Hollow-photon-crystal-fiber gas absorbing pool and manufacturing method thereof

A technology of hollow photonic crystals and gas absorption cells, which is applied in optics, light guides, optical components, etc., can solve problems such as deterioration of frequency stabilization performance, Fresnel reflection, and continuous change of spot centroid, achieving strong repeatability and easy operation. Realize and reduce the effect of transmission spectrum background noise oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with examples and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

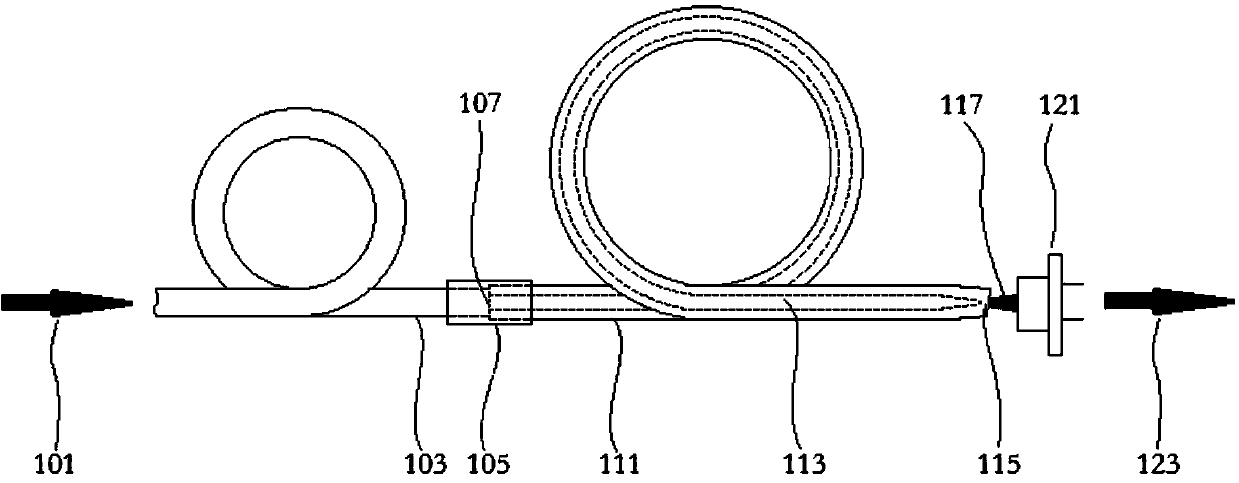

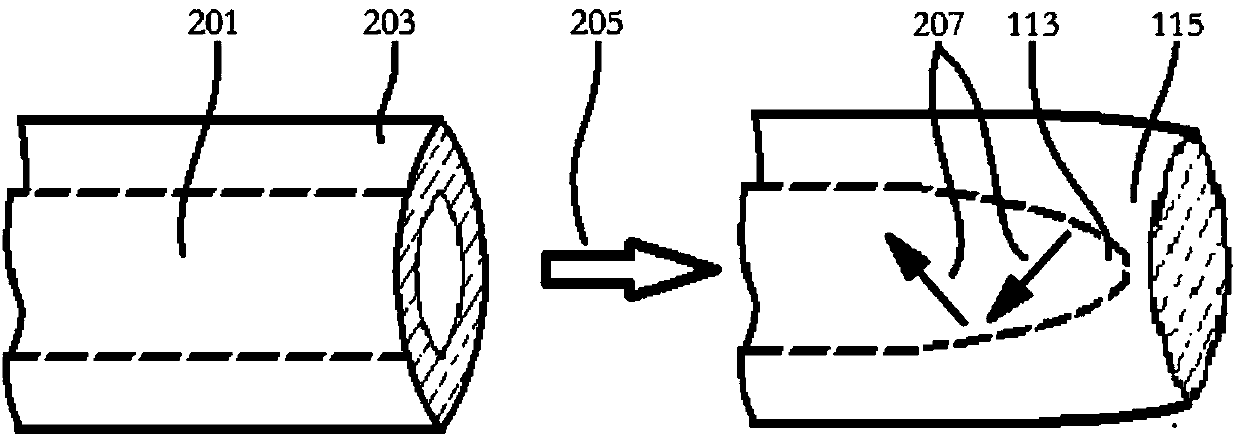

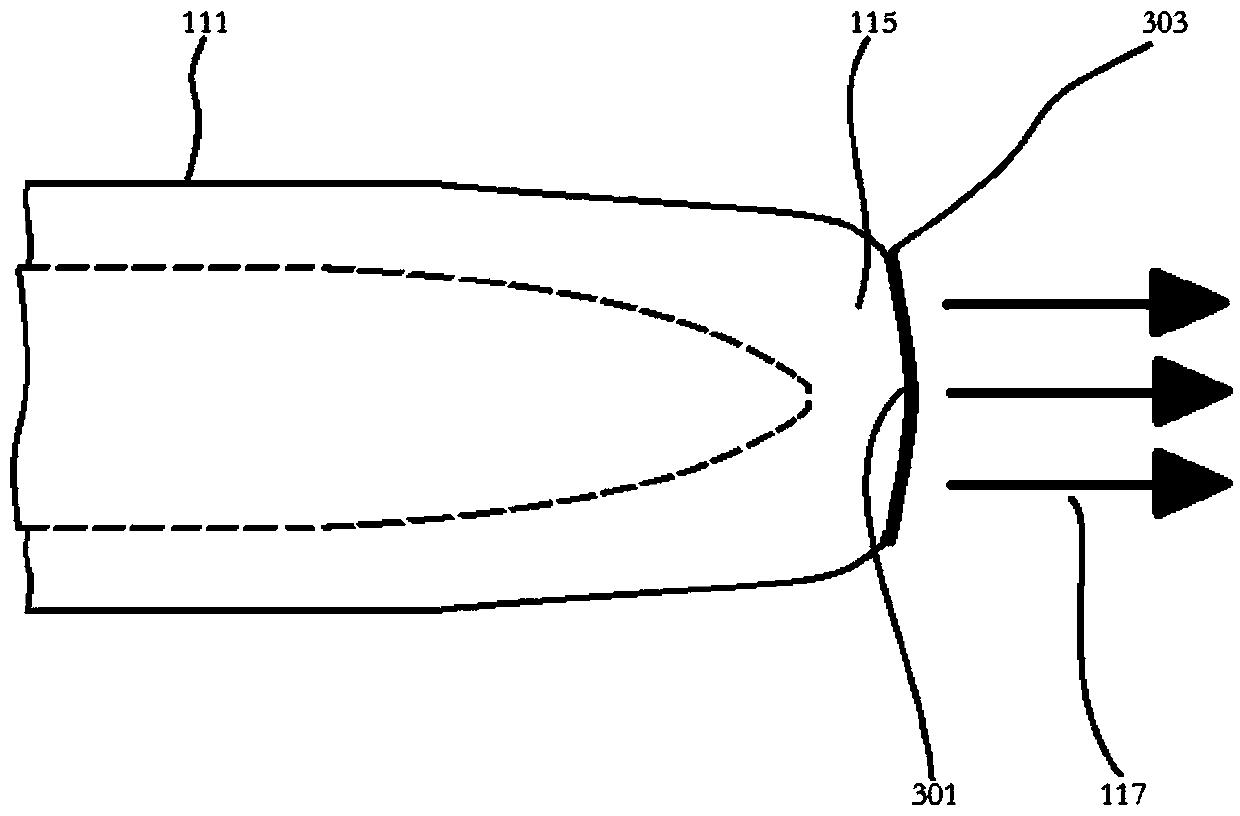

[0031] see first figure 1 The hollow photonic crystal fiber gas absorption cell of the present invention comprises a single-mode fiber 103, an optical fiber fusion splice protection sleeve 105, a hollow photonic crystal fiber 111 and a photodetector 121, one end of the single-mode fiber 103 and One end of the hollow photonic crystal fiber 111 is fused to form a fusion joint 107, forming one end of a sealed hollow photonic crystal fiber gas absorption pool. The optical fiber fusion protection sleeve 105 covers and protects the fusion joint 107. The hollow photonic crystal fiber The other end of the crystal fiber 111 is melt-sealed to form an output end 115 with an inclined plane, which is opposite to but not parallel to the detection plane of the photodetector 121 .

[0032] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com