35kV - 220kV casting-type cable body fusion joint and making method thereof

A 35kv--220kv, cable body technology, applied in the direction of circuits, connections, electrical components, etc., can solve problems such as joint breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

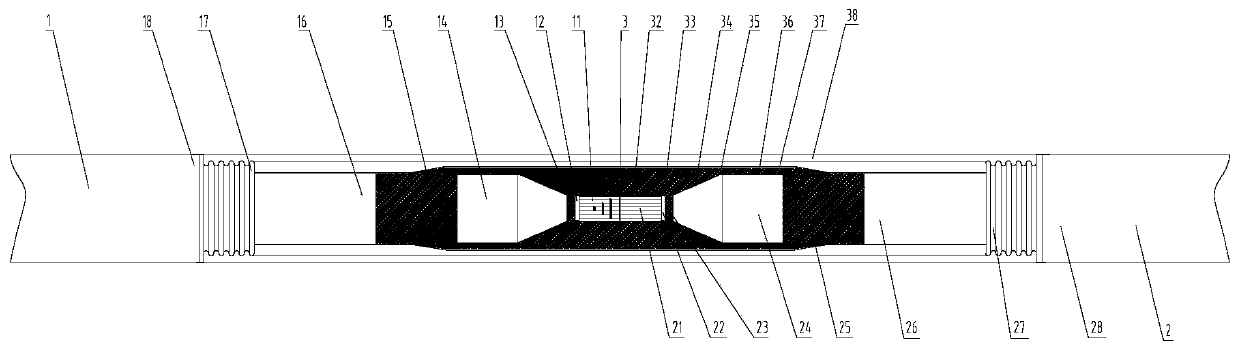

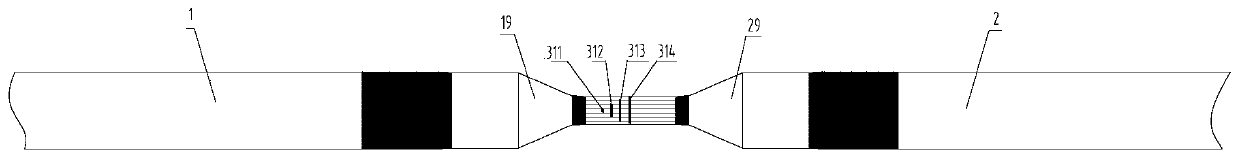

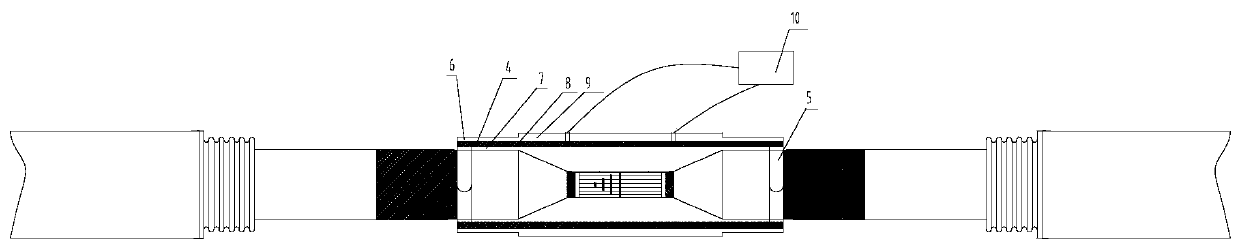

[0065] like figure 1 As shown, the 35kV--220kV castable cable body fusion joint of the present invention includes a first cable body 1 and a second cable body 2, the first cable body 1 is composed of the first cable body core 11, the second cable body core 11, and the second A semi-conductive cloth layer 12 in the cable body, a semi-conductive shielding layer 13 in the first cable body, a first cable body insulating layer 14, a first cable body insulating shielding layer 15, a first cable body semi-conductive water-blocking buffer layer 16, The first cable body aluminum sheath metal layer 17 and the first cable body outer sheath insulation protection layer 18 are composed of the second cable body core 21, the second cable body inner semi-conductive cloth layer 22, the second cable body 2 Two cable body inner semiconducting shielding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding thickness | aaaaa | aaaaa |

| Winding thickness | aaaaa | aaaaa |

| Winding thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com