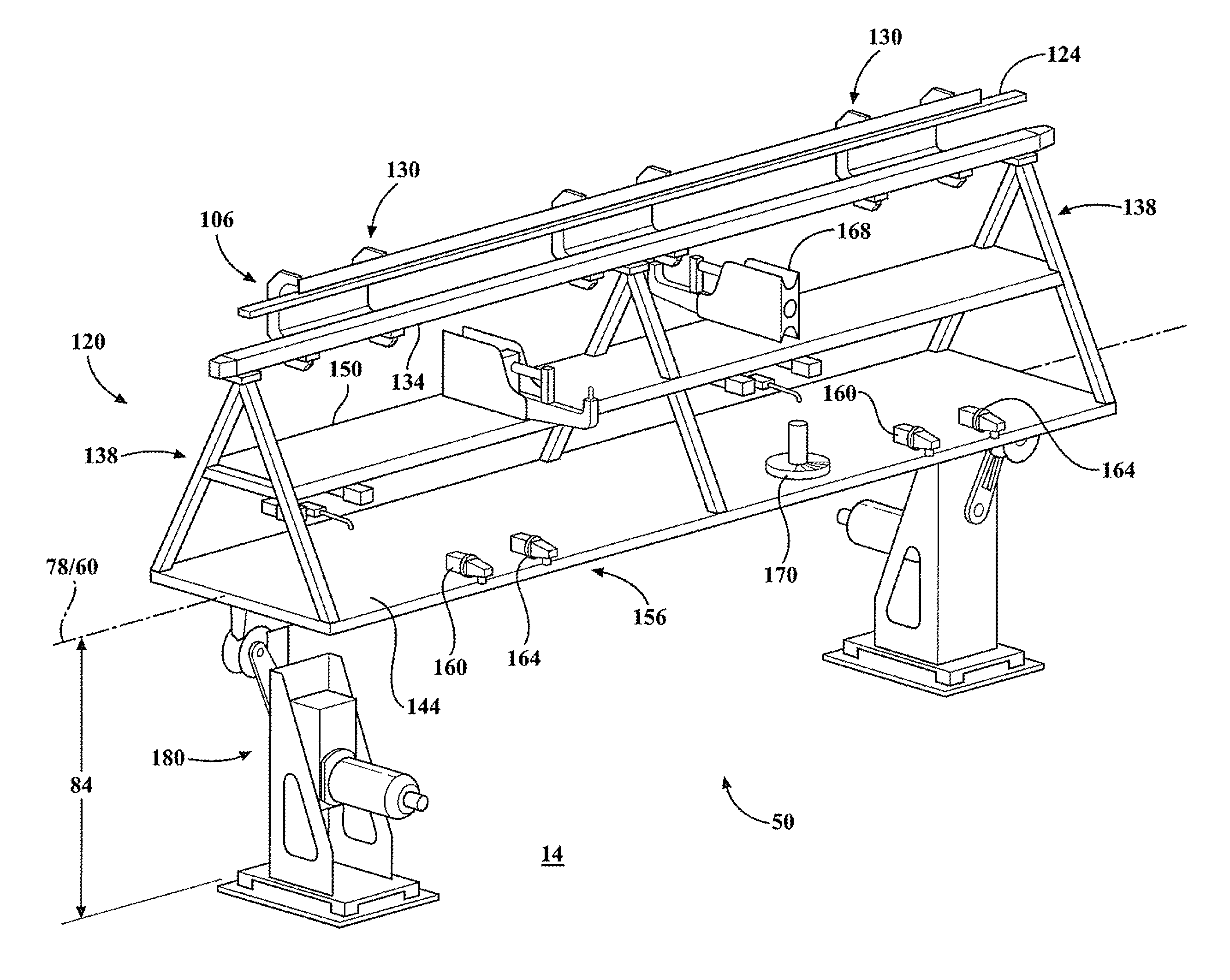

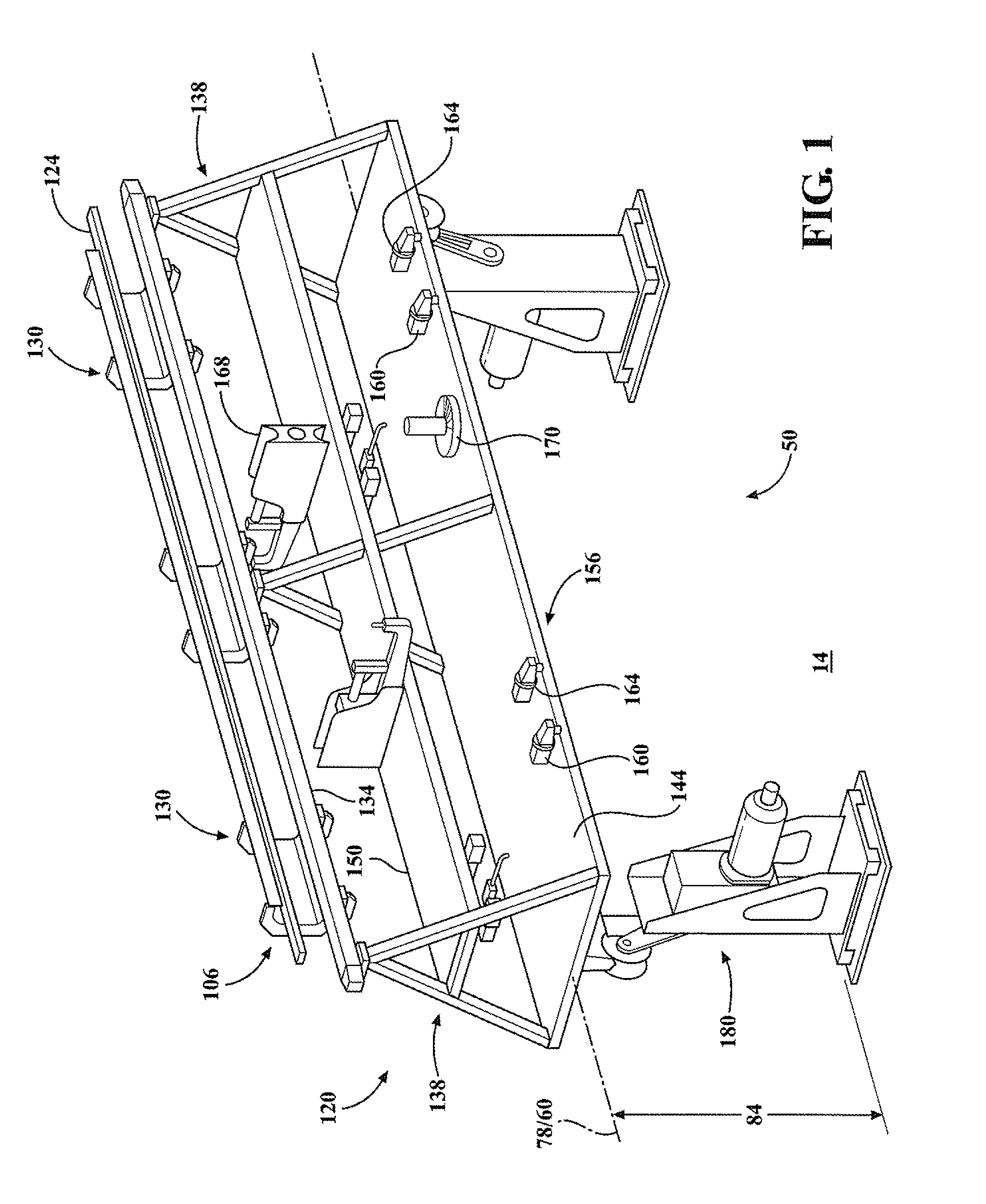

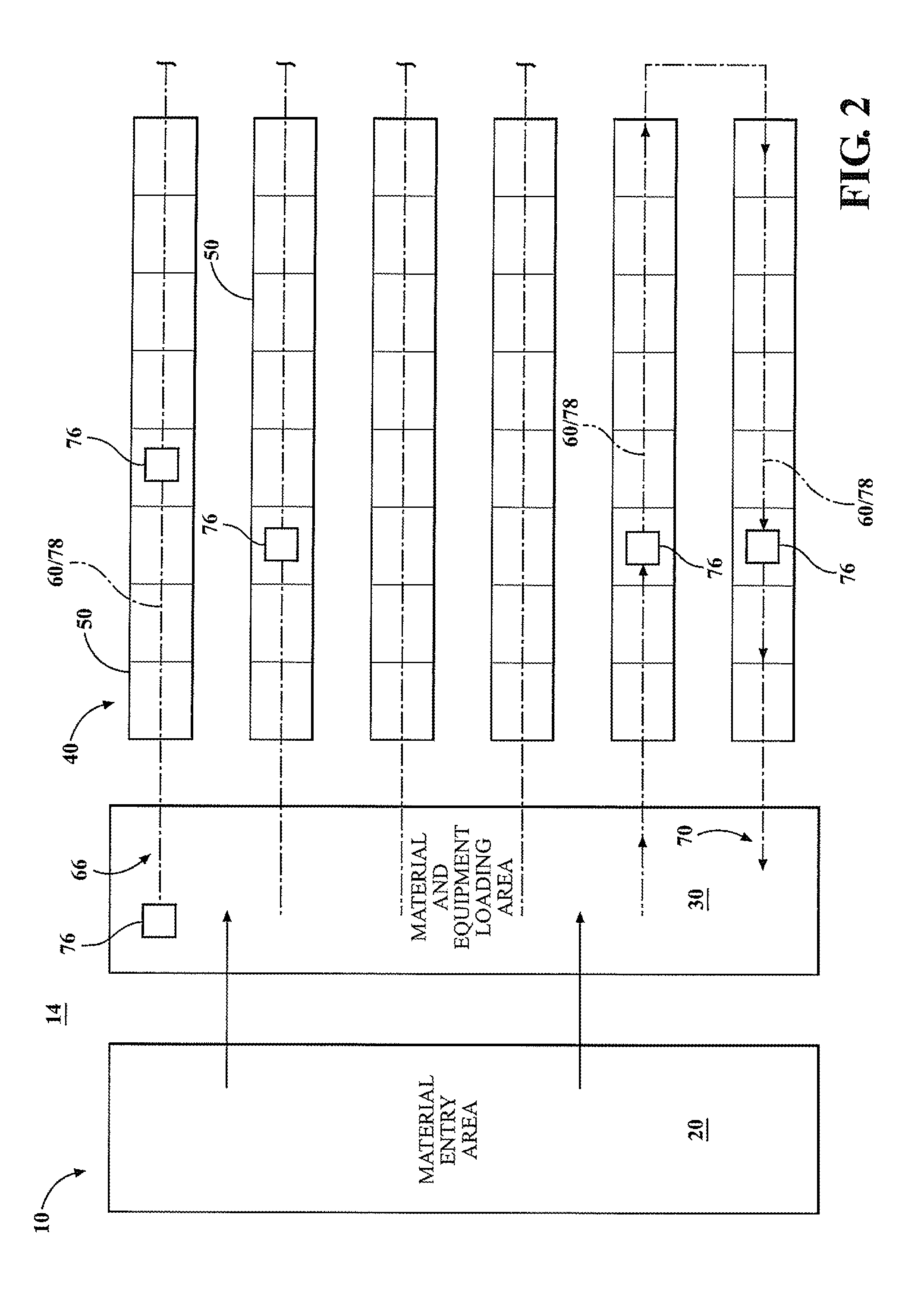

Assembly line quality control cart and method

InactiveUS20150128719A1Insufficient improvementReduce buildAssembly machinesElectrode supporting devicesTest couponQuality control

Disclosed are assembly line equipment maintenance devices and methods. A maintenance cart is selectively engaged to a transport conveyor and integrated into a moving assembly line. The cart can include maintenance tools to refurbish robot end effector tools or replacement tools engageable by robot wrists. The maintenance or replacement tools can include a variety of maintenance equipment including weld tip dressing tools, weld force gauges, replacement weld guns, and test coupon disks.

Owner:COMAU LLC

Nondestructive verification of minimum tensile elongation of manufactured parts

InactiveUS20060075827A1Eliminate needEasily sample different areas of the partMaterial strength using tensile/compressive forcesCrazingTest coupon

The minimum tensile elongation specification of a manufactured part, such as metal castings, forgings and premium mill products, is verified in-situ using a simple, inexpensive, nondestructive apparatus and method in which a through-hole is formed in the part to be tested. A disposable mandrel having a diameter adapted to expand the hole to the minimum elongation required in the part's specification is pressed into the hole. The presence of radial cracks in the part adjacent to the hole after the mandrel has been pressed in indicates that the part does not meet the specification, and the absence of such cracks indicates that it does. Since the test is performed on the part itself, the cost of the manufacture and testing of tensile test coupons is eliminated, and different areas of the part may be sampled easily, thereby enabling a closer, more thorough evaluation of part's material bulk properties.

Owner:THE BOEING CO

Method and template for producing a tensile test coupon

ActiveUS20110067500A1Precise positioningMaterial strength using tensile/compressive forcesUsing mechanical meansTest couponFusion joints

A method and template enable the testing of fusion joints of plastic pipes to be conducted by a single operator in the field at the welding site by the efficient and precise extraction from the joints to be tested of a number of high quality tensile coupons. The coupons are tested to failure in a field-suitable, well controlled, self contained, tensile testing apparatus. A narrowing bow-tie-like pattern of the coupon ensures that the failure of the coupon in the tensile test will occur at the narrowest section of the coupon. The template can be visually aligned with the joint to ensure that it is the joint that will be tested.

Owner:MCELROY MFG

Method and template for producing a tensile test coupon

ActiveUS8371036B2Precise positioningMaterial strength using tensile/compressive forcesUsing mechanical meansFusion jointsTest coupon

A method and template enable the testing of fusion joints of plastic pipes to be conducted by a single operator in the field at the welding site by the efficient and precise extraction from the joints to be tested of a number of high quality tensile coupons. The coupons are tested to failure in a field-suitable, well controlled, self contained, tensile testing apparatus. A narrowing bow-tie-like pattern of the coupon ensures that the failure of the coupon in the tensile test will occur at the narrowest section of the coupon. The template can be visually aligned with the joint to ensure that it is the joint that will be tested.

Owner:MCELROY MFG

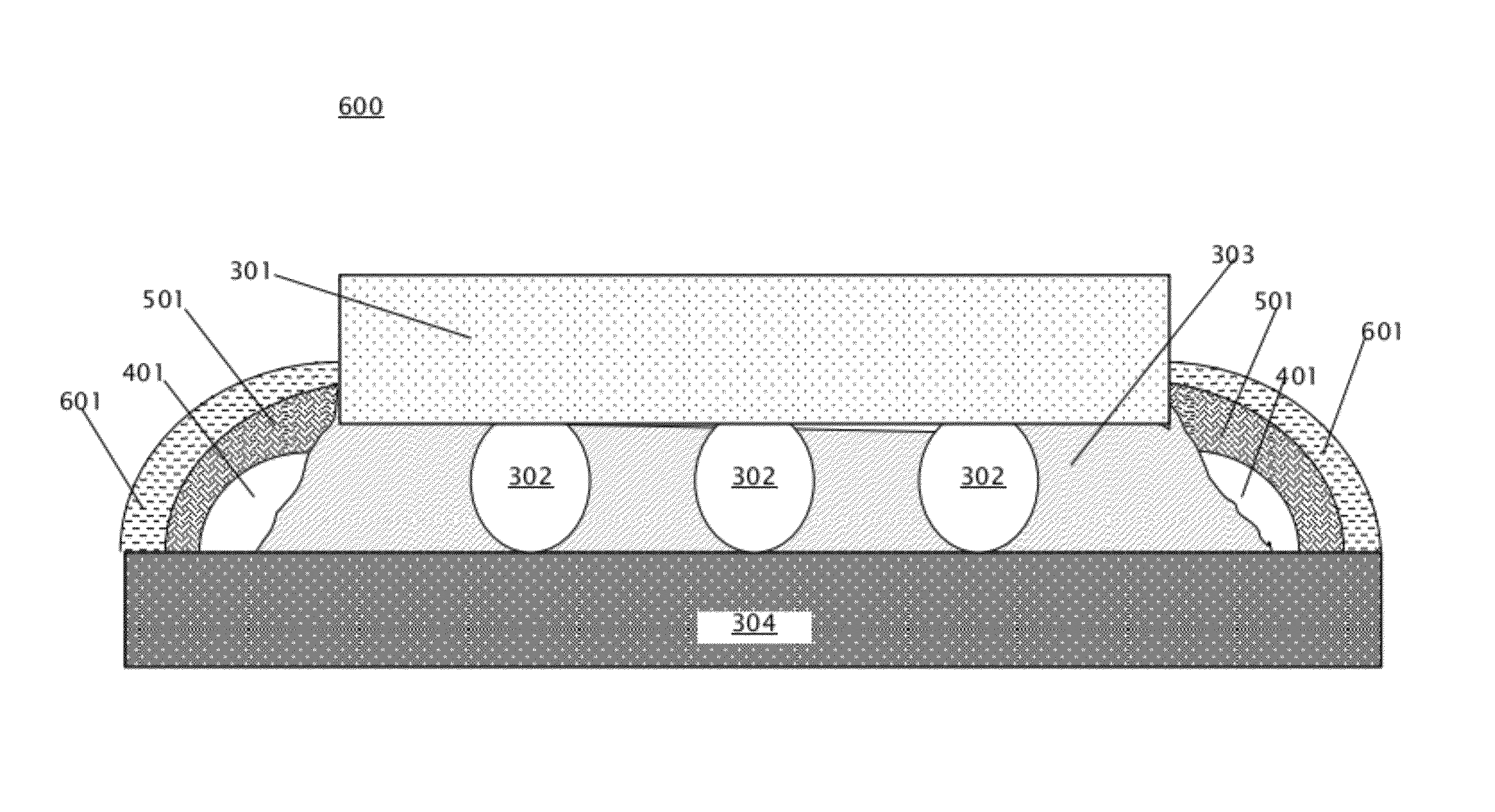

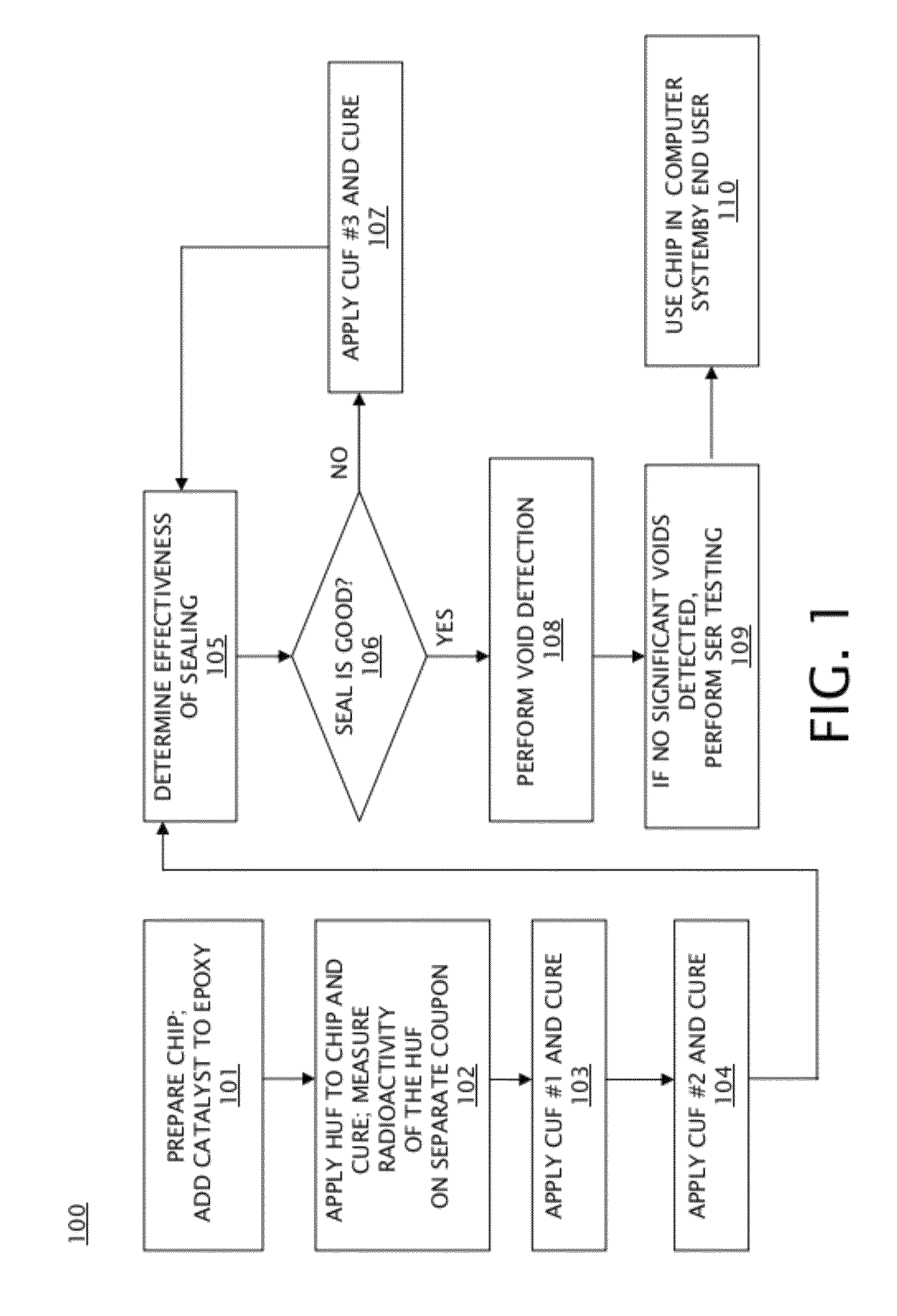

SER testing for an IC chip using hot underfill

InactiveUS8288177B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEpoxyTest coupon

Owner:ALSEPHINA INNOVATIONS INC

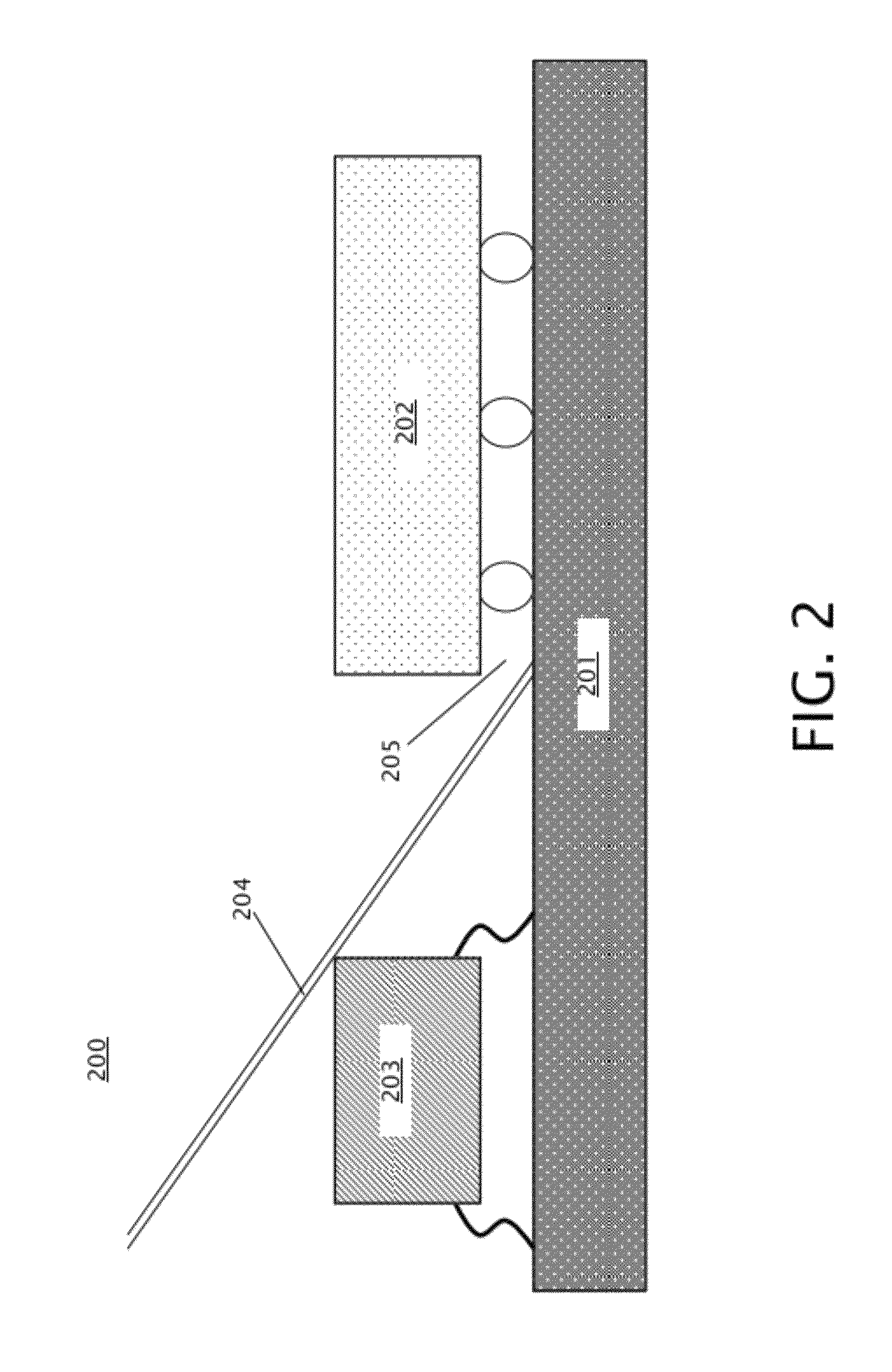

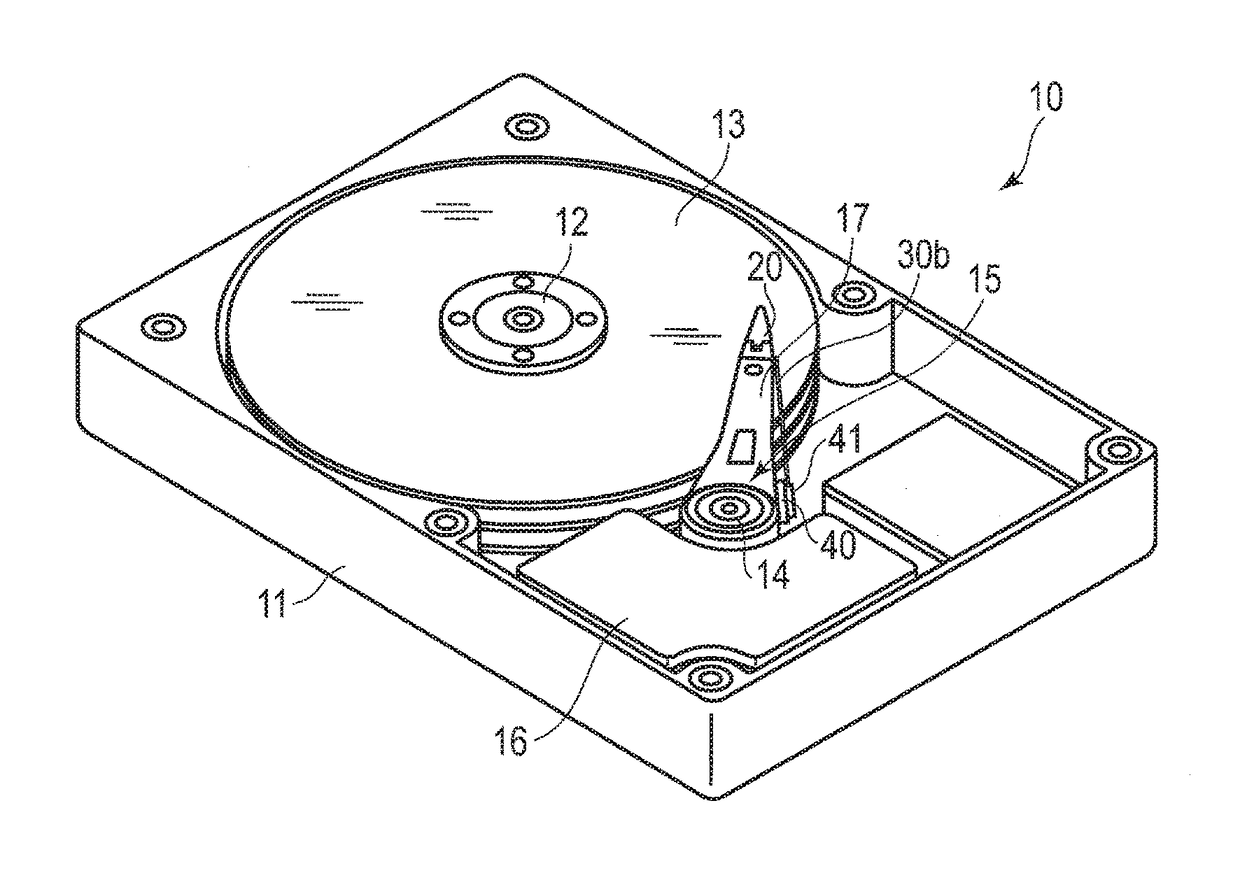

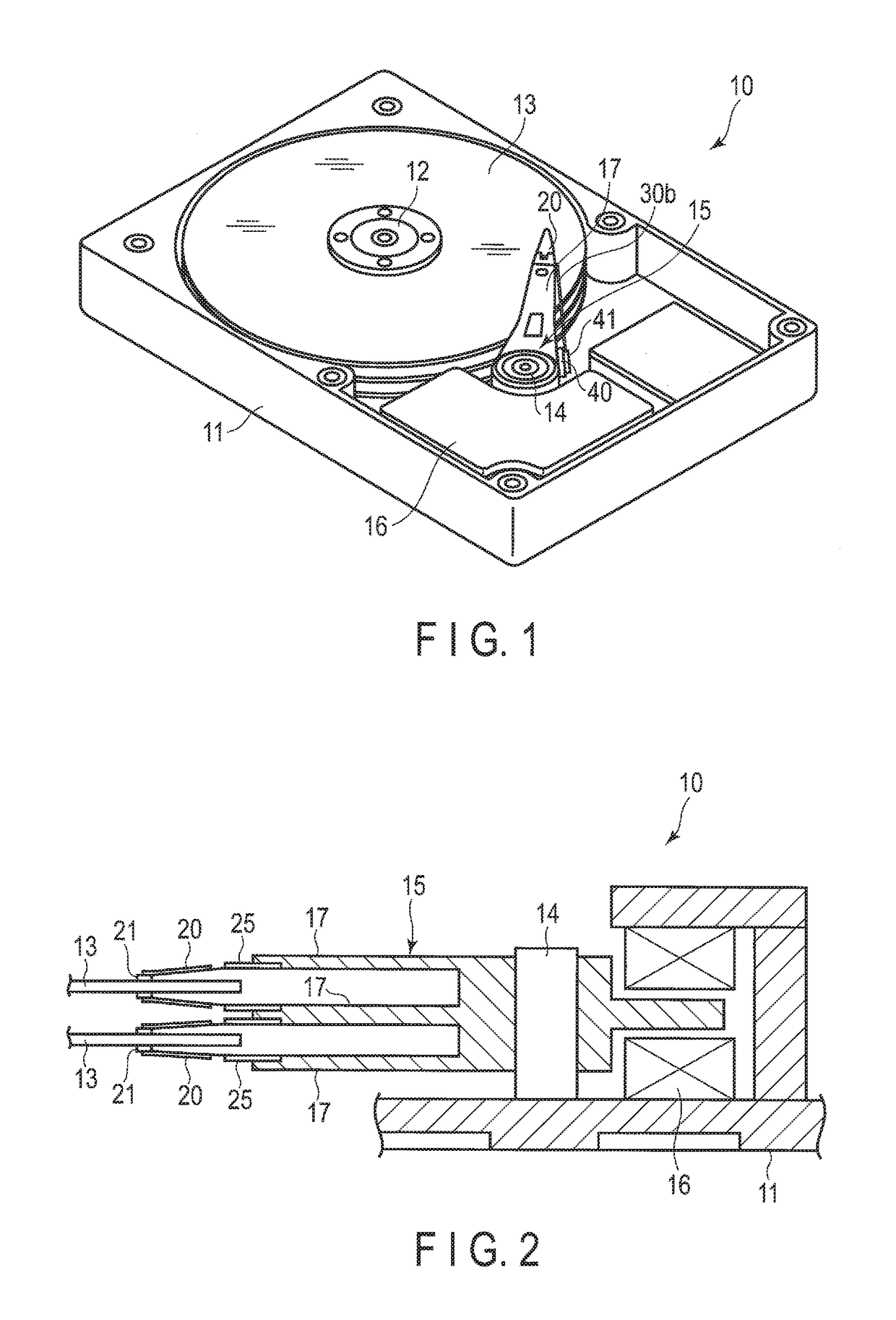

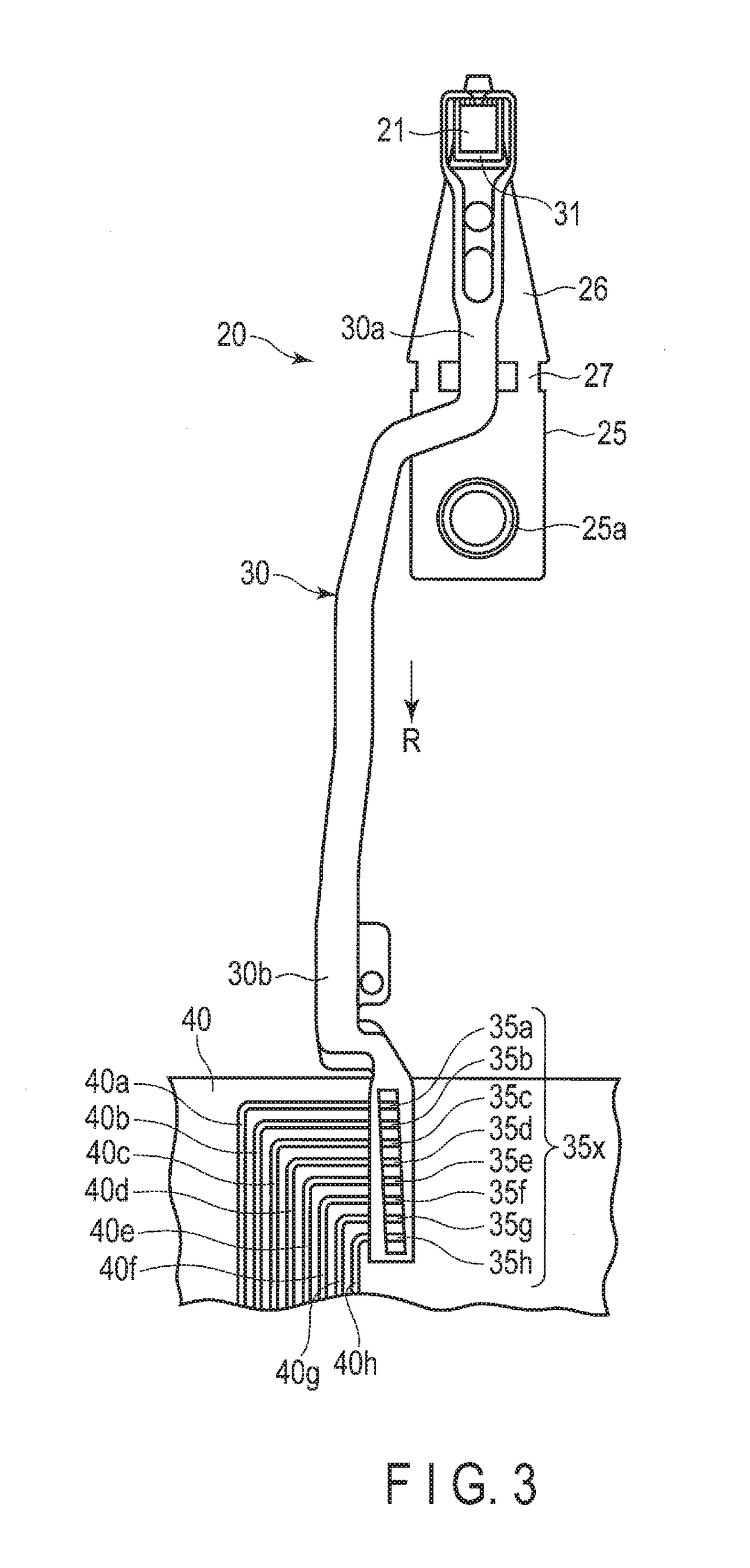

Pseudo flexure for disk drive and method of testing electronic circuit for disk drive

ActiveUS9841457B1Record information storageFunctional testing of recording headsElectrical conductorTest coupon

A test coupon includes a pseudo element circuit which is constituted of a main circuit section and an adjusting section. The main circuit section includes a first pattern conductor and second pattern conductors. The first pattern conductor and the second pattern conductors overlap one another with a dielectric layer interposed therebetween. The first pattern conductor electrically conducts to the second pattern conductors. The main circuit section represents the R-component and the L-component of an equivalent circuit, and is a dominant circuit element which determines a signal waveform. The adjusting section includes linear conductors. A peak of a voltage waveform is suppressed by the R- and L-components of the adjusting section.

Owner:NHK SPRING CO LTD

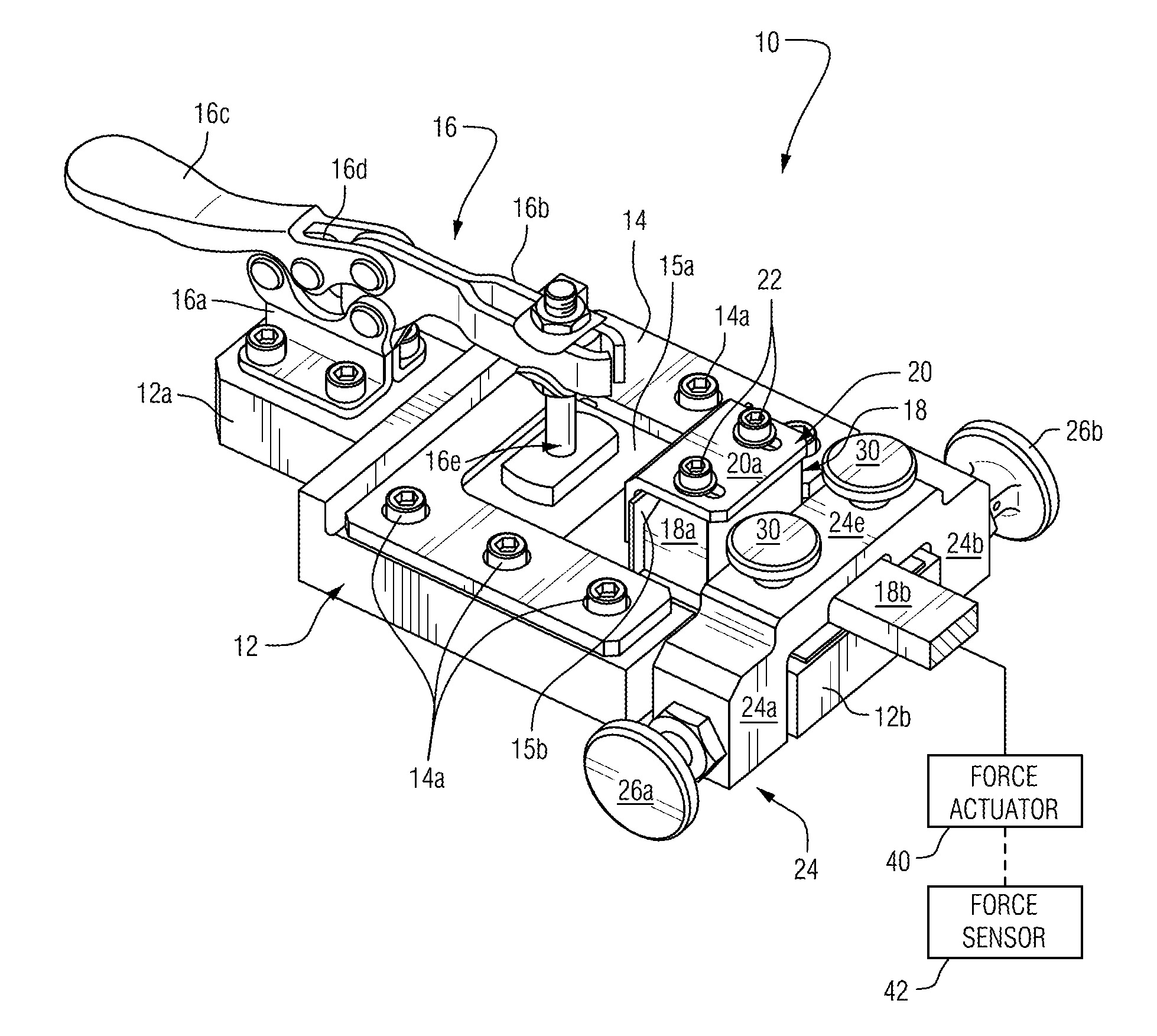

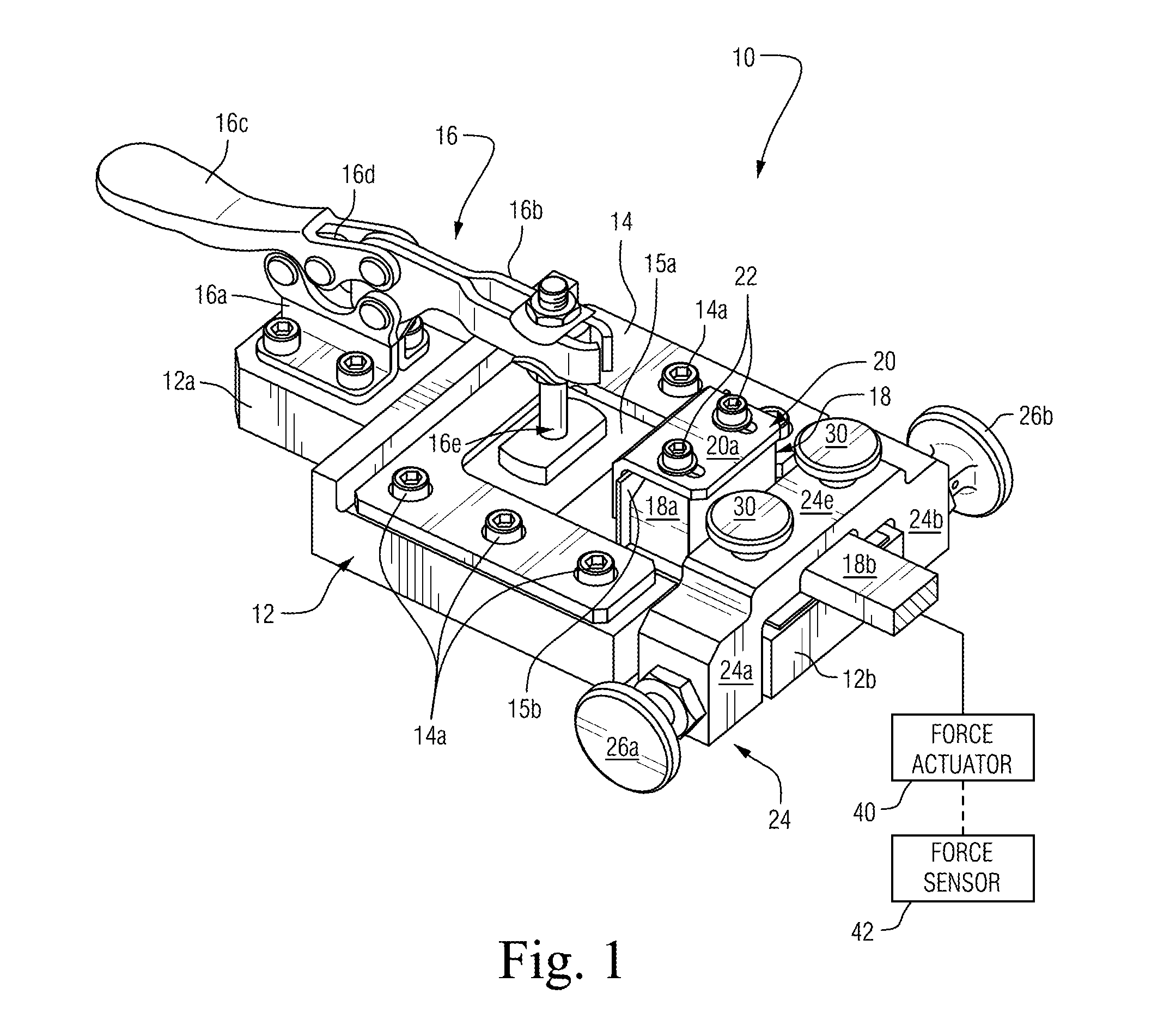

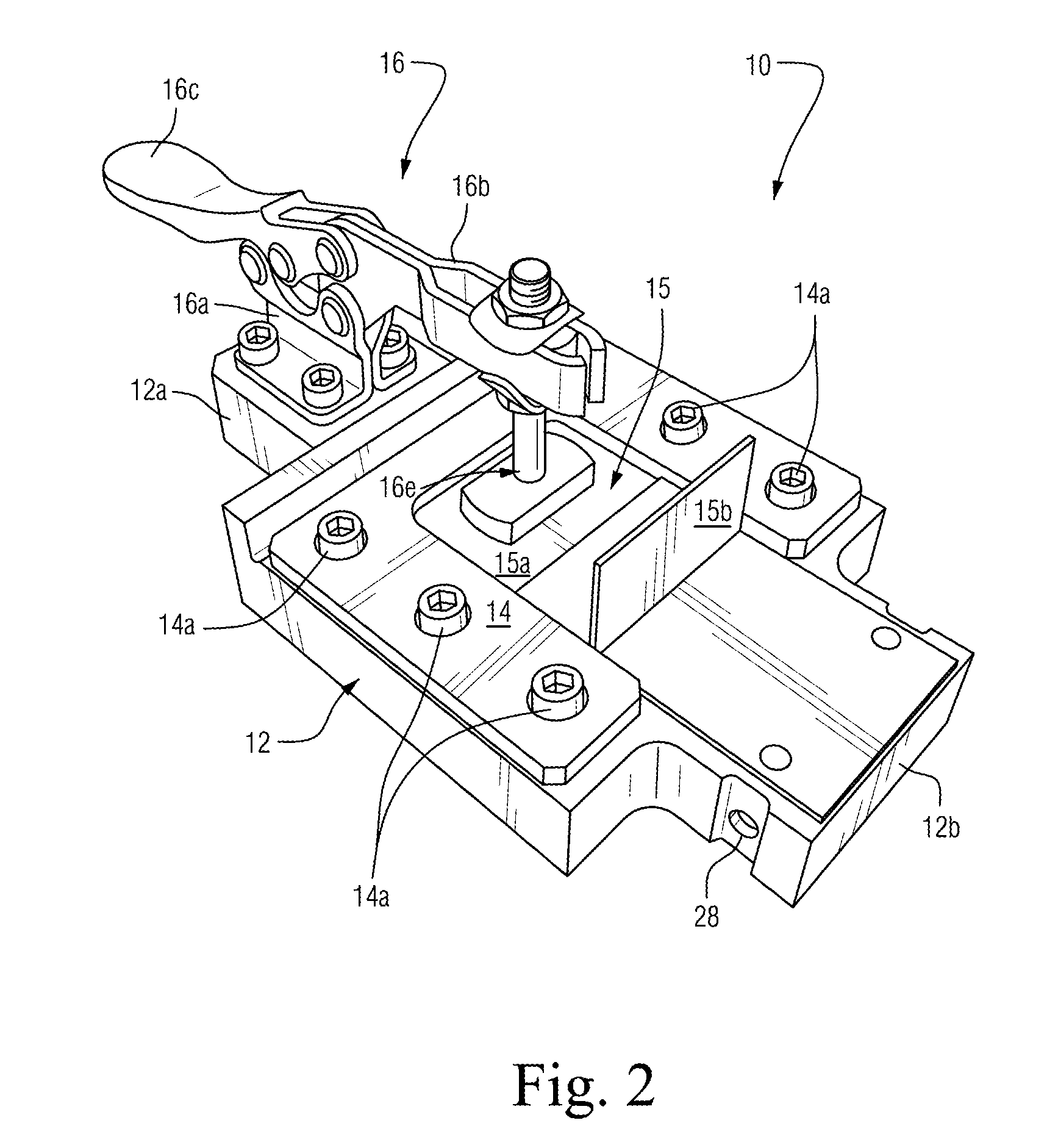

Device and methods for testing quality of welding joints

ActiveUS20140157862A1Acceleration measurementMaterial strength using single impulsive forceTest couponTest quality

Devices and methods are provided for testing weld strengths of a test coupon joint. A test coupon is positionally fixed to a base of the testing device. A punch assembly having a head portion is provided so as to exert an axial force against an upright part of the test coupon to thereby determine weld strength between the planar and upright parts of the test coupon (e.g., a maximum force at which weld failure occurs).

Owner:EMBRAER SA

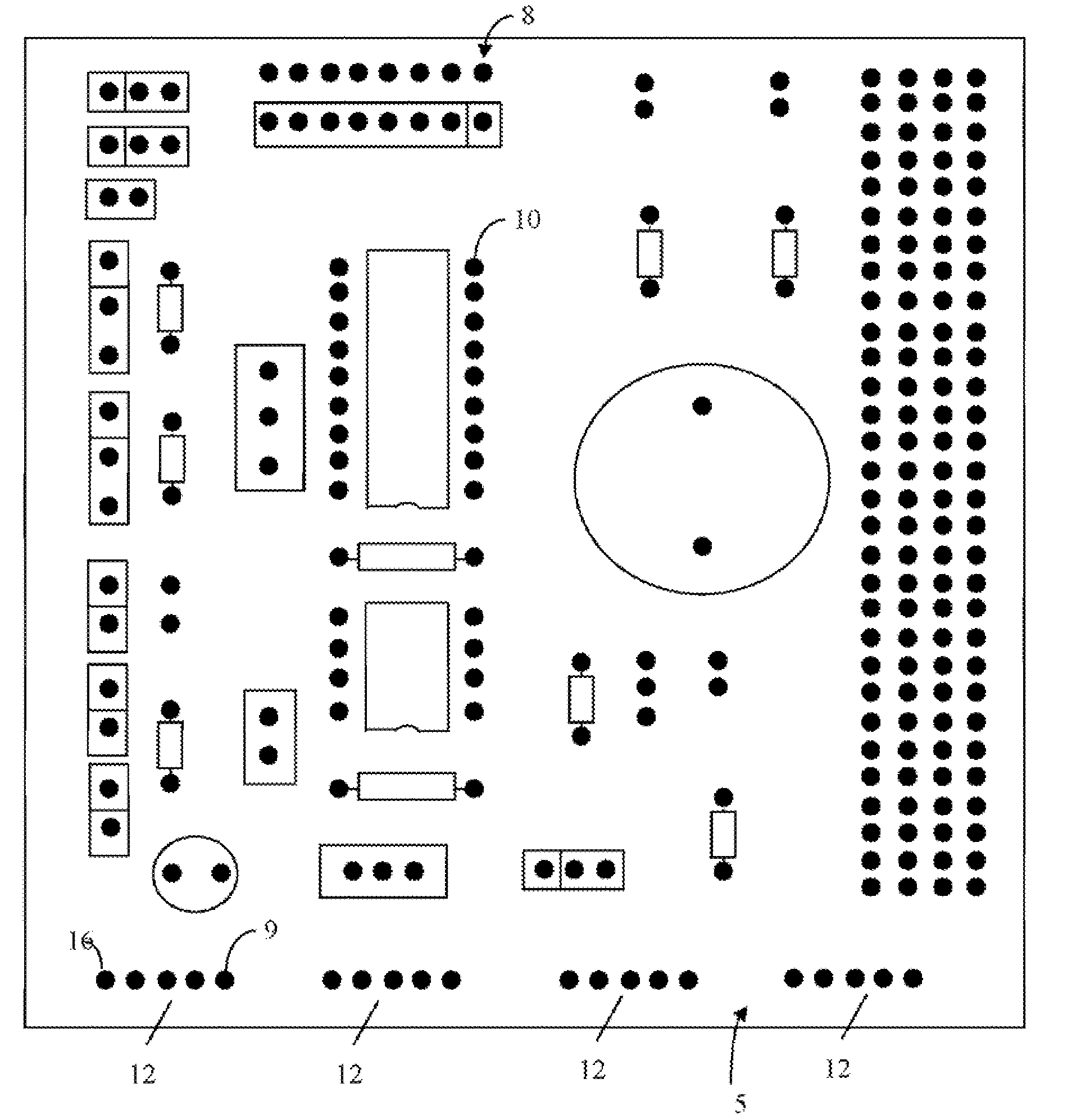

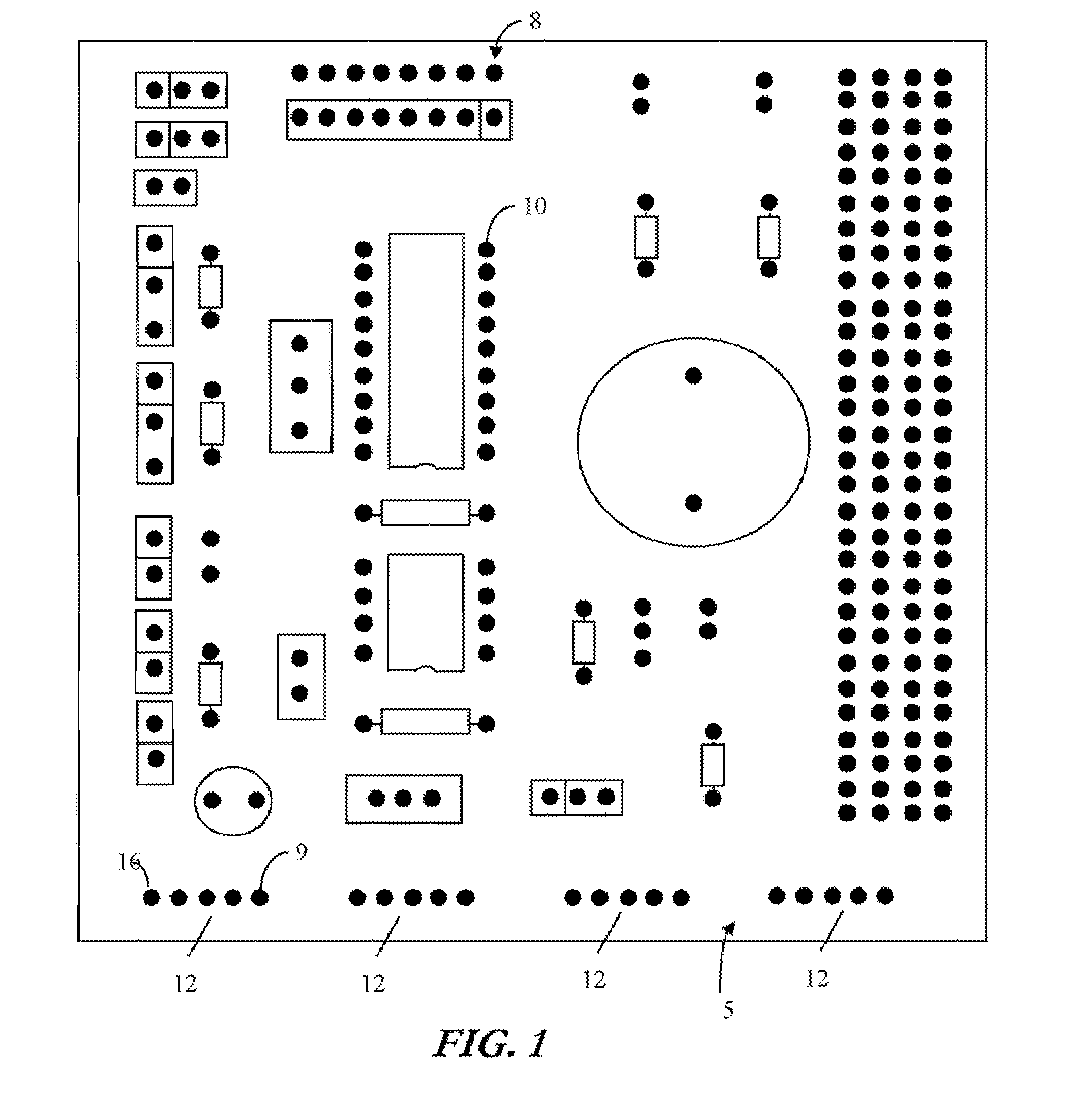

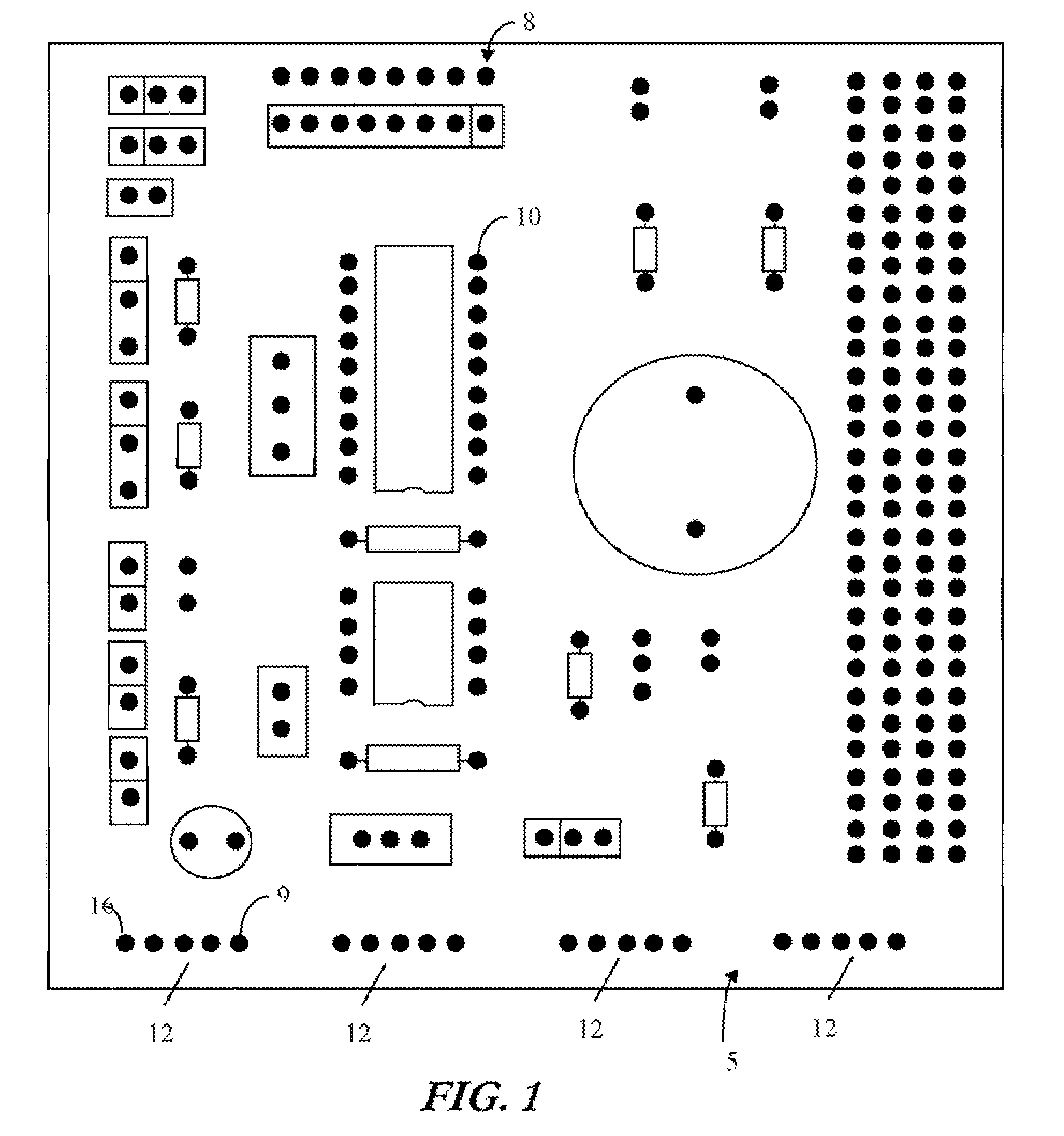

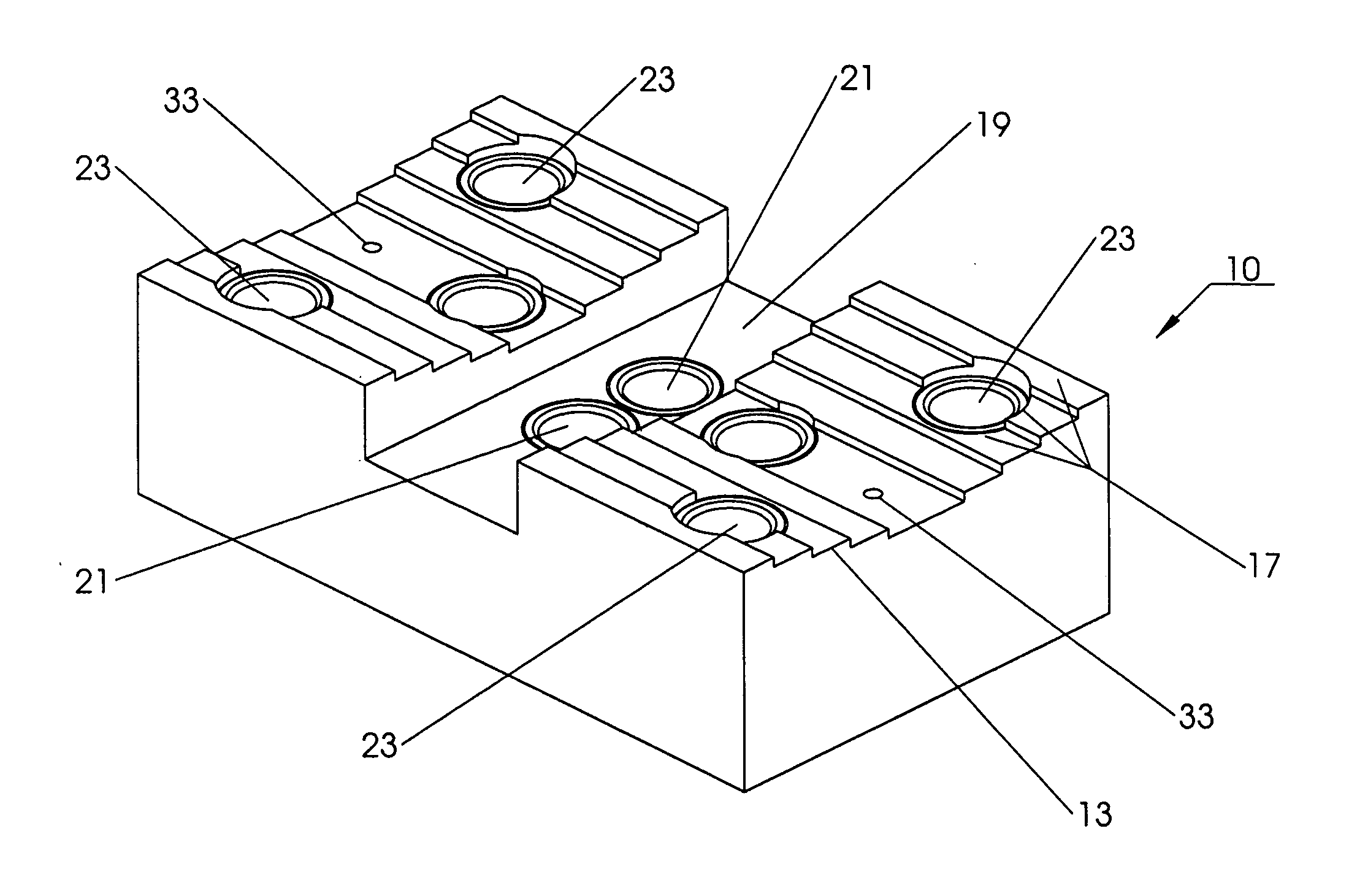

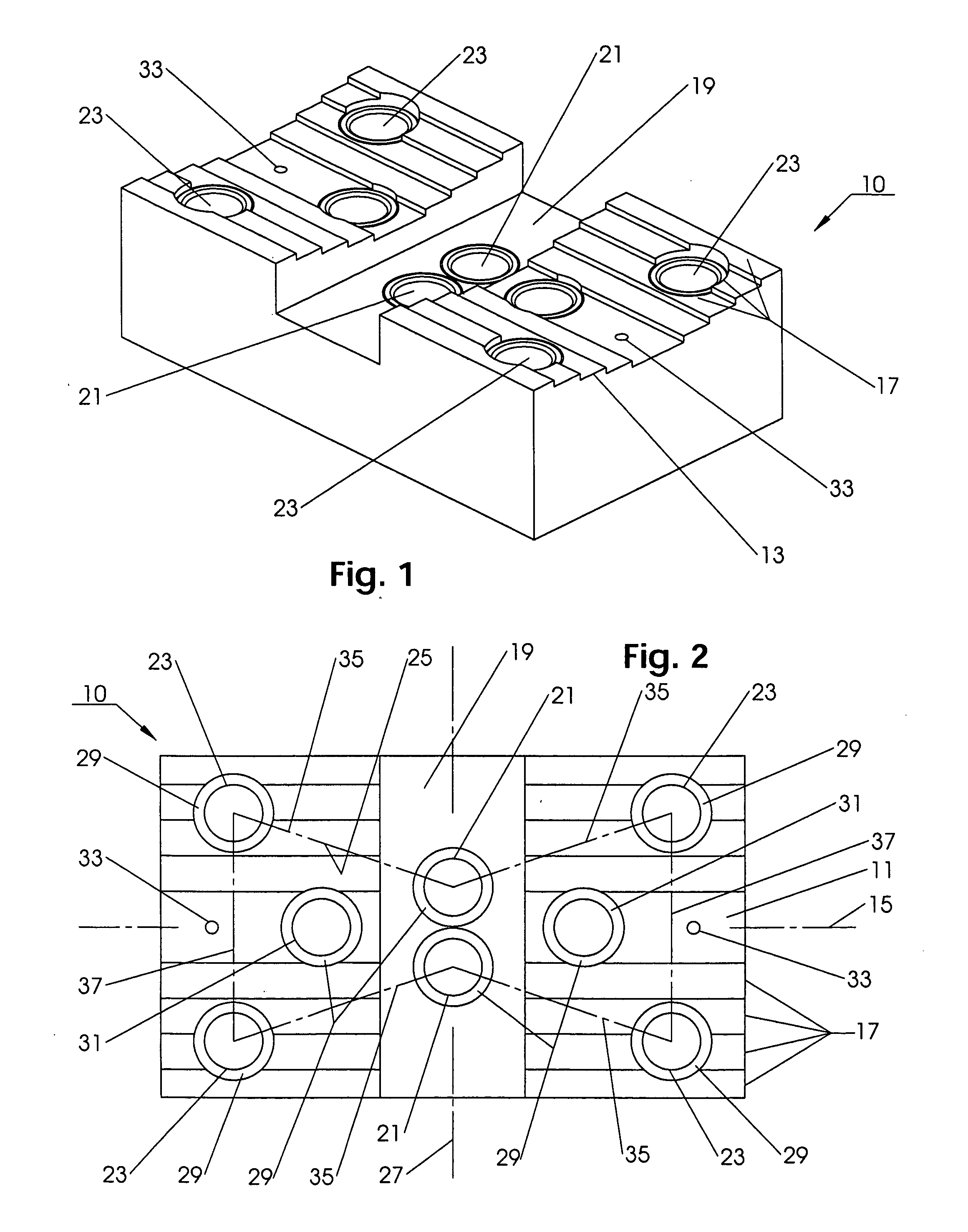

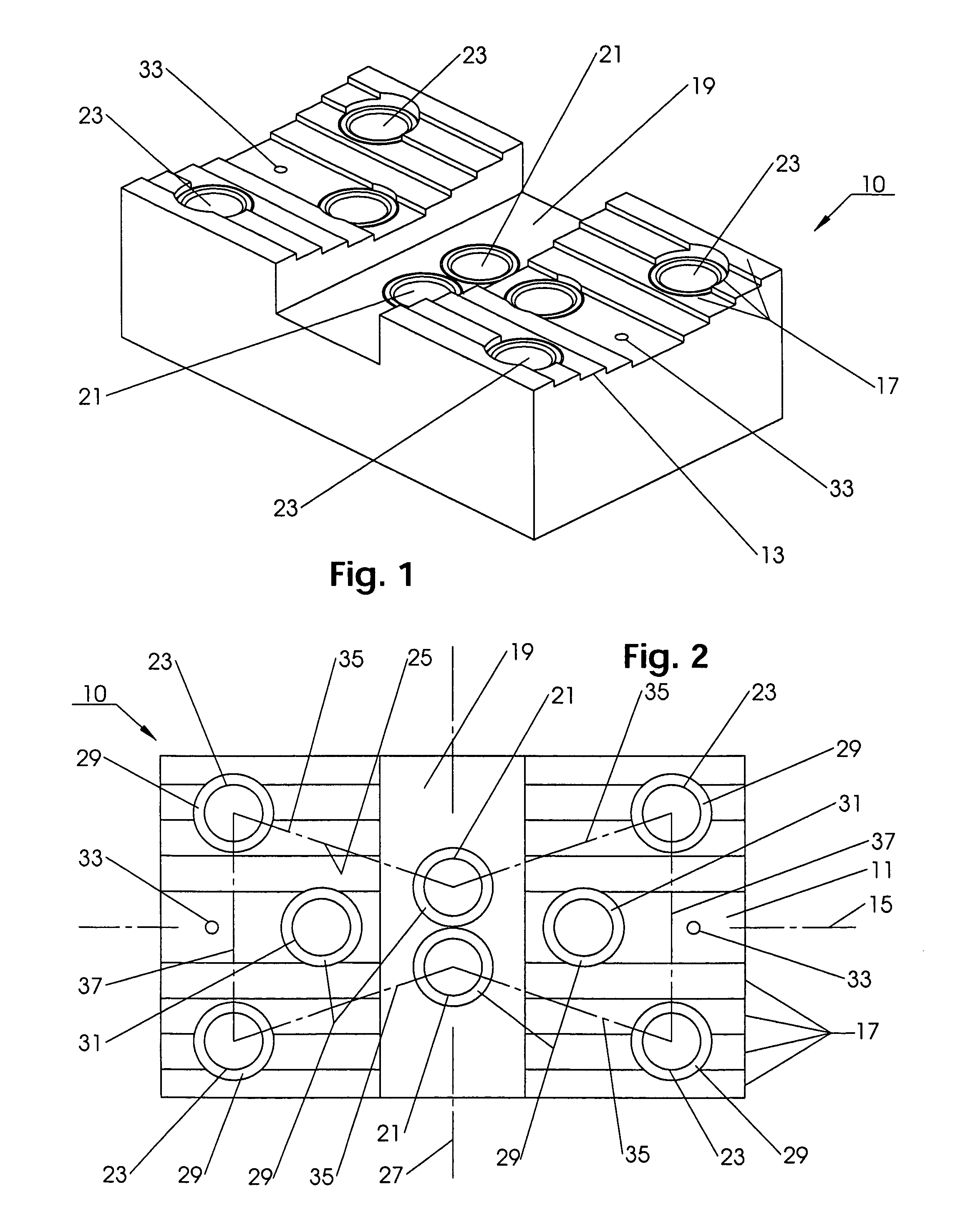

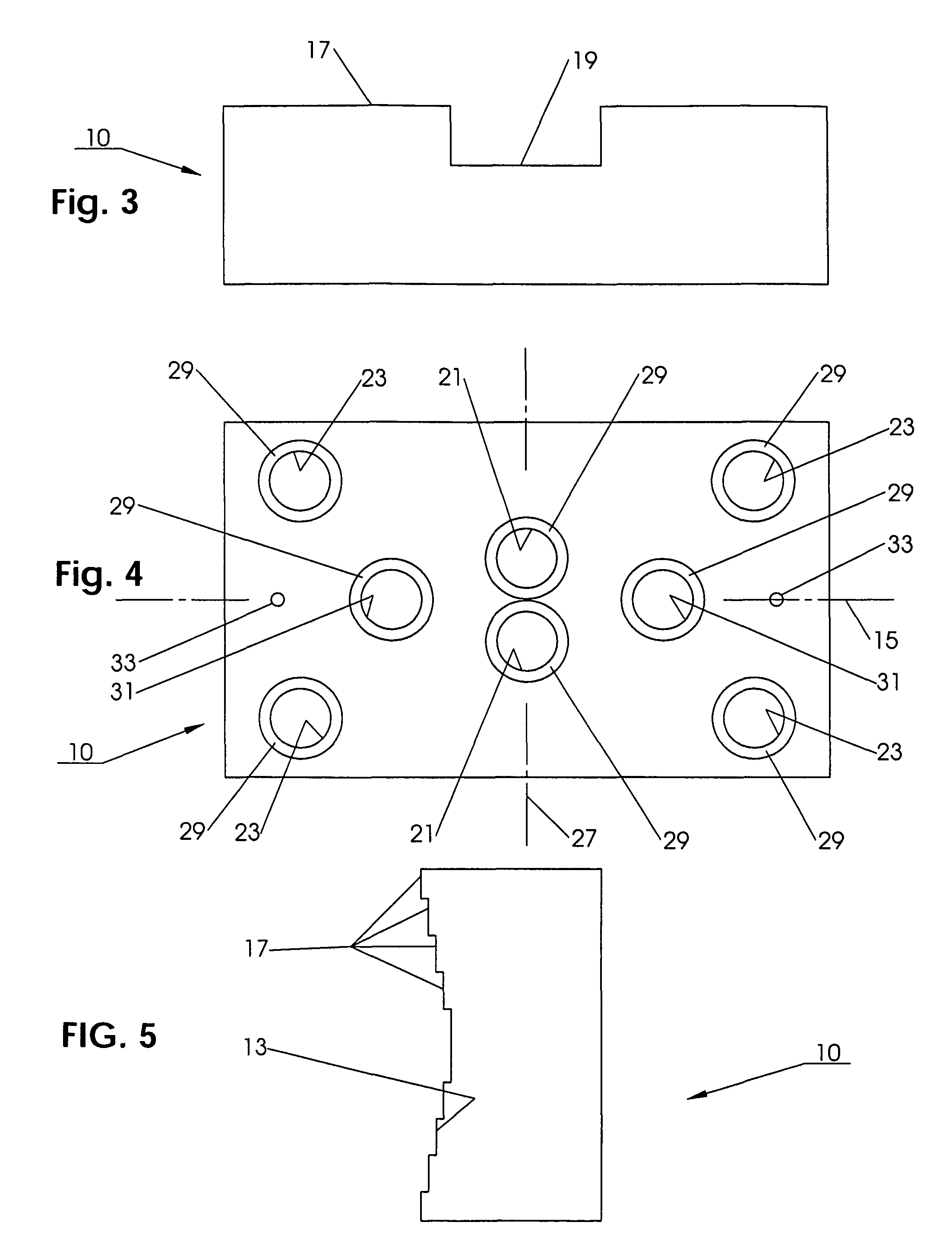

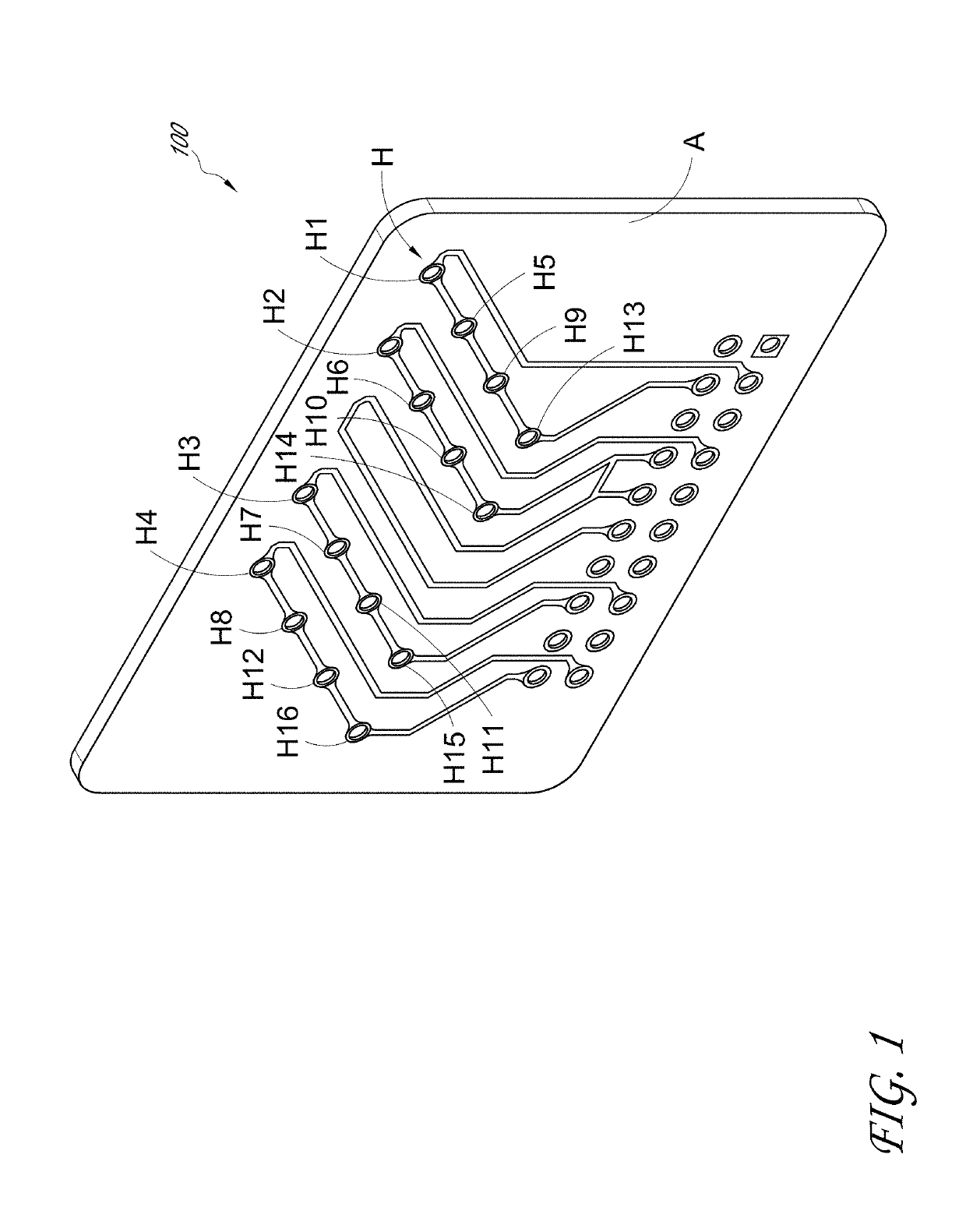

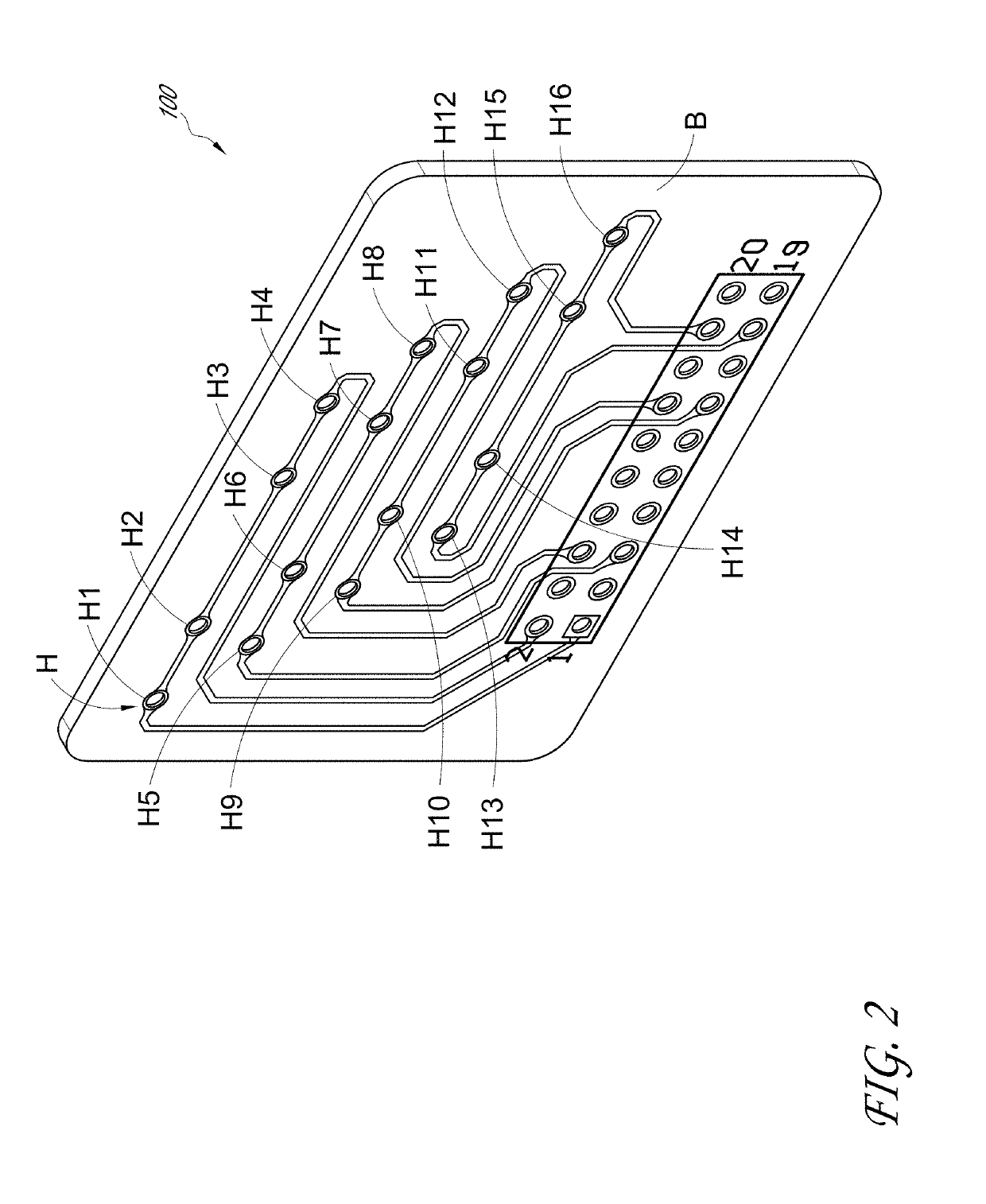

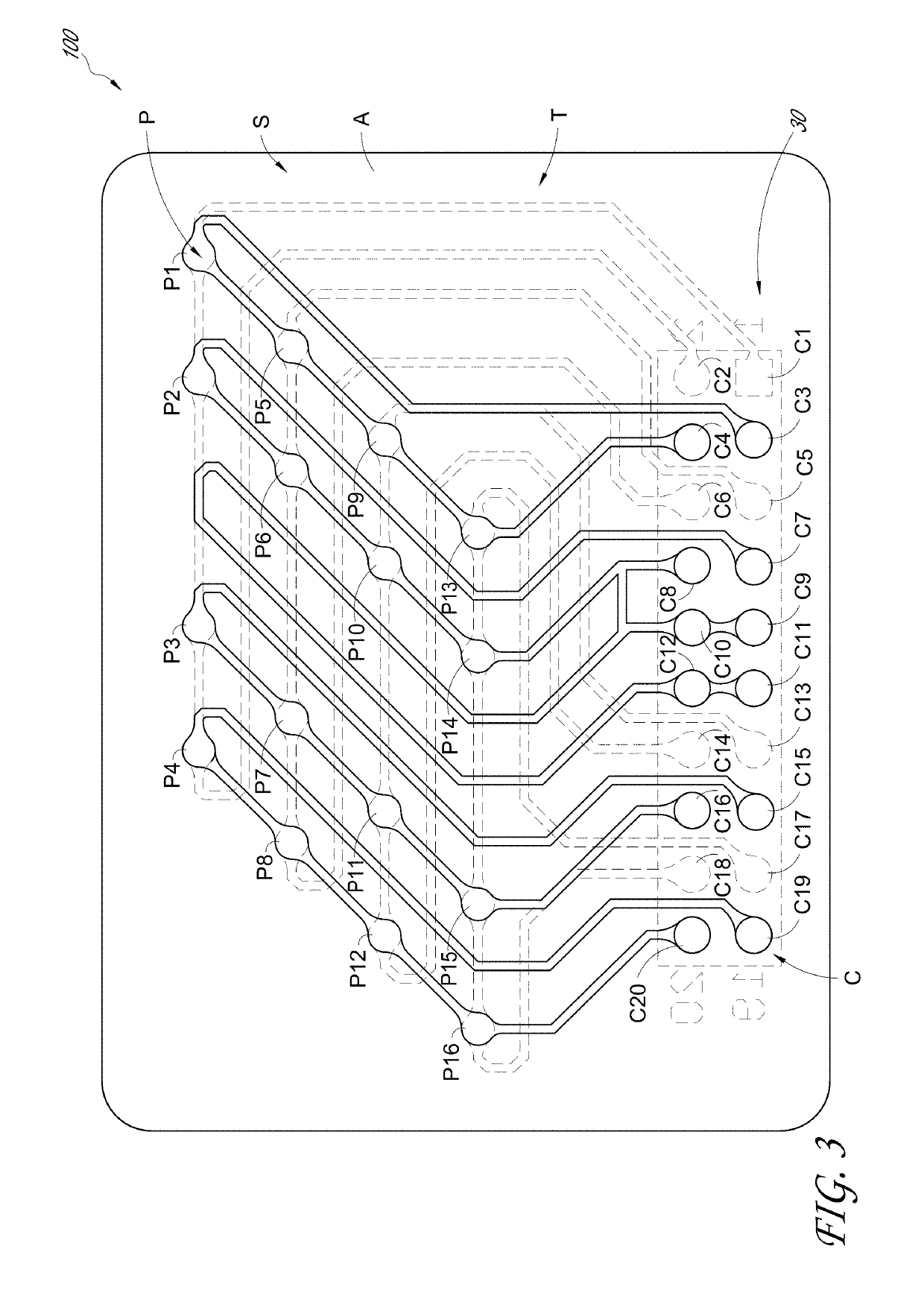

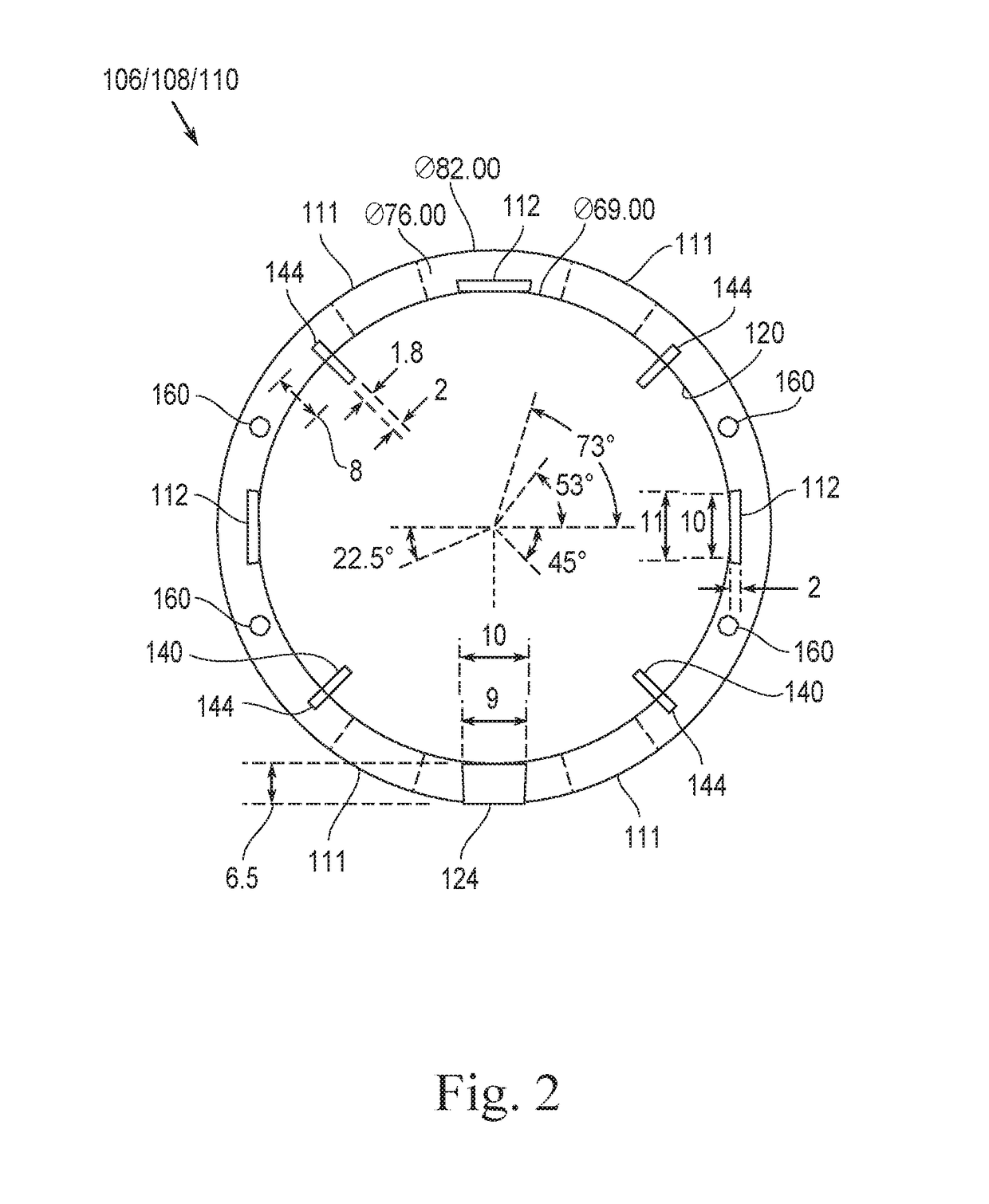

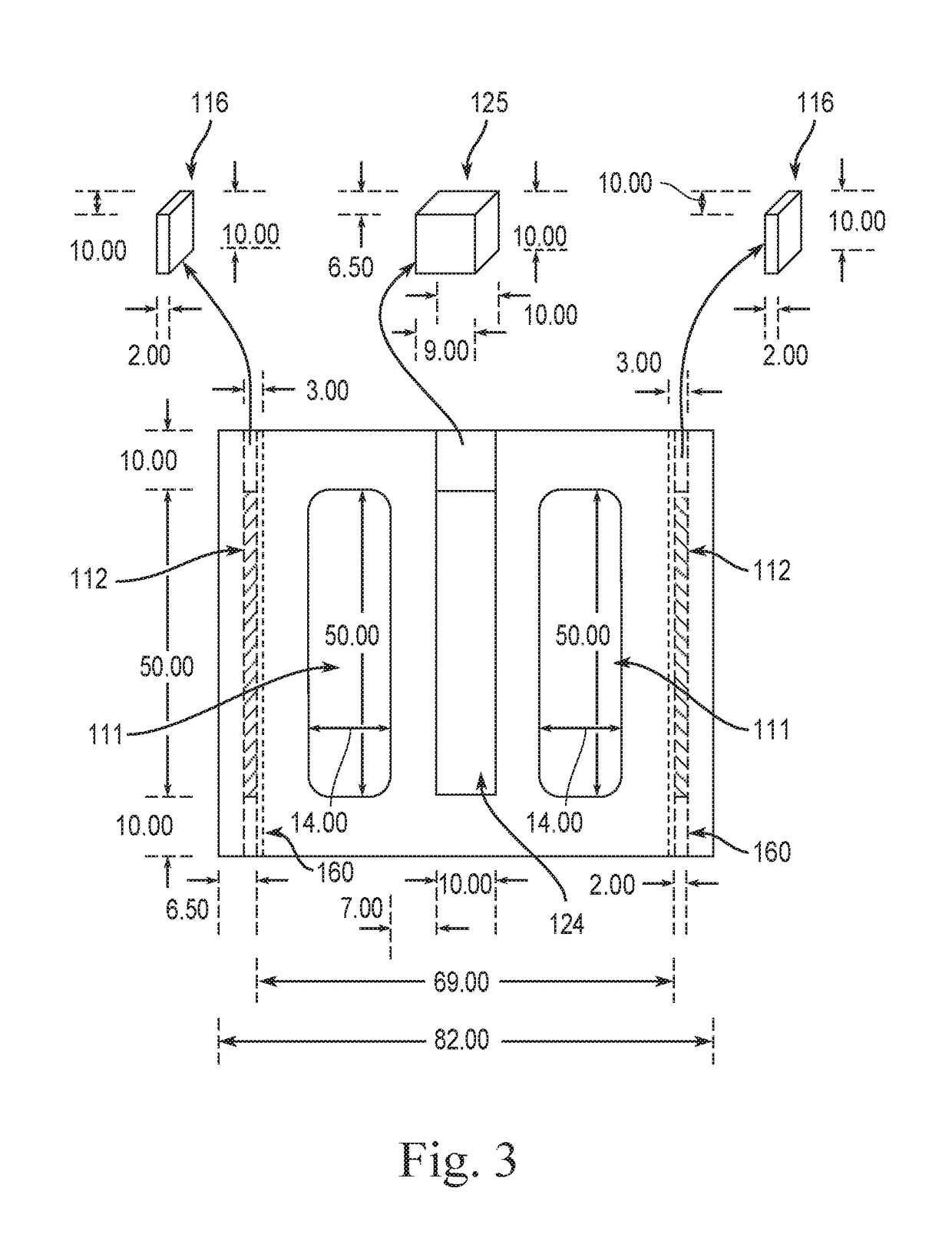

Printed circuit board test coupon for electrical testing during thermal exposure and method of using the same

ActiveUS10379153B1Printed circuit aspectsInspection/indentification of circuitsElectricityElectrical resistance and conductance

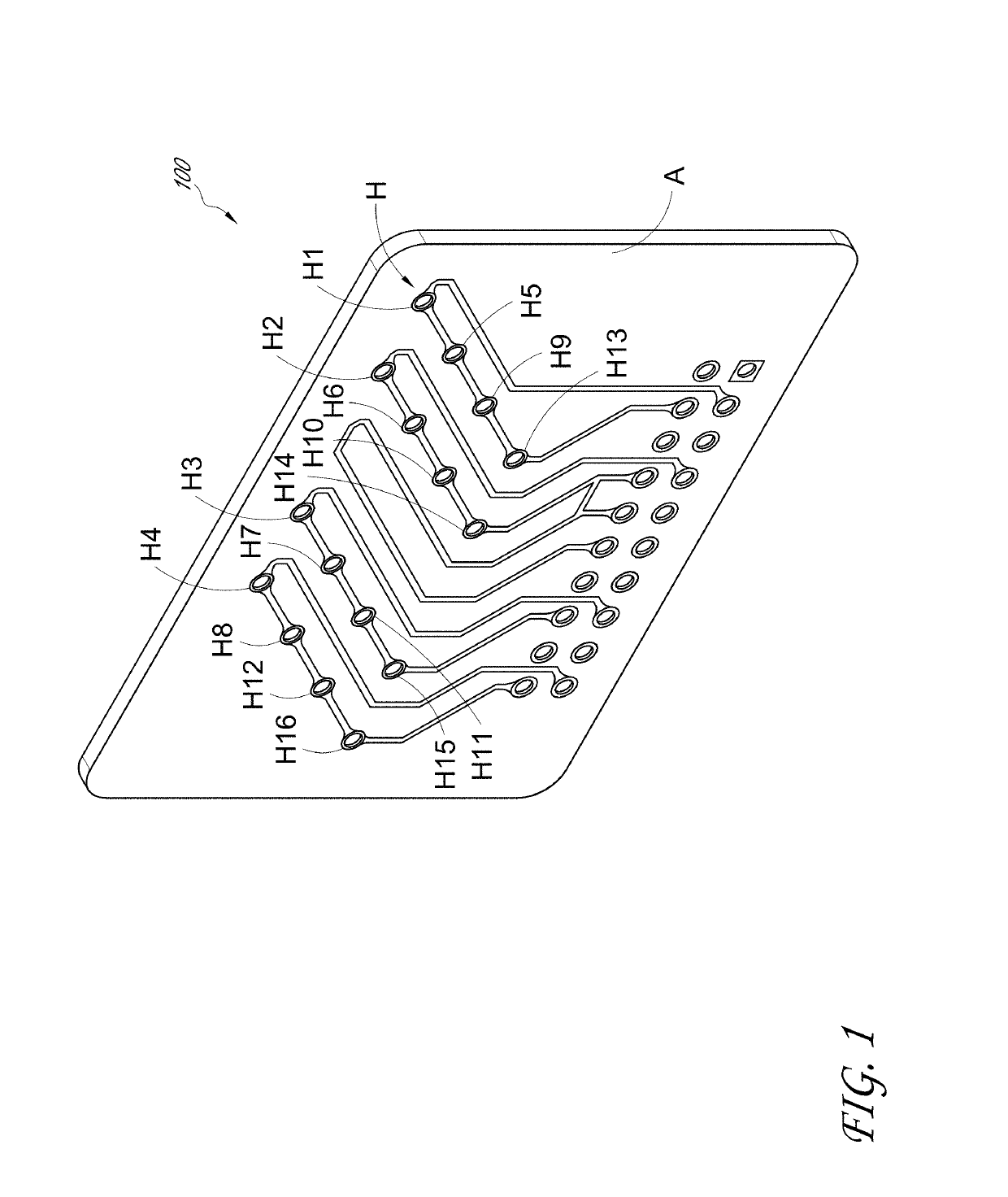

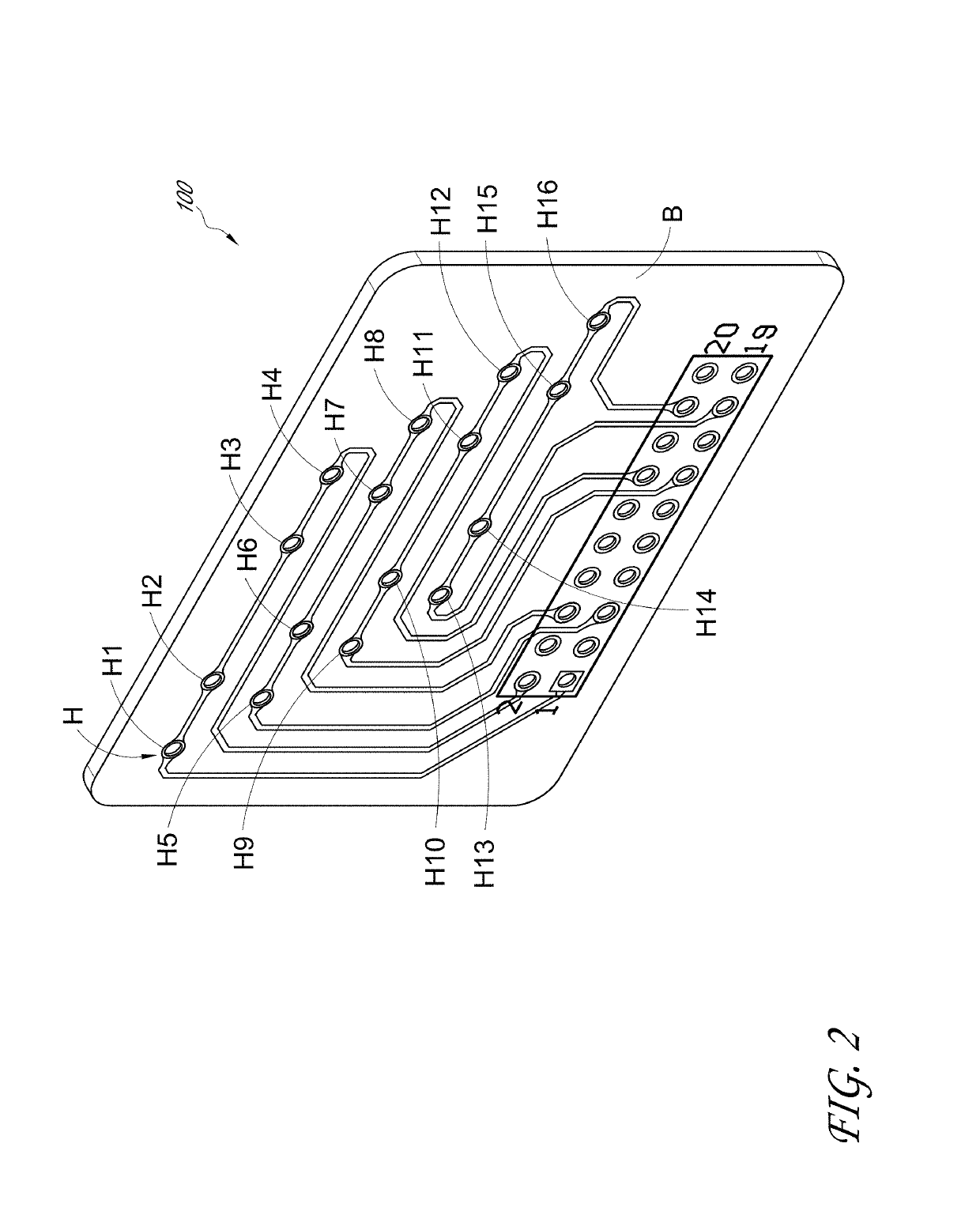

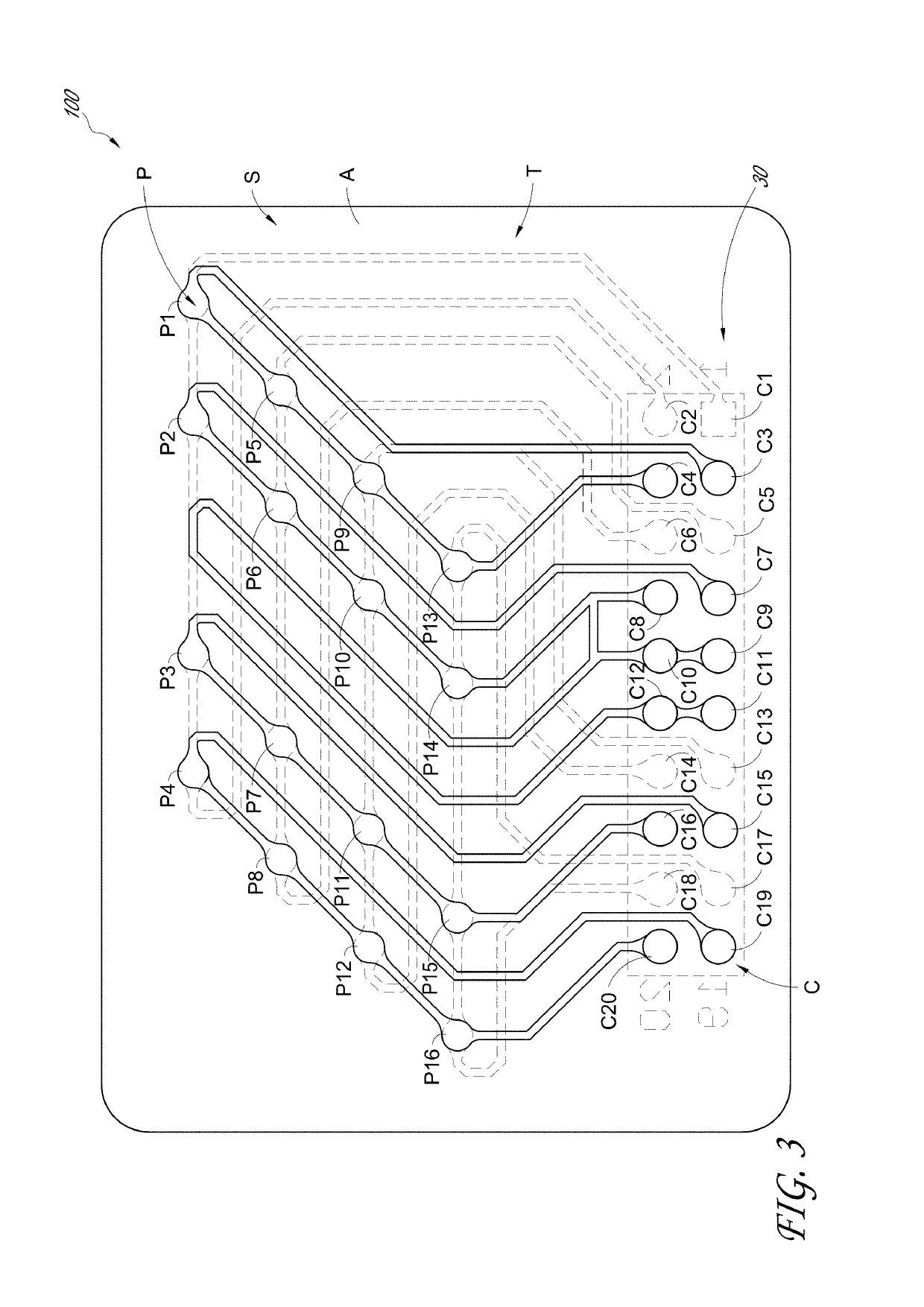

A printed circuit board (PCB) test coupon for thermal exposure and electrical testing includes a double sided or multi-layer substrate with a plurality of vias formed within the substrate of the test coupon (blind, buried, stacked vias) or extending through the entire substrate (through hole / via) from a first surface on the first side of the plated hole / via to a second surface on the second side of the plated hole / via. Each of a first plurality of trace patterns interconnect a subset of the plurality of plated holes / vias on the first side of the plated holes / vias, and each of a second plurality of trace patterns interconnect a different subset of the plurality of plated holes / vias on the second side of the plated holes / vias. The first and second pluralities of trace patterns have different patterns and connect to connection points in a connector pattern defined in the substrate. One of the second plurality of trace patterns is configured to measure temperature and two of the second plurality of trace patterns are configured to measure calibration / drift by resistance measurements. The test coupon provides test nets that include a single plated hole / via, and optionally includes daisy chain test nets. A resistance measurement of each plated hole / via (or daisy chain) is provided by connecting 2 wires of a 4-wire kelvin bridge measurement system to the first and second sides of the plated hole / via (or daisy chain) using connection points for one of the first plurality of trace patterns and one of the second plurality of trace patterns that connect to each side of the said plated hole / via (or daisy chain).

Owner:RELIABILITY ASSESSMENT SOLUTIONS INC

Printed circuit board test coupon for electrical testing during thermal exposure and method of using the same

ActiveUS10334720B1Printed circuit aspectsInspection/indentification of circuitsElectrical resistance and conductanceElectricity

A printed circuit board (PCB) test coupon for thermal exposure and electrical testing includes a double sided or multi-layer substrate with a plurality of vias formed within the substrate of the test coupon (blind, buried, stacked vias) or extending through the entire substrate (through hole / via) from a first surface on the first side of the plated hole / via to a second surface on the second side of the plated hole / via. Each of a first plurality of trace patterns interconnect a subset of the plurality of plated holes / vias on the first side of the plated holes / vias, and each of a second plurality of trace patterns interconnect a different subset of the plurality of plated holes / vias on the second side of the plated holes / vias. The first and second pluralities of trace patterns have different patterns and connect to connection points in a connector pattern defined in the substrate. One of the second plurality of trace patterns is configured to measure temperature and two of the second plurality of trace patterns are configured to measure calibration / drift by resistance measurements. The test coupon provides test nets that include a single plated hole / via, and optionally includes daisy chain test nets. A resistance measurement of each plated hole / via (or daisy chain) is provided by connecting 2 wires of a 4-wire kelvin bridge measurement system to the first and second sides of the plated hole / via (or daisy chain) using connection points for one of the first plurality of trace patterns and one of the second plurality of trace patterns that connect to each side of the said plated hole / via (or daisy chain).

Owner:RELIABILITY ASSESSMENT SOLUTIONS INC

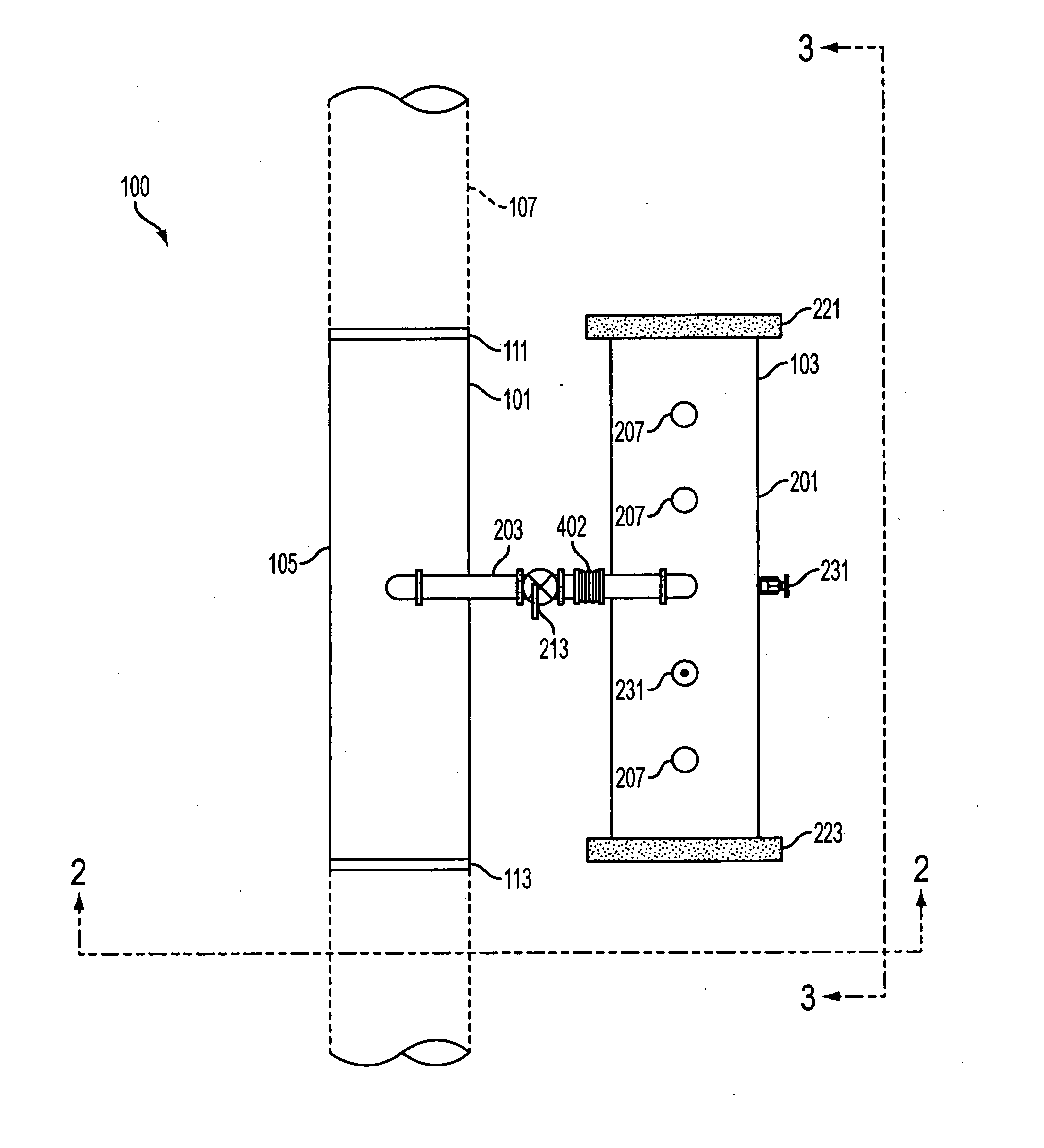

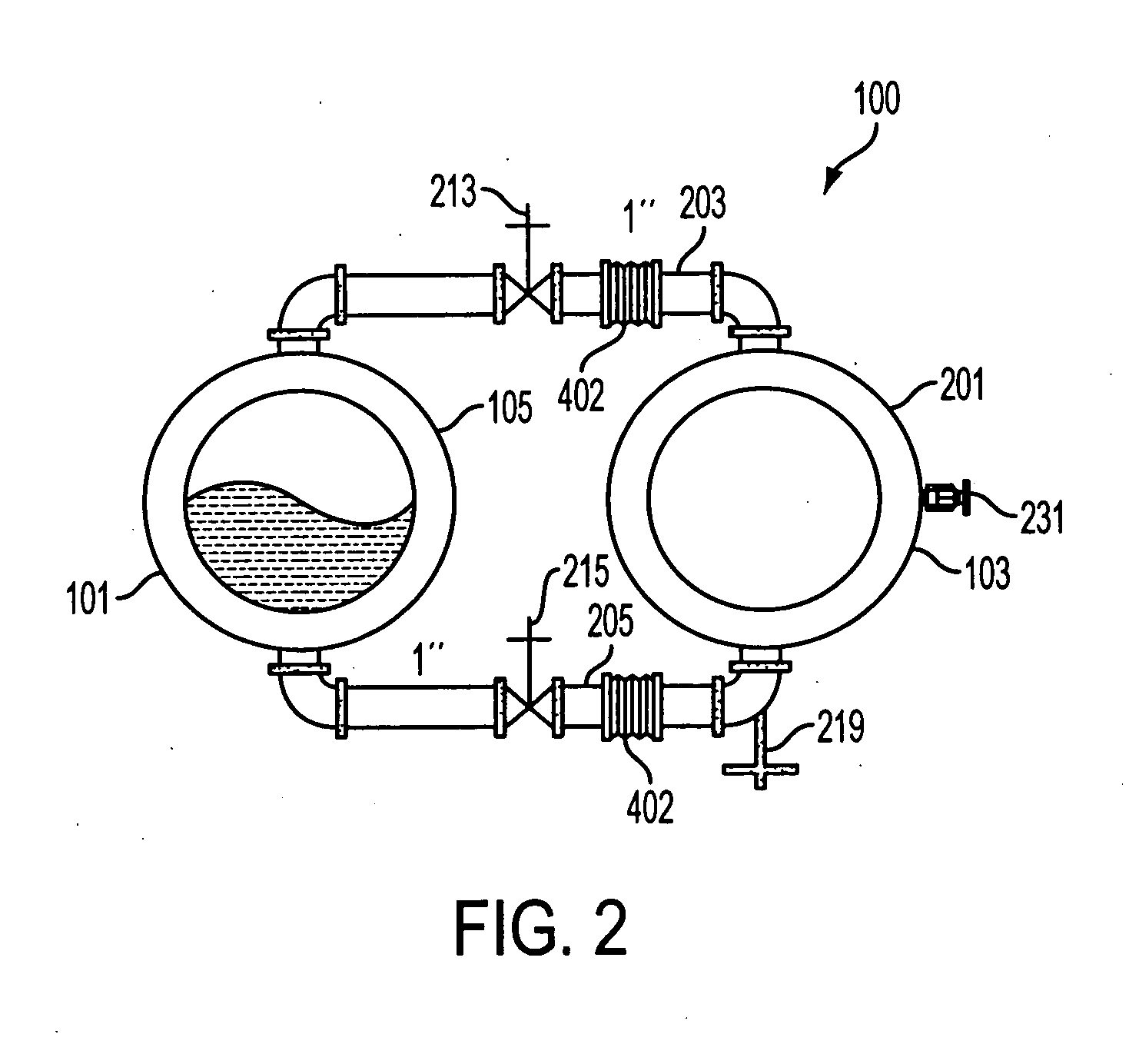

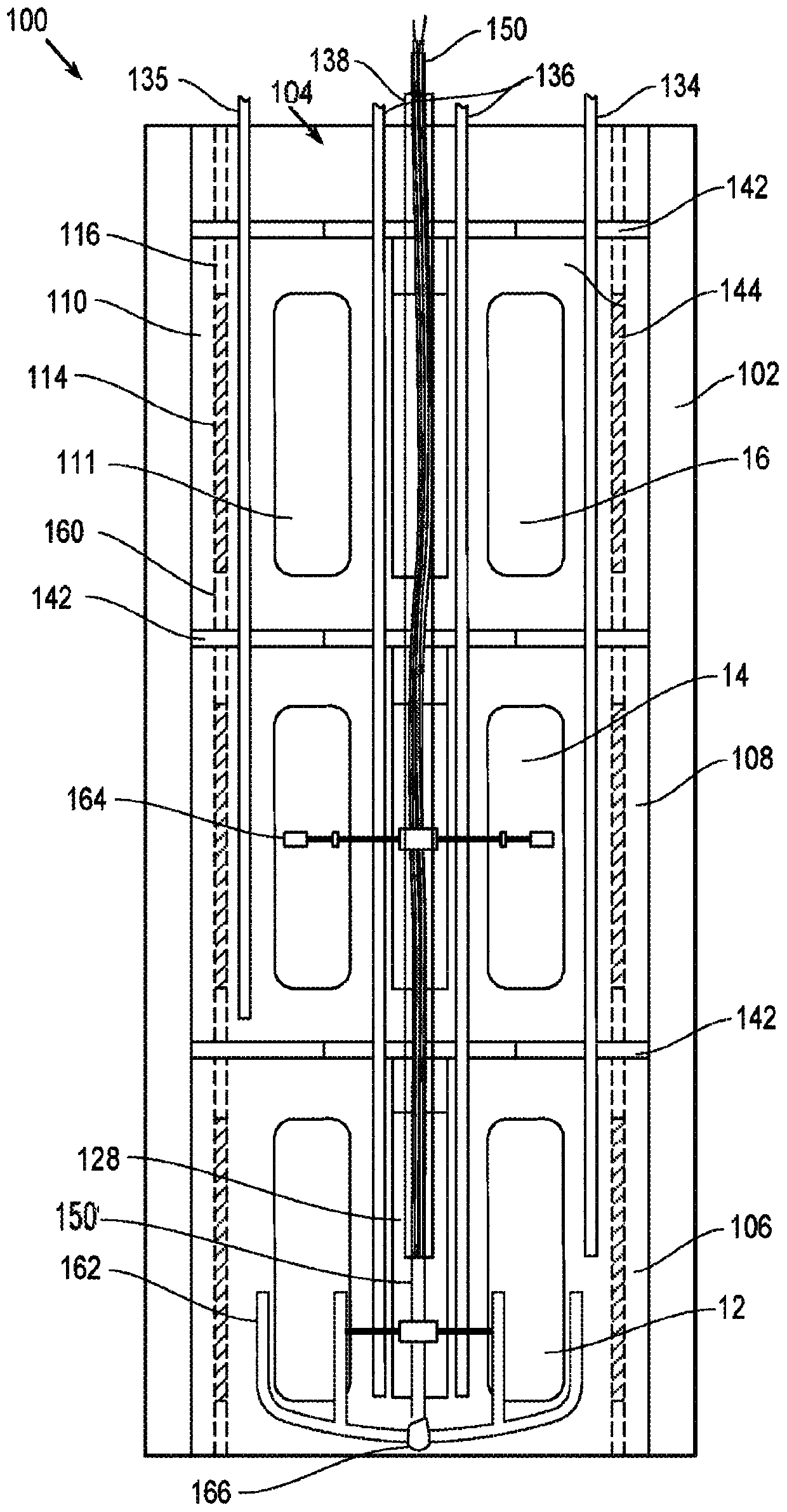

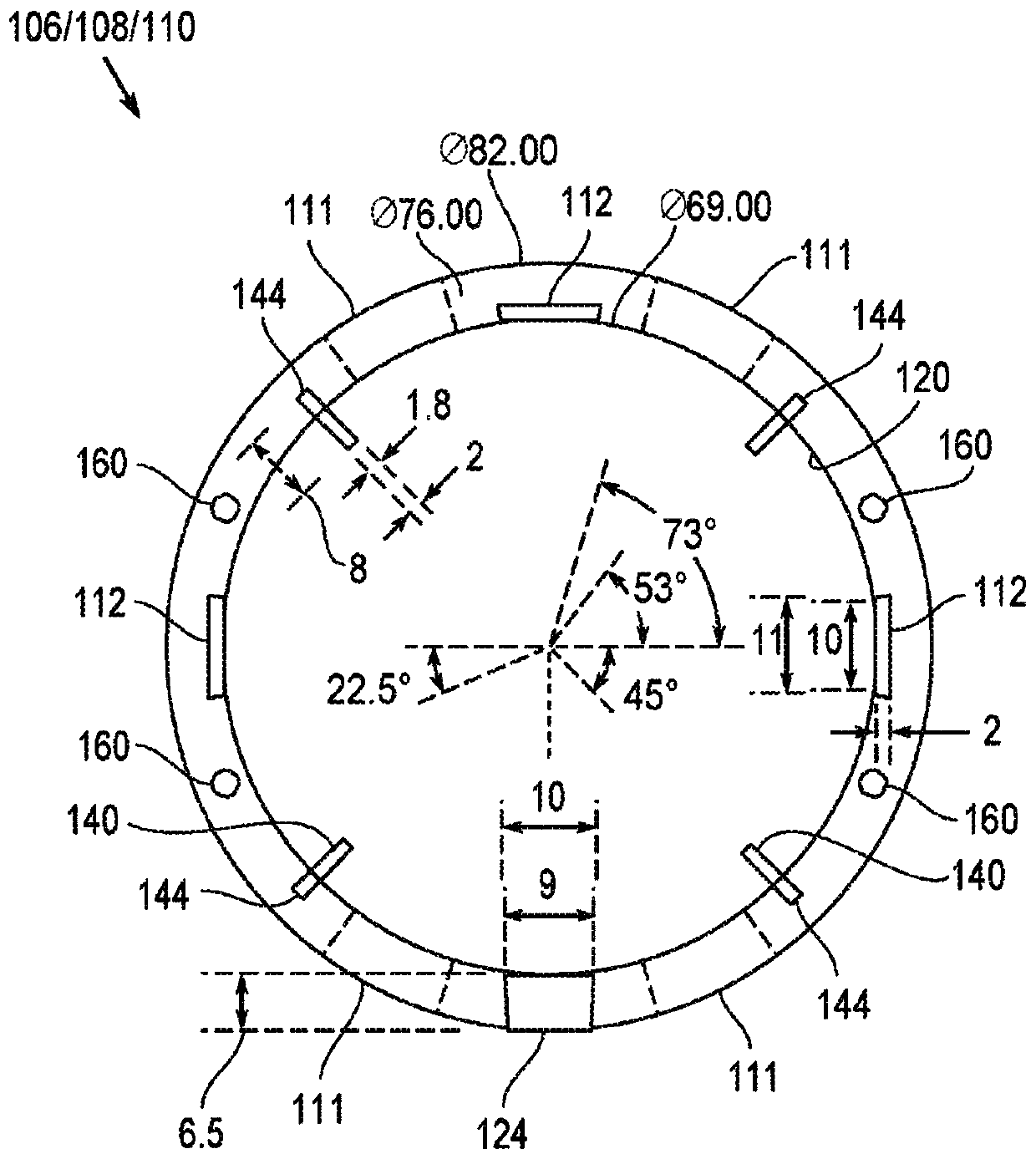

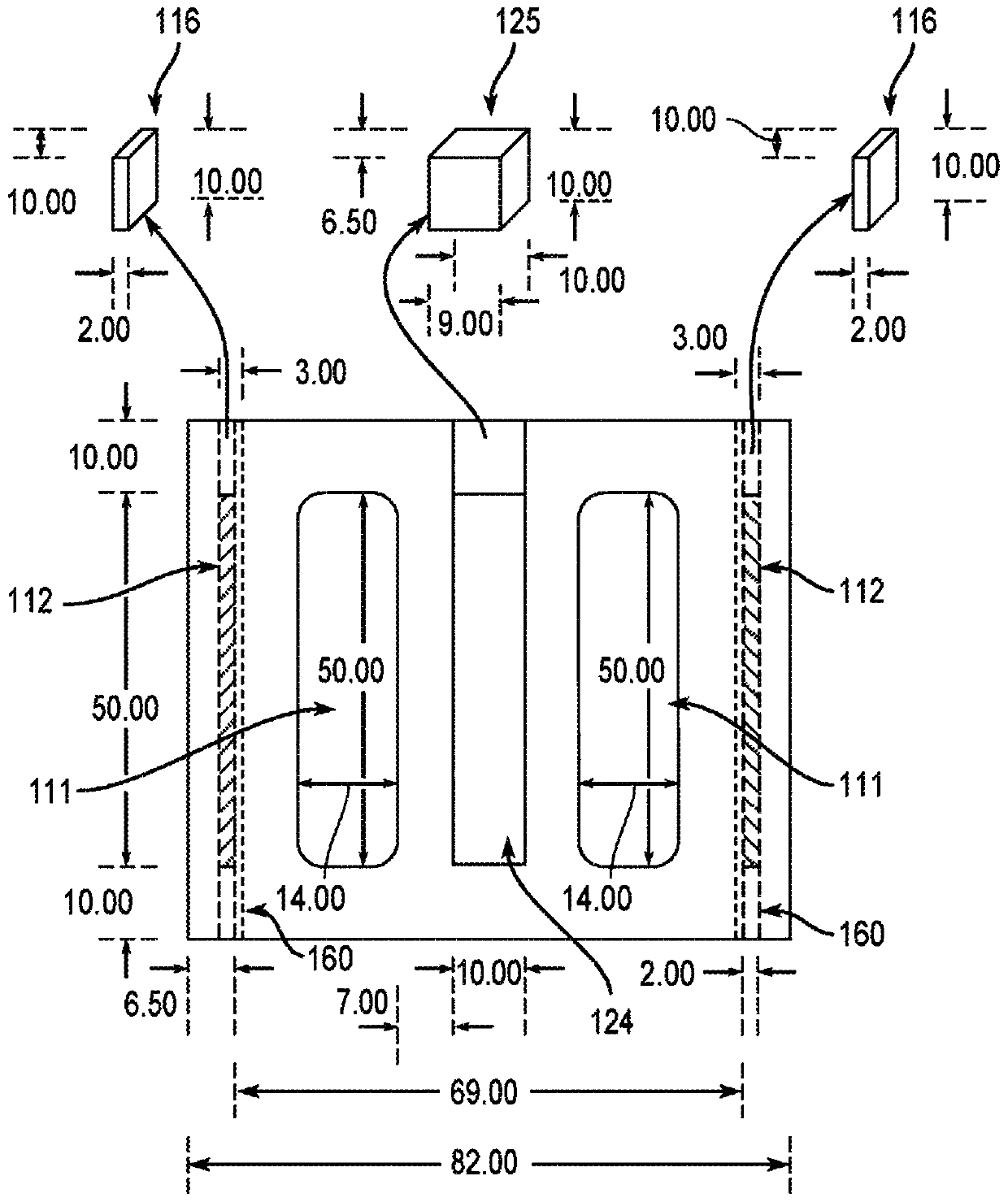

Corrosion testing system for multiphase environments using electrochemical and weight-loss methods

A system for conducting measuring corrosion rates in a multiphase environment using electrochemical and weight-loss measurement methods on test coupons is provided. A plurality of inserts is disposed within a test vessel in a vertical arrangement. Each insert is provided with at least one test coupon and at least one working electrode that are exposed to the corrosive test environment within vessel. A test fluid mixture is added to the vessel and the temperature and pressure is maintained such that the mixture exists in a multiphase condition that has a vertical stratification such that each insert is exposed to a different phase of the fluid. Electrical signals from the working electrode is measured to determine the corrosion rate using an electrochemical method. The pre-test weight of the coupon is compared to the post-test weight to determine the corrosion rate using a weight-loss method.

Owner:SAUDI ARABIAN OIL CO

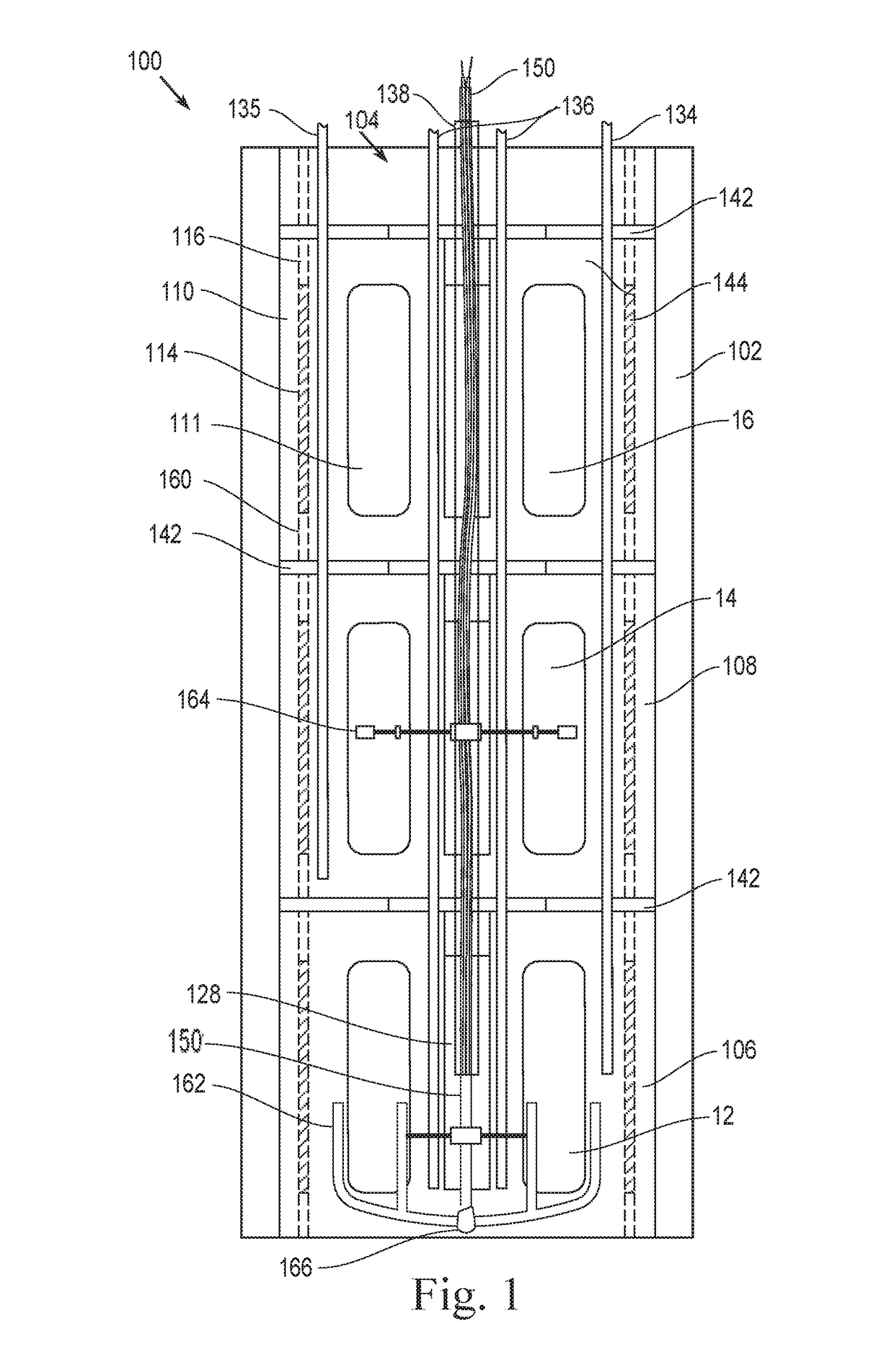

Method and apparatus for rapid thermal testing

InactiveUS20040233966A1Weather/light/corrosion resistanceResistance/reactance/impedenceElectrical resistance and conductanceSingle sample

An apparatus for rapid thermal testing of samples consisting of a single sample chamber in which the samples are preferably arranged circularly around the opening through which a fluid of varying temperature, preferably air, is introduced to provide for rapid, uniform cooling and heating of the samples. The samples are preferably uniformly spaced to allow for uniform air flow. The samples are mounted in slots which are preferably oriented radially outward from the opening. The sample mounts comprise electrical connectors which form a network connected to at least one ohmmeter for measuring the resistance of the samples. The samples preferably comprise test coupons, each with multiple daisy-chained nets of vias or other components to be tested. Also a method for thermal testing of samples consisting of steps to characterize the samples before the test is run. First, the resistance of the samples which correlates to each target temperature is determined, and the time required for the samples to reach that resistance when they are heated or cooled is measured. Then, for reliability testing, the temperature of the samples is cycled between the target temperatures, where the cycle segment durations are given by the times measured in the characterization steps.

Owner:CONDUCTOR ANALYSIS TECH

Corrosion testing system for multiphase environments using electrochemical and weight-loss methods

A system for measuring corrosion rates in a multiphase environment using electrochemical and weight-loss measurement methods on test coupons is provided. A plurality of inserts is disposed within a test vessel in a vertical arrangement. Each insert is provided with at least one test coupon and at least one working electrode that are exposed to the corrosive test environment within vessel. A test fluid mixture is added to the vessel and the temperature and pressure is maintained such that the mixture exists in a multiphase condition that has a vertical stratification such that each insert is exposed to a different phase of the fluid. Electrical signals from the working electrode is measured to determine the corrosion rate using an electrochemical method. The pre-test weight of the coupon iscompared to the post-test weight to determine the corrosion rate using a weight-loss method.

Owner:SAUDI ARABIAN OIL CO

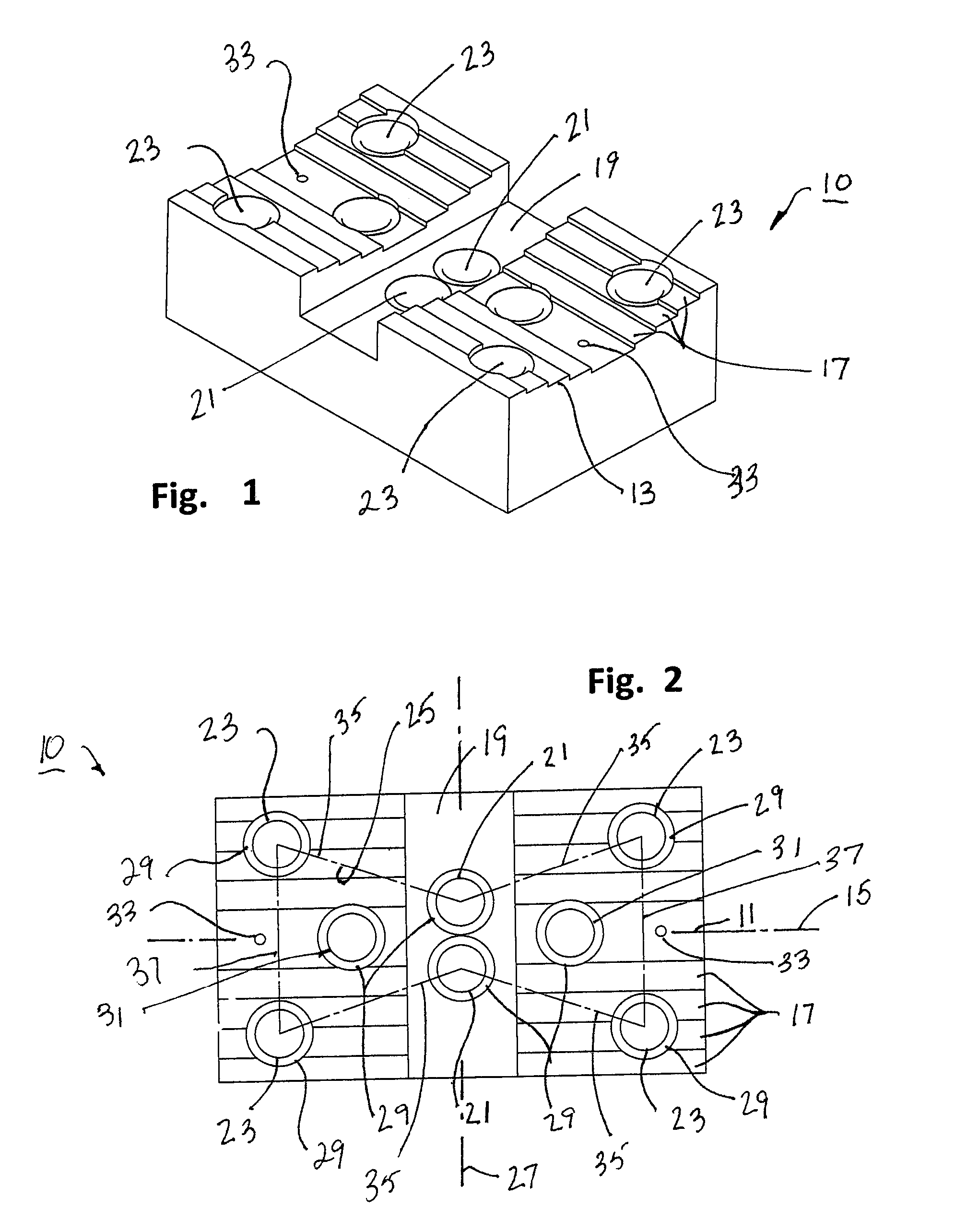

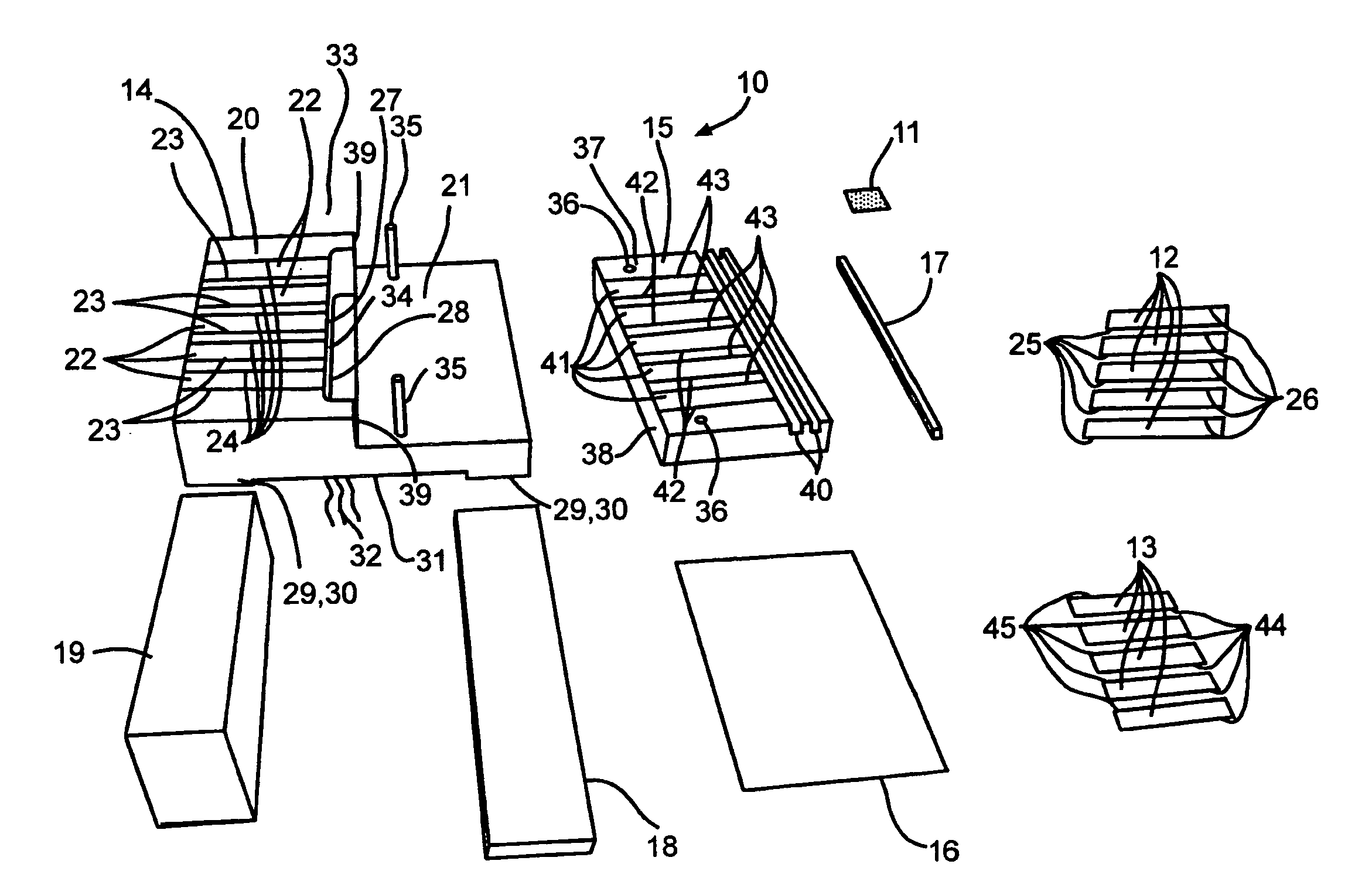

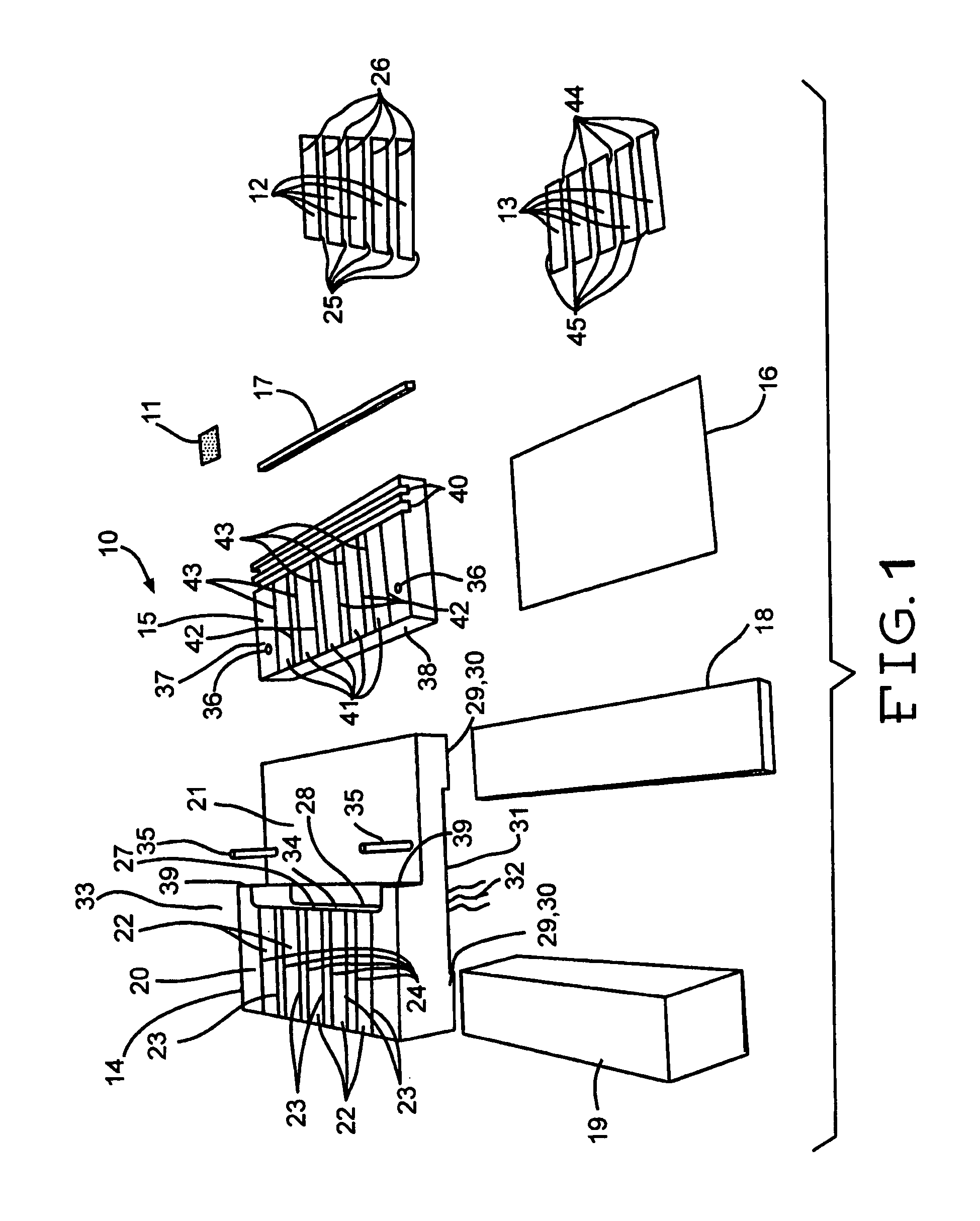

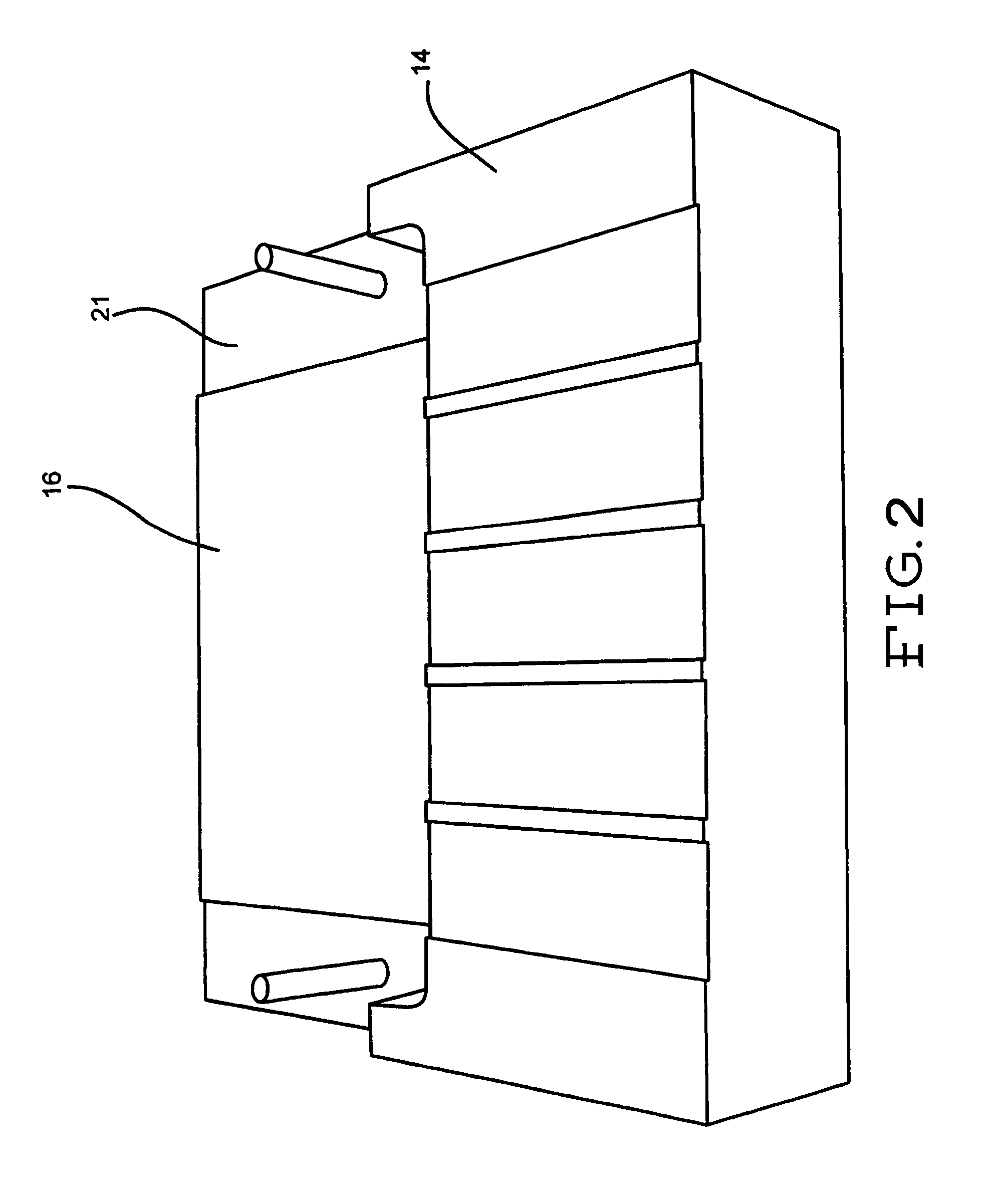

Apparatus and method for fabricating shear test coupons

ActiveUS8043449B1Small sizeLamination ancillary operationsControlling laminationTest couponBiomedical engineering

An apparatus for adhering coupons together for adhesive shear testing may include a first member, a second member, at least one alignment device, and at least one separation device. The first member may have at least one first member cavity for holding at least one first member coupon. The second member may have at least one second member cavity for holding an overlapping area of at least one second member coupon adjacent to and separate from the at least one first member coupon. The overlapping area of the at least one second member coupon may be adhered to the at least one first member coupon. The at least one alignment device may control a size of the overlapping area. The at least one separation device may control a separation distance between the overlapping area of the at least one second member coupon and the at least one first member coupon.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com