Three-core cable fusion joint and installation technology thereof

A three-core cable and installation process technology, applied in the direction of welding/fusion connection, connection/termination cable equipment, insulation/armoured cable repair equipment, etc., can solve the problem of water leakage at the lap joint, which affects the repair effect The guide core is prone to problems such as offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

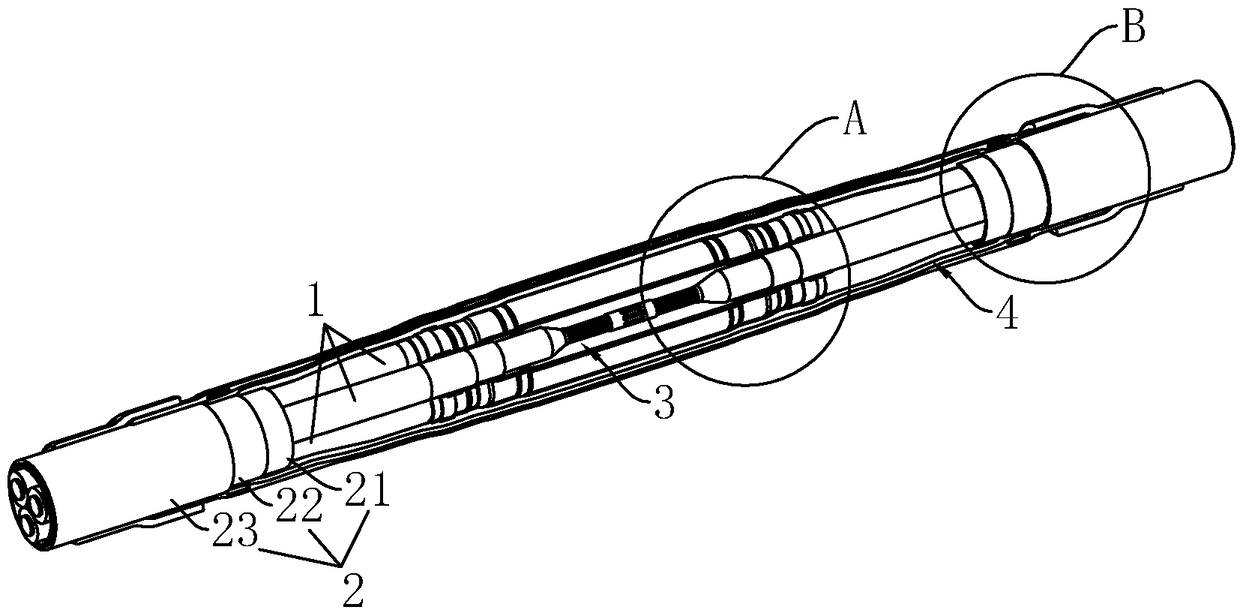

[0059] refer to figure 1 , is a three-core cable fusion joint disclosed by the present invention (the specification is 3kV-35kV three-core XLPE cable), including two interconnected cables and an inner repair layer group 3 and an outer repair layer for repairing the cables Group 4. Each cable includes three guide cores 1 and an outer protective layer group 2 covering the outside of the three guide cores 1 , the inner repair layer group 3 and the outer repair layer group 4 are used for repairing the guide core 1 and the outer protective layer group 2 respectively.

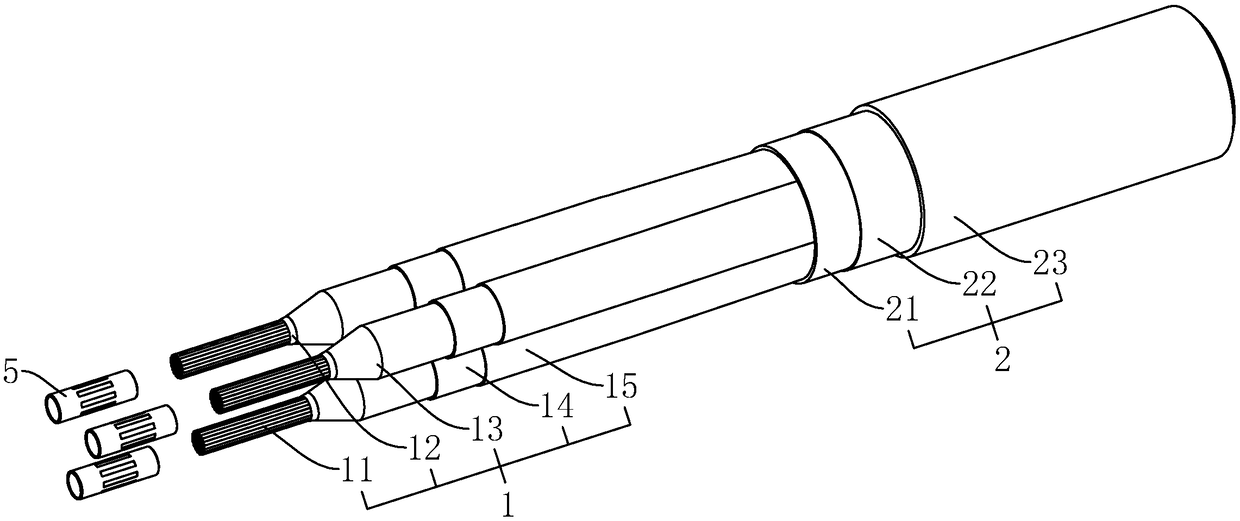

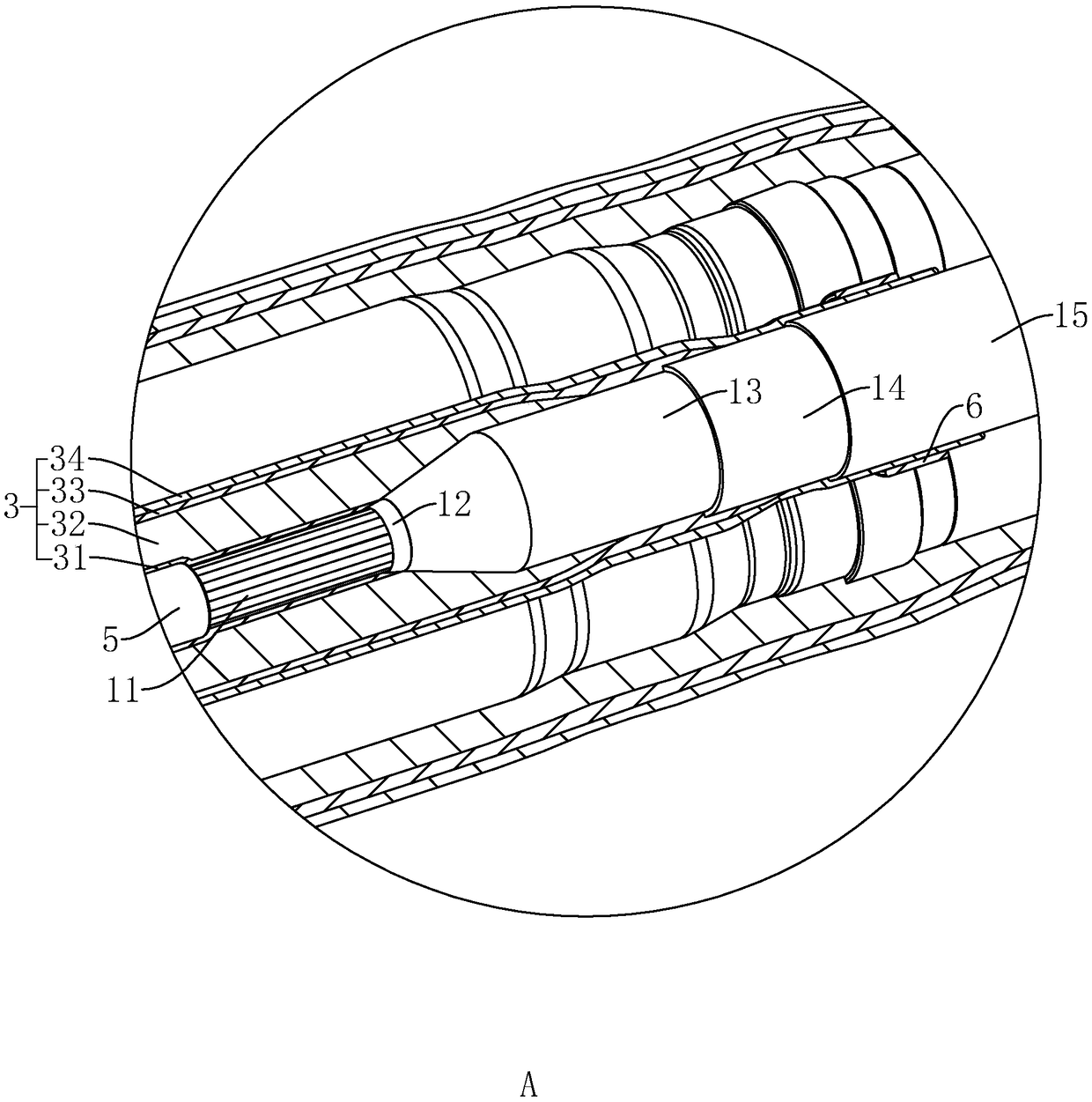

[0060] refer to figure 2 , image 3 Each guide core 1 includes a conductor 11, an inner semiconductive layer 12, an insulating layer 13, an outer semiconductive layer 14, and a copper shielding layer 15 from inside to outside, and the inner repair layer group 3 includes from inside to outside in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com