Apparatus for purifying exhaust gas

A catalyst, turbocharger technology, applied in the direction of exhaust device, muffler device, charging system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

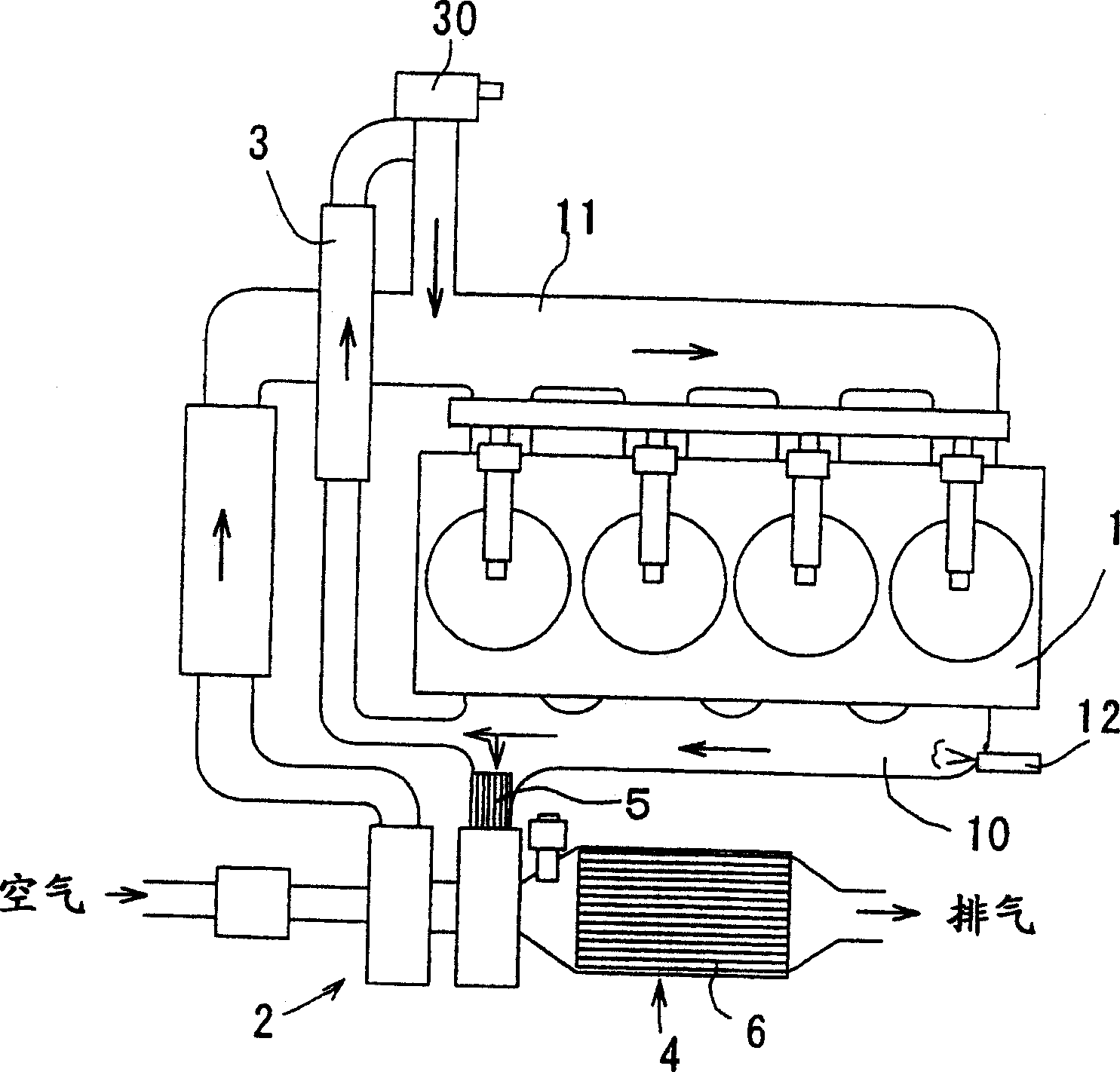

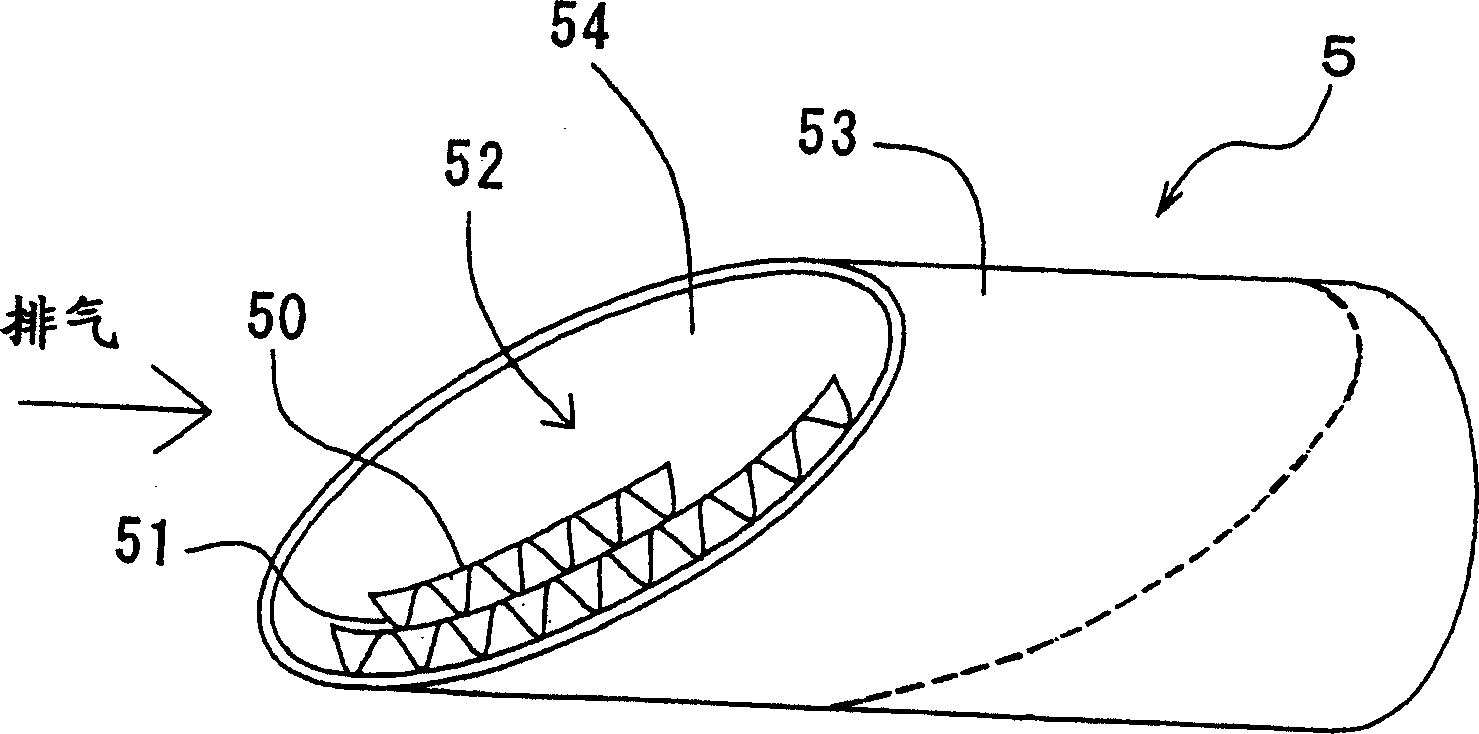

[0044] figure 1 An exhaust purification device according to Example 1 of the present invention is shown. The exhaust system of the direct injection diesel engine 1 is branched from the exhaust manifold 10 into two flow paths. A turbocharger 2 is provided in one of the flow passages, and an exhaust gas circulation (hereinafter abbreviated as "EGR") cooler 3 is provided in the other flow passage. Exhaust gas discharged from the turbocharger 2 passes through the catalytic converter 4 and is discharged to the outside. On the other hand, the exhaust gas passing through the EGR cooler 3 is returned to the intake manifold 11 , and the flow rate is controlled by the EGR valve 30 . An injector 12 is installed on the upstream side of the exhaust gas flow with respect to the turbocharger 2 in order to add light oil to the exhaust gas. A small honeycomb oxidation catalyst 5 is disposed between the injector 12 and the turbocharger 2 . In addition, the catalytic converter 4 is equipped ...

example 2

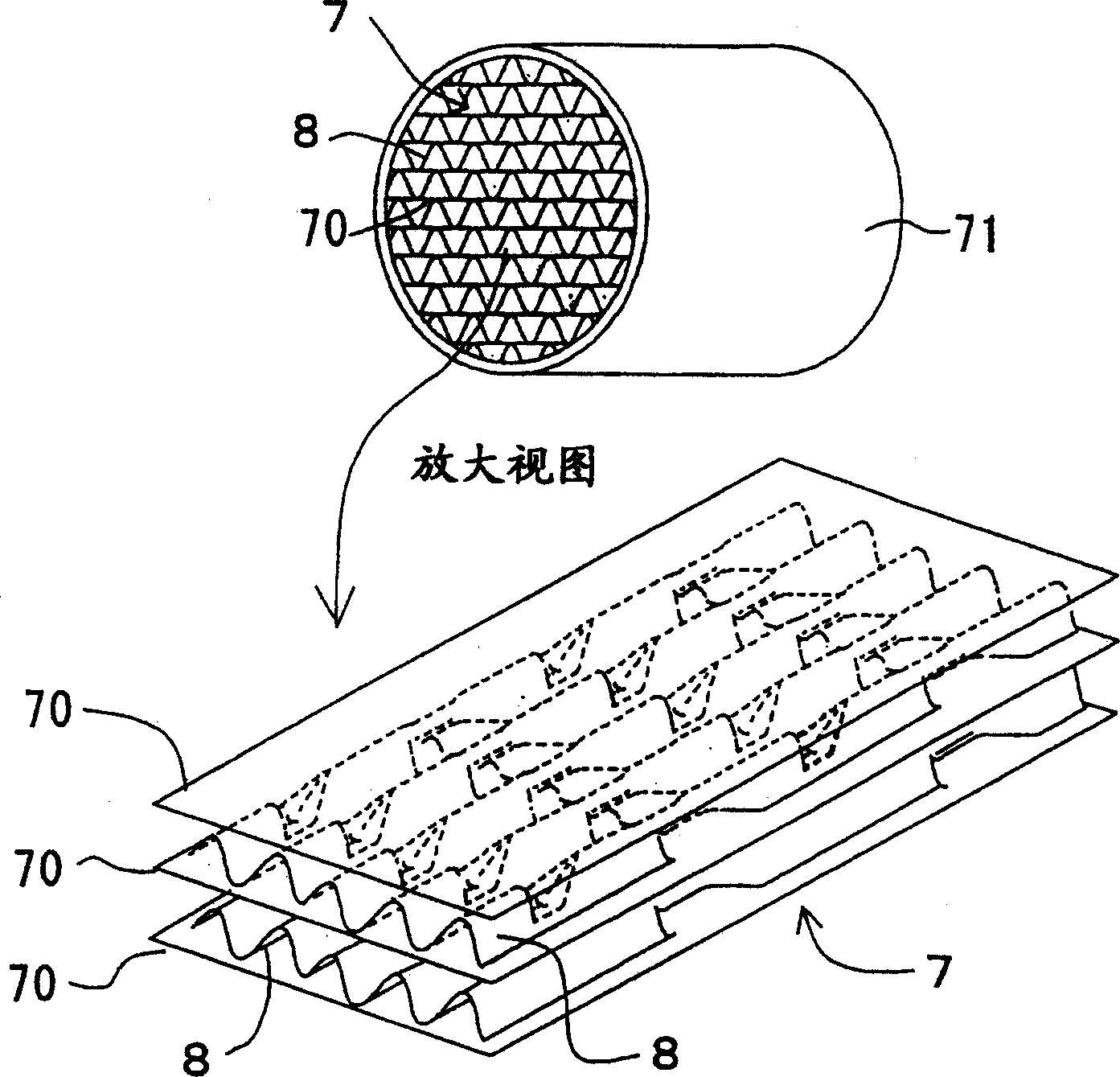

[0050] In addition to setting image 3 The arrangement of the exhaust gas purification device according to Example 2 of the present invention is the same as that of the exhaust gas purification device according to Example 1, except that the honeycomb body 7 is shown instead of the oxidation catalyst 5 . It should be noted that the honeycomb body 7 is made of metal and has a volume of 24c.c. Specifically, as shown in the accompanying drawings, the honeycomb body 7 includes Figure 4 The corrugated plate 8 and the metal plate 70 shown in. The corrugated plate 8 and the flat plate 70 are stacked one on top of the other. The obtained subassembly of stacked corrugated plates 8 and flat plates 70 is housed in a metal outer cylinder 71 .

[0051] like Figure 4As shown in , the corrugated sheet 8 of the honeycomb body 7 includes a corrugated ridge 82 , a secondary root 83 , a secondary corrugated ridge 82 , a secondary top 84 and a second secondary root 83 . The wavy ridges 82 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com