Preparation method of porous biomedical metal, ceramic or metal/ceramic composite material

A ceramic composite material, biomedical technology, applied in the field of ceramics or metal/ceramic composite materials, porous biomedical metal, can solve the problems of insufficient surface roughness, high process cost, difficult bone tissue integration, etc., to achieve uniform distribution of porosity , simple process and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

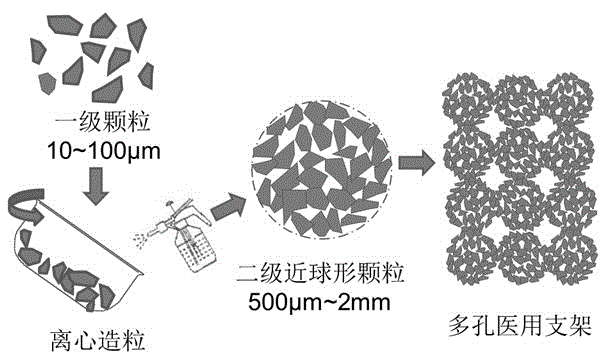

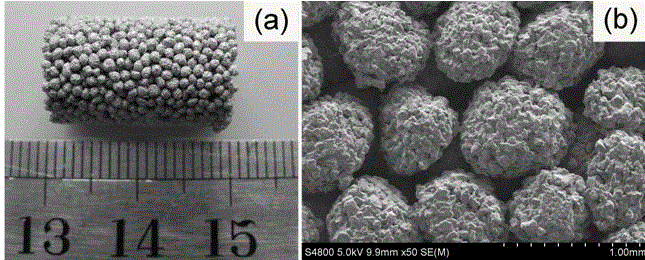

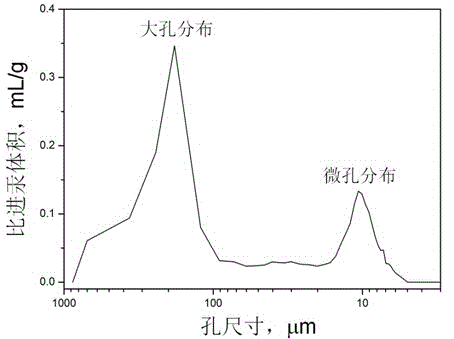

[0048] Embodiment 1: Preparation of porous titanium

[0049] Take 20g of titanium powder with a particle size distribution between 45 and 56mm as primary particles; put a certain amount of the above-mentioned primary particles in the centrifugal turntable as master batches, adjust the rotational speed of the centrifugal turntable to make these master particles form a moving particle flow , while spraying atomized 5% polyvinyl alcohol aqueous solution to its surface, and replenishing new primary particles in time, so that the masterbatch will continue to grow to obtain the required secondary nearly spherical particles, in a vacuum sintering furnace at 1000 ° C Pre-sintering for 1 hour; sieve these secondary nearly spherical particles with a sample sieve, take a certain amount of secondary nearly spherical particles with a particle size distribution between 850 and 1000 mm, soak the surface with 5% polyvinyl alcohol aqueous solution and dry at room temperature After drying, it...

Embodiment 2

[0051] Example 2: Preparation of porous hydroxyapatite ceramics

[0052] Take 20g of hydroxyapatite micropowder with a particle size distribution between 25 and 38mm as primary particles; put a certain amount of the above-mentioned primary particles in the centrifugal turntable as masterbatch, adjust the rotational speed of the centrifugal turntable to make these masterbatches move At the same time, the mixed aqueous solution of 30% water-soluble starch and 5% polyvinyl alcohol is sprayed on its surface, and new primary particles are added in time to make the masterbatch grow continuously to obtain the required secondary near Spherical particles, and pre-sintered in a muffle furnace at 800 ° C for 1 h; these secondary nearly spherical particles were screened with a sample sieve, and a certain amount of secondary nearly spherical particles with a particle size distribution between 600 and 710 mm were taken. Infiltrated with 10% polyvinyl alcohol aqueous solution and dried at ...

Embodiment 3

[0054] Example 3: Preparation of porous iron / β-tricalcium phosphate composite scaffold

[0055] Take 10g of pure iron powder with a particle size distribution between 38~45mm and 10g of tricalcium phosphate micropowder with a particle size distribution between 38~45mm, mix them well and use them as primary particles; put a certain amount of The above-mentioned primary particles are used as master batches. Adjust the rotational speed of the centrifugal turntable so that these master batches form a moving particle flow. At the same time, spray an atomized mixed aqueous solution of 5% polyethylene glycol and 3% methylcellulose on the surface, and replenish The new primary particles, make the master batch grow continuously to obtain the required secondary nearly spherical particles, and pre-sinter in a vacuum sintering furnace at 800 ° C for 1 hour; these secondary nearly spherical particles are screened with a sample sieve, Take a certain amount of secondary nearly spherical pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com