Gas engine

A gas engine and fuel technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as easy frosting and icing, affecting the normal operation of the fuel supply system, and deterioration of gaseous fuel vaporization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

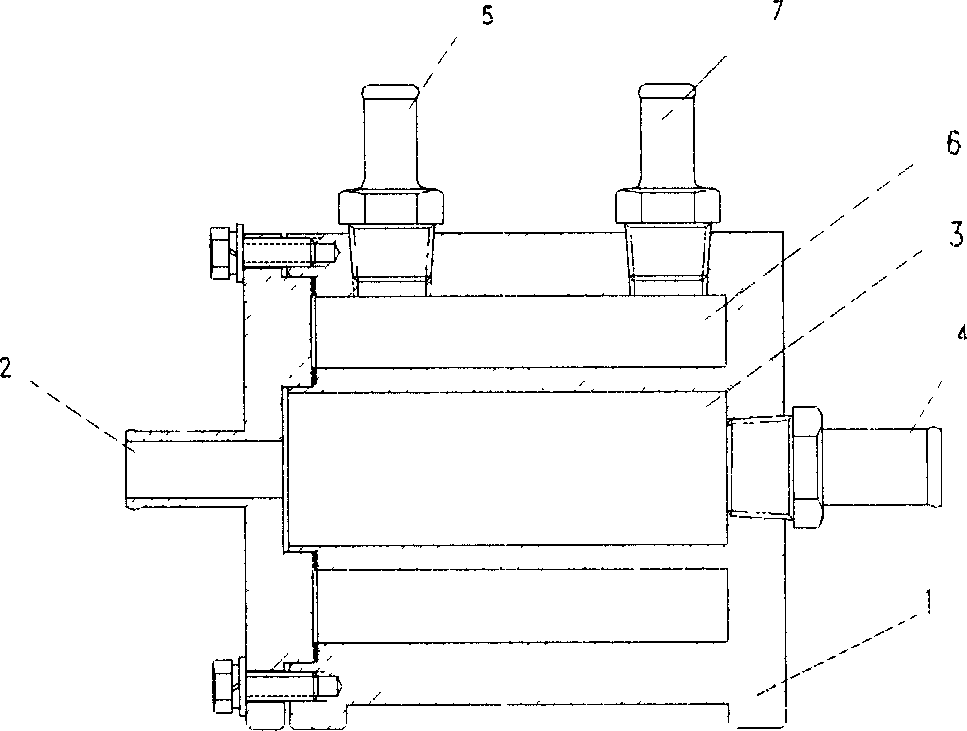

[0012] See attached figure 1 , the secondary vaporizer 1 described in the present embodiment is composed of two mutually closed and thermally contacted water and gas pipelines, the water inlet and outlet interfaces 2 and the water chamber 3 and the water inlet and outlet 4 constitute the water pipeline, the air inlet and outlet 5 and the air chamber 6 and the gas inlet and outlet 7 form a gas pipeline, and water and gas go their own way in the secondary vaporizer 1 and can perform heat exchange.

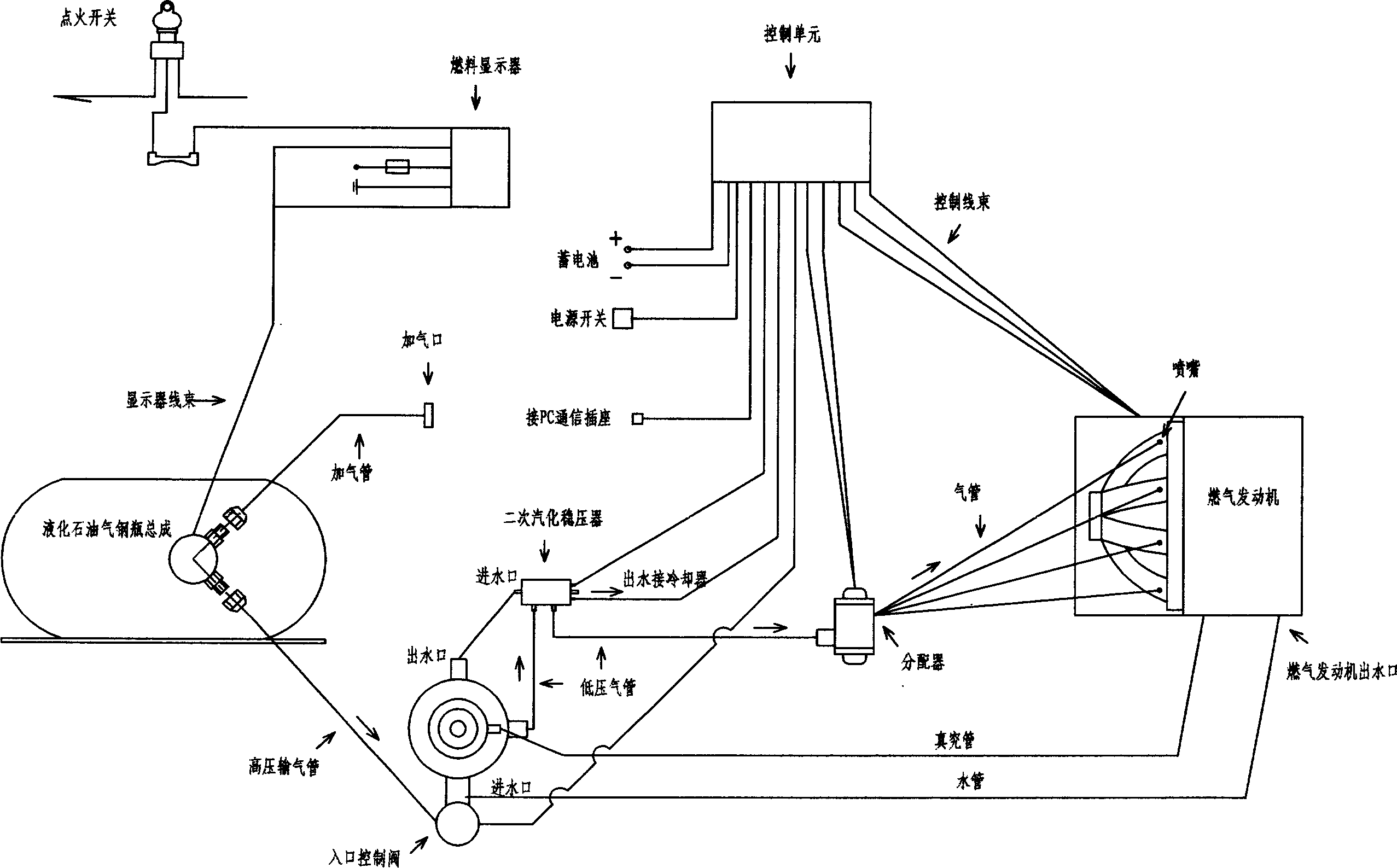

[0013] See attached figure 2 , the electric heating tube 8 and the temperature sensor 9 are installed on one wall of the secondary vaporizer 1, and are respectively connected with the control unit of the gas engine, and when the temperature sensor 9 detects that the gas in the air chamber 6 is too low, a signal is sent to the control unit , the control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com