Microwave sintering

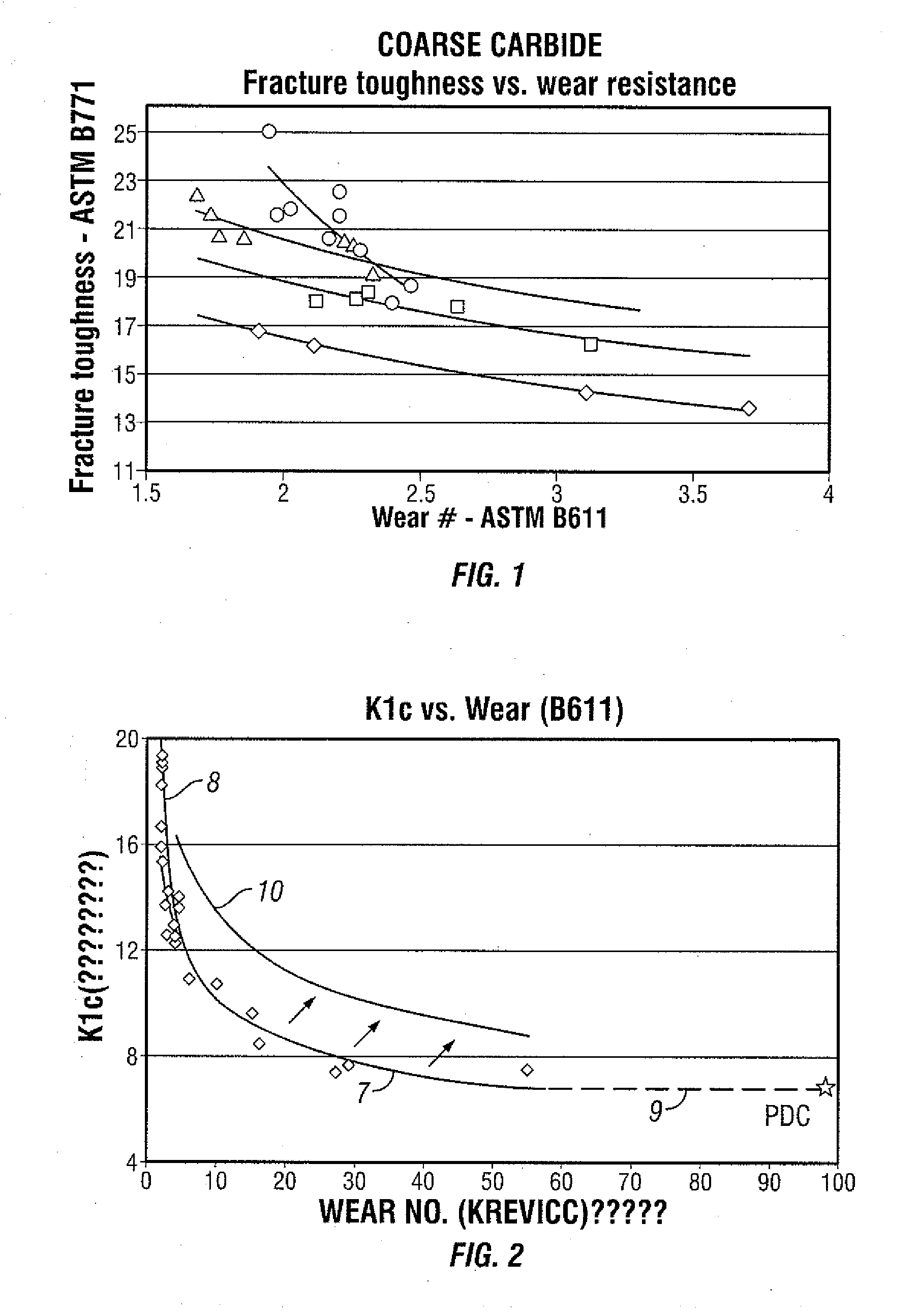

a technology of microwave sintering and tungsten carbide, which is applied in the direction of drill bits, drilling accessories, earthwork drilling and mining, etc., can solve the problems of residual stresses induced on composite materials, material sintering under high pressure and high temperature, and tungsten carbide cutting elements tend to fail by excessive wear, etc., to achieve rapid consolidation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

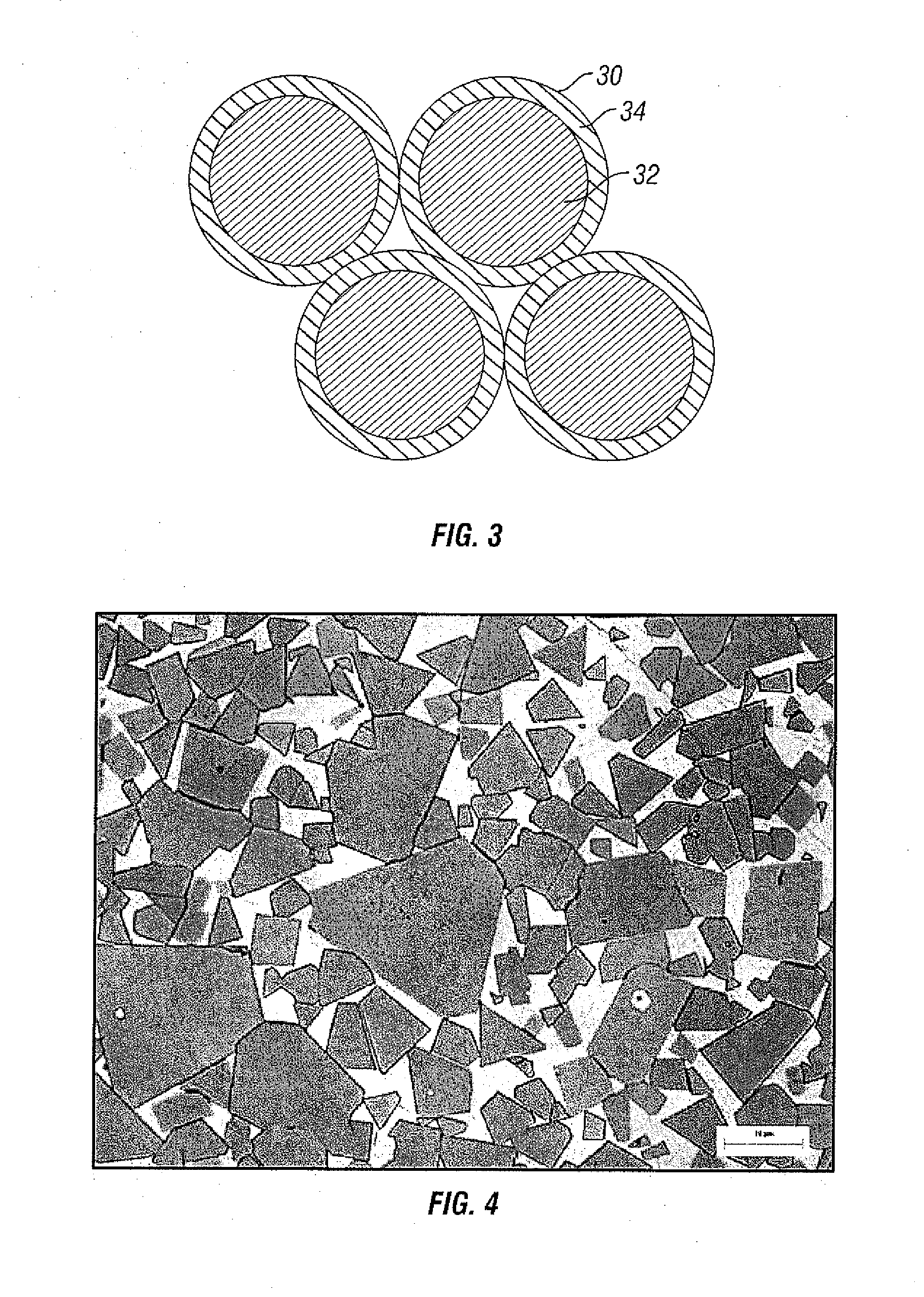

[0031] In one aspect, embodiments of the invention relate to wear resistant elements and carbide composites having nano-scale carbide particles. In another aspect, embodiments of the invention relate to microwave sintered composites. Microwave sintering may provide for a process of forming a hard composite. As compared to a conventional high temperature, high pressure (HTHP) sintering process, such as that disclosed in U.S. Pat. Nos. 4,694,918; 5,370,195; and 4,525,178, sintering using microwave energy may reduce the pressures used, decrease the applied temperature, and reduce the sintering time. The microwave sintering process may be applied to a number of composite materials and may thus form composites having greater wear resistant properties. Tungsten carbide, polycrystalline diamond, thermally stable polycrystalline diamond, silicon carbide, etc, are among the materials suitable for microwave sintering.

[0032] In one embodiment, a microwave sintered composite made in accordance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com