Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Stably form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

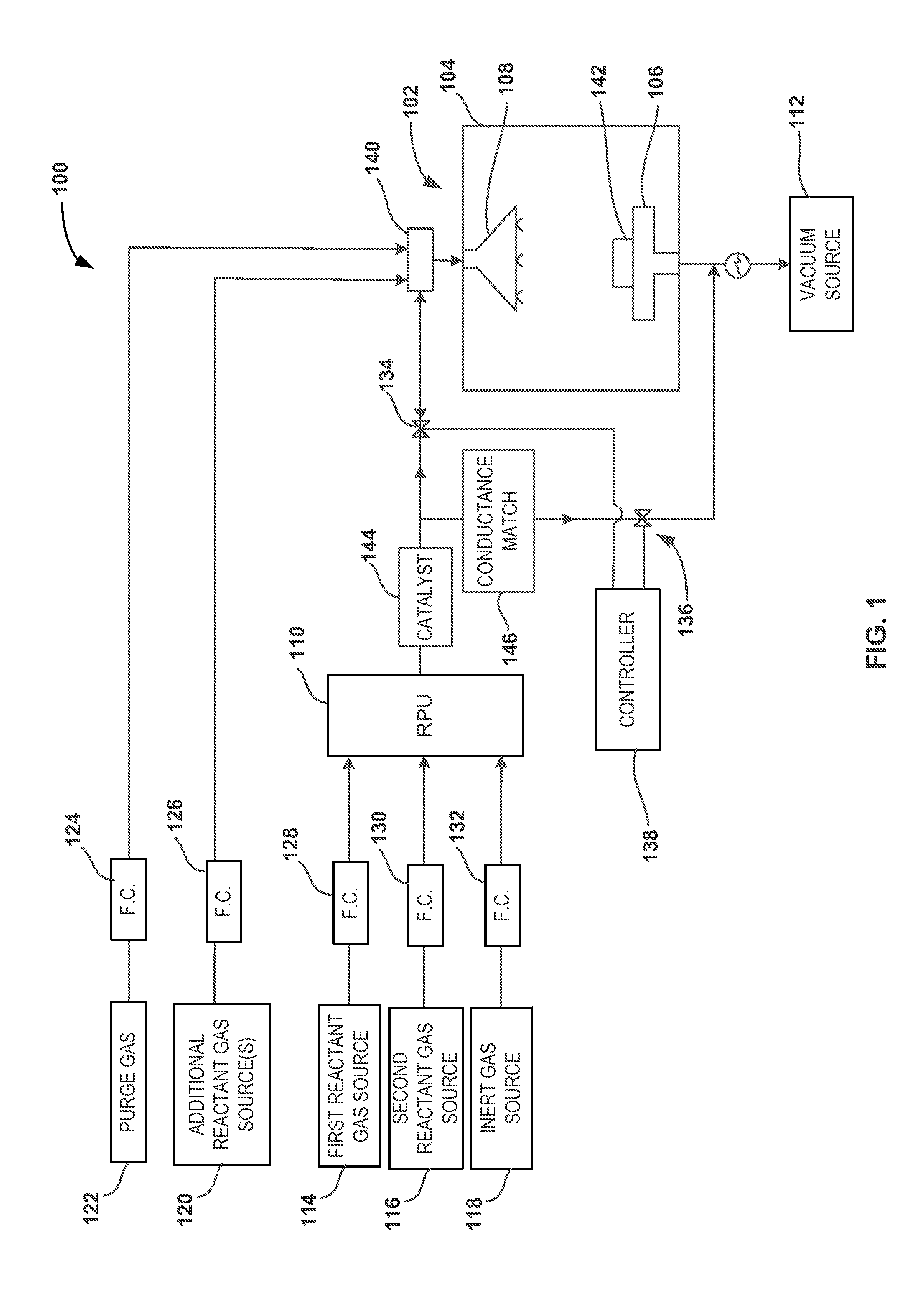

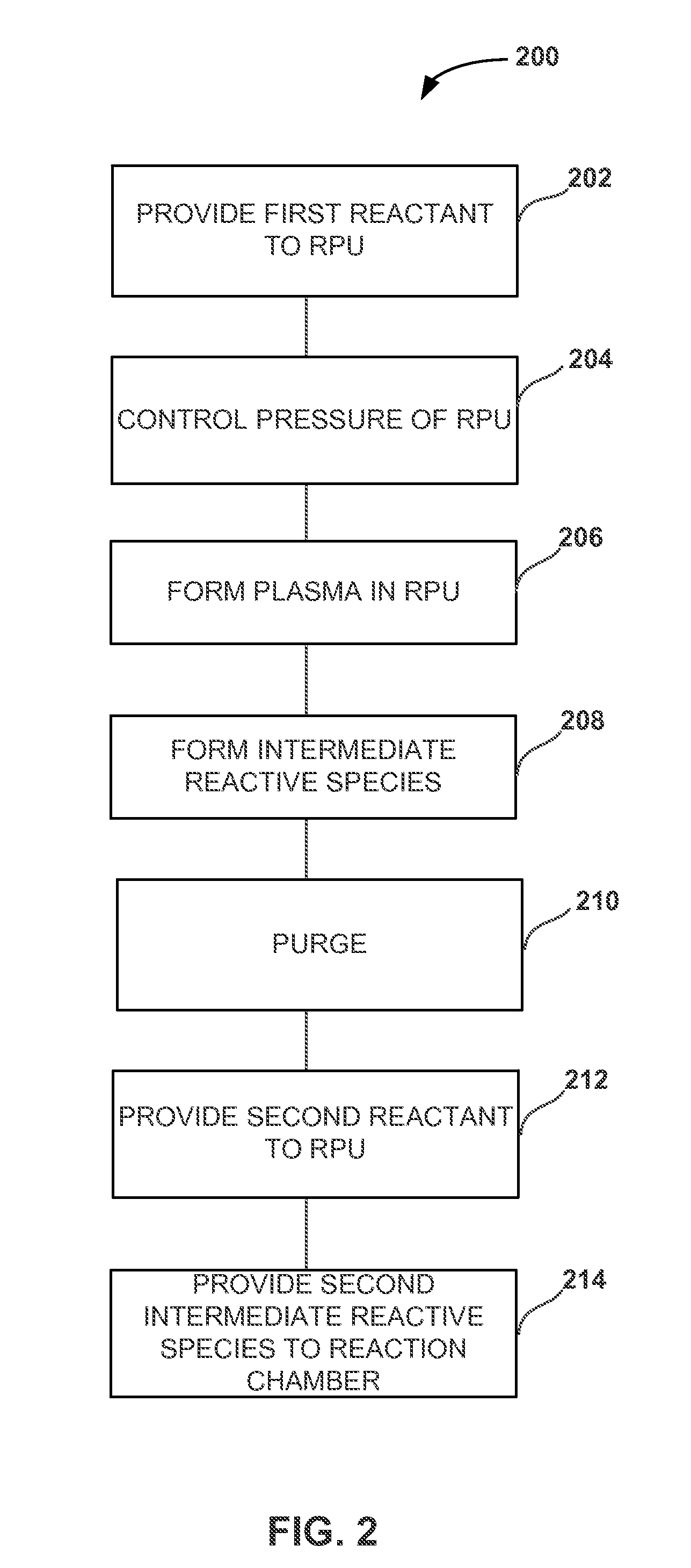

Method and systems for in-situ formation of intermediate reactive species

ActiveUS20140251953A1Stably formElectric discharge tubesDecorative surface effectsRemote plasmaEngineering

A system and method for providing intermediate reactive species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as intermediate reactive species from the remote plasma unit are provided to the reaction chamber.

Owner:ASM IP HLDG BV

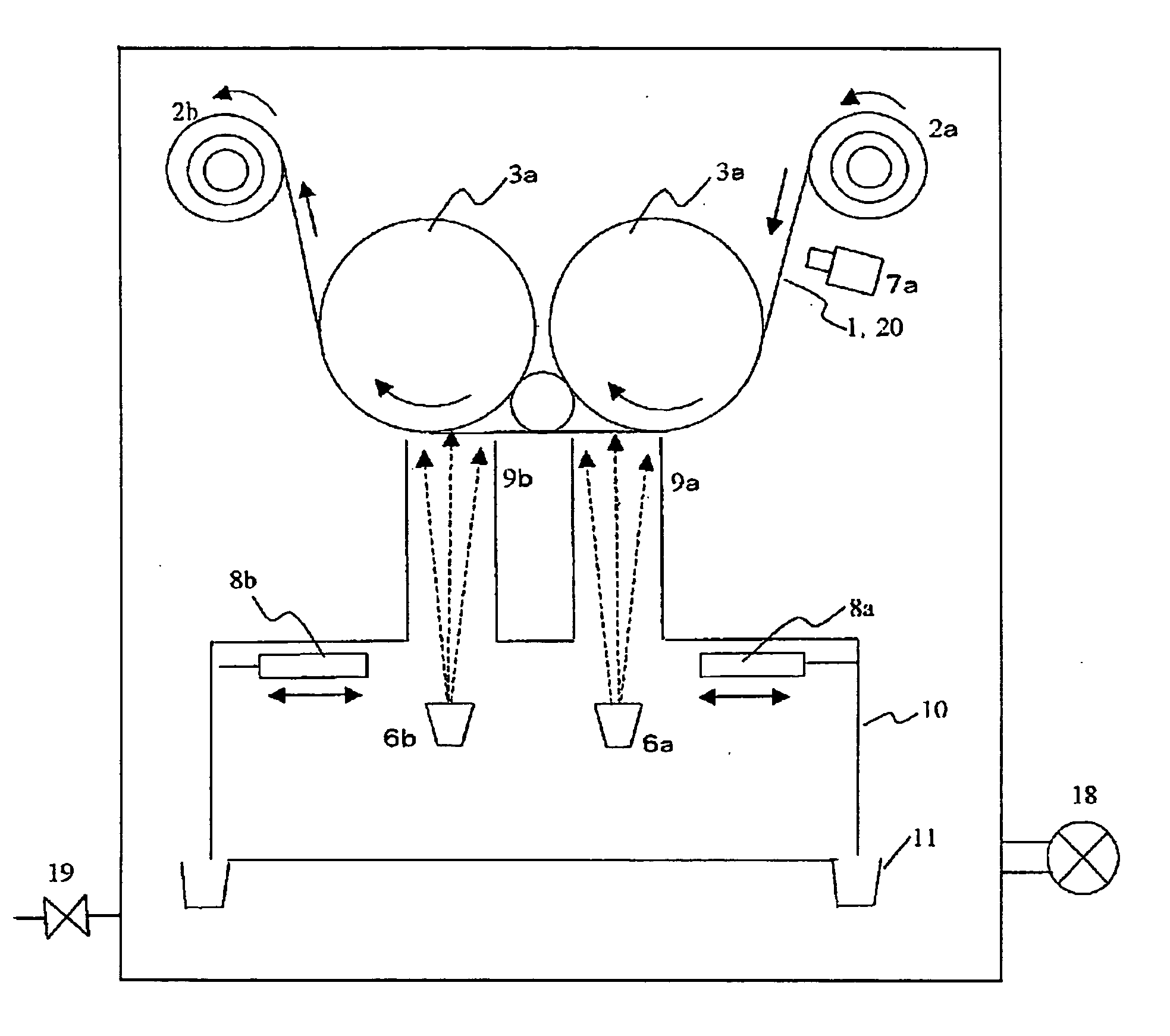

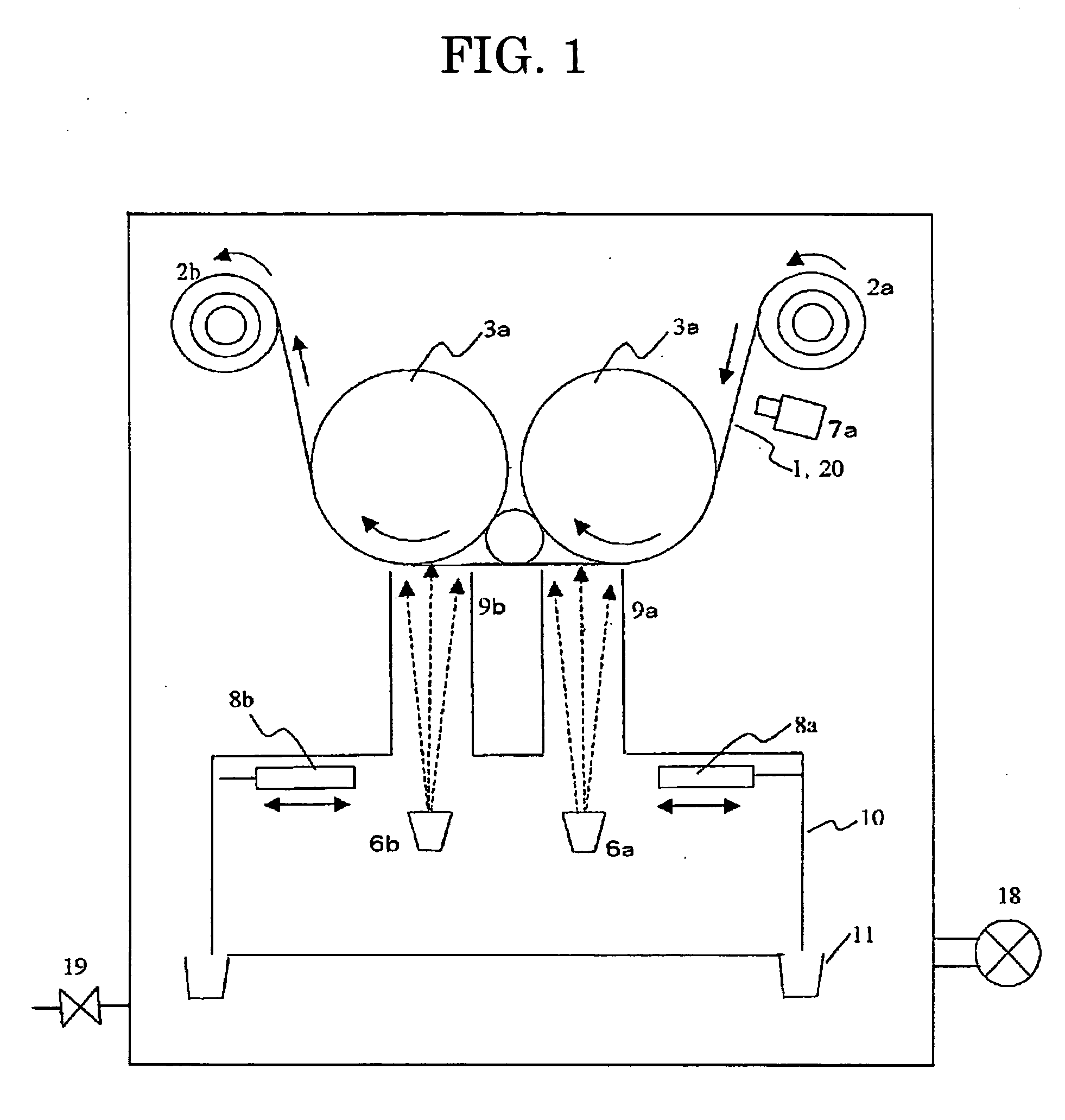

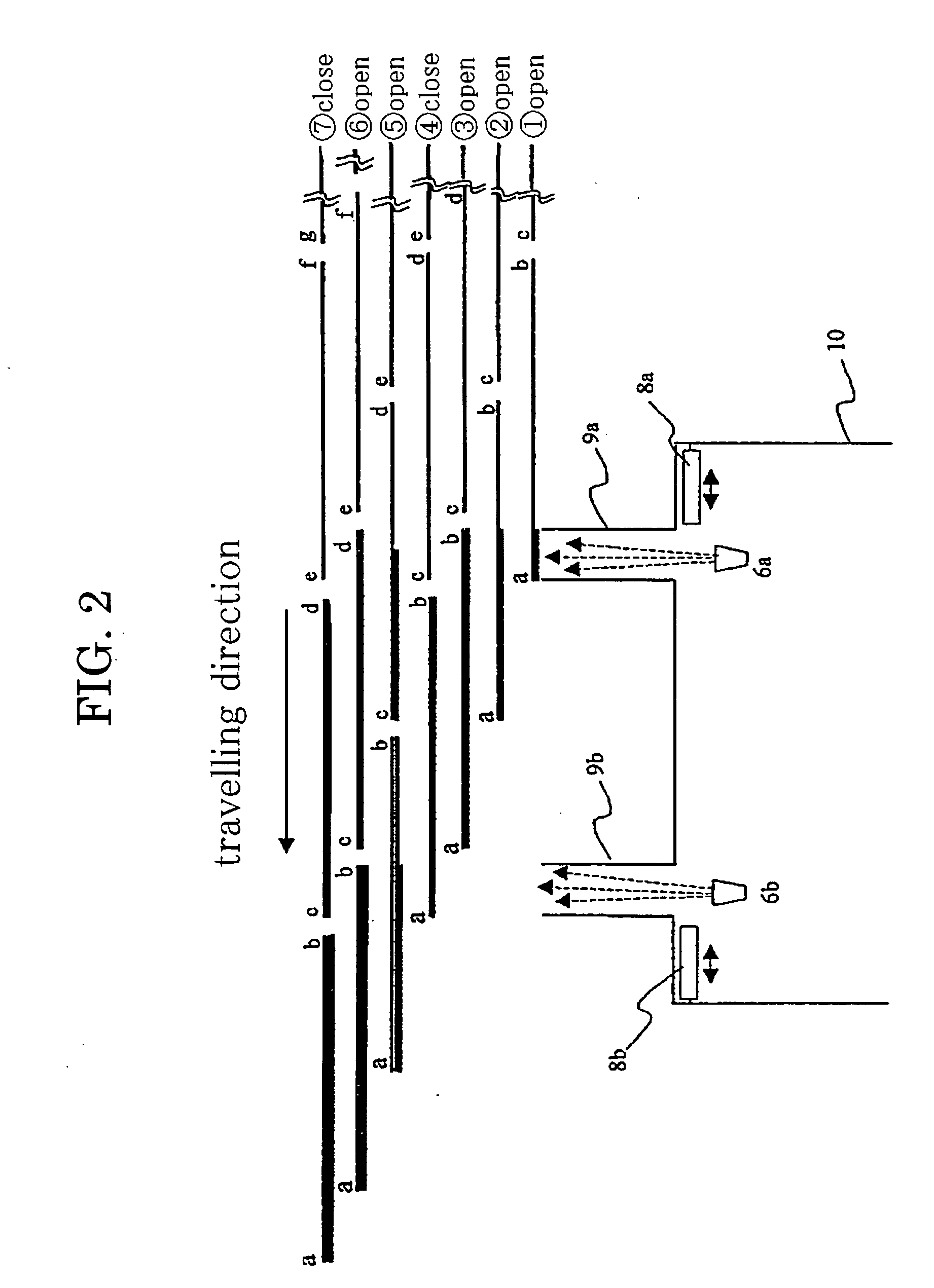

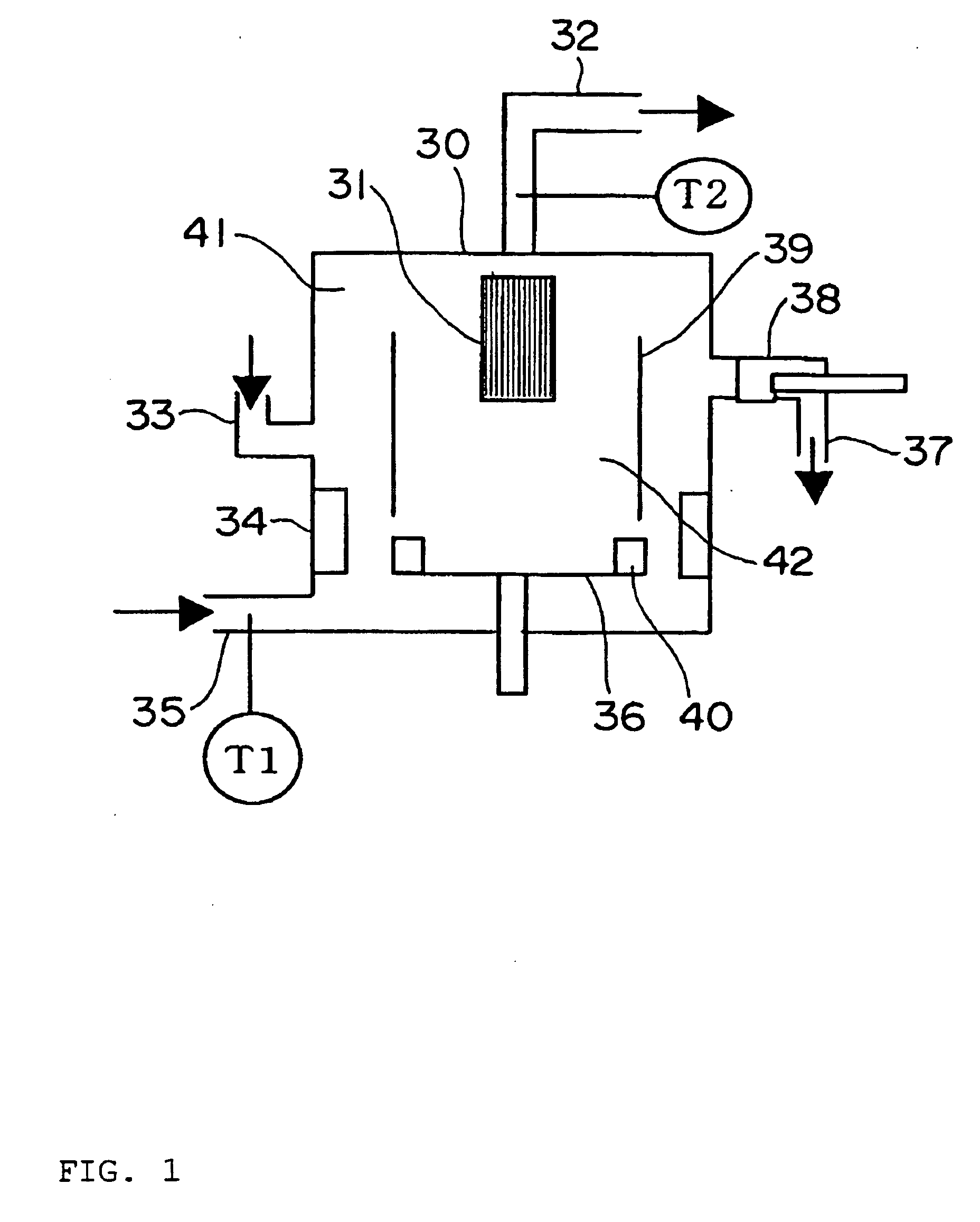

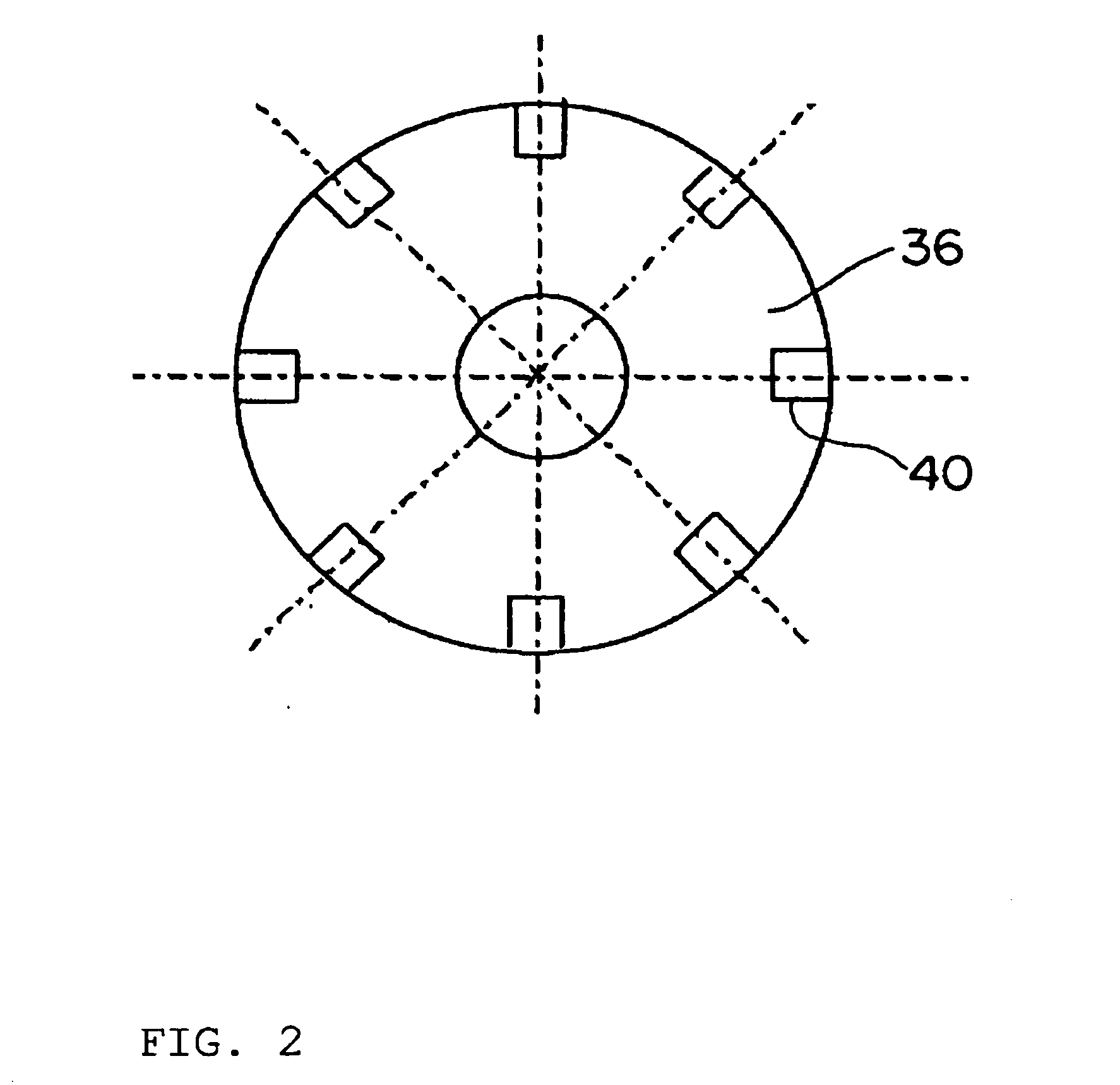

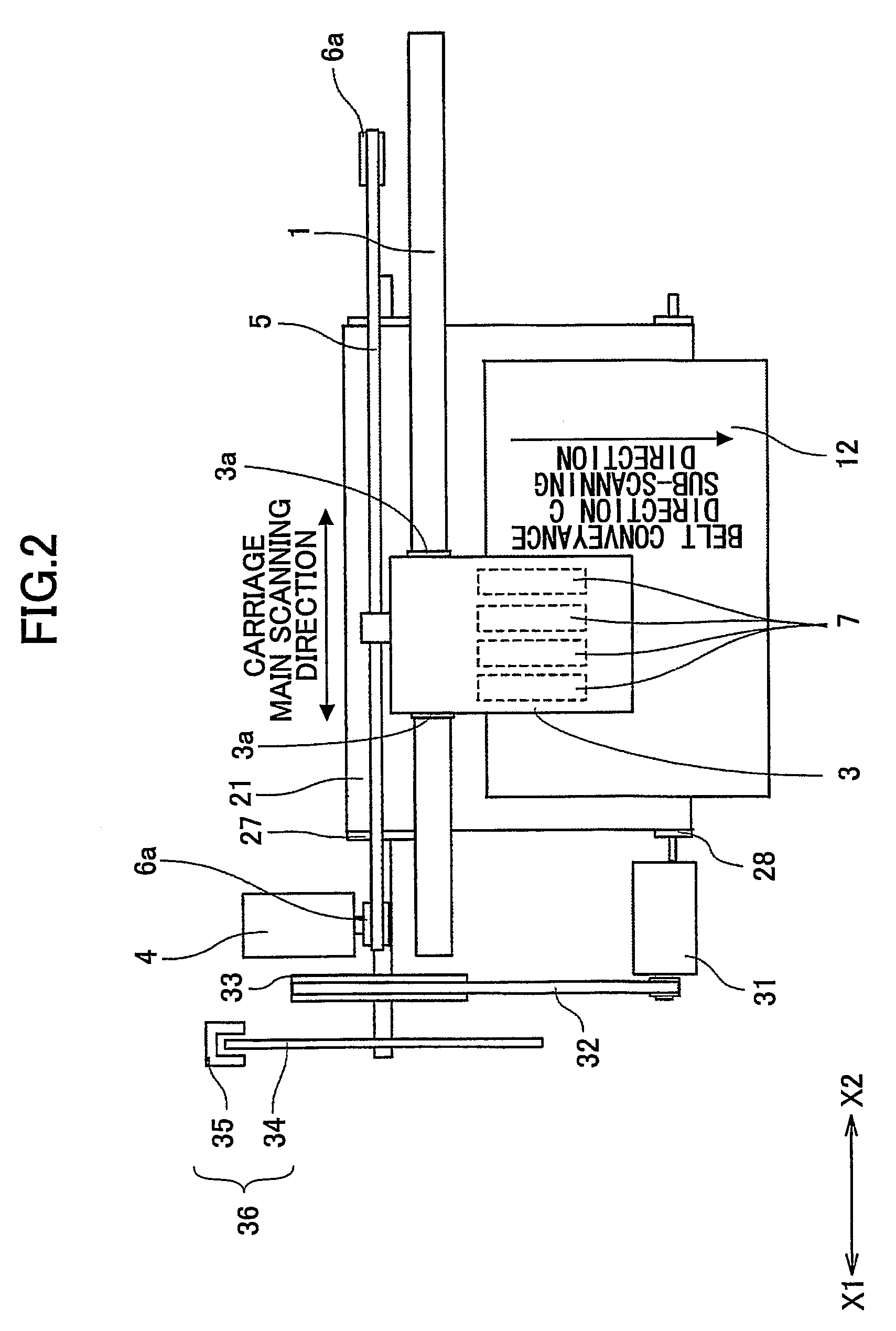

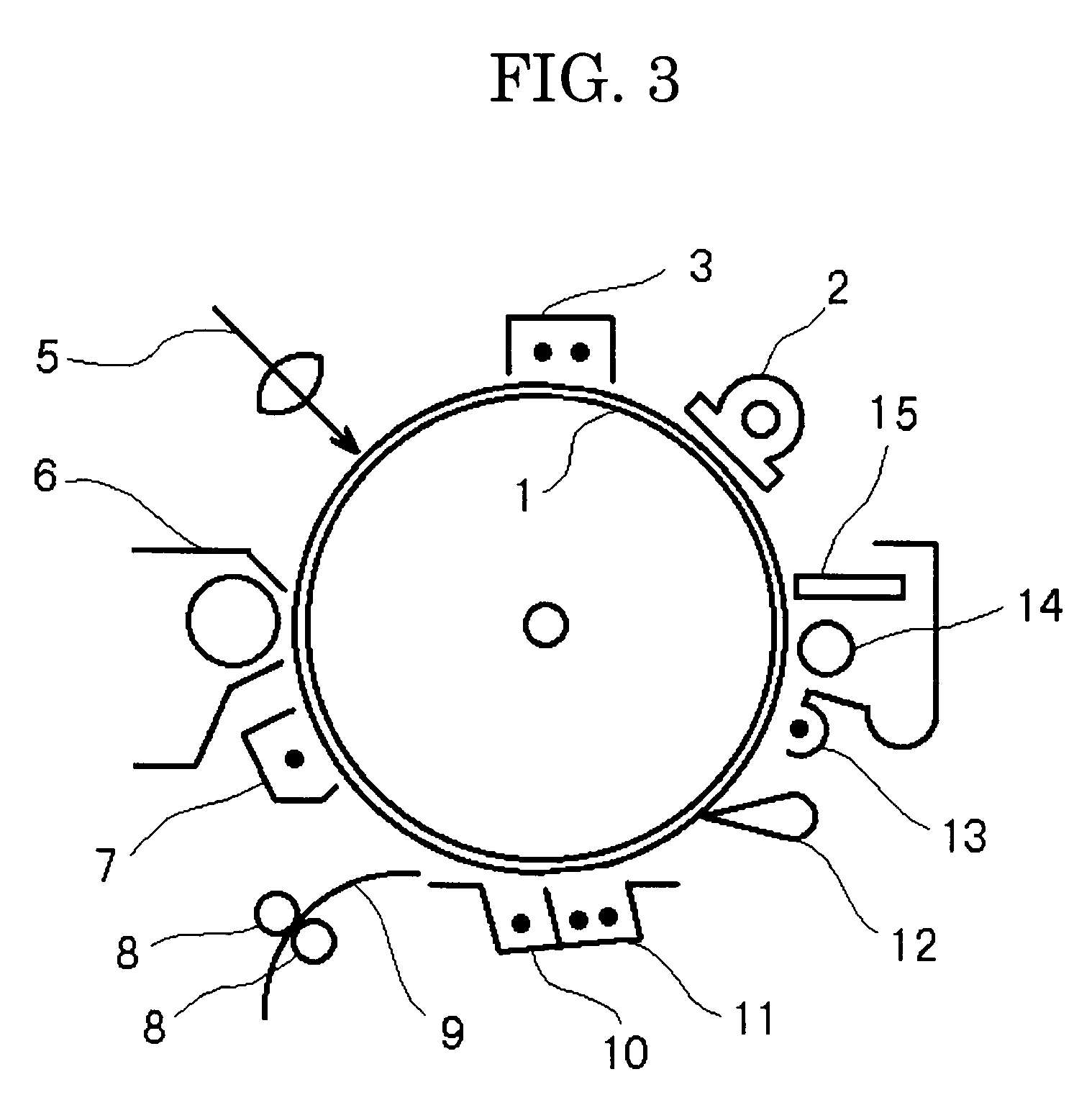

Device and method for vacuum film formation

InactiveUS20050008778A1High controllabilityStably formVacuum evaporation coatingSputtering coatingEngineeringVacuum deposition

A vacuum deposition apparatus is used for deposit evaporated substance from evaporation sources (6a and 6b) on the desired position of a flexible substrate (1). While the flexible substrate (1) is carried using rollers in a vacuum, shutters (8a and 8b) are opened and closed to control the movement of the evaporated substance via openings. A film having a desired shape of pattern is formed on the flexible substrate (1) with higher controllability.

Owner:NEC CORP

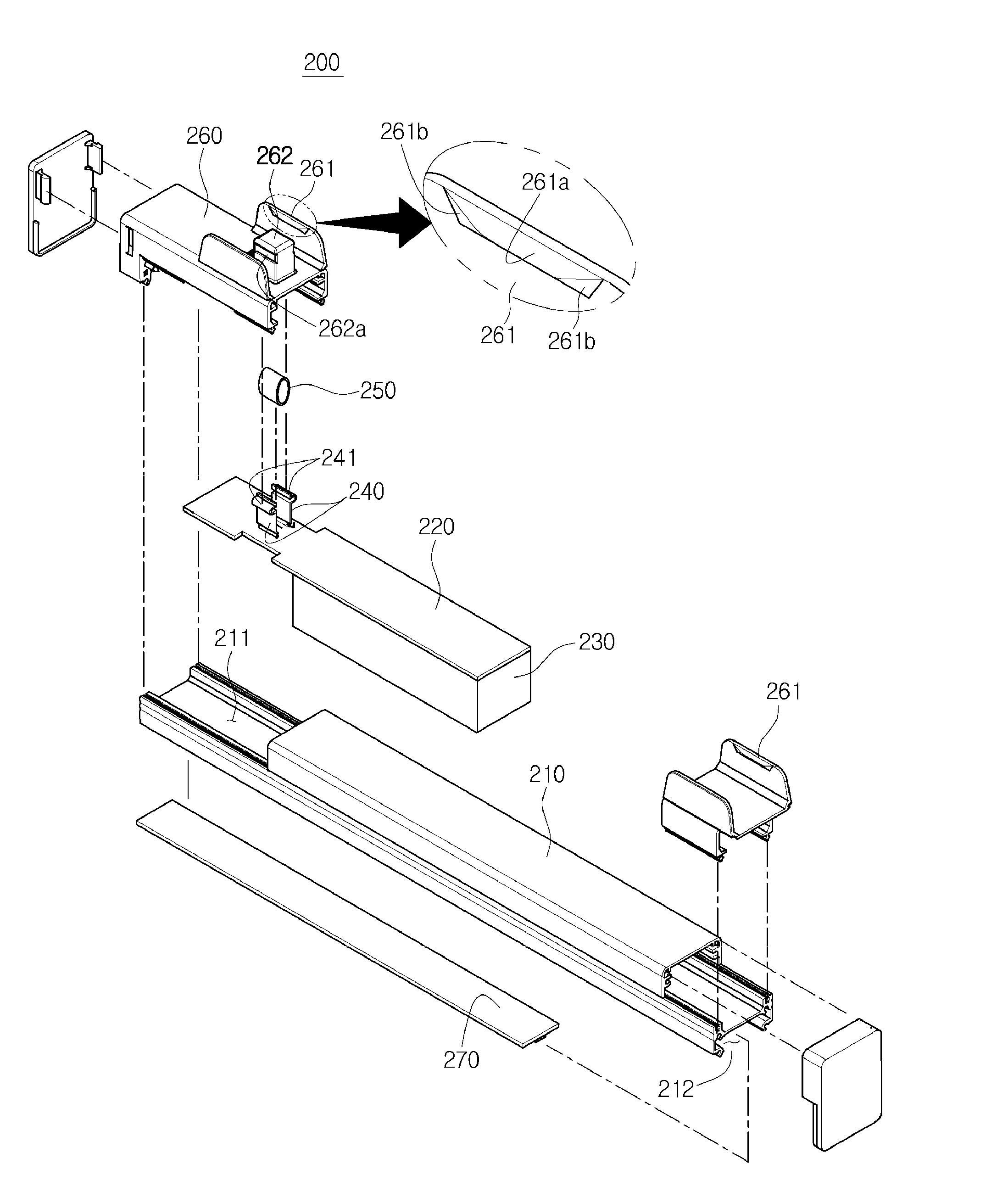

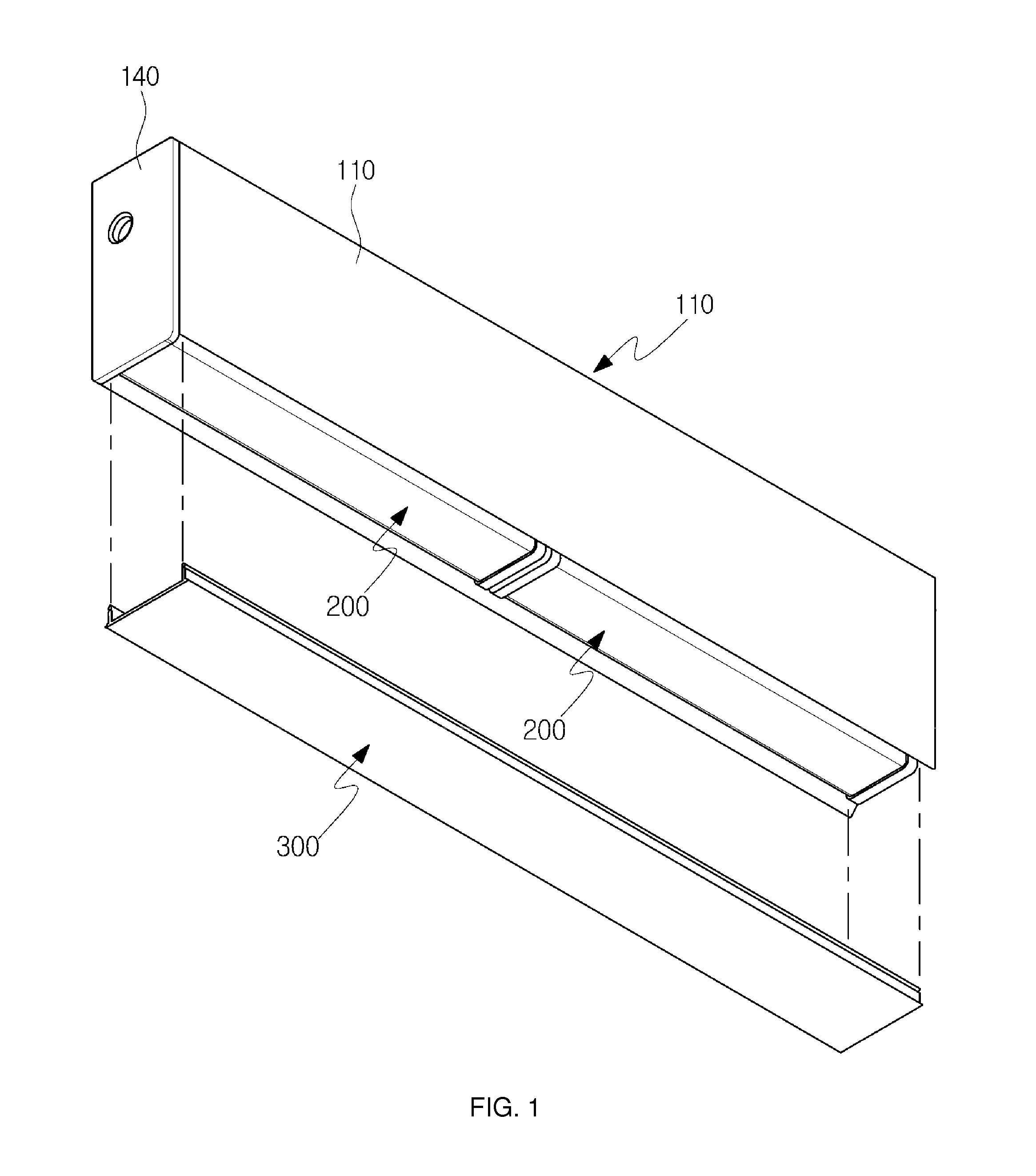

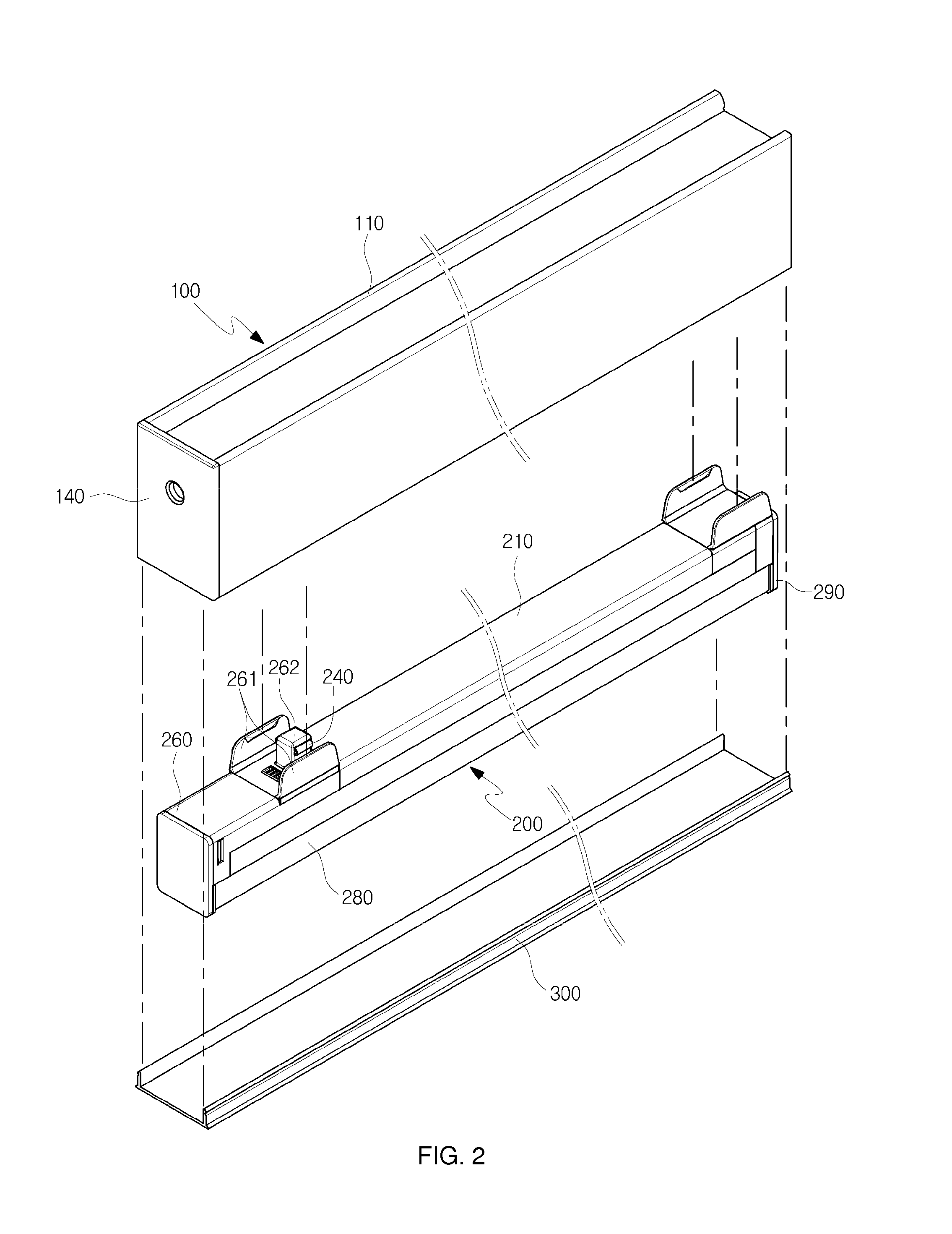

Bar-type lighting apparatus

ActiveUS20150226384A1Stably formReduce riskPoint-like light sourceLighting support devicesElectricityLight emitting device

A linear lighting device may include: an installation rail including a housing and a power supply terminal, the housing being fixed to an installation object surface and having an accommodating space formed therein, the accommodating space having an open side in one surface thereof, the power supply terminal being disposed in the accommodating space of the housing in a length direction thereof; at least one linear lighting module including a power connection terminal and a light emitting device, the power connection terminal being electrically connected to the power supply terminal, the light emitting device being electrically connected to the power connection terminal, the linear lighting module being detachably coupled to the accommodating space of the housing; and a light transmissive cover detachably coupled to the housing so as to close the open side of the accommodating space of the housing.

Owner:LINNO

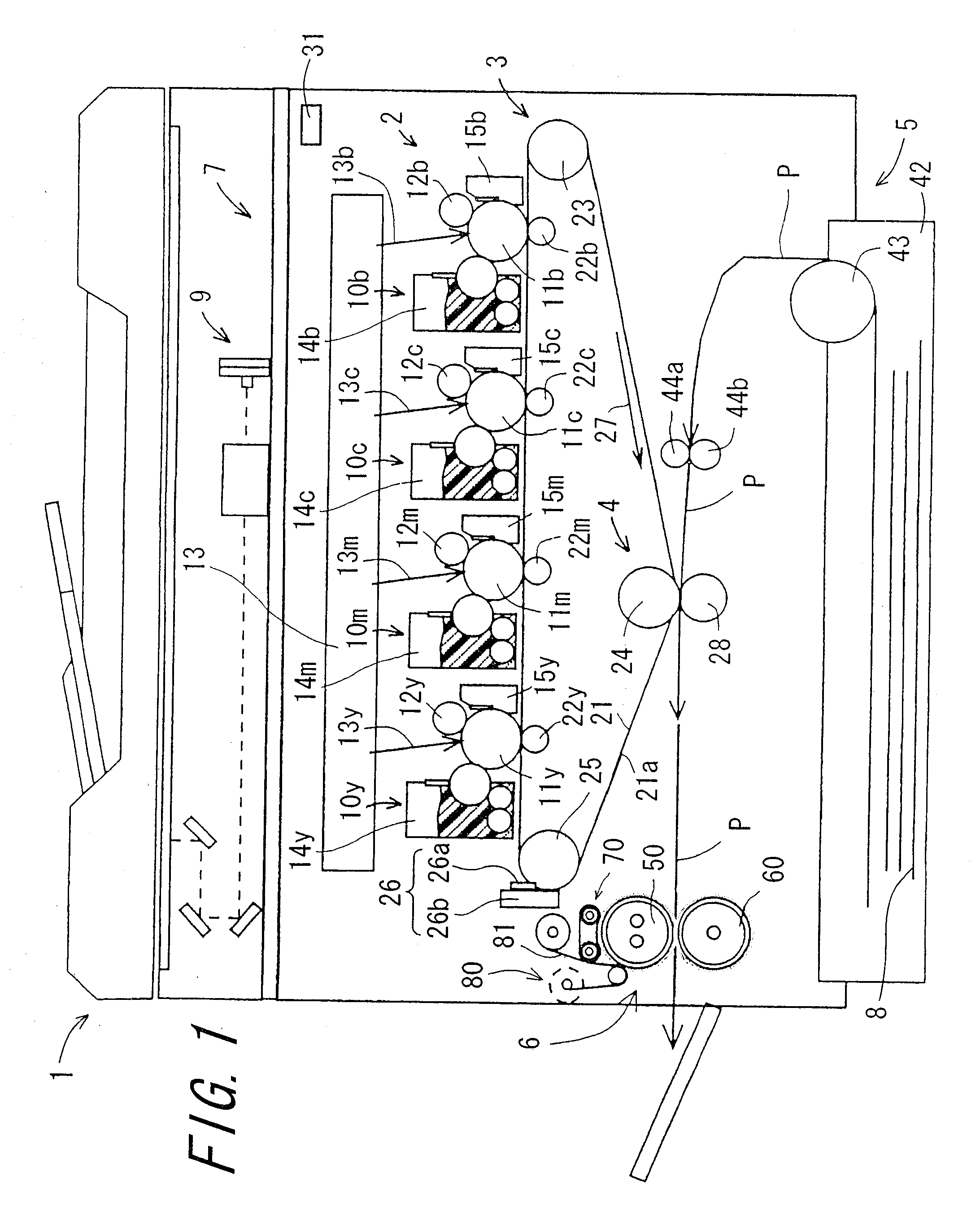

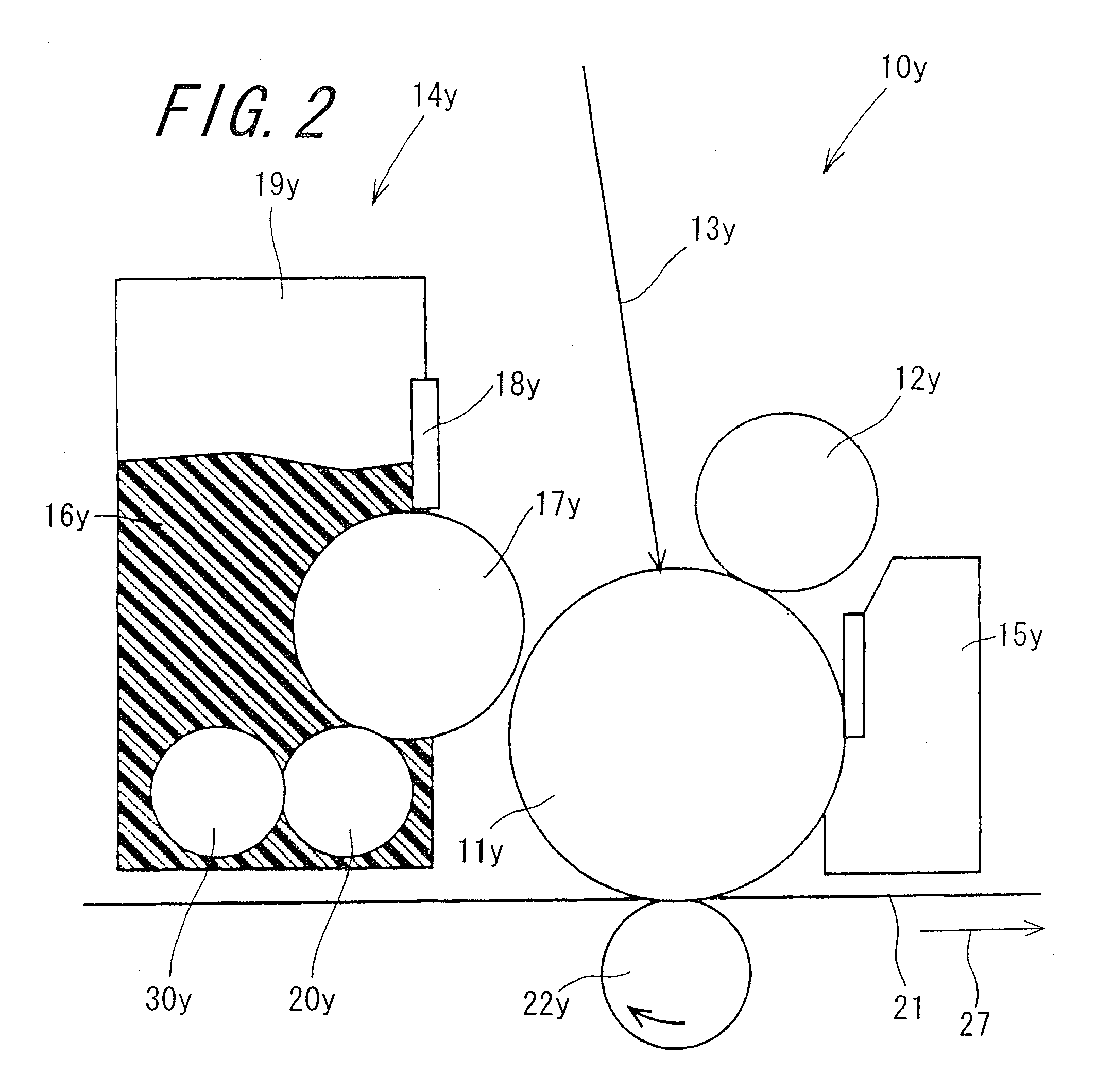

Color toner and two-component developer

The present invention relates to a toner which has good property such as fixability, coloring power, developability, durability, and environmental stability and so on. More specifically, the present invention relates to a color toner containing at least a binder resin, a colorant, and a wax, in which: a wax concentration of an extract obtained by dispersing the toner into n-hexane at a concentration of 15 mg / cm3 at 23° C. and by subjecting the resultant dispersion to extraction treatment at 23° C. for 1 minute is in the range of 0.080 to 0.500 mg / cm3; an average circularity of particles each having a circle-equivalent diameter of 3 μm or more in the toner is in the range of 0.925 to 0.965; and a content of the wax is in the range of 1 to 15 parts by mass with respect to 100 parts by mass of the binder resin.

Owner:CANON KK

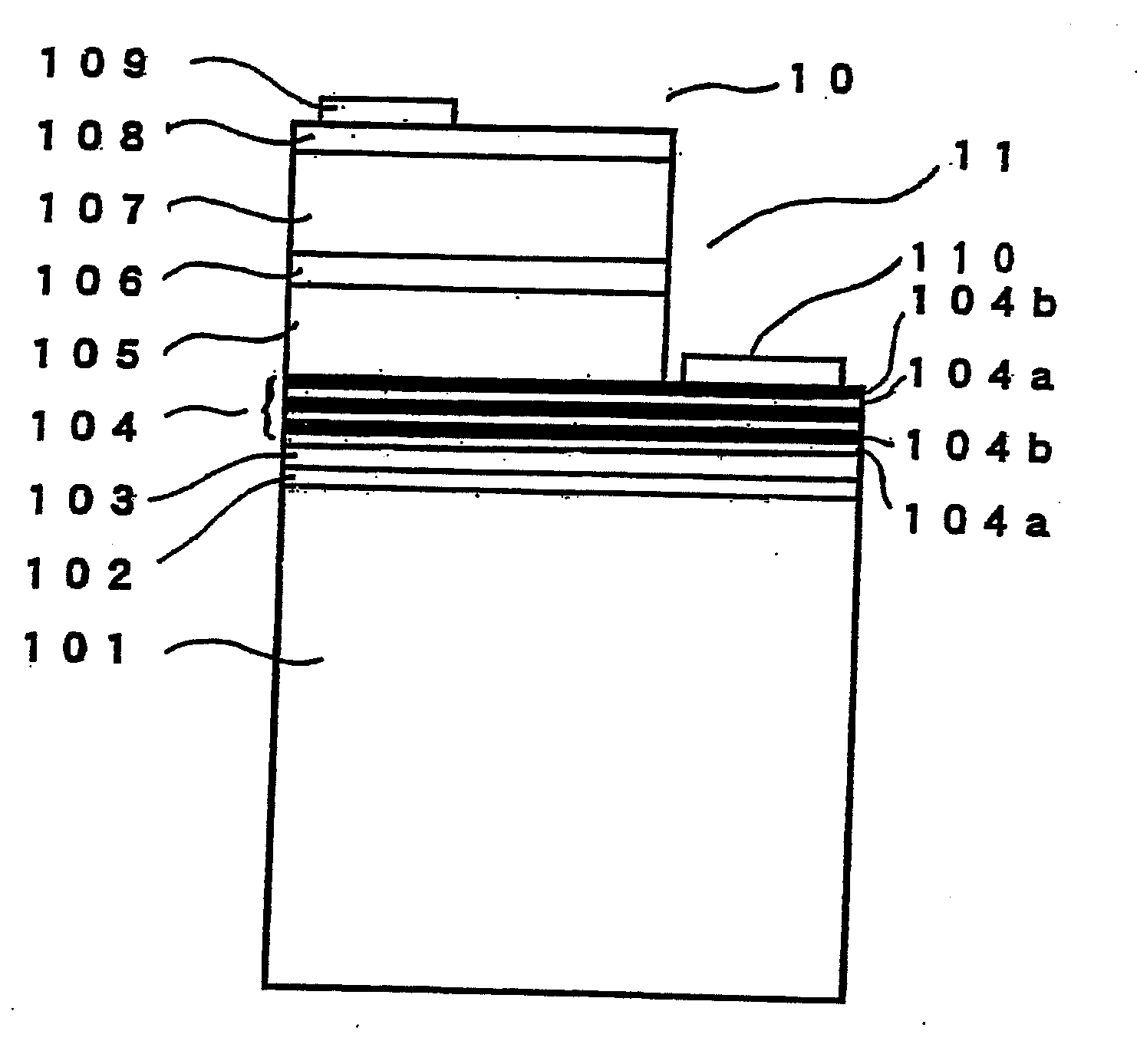

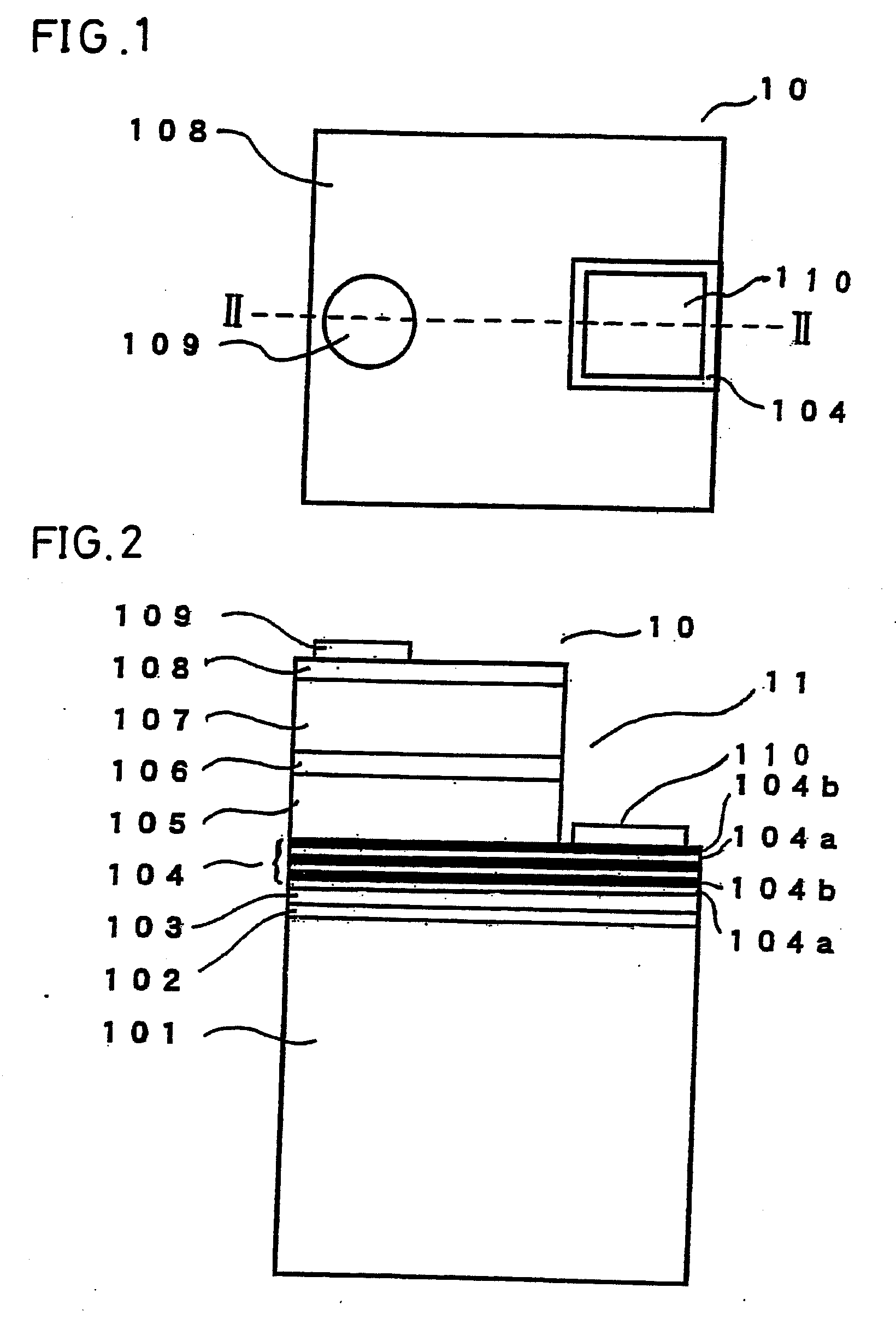

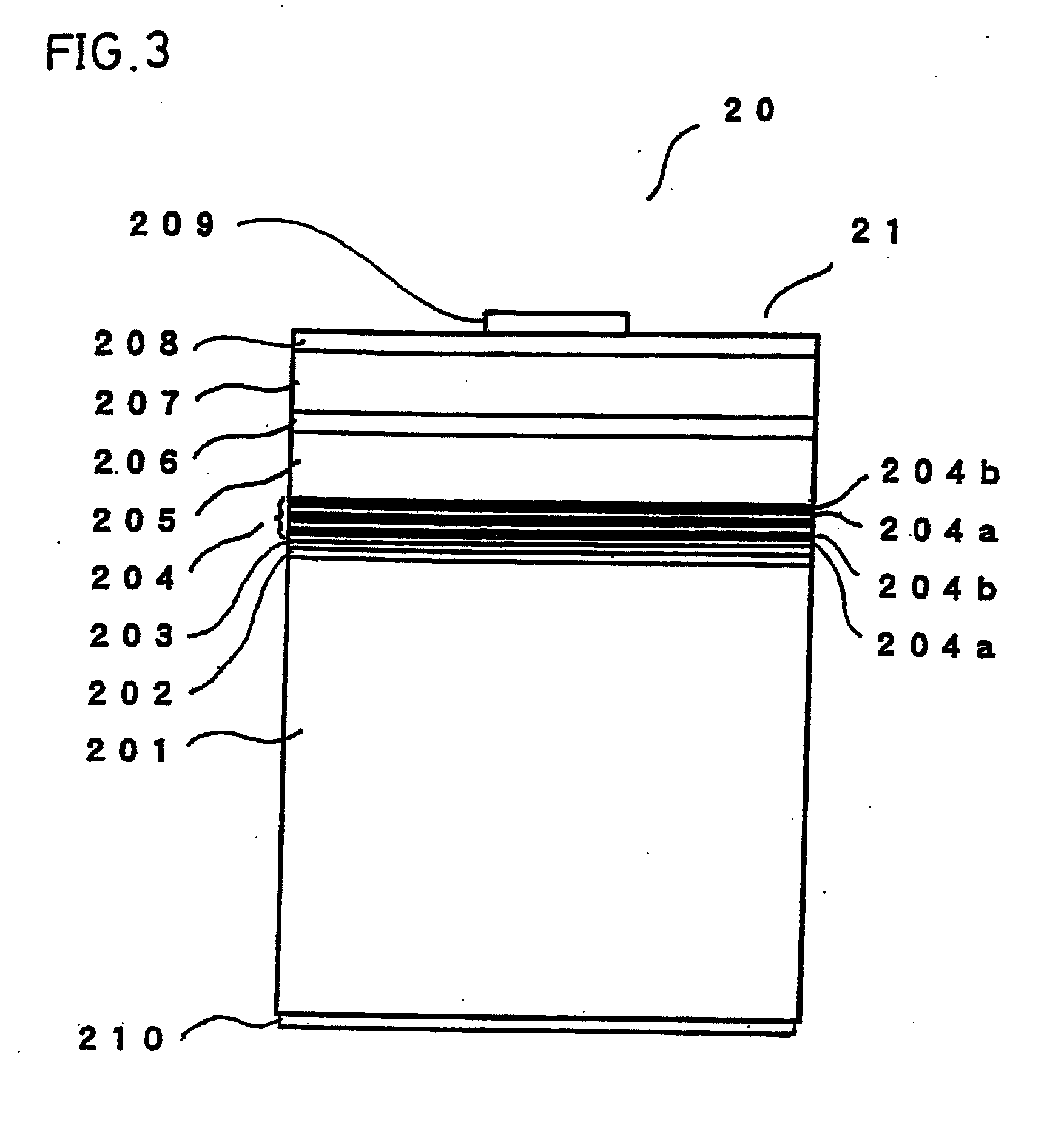

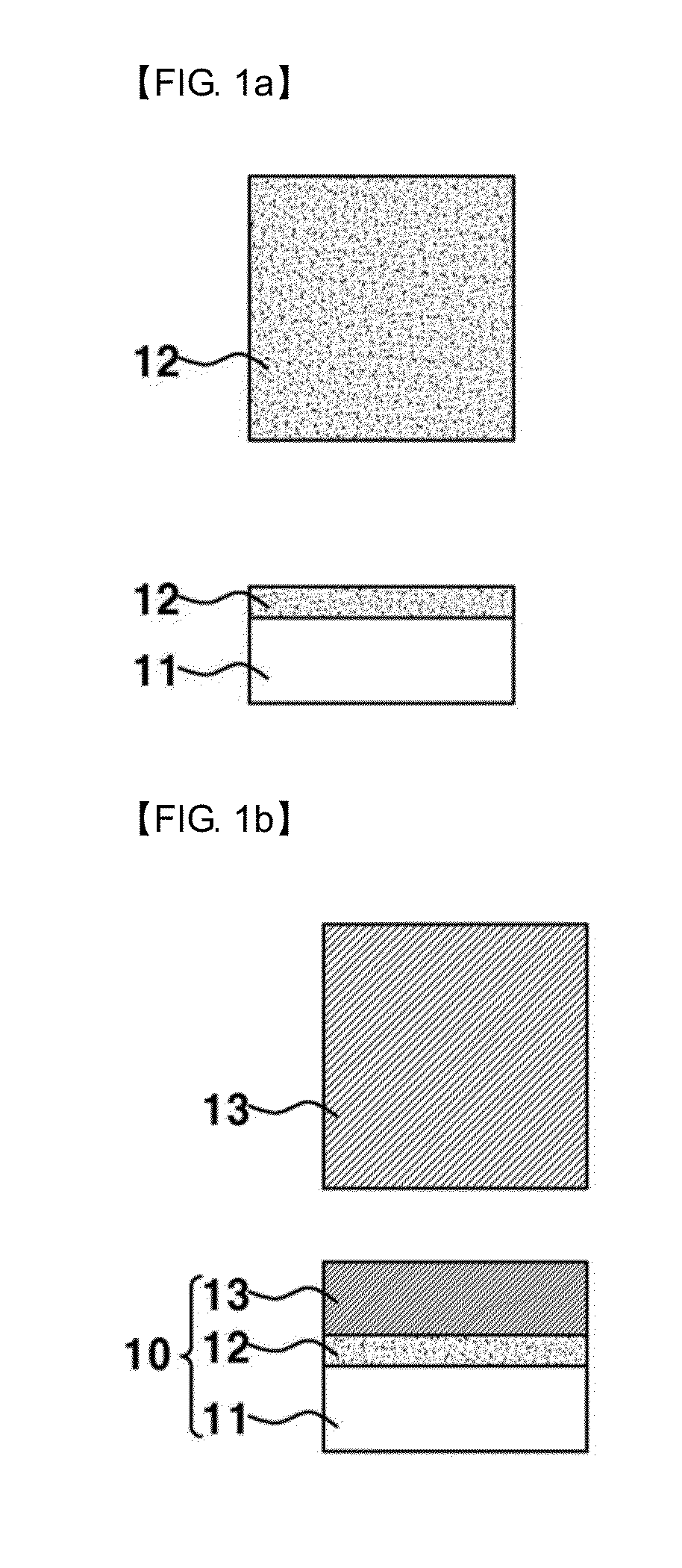

Semiconductor device and method of manufacturing the same

InactiveUS20090127583A1Excellent crystallinityStably formPolycrystalline material growthSolid-state devicesSuperlatticeNitrogen

Provided is a semiconductor device containing a silicon single crystal substrate 101, a silicon carbide layer 102 provided on a surface of the substrate, a Group III nitride semiconductor junction layer 103 provided in contact with the silicon carbide layer, and a superlattice-structured layer 104 constituted by Group III nitride semiconductors on the Group III nitride semiconductor junction layer. In this semiconductor device, the silicon carbide layer is a layer of a cubic system whose lattice constant exceeds 0.436 nm and is not more than 0.460 nm and which has a nonstoichiometric composition containing silicon abundantly in terms of composition, and the Group III nitride semiconductor junction layer has a composition of AlxGayInzN1-αMα (0≦X, Y, Z≦1, X+Y+Z=1, 0≦α<1, M is a Group V element except nitrogen).

Owner:SHOWA DENKO KK +1

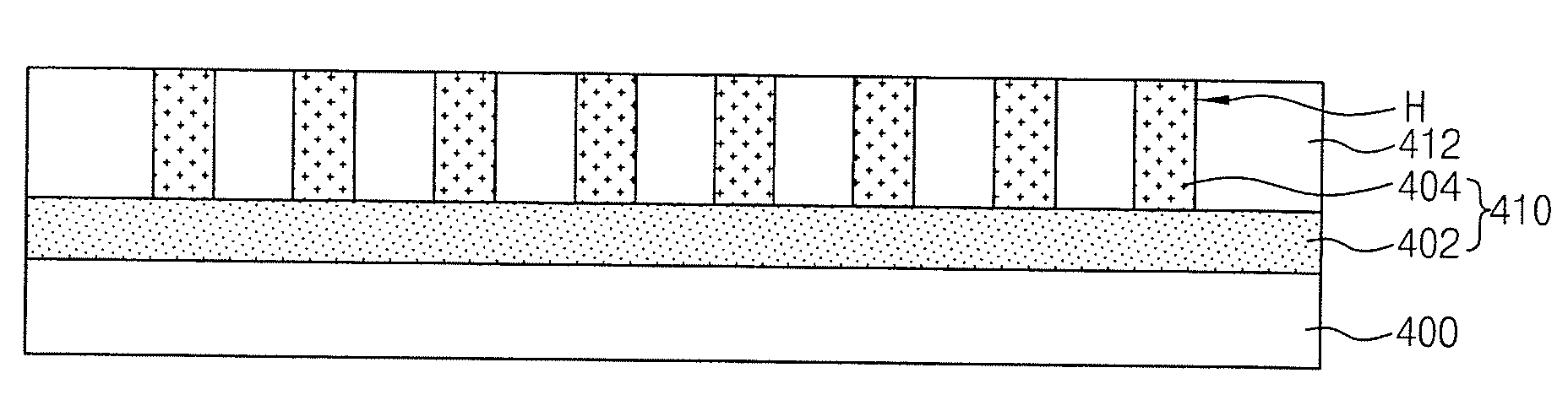

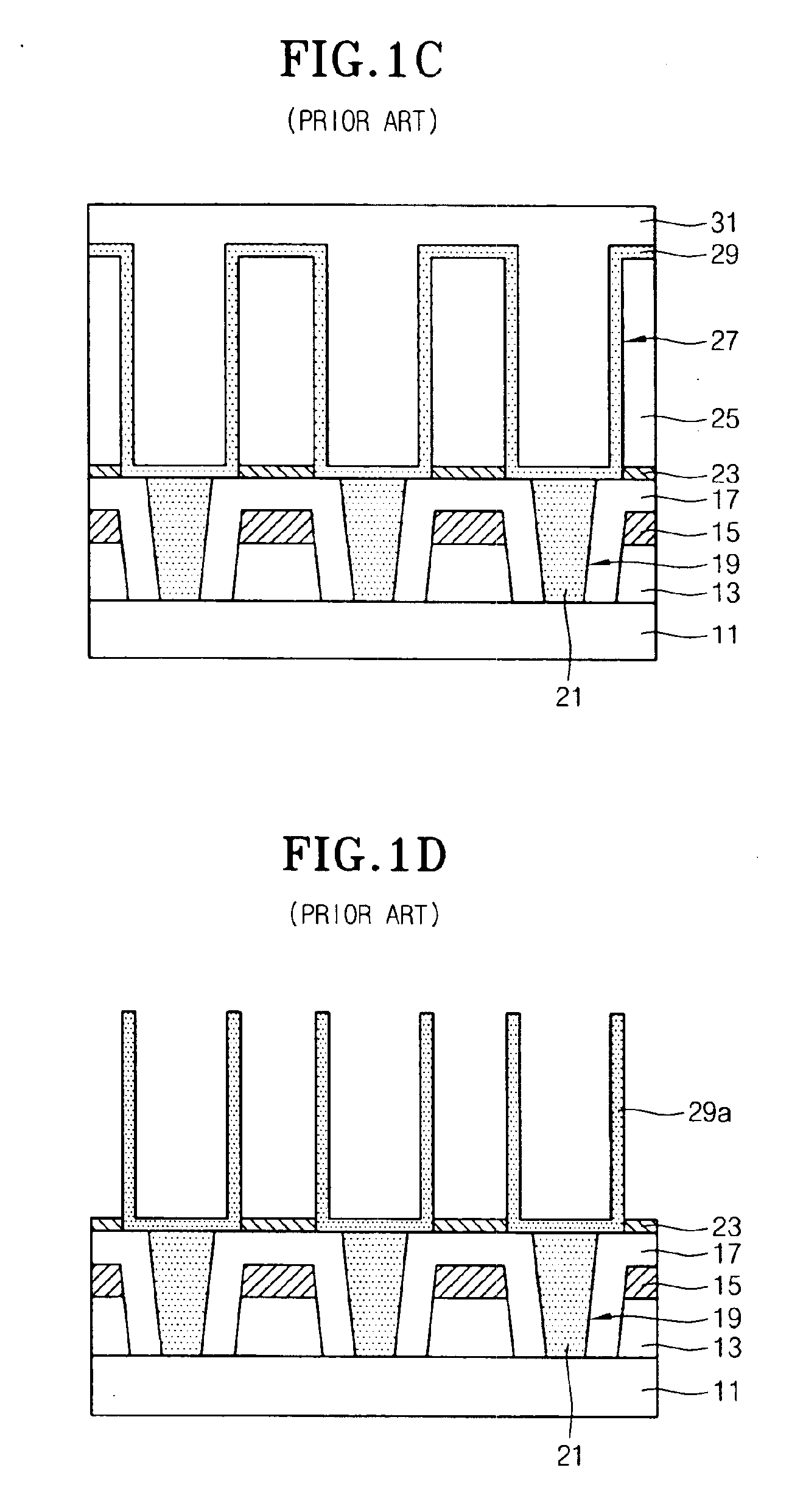

Method for forming a pn diode and method of manufacturing phase change memory device using the same

InactiveUS20080280440A1Stably formStably form P-regionsSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsPn diode

Disclosed is a method of forming a PN diode and a method of manufacturing a phase change memory device using the same. Formation of a PN diode includes forming a first conductivity type region in a surface of a semiconductor substrate. A polysilicon layer doped with second conductivity type impurities is then deposited on the semiconductor substrate formed with the first conductivity type region. Forming a plurality of second conductivity type regions by etching the polysilicon layer doped with the second conductivity type impurities completes the PN diode. Since the P-regions of a PN diode are formed through the deposition and etching of a polysilicon layer doped with second conductivity type impurities rather than an SEG process, a uniformity of resistance in the PN diode can be obtained.

Owner:SK HYNIX INC

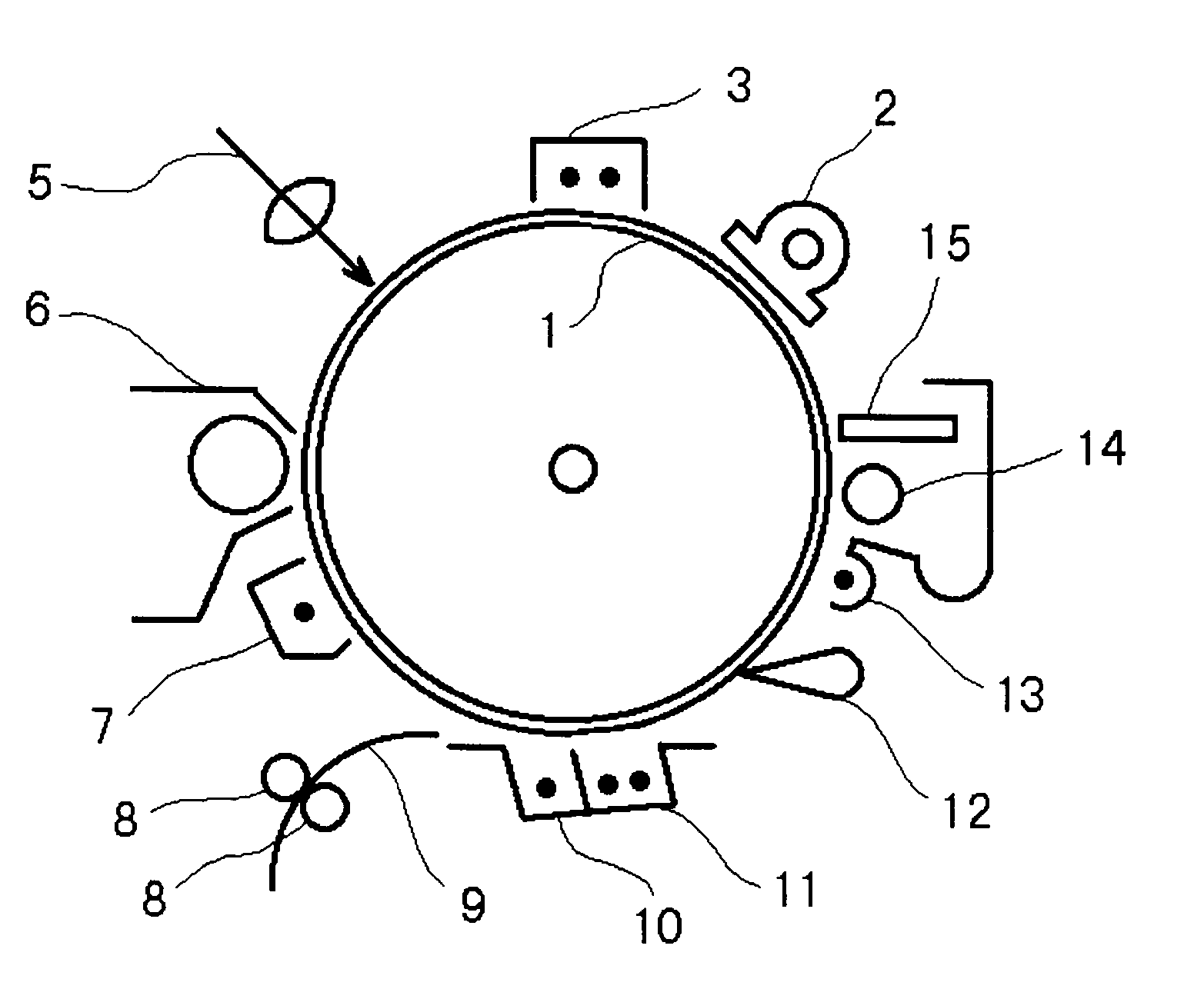

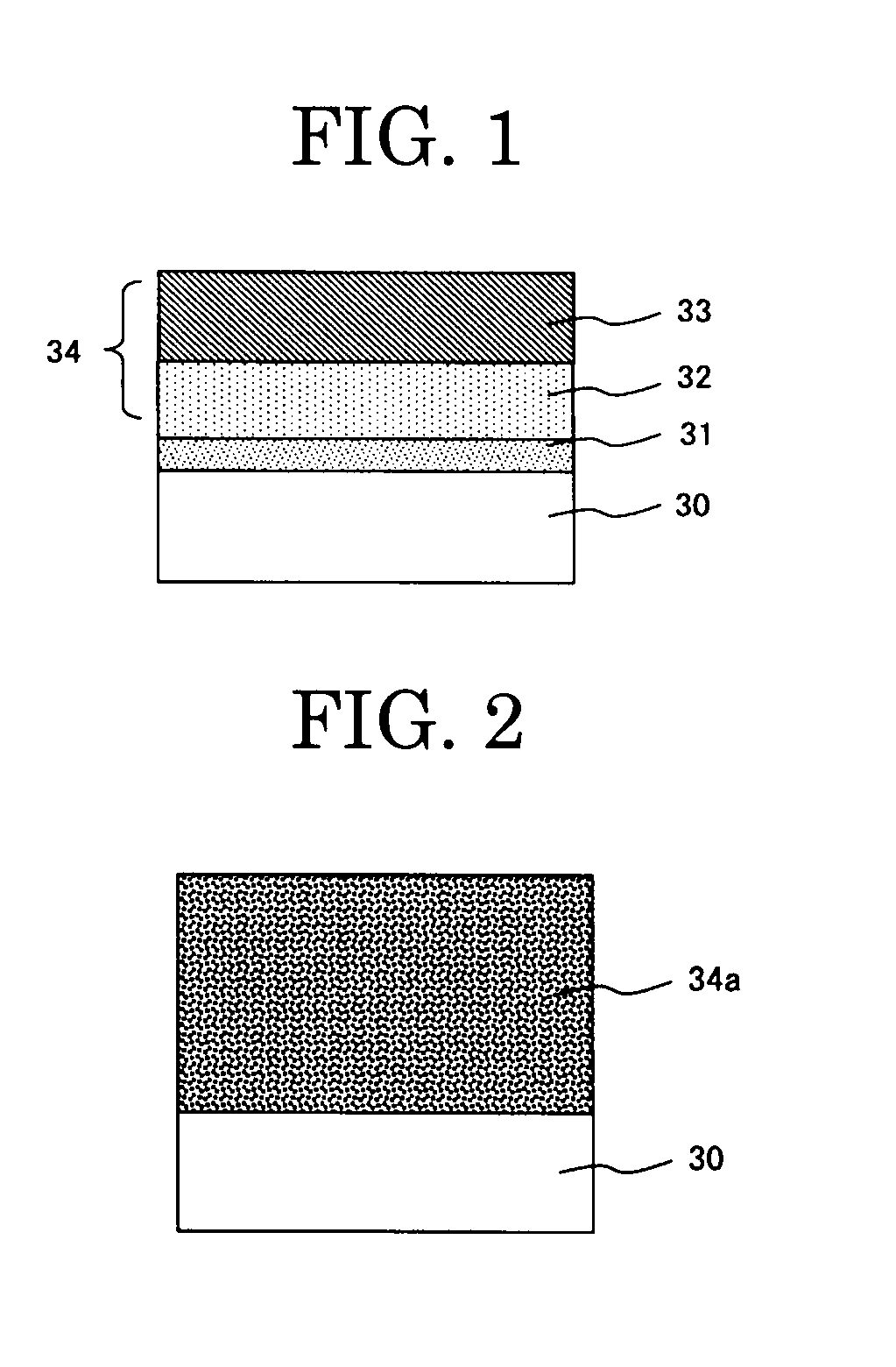

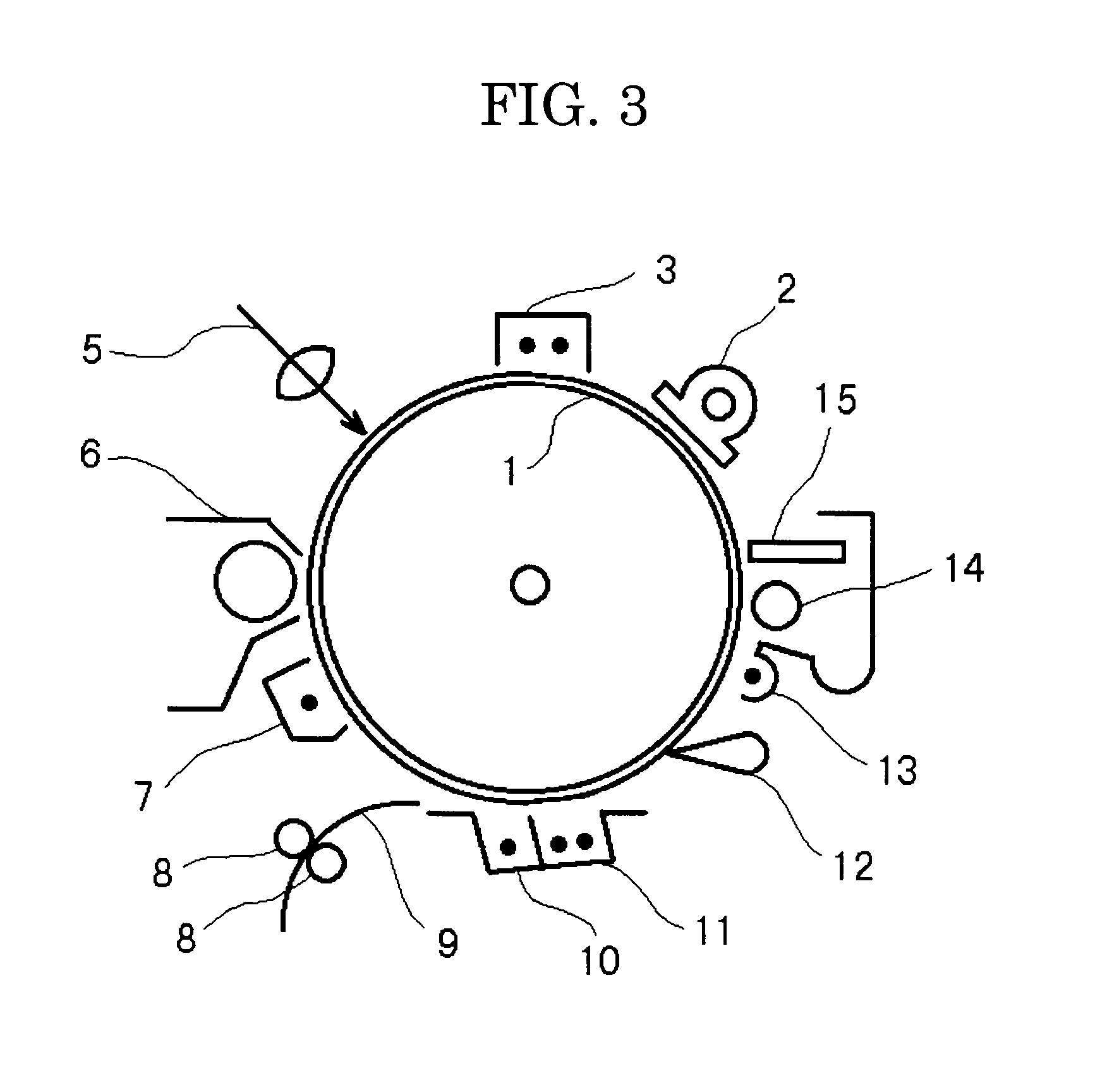

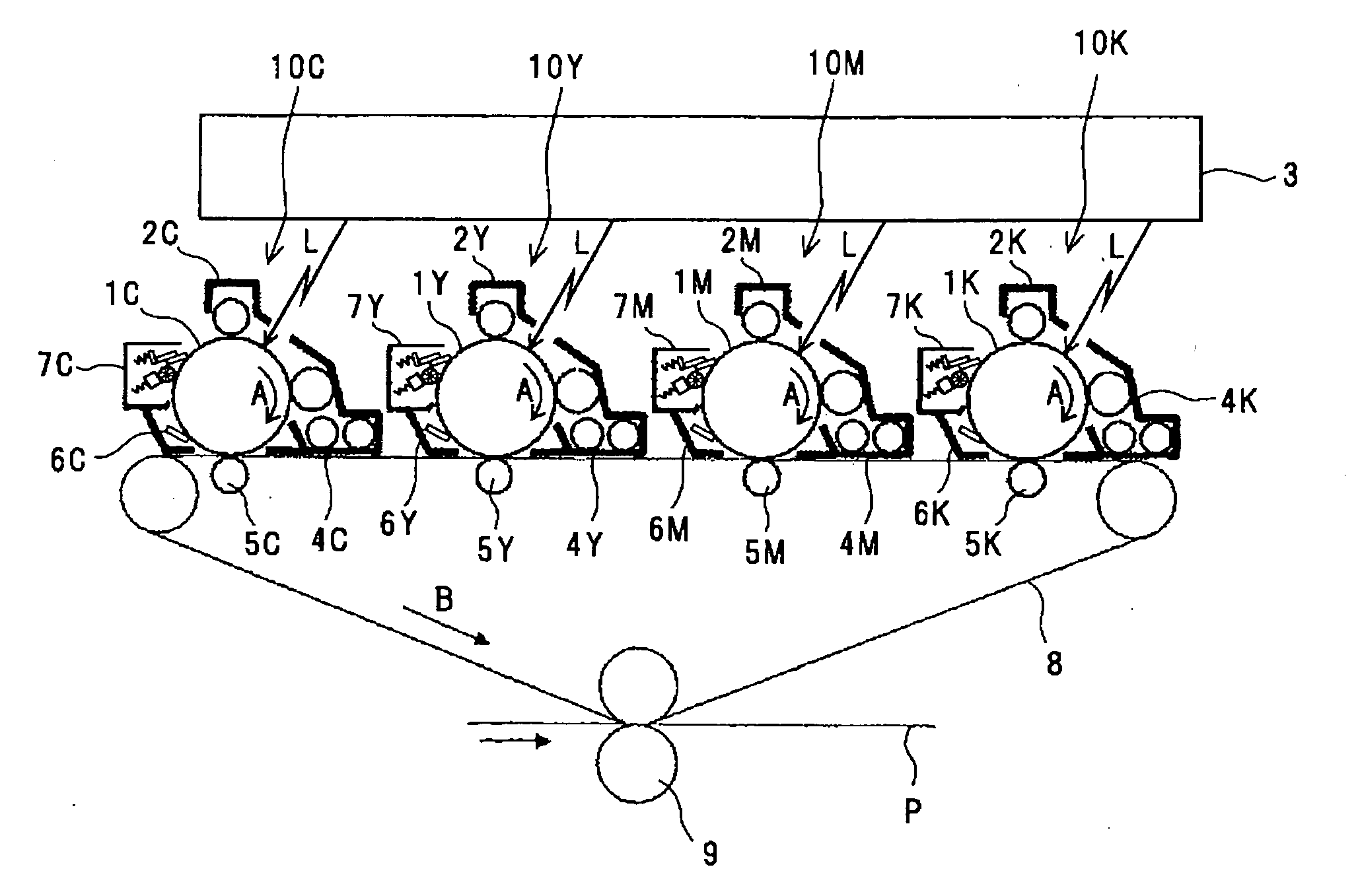

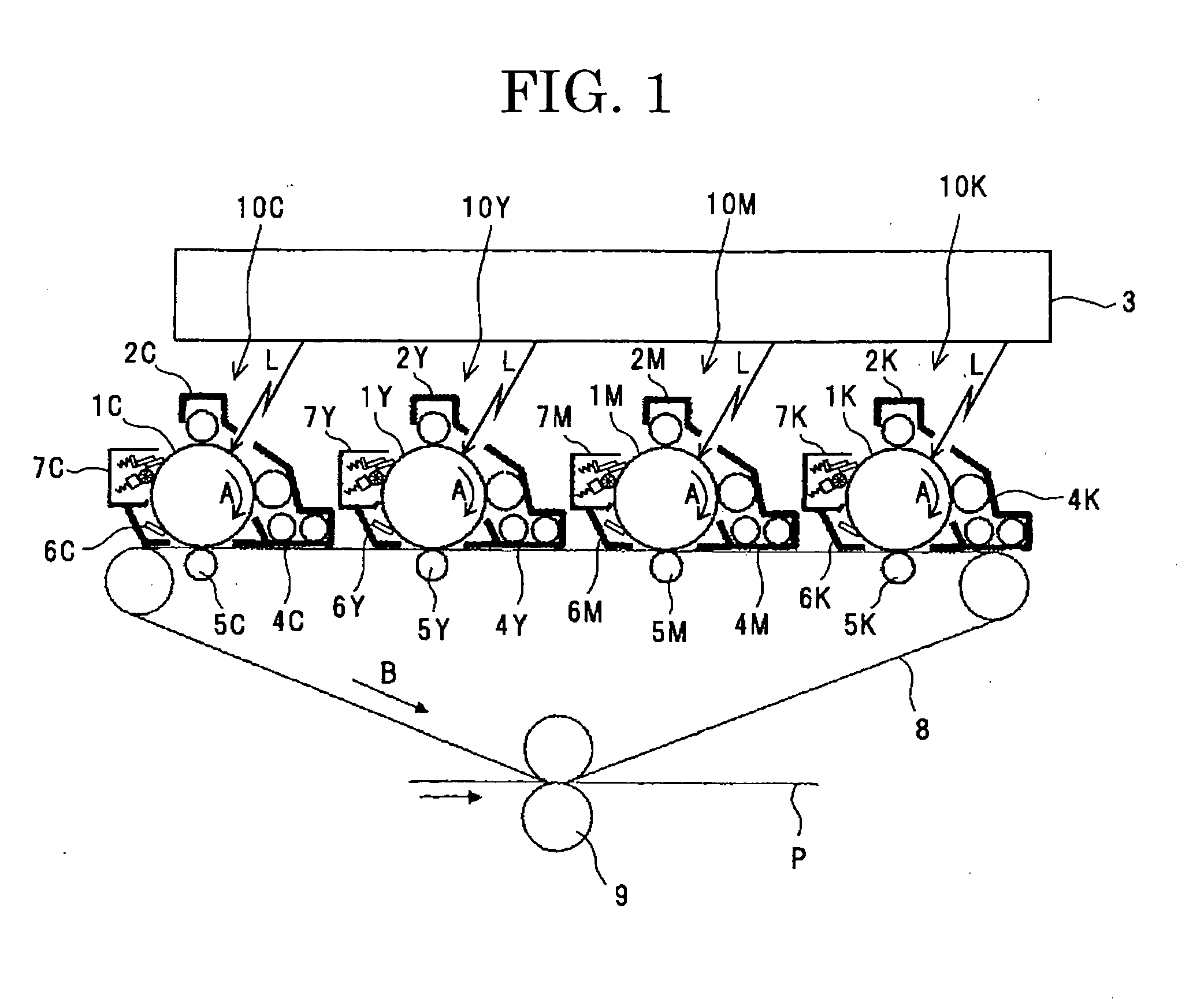

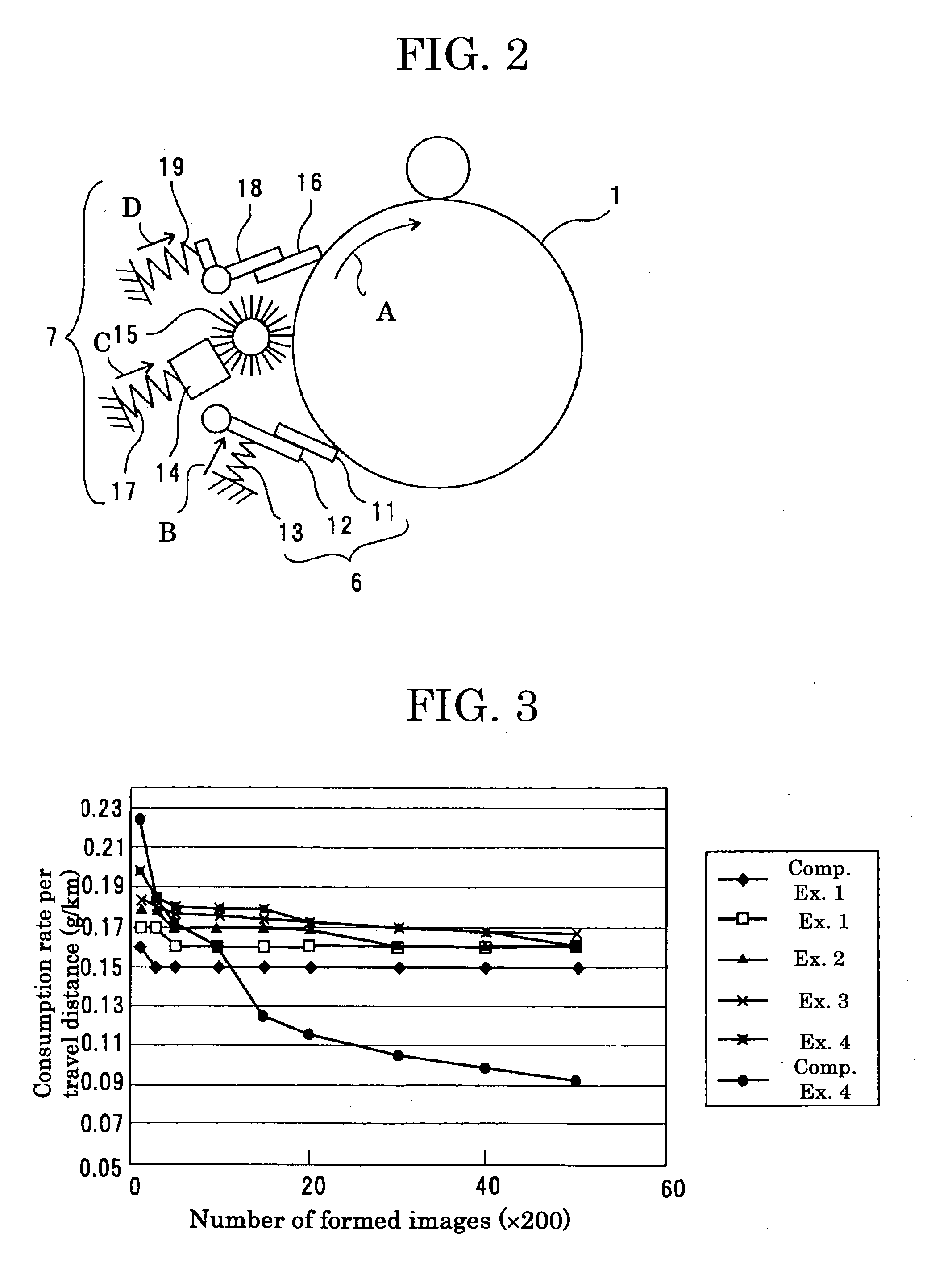

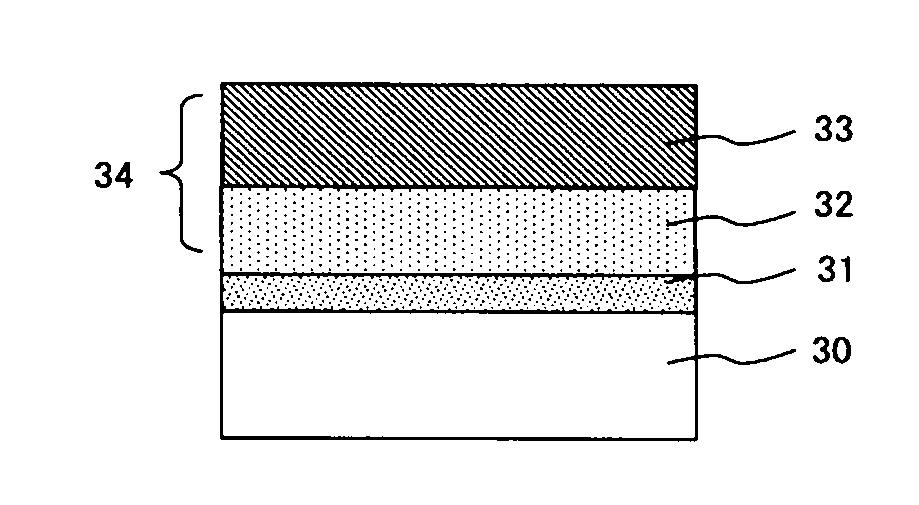

Electrophotographic photoconductor, and electrophotographic method, electrophotographic apparatus and process cartridge containing the electrophotographic photoconductor

InactiveUS20100290807A1Promote degradationIncreased durabilityElectrographic process apparatusCorona dischargeHydrogenElectrical conductor

An electrophotographic photoconductor including a conductive substrate and a photoconductive layer thereover, wherein the photoconductive layer contains a charge generation agent and a charge transport agent represented by General Formula (A-I), (B-I) or (C-I), and an amine compound represented by General Formula (II):where R1-3 each represent hydrogen, halogen or (un)substituted C1-6 alkyl, and n is 1 or 2,where R1-2 each represent C1-6 alkyl and R3-6 each represent hydrogen, halogen or (un)substituted C1-6 alkyl,where R8-33 each represent hydrogen, C1-4 alkyl, C1-4 alkoxy, or (un)substituted phenyl, and may be identical or different,where A and B each represent a group represented by formula (i) or (ii), and may be identical or different:—CH2X formula (i)—CH2CH2Y formula (ii)where X and Y each represent an (un)substituted aromatic group.

Owner:RICOH KK

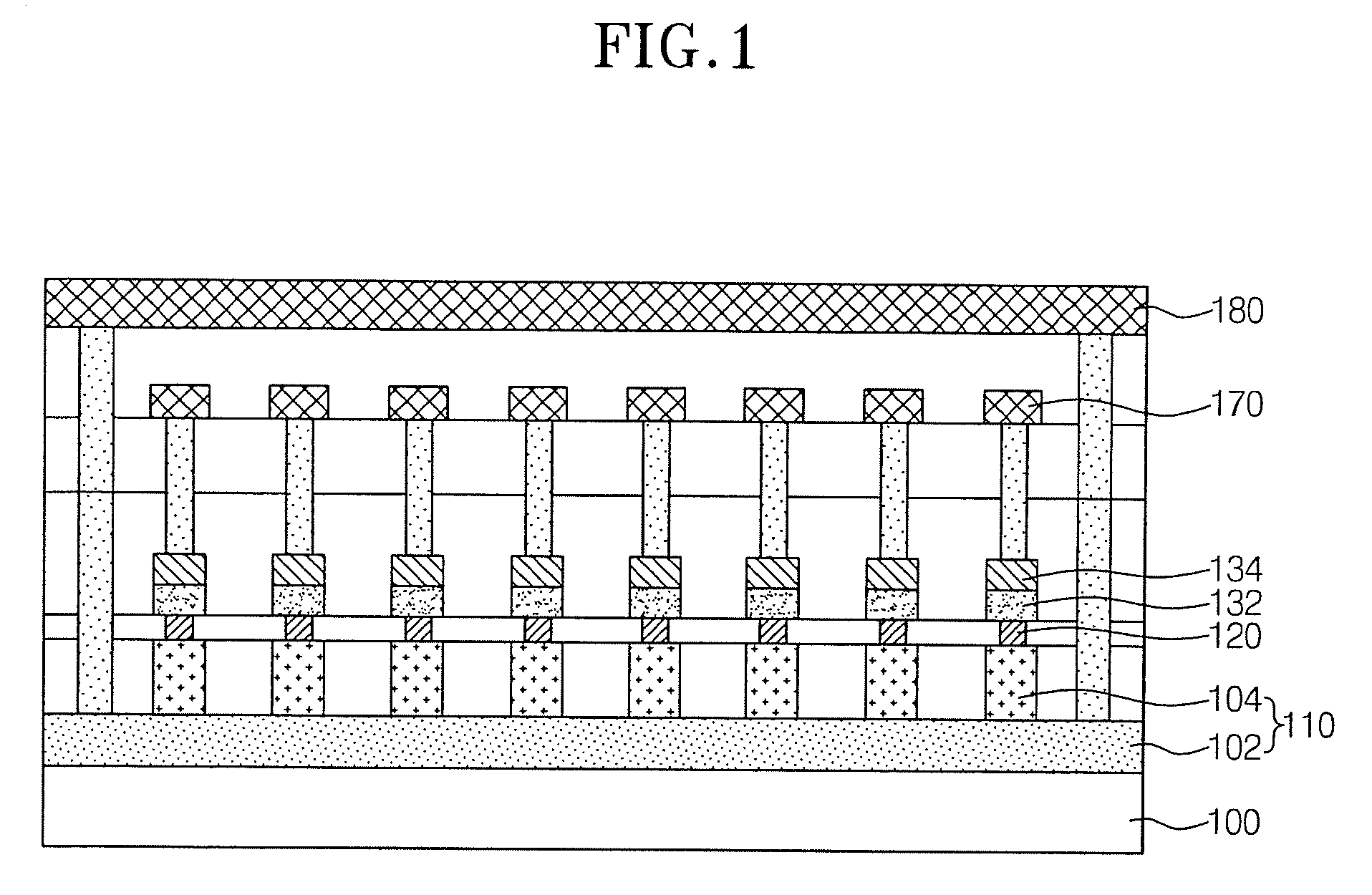

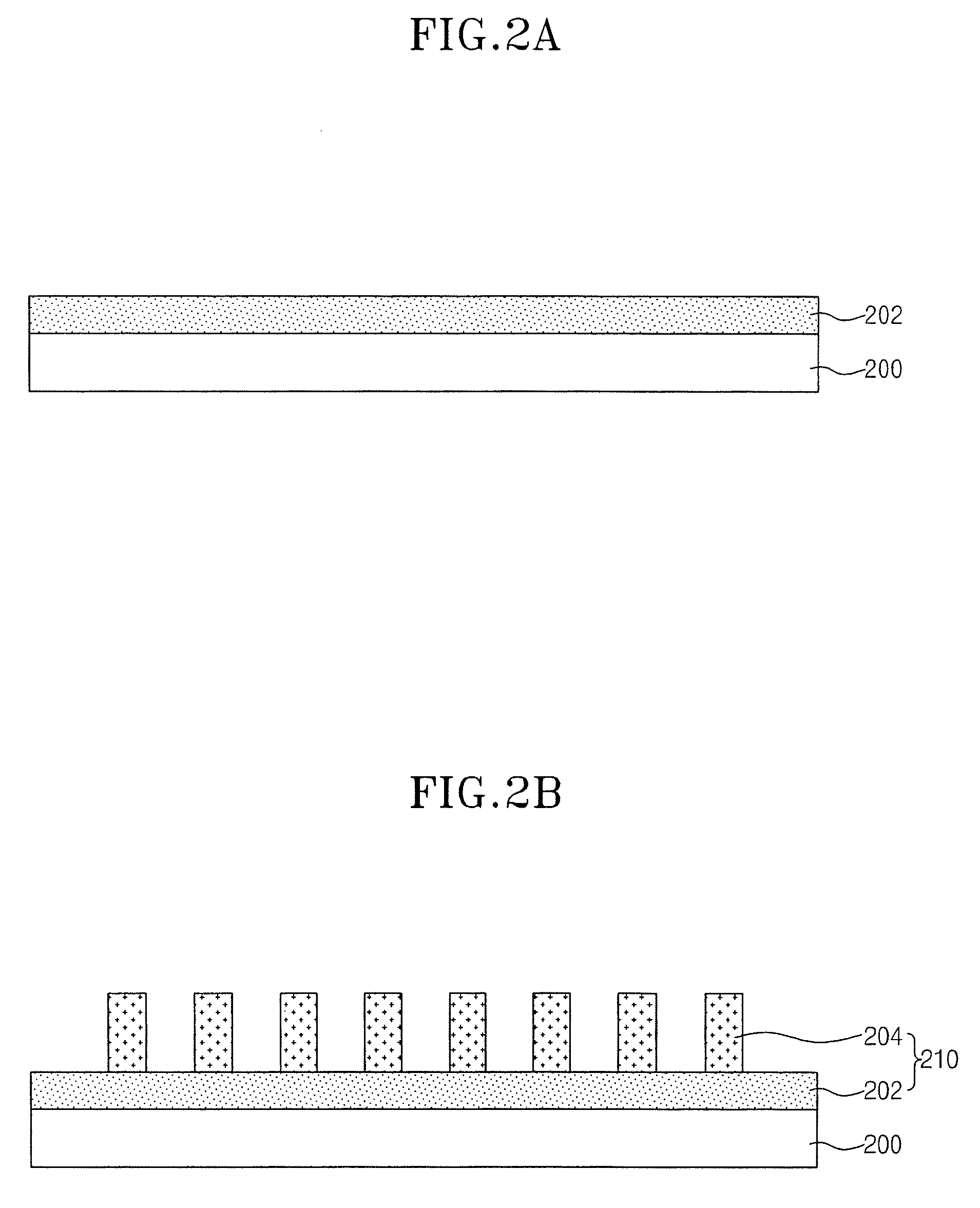

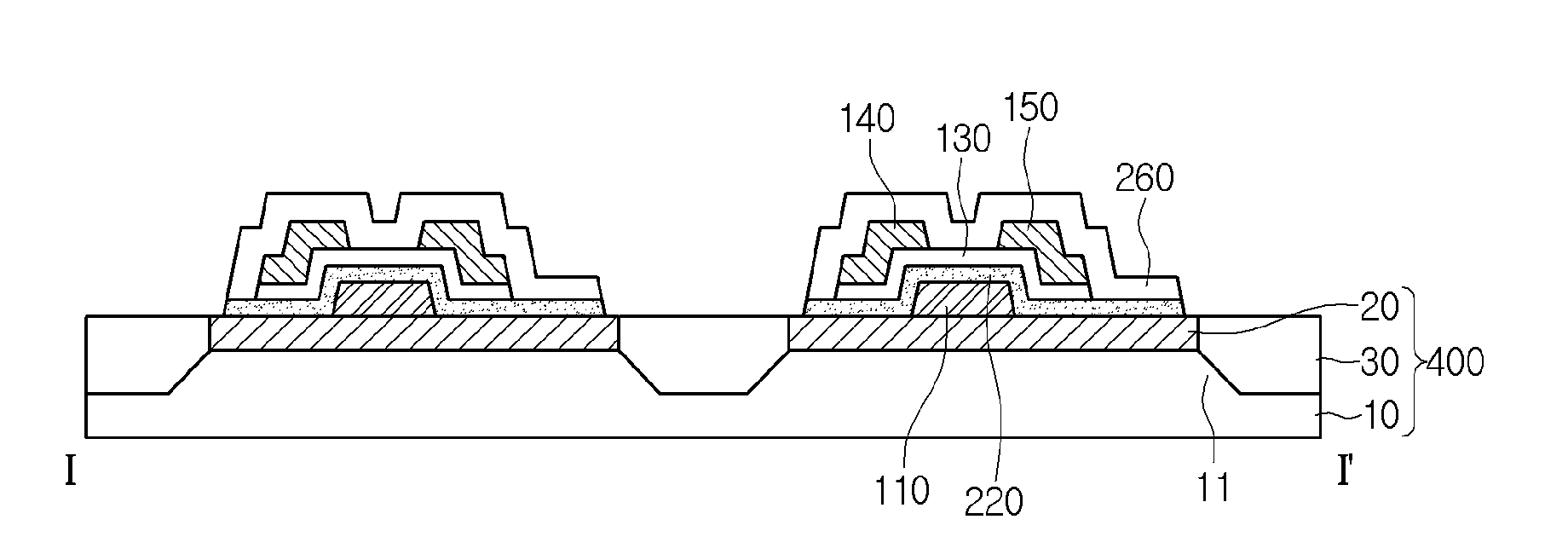

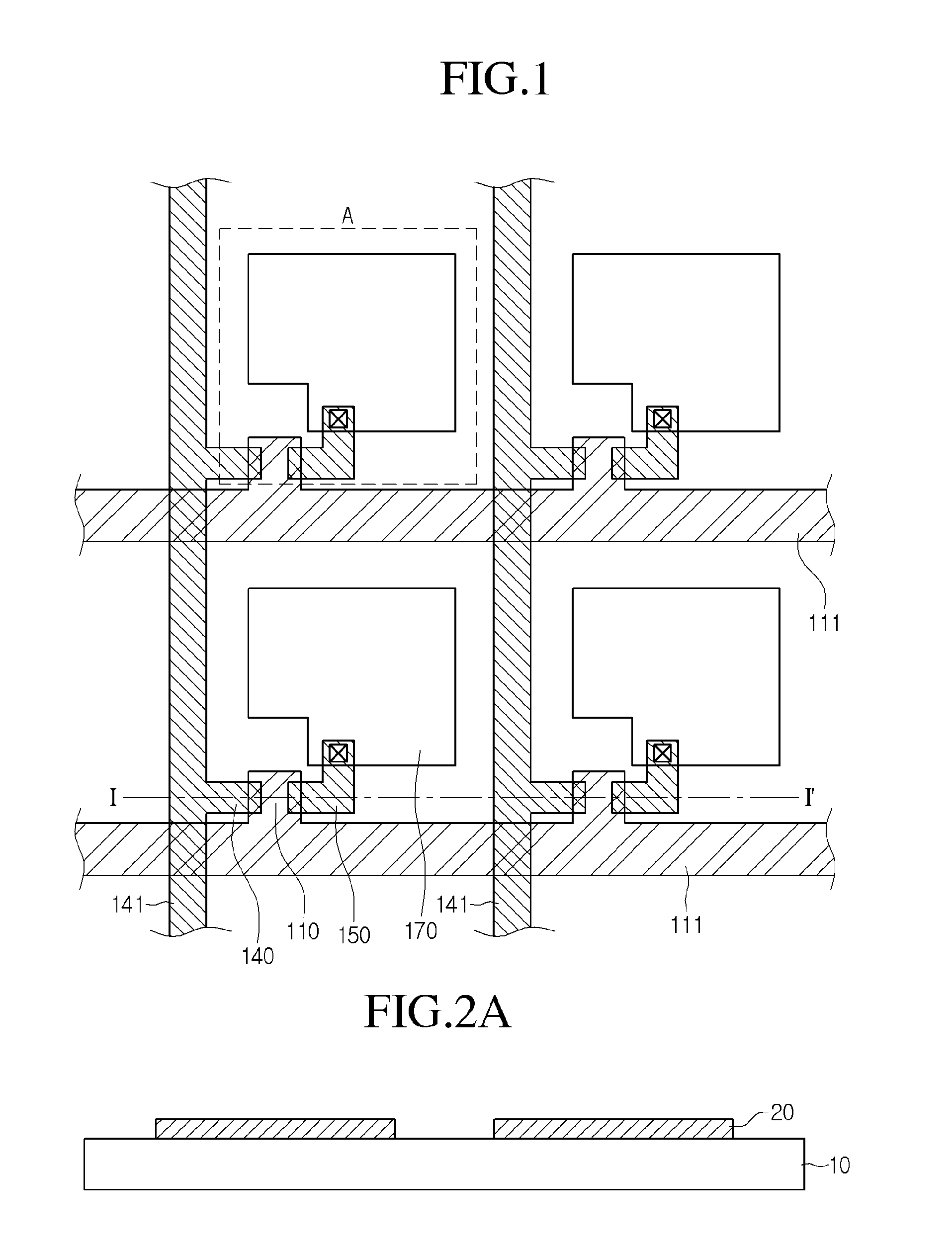

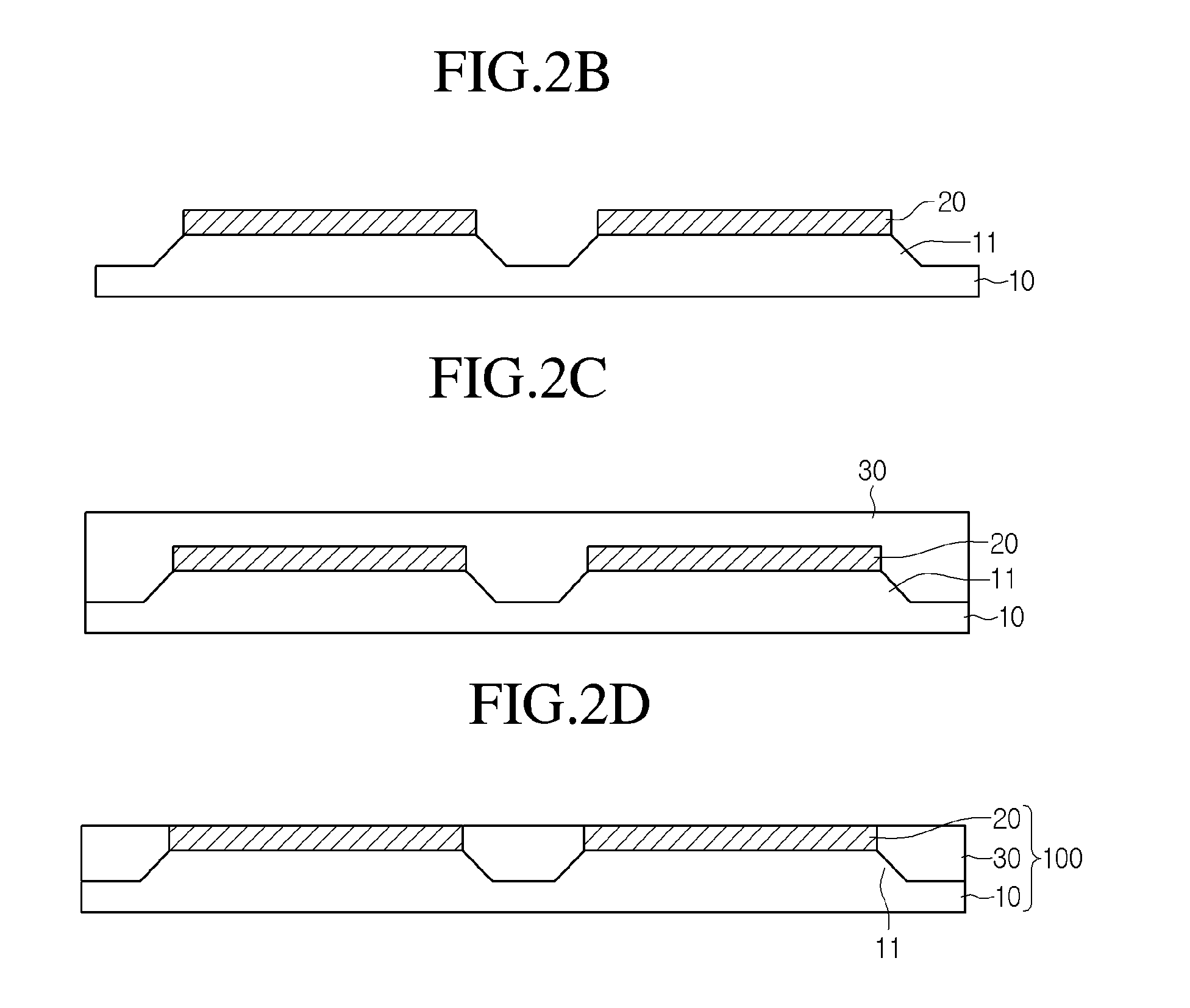

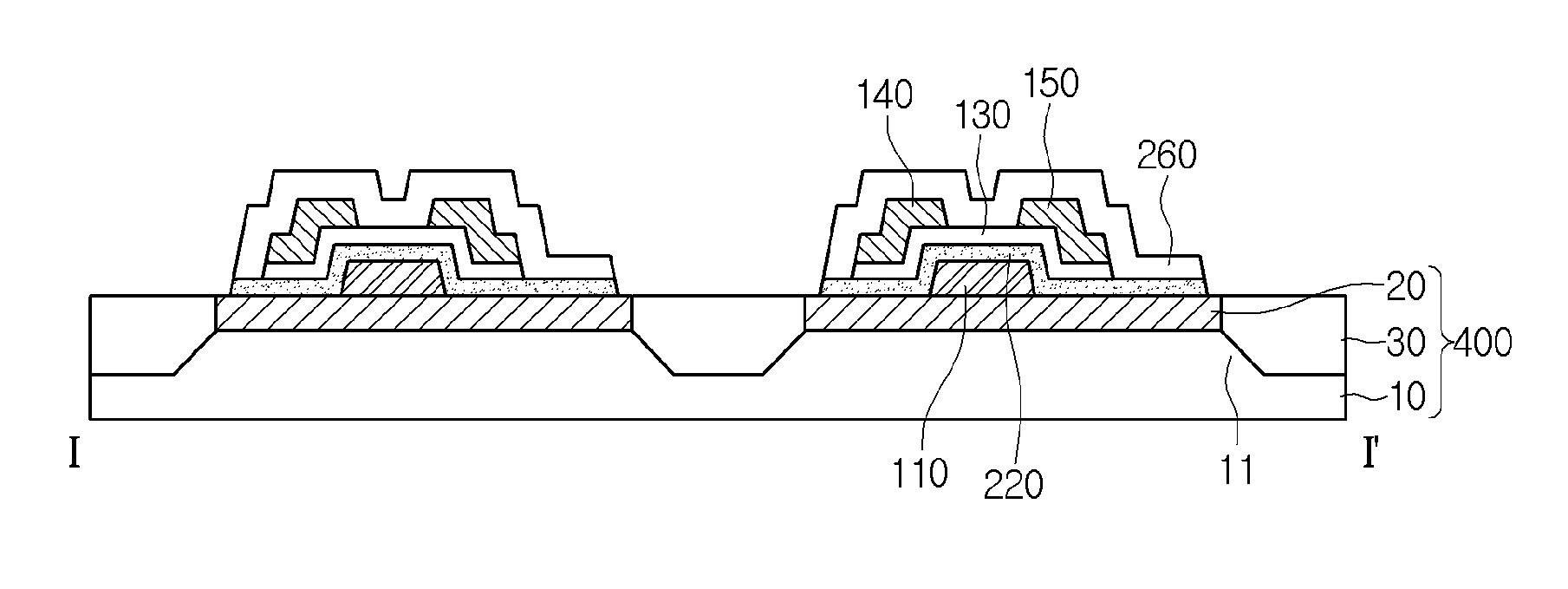

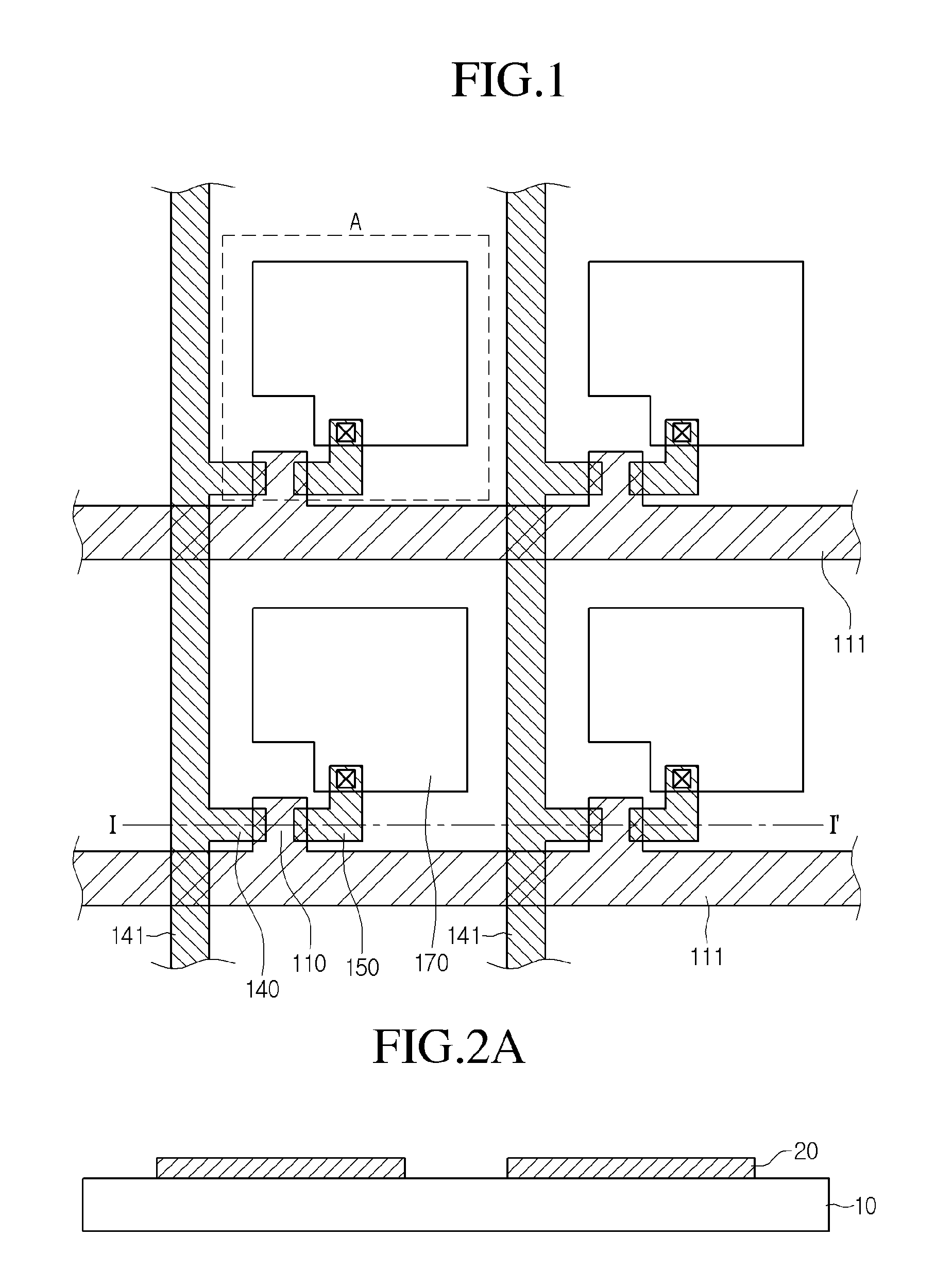

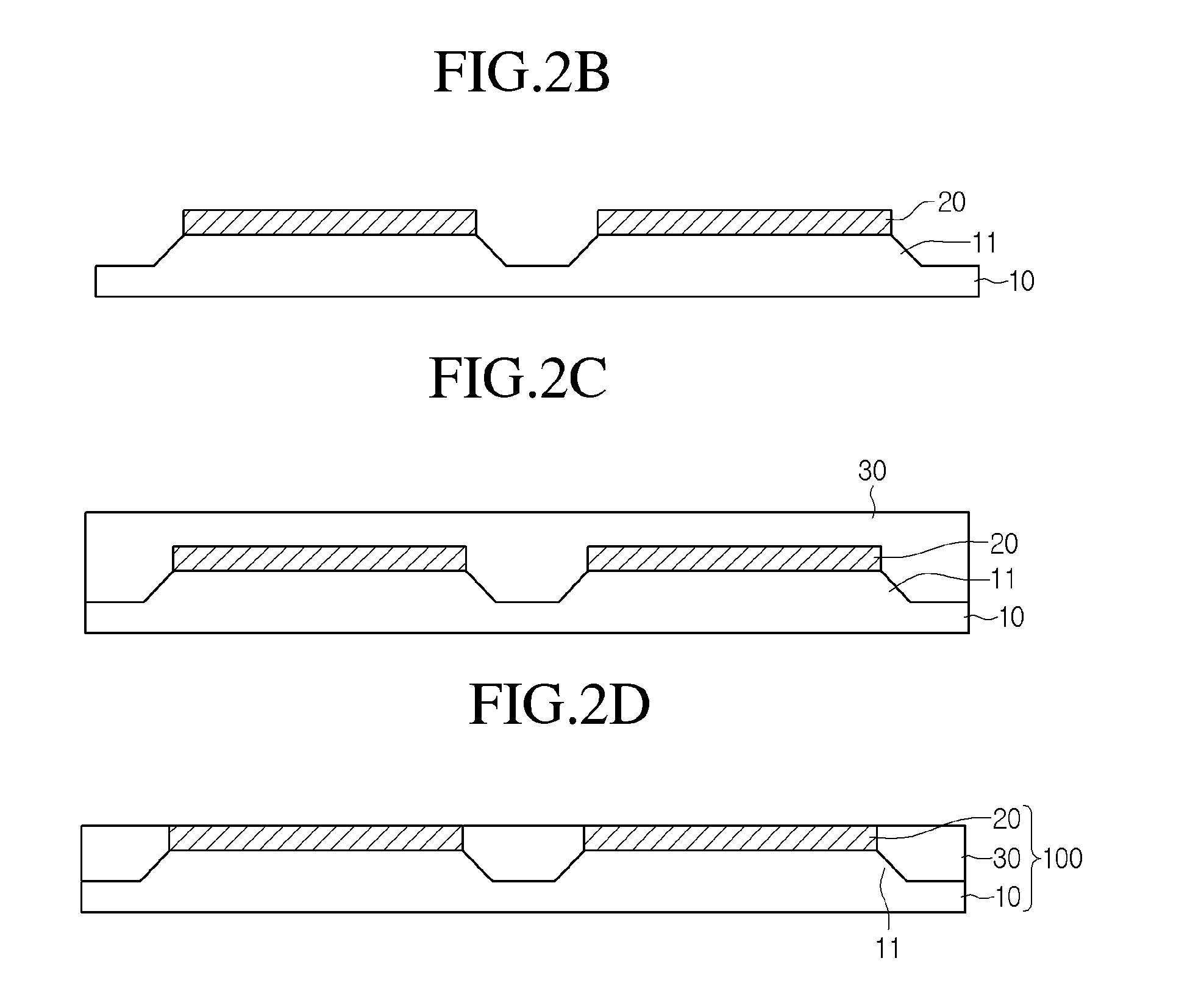

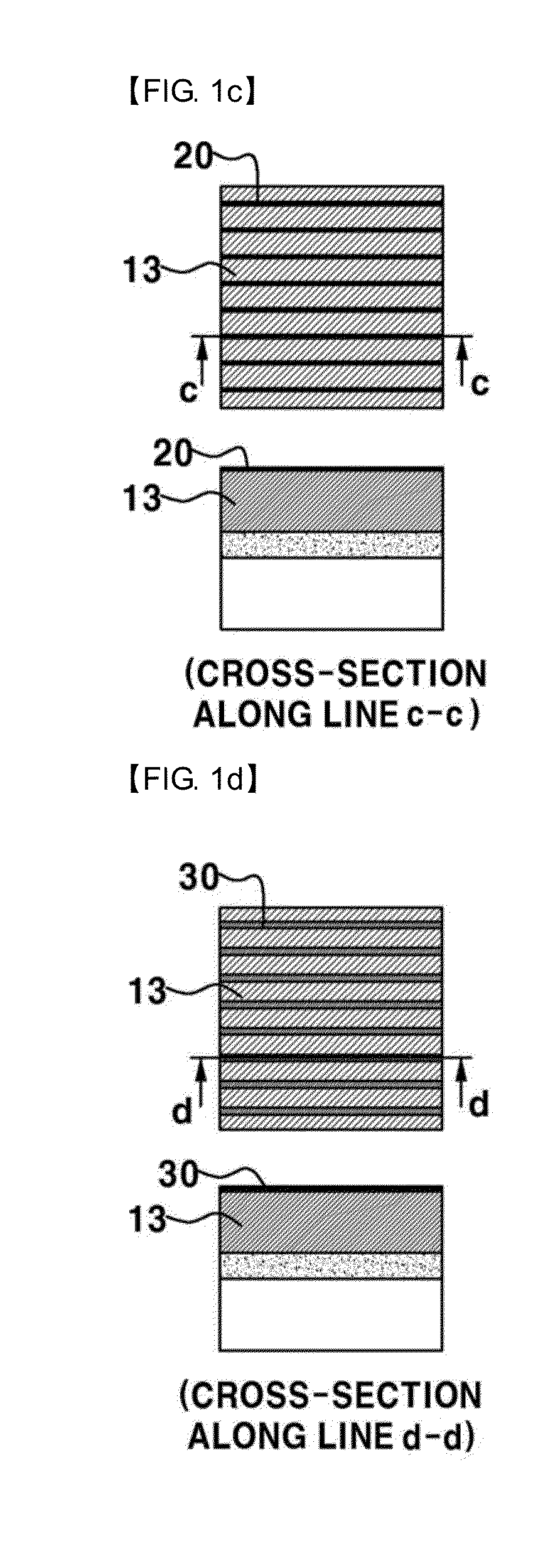

Flexible display device and manufacturing method thereof

ActiveUS20150091005A1Increase flexibilityPreventing property deteriorationSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayTransistor

A flexible display device includes: a flexible substrate having a lower substrate including a prominence pattern, a barrier layer pattern on the prominence pattern, and a planarization film; a gate line on the flexible substrate; a data line crossing the gate line with having a gate insulation film therebetween to define a pixel region; a thin film transistor formed at an intersection of the gate line and the data line; and a passivation layer on the flexible substrate including the thin film transistor. With this configuration, the flexible substrate and the flexible display device can be enhanced by preventing property deterioration of the elements due to bending stresses.

Owner:LG DISPLAY CO LTD

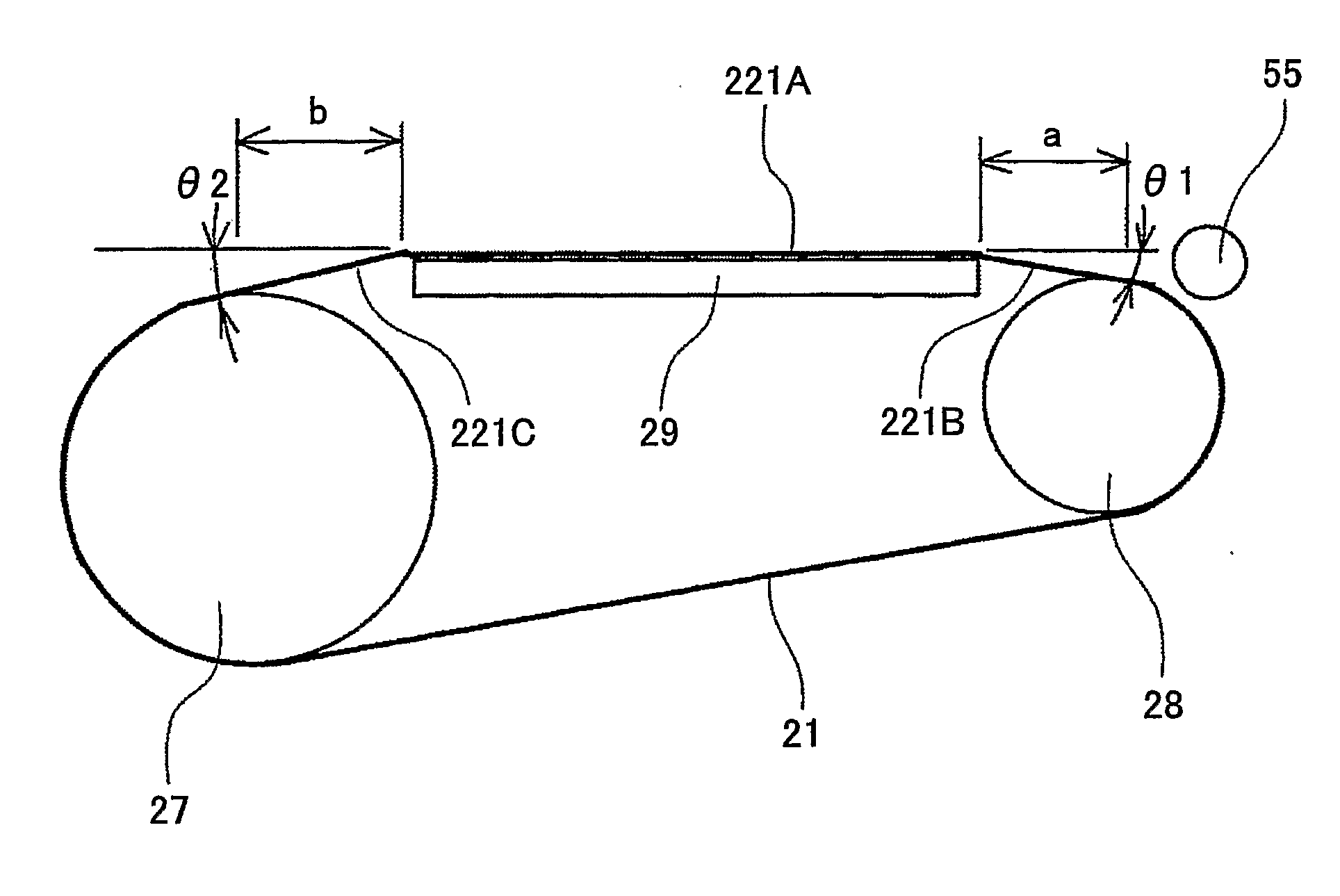

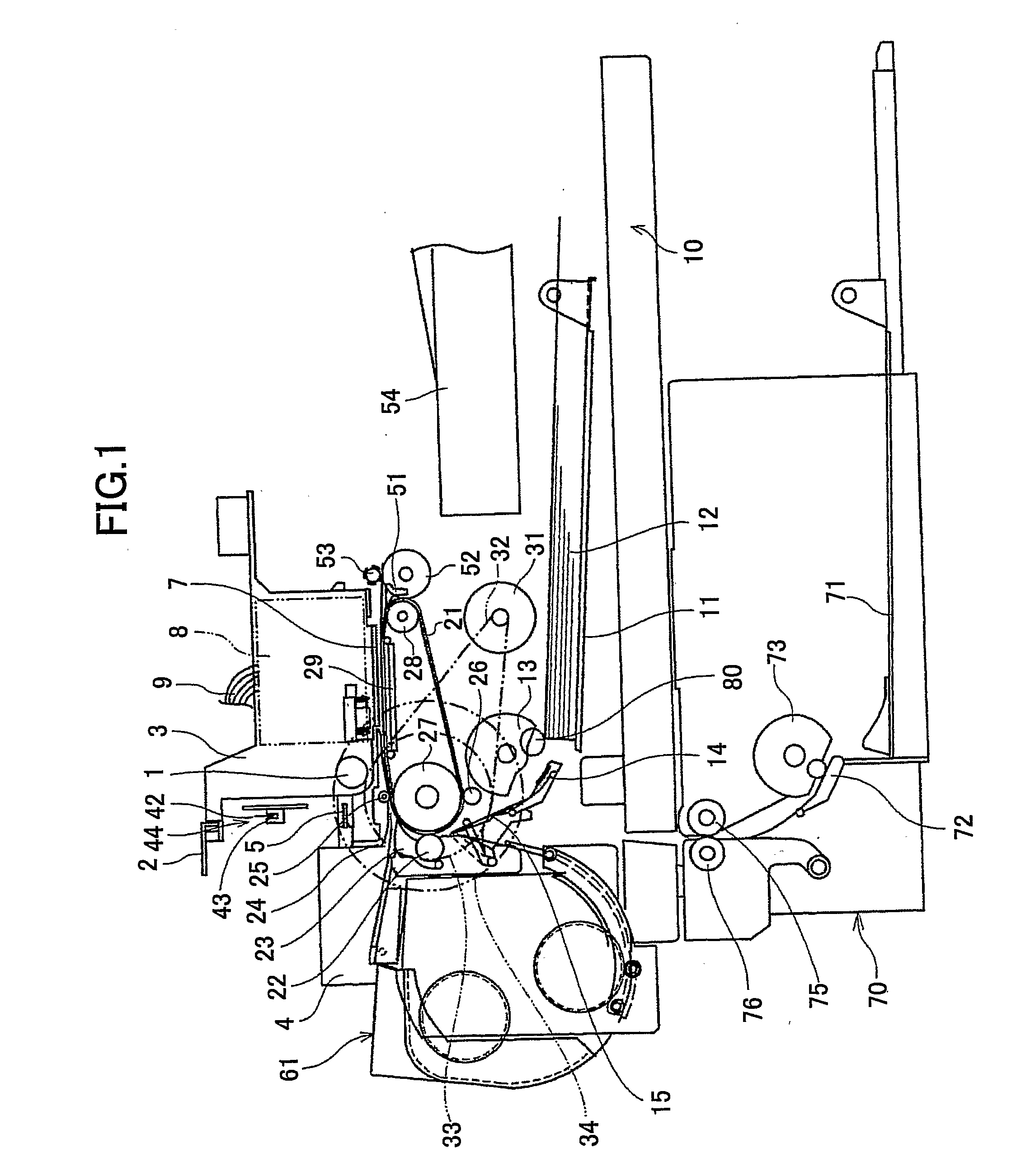

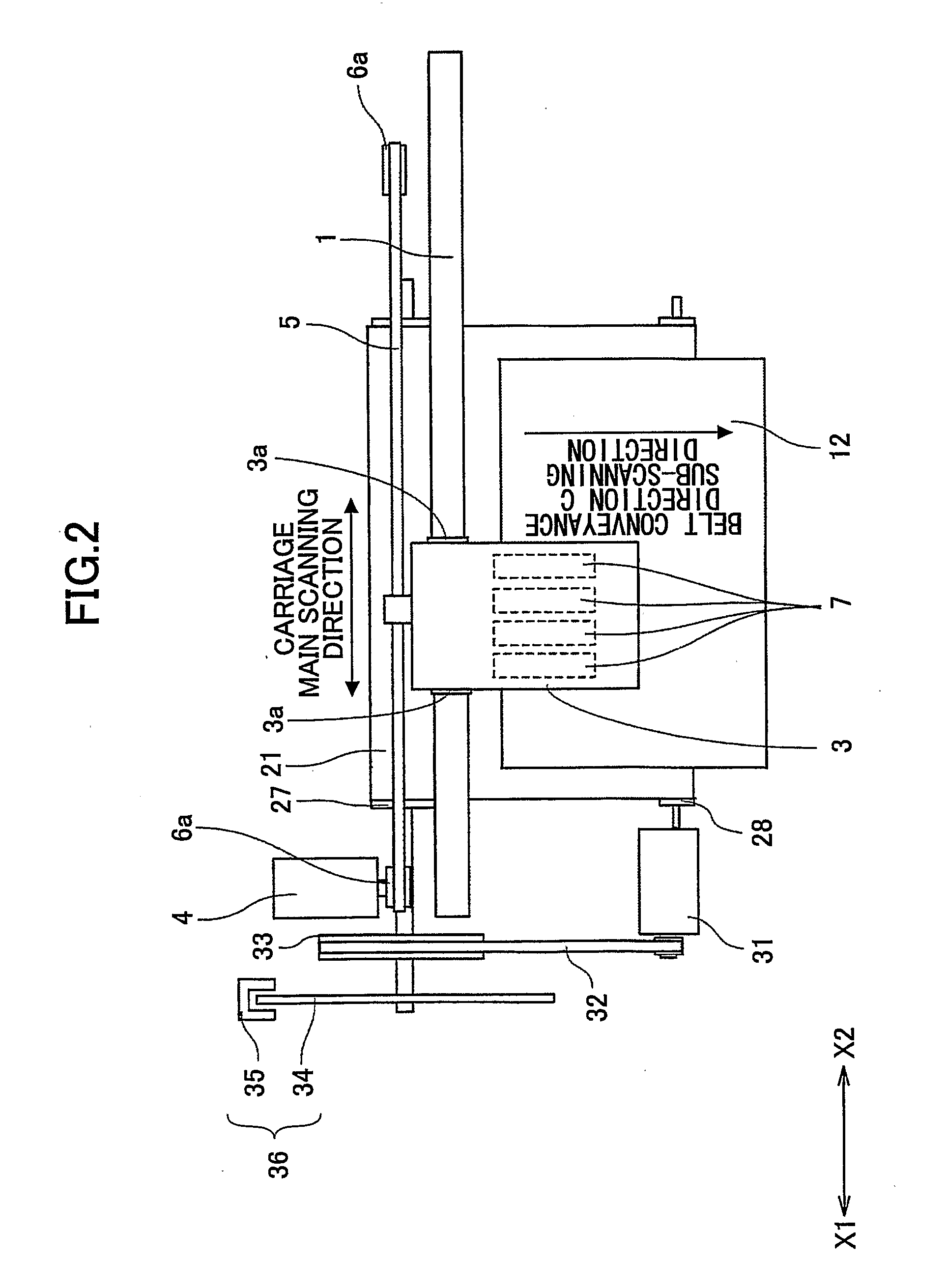

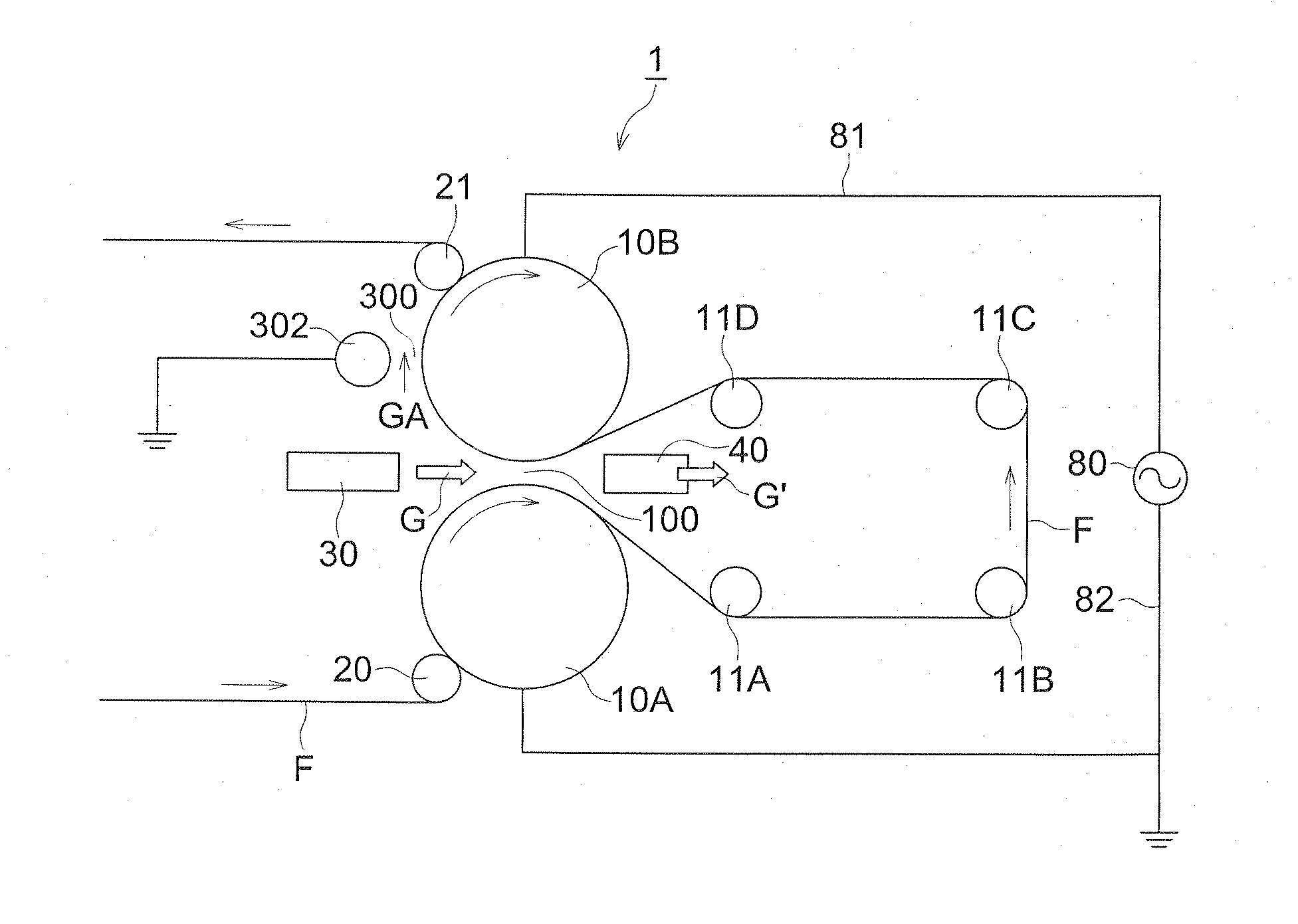

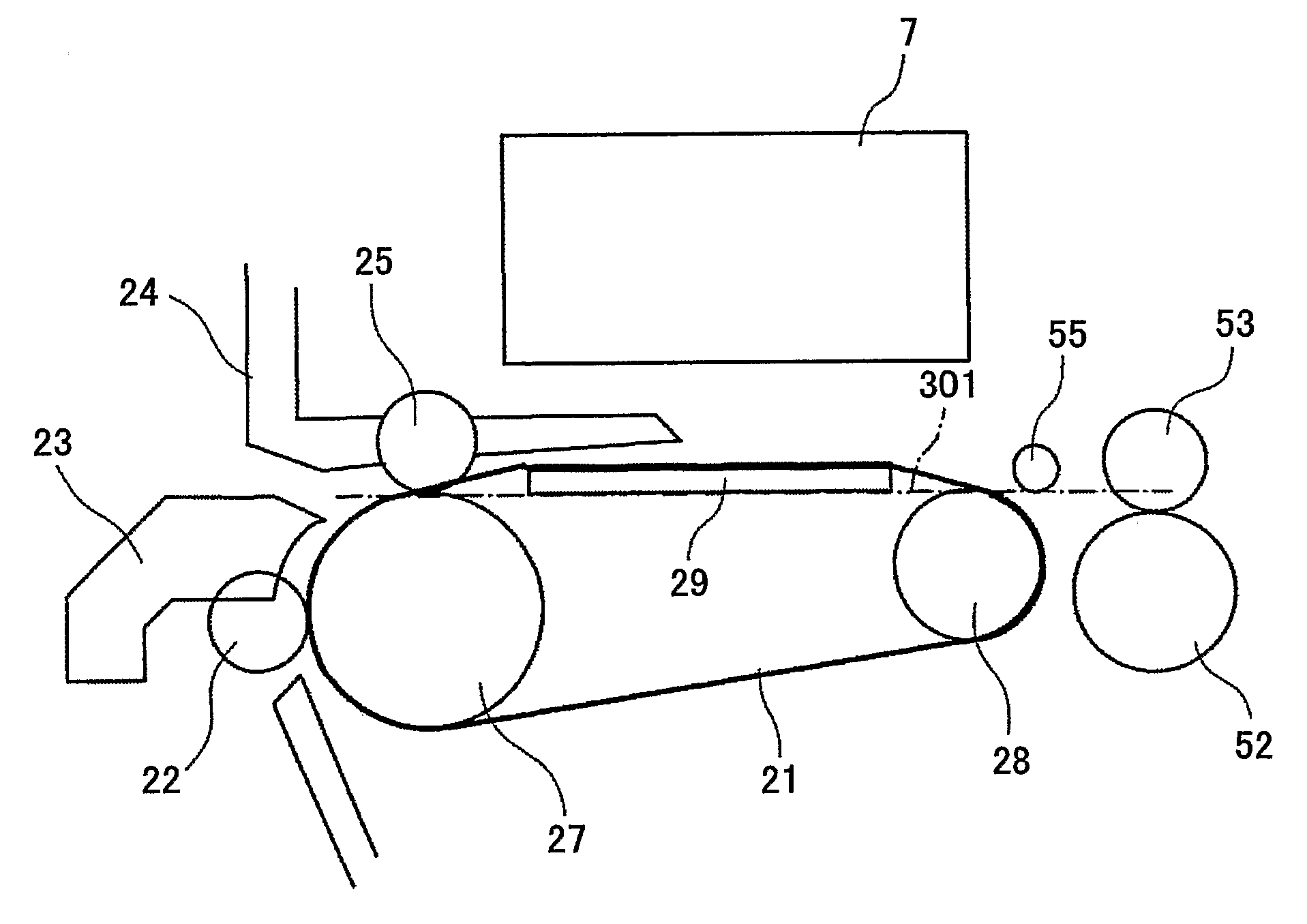

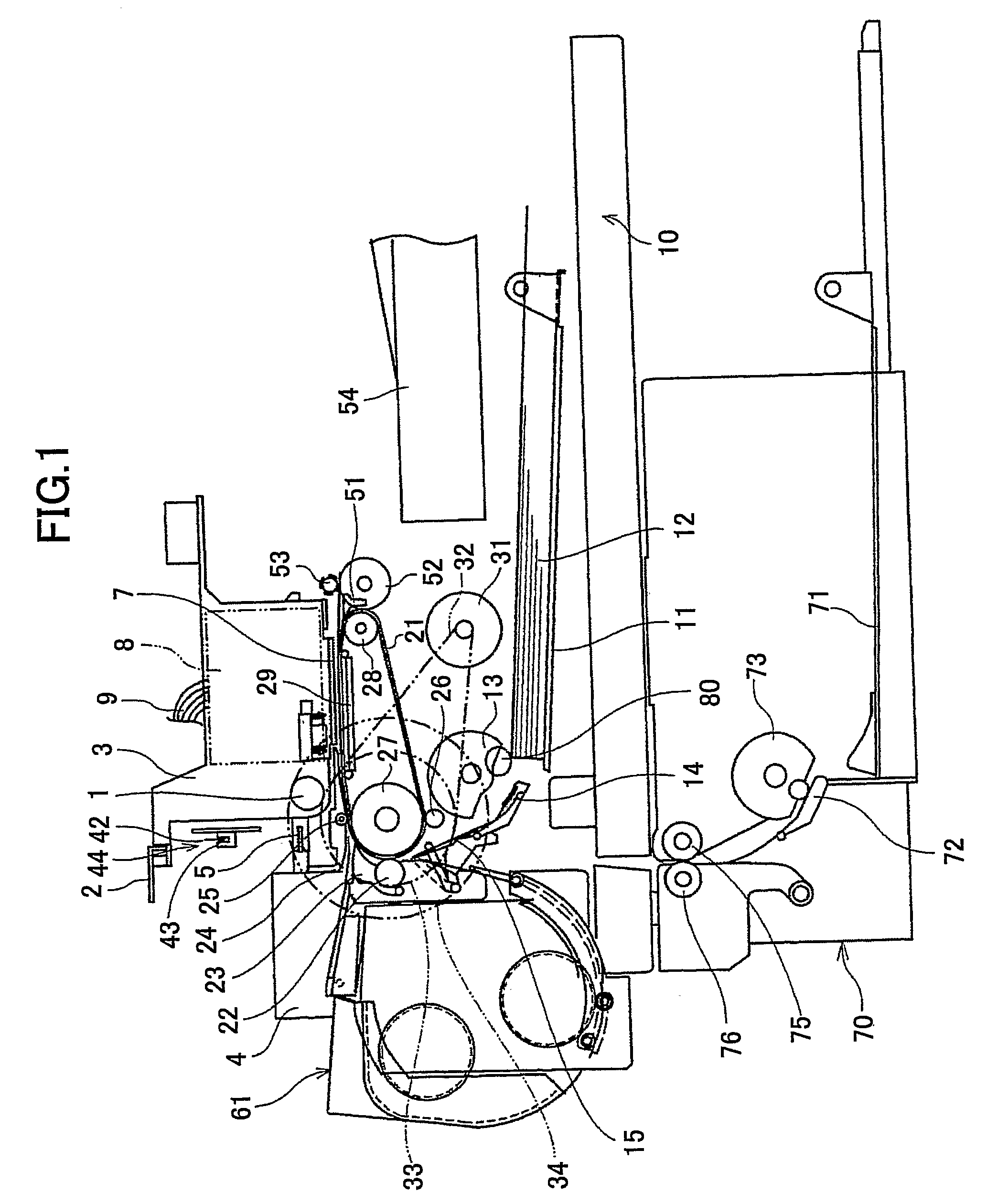

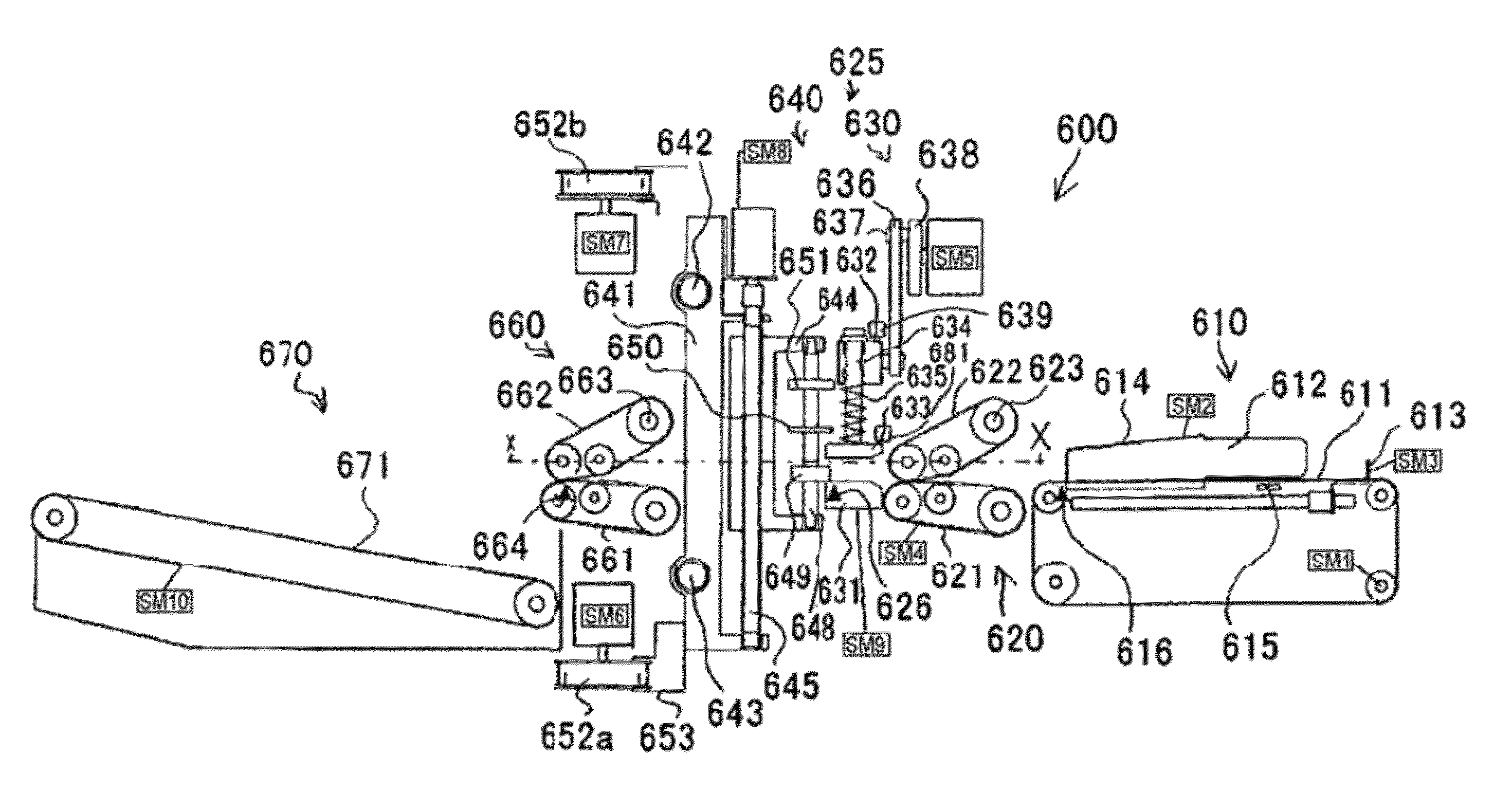

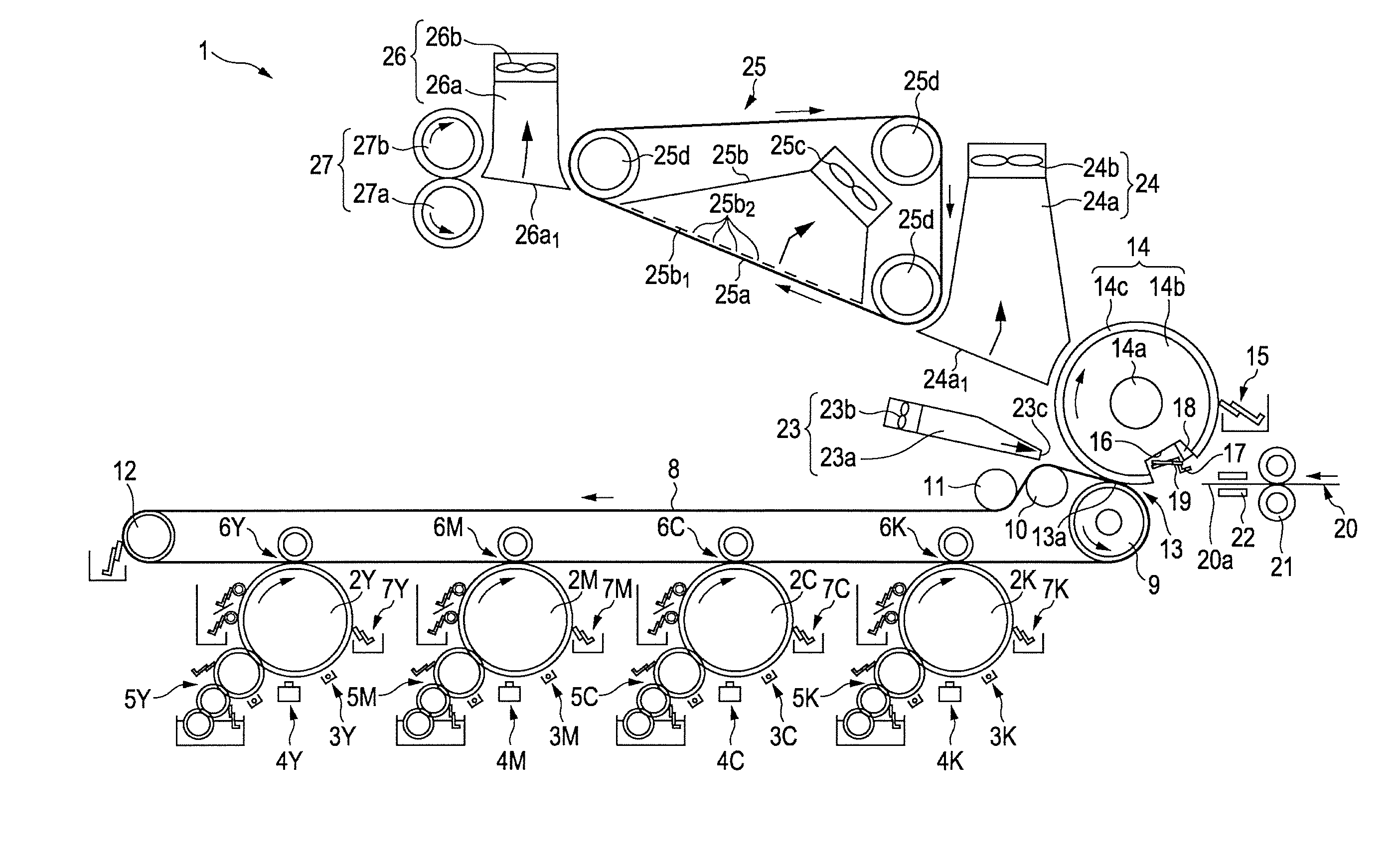

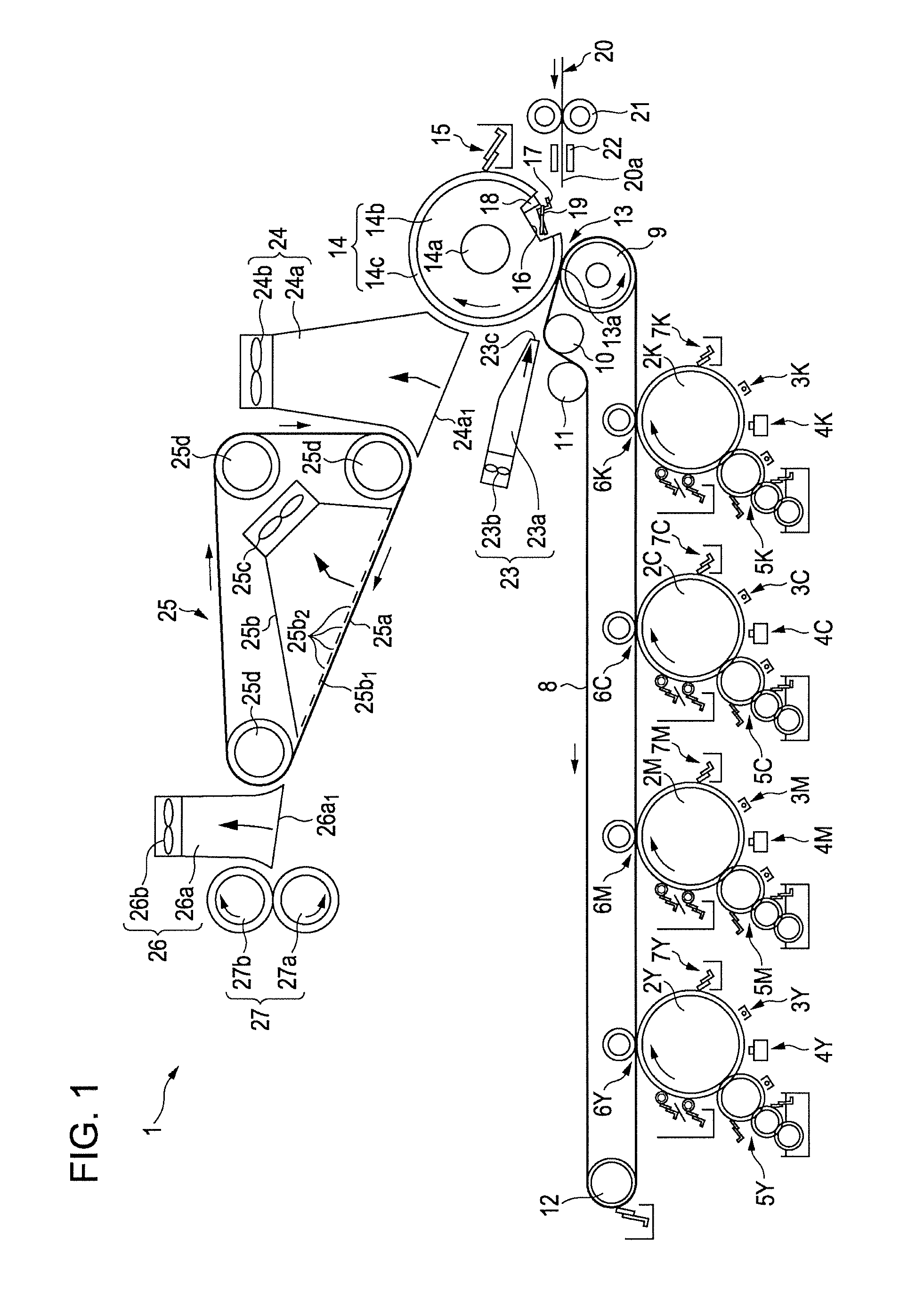

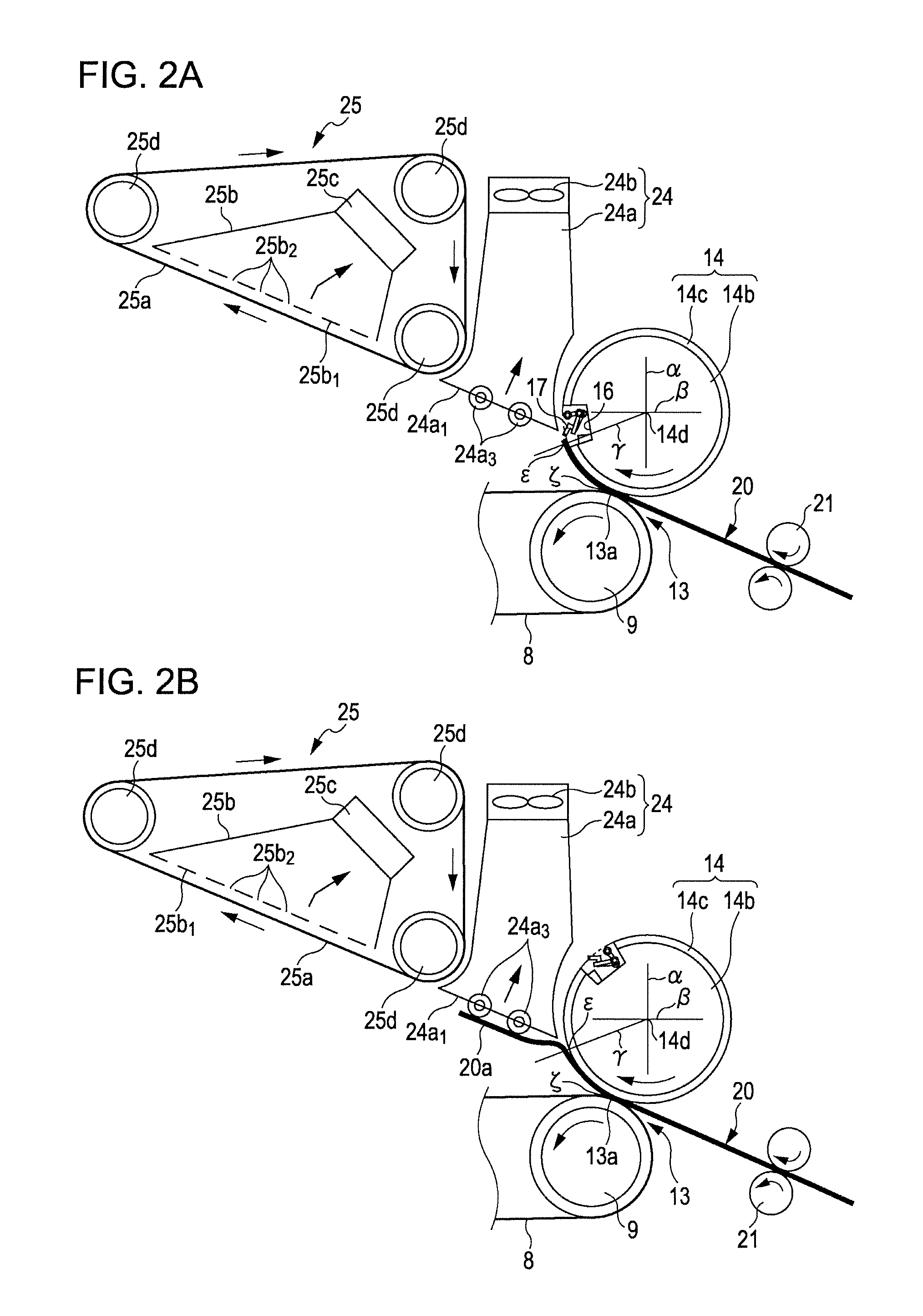

Image Forming Device

ActiveUS20080043083A1Stable formAvoid separationOther printing apparatusImage formationMechanical engineering

An image forming device, includes a recording head configured to jet a liquid drop of recording liquid to a recording medium so that an image is formed; and a conveyance belt adhering the recording medium by an electrostatic force. The recording medium adhered to the conveyance belt by the electrostatic force is not separated from the conveyance belt at an angle formed by a flat surface of the conveyance belt facing the recording head and a tilt surface of the conveyance belt tilting downward at a downstream side of the recording head.

Owner:RICOH KK

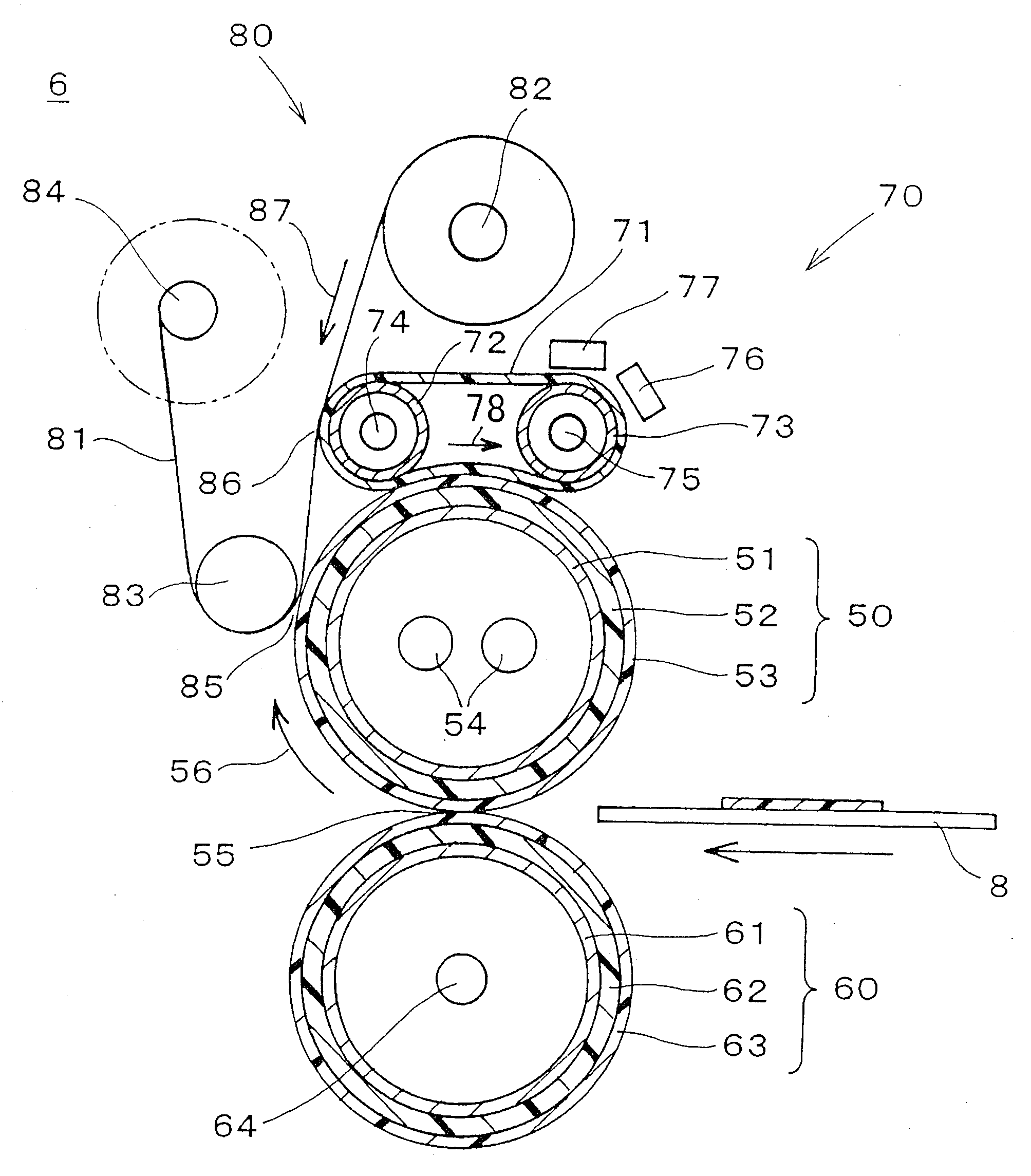

Image bearing member-protecting agent, protective layer-forming device using the same, and image forming apparatus

InactiveUS20120060753A1High consumption rateImprove the lubrication effectLiquid surface applicatorsElectrography/magnetographyCompression moldingBoron nitride

An image bearing member-protecting agent including a fatty acid metal salt and boron nitride, wherein the image bearing member-protecting agent contains the fatty acid metal salt in an amount of 60% by mass to 87% by mass, and is formed by compression molding; or an image bearing member-protecting agent including a fatty acid metal salt and boron nitride, wherein the image bearing member-protecting agent contains the fatty acid metal salt in an amount of 88% by mass to 99% by mass, and is formed by melt molding.

Owner:RICOH KK

Fixing apparatus and image forming apparatus

InactiveUS20080124144A1High qualityStably formElectrographic process apparatusEngineeringForming processes

Owner:SHARP KK

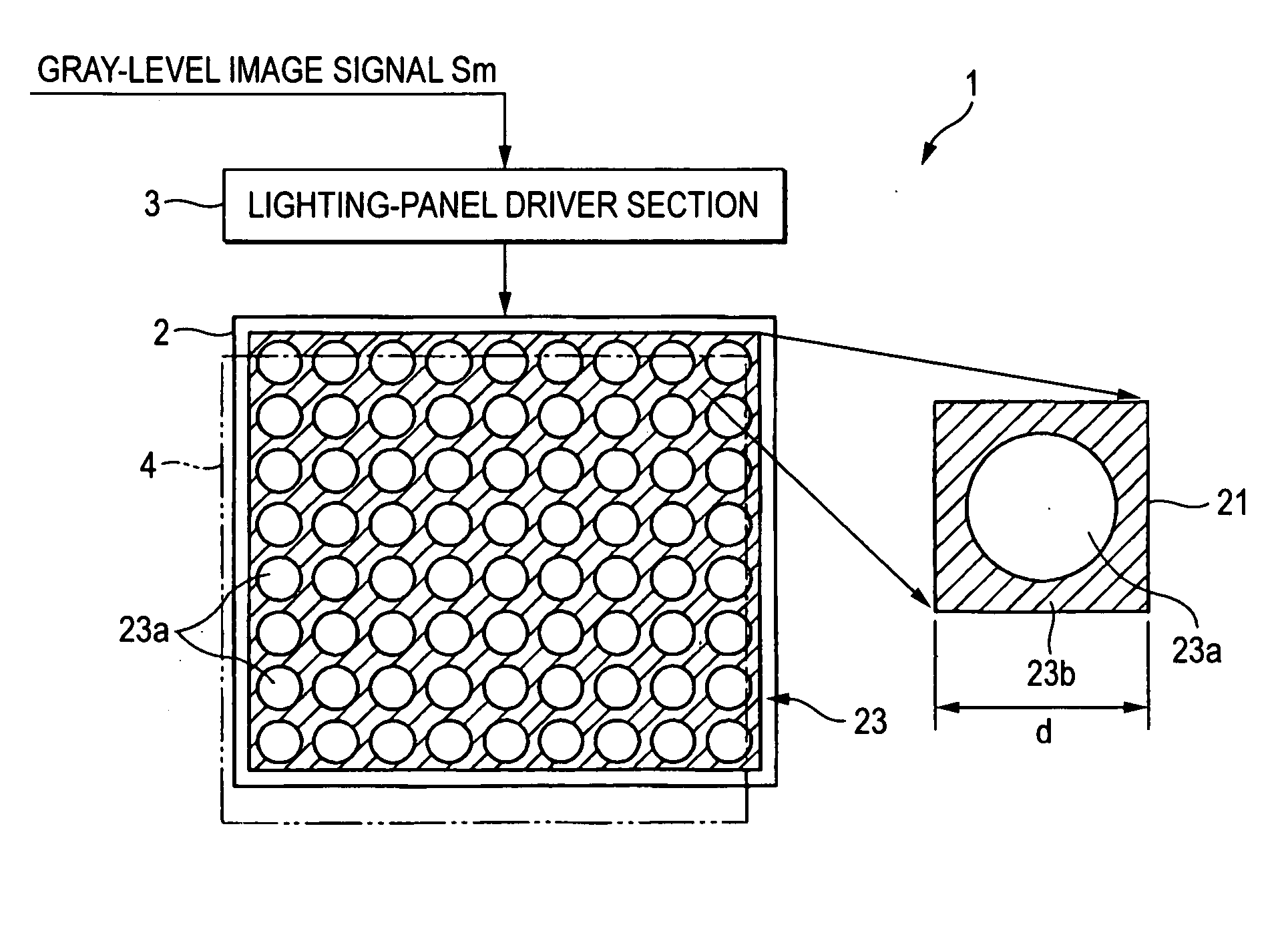

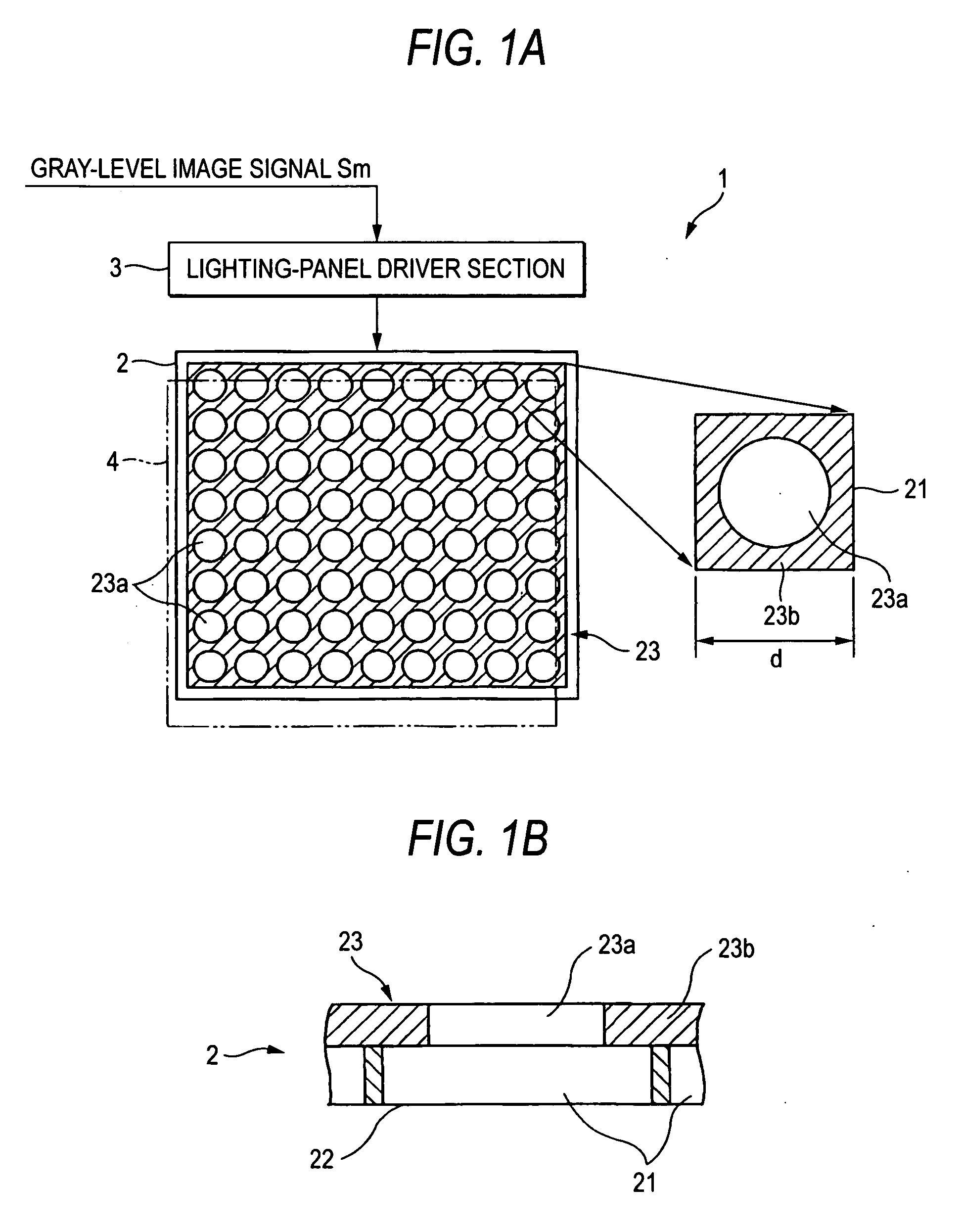

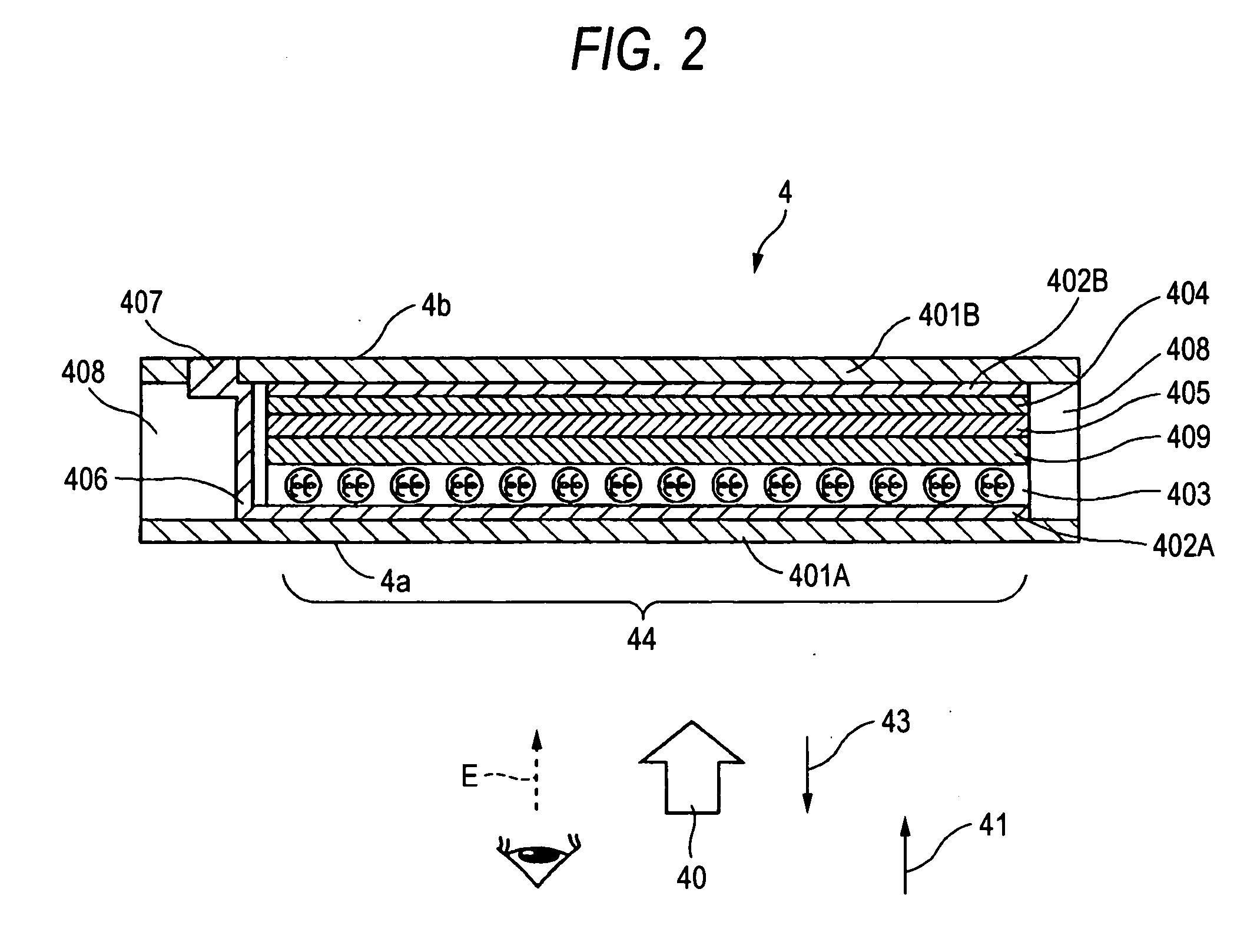

Multi-level optical writer

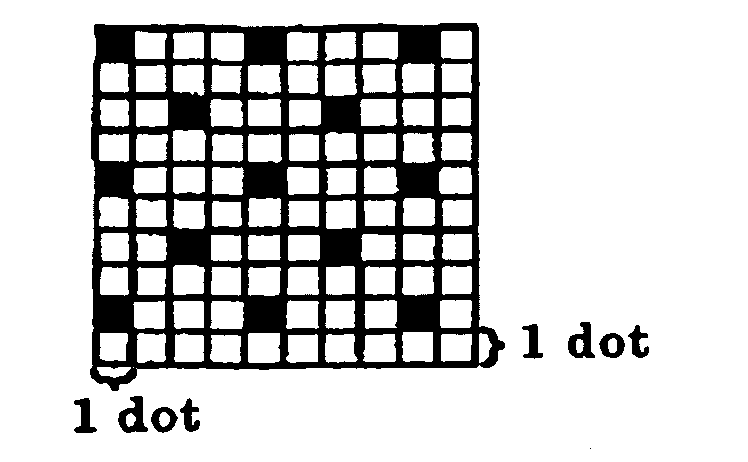

InactiveUS20060244698A1Stably formSimple structureCathode-ray tube indicatorsNon-linear opticsOpto electronicGray level

A multi-level optical writer for writing an image by illumination to an optical-write-type recording medium laid with a display layer having a memory nature and a photoconductive layer, the optical writer includs: a holding portion holding the optical-write-type recording medium; and a write section for writing a multi-level image to the display layer by illuminating, to the photoconductive layer, image light having optical dots different in size in accordance with a gray level.

Owner:FUJIFILM BUSINESS INNOVATION CORP

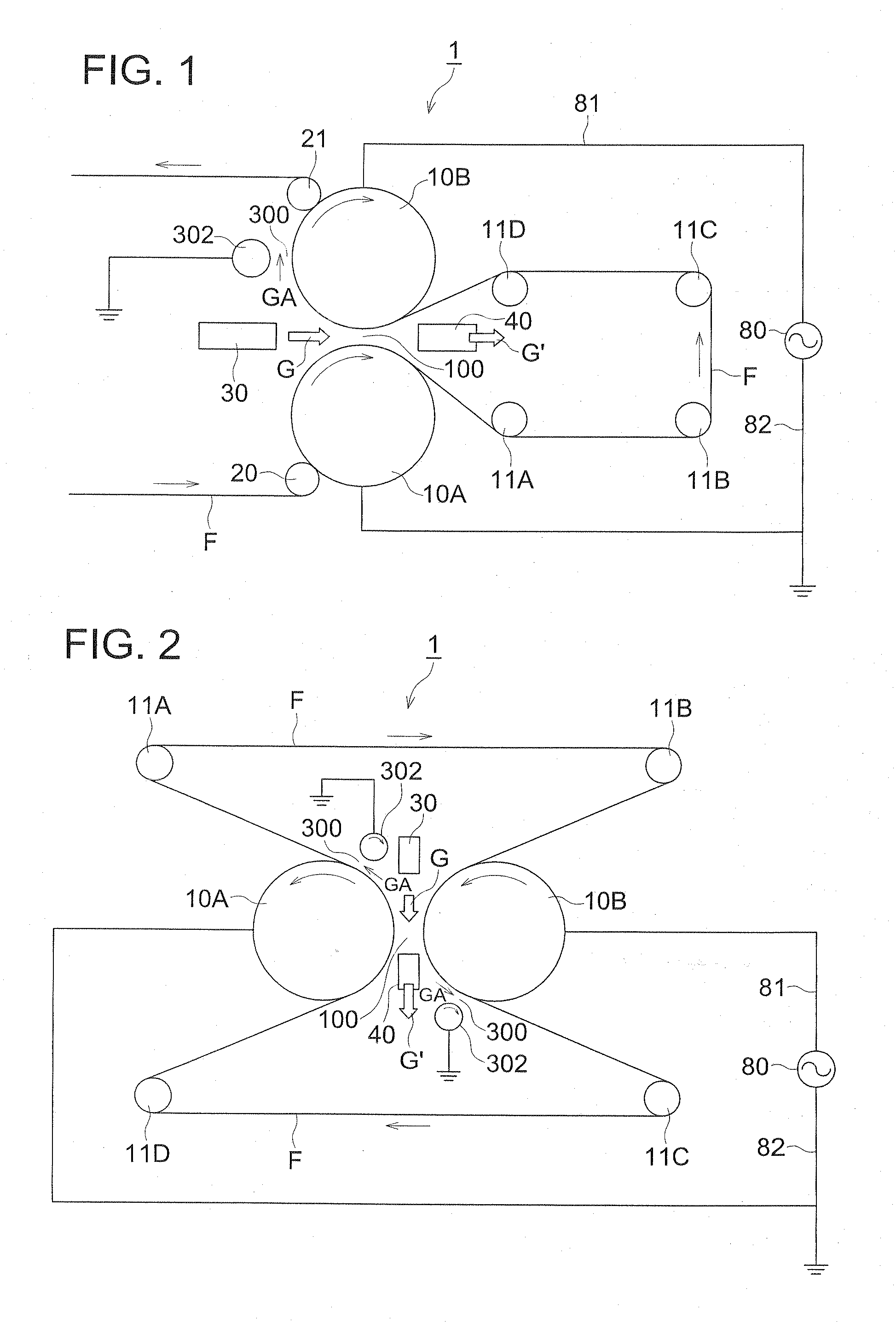

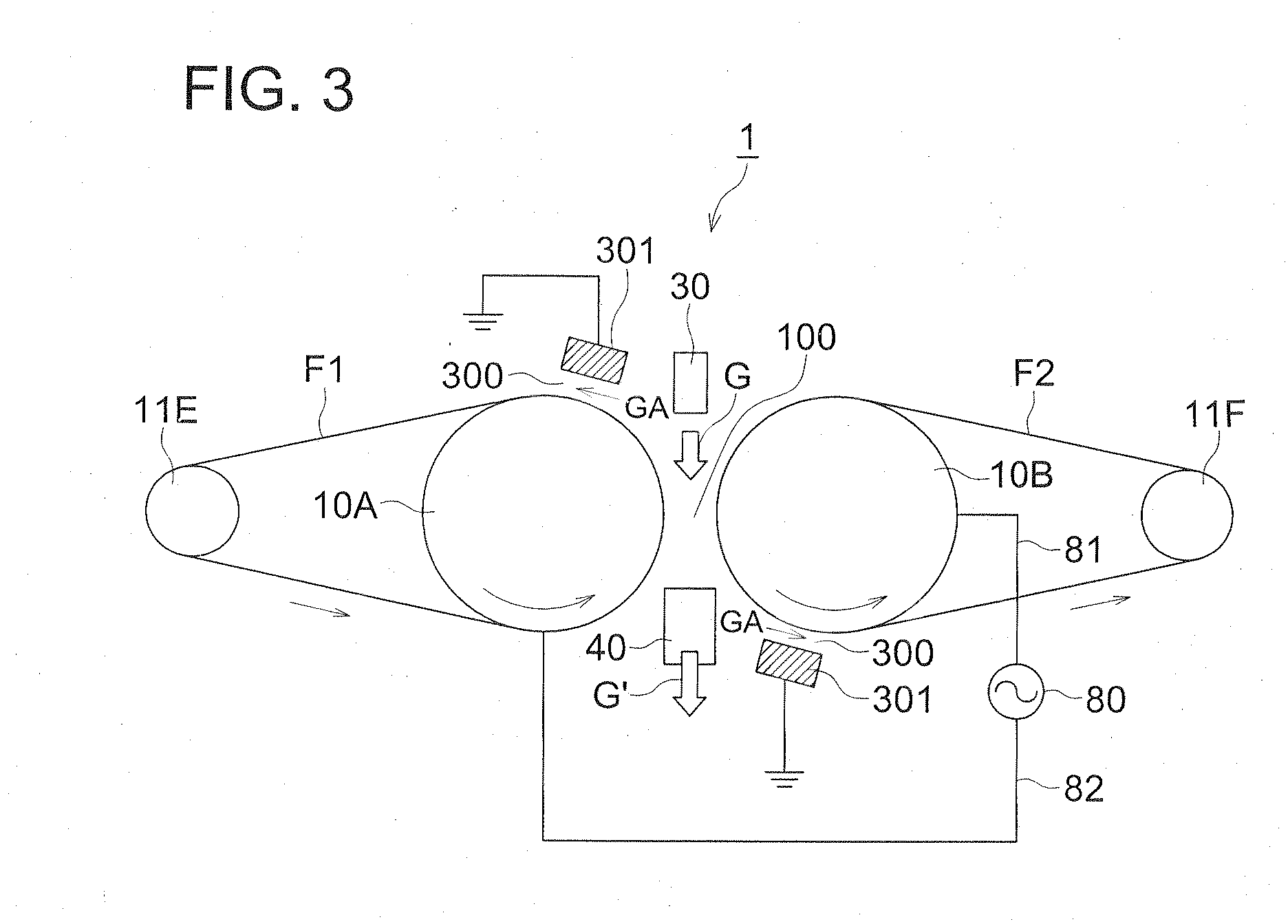

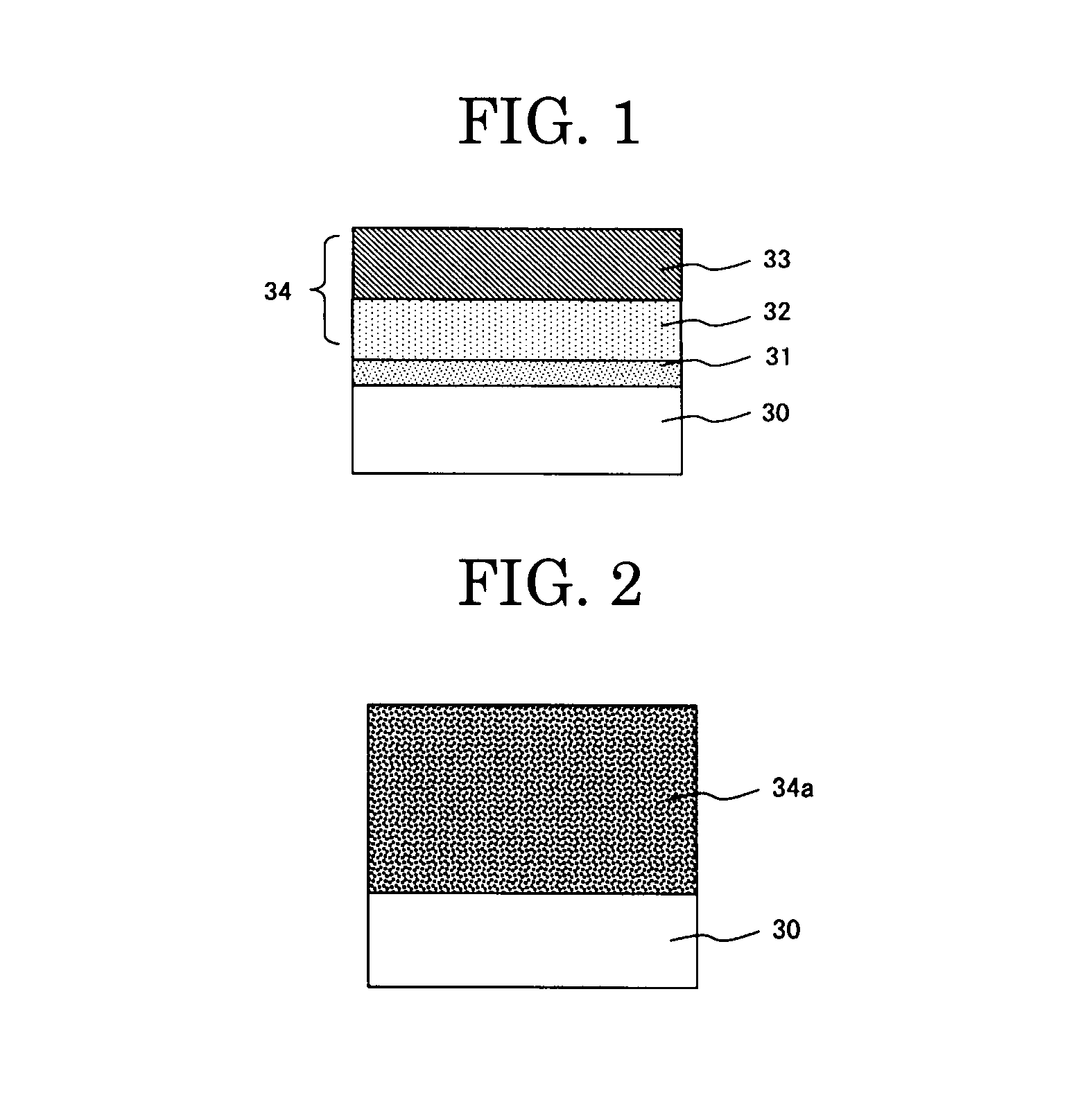

Thin film forming method and thin film stack

InactiveUS20110052924A1High production efficiencyStably formElectric discharge tubesLayered productsElectric fieldForming gas

A thin film forming method by a plasma discharging treatment under atmospheric pressure with a thin film forming apparatus which has a first discharging space for forming a functional thin film on a substrate, and a second discharge space for post-treating the substrate which formed the thin film. The first discharge space has a roller electrodes pair. The thin film forming method includes, a film forming process at the first discharge space which includes the steps of transporting the substrate by the roller electrodes; supplying discharging gas and thin film forming gas into the first discharging space; and generating a high frequency electric field between the roller electrodes. The post-treatment process includes the steps of introducing the substrate on which the functional film is formed; and supplying a discharging gas and post-treatment gas between the facing electrodes; and, generating a high frequency electric field between the facing electrode and the roller electrode.

Owner:KONICA MINOLTA INC

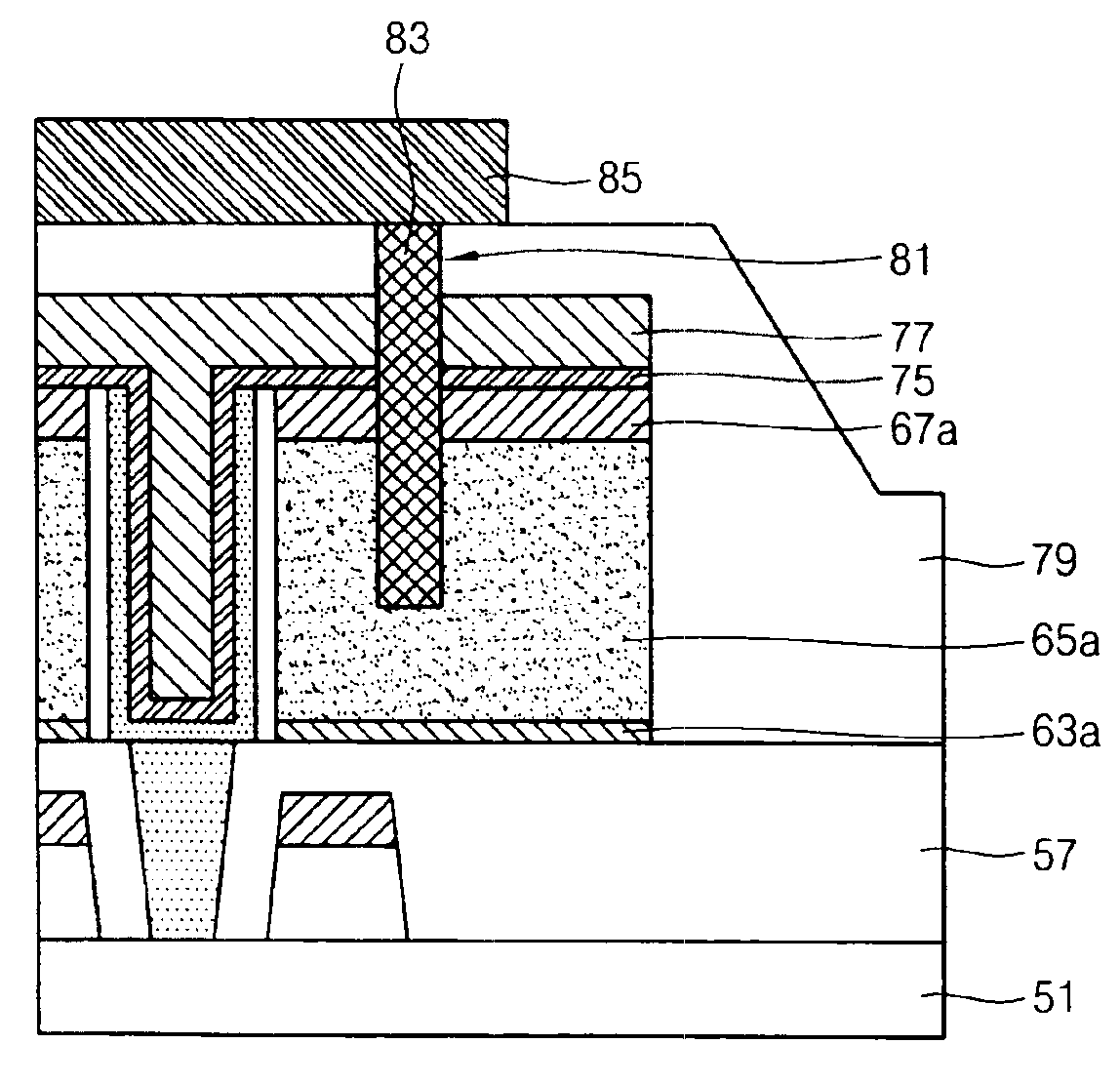

Method for fabricating capacitor of semiconductor device

InactiveUS6949428B2Increase capacitanceStably formSemiconductor/solid-state device manufacturingCapacitorsContact holeSemiconductor

In fabricating a capacitor of a semiconductor device, a first contact plug is formed in a plug contact hole formed by patterning a portion of a first interlayer insulating film formed on a substrate. A first barrier layer, a first polysilicon layer, and a second barrier layer are formed. A first contact hole is formed after sequentially patterning the second barrier layer, the first polysilicon layer, and the first barrier layer. A first dielectric layer is formed to have portions located at outside and bottom parts of the first contact hole. A second polysilicon layer is formed to have its portions located at portions except for the first contact hole. A second dielectric layer and a third polysilicon layer are formed. A second interlayer insulating film is formed after patterning the third polysilicon layer. The second interlayer insulating film, the patterned third polysilicon layer, the second dielectric layer, the second barrier layer, and the first polysilicon layer are selectively removed to form a second contact hole and a second contact plug, and then forming a metal wiring.

Owner:SK HYNIX INC

Image forming device

ActiveUS7891805B2Quality improvementStable formationOther printing apparatusImage formationEngineering

An image forming device, includes a recording head configured to jet a liquid drop of recording liquid to a recording medium so that an image is formed; and a conveyance belt adhering the recording medium by an electrostatic force. The recording medium adhered to the conveyance belt by the electrostatic force is not separated from the conveyance belt at an angle formed by a flat surface of the conveyance belt facing the recording head and a tilt surface of the conveyance belt tilting downward at a downstream side of the recording head.

Owner:RICOH KK

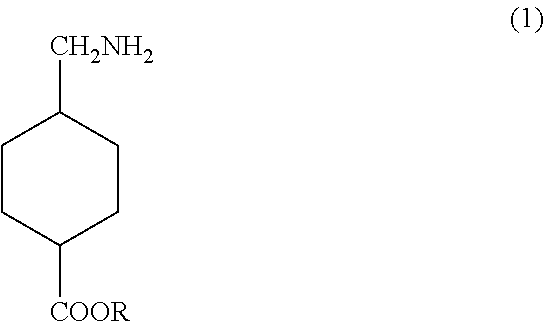

Complexes

ActiveUS20170120231A1Stably formReduce congestionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHeteroatomCoupling reaction

A palladium(II) complex of formula (1) or a palladium(II) complex of formula (3).Also, processes for the preparation of the complexes, and their use in carbon-carbon and carbon-heteroatom coupling reactions.

Owner:JOHNSON MATTHEY PLC

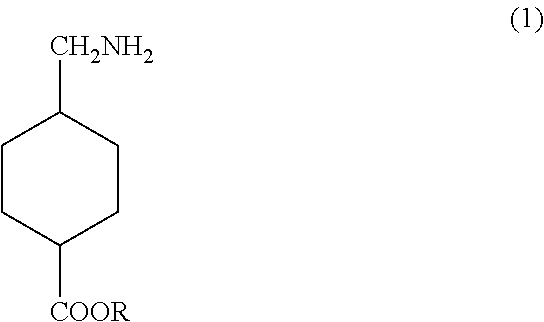

Oil-in-water emulsion composition and method for producing the same

Disclosed is an oil-in-water type emulsion composition containing a physiologically acceptable salt of a tranexamate ester and a method for producing the same. An oil-in-water type emulsion composition containing a physiologically acceptable salt of a tranexamate ester can be obtained by preparing an oil phase including: A) a physiologically acceptable salt of a tranexamate ester; B) an amphiphilic substance; C) an oily substance; and D) water, a water-soluble organic solvent or a mixture thereof wherein the weight ratio of the ingredients A:B is in the range of 1:0.5 to 1:2.5, the weight ratio of the ingredients A:C is in the range of 1:1 to 1:5.0, and the weight ratio of the ingredients A:D is 1:0.2 to 1:5.0, and adding the oil phase to a water phase including E) water, a water-soluble organic solvent or a mixture thereof.

Owner:CHANEL PARFUMS BEAUTE SAS

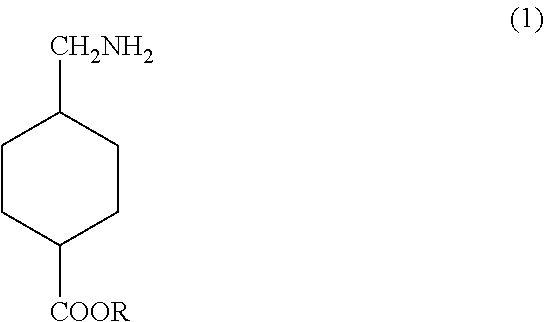

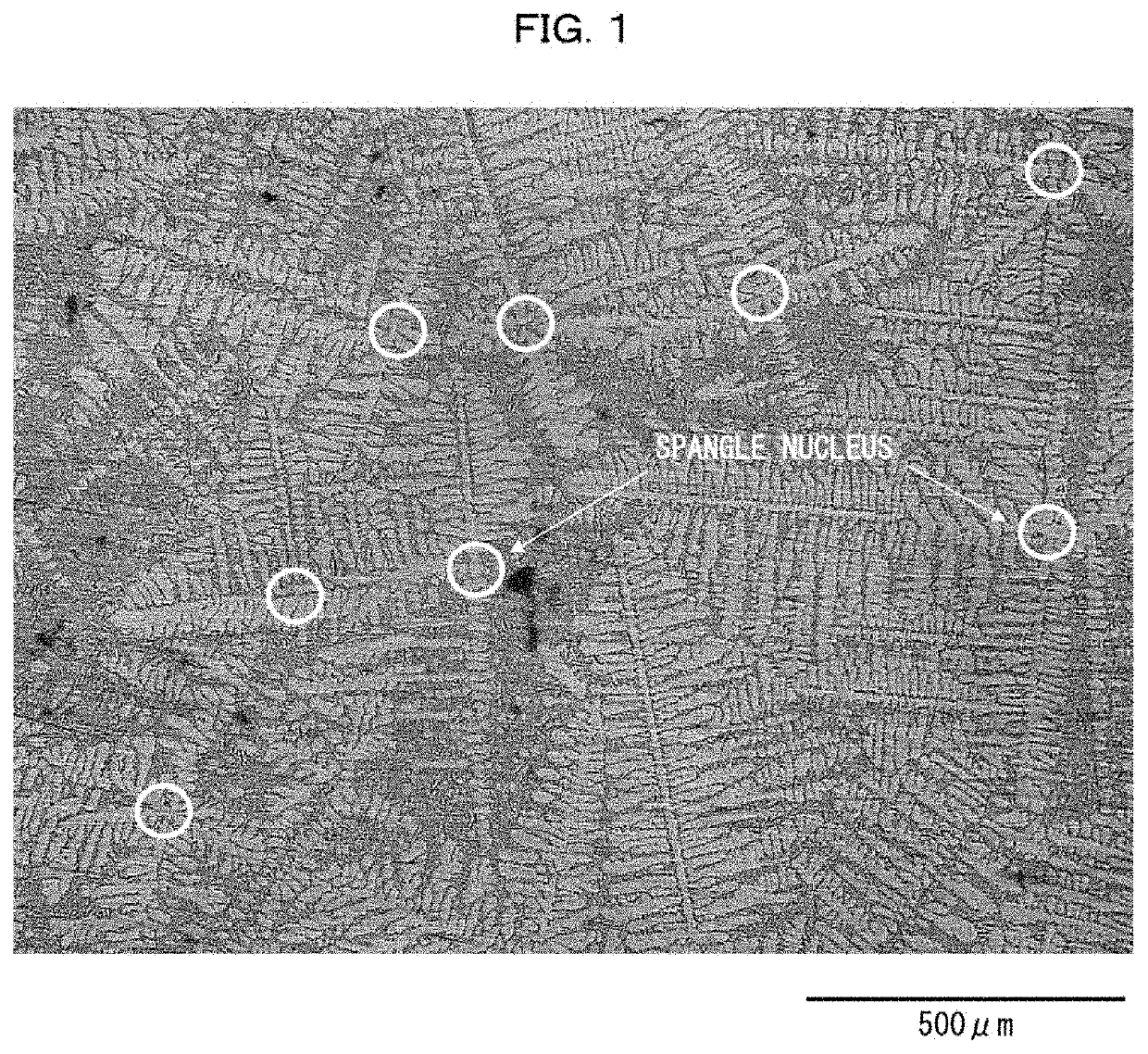

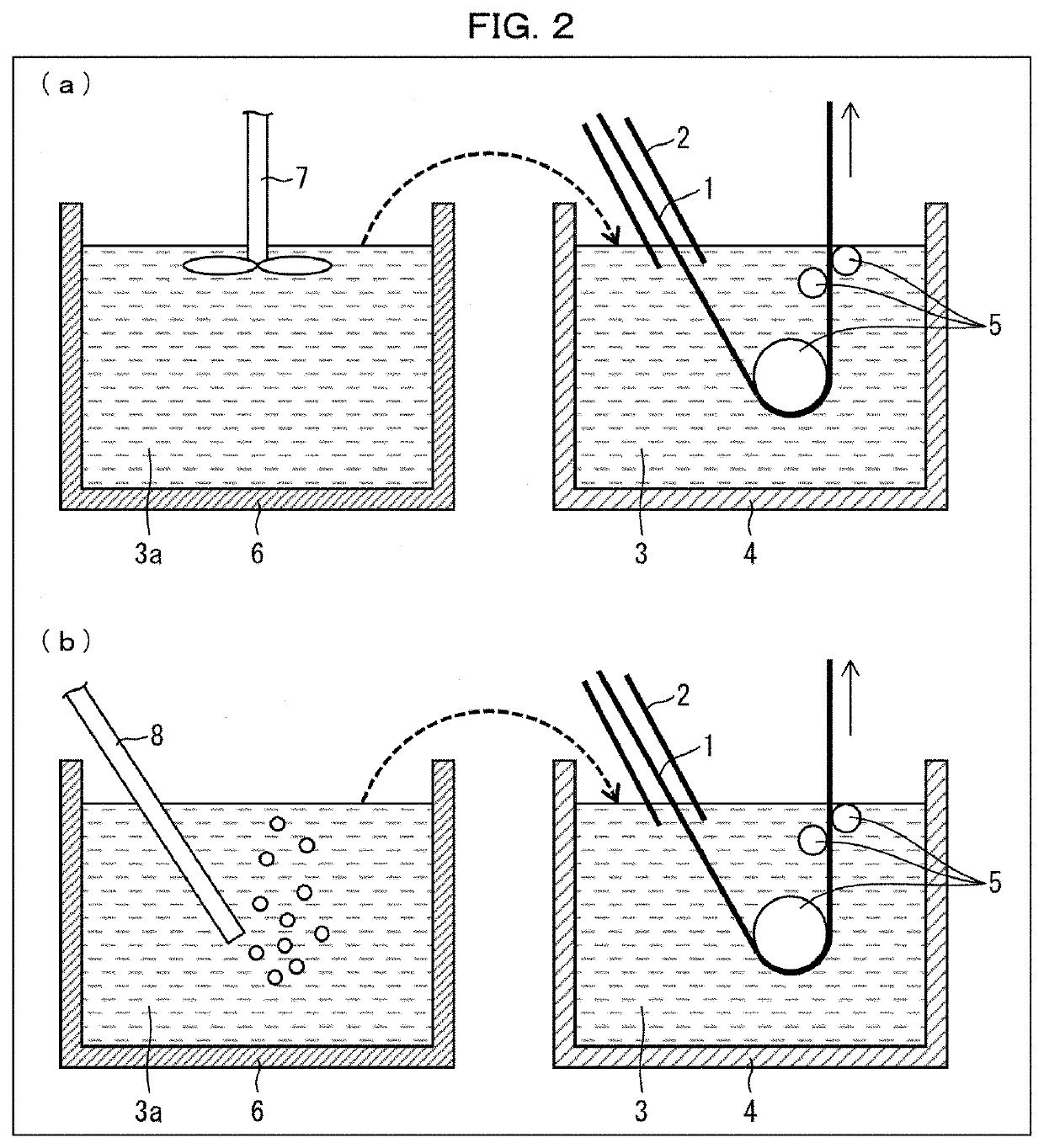

Hot-dip al-plated steel sheet production method, and hot-dip al-plated steel sheet

InactiveUS20210002752A1Stably formStable formationHot-dipping/immersion processesSteel platesBase metal

Provided is a method for producing a hot-dip Al-based metal-plated steel sheet including a plated layer having a surface on which fine spangle are stably formed. A method for producing a hot-dip Al-based metal-plated steel sheet, includes a composition adjusting step of adding a B-containing master alloy so as to adjust a composition of an Al-based hot-dip plating bath (3) containing aluminum as a main component, the composition being adjusted so that the Al-based hot-dip plating bath has a B concentration of not less than 0.005 mass % and a K concentration of more than 0 mass % and less than 0.0005 mass %, the K concentration being reduced in the Al-based hot-dip plating bath by supplying gas into the Al-based hot-dip plating bath so as to remove a suspended matter on a surface of the Al-based hot-dip plating bath.

Owner:NIPPON STEEL CORP

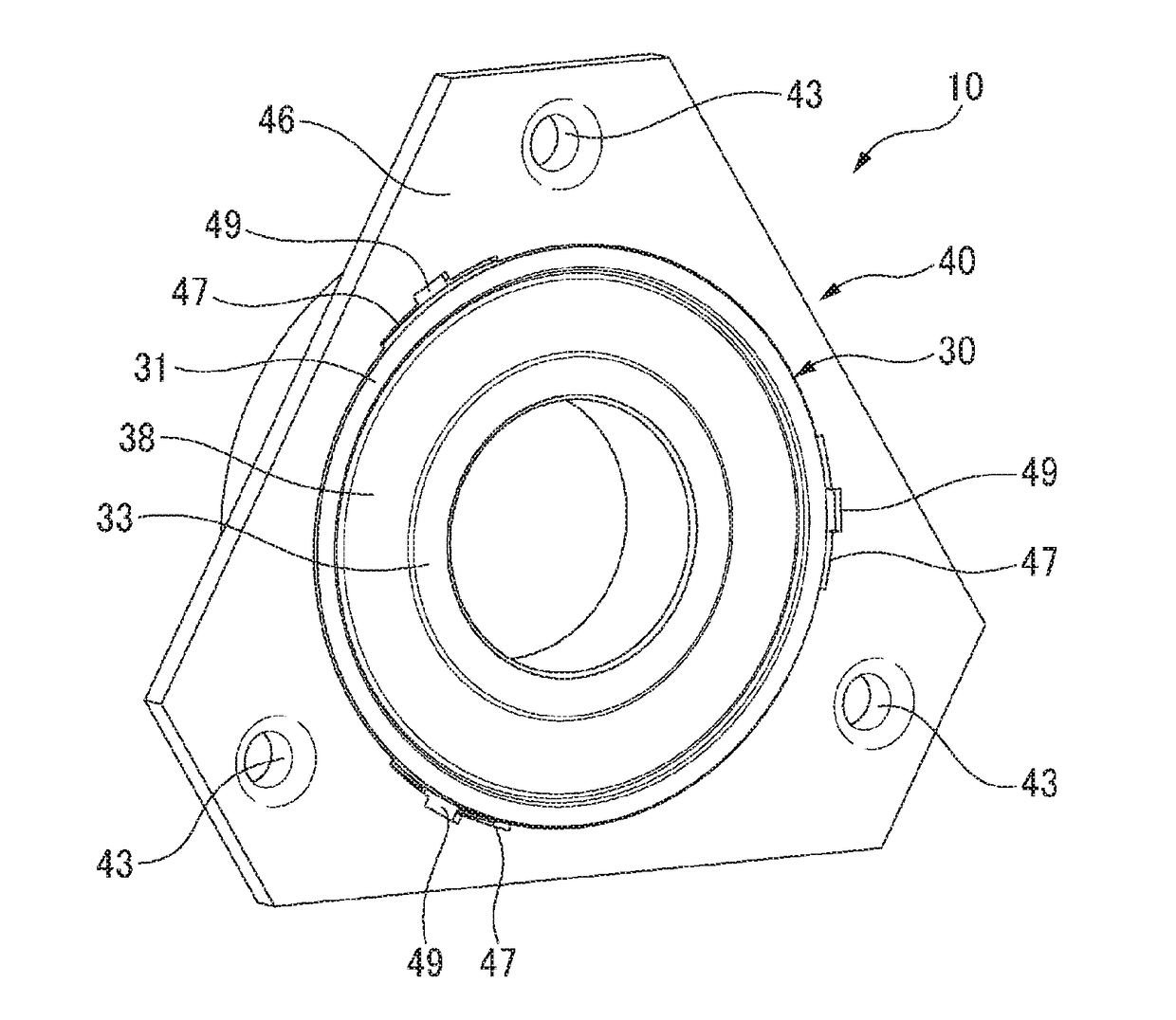

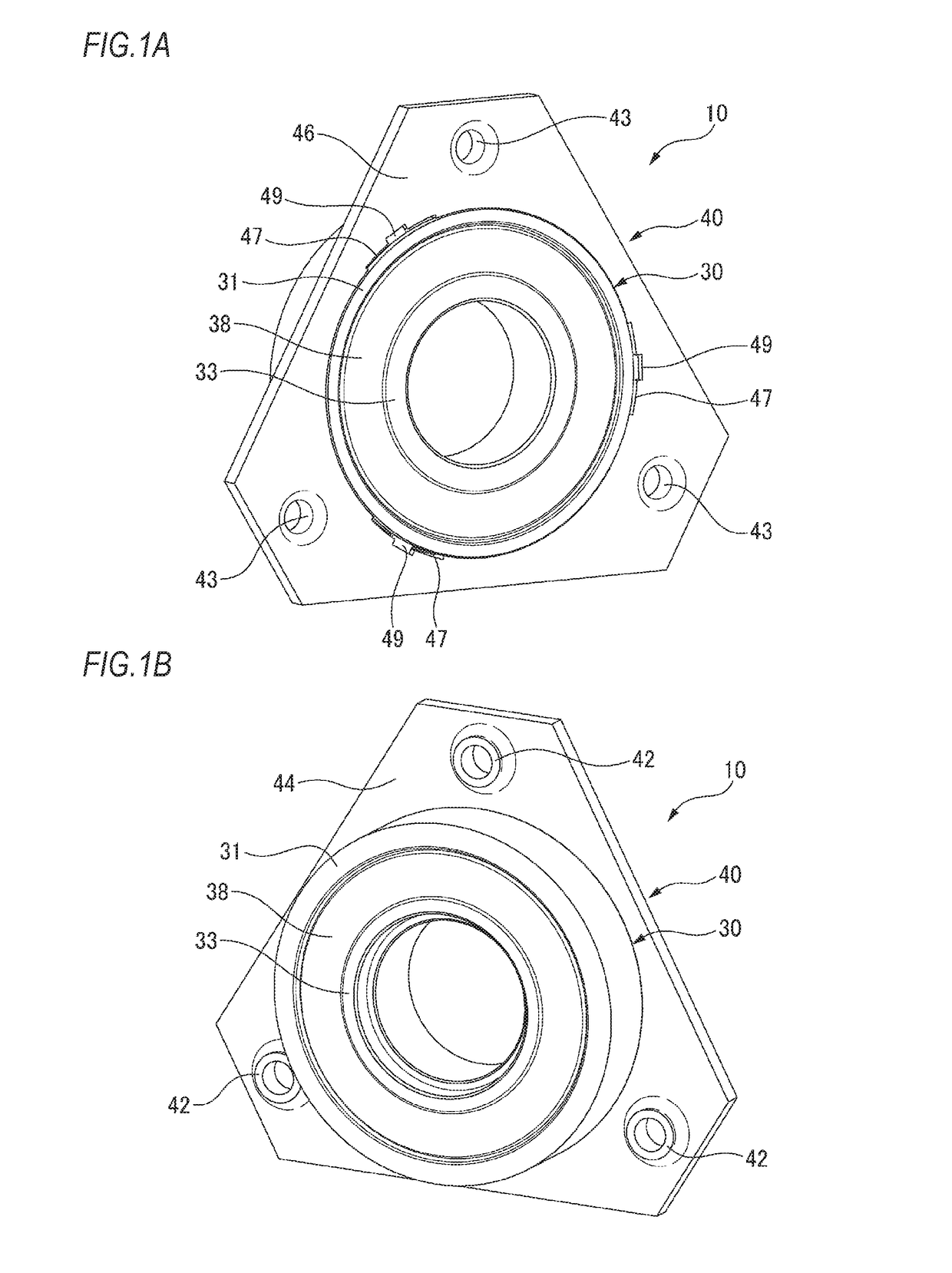

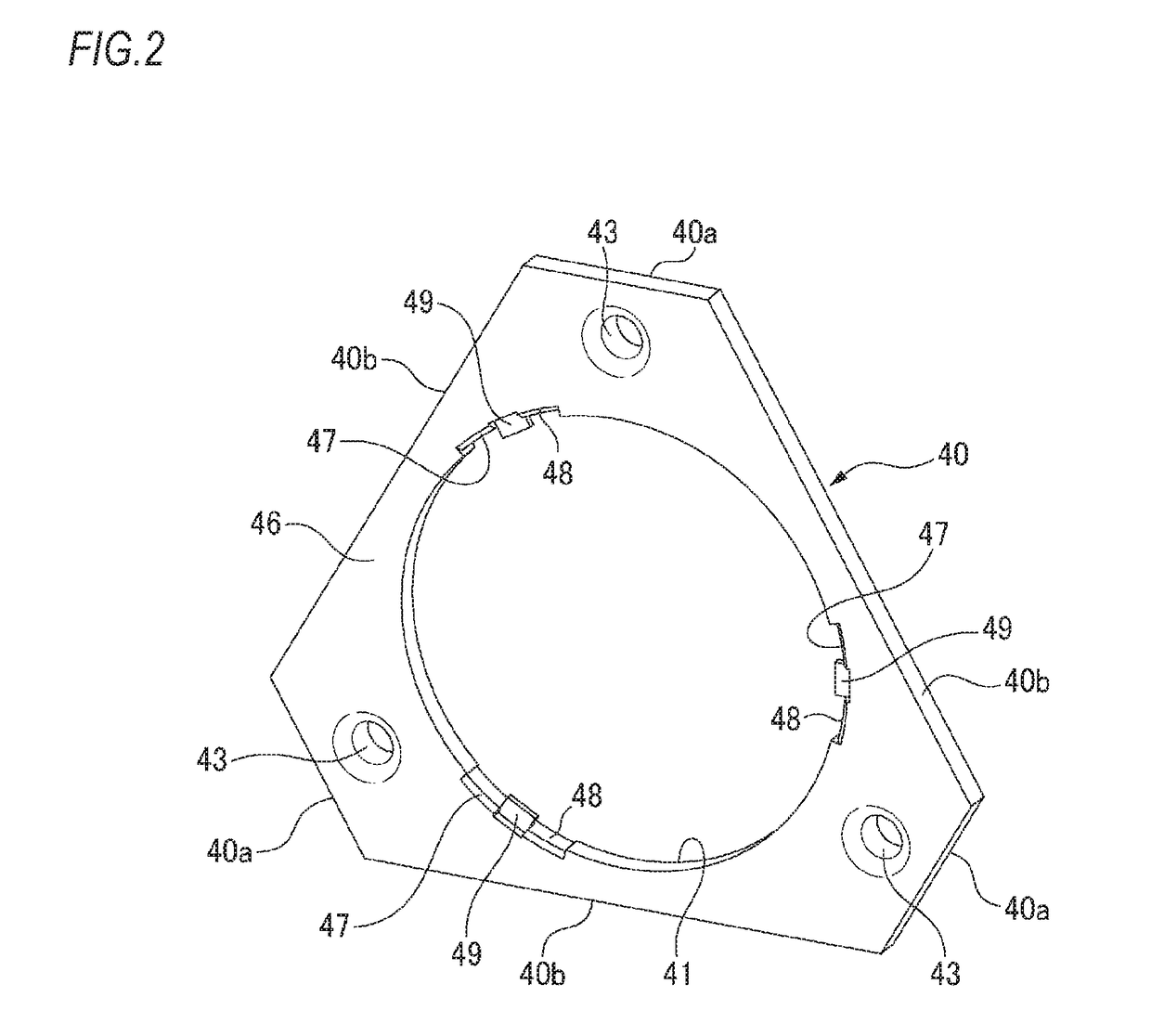

Bearing device and method for manufacturing bearing device

ActiveUS20170114829A1Improve productivityStably formBearing assemblyBall bearingsEngineeringMechanical engineering

An outer peripheral surface of the small-diameter step portion is formed with an engagement groove extending in a circumferential direction. The retainer plate has a plurality of engagement claws protruding radially inward from an inner periphery of the retainer plate defining the fitting hole and configured to be engaged to the engagement groove. In a state that the fitting hole is fitted to the small-diameter step portion, the engagement claws are formed by axially pressing the inner periphery of the retainer plate, including at least thickness reduction parts formed in advance at a peripheral edge between an inner peripheral surface of the fitting hole and a side surface of the retainer plate, and plastically deforming the inner periphery of the retainer plate so as to protrude radially inward, and the engagement claws are engaged to the engagement groove.

Owner:NSK LTD

Electrophotographic photoconductor, and electrophotographic method, electrophotographic apparatus and process cartridge containing the electrophotographic photoconductor

InactiveUS8349529B2Promote degradationIncreased durabilityElectrographic process apparatusCorona dischargeHydrogenHalogen

An electrophotographic photoconductor including a conductive substrate and a photoconductive layer thereover, wherein the photoconductive layer contains a charge generation agent and a charge transport agent represented by General Formula (A-I), (B-I) or (C-I), and an amine compound represented by General Formula (II):where R1-3 each represent hydrogen, halogen or (un)substituted C1-6 alkyl, and n is 1 or 2,where R1-2 each represent C1-6 alkyl and R3-6 each represent hydrogen, halogen or (un)substituted C1-6 alkyl,where R8-33 each represent hydrogen, C1-4 alkyl, C1-4 alkoxy, or (un)substituted phenyl, and may be identical or different,where A and B each represent a group represented by formula (i) or (ii), and may be identical or different:—CH2X formula (i)—CH2CH2Y formula (ii)where X and Y each represent an (un)substituted aromatic group.

Owner:RICOH KK

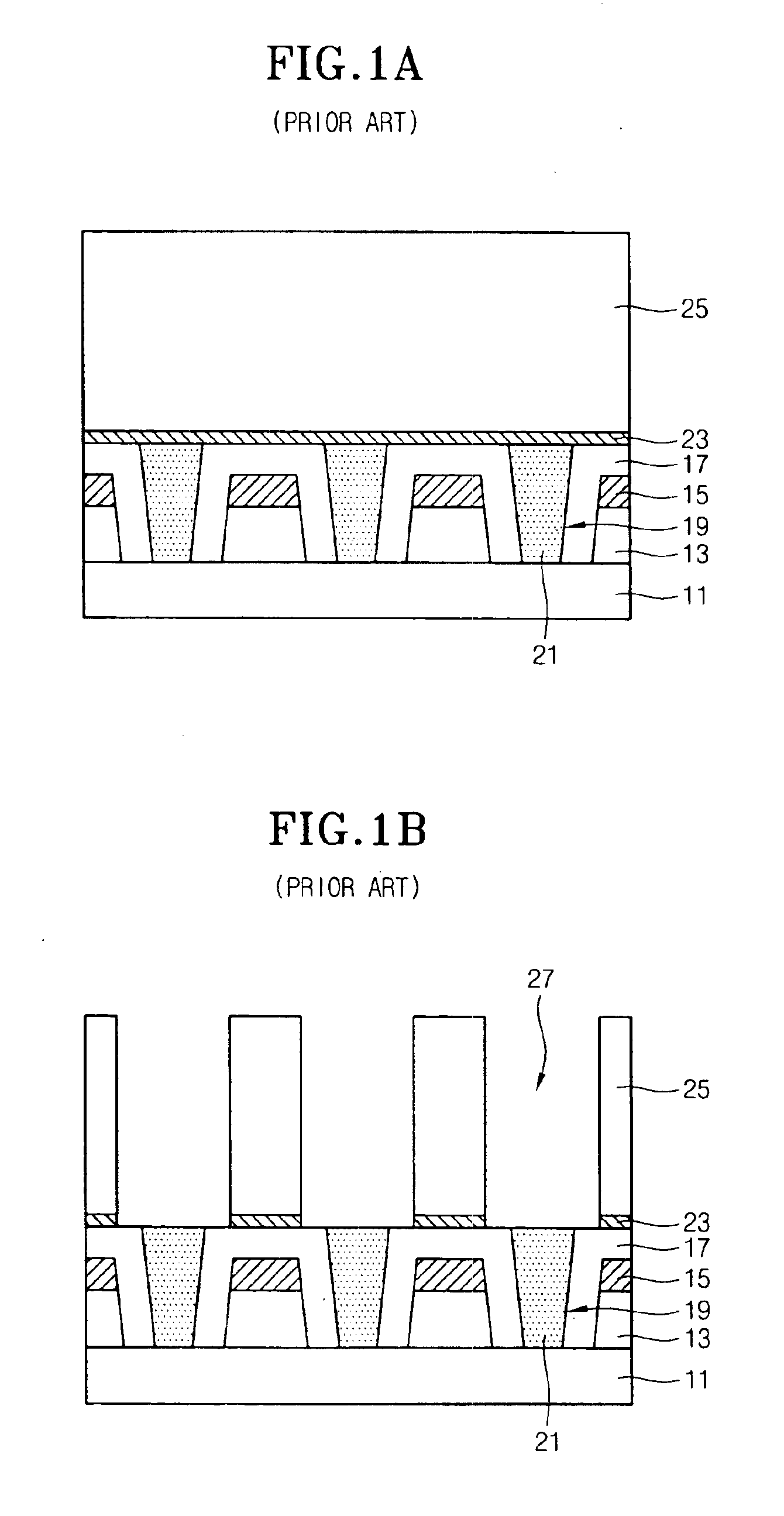

Flexible display device and manufacturing method thereof

ActiveUS9177973B2Increase flexibilityPreventing property deteriorationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

A flexible display device includes: a flexible substrate having a lower substrate including a prominence pattern, a barrier layer pattern on the prominence pattern, and a planarization film; a gate line on the flexible substrate; a data line crossing the gate line with having a gate insulation film therebetween to define a pixel region; a thin film transistor formed at an intersection of the gate line and the data line; and a passivation layer on the flexible substrate including the thin film transistor. With this configuration, the flexible substrate and the flexible display device can be enhanced by preventing property deterioration of the elements due to bending stresses.

Owner:LG DISPLAY CO LTD

Method of manufacturing nanowire array using induced growth

InactiveUS20160189960A1Accurately controlStably formCellsLiquid surface applicatorsNanometreSapphire

Provided is a method of manufacturing a nanowire array using induced growth, in which a nitride inorganic nanowire is grown from a nitride seed by forming the nitride seed on a sapphire or silicon substrate, forming an organic nanowire pattern and a dielectric nanotunnel using the nanowire pattern as a template on the nitride seed, and using the nanotunnel as an induced growth mask.

Owner:POSTECH ACAD IND FOUND

Detergent composition

A detergent composition contains a polyglycerol monoalkyl ether, water, a fat or oil, and a polyol. The polyglycerol monoalkyl ether is present in the composition at a content of 1 to 50 percent by weight based on the total amount of the composition. The detergent composition is useable as a foamable cleansing agent kind to the skin, exhibits superior detergency for oily cosmetics, and is usable even under wet conditions.

Owner:DAICEL CHEM IND LTD

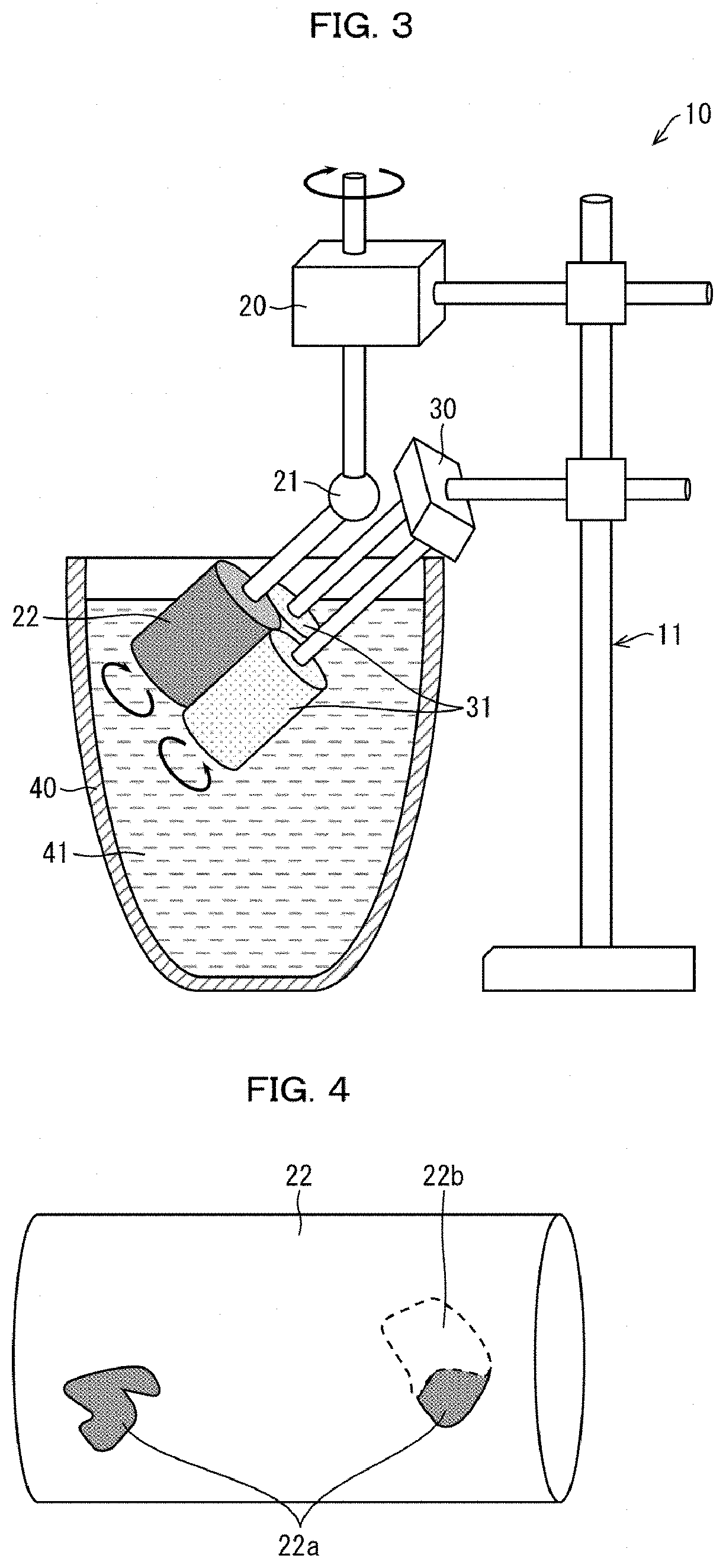

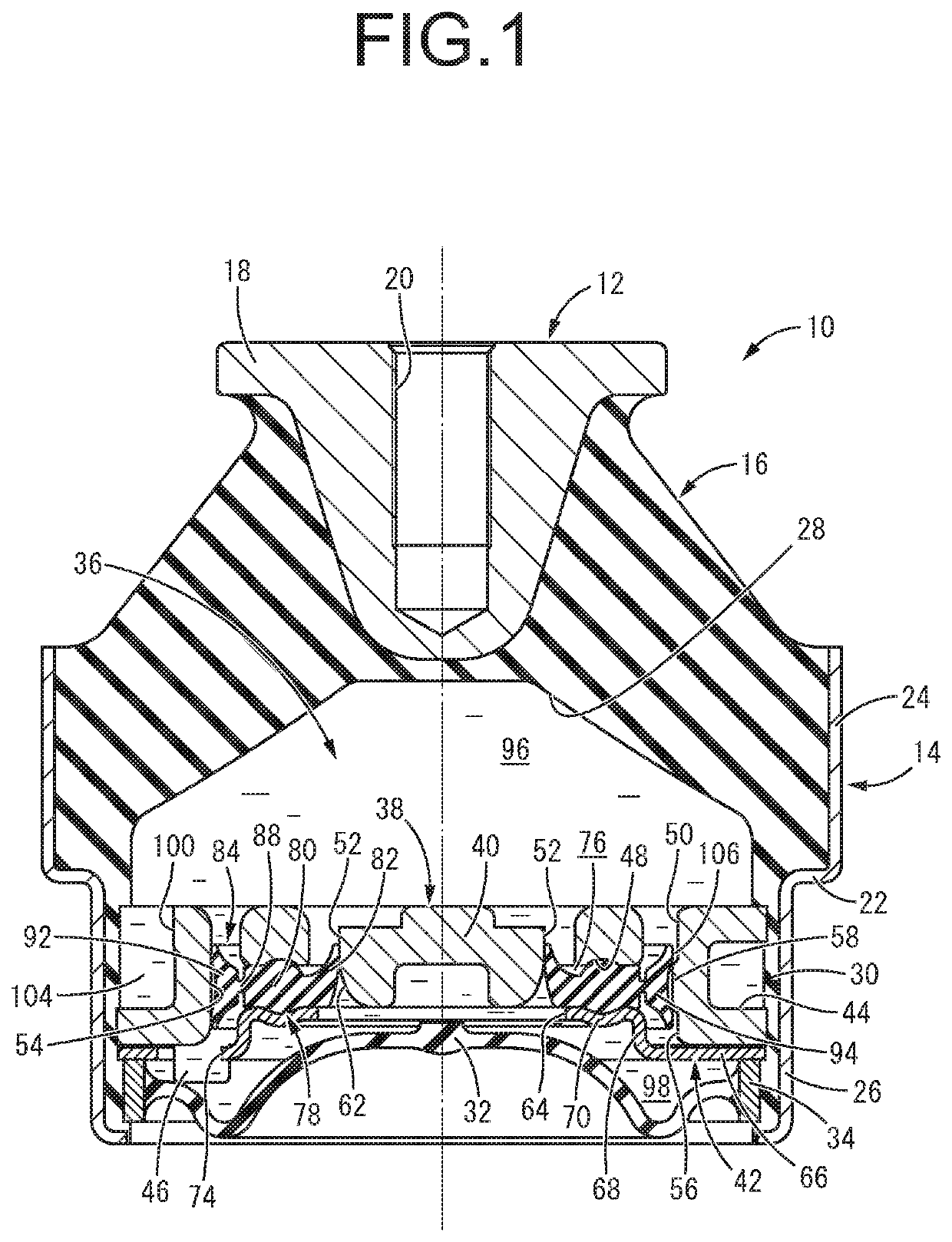

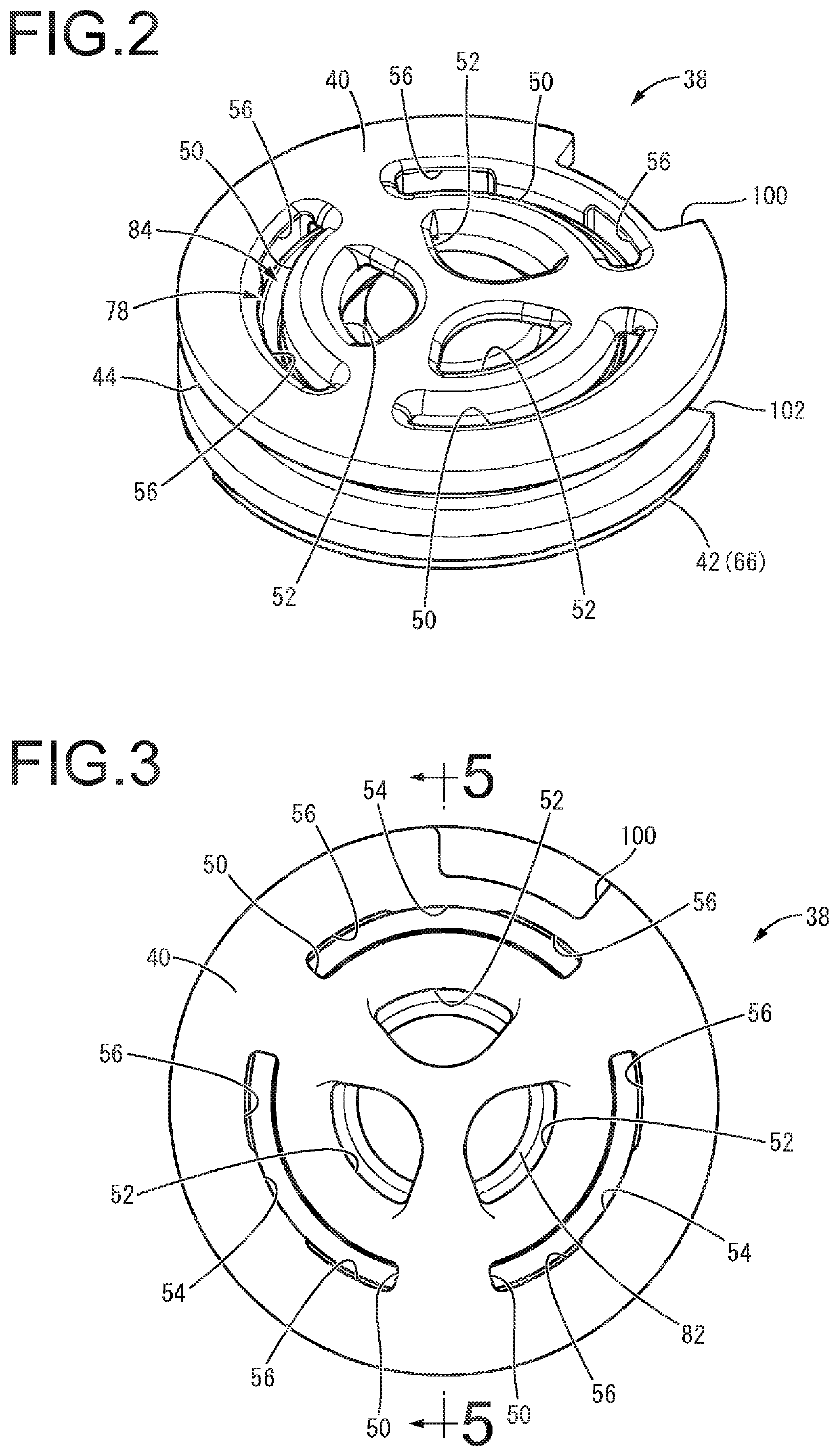

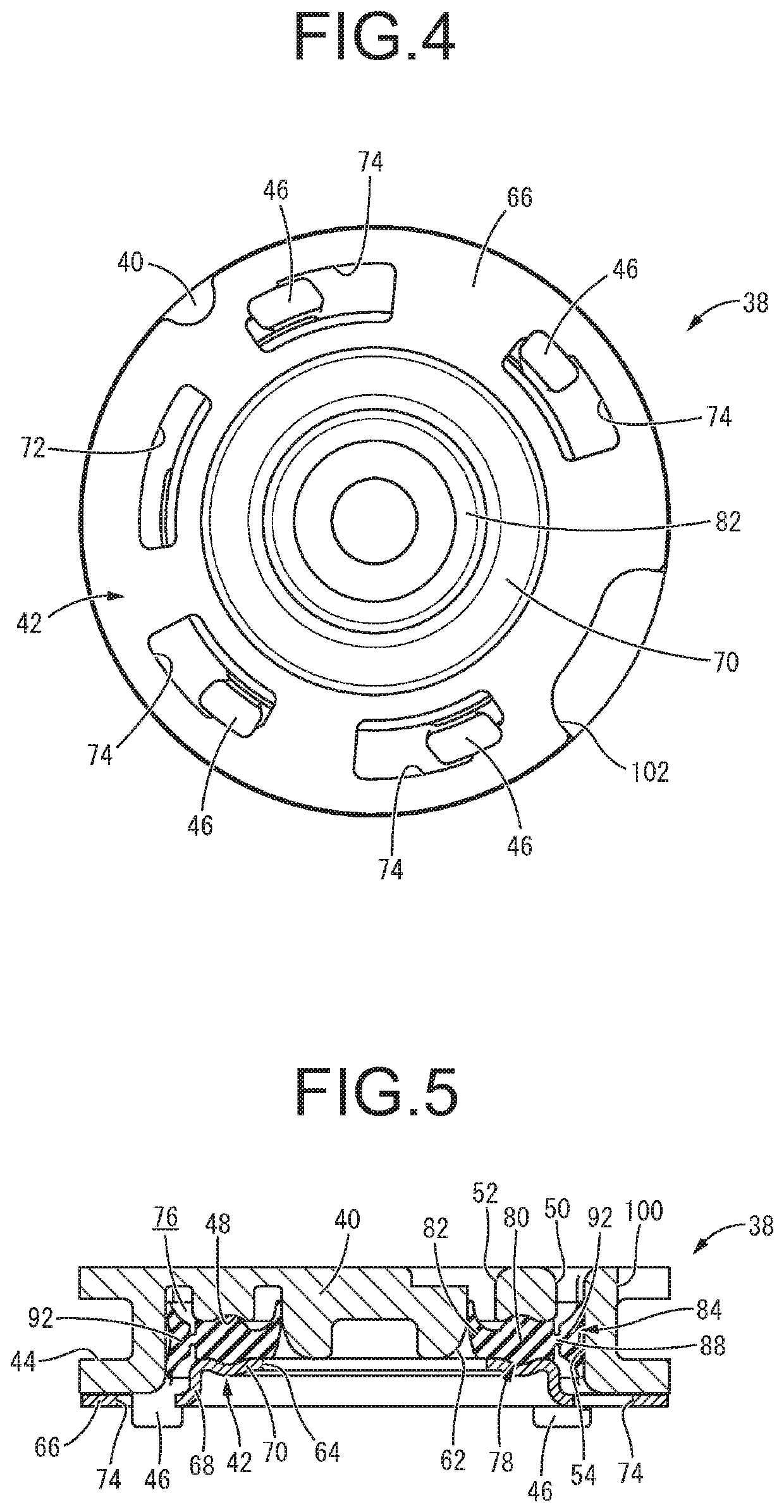

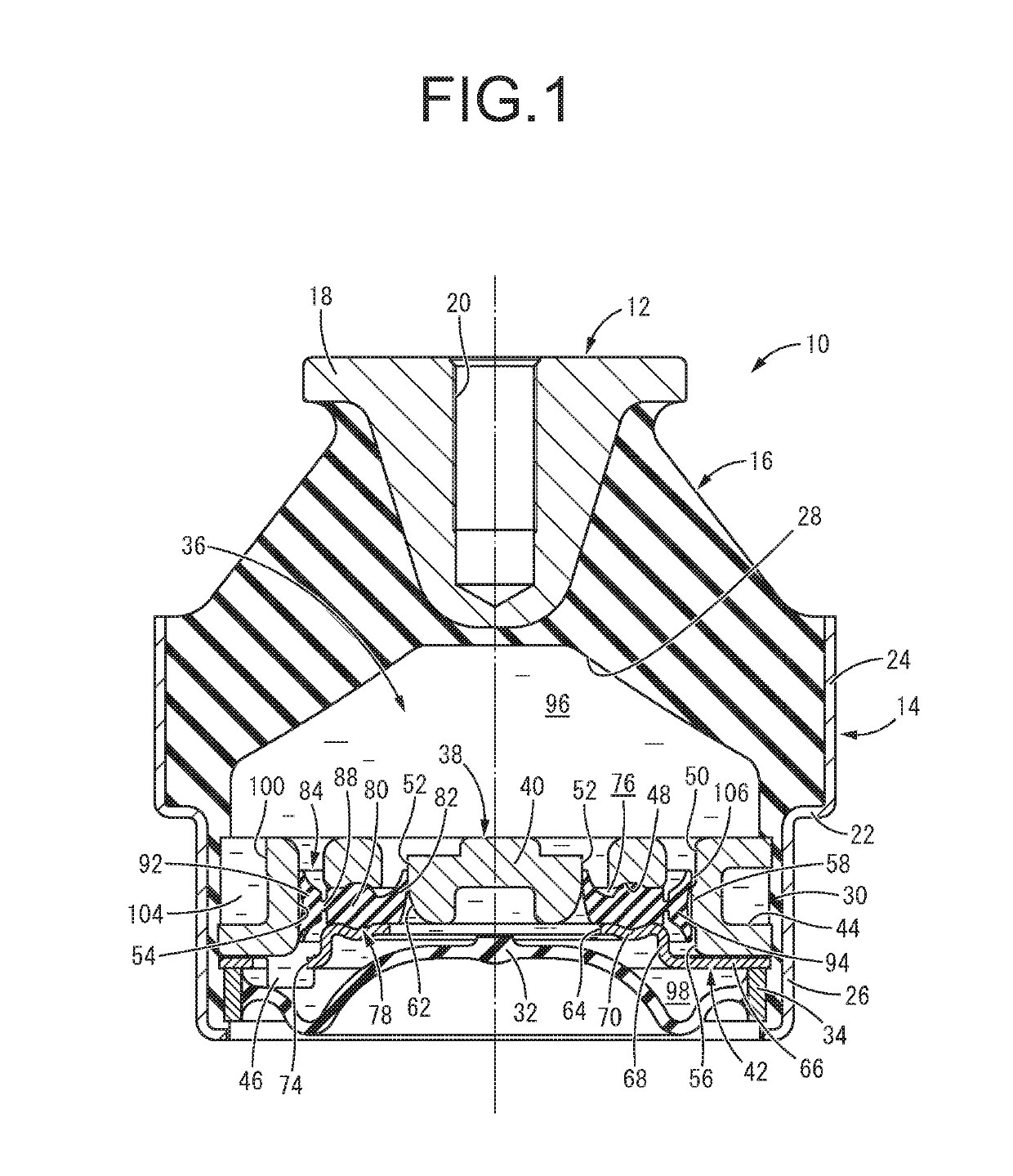

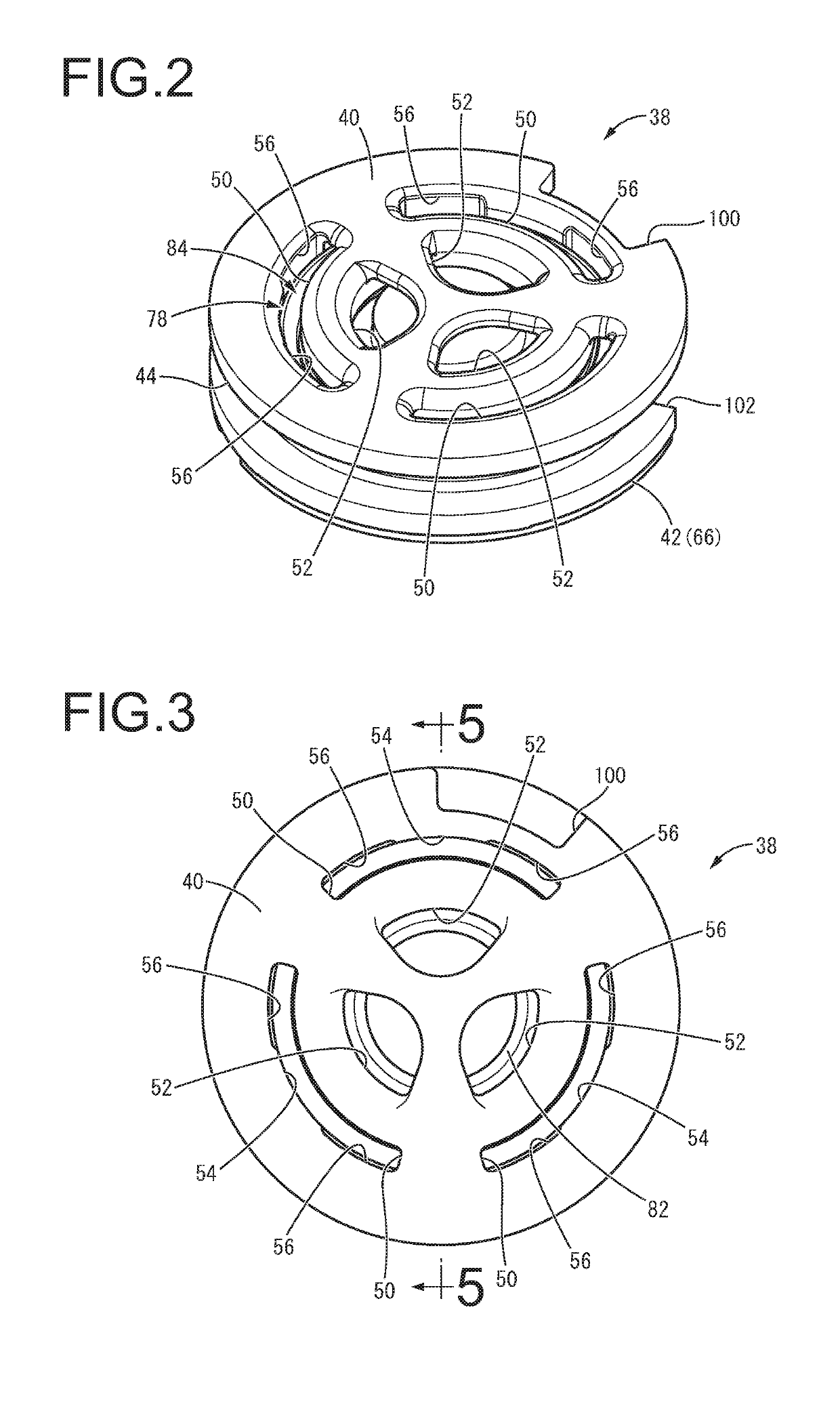

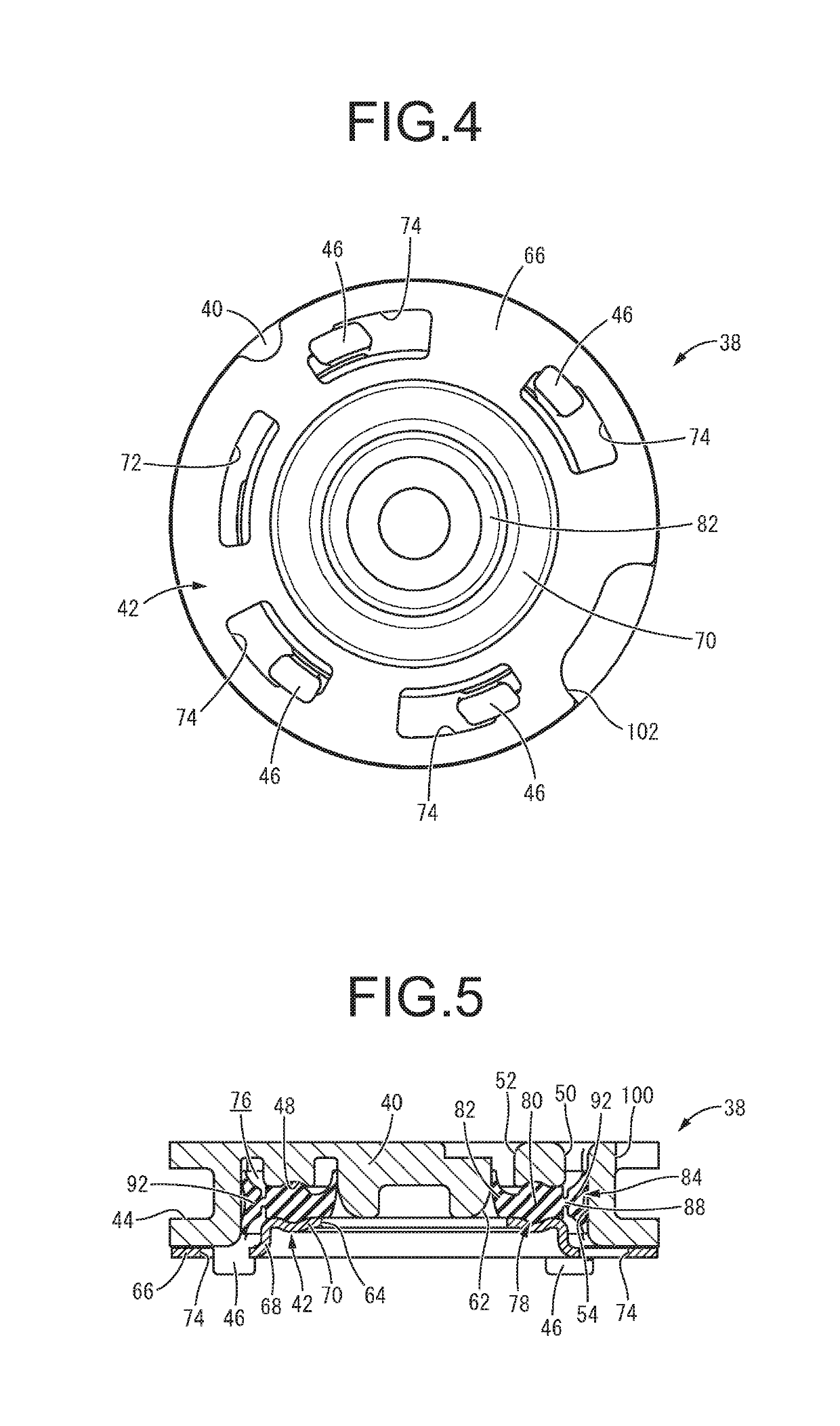

Fluid-filled vibration-damping device

A fluid-filled vibration-damping device including: two elastically-connected attachment members; two liquid chambers divided by a partitioner having a storing space; an elastic mover disposed in the storing space and having a support supported by the partitioner; a positioner provided on at least one of radial inside and outside of the support, partially in a peripheral direction of the support, in abutment against a peripheral wall face of the storing space; a valve separate from the positioner in the peripheral direction, and the peripheral wall face in opposition; an axially-thin part connecting the positioner and the valve to the support in a displaceable manner; a communication passage connecting the liquid chambers formed between the peripheral wall face and the valve; and a switch configured to obstruct the communication passage by abutment of the valve against the peripheral wall face.

Owner:SUMITOMO RIKO CO LTD

Fluid-filled vibration-damping device

ActiveUS20190285133A1Smooth switchingStably formSpringsJet propulsion mountingAbutmentMechanical engineering

A fluid-filled vibration-damping device including: two elastically-connected attachment members; two liquid chambers divided by a partitioner having a storing space; an elastic mover disposed in the storing space and having a support supported by the partitioner; a positioner provided on at least one of radial inside and outside of the support, partially in a peripheral direction of the support, in abutment against a peripheral wall face of the storing space; a valve separate from the positioner in the peripheral direction, and the peripheral wall face in opposition; an axially-thin part connecting the positioner and the valve to the support in a displaceable manner; a communication passage connecting the liquid chambers formed between the peripheral wall face and the valve; and a switch configured to obstruct the communication passage by abutment of the valve against the peripheral wall face.

Owner:SUMITOMO RIKO CO LTD

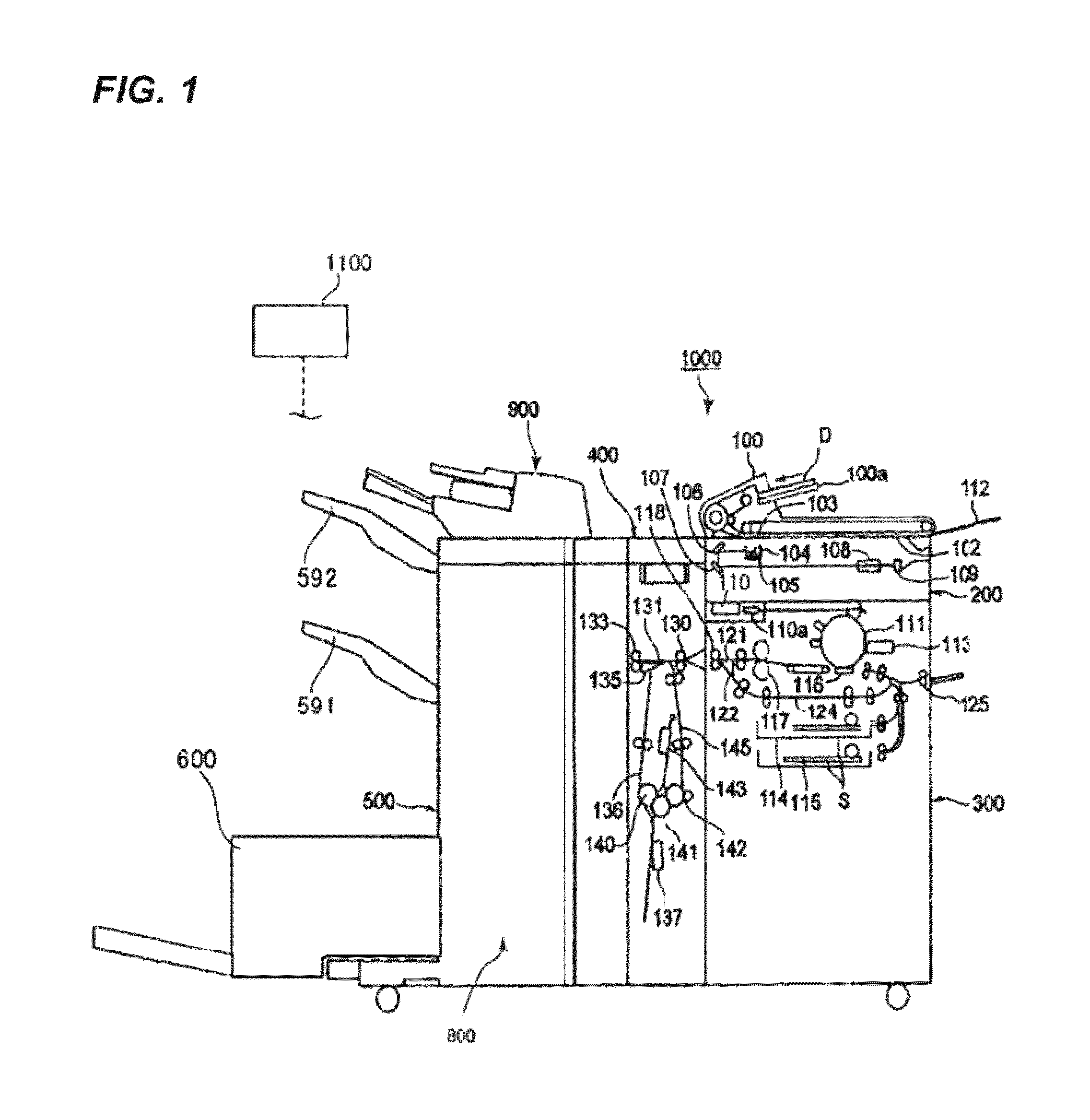

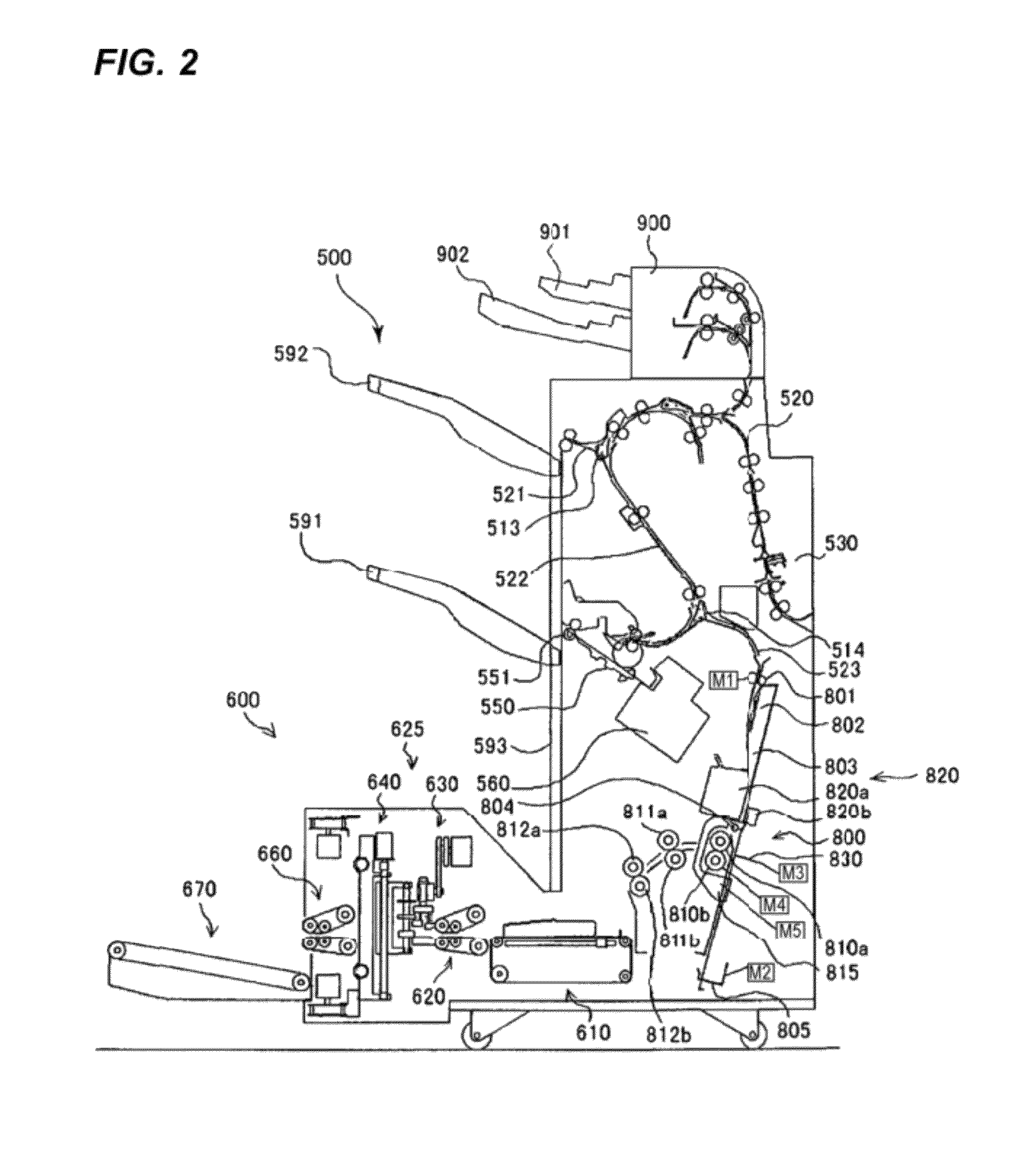

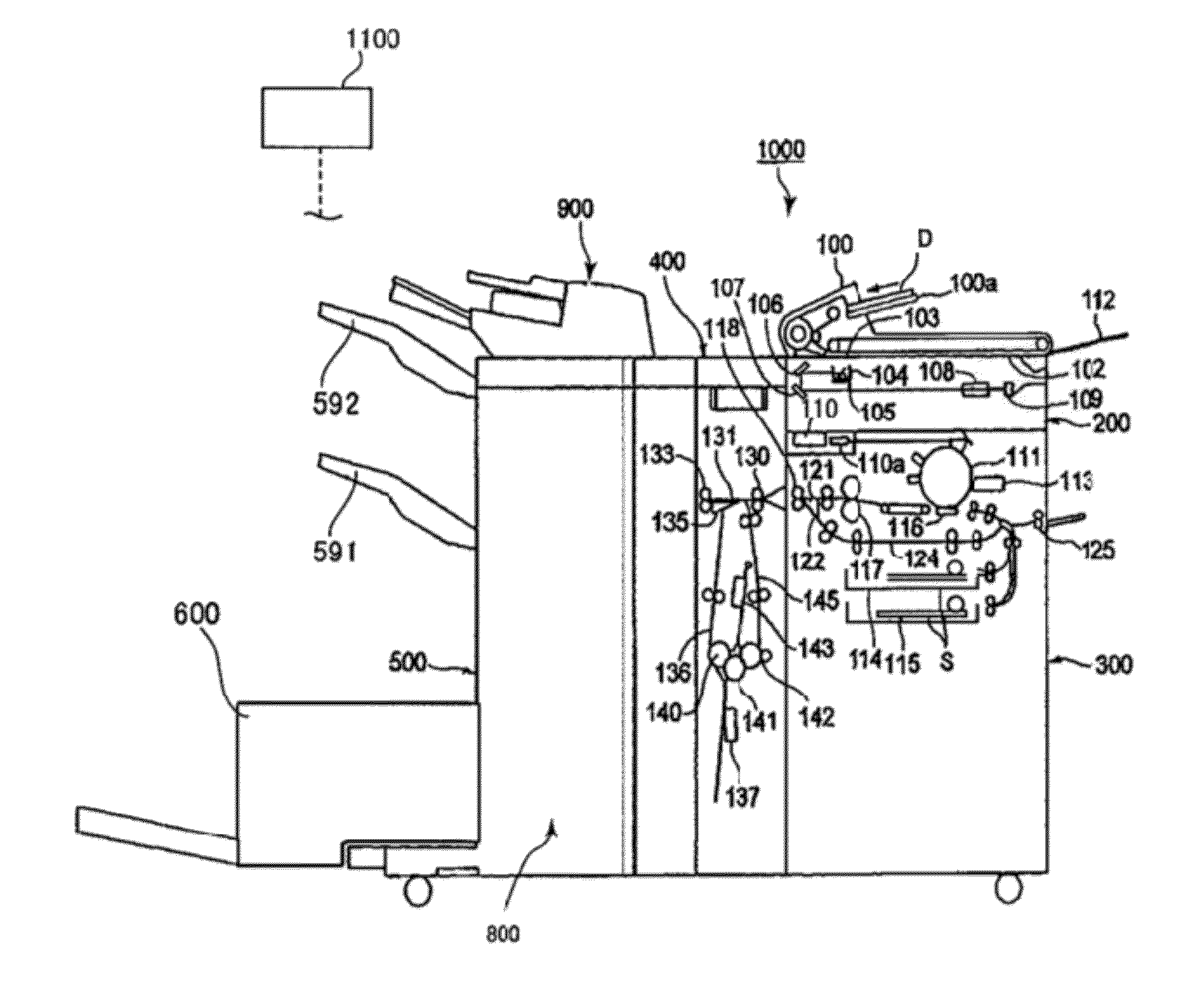

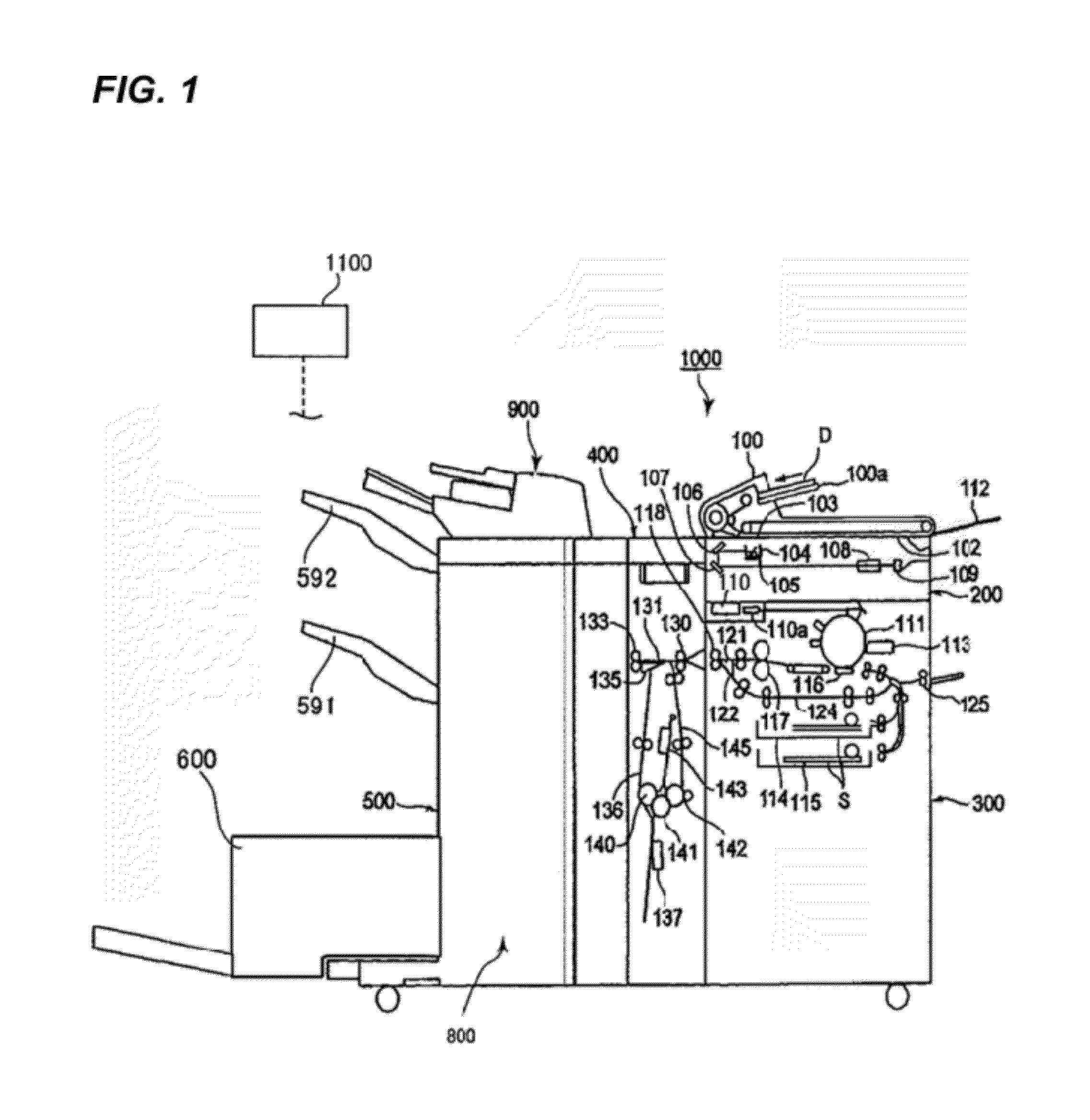

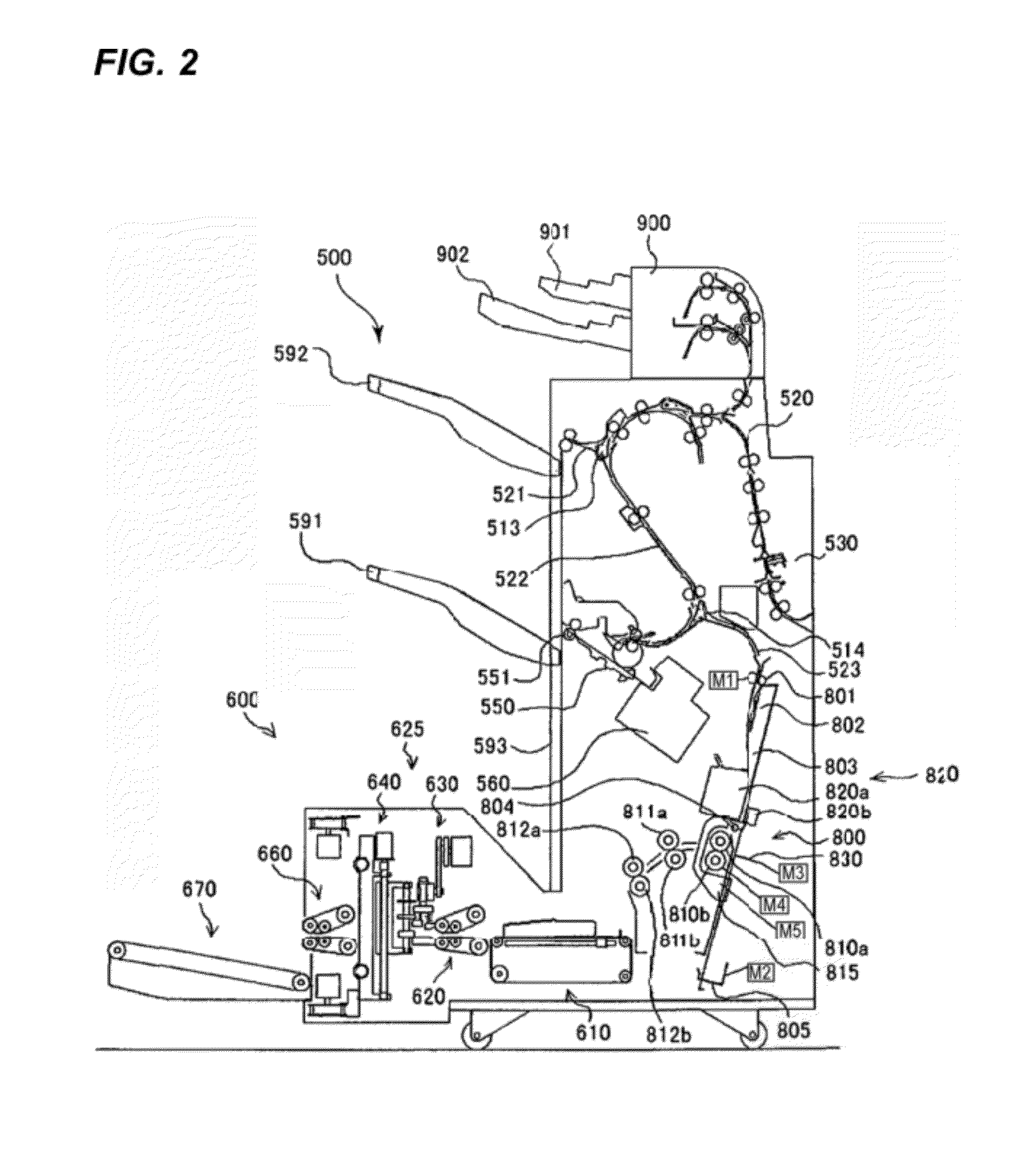

Sheet processing apparatus and image forming apparatus

InactiveUS8544834B2Stably formAvoid bendingMechanical working/deformationFunction indicatorsEngineeringMechanical engineering

Owner:CANON KK

Sheet Processing Apparatus and Image Forming Apparatus

InactiveUS20120028778A1Stably formAvoid bendingMechanical working/deformationFunction indicatorsEngineeringMechanical engineering

Owner:CANON KK

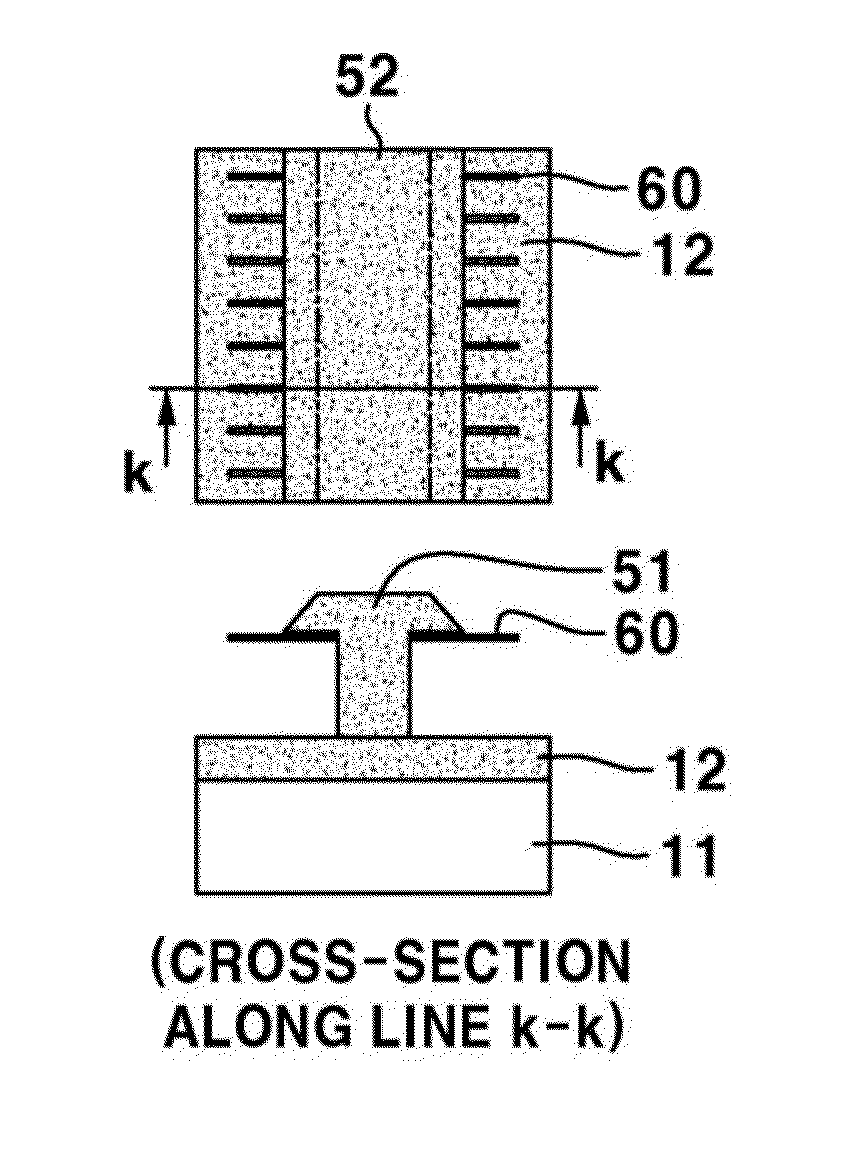

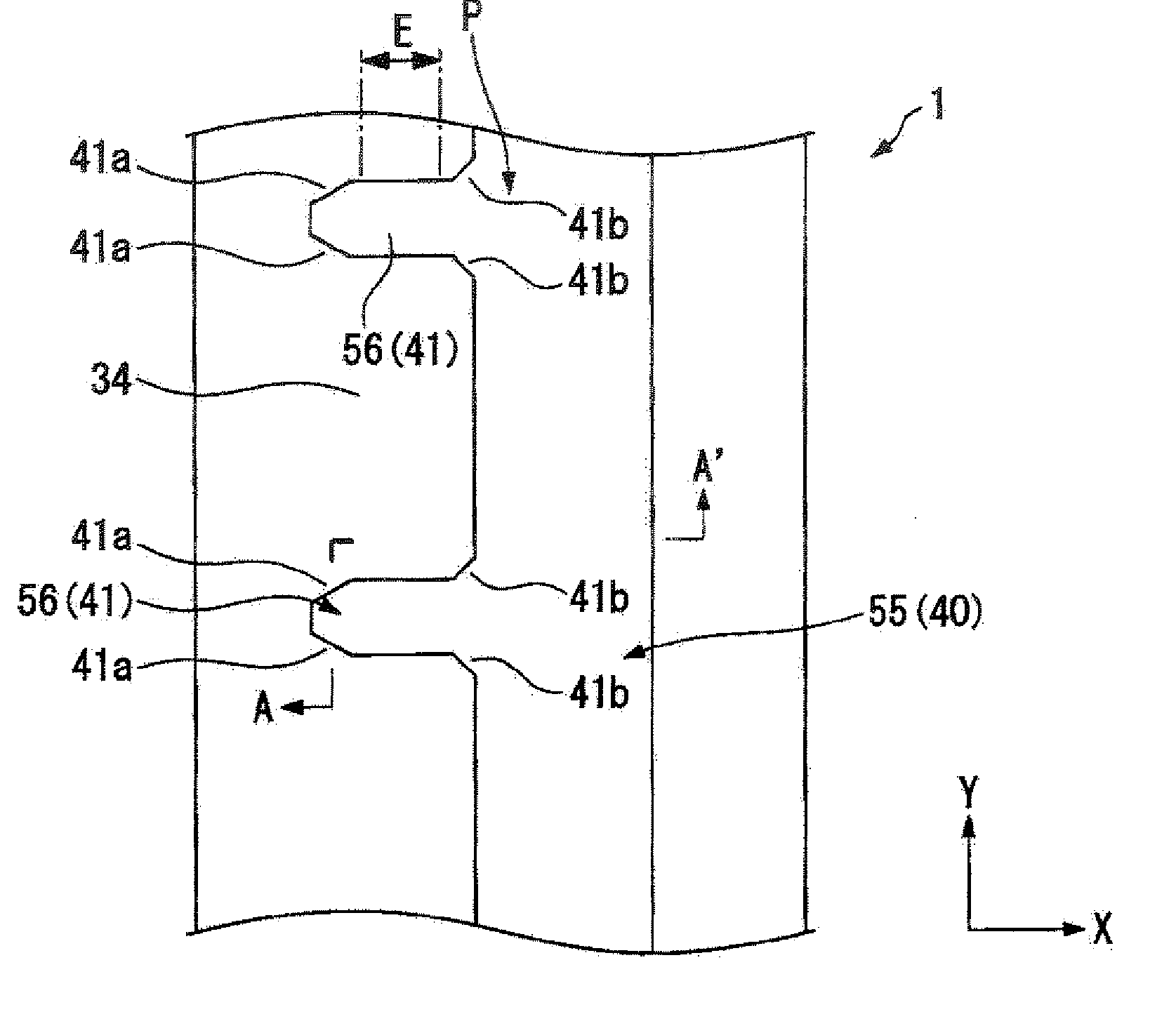

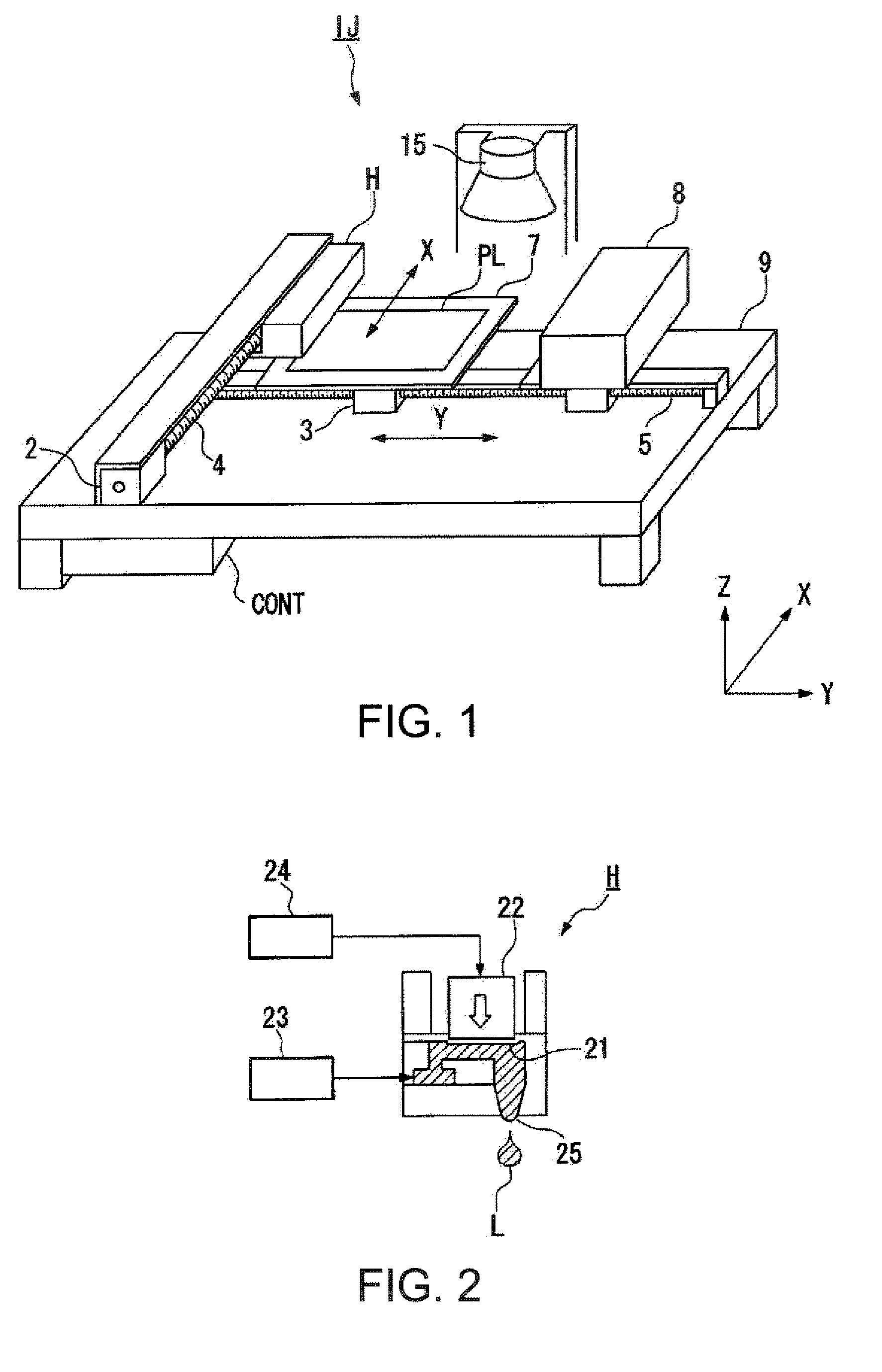

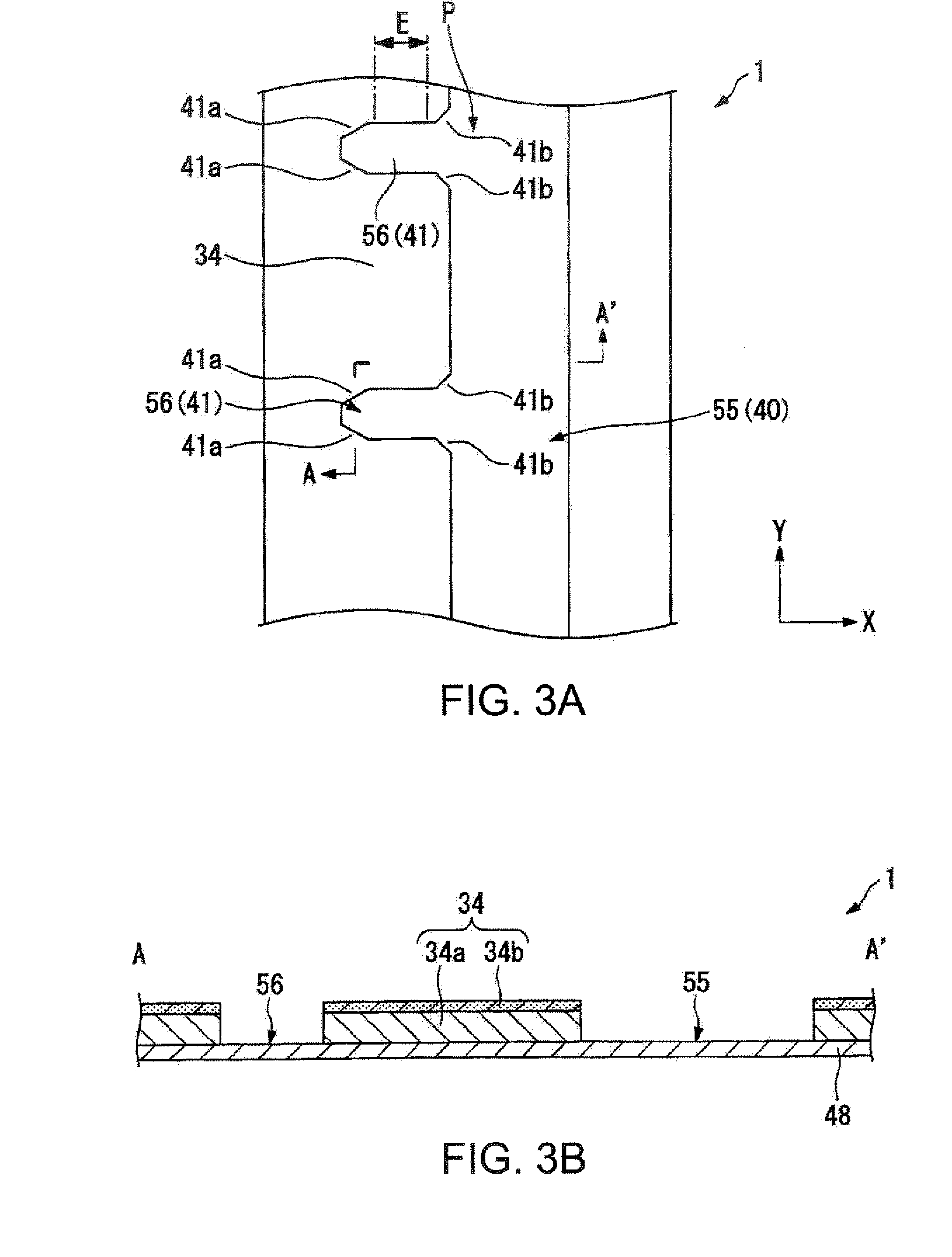

Film pattern forming method, device, electro-optical apparatus, and electronic appliance

InactiveUS20070117233A1Stably formFlow length be shortenPrinted circuit aspectsPhotomechanical apparatusEngineeringElectro-optics

A method for forming a film pattern by disposing a functional fluid on a substrate, includes: forming a partition wall that includes a first opening that corresponds to a first film pattern and a second opening that corresponds to a second film pattern; and disposing a droplet of the functional fluid into the first opening, so that the functional fluid is disposed into the second opening by a self-flow of the functional fluid; wherein: the first film pattern is linear; the second film pattern is narrower than the first film pattern, and is connected to the first film pattern at a rear edge thereof; and a front edge of the second film pattern has a missing part in which a corner of a rectangular contour is missing.

Owner:SEIKO EPSON CORP

Image forming apparatus and image forming method

InactiveUS20110129265A1Reduce frictionStably formElectrographic process apparatusMechanical engineeringImage formation

Owner:SEIKO EPSON CORP

Detergent composition

A detergent composition contains a polyglycerol monoalkyl ether, water, a fat or oil, and a polyol. The polyglycerol monoalkyl ether is present in the composition at a content of 1 to 50 percent by weight based on the total amount of the composition. The detergent composition is useable as a foamable cleansing agent kind to the skin, exhibits superior detergency for oily cosmetics, and is usable even under wet conditions.

Owner:DAICEL CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com