Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Fusion joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

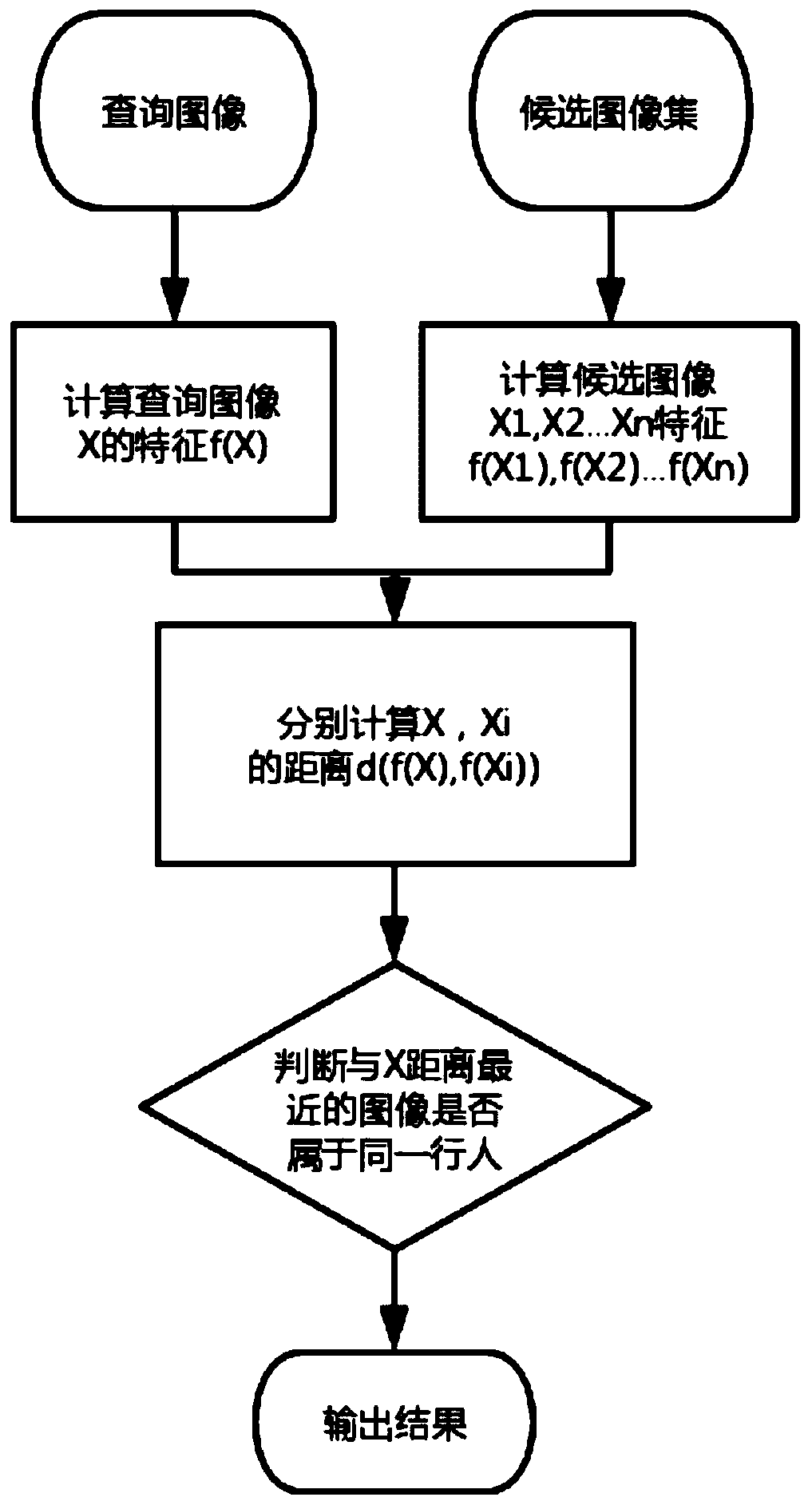

Pedestrian re-identification method based on depth multi-loss fusion model

PendingCN110008842AReduce environmental differencesImprove re-identification performanceImage enhancementGeometric image transformationData setFeature extraction

The invention relates to a pedestrian re-identification method based on a depth multi-loss fusion model. According to the method, a deep learning technology is used, pre-processing operations such asoverturning, cutting, random erasing and style migration are carried out on the training set picture. Feature extraction is carried out through a basic network model. A plurality of loss functions areused for carrying out fusion joint training on the network. Compared with a pedestrian re-identification algorithm based on deep learning, since the method uses a plurality of preprocessing modes, fusion of three loss functions and an effective training strategy, the pedestrian re-identification performance on the data set is greatly improved. On one hand, multiple preprocessing modes can expanda data set, the generalization capability of the model is improved, the occurrence of an overfitting condition is avoided, and on the other hand, the three loss functions have respective advantages and disadvantages, and when the three loss functions are effectively combined, the used model can obtain a better recognition result.

Owner:TONGJI UNIV +2

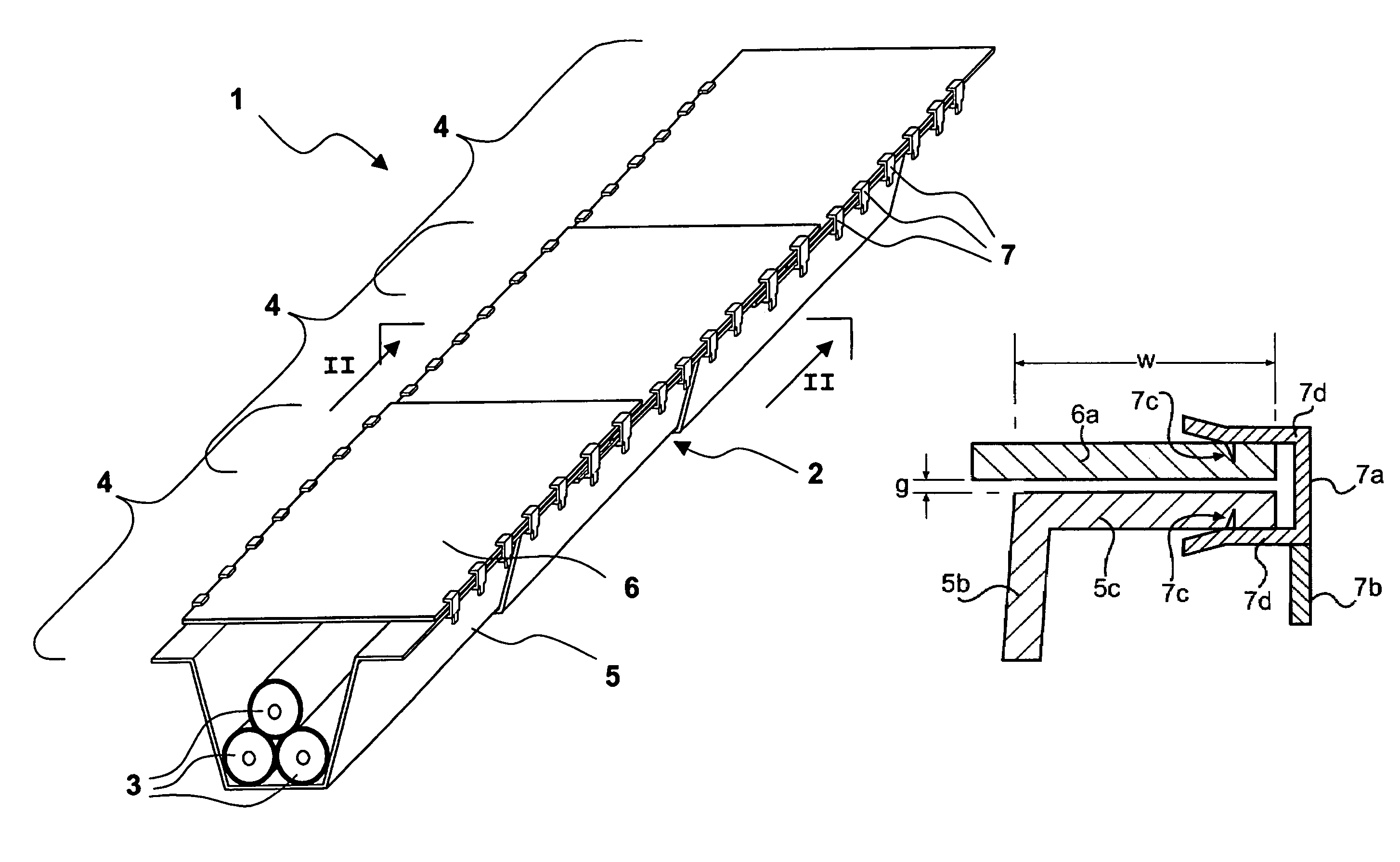

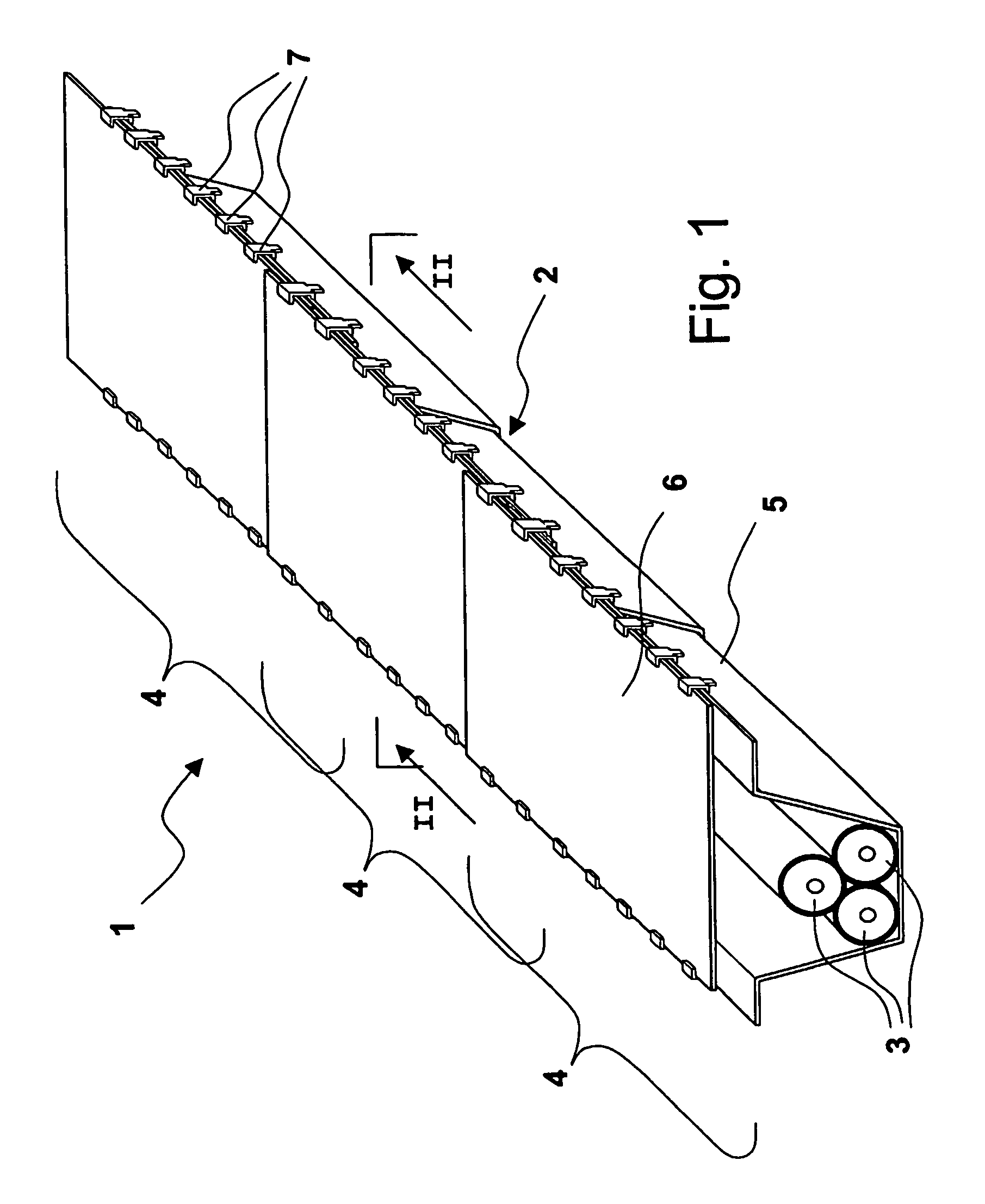

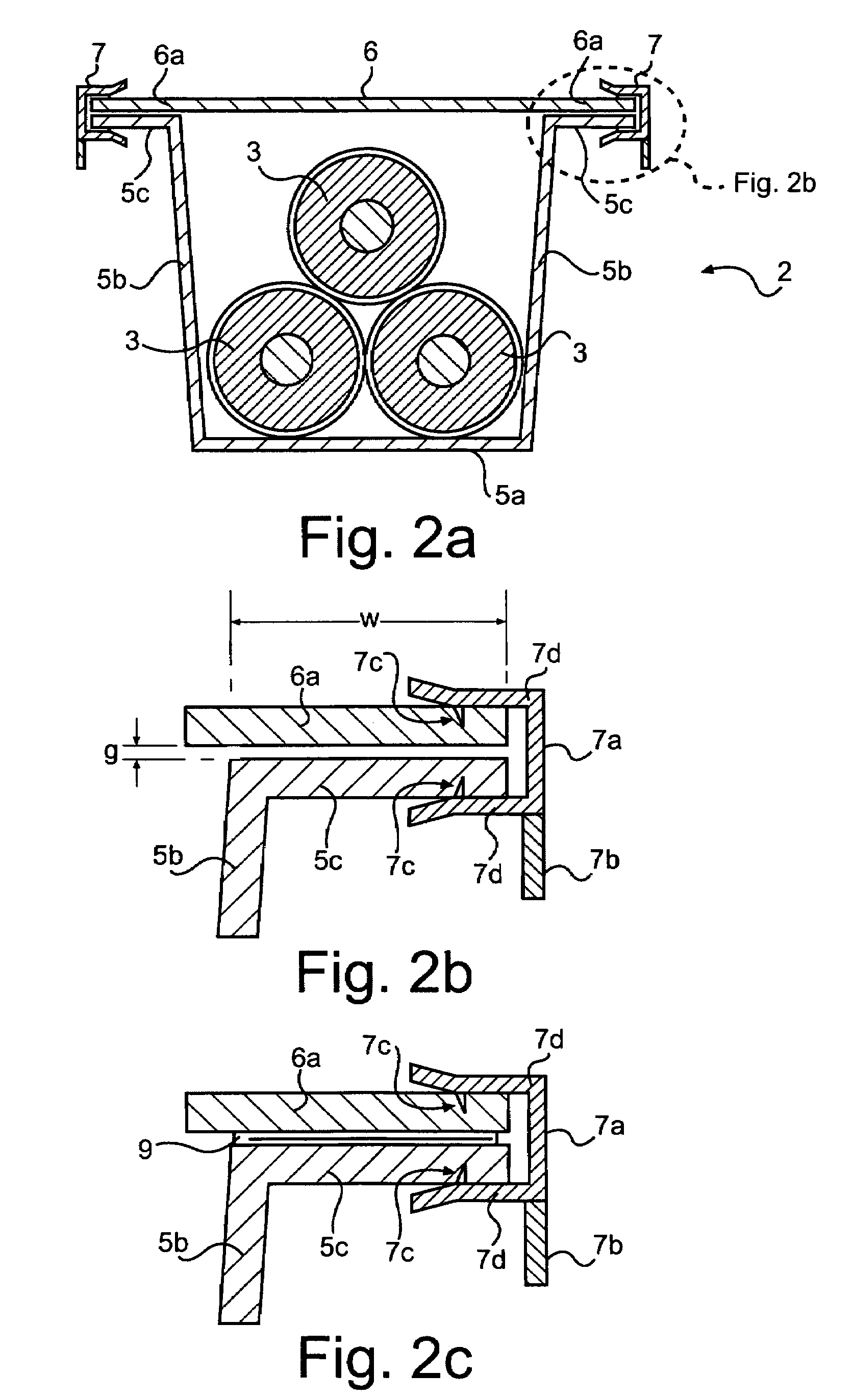

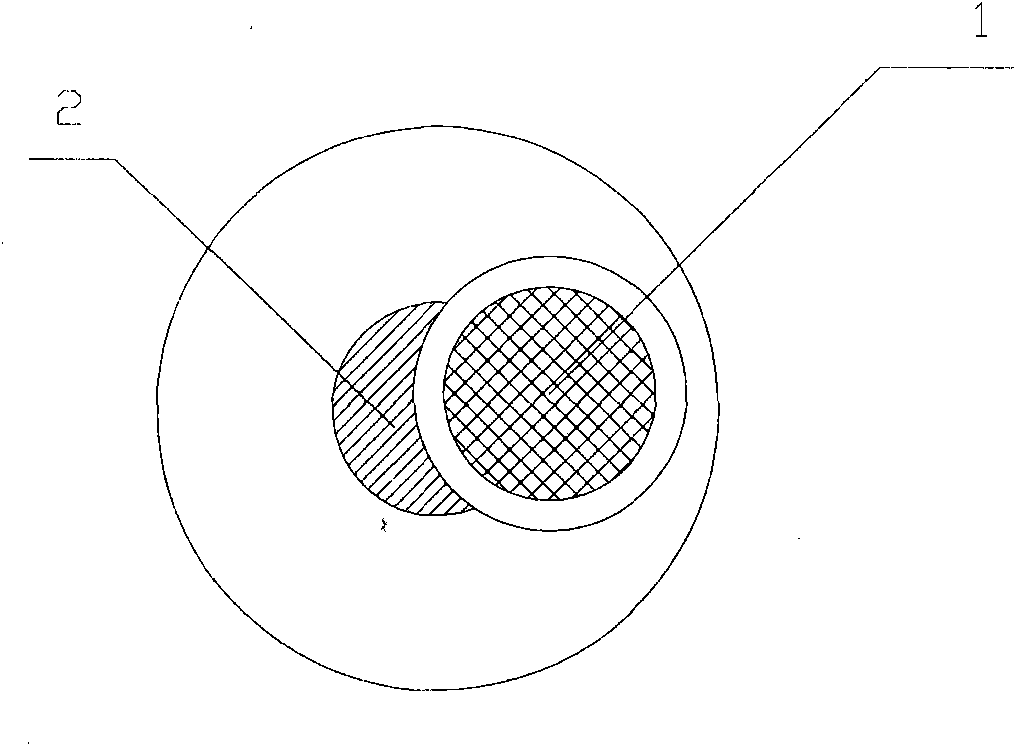

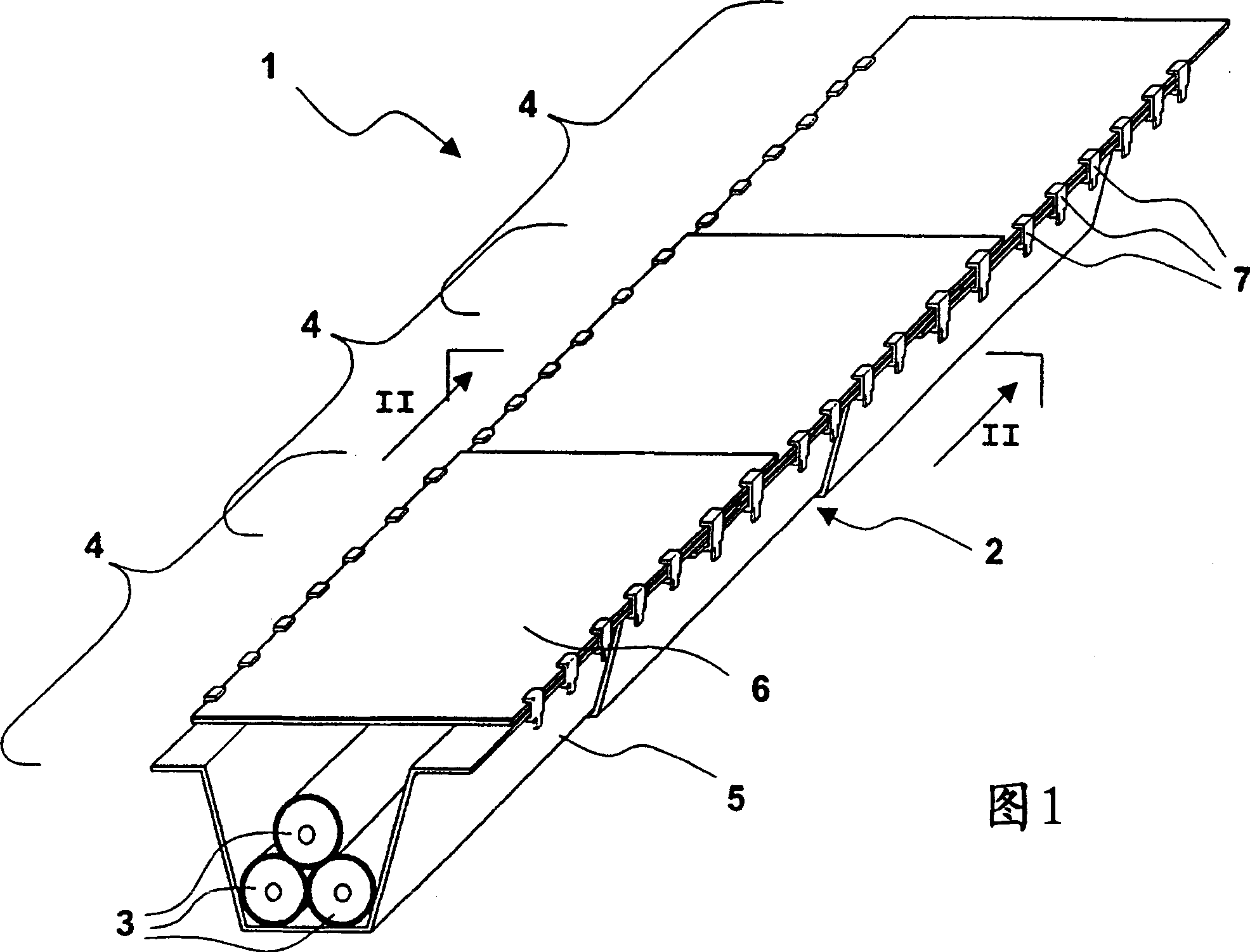

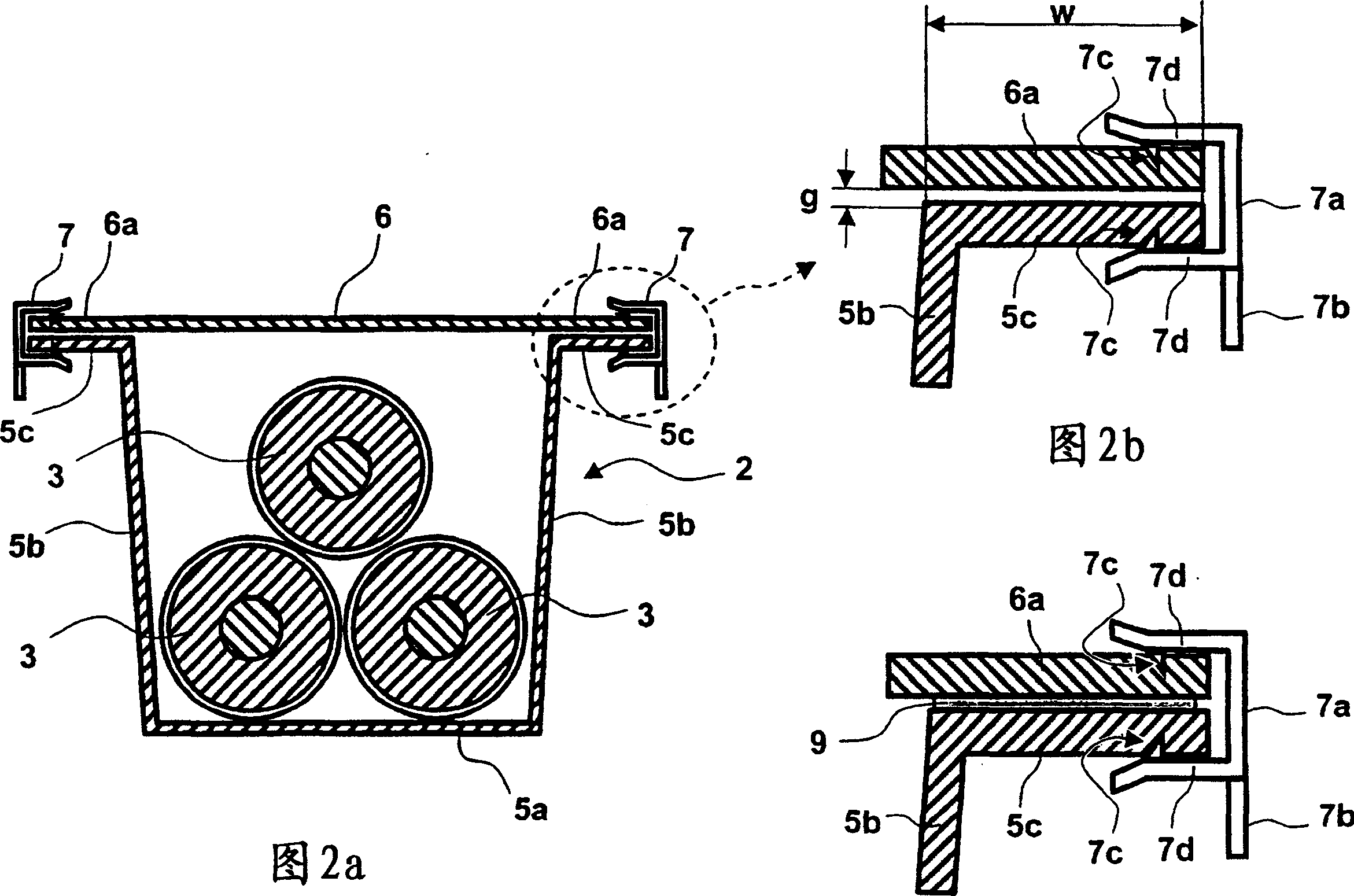

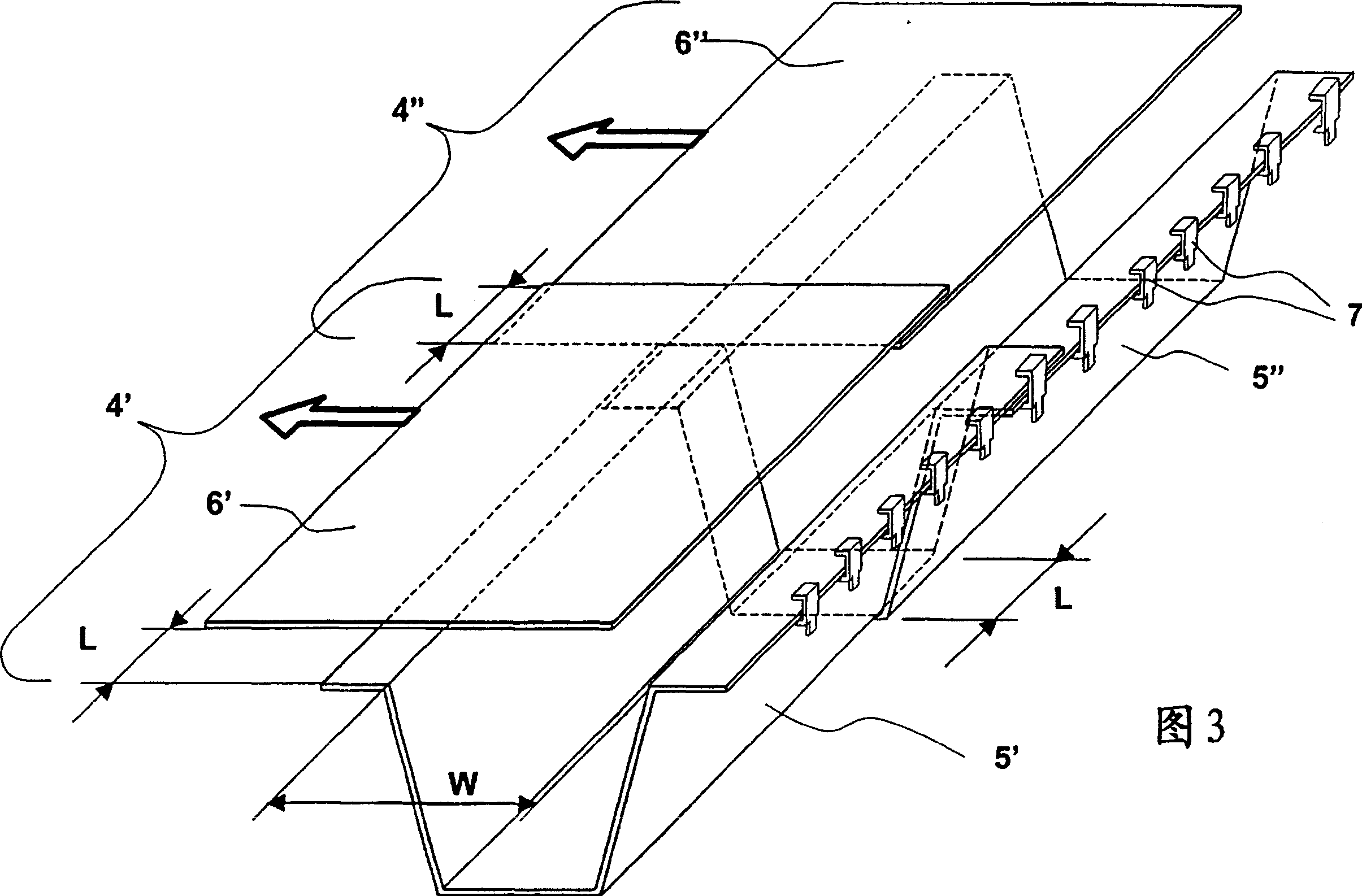

Method of screening the magnetic field generated by an electrical power transmission line and electrical power transmission line so screened

InactiveUS7365269B2Improve continuityReduce air gapCable installations on groundCable installations in surface ductsElectric power transmissionElectricity

An electrical power transmission line having at least one electrical cable, a conduit of ferromagnetic material enclosing the electrical cable and having a base and a cover and electrical contact elements for electrically connecting the base and the cover, wherein the electrical contact elements are metal fusion joints or metal resilient members suitable to pierce the ferromagnetic material.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

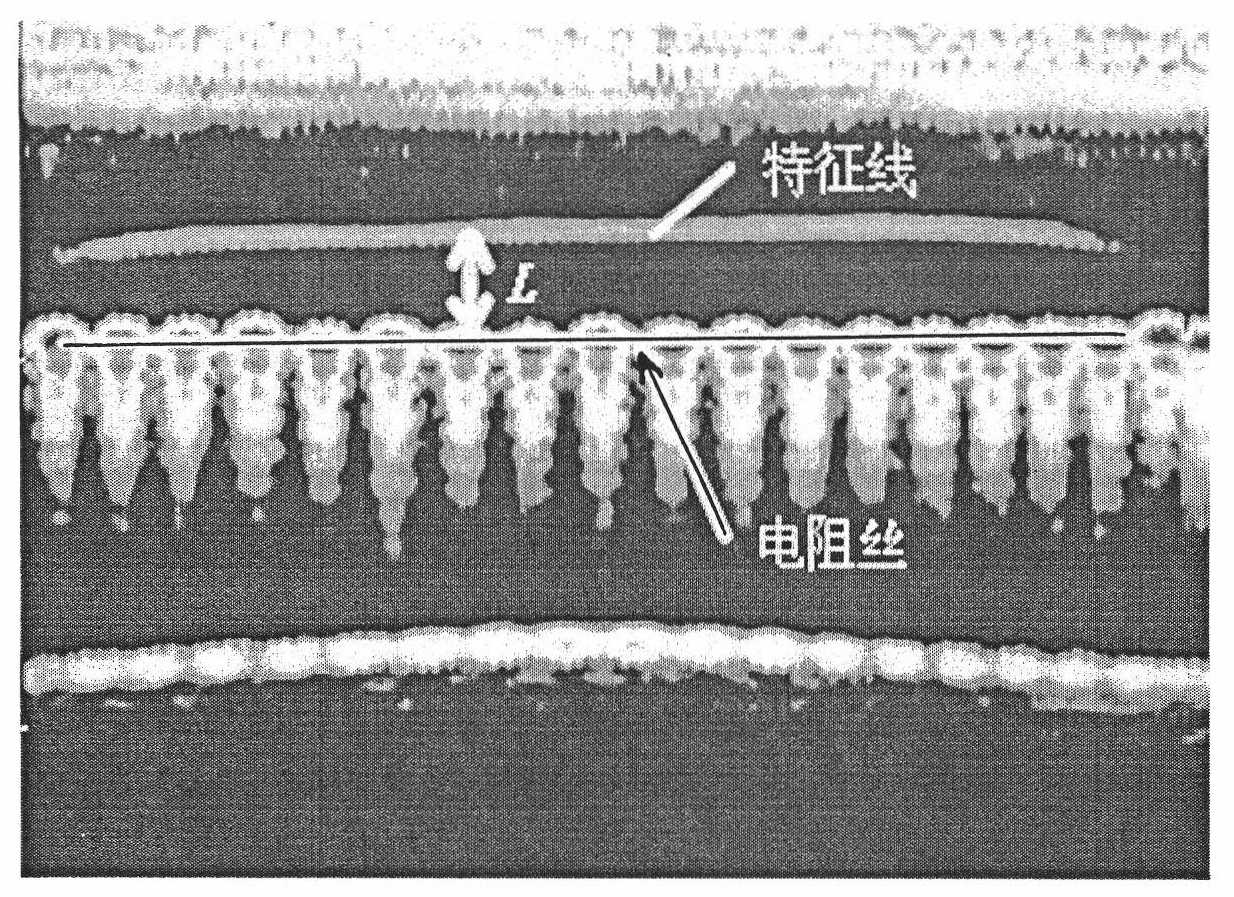

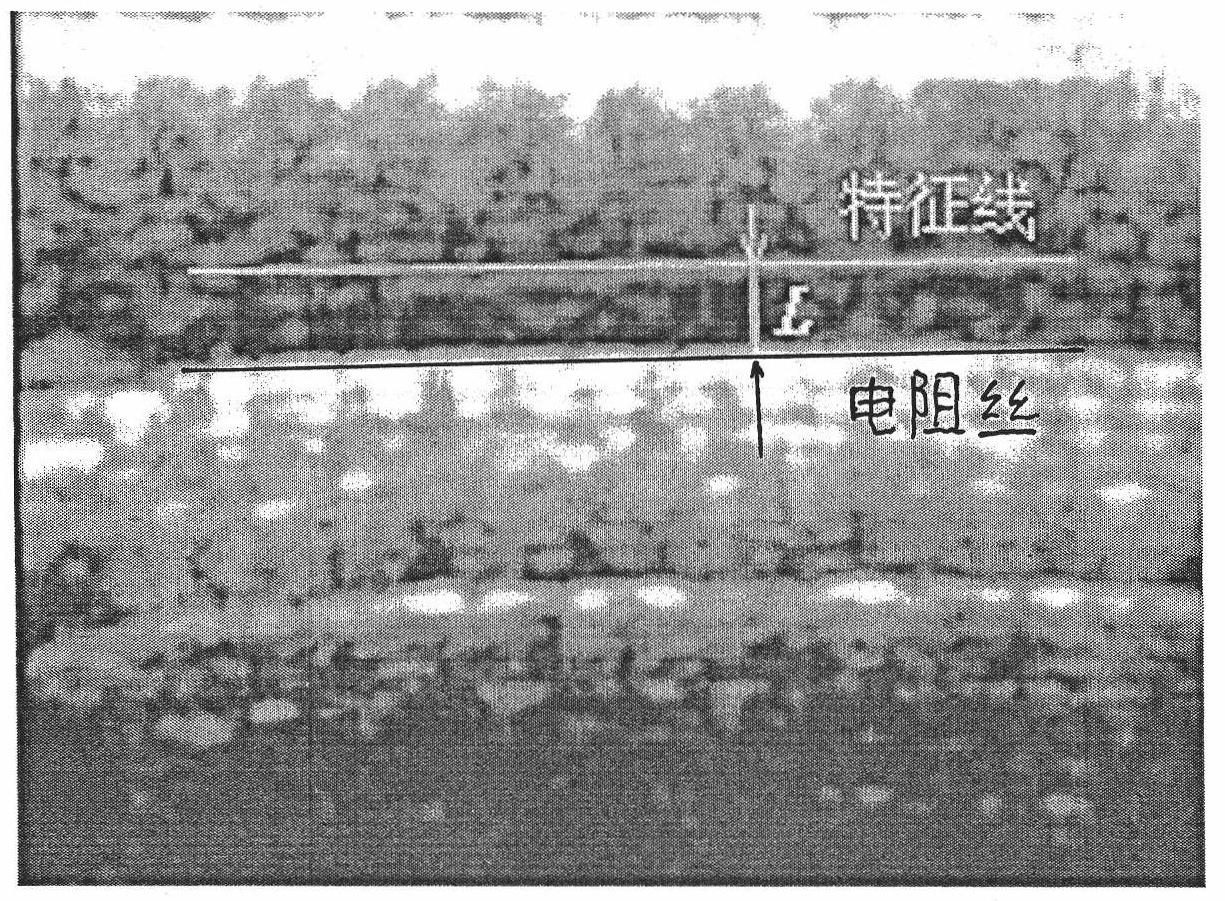

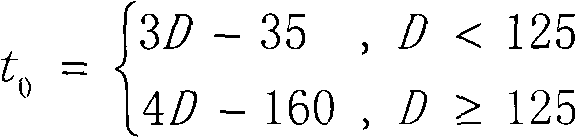

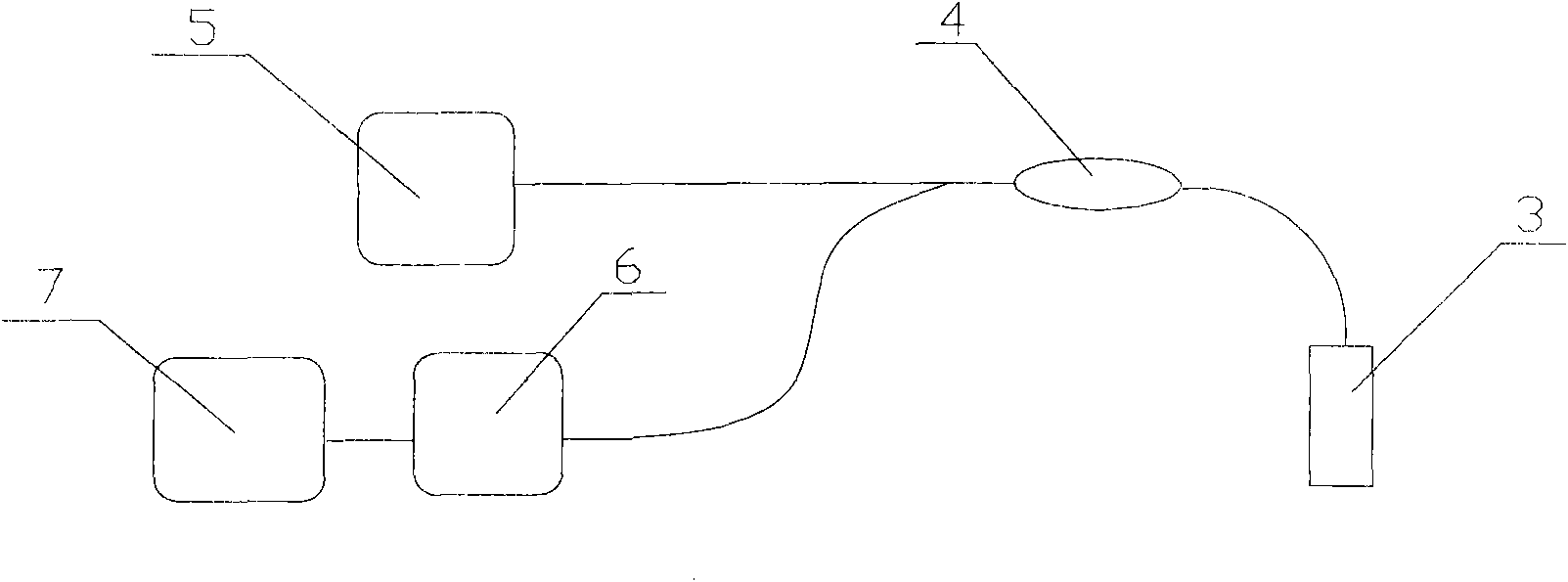

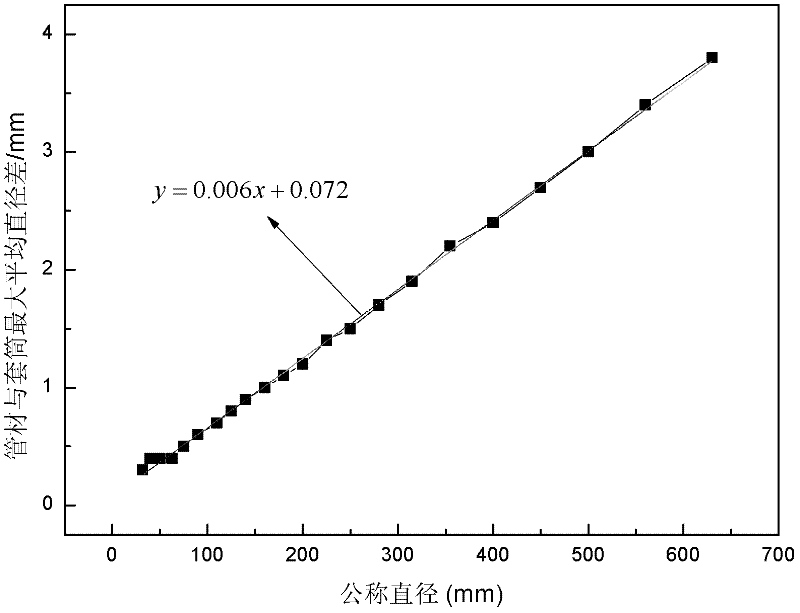

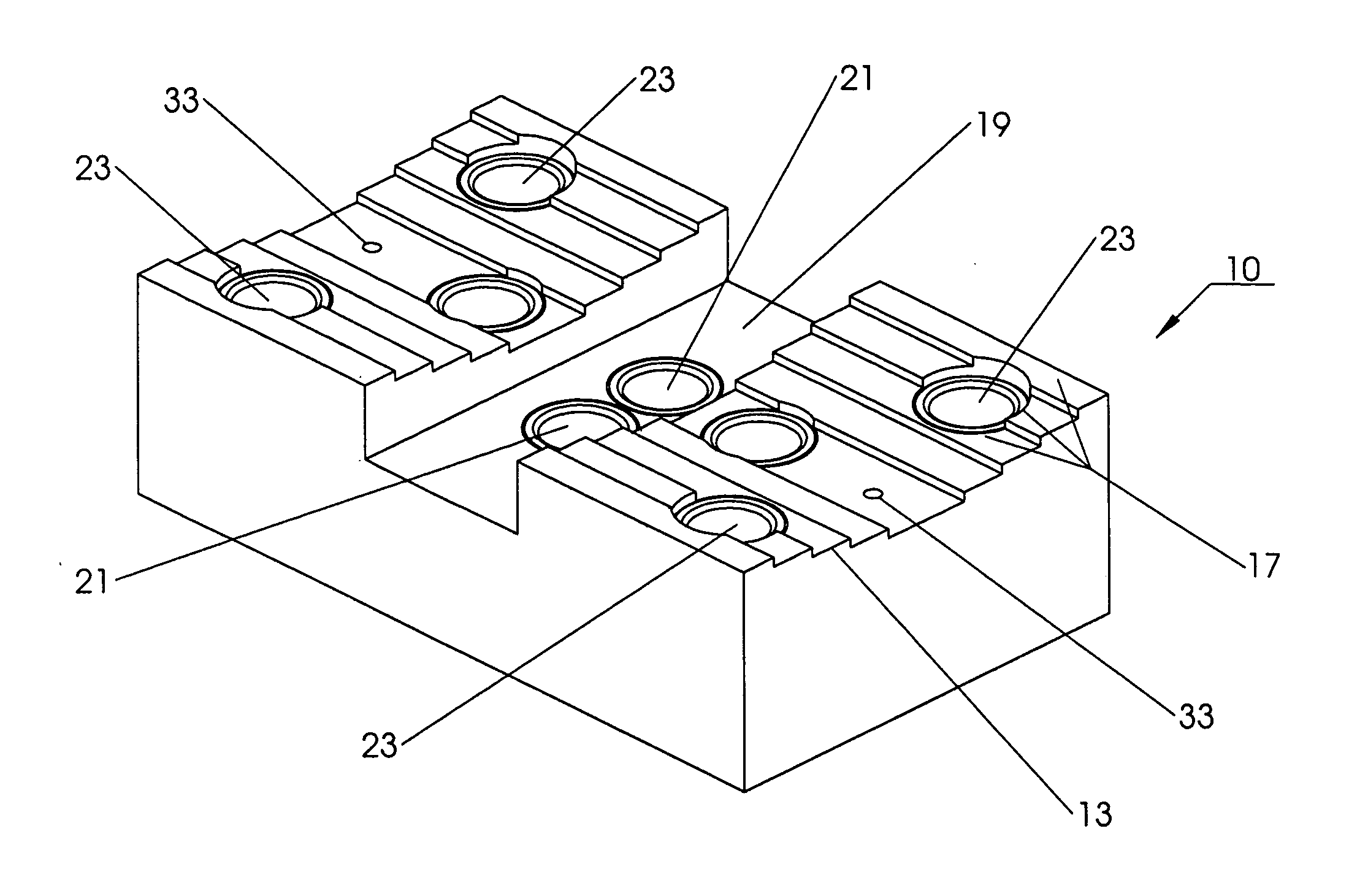

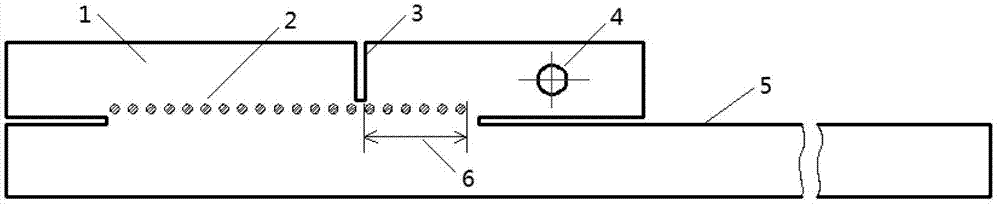

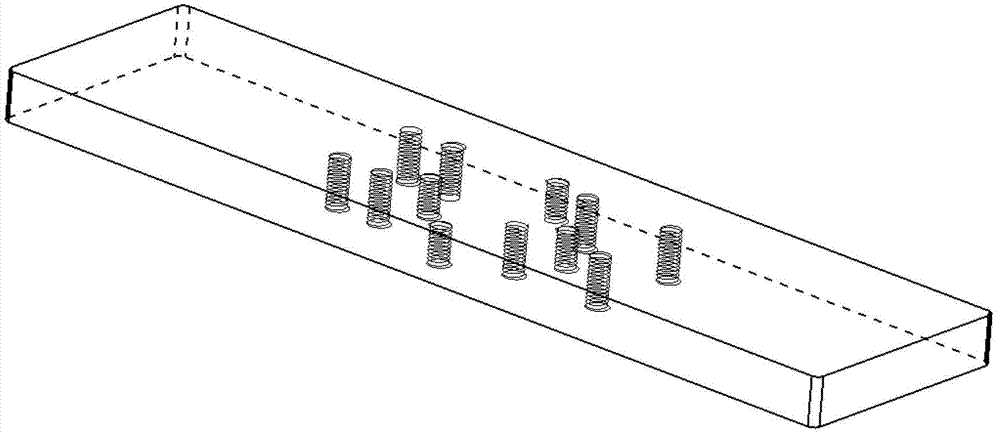

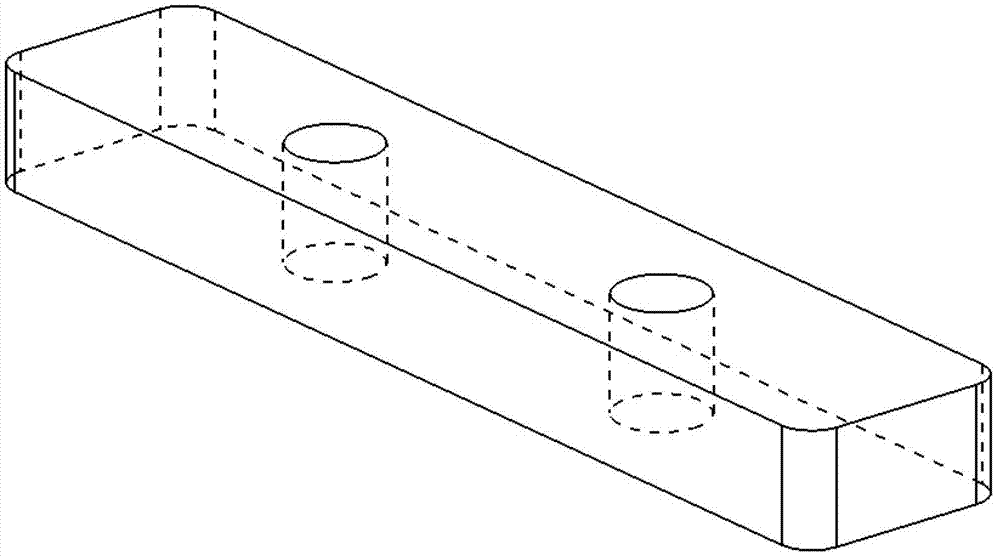

Method for testing welding quality of electro-fusion joint and realizing automatic evaluation

ActiveCN102009474AQuality improvementAvoid putting into useTubular articlesElectrical resistance and conductanceEvaluation result

The invention relates to electro-fusion welding technology for plastic pipelines or plastic composite pipelines, and aims to provide a method for testing the welding quality of an electro-fusion joint and realizing automatic evaluation. The method comprises the following steps of: measuring peeling energies E of the electro-fusion joint and the distance L between a characteristic line and a resistance wire under different welding conditions, and acquiring a fitted curve, serving as a calibration basis, of the peeling energy per unit area Ep and the distance L; and testing the welding quality of the electro-fusion joint and realizing the automatic evaluation. The method can prevent unqualified electro-fusion joints from being put into use, so that the safety of plastic pipes and composite pipe systems is ensured. A software module for realizing the method is integrated on an electro-fusion welded or electro-fusion jointed ultrasonic testing instrument, so that a welder automatically controls the welding quality or the testing instrument automatically evaluates an electro-fusion welded joint to be tested, the influence of human factors is avoided, and the quality of a welded joint is more reliable and the evaluation result is more objective.

Owner:ZHEJIANG UNIV

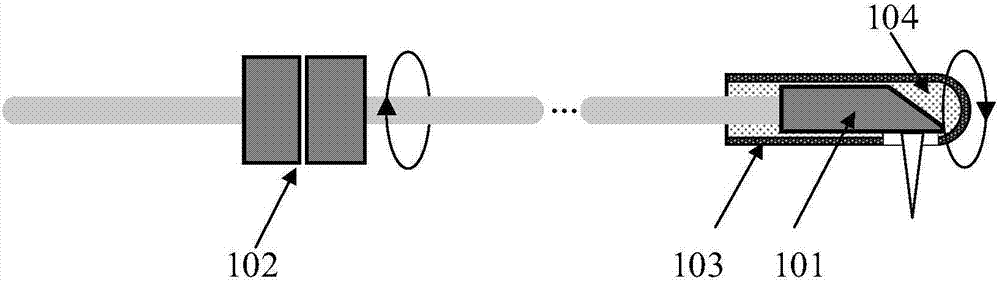

Internal fiber integration type miniature Michelson interferometric sensor and manufacturing method thereof

ActiveCN101614601AEasy to makeLow costThermometers using physical/chemical changesCoupling light guidesInterferometric sensorElectromagnetic interference

The invention discloses an internal fiber integration type miniature Michelson interferometric sensor and a manufacturing method thereof. The sensor comprises two single mode fibers with different external diameters and the same core diameters; the single mode fiber with small external diameter is fusion-jointed on the single mode fiber with large external diameter by axis dislocation; the core parts of the two single mode fibers are overlapped; the uncovered part of the end face of the core of the single mode fiber with large external diameter is the reflecting surface of a reference arm; the core end of the exposed end of the single mode fiber with small external diameter is the reflecting surface of a measuring arm; the cores of the two fibers are made of SiO2. The sensor has the beneficial technical effects of simple manufacturing, low cost, small volume, good electromagnetic interference resistance, good high temperature resistance and good electric insulativity.

Owner:SICHUAN GUANGSHENG IOT TECH CO LTD

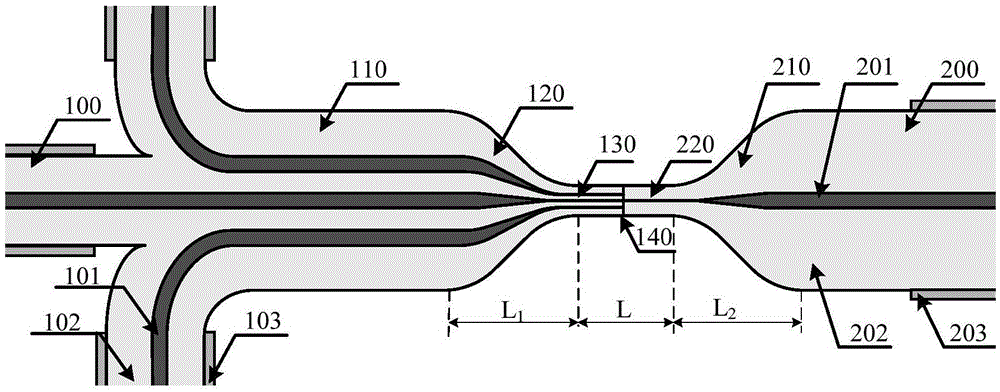

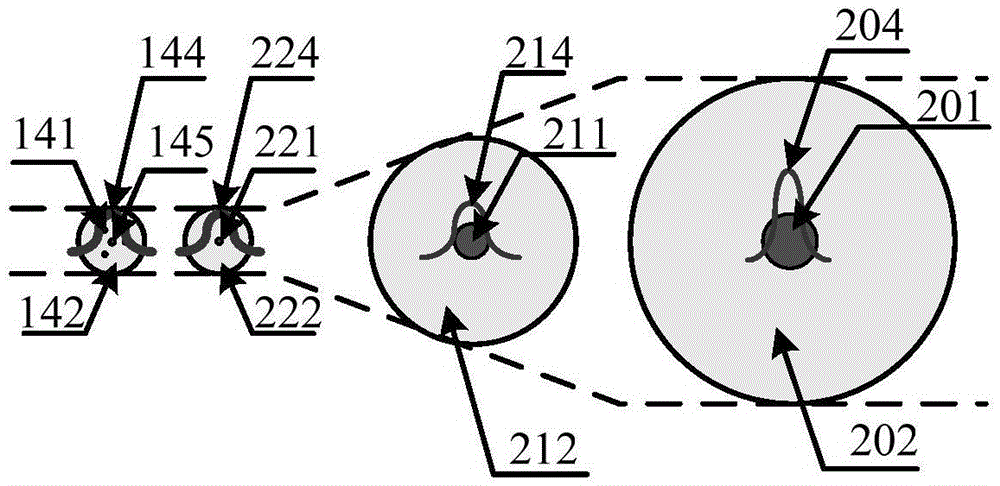

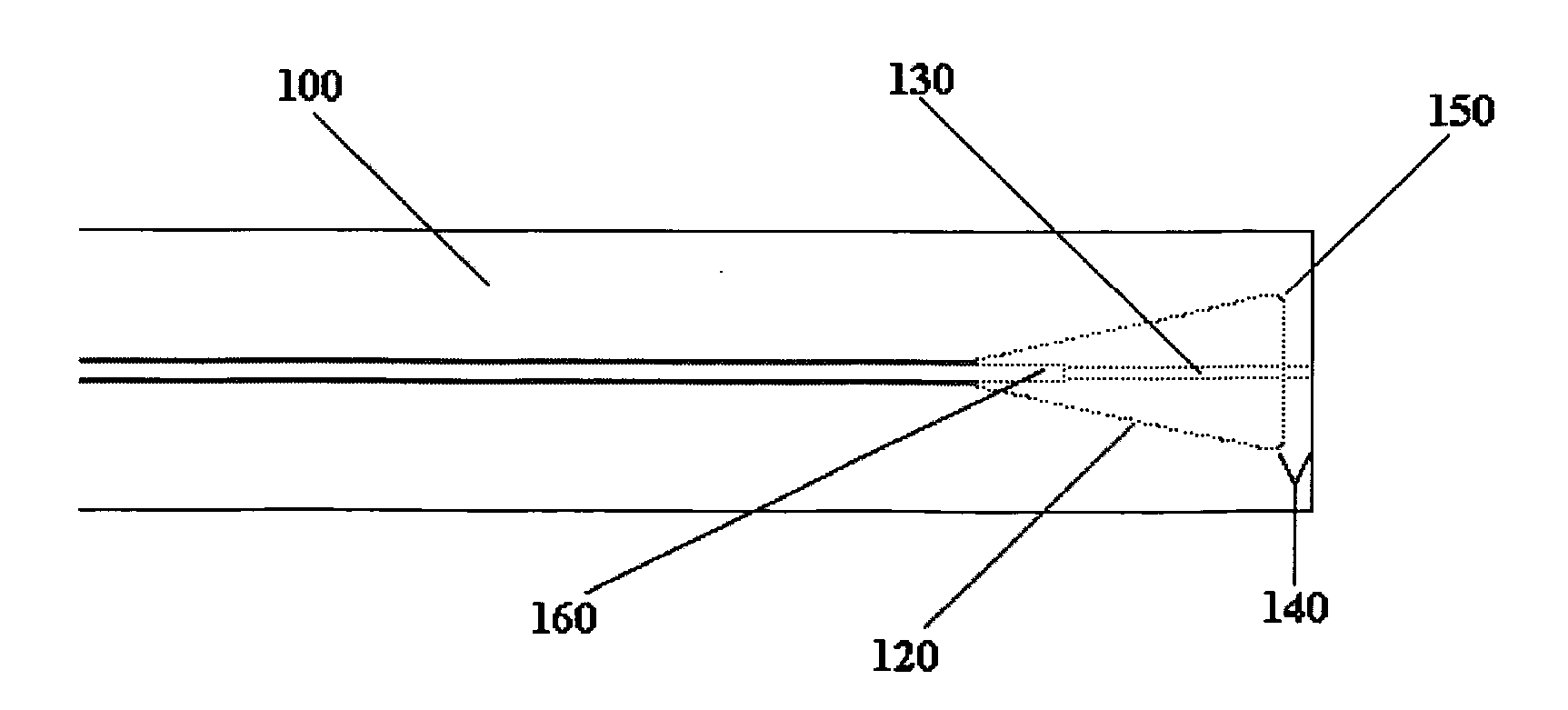

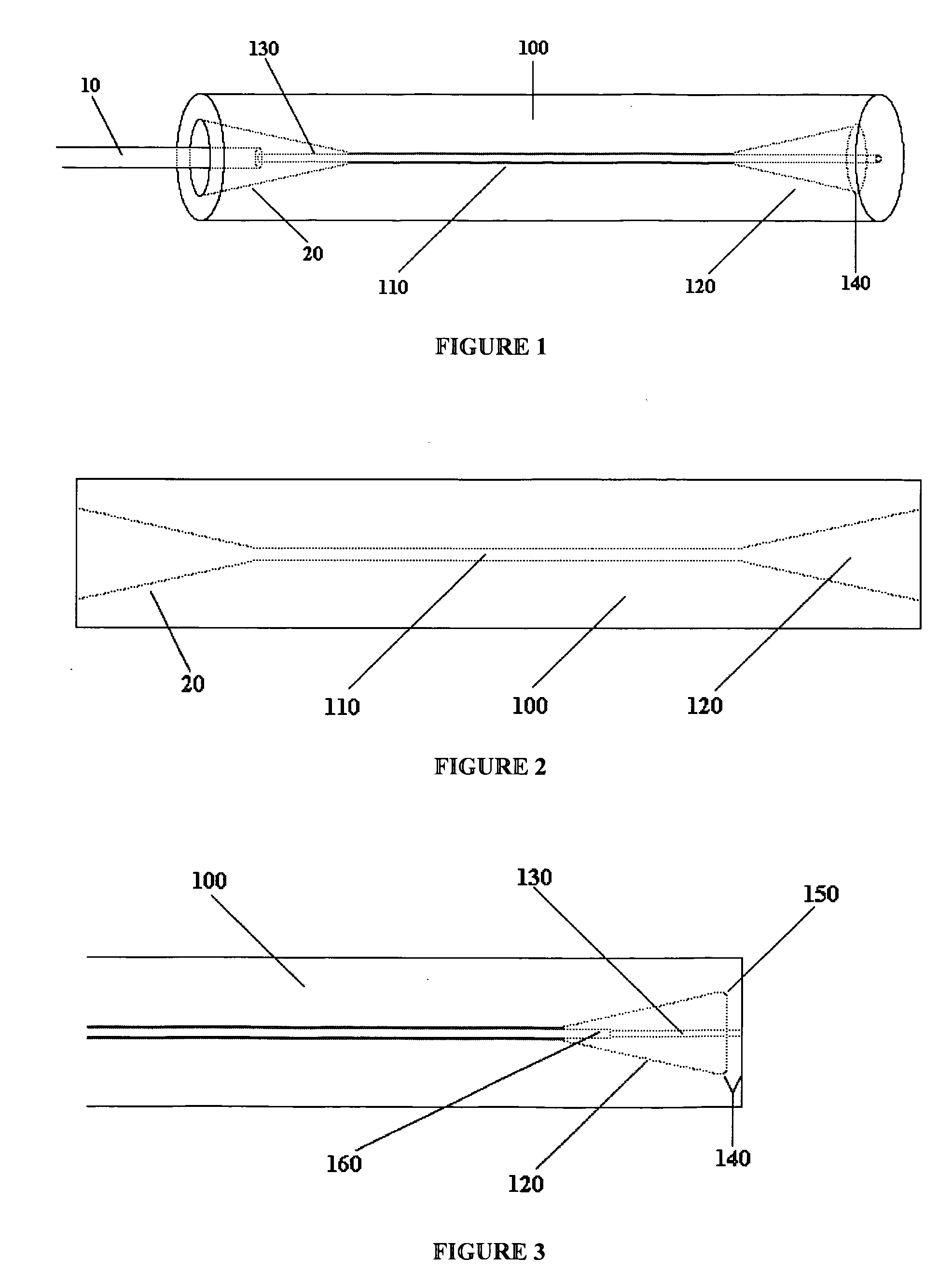

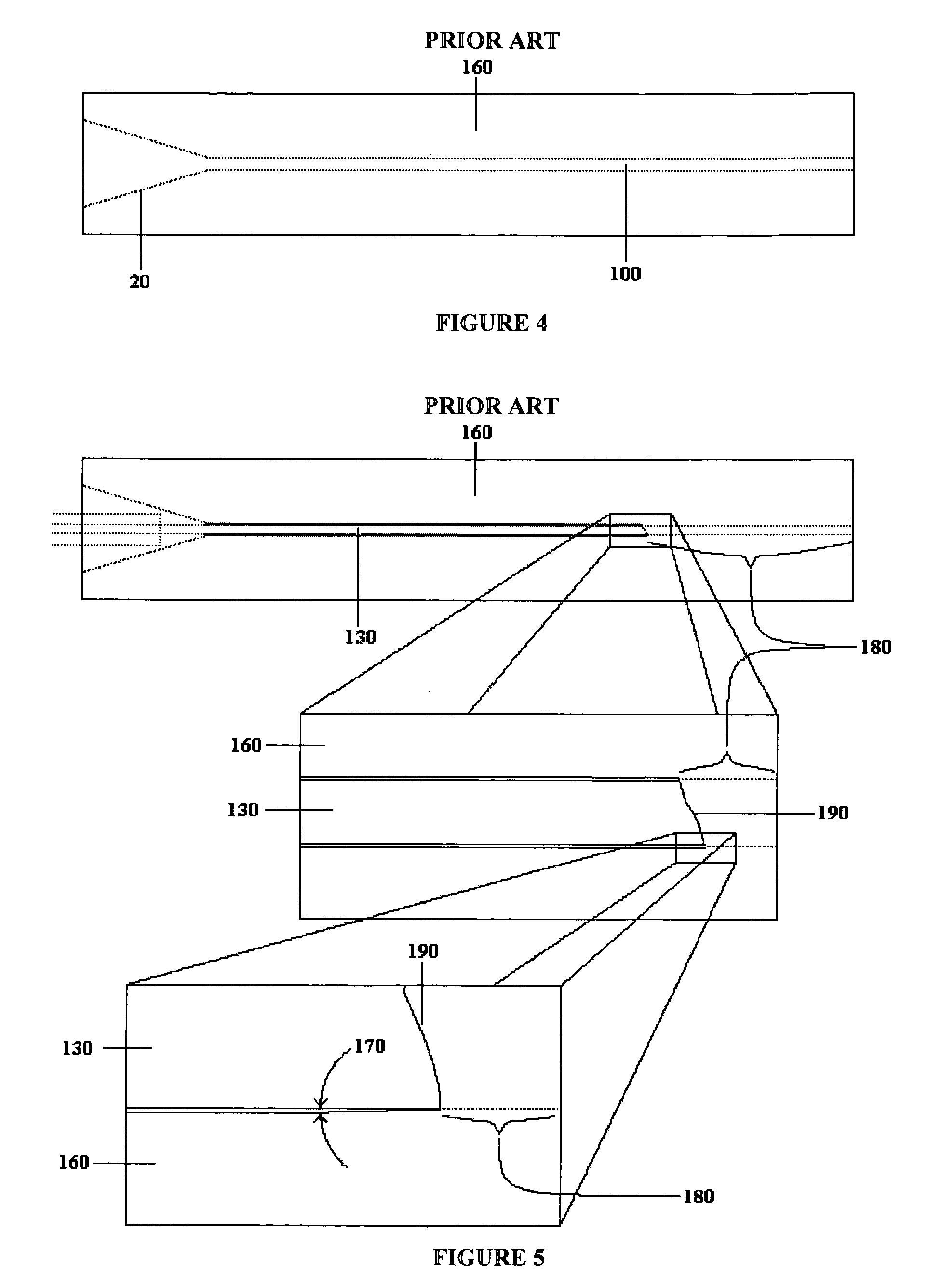

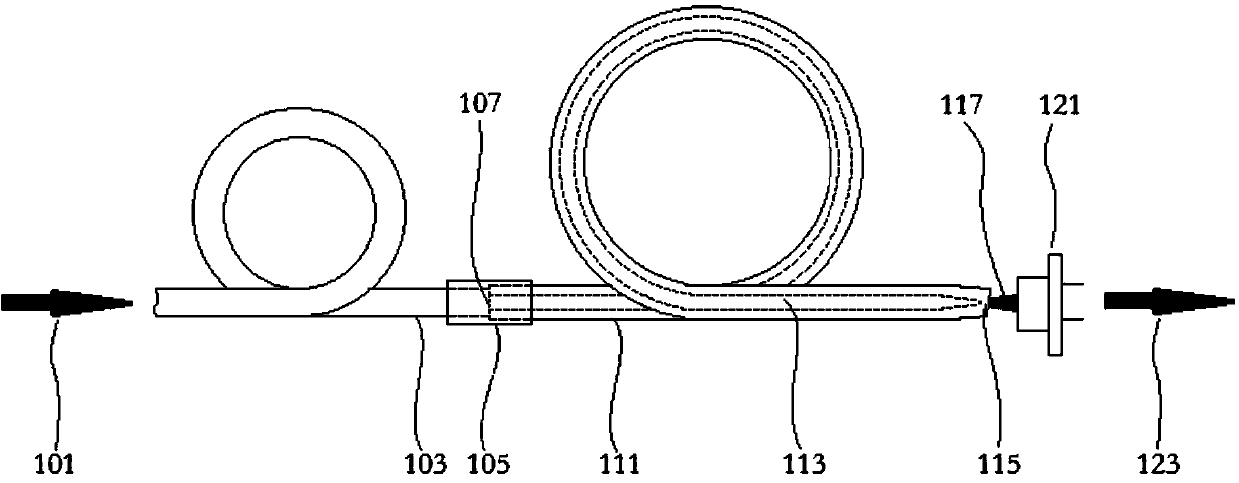

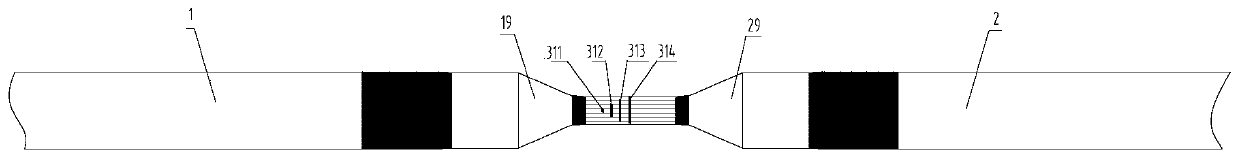

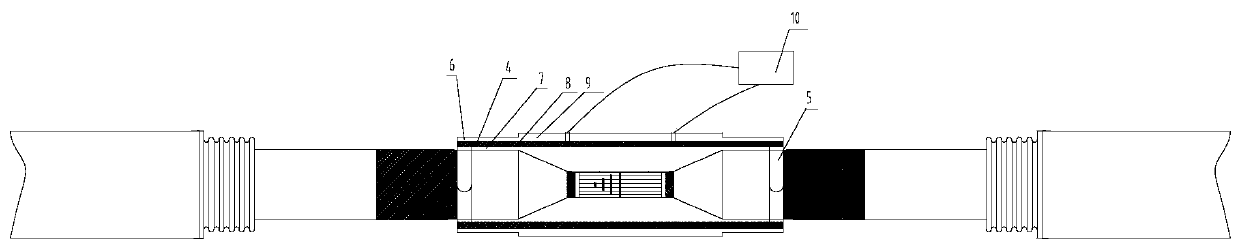

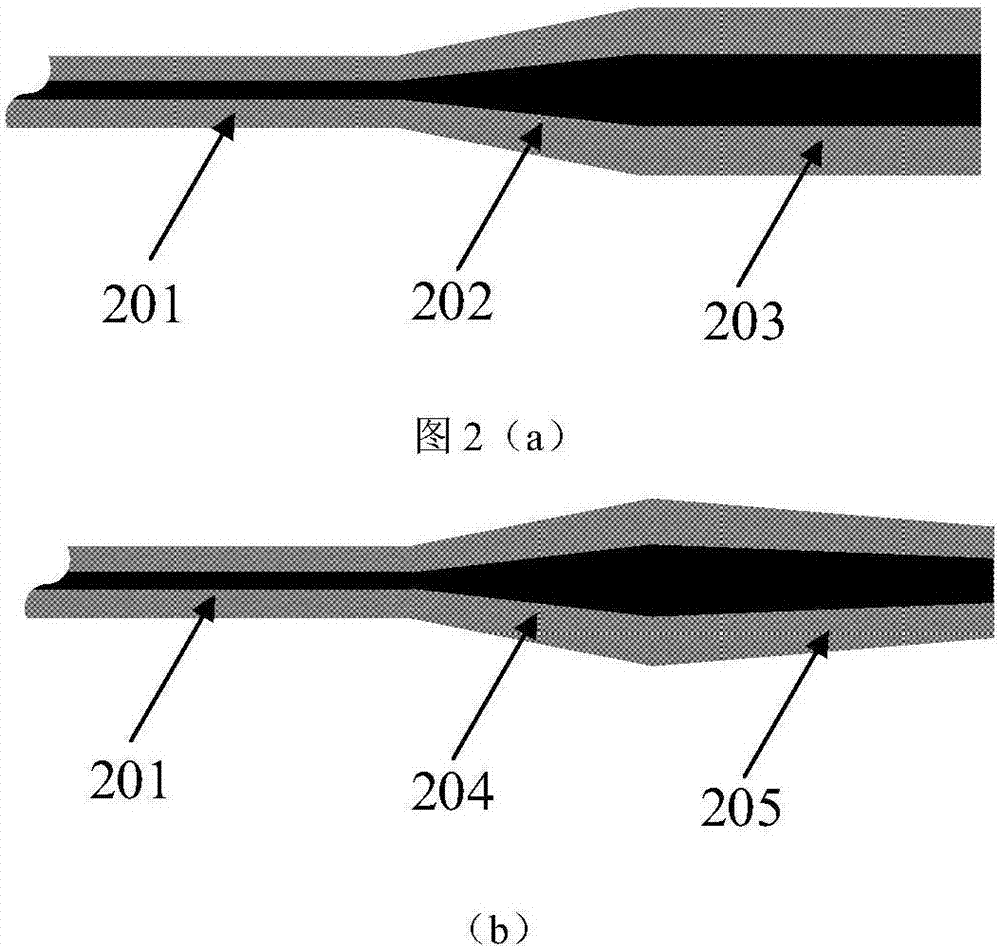

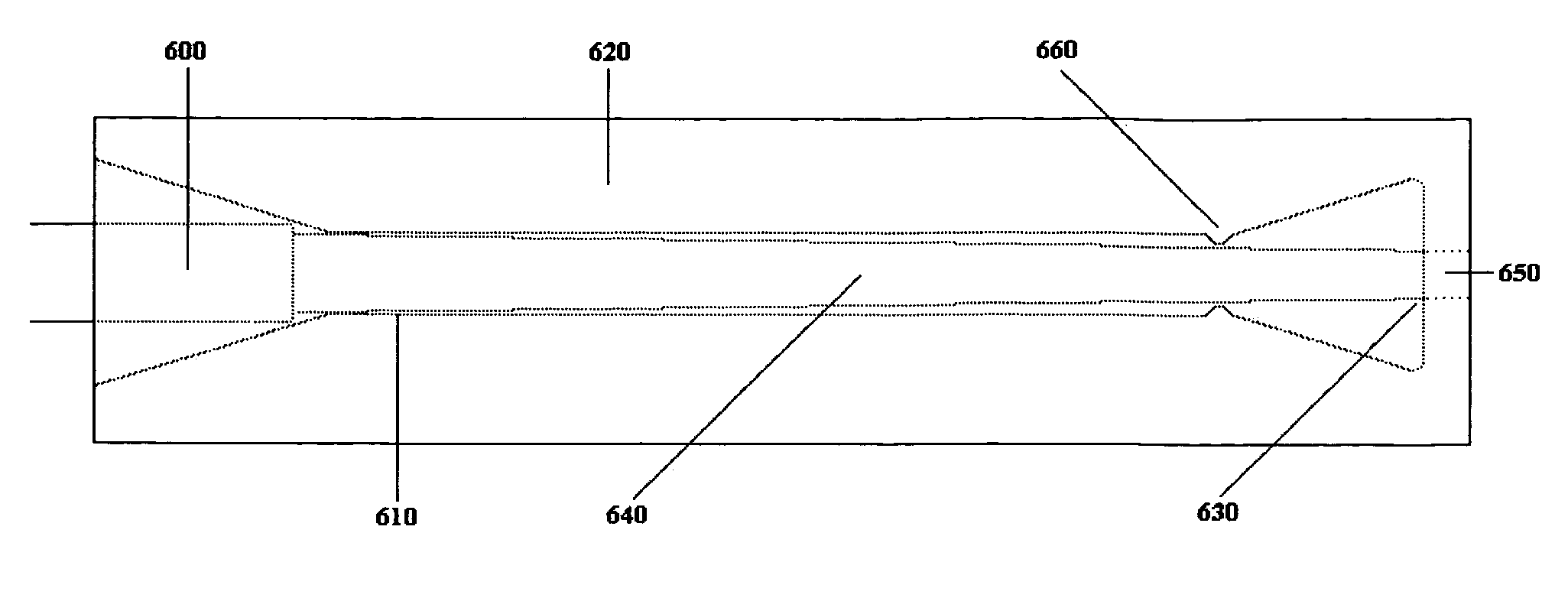

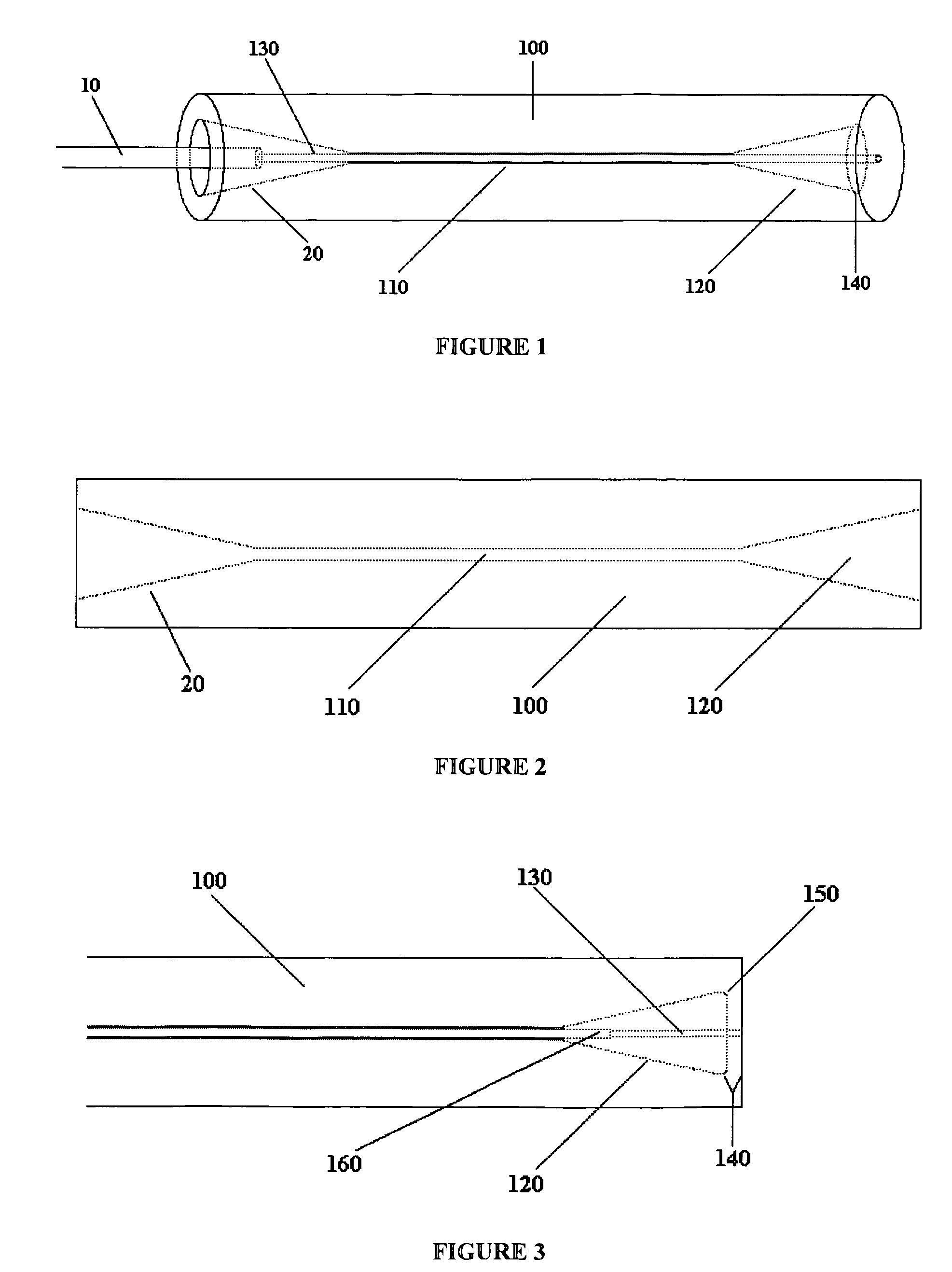

Fusion tapered optical fiber power beam combiner and manufacturing method thereof

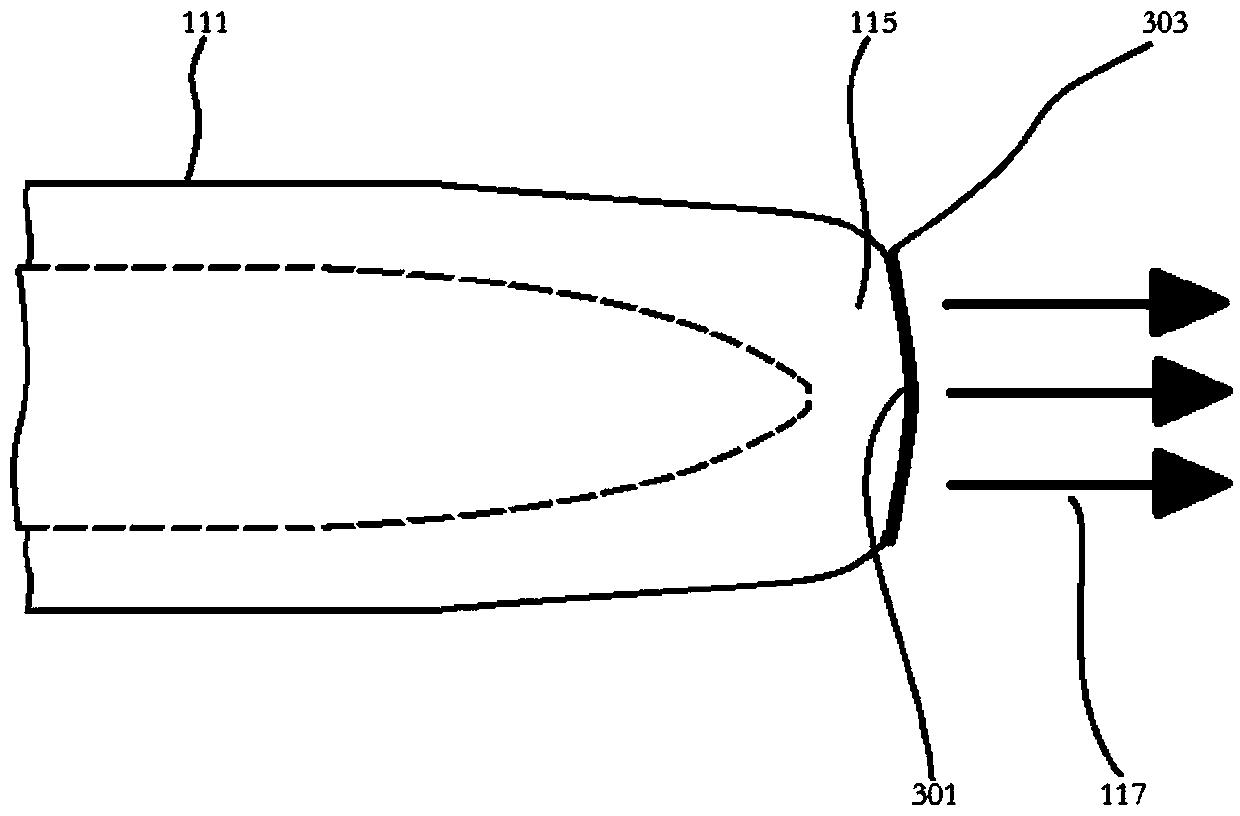

InactiveCN105572803ACore Size ReductionIncrease brightnessCoupling light guidesDouble-clad fiberHigh power lasers

The invention provides a fusion tapered optical fiber power beam combiner and a manufacturing method thereof. The beam combiner consists of an input signal optical fiber (100), a fused optical fiber beam (110), a tapered transition region optical fiber beam (120), a tapered homogeneity region (130), a fusion joint (140), a tapered homogeneity region output optical fiber (220), a tapered transition region output optical fiber (210) and an output doubly-clad optical fiber (200). The manufacturing method comprises the following steps: firstly fusing and tapering the input optical fiber beam to a cladding size matched with that of the output optical fiber, then performing fusion welding on the fusion tapered optical fiber beam and the output optical fiber, and finally re-tapering the fusion welding point region, thereby finishing manufacturing of the beam combiner. The beam combiner is capable of realizing high-brightness signal laser beam combination while ensuring the coupling efficiency and realizing high-power output, and has great significance for high-power laser.

Owner:NAT UNIV OF DEFENSE TECH

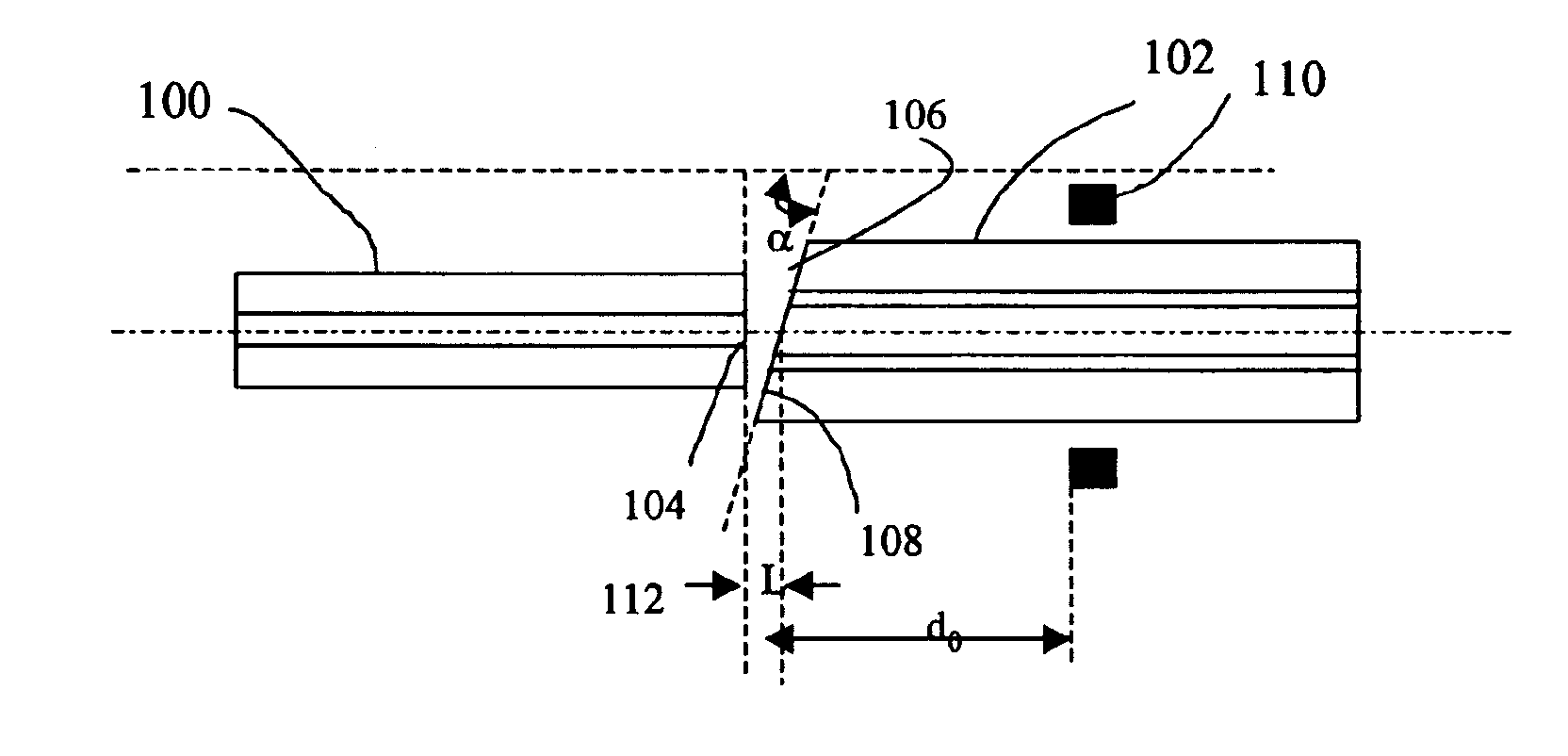

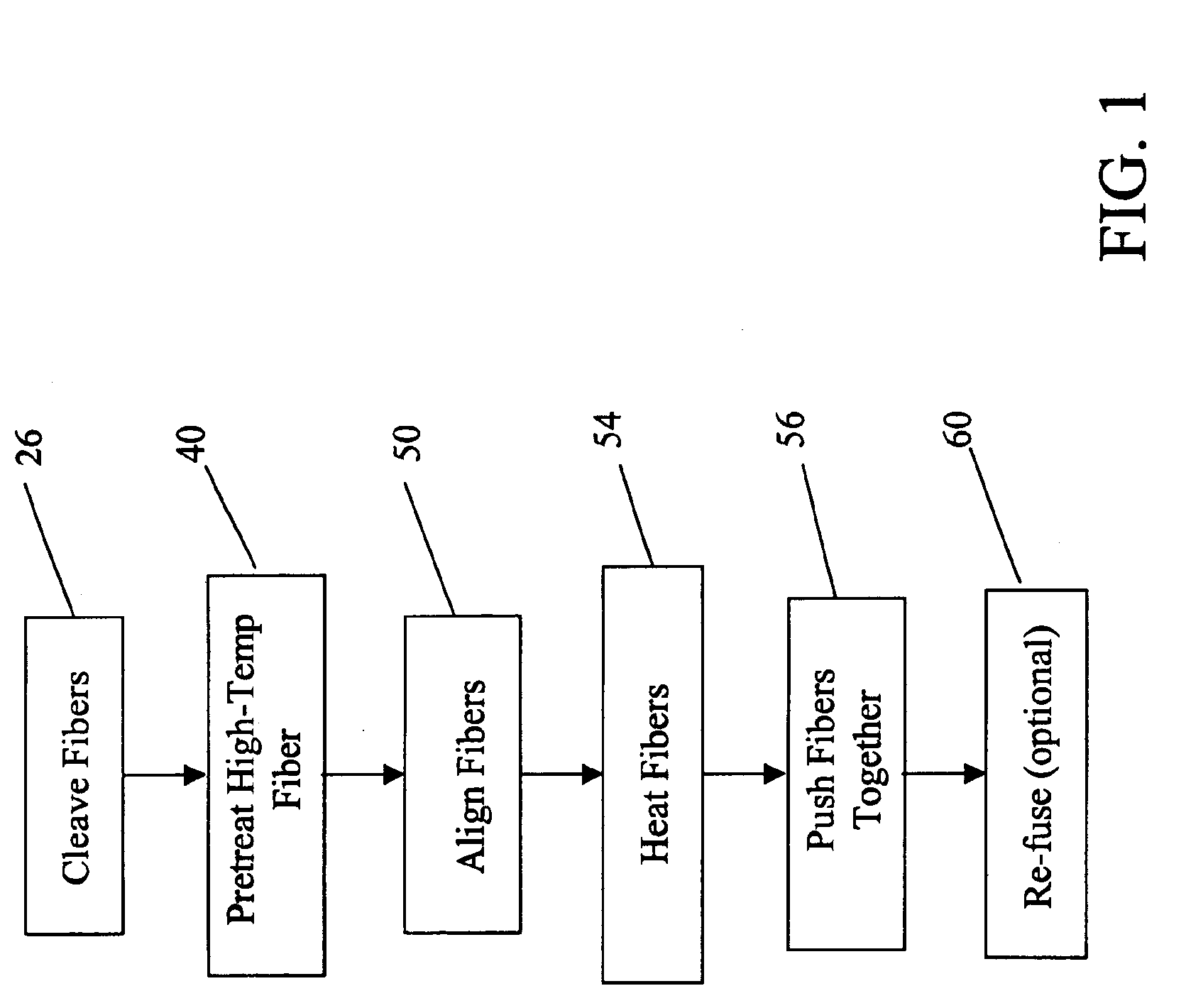

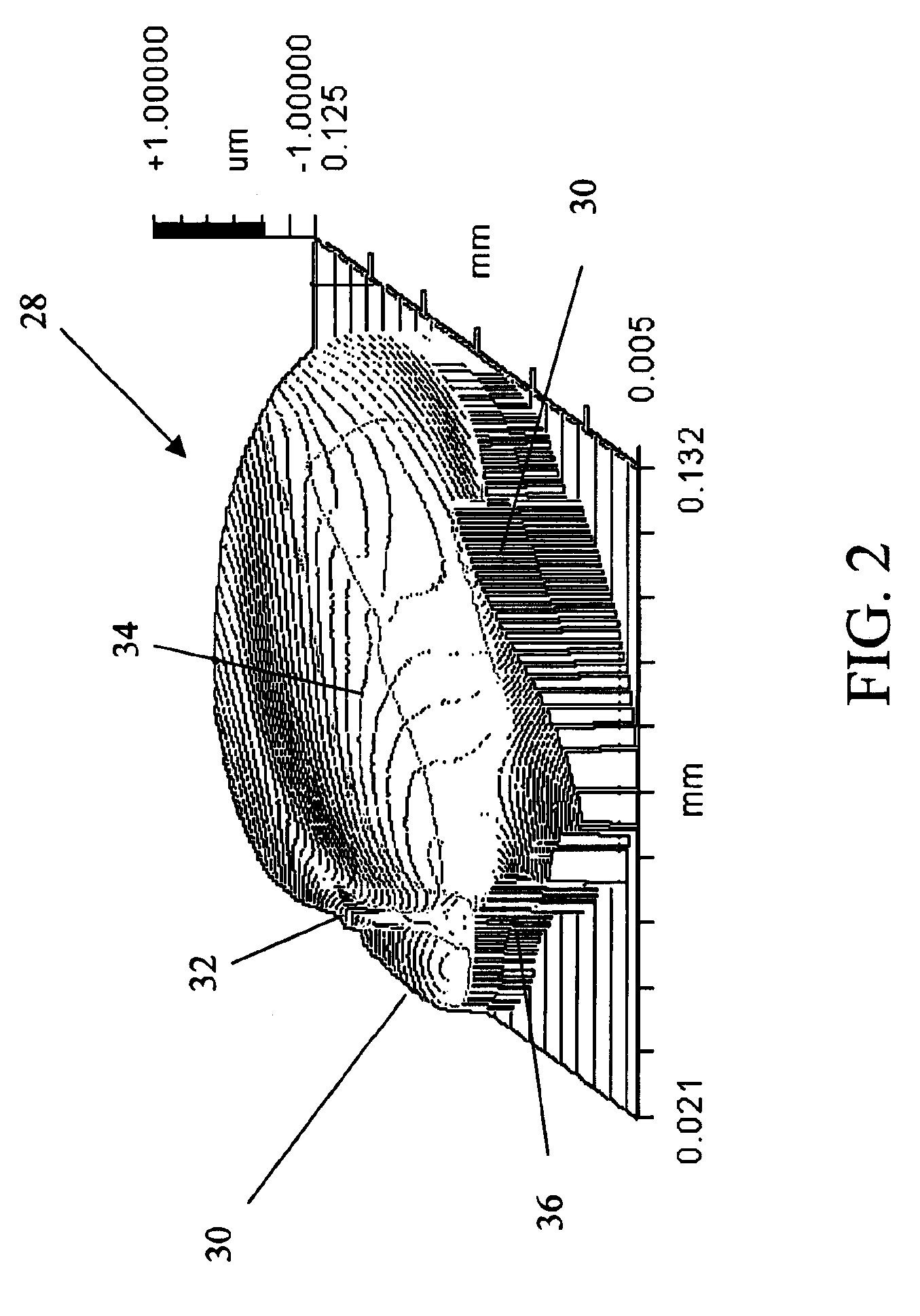

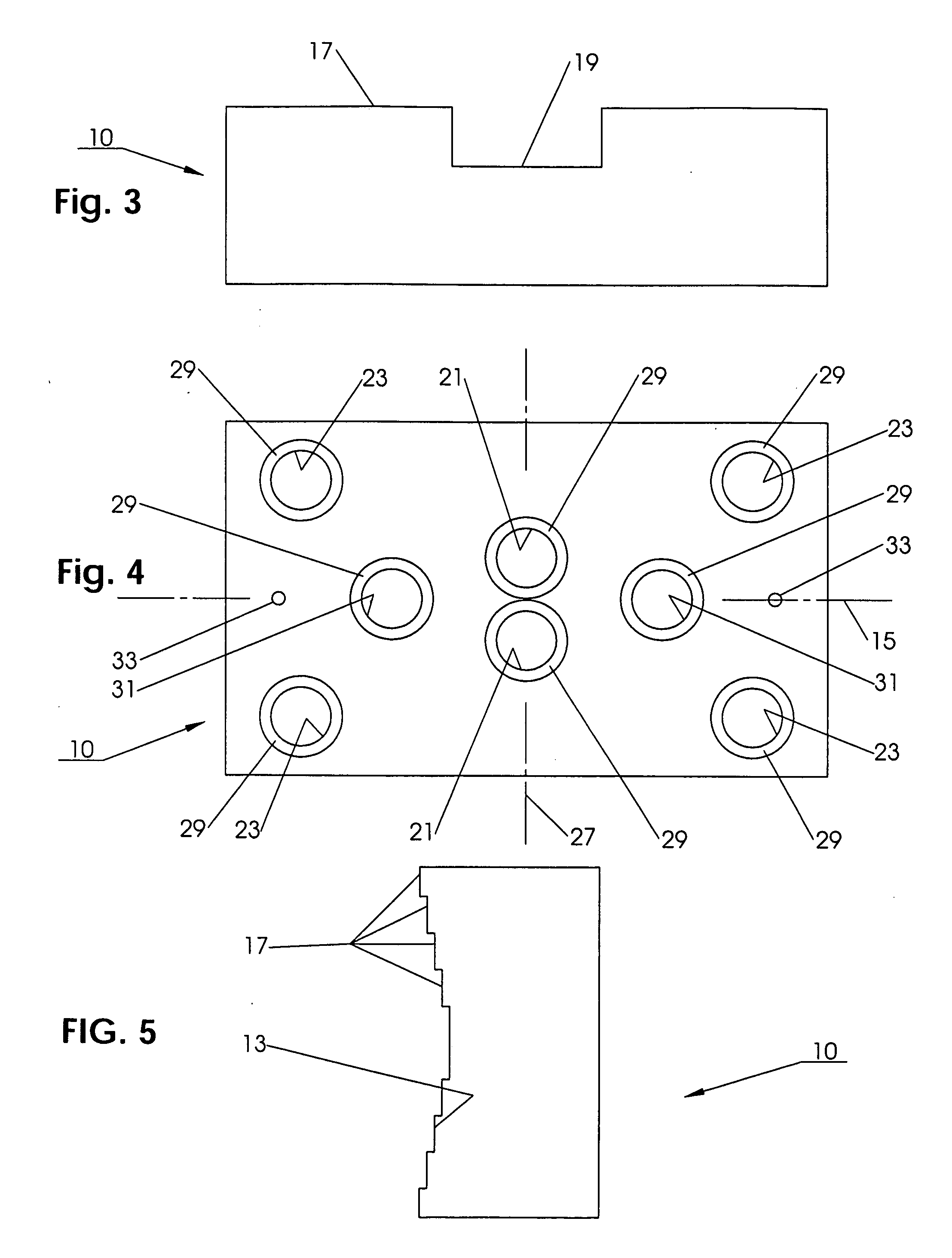

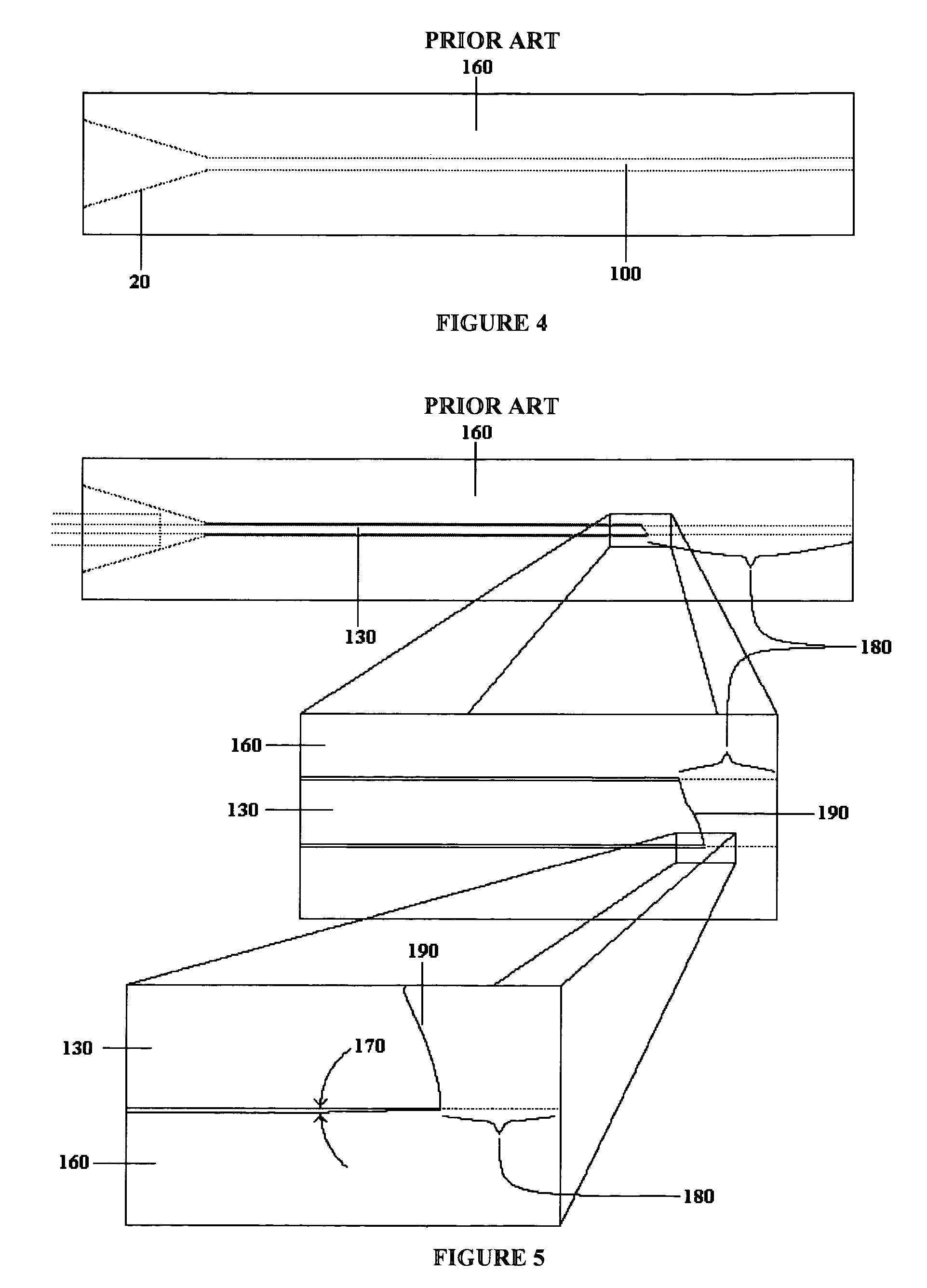

Method of fusion splicing thermally dissimilar glass fibers

InactiveUS6921216B1Speed up heat dissipationReduce direct heatingGlass making apparatusCoupling light guidesGlass fiberFusion joints

Thermally dissimilar glass fibers are fusion spliced by pretreating the cleaved end surface of the high-temperature fiber to provide a smooth surface for making good contact with the low-temperature fiber. The fibers are heated to a temperature that is high enough to soften the low-temperature fiber but not the high-temperature fiber and brought in contact to form the fusion joint.

Owner:NP PHOTONICS A CORP OF DELAWARE

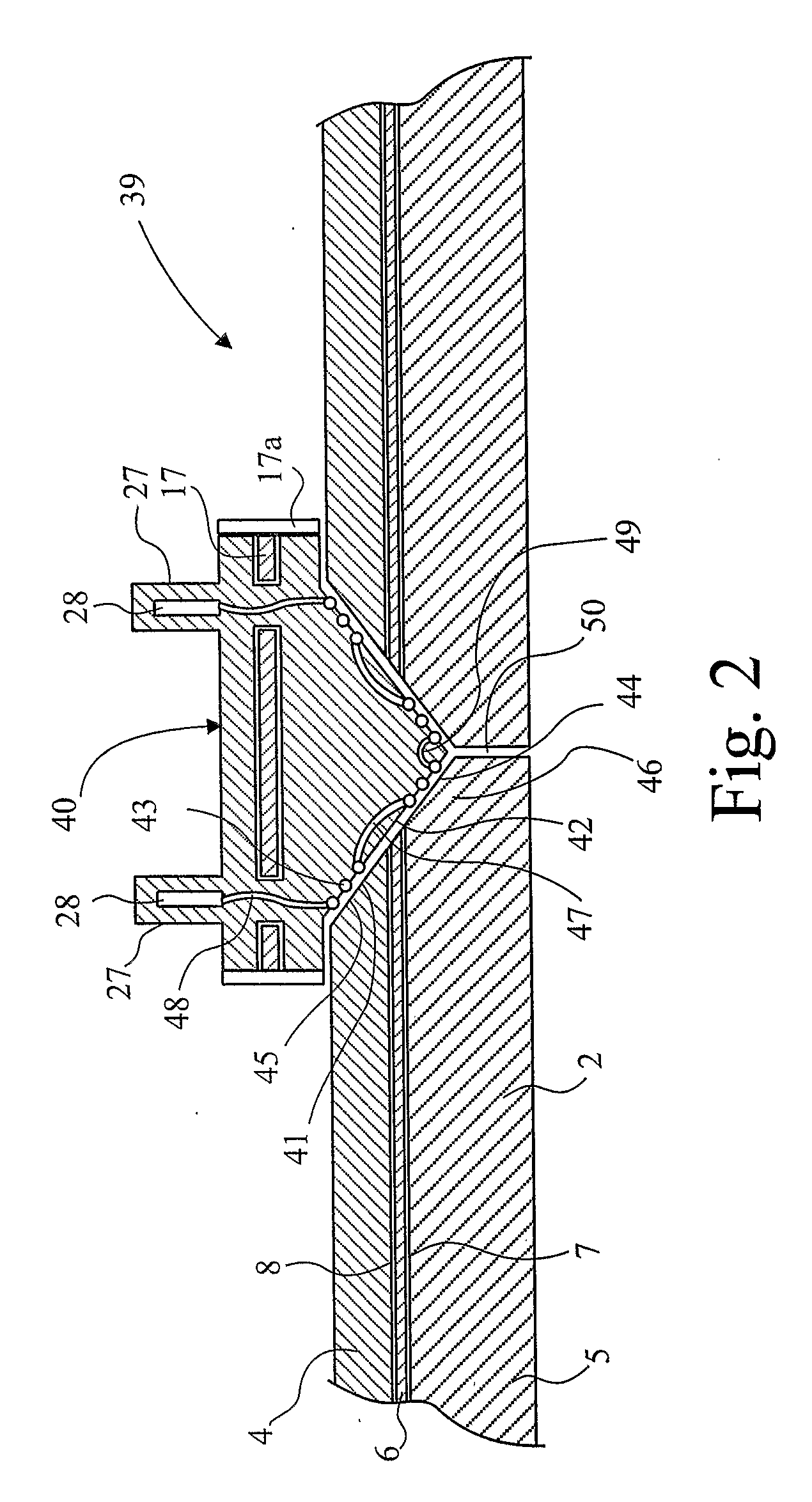

High energy fiber terminations and methods

A ferrule and method are presented that fuses optical fibers, capillaries and the like to ferrules while reducing deformation of the fused component and the ferrule and minimizing stresses within the assembly. Reduced deformation and stress is accomplished by providing high contact angles in a symmetrical, short section of fusion in fusing the component carried by the ferrule to the ferrule. It is particularly applicable to hermetic terminations of polymer clad fiber optics where irregular glass fusion joints cause irregular light leakage at the fiber launch but benefits are significant when used for other fiber and capillary architectures as well.

Owner:BOSTON SCI SCIMED INC +1

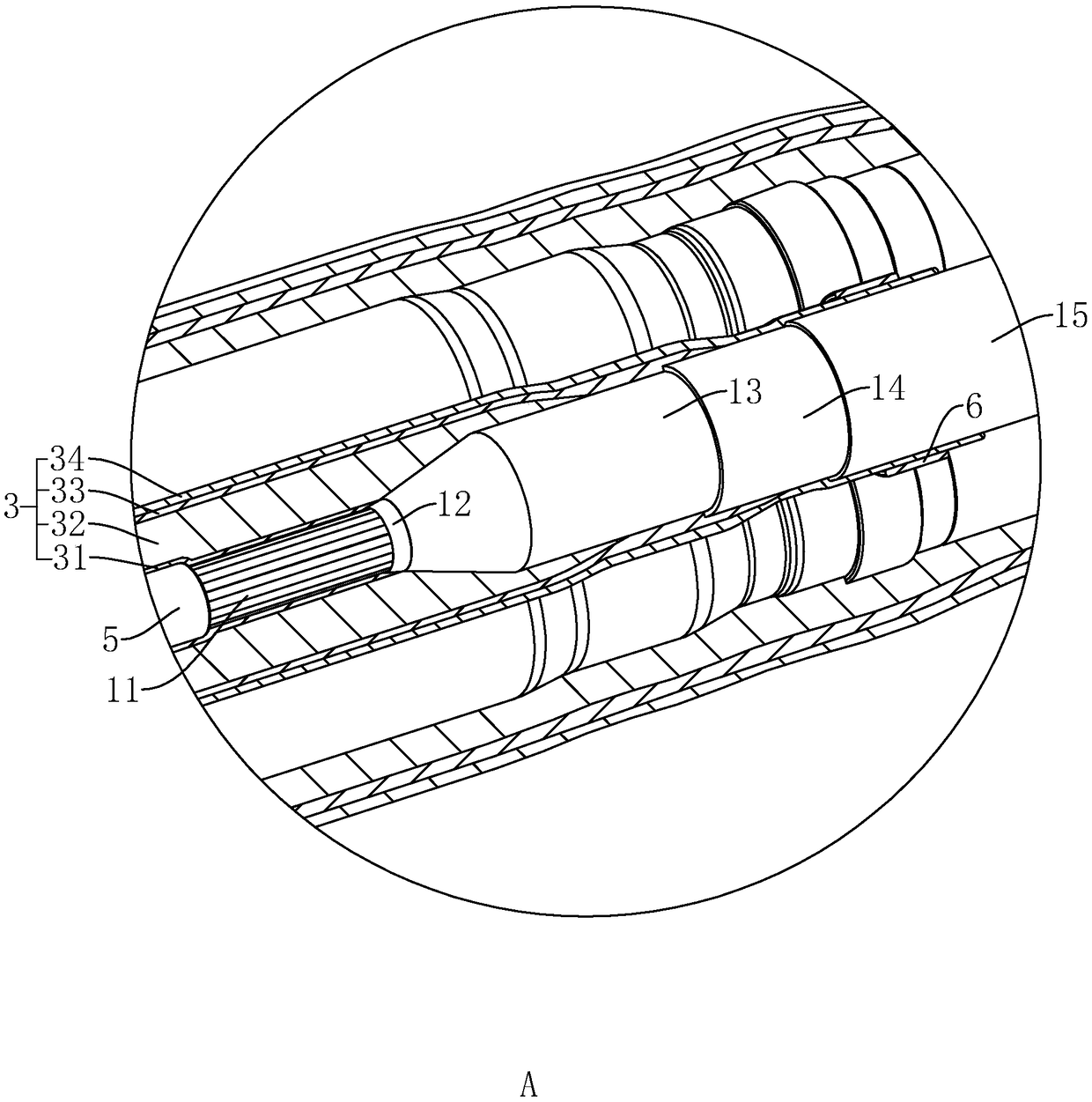

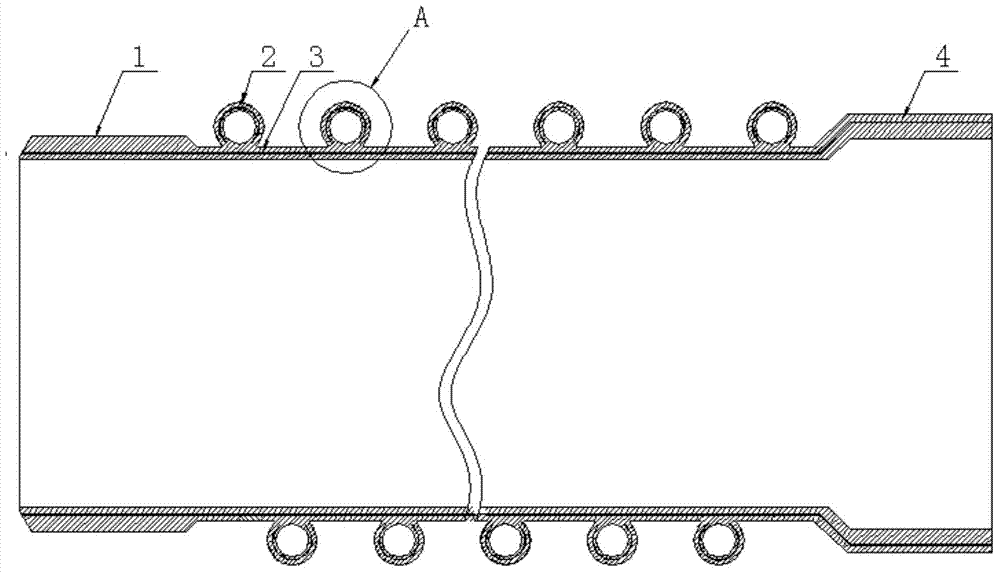

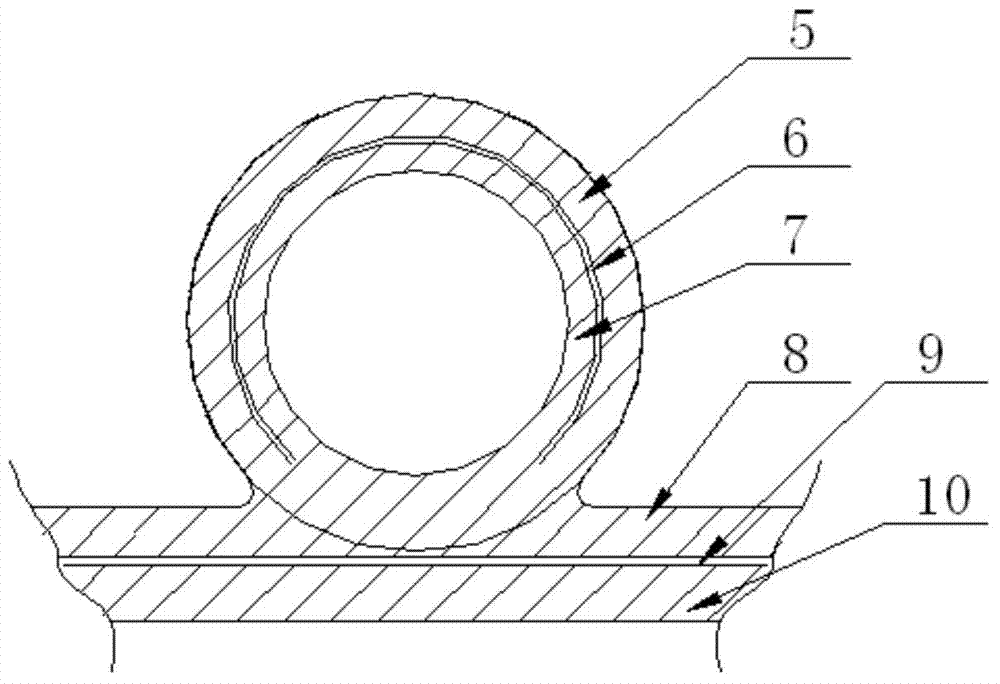

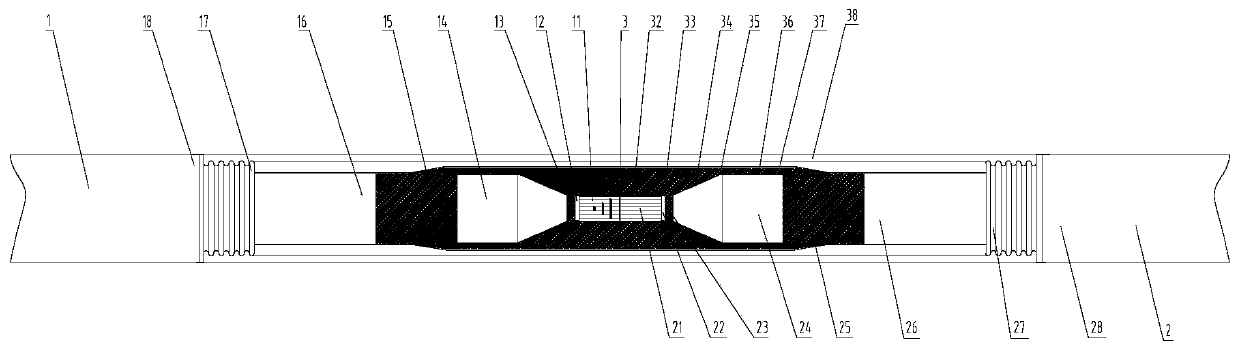

Three-core cable fusion joint and installation technology thereof

InactiveCN109286083ALarge elastic shrinkageFit tightlyLine/current collector detailsSoldered/welded conductive connectionsInterference fitElectric power transmission

The invention discloses a three-core cable fusion joint, and relates to the technical field of electric power transmission. The joint comprises two mutually connected cables, an inner repairing layergroup and an outer repairing layer group, wherein the inner repairing layer group and the outer repairing layer group are used for repairing the cables, each cable includes three conductor cores and an outer protection layer group coated outside the three conductor cores, the outer protection layer group includes an inner sheath layer, an armor layer and an outer sheath layer in sequence, the outer repairing layer group includes an inner sheath repairing layer, an armor repairing layer and an outer sheath repairing layer in sequence, the outer sheath repairing layer is set to be a heat shrinkable casing, and two ends, which are lapped with the outer sheath repairing layer, of the outer sheath layer are sleeved with cold shrinkage casings. The cold shrinkable casings are great in elastic shrinkage force and can carry out permanent elastic coating on the lapping parts at two ends of the outer sheath repairing layer, thereby forming interference fit for a long time, and effectively improving the relative stability between two ends of the outer sheath repairing layer and the outer sheath layer. In addition, the cold shrinkable casings can firmly adhered to the outer side of the outer sheath layer, thereby effectively improving the waterproof performance of the cable after the repair.

Owner:华依电缆附件有限公司

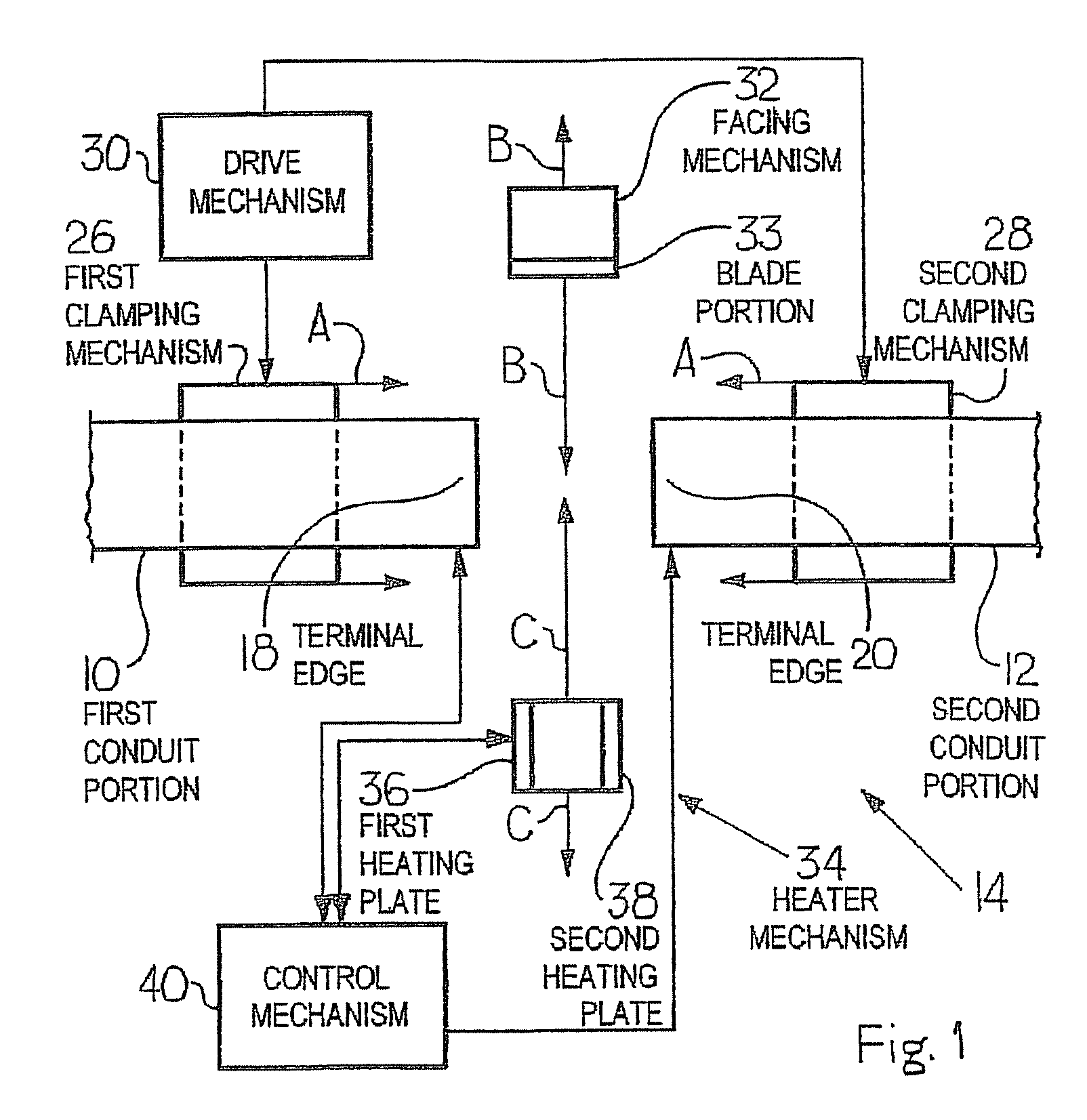

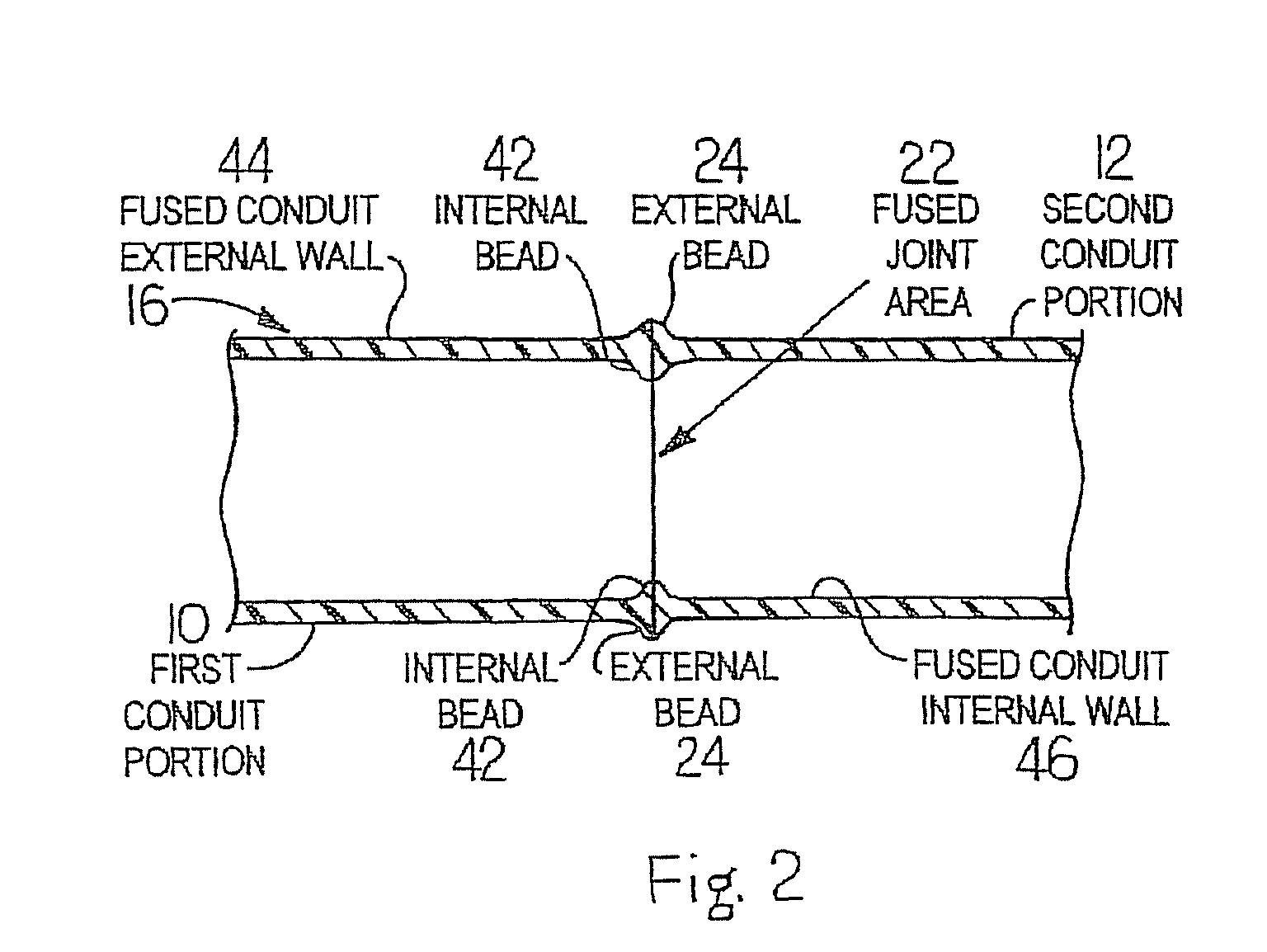

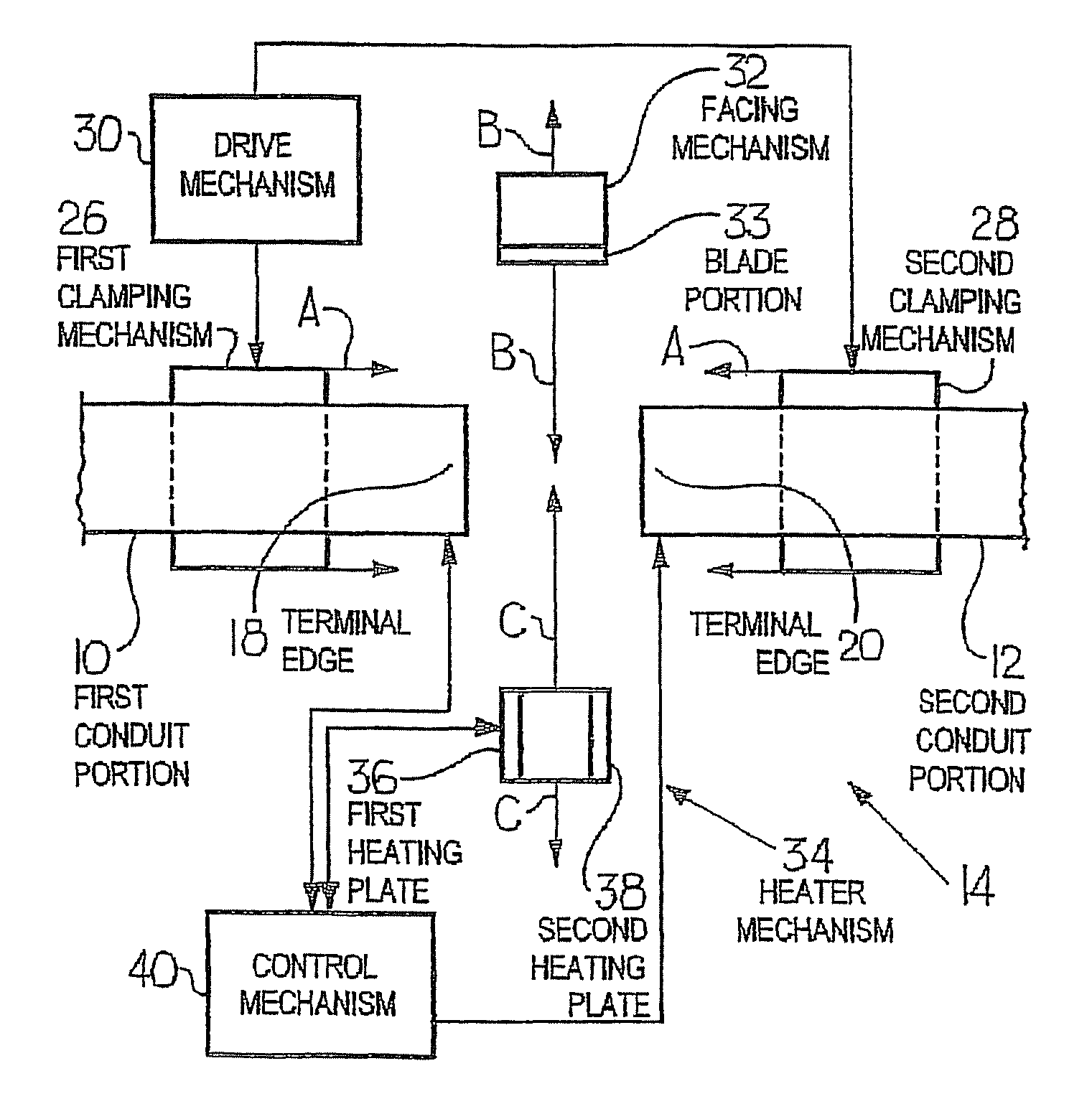

Polyvinyl chloride formulations

ActiveUS7842769B1Overcome deficienciesLabelling non-rigid containersMechanical working/deformationPolyvinyl chlorideFusion joints

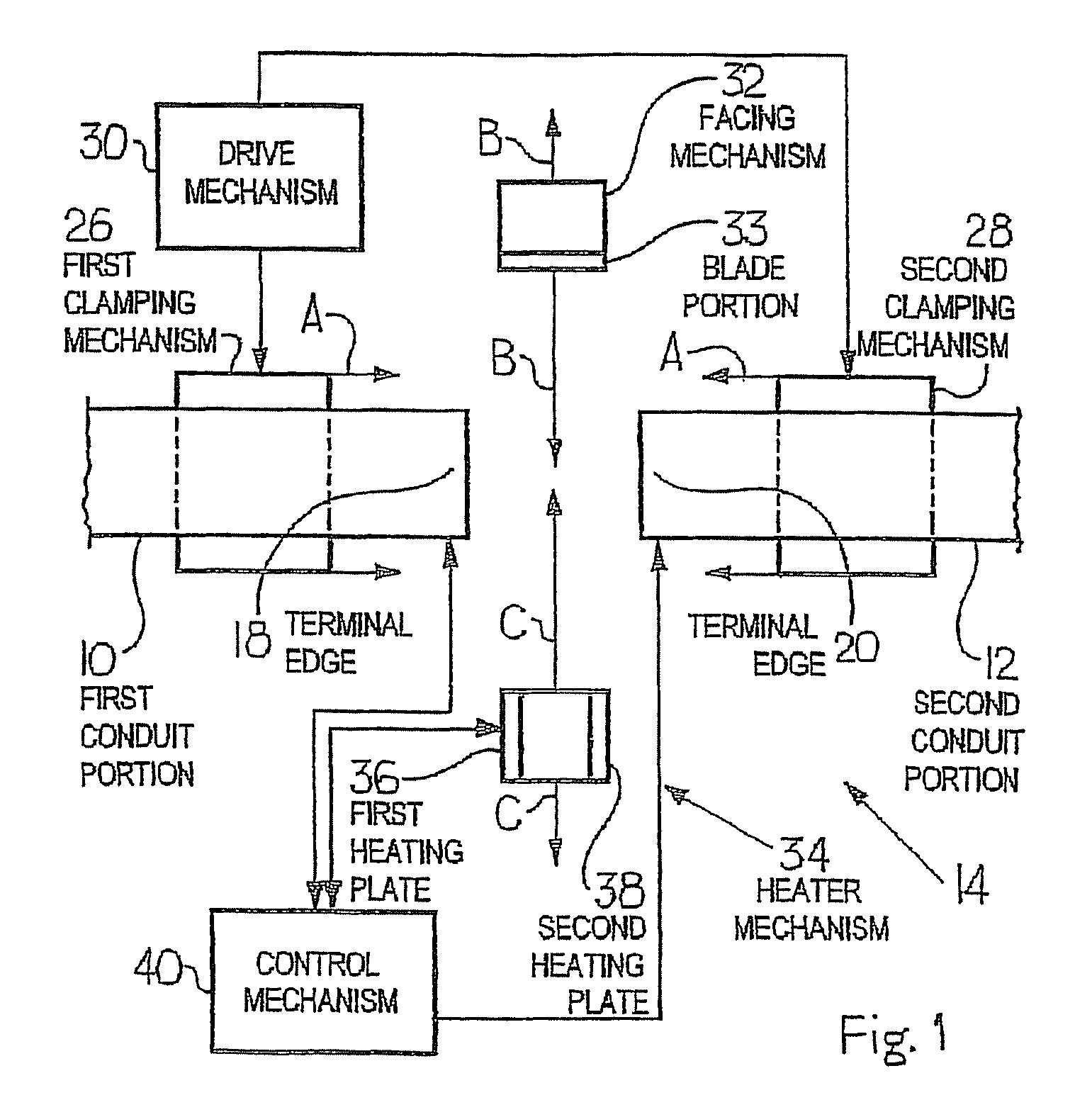

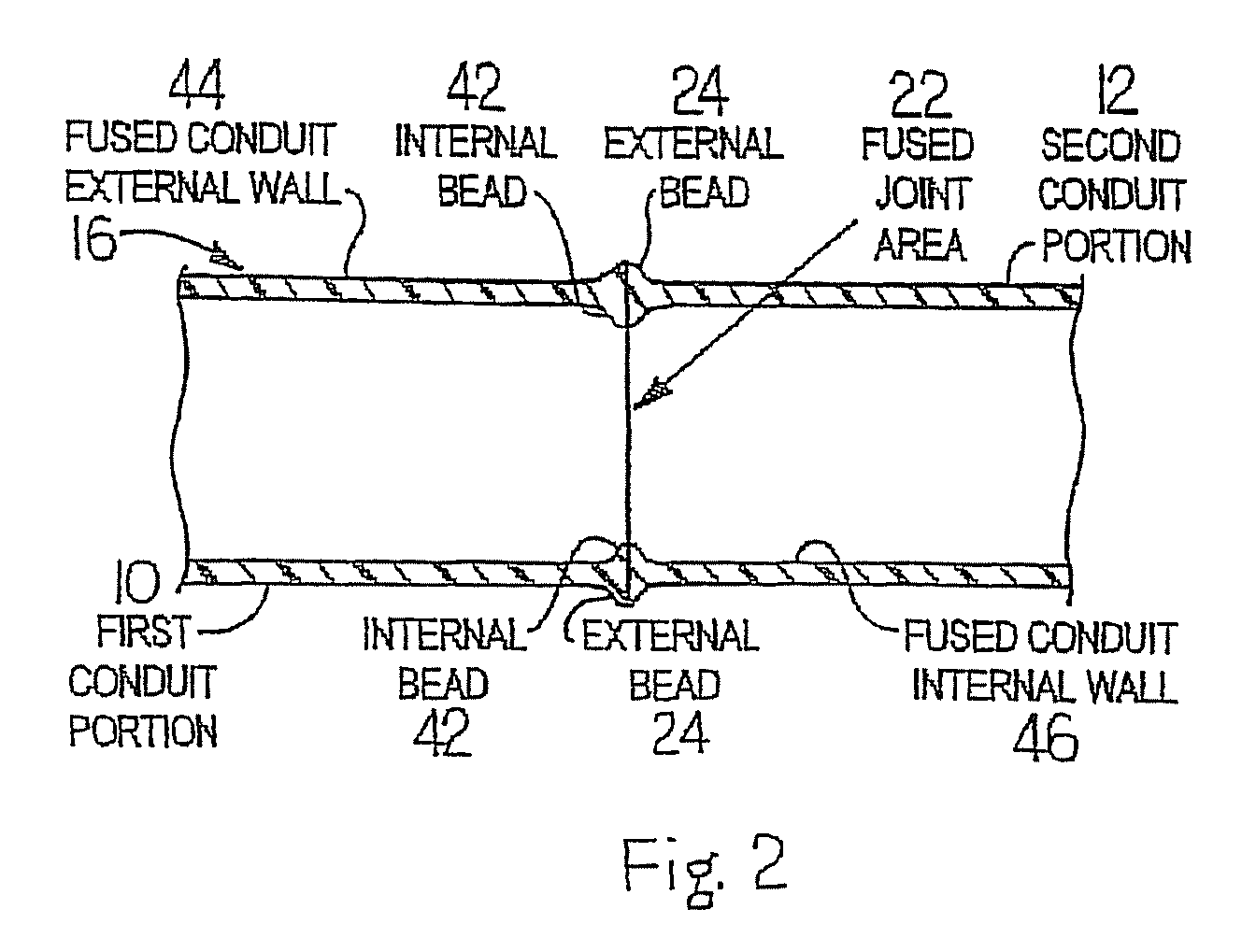

An extrudable polyvinyl chloride composition comprising from 80 to 99.9 percent by weight polyvinyl chloride for use in extruding a first part and a second part, wherein a fusion joint between the first extruded part and the second extruded part is formed by: A) composition at least a portion of a first terminal edge of the first extruded part and a first terminal edge of the second extruded part; B) engaging the melted terminal edges; and C) maintaining pressure between the engaged terminal edges to create a fused joint having a strength that is at least 50% of the tensile strength of the extruded part as measured by ASTM D638-2a. The extruded parts can be pipe sections.

Owner:UNDERGROUND SOLUTIONS INC

Welding joint method of glass optical fibre with different component

InactiveCN101183161AAchieve connectionLarge tunable rangeCoupling light guidesGlass fiberFusion joints

The present invention discloses a fusion welding method for glass fiber with different components. Air flow is used for vertically blowing discharge arc to form a temperature gradient field. So optical fibers with different hot melting properties are melted at the same time and the permanent connection is realized. Two optical fibers are placed symmetrically between a pair of discharge electrodes. The optical fiber with low melting temperature is placed in a vent pipe or the vent pipe is placed parallel to the optical fiber with low melting temperature. Through air blowing arc, the size of the air flow is adjusted and the suitable temperature gradient field is obtained. The temperature field is capable of resulting in that the optical fibers with different melting temperatures placed at the two sides of the electrode show the melting state at the same time. A connecting joint with low loss and high intension is formed after the optical fibers being contacted. The present invention has the advantages that the tunable range is big and the optical fibers with different thermal properties which can not be fusion jointed by the traditional method can be fusion jointed by the present invention.

Owner:SOUTH CHINA UNIV OF TECH

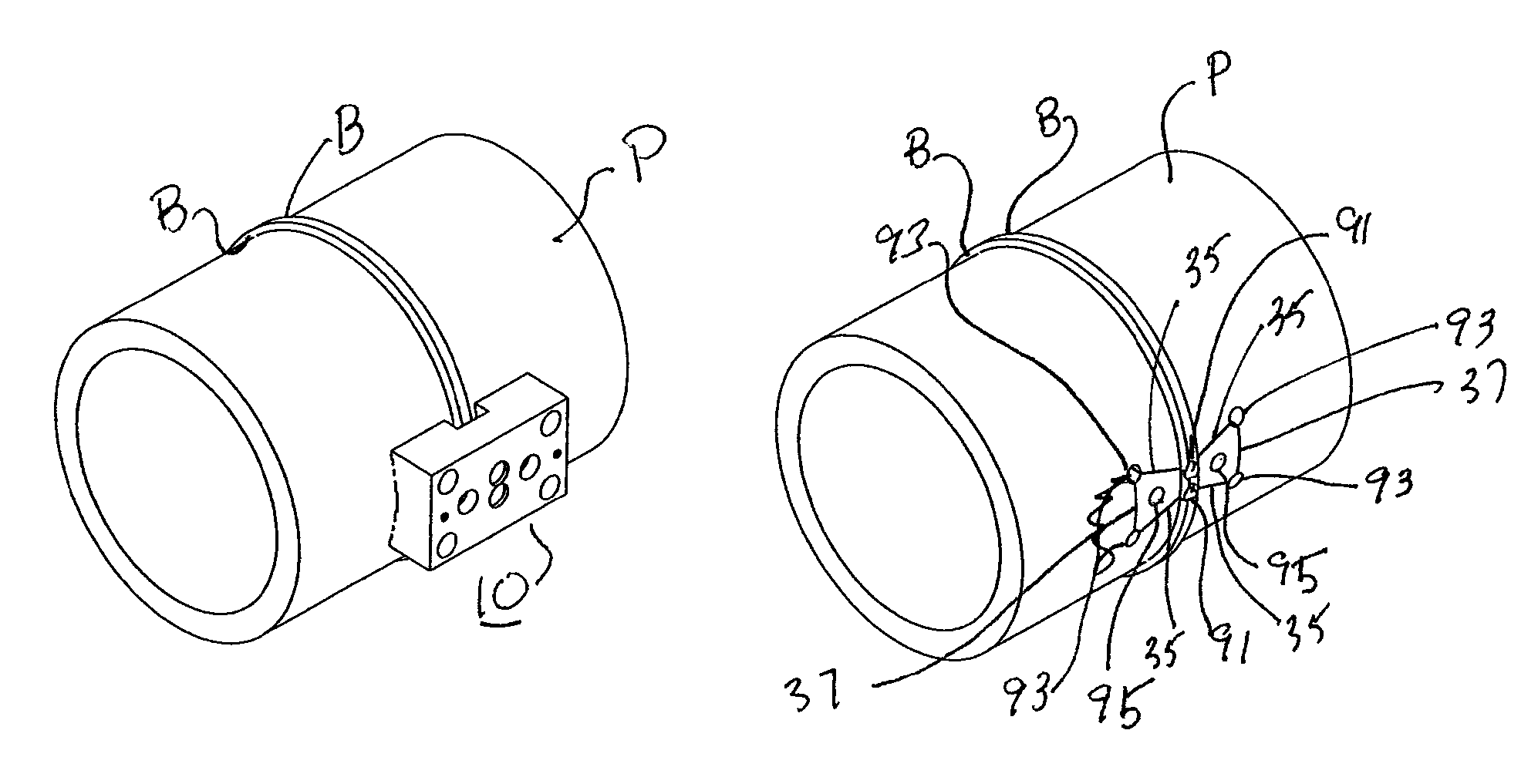

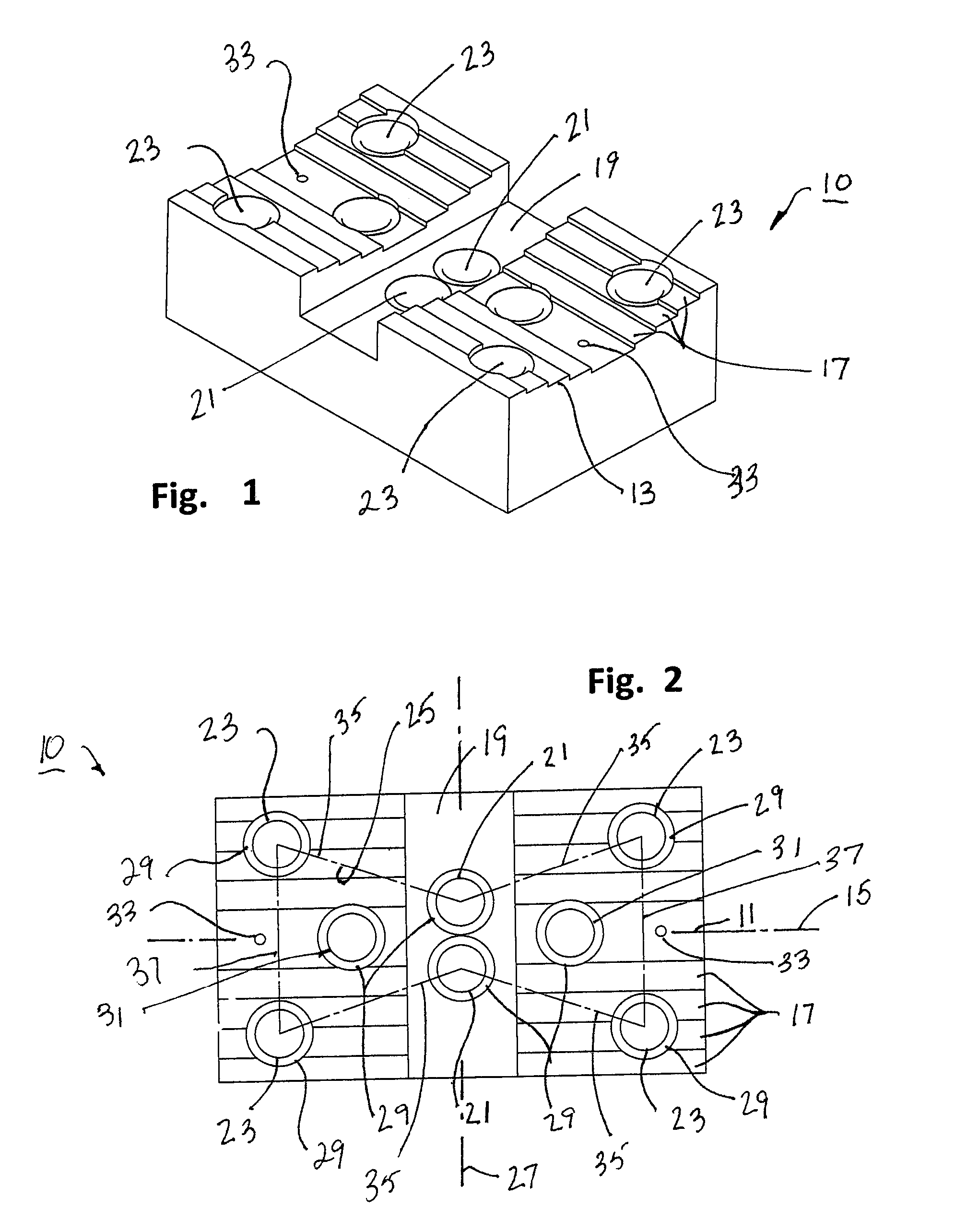

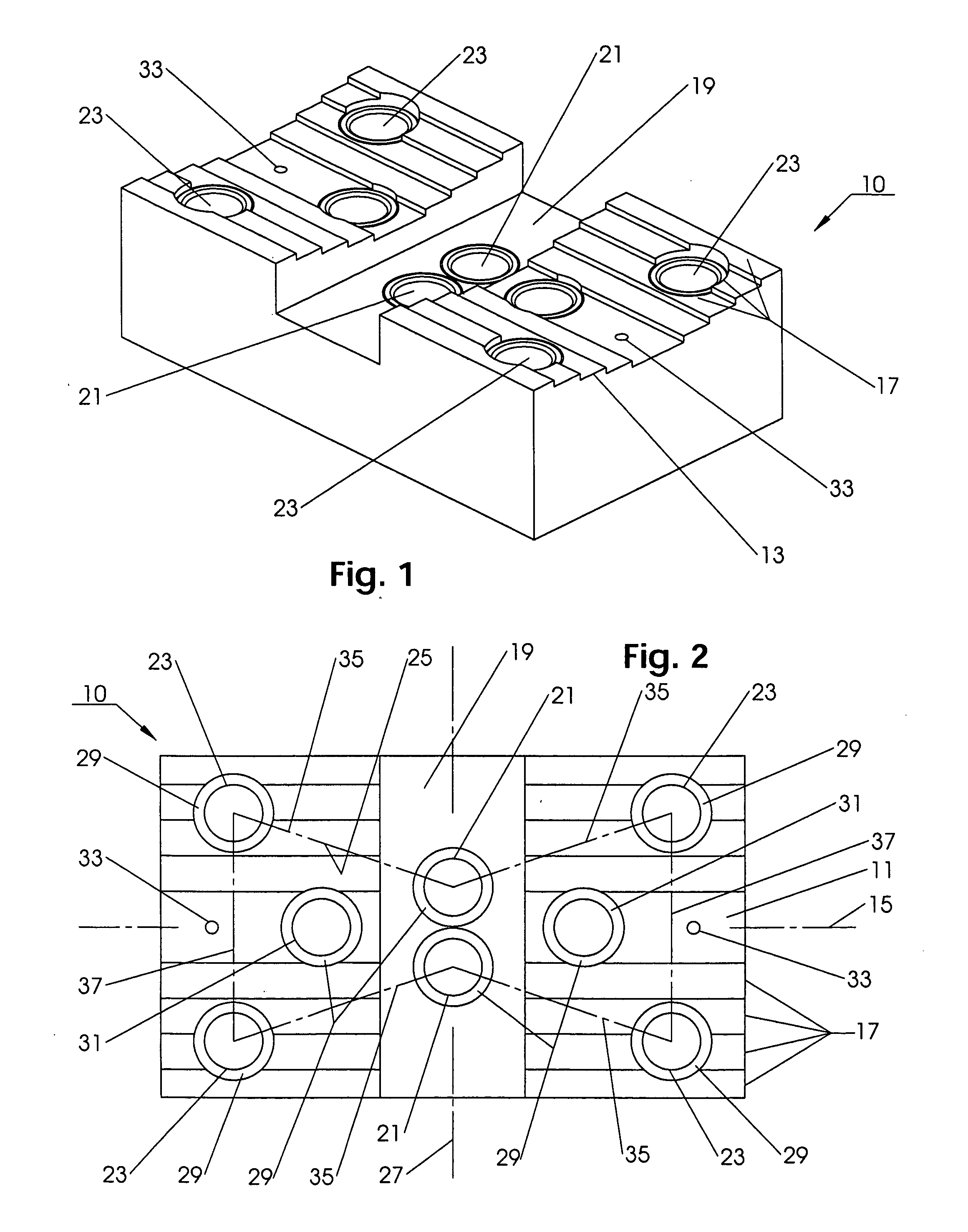

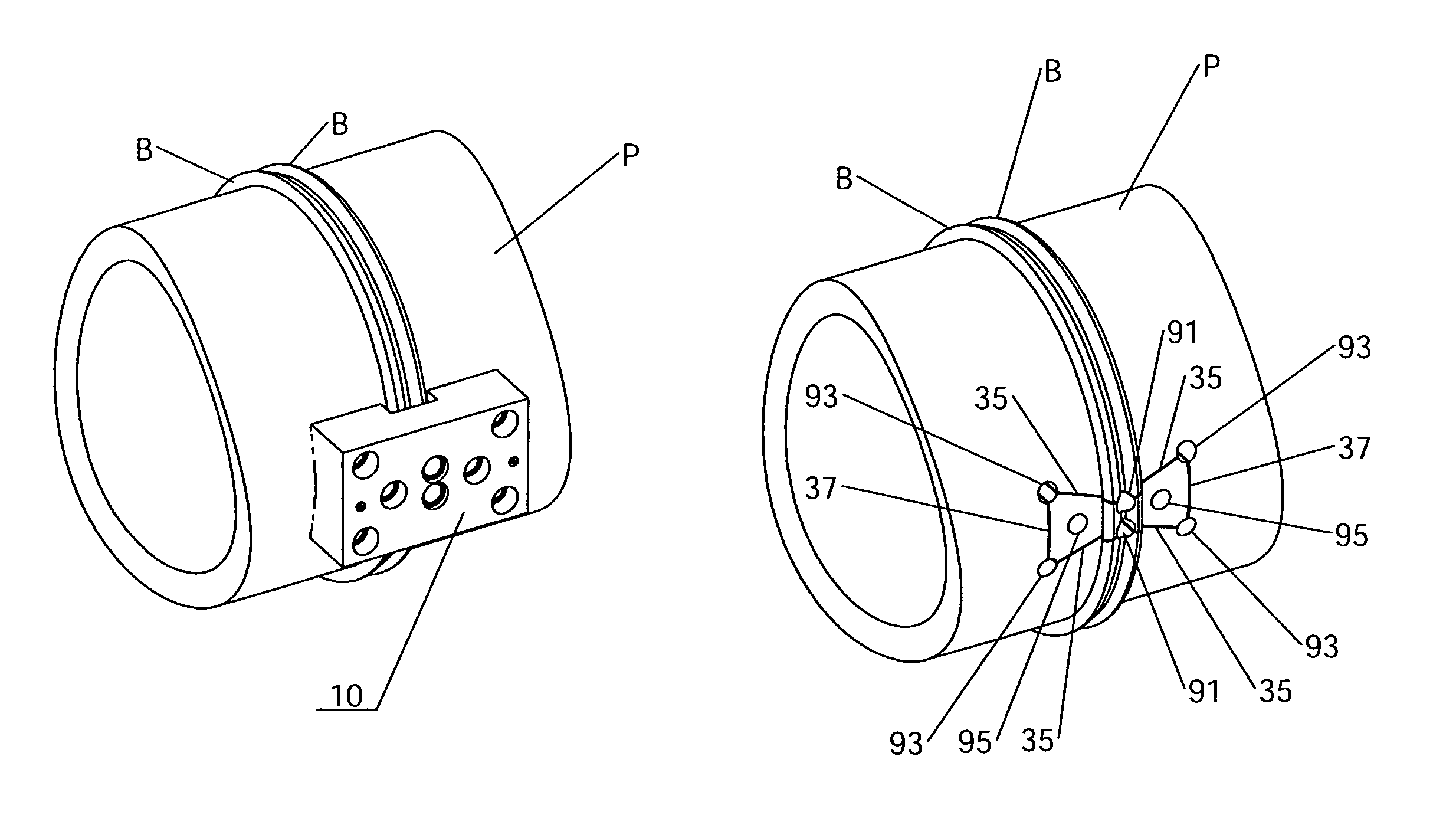

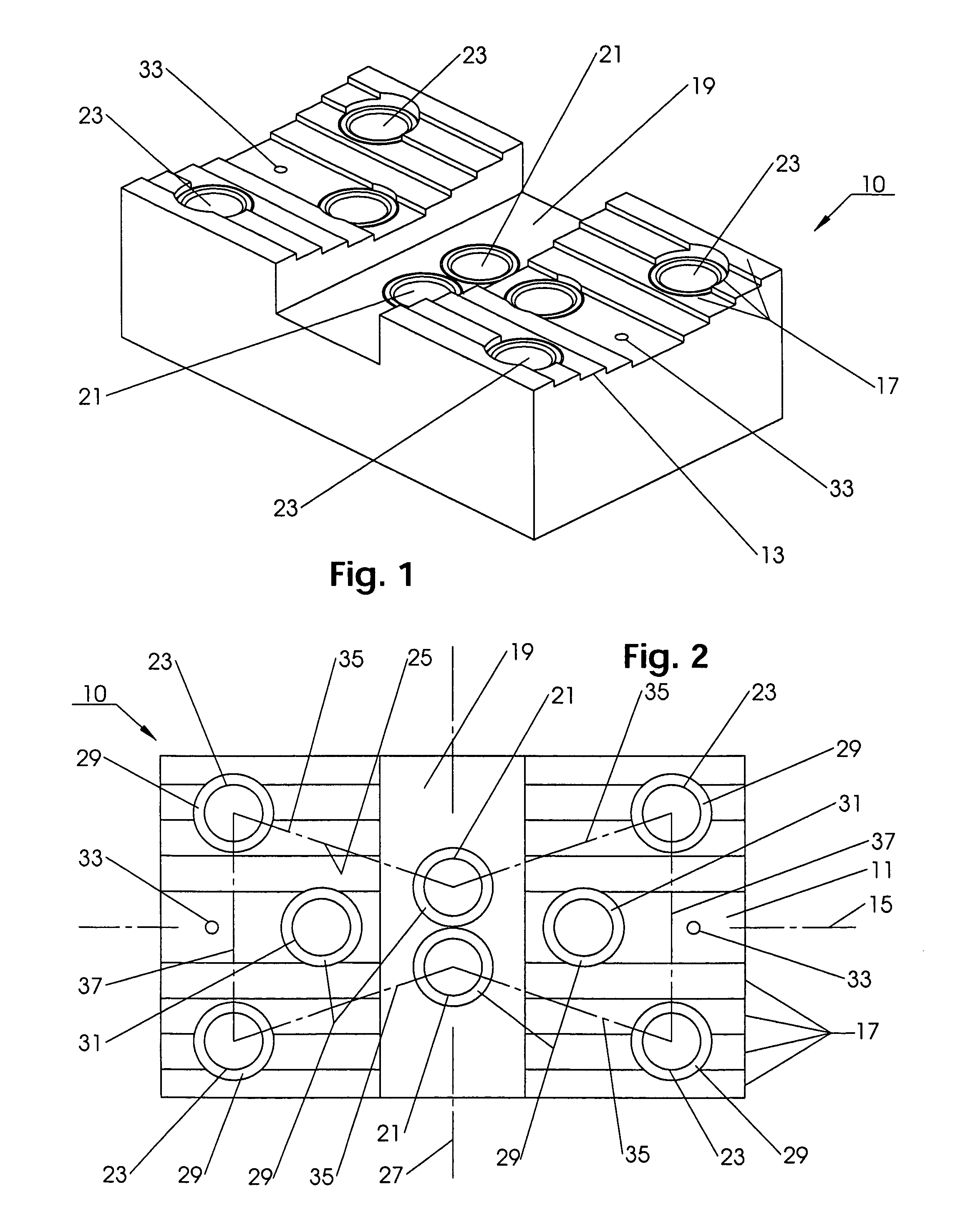

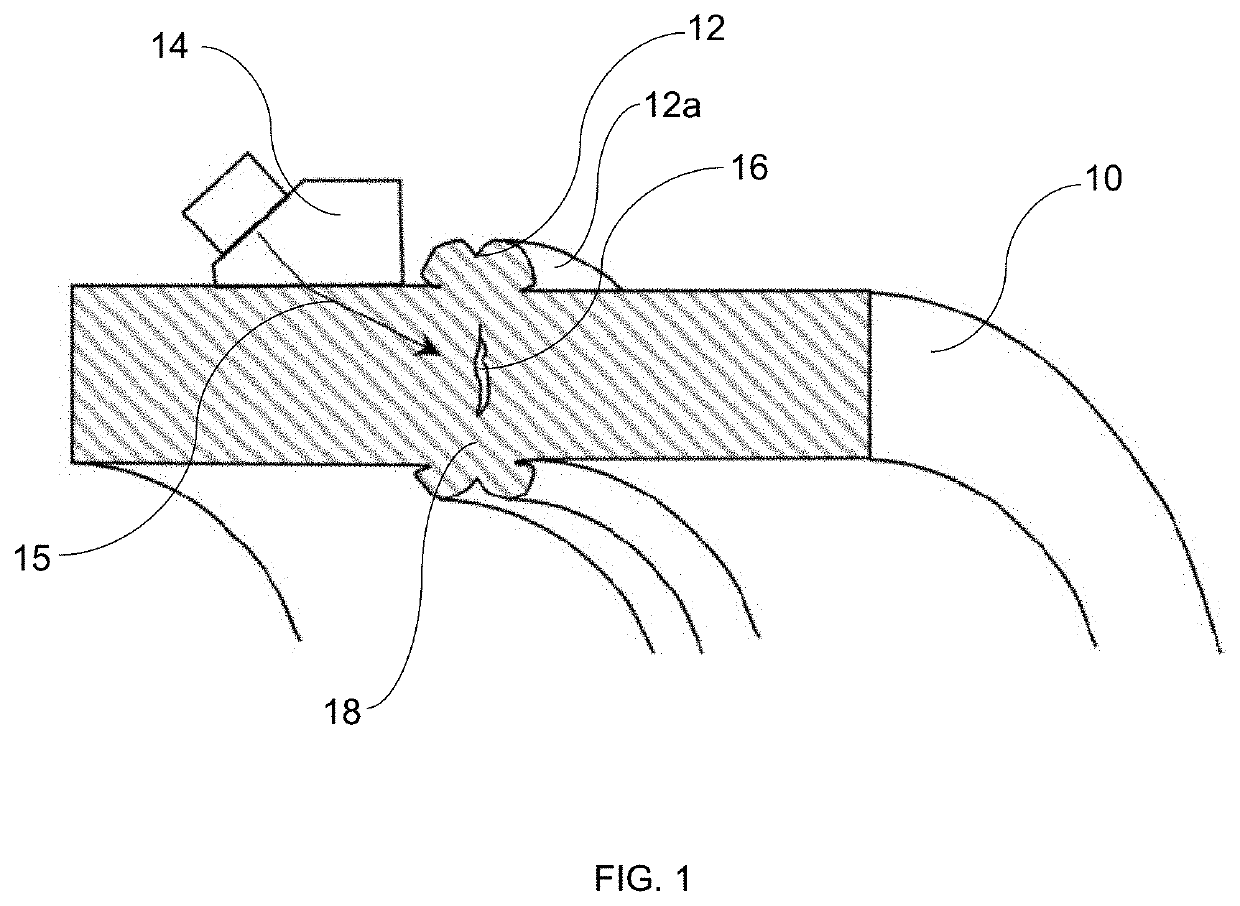

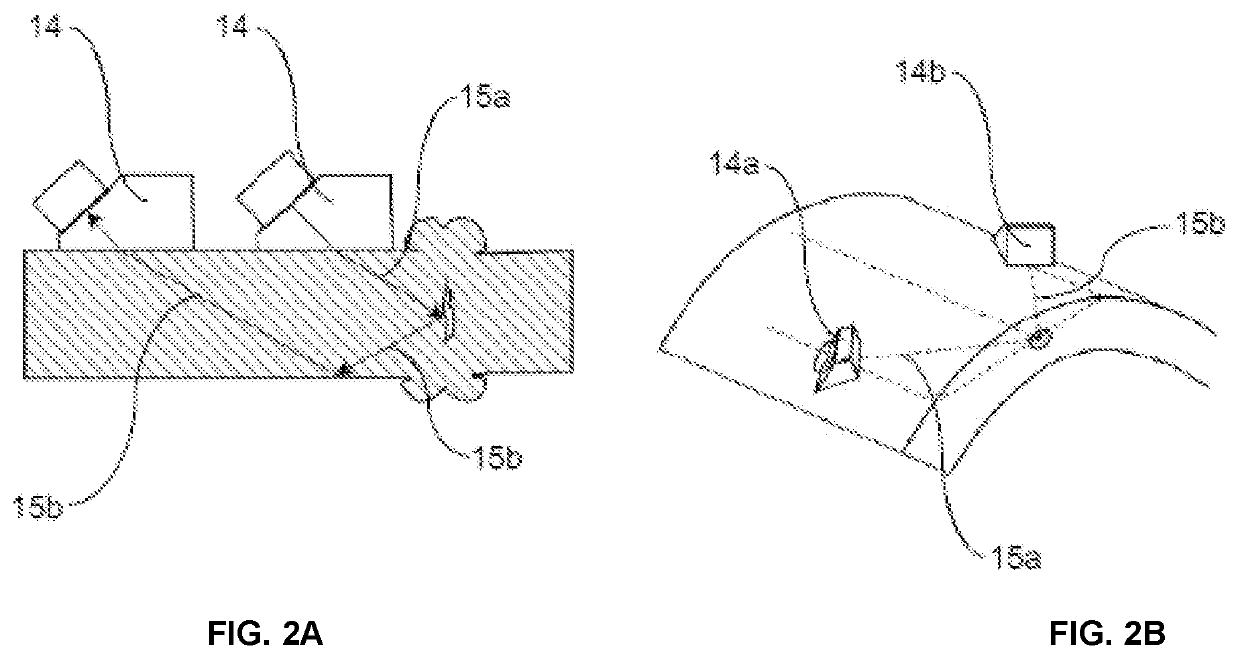

Method and template for producing a tensile test coupon

ActiveUS8365429B2Material strength using tensile/compressive forcesUsing mechanical meansFusion jointsTest coupon

A method and template enable the testing of fusion joints of plastic pipes to be conducted by a single operator in the field at the welding site by the efficient and precise extraction from the joints to be tested of a number of high quality tensile coupons. The coupons are tested to failure in a field-suitable, well controlled, self contained, tensile testing apparatus. A narrowing bow-tie-like pattern of the coupon ensures that the failure of the coupon in the tensile test will occur at the narrowest section of the coupon. The template can be visually aligned with the joint to ensure that it is the joint that will be tested.

Owner:MCELROY MFG

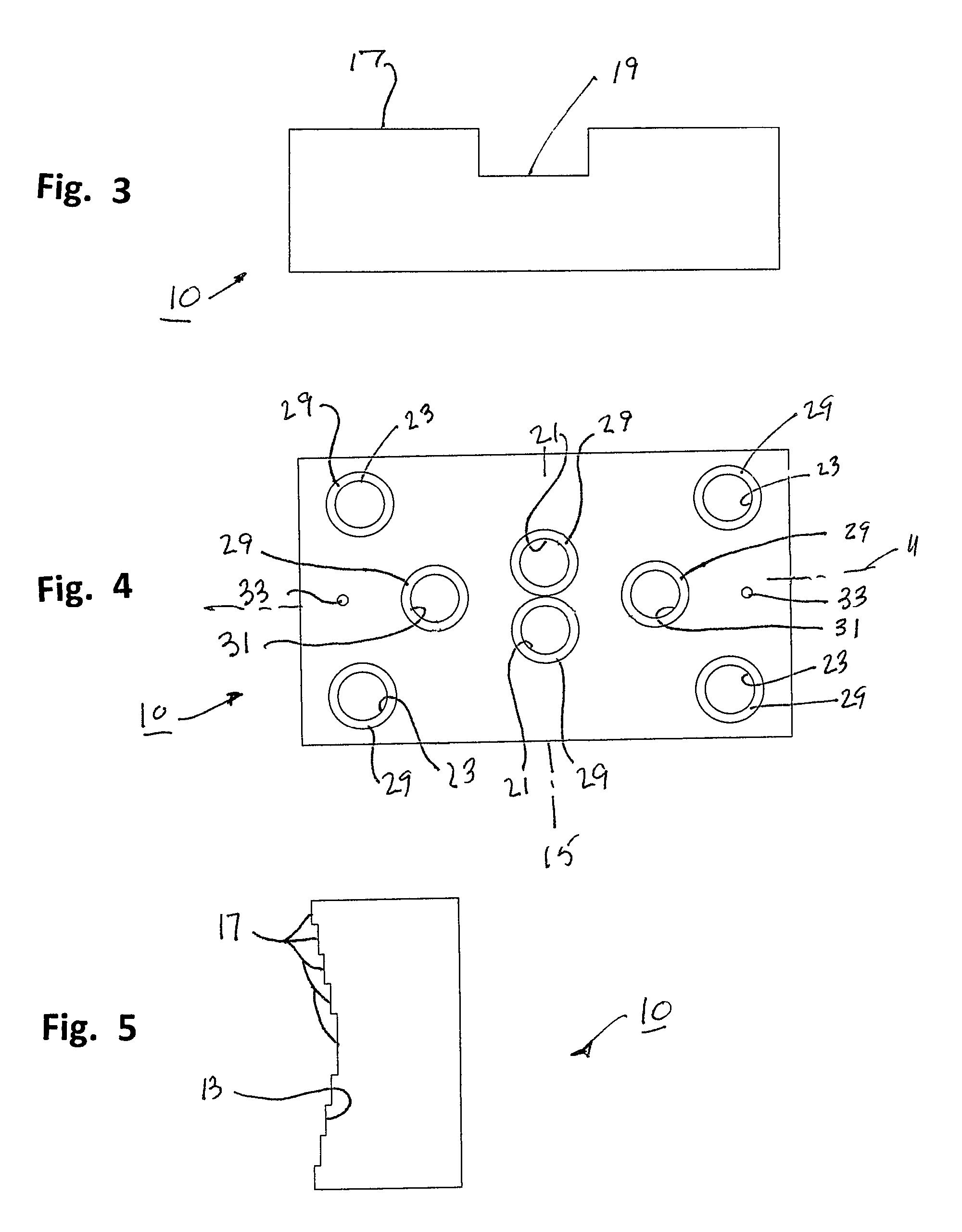

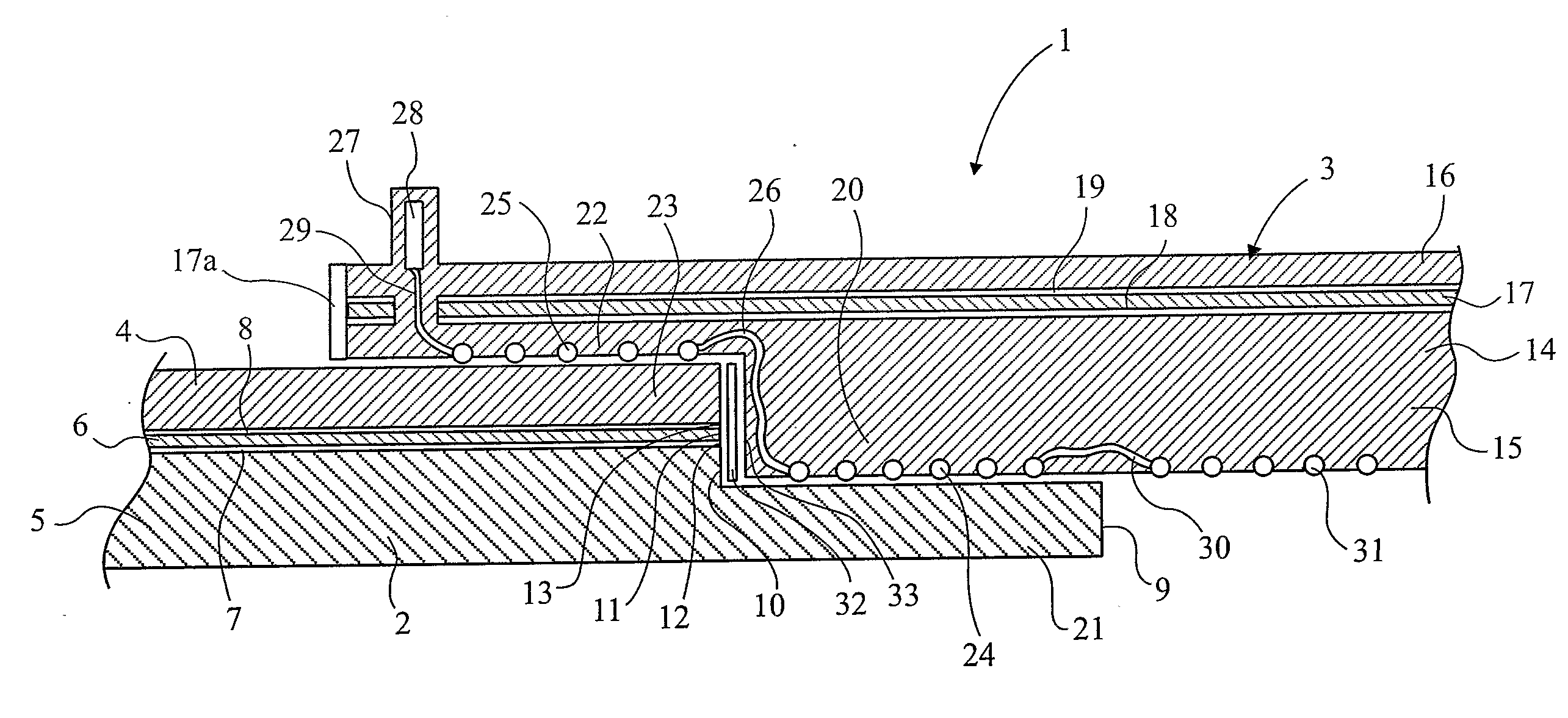

Electrofusion fitting for a composite pipe

InactiveUS20090026756A1Avoid easy sealingPreventing shorting outPipe elementsHose connectionsFusion jointsEngineering

An electrofusion fitting for a composite plastics pipe, the pipe comprising at least one inner plastics layer, at least one outer plastics layer and at least one barrier layer therebetween, the fitting comprising a tubular body formed at least in part from a thermoplastic polymer material and adapted to receive a cut end of the pipe, and a plurality of electric heating elements disposed within the body, the body having a first section adapted to receive a length of the inner plastics layer and a second section adapted to receive a cut-back length of the outer plastics layer, each of the first and second sections being provided with a discrete heating element adapted, when energized, to make a fusion joint between the section and its adjacent pipe layer, such that the exposed barrier layer at the cut end of the pipe is environmentally sealed on each side by a fusion joint.

Owner:UPONOR INNOVATION AB

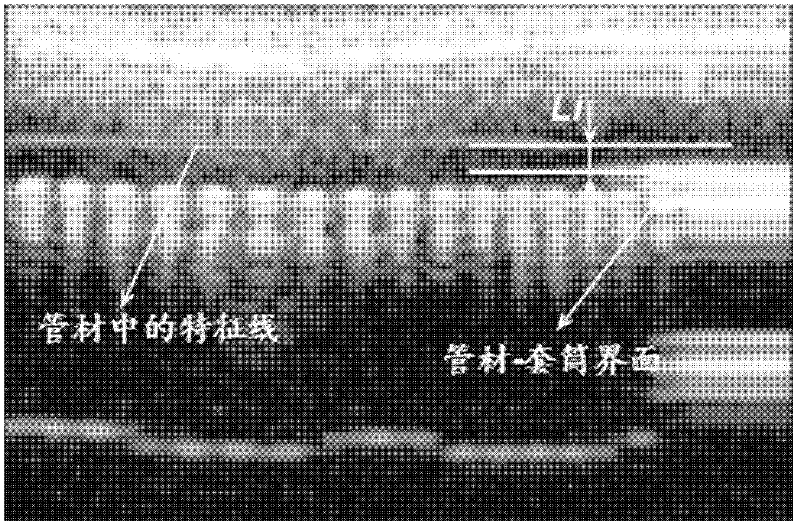

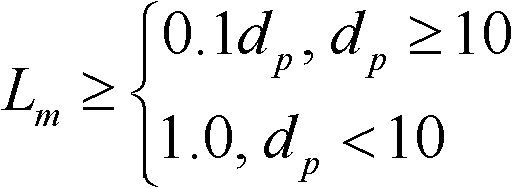

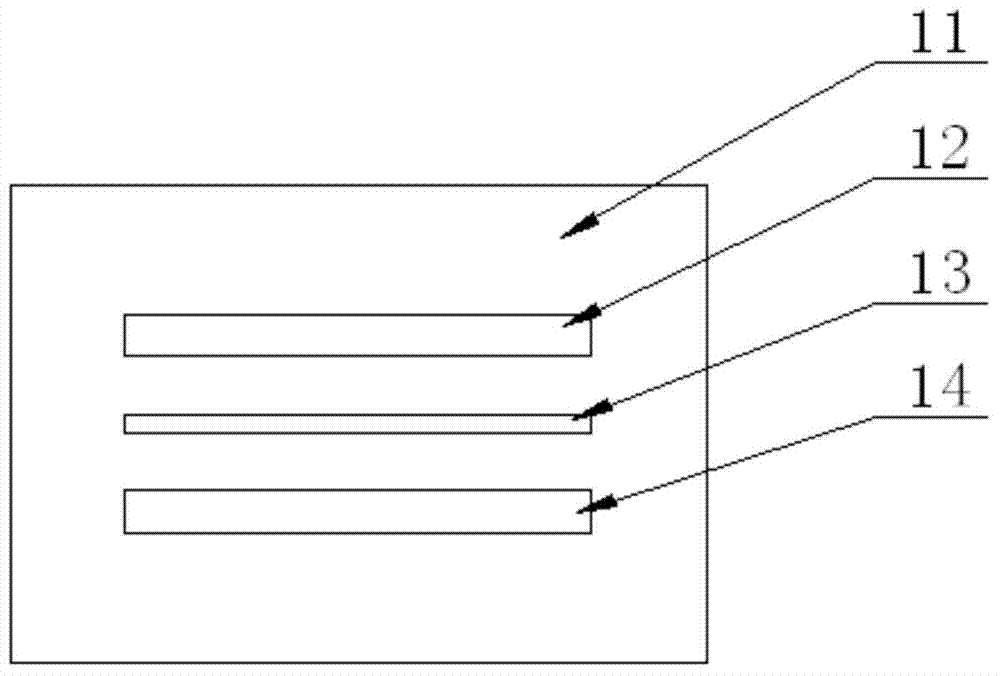

Judgment method for cold welding defects of electrofusion joints

ActiveCN102285120AGreat practicabilitySuitable for cold welding inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityFusion joints

The invention relates to a technology for welding a plastic pipeline and aims to provide a method for determining electro-fusion joint cold-welding defects. The method comprises the following steps of: detecting from an inner surface of a pipe on an electro-fusion joint welding part through an ultrasonic phased array detection imaging instrument to obtain an ultrasonic detection graph; and measuring a distance Li between a characteristic line in the ultrasonic detection graph and a pipe-sleeve interface in different directions, wherein no cold-welding defect is present at the detected electro-fusion joint if the minimum Lm accords with the set criteria. The method for detecting the electro-fusion joint cold-welding defects is higher in practicality, is generally applicable to different types of electro-fusion sleeves by different welding processes in different manufacturers and can be applied to cold-welding detection of electro-fusion joints formed by the pipes and the electro-fusionsleeves in different matching relationships; and the cold-welding conditions can be determined by measuring welding conditions of one electro-fusion joint only, a normal welding joint is not needed to be welded to perform secondary measurement, and the cost of welding joint preparation and ultrasonic detection is saved.

Owner:ZHEJIANG UNIV

Polythene glass fiber winding structure wall tube stock and production method thereof

ActiveCN103925431AEnhanced centroid heightReduce consumptionFlexible pipesFiberglass meshGlass fiber

The invention relates to a polythene glass fiber winding structure wall tube stock which is composed of an inner wall layer and an outer wall layer. The inner wall layer is characterized in that a composite material strip formed by adding a glass fiber material strip between an upper flaky polyethylene strip and a lower flaky polyethylene strip winds a roller mold, and edges of the neighboring composite strips are sequentially mutually lapped to form a continuous solid wall tube; the outer wall layer is characterized by being formed by outer protruding reinforcing ribs formed by the fact that another glass fiber material strip covering between an outer tubular polyethylene strip and an inner tubular polyethylene strip winds the outer surface of the inner wall layer, and the outer protruding reinforcing ribs spirally strides a lapping fusion joint of edges of the neighboring composite strips of the inner wall layer. The tubular pitch height of the reinforcing ribs can be guaranteed by adopting the glass fiber strips, good alkali resistance, flexibility and tensile resistance in the longitude and latitude height are achieved by the aid of fiberglass mesh fabric, the weight of the product is reduced, raw material consumption is reduced, cost of the product is low, internal stress of the tube stock is greatly reduced, consumption is reduced, and ring stiffness, ring flexibility and crack resistance are improved.

Owner:天津业和科技有限公司

Method and template for producing a tensile test coupon

ActiveUS20110067500A1Precise positioningMaterial strength using tensile/compressive forcesUsing mechanical meansTest couponFusion joints

A method and template enable the testing of fusion joints of plastic pipes to be conducted by a single operator in the field at the welding site by the efficient and precise extraction from the joints to be tested of a number of high quality tensile coupons. The coupons are tested to failure in a field-suitable, well controlled, self contained, tensile testing apparatus. A narrowing bow-tie-like pattern of the coupon ensures that the failure of the coupon in the tensile test will occur at the narrowest section of the coupon. The template can be visually aligned with the joint to ensure that it is the joint that will be tested.

Owner:MCELROY MFG

Hollow-photon-crystal-fiber gas absorbing pool and manufacturing method thereof

ActiveCN104181648AElimination of Fabry-Perot interference fringesEasy to implementColor/spectral properties measurementsCoupling light guidesPhotovoltaic detectorsFusion joints

Disclosed is a hollow-photon-crystal-fiber gas absorbing pool and a manufacturing method thereof. The absorbing pool includes a single-mode fiber, a fiber fusion protective sleeve, a hollow photon crystal fiber and a photoelectric detector. One end of the single-mode fiber is fused with one end of the hollow photon crystal fiber so that a fusion joint is formed and an end of a sealing hollow-photon-crystal-fiber gas absorbing pool is formed. The fiber fusion protective sleeve protects the fusion joint in a coverage manner. The hollow-photon-crystal-fiber gas absorbing pool is characterized in that the other end of the hollow photon crystal fiber is processed into an output end in a fusion sealing manner. An output end face faces, but is not parallel to, a detection face of the photoelectric detector. The hollow-photon-crystal-fiber gas absorbing pool effectively overcomes a background noise problem of transmitting light of the prior hollow-photon-crystal-fiber gas absorbing pools and has the characteristics of being small in size, light in weight and high in stability.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Method and template for producing a tensile test coupon

ActiveUS8371036B2Precise positioningMaterial strength using tensile/compressive forcesUsing mechanical meansFusion jointsTest coupon

A method and template enable the testing of fusion joints of plastic pipes to be conducted by a single operator in the field at the welding site by the efficient and precise extraction from the joints to be tested of a number of high quality tensile coupons. The coupons are tested to failure in a field-suitable, well controlled, self contained, tensile testing apparatus. A narrowing bow-tie-like pattern of the coupon ensures that the failure of the coupon in the tensile test will occur at the narrowest section of the coupon. The template can be visually aligned with the joint to ensure that it is the joint that will be tested.

Owner:MCELROY MFG

35kV - 220kV casting-type cable body fusion joint and making method thereof

PendingCN109935981AEnsure power supply reliabilitySame electrical performanceLine/current collector detailsConnection insulationFusion jointsWater block

The invention relates to the field of cable connection, and discloses a 35kV - 220kV casting-type cable body fusion joint. The 35kV - 220kV casting-type cable body fusion joint comprises two cables; each cable is composed of a body wire core, an inner semi-conductive cloth layer, an inner semi-conductive shielding layer, an insulating layer, an insulating shielding layer, a semi-conductive water blocking buffer layer, an aluminum sheath metal layer and an outer sheath insulating protective layer which are sequentially arranged from inside to outside; the exposed sections of the two cables arewelded to form a welding point; the welding point is sequentially coated with a recovery inner semi-conductive cloth layer, a recovery inner semi-conductive shielding layer, a recovery insulating layer, a recovery insulating shielding layer, a recovery semi-conductive water blocking buffer layer, a recovery aluminum sheath metal layer and a recovery outer sheath insulating protective layer. The invention also discloses a method of making the 35kV - 220kV casting-type cable body fusion joint. According to the 35kV - 220kV casting-type cable body fusion joint and the making method thereof, the electric field at the cable joint and the electric field of the cable body can realize the same equipotential distribution, no breakdown happens, and the power supply reliability is ensured.

Owner:广东科启电力技术有限公司

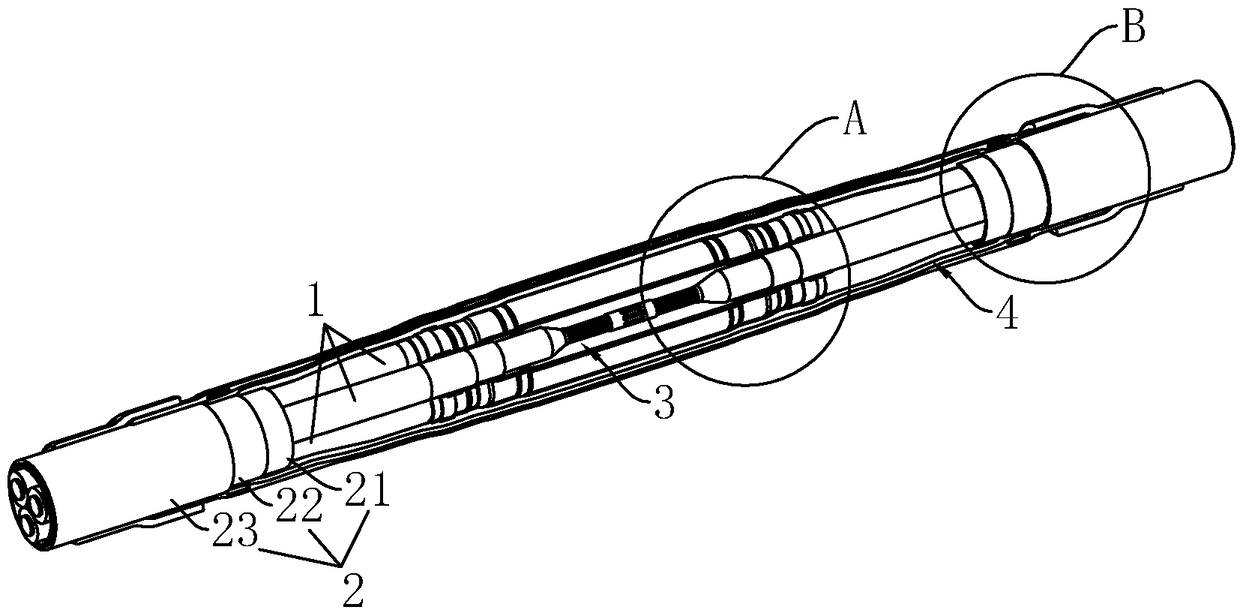

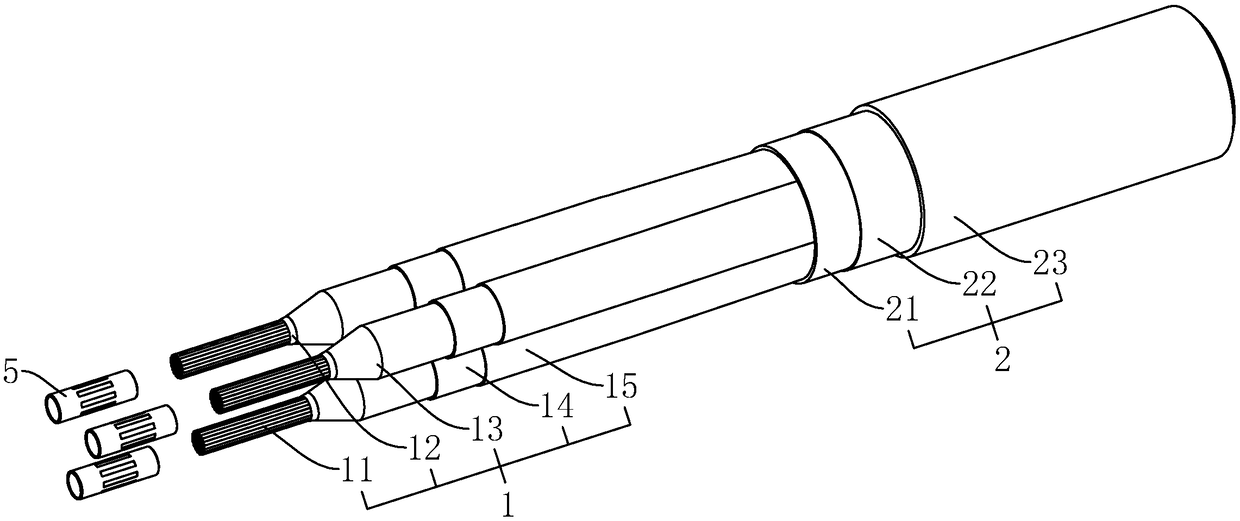

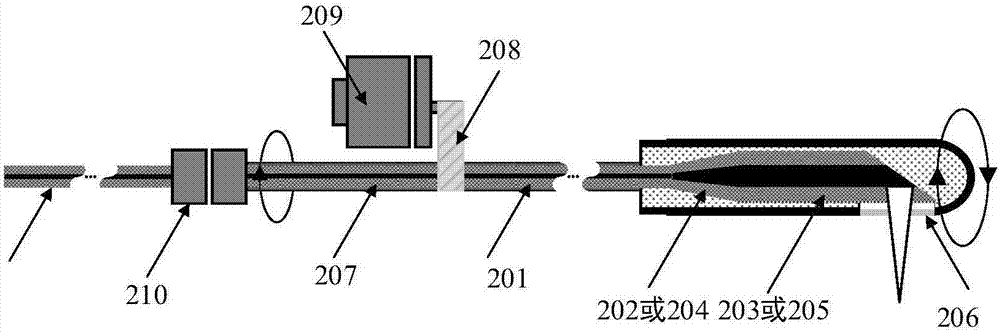

All-fiber endoscopic OCT probe based on unit conic structure

The invention discloses an all-fiber endoscopic OCT probe based on a unit conic structure. The probe comprises an optical assembly formed through fusion of multiple optical fiber sections, a transmission assembly and a protective cover. The optical assembly has two structures, wherein one structure is composed of transmission single mode fibers, transition section tapering fibers and large fiber-core multi-mode fibers; and the other structure is composed of transmission single model fibers and asymmetrical dual tapering fibers. The tapering fibers are formed through tapering of large-fiber core multi-mode fibers; and the mode field diameter at fusion joints of each section of fibers of the optical assembly is consistent. The endoscopic OCT probe disclosed by the invention has the advantages that no optical focusing lens is needed; the structure is compact; transmission efficiency is high; the focus depth scope is large; and the probe is highly applicable to high-quality OCT imaging of heart and cerebral vessels.

Owner:宁波核芯光电科技有限公司

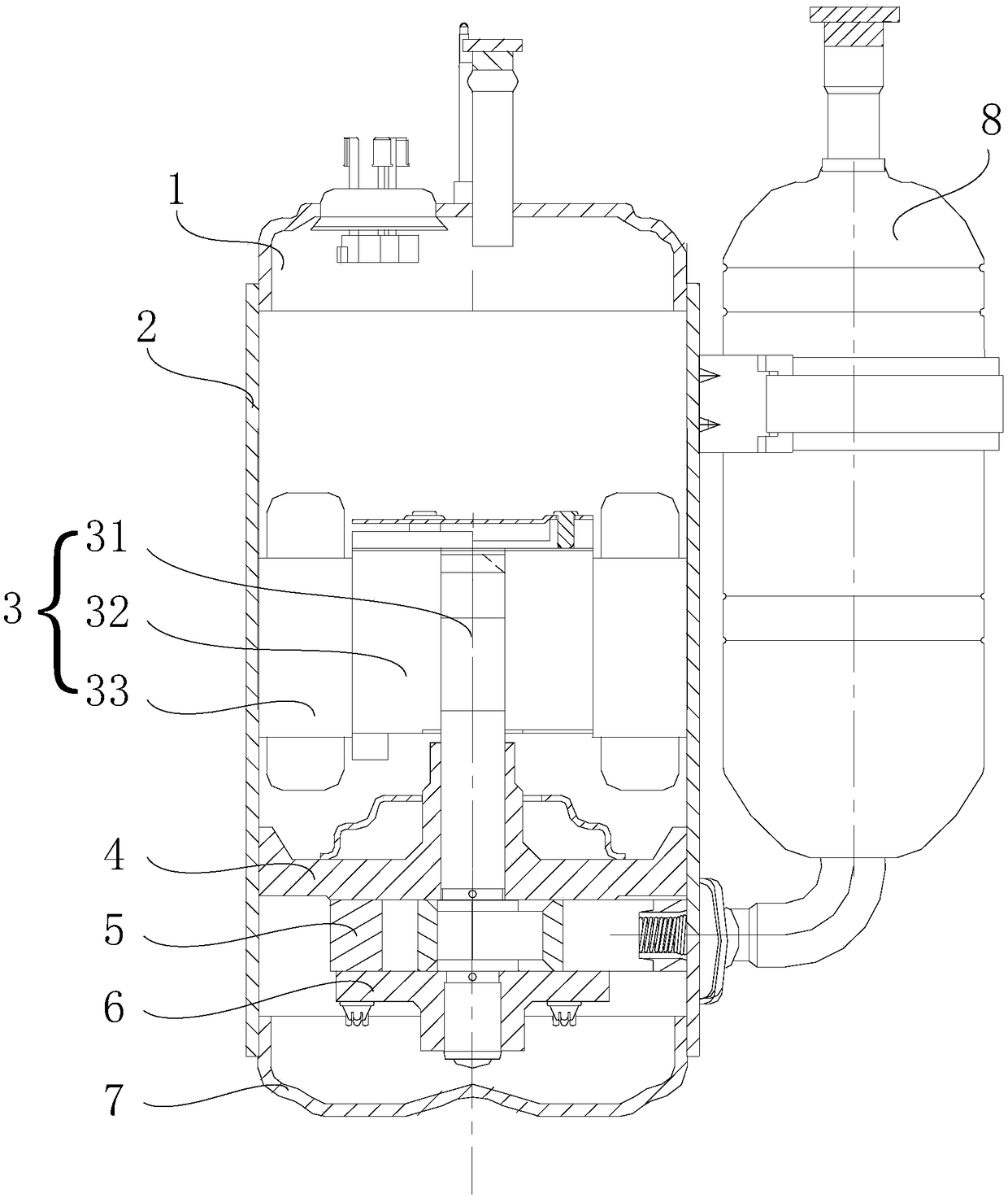

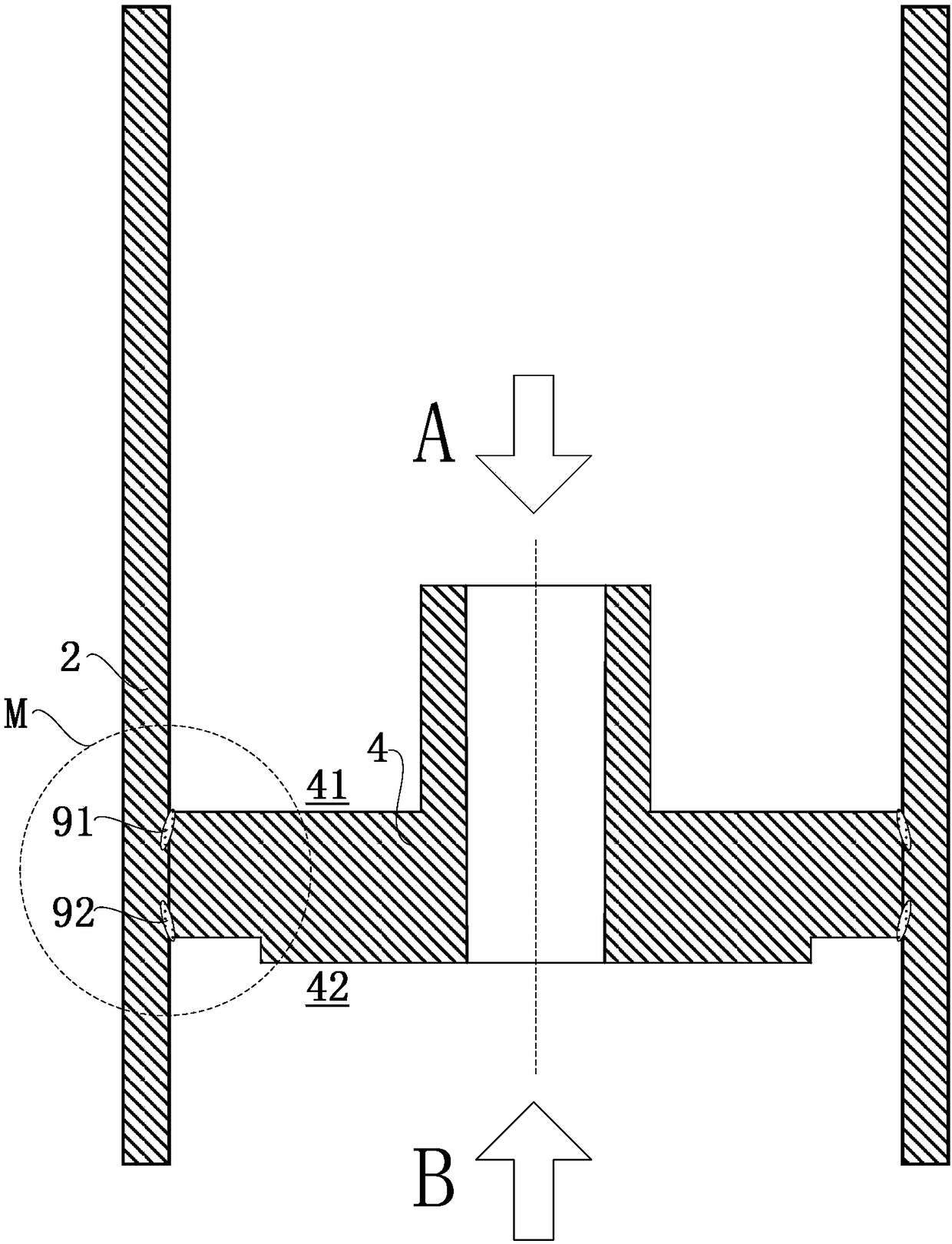

Compressor and manufacturing method thereof

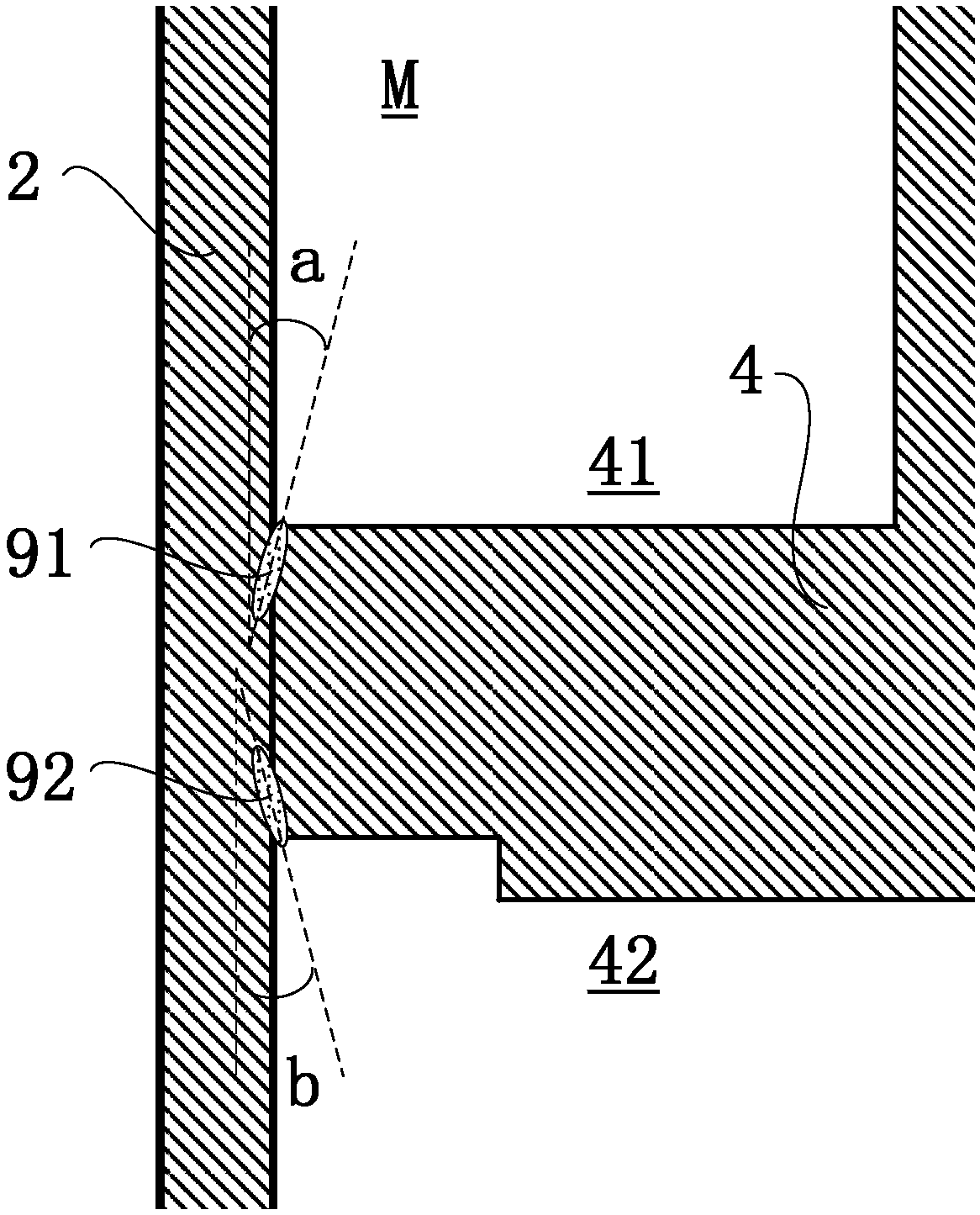

PendingCN109458334AUniform air gapReduce noiseRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsFusion jointsControl theory

The invention provides a compressor and a manufacturing method thereof. The compressor comprises a shell, a motor, an air cylinder, a crankshaft, an upper cylinder cover and a lower cylinder cover. The motor and the air cylinder are contained in the shell. The crankshaft transmits rotation force of the motor to a piston in the air cylinder so as to compress a refrigerant. Compression space is jointly defined by the upper cylinder cover, the lower cylinder cover and the air cylinder, and the crankshaft is supported. The upper cylinder cover is located between the motor and the air cylinder, theupper cylinder cover is provided with a through hole for the crankshaft to penetrate, and the upper cylinder cover is provided with a first side facing the motor and a second side facing the air cylinder. The inner wall of the shell is in laser fusion joint with the periphery of the first side of the upper cylinder cover and / or the periphery of the second side, and the included angle formed by the axial direction of the fusion joint welding point and the inner wall of the shell ranges from 0 degree to 45 degrees. According to the compressor and the manufacturing method thereof, the original assembling precision cannot be damaged even when welding deformation happens, accordingly, it can be guaranteed that stator and rotor air gaps are uniform, noise is lowered, and performance becomes good.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

High energy fiber terminations and methods

A ferrule and method are presented that fuses optical fibers, capillaries and the like to ferrules while reducing deformation of the fused component and the ferrule and minimizing stresses within the assembly. Reduced deformation and stress is accomplished by providing high contact angles in a symmetrical, short section of fusion in fusing the component carried by the ferrule to the ferrule. It is particularly applicable to hermetic terminations of polymer clad fiber optics where irregular glass fusion joints cause irregular light leakage at the fiber launch but benefits are significant when used for other fiber and capillary architectures as well.

Owner:BOSTON SCI SCIMED INC +1

Method for screening magnetic field generated by electrical power transmission line and electrical power transmission line so screened

InactiveCN1685580ASolve the problem of improving the magnetic shielding performanceCable installations on groundCable installations in surface ductsElectric power transmissionElectricity

An electrical power transmission line, comprises at least one electrical cable, a conduit of ferromagnetic material enclosing the electrical cable and comprising a base and a cover, and electrical contact elements for electrically connecting the base and the cover, wherein the electrical contact elements are selected from the group consisting of metal fusion joints and metal resilient members suitable to pierce the ferromagnetic materials, so that an electromagnetic continuity between base and cover can be provided for improving the magnetic shileding properties of the conduit.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA +1

Polyvinyl chloride formulations

ActiveUS7915366B1Labelling non-rigid containersMechanical working/deformationPolyvinyl chlorideFusion joints

An extrudable polyvinyl chloride composition comprising from 80 to 99.9 percent by weight polyvinyl chloride for use in extruding a first part and a second part, wherein a fusion joint between the first extruded part and the second extruded part is formed by: A) composition at least a portion of a first terminal edge of the first extruded part and a first terminal edge of the second extruded part; B) engaging the melted terminal edges; and C) maintaining pressure between the engaged terminal edges to create a fused joint having a strength that is at least 50% of the tensile strength of the extruded part as measured by ASTM D638-2a. The extruded parts can be pipe sections.

Owner:UNDERGROUND SOLUTIONS INC

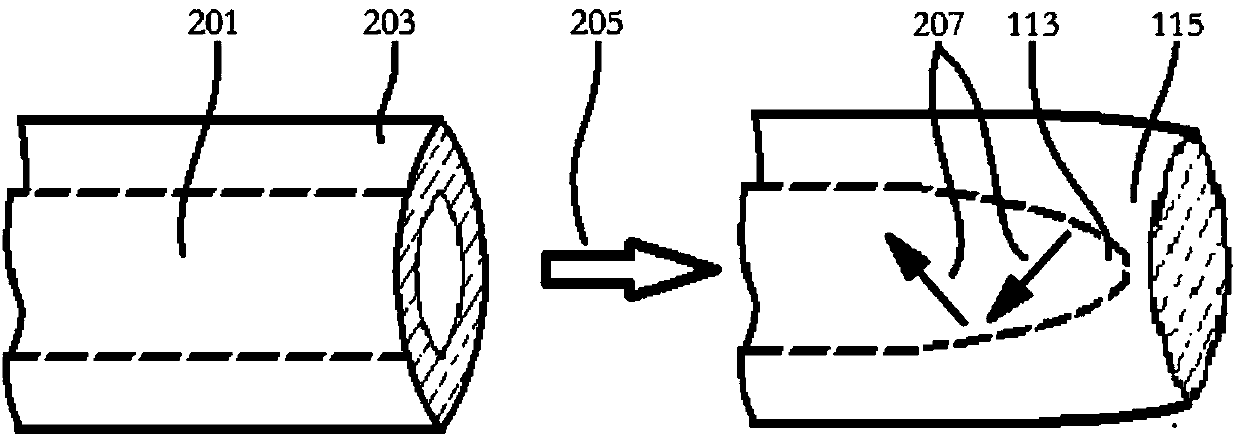

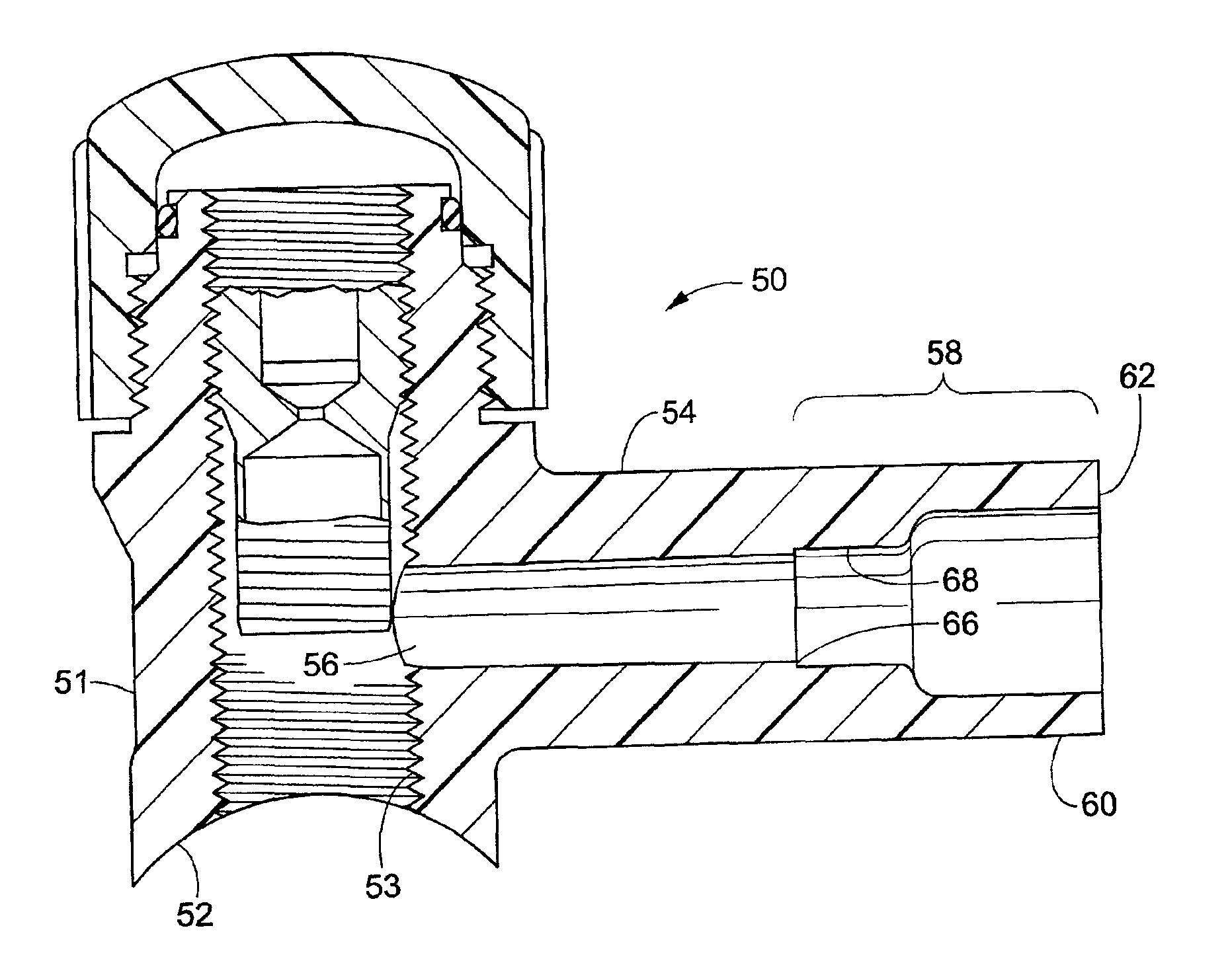

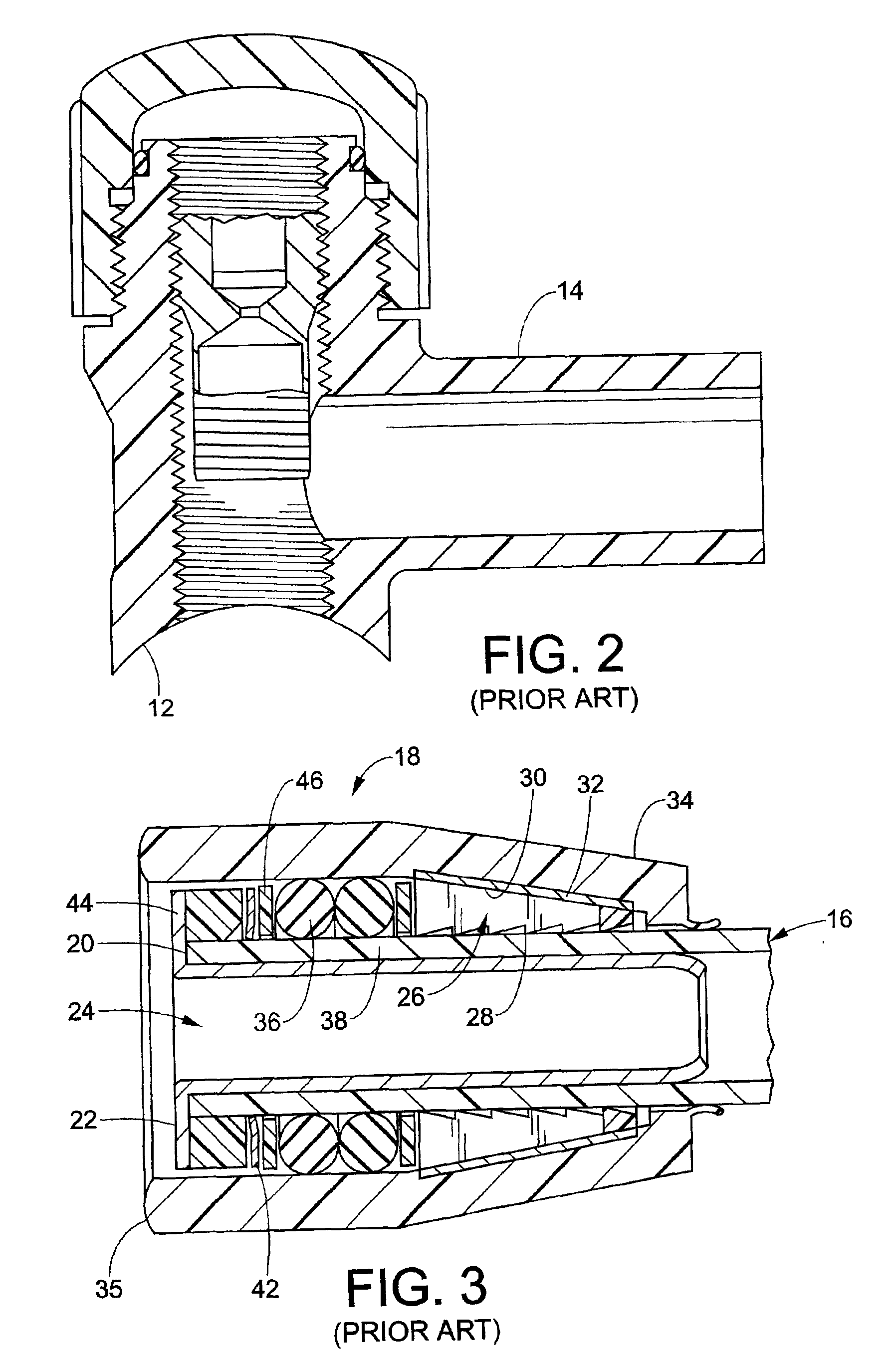

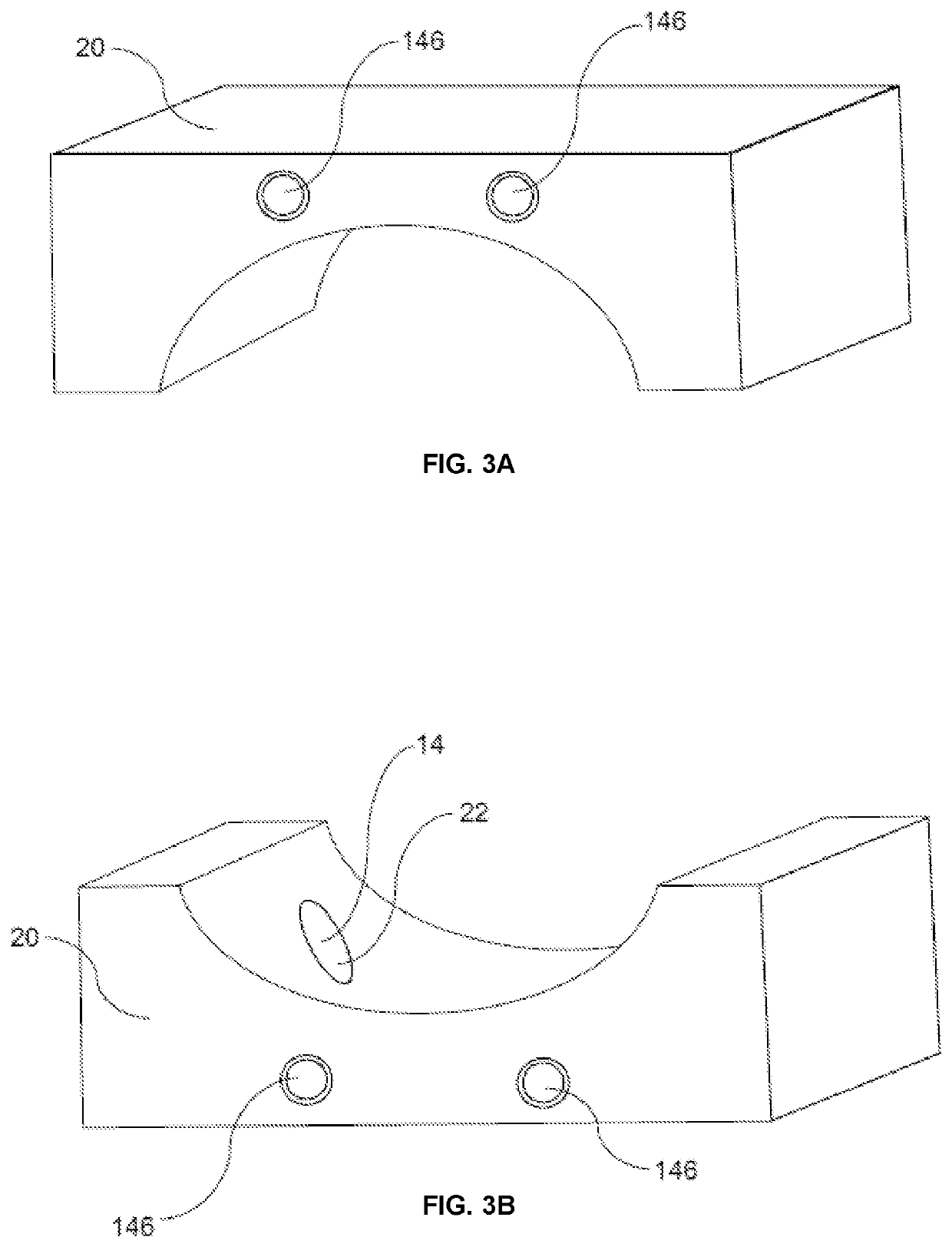

Structure for converting a mechanical joint to a fusion joint

InactiveUS6892753B2Prevent removalPrevent insertionTurning machine accessoriesWorkpiecesCouplingFusion joints

The converter for converting a mechanical joint to a socket fusion joint includes a body having an inner surface, a stop disposed on the inner surface, and a fusion surface extending from the stop for a distance d1. The converter also includes a marker disposed on the outer surface for providing a reference location as to where the body can be severed to keep d1≧FM, wherein FM is the minimum fusion surface length allowable for the fusion socket joint. A method for repairing a leaking mechanical joint is provided which includes severing the mechanical coupling from the converter and the pipe. The method also includes performing a facing operation on the converter end surface to form a faced end such that the fusion surface extends between the faced end and a stop for an axial distance d1≧FM. The method also includes delineating a stab depth measurement on the outer surface of the pipe, inserting the pipe into the passage until the stab depth measurement is adjacent the faced end, and forming a socket fusion joint having a uniform fusion length FL=d1.

Owner:ELSTER PERFECTION CORP

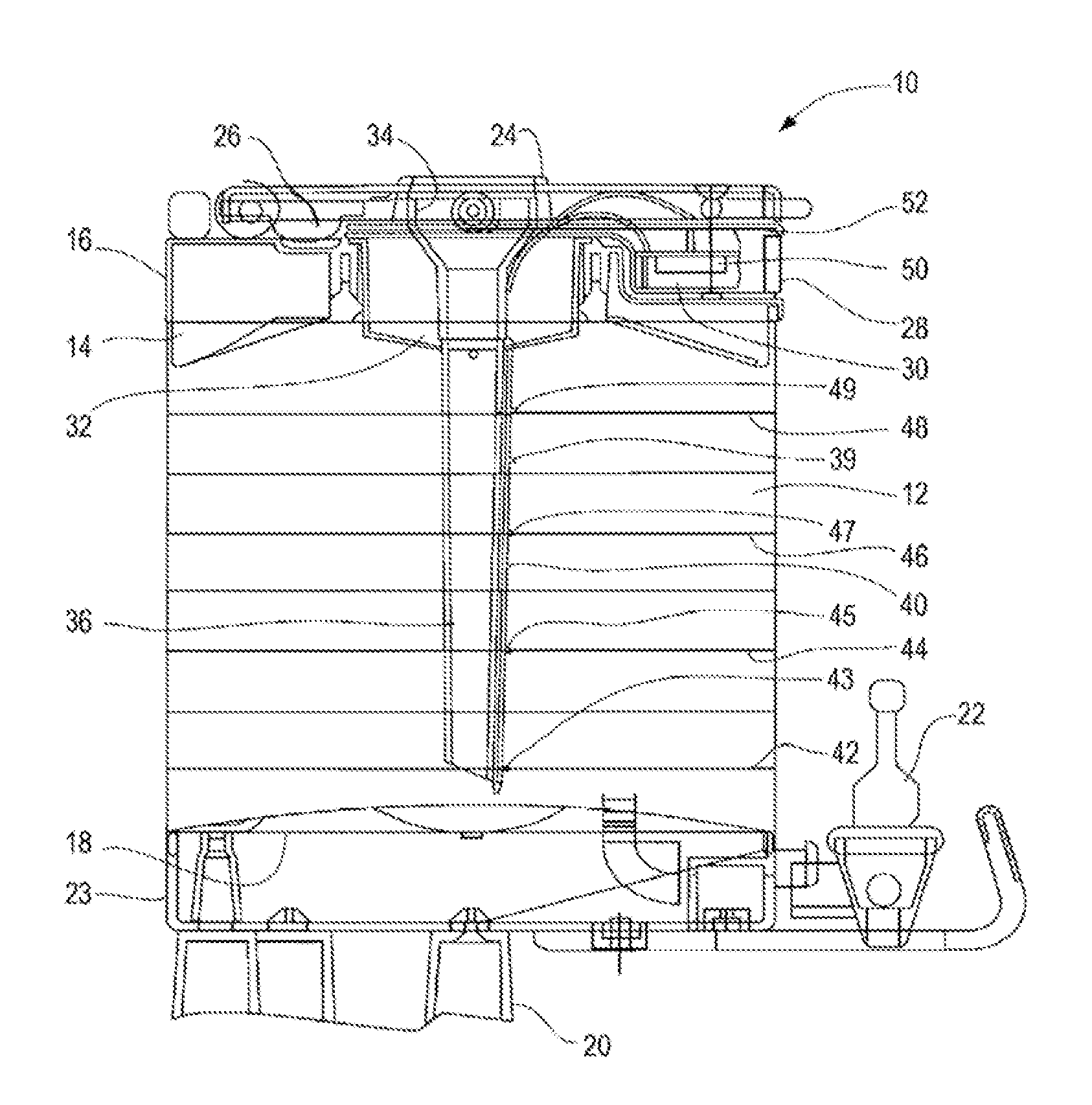

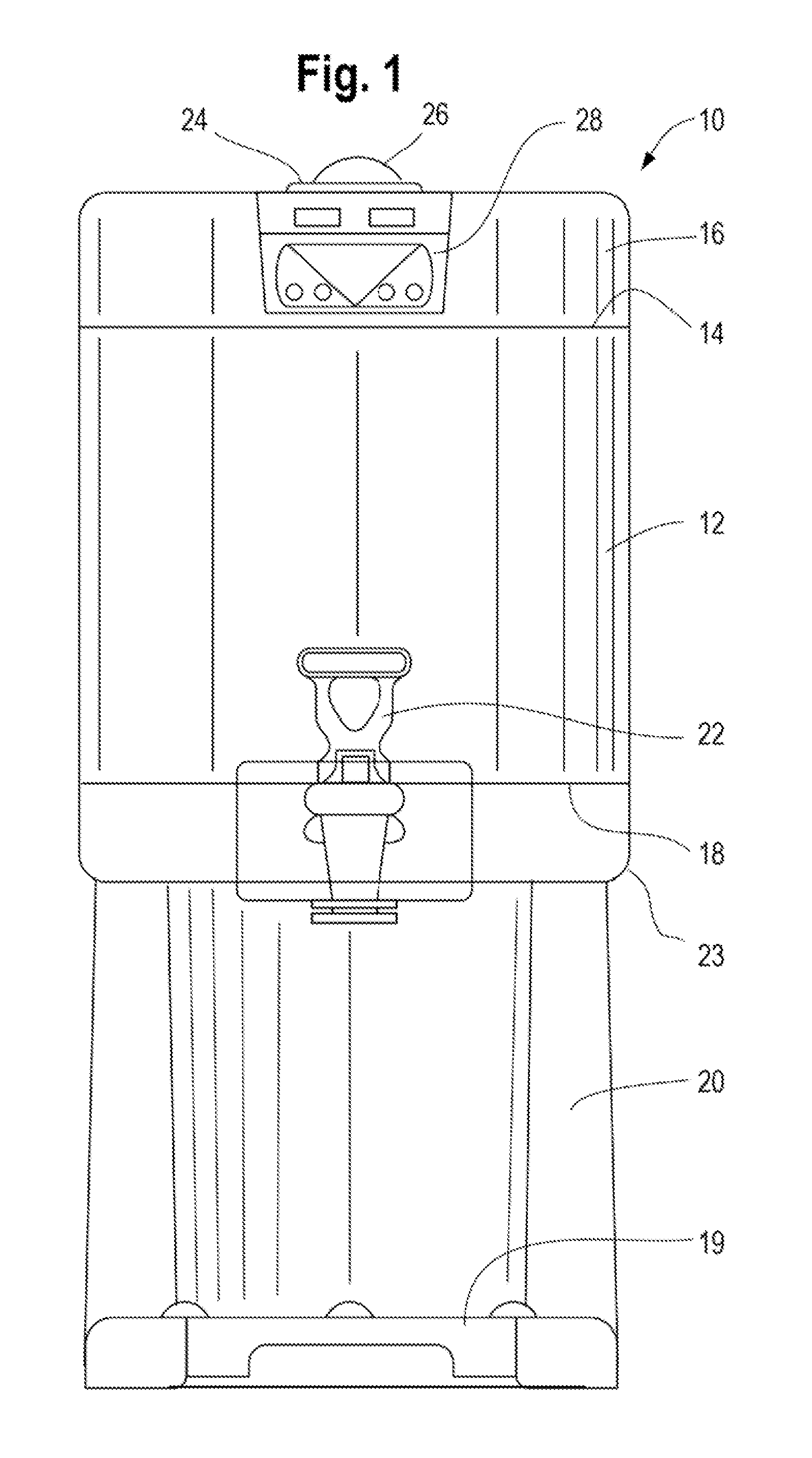

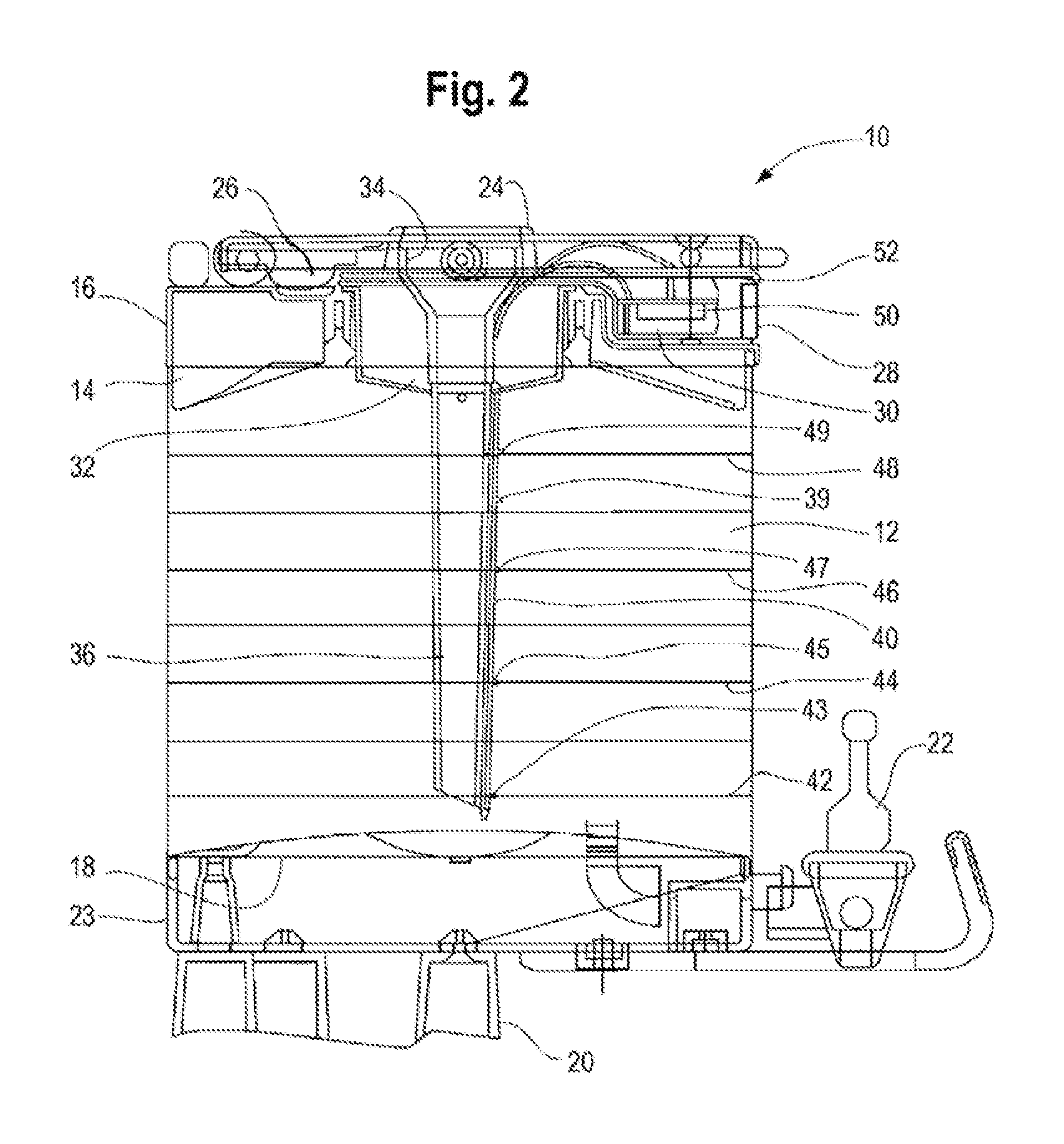

Hot beverage dispenser with level sensing probe and method of making same

ActiveUS9121744B1Inexpensive mass productionCheap productionLiquid flow controllersLiquid dispensingFusion jointsHot melt

A beverage dispenser (10) having a hollow, insulated dispenser body (12), a removable cover (16) with an inlet opening (24) for receipt of freshly brewed beverage to an interior of the dispenser body (12), a closed bottom (18) and a faucet (22) for dispensing beverage from the body (12) has a level display system including an elongate, relatively flexible, probe body, or down tube (40) with a flexible probe circuit and having a bottom and a top with a plurality of electrically conductive sensors (43, 45, 47 and 49) mounted within an elongate mounting groove (182, FIGS. 21-23) formed in, and extending along, the elongate relatively rigid probe body (36). The flexible probe assembly (40) is secured within the groove by non-adhesive means, either by a thermal fusion joint 183) formed during injection molding (FIG. 20) of the rigid probe body (36) or by mechanical tabs (178, 180). The flexible probe circuit is made of a flexible plastic strip (127) with sensor locations (124) and a leads connector (130) on one side (125) of a middle layer (127) through-connected (136) to associated elongate leads (134) on the opposite side of the middle layer (127) and two covering top and bottom protective covering layers (114, 138) on opposite sides of the middle layer (127).

Owner:FOOD EQUIP TECH

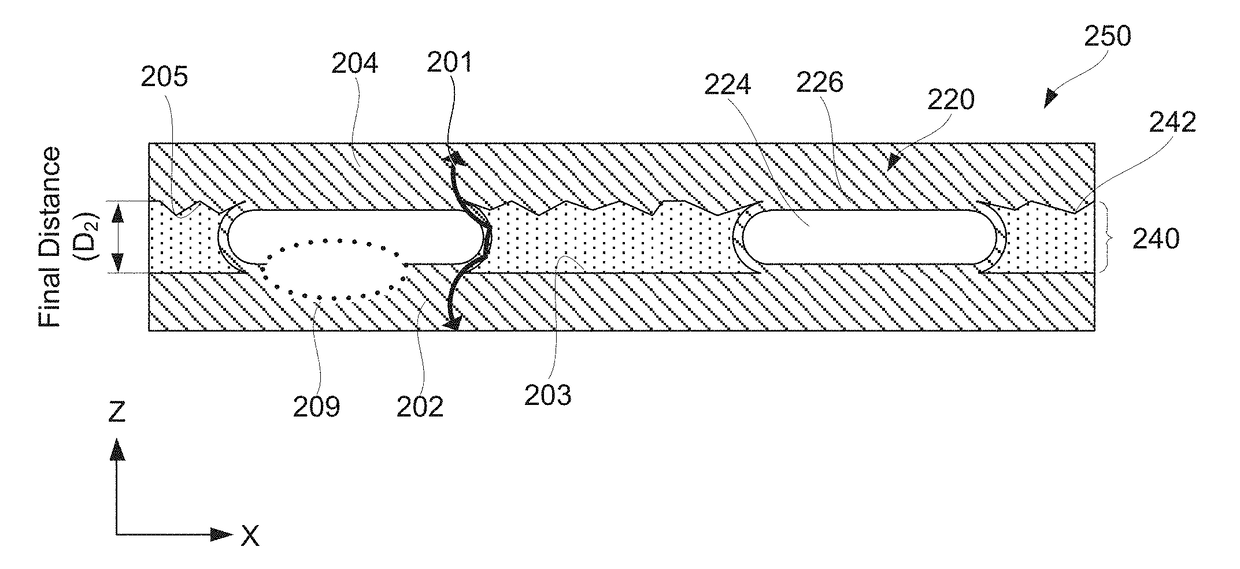

Method, device and system for non-destructive evaluation of polyethylene pipe joints using ultrasound and machine learning

PendingUS20220317095A1Analysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasound deviceFusion joints

An aspect provides an ultrasound device for non-destructive evaluation of a butt-fusion joint or electro-fusion joint, the device comprising: an ultrasonic unit; a transducer operable remotely from the ultrasonic unit and including an ultrasound signal transmitter positionable to transmit the signal towards the joint, and an ultrasound signal receiver positionable to detect a reflection of the signal; a processor; memory including instructions executable by the processor and first data relating to a plurality of first sample joints of acceptable quality and second data relating to a plurality of second sample joints of unacceptable quality; and an output device. The instructions include a machine learning algorithm trained for analysis of the joint and to send assessment output to the output device indicative of whether the joint is of acceptable or unacceptable quality based on the signal reflection and the first and second data.

Owner:JANA CORP

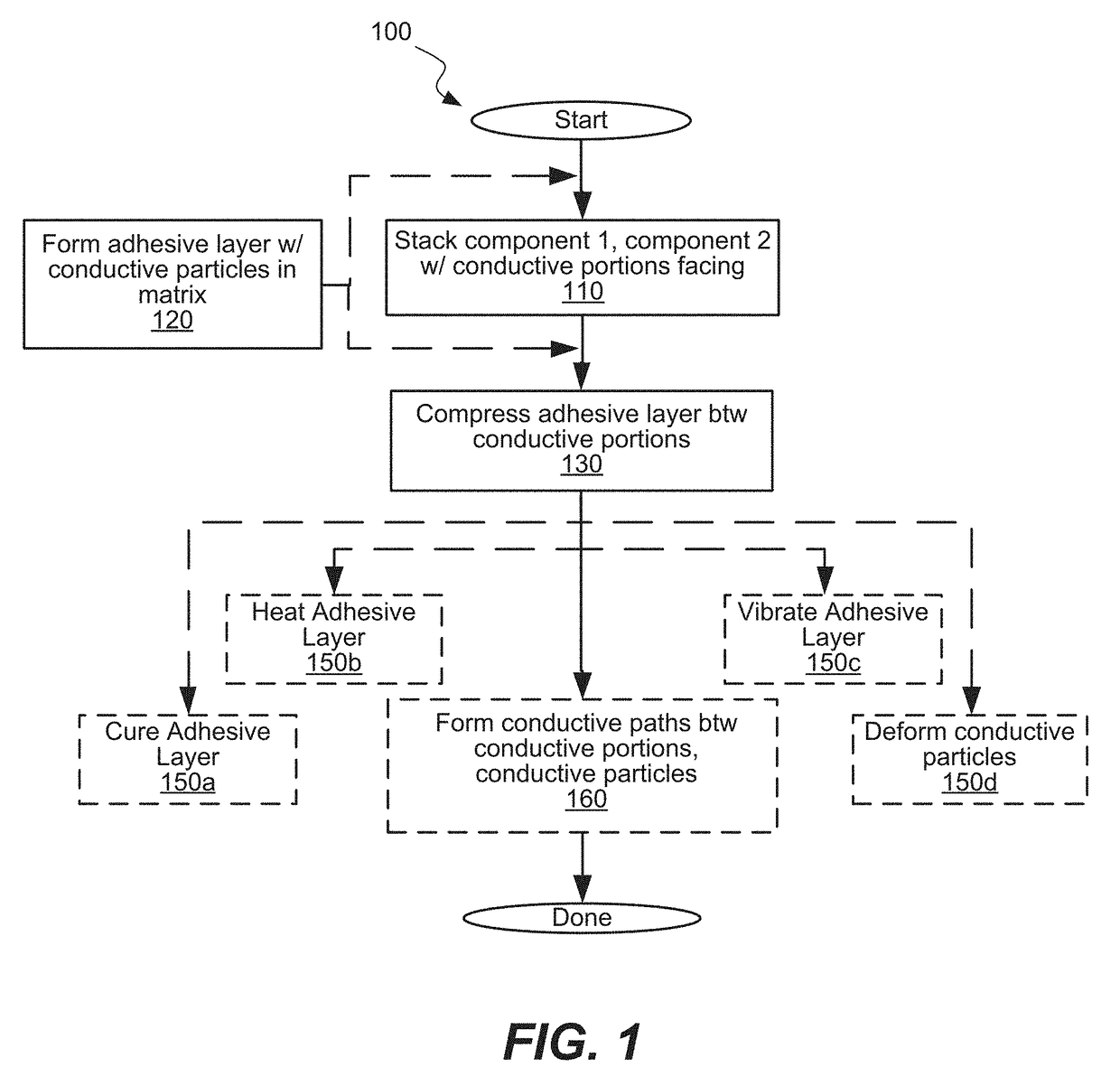

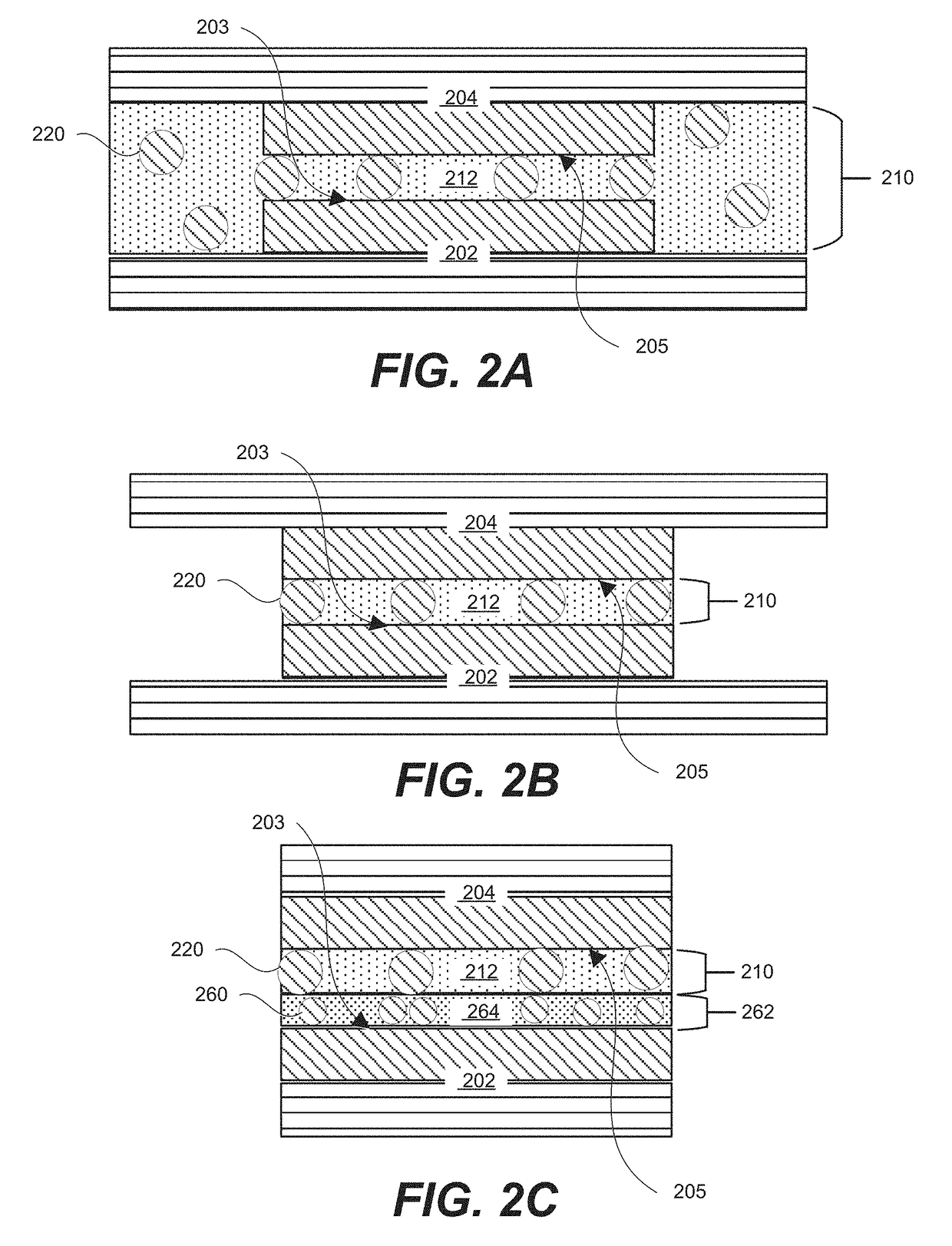

Bonding using conductive particles in conducting adhesives

ActiveUS20170194526A1Eliminate needRatio is smallAdhesive processesLamination ancillary operationsAdhesiveFusion joints

An anisotropic conducting adhesive is improved in conductivity without increasing the density of admixed conductive particles by inducing metallic fusion between the surfaces of the conducting particles and the surfaces being bonded. The metallic fusion may be promoted by physical / chemical interaction characteristic of certain materials at a compressed interface; by compression sufficient to deform the conductive particles in a manner that increases the mechanical contact area; by heating (with or without melting of a material), which may also serve to cure the adhesive matrix; or by acoustic vibration, e.g., ultrasonic vibration. The resulting metallic-fusion joint is stronger, as well as more conductive, than a joint in which the particles and surfaces are held in unfused mechanical contact.

Owner:THE BOEING CO

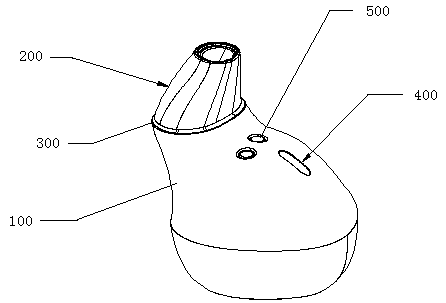

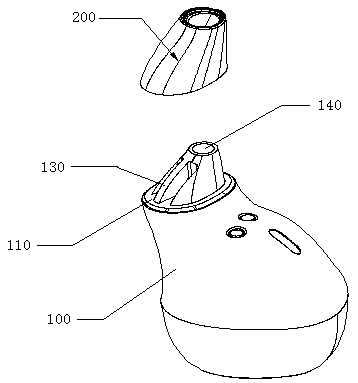

Ear-canal type Bluetooth headset and manufacture method of ear-canal type Bluetooth headset

The invention relates to the field of Bluetooth headphones, ear canal Bluetooth headphones, includes an earphone body for placement in the auricle and an ear canal soft plug for insertion into the earcanal interior, a main body of the earphone comprises a connection part and a connection part, the connection part and the ear canal soft plug are integrally connected, and the ear canal soft plug iswrapped on the connection part, and the extending direction of the ear canal soft plug and the extending direction of the connecting part are provided with an included angle, so that a soft glue hardglue fusion joint is formed between the connecting part and the ear canal soft plug, and the wearing comfort of the Bluetooth headset is better. The ear canal type Bluetooth headset adopts two-colormold which combines soft glue and hard glue to simulate ergonomics. Better looking, comfortable to wear and concealed in the ear. In addition, the invention also provides a manufacturing method of anear canal type Bluetooth headset.

Owner:深圳市睿良实业发展有限公司

Device and method for stripping test of electro-fusion joint

ActiveCN103203874AEffective peelingIncrease roughnessMaterial strength using steady shearing forcesFusion jointsEngineering

The invention relates to a stripping test of an electro-fusion joint and aims at providing a device and method for a stripping test of an electro-fusion joint. The device comprises a carrying platform, an end plate pressure plate, a tail part pressure plate, a detachable joint and a chain, wherein the end part pressure plate, the tail part pressure plate and the carrying platform are connected through bolts and used for fixing a test sample; a carrying flat plate is further connected with the detachable joint through a bolt, and the detachable joint is linked with a lower clamp of a tensile testing machine through a pin; and one end of the chain is linked with an upper clamp of the testing machine, and the other end of the chain is connected with a towing hole formed in the test sample through the pin. According to the device provided by the invention, the effective length in the position of the combination surface of weld joints is reduced, and the strength is reduced so as to be favorable for realizing effective stripping of a high-strength joint test sample; and the difficulty in stripping a fusion area of the joint test sample is embodied, the influence of environmental factors is smaller, and the bonding strength of the joint can be objectively and quantitatively evaluated without relying on the subjective judgment of testing staff.

Owner:ZHEJIANG UNIV

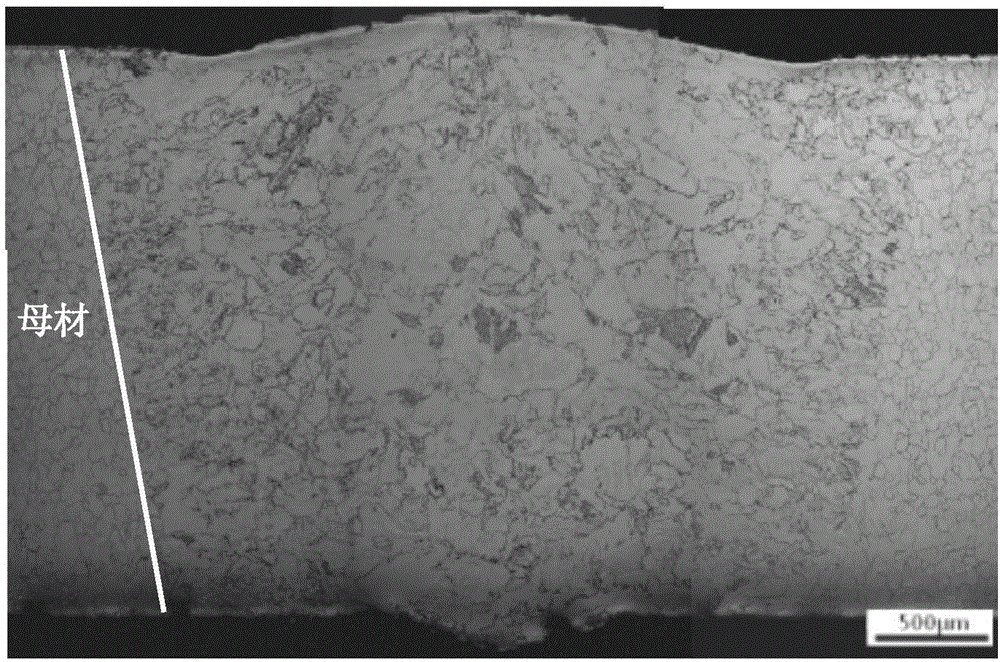

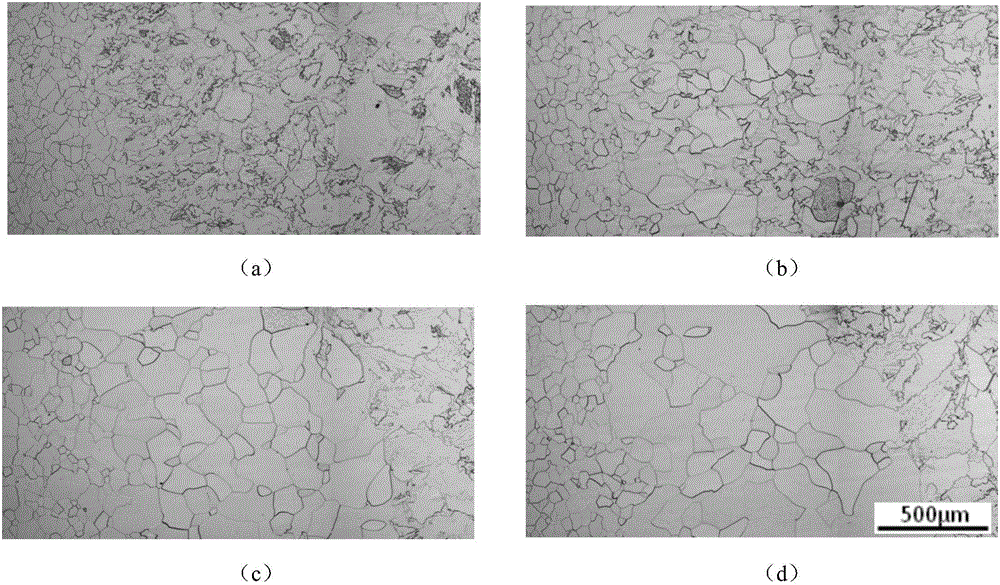

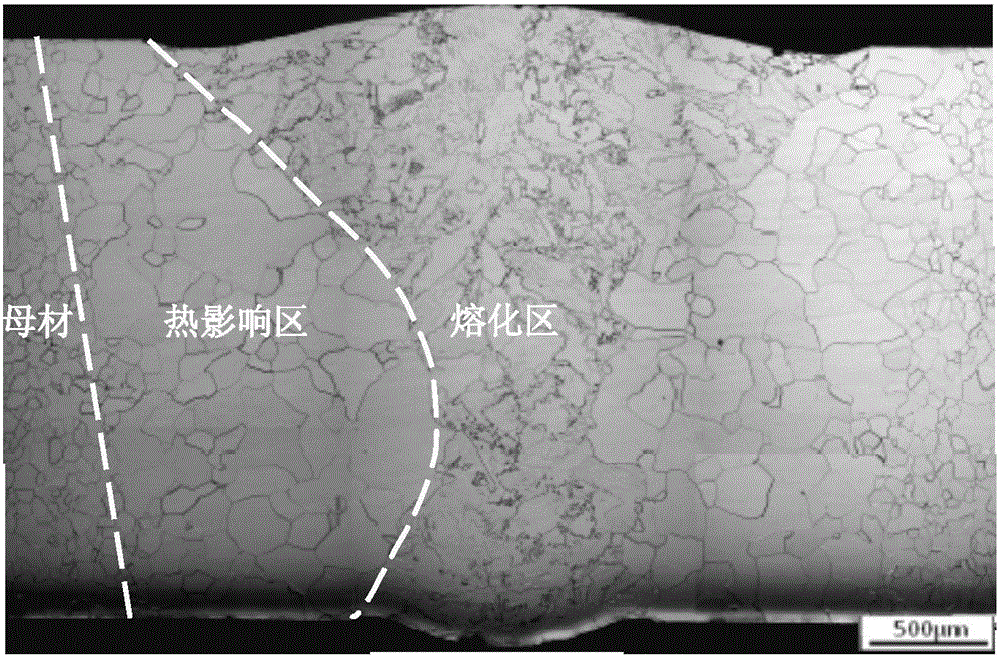

Method for determining positions of all areas of cross section of industrial pure-titanium fusion welding joint

ActiveCN106670674AThe method is simple and reliableFurnace typesWelding apparatusHeat-affected zoneFusion joints

The invention discloses a method for determining the positions of all areas of the cross section of an industrial pure-titanium fusion welding joint. After joint parent metal and a heat affected area are differentiated through metallographic observation and then sufficient heat treatment is conducted, grain growth or recrystallization occurs in the heat affected area, and the heat affected area and a melting area are differentiated according to the characteristics of grain growth. By utilizing the method for determining the positions of all areas of the cross section of the industrial pure-titanium fusion welding joint, all areas of the industrial pure-titanium fusion welding joint can be definitely divided, the effect that the change rules of the formation mechanism and the mechanical property of industrial pure-titanium fusion welding joint microstructures are comprehended in essence is facilitated, and preconditions are provided for subsequent welding fusion joint relevant studies.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com