Coal seam liquid carbon dioxide fracturing device and method

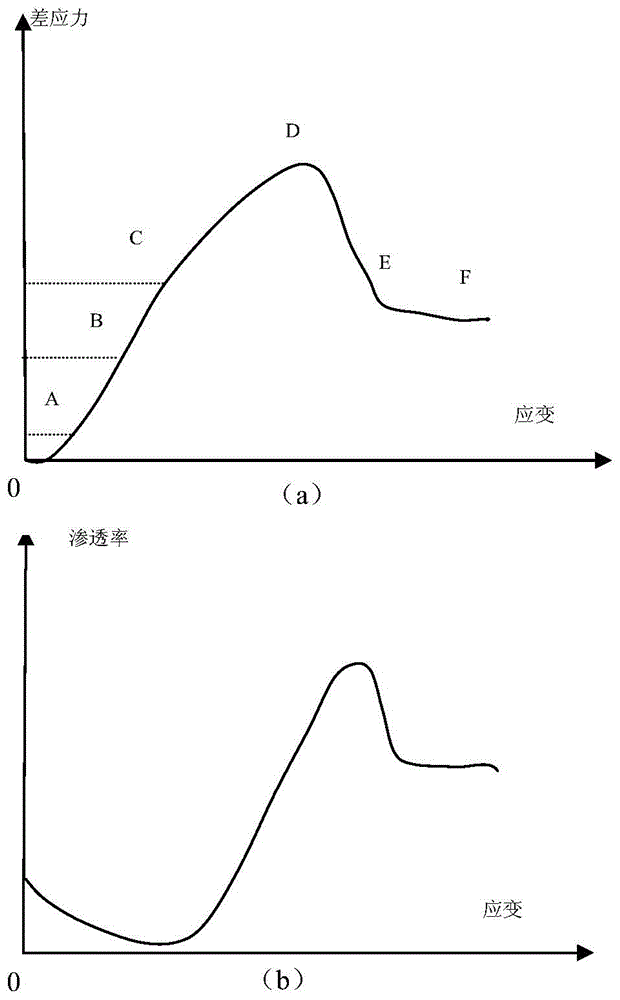

A liquid carbon dioxide, coal seam technology, applied in earthwork drilling, fluid extraction, measurement, etc., can solve problems such as high peak pressure, affecting coal seam permeability, and not adapting to gas emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

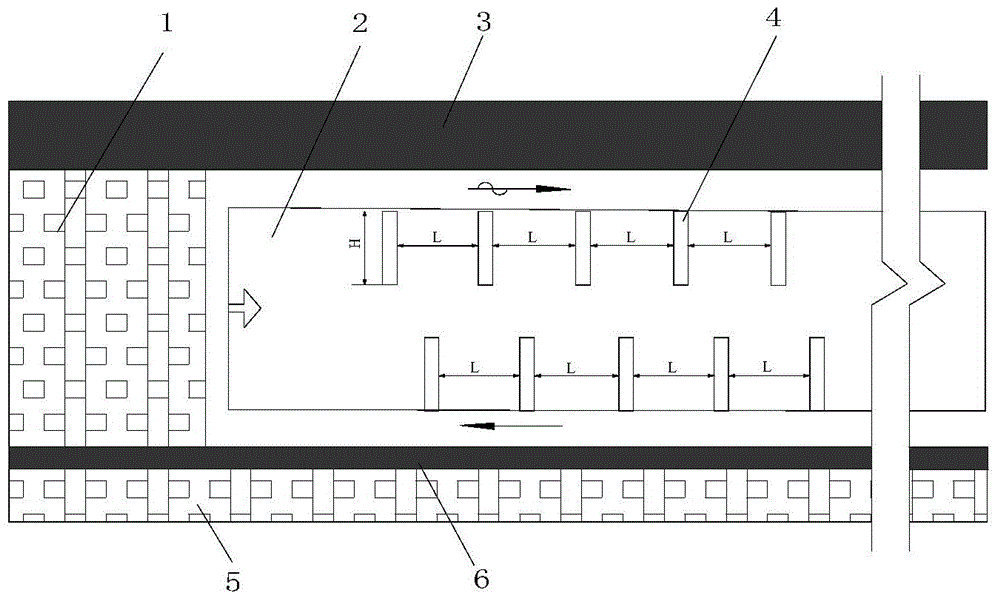

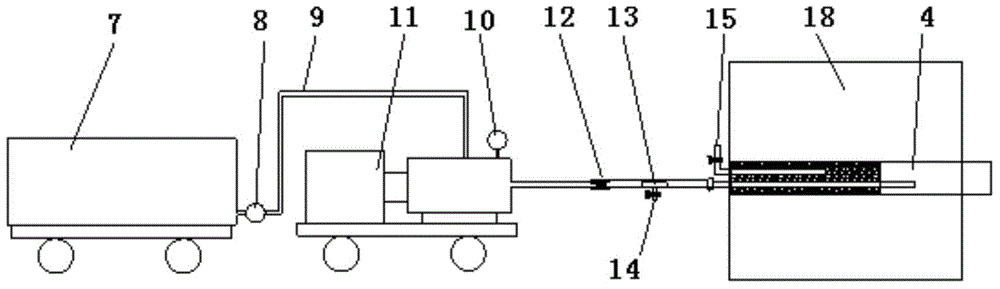

[0059] as liquid CO 2 As the fracturing medium, the liquid CO 2 Transported to the downhole, the carbon dioxide booster pump is used to inject into the borehole, and the gasified CO in the borehole 2 Volume expansion boosts pressure to realize safe fracturing of coal seams. The specific implementation is as follows:

[0060] coal seam liquid CO 2 The fracturing device is powered by liquid CO 2 Tank car, fracturing pump, fracturing pipe, hole sealer, monitoring instrument, first pipeline and second pipeline and accessories. Liquid CO 2 The tank truck provides fracturing fluid for the whole fracturing process, and the fracturing pump is used as the power facility for the fracturing process to control the liquid CO 2 Boost the pressure, enter the fracturing pipe through the high-pressure and low-temperature pipeline, and transport it to the drill hole sealed with a special hole sealer to perform fracturing operations on the coal seam. During the fracturing process, the coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com