Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "High production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

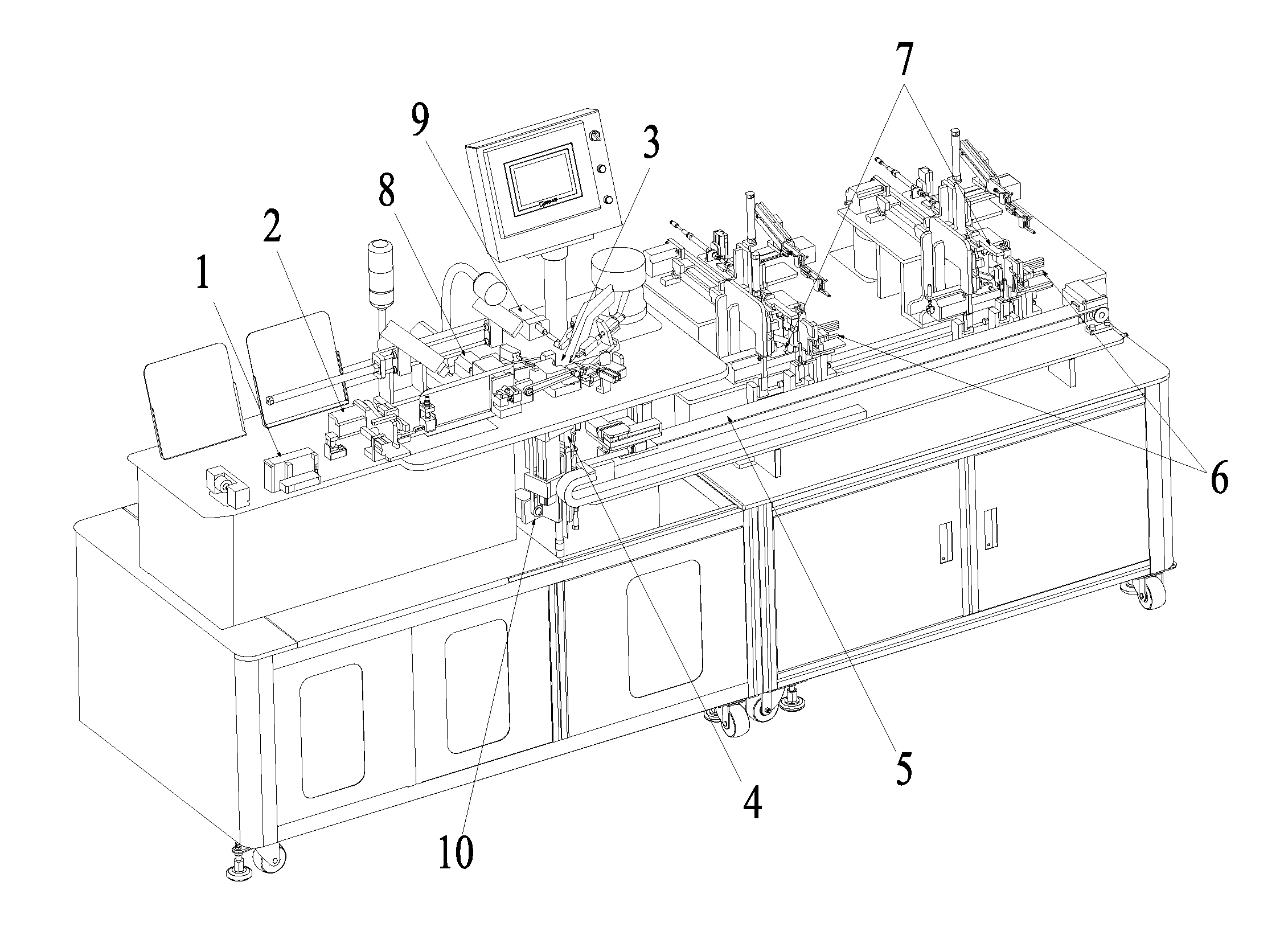

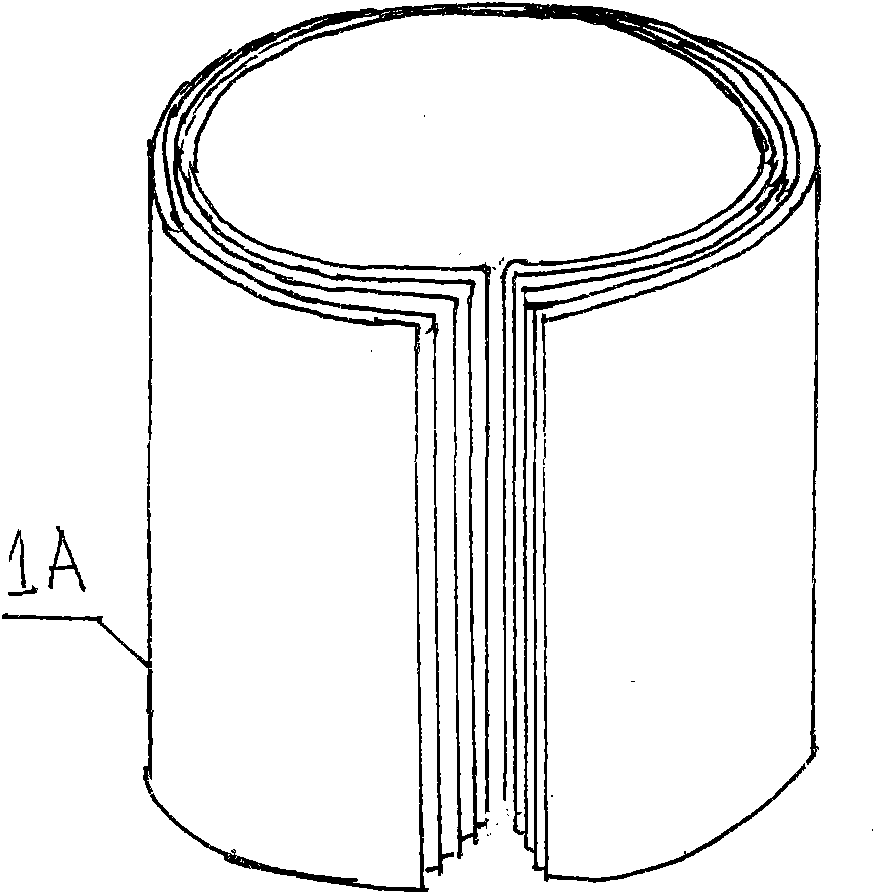

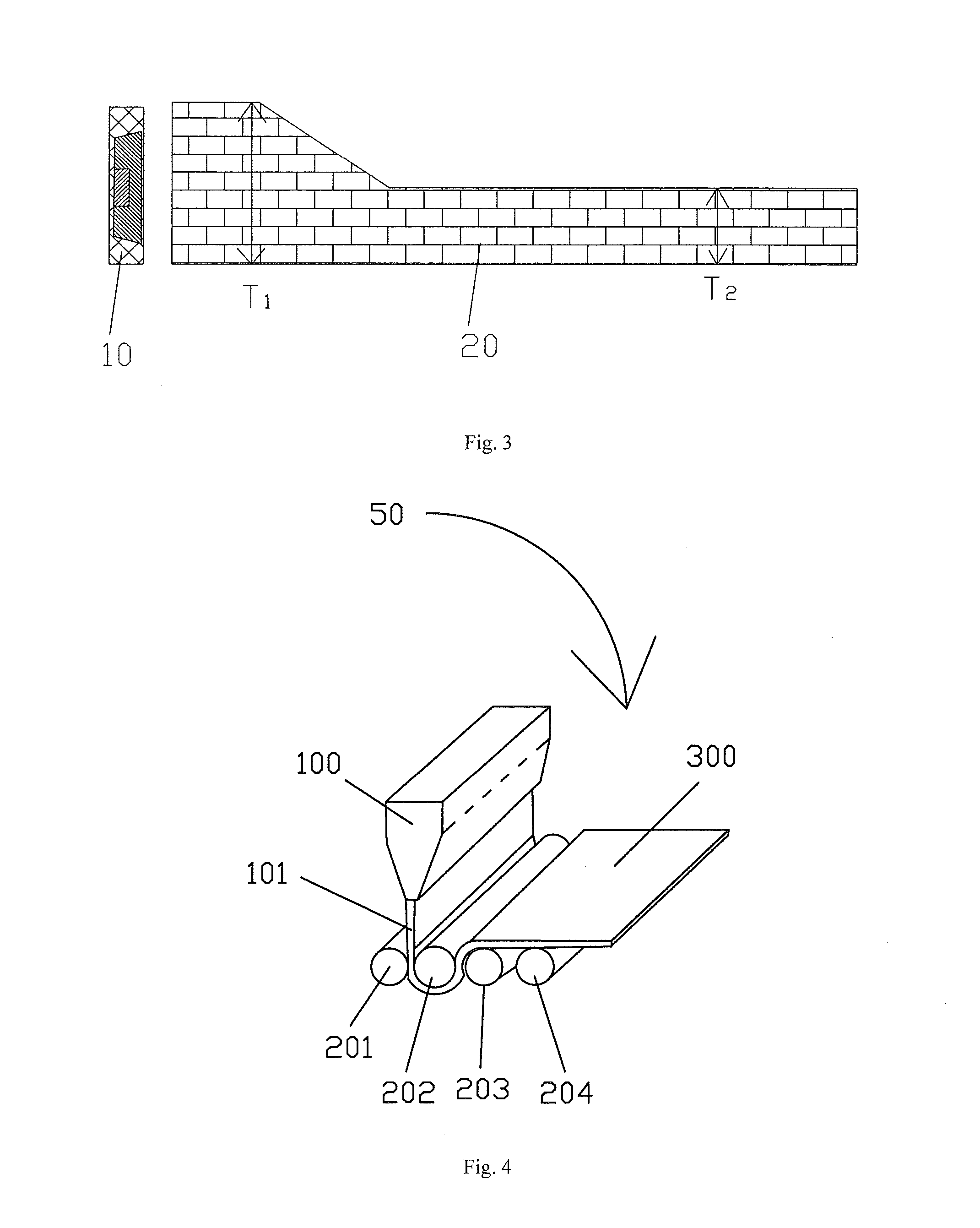

Full-automatic Network Transformer Winding Machine

ActiveUS20160307698A1High production efficiencyHigh product acceptabilityCoils manufactureWire cuttingWinding machine

The invention provides a full-automatic network transformer winding machine, comprising a T1 ring winding device and a T2 ring winding device connected with said T1 ring winding device, wherein said T1 ring winding device includes an enameled wire pre-cutting mechanism, a stranding mechanism before T1 ring winding, a T1 ring winding mechanism and a tail wire-cutting mechanism which are connected with one another sequentially, and said T2 ring winding device includes a separating mechanism, a stranding mechanism before T2 ring winding and a T2 ring winding mechanism which are connected with one another sequentially. The full-automatic network transformer winding machine of the invention can completely replace manual winding to manufacture the network transformer, has high production efficiency and high product acceptability, and meanwhile provides great convenience to automatically realize shell mounting and end wrapping in subsequent processes.

Owner:ZHUHAI HENGNUO SCI & TECH CO LTD

High counts and high density down-proof fabric production method

The invention discloses a manufacturing method of high count and high density down-proof cloth. The cloth of the invention is made from a long-staple cotton combed yarn after procedures of warping, sizing, reeding, air-jet weaving, cloth inspecting, finishing, packing and stocking, etc. The sized yarn is made from mixed slurry of PVA and etherifying starch and sized by double-clip-double-nip and high temperature sizing; the weaving adopts the air-jet weaving and the ratio of a weft tension peak value and weft tension strength is controlled to be less than or equal to 55 percent. The invention is characterized by simple operation, easy control, high production efficiency and product quality, high cloth quality of produced products, smooth, even and clean cloth surface, soft and fine texture, erect and smooth hand feeling, special high moisture absorption and discharging performance, and the invention resembles to imitating the style of silk fabric, which is beneficial for improving downstream processing procedure and processing quality.

Owner:丁宏利

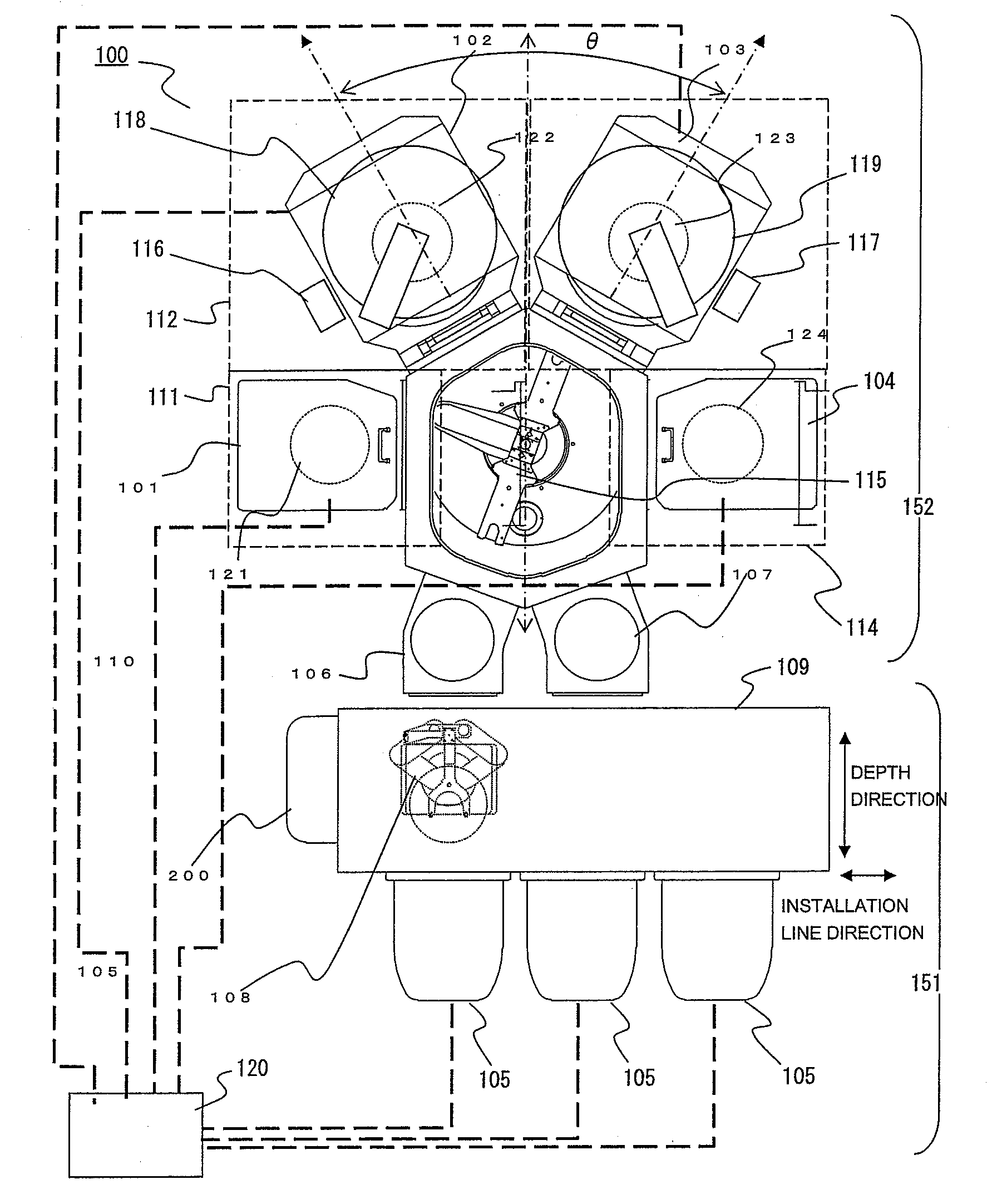

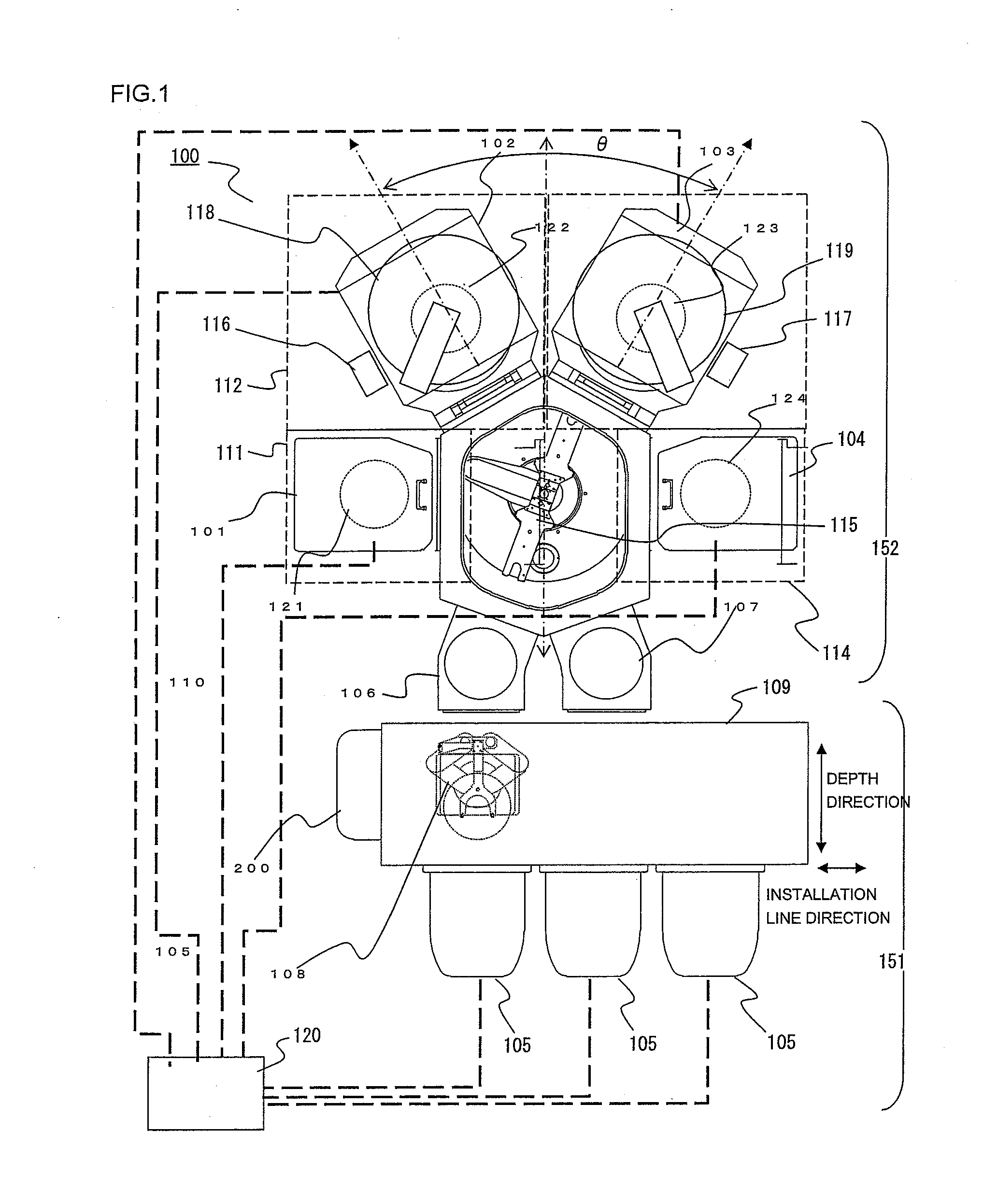

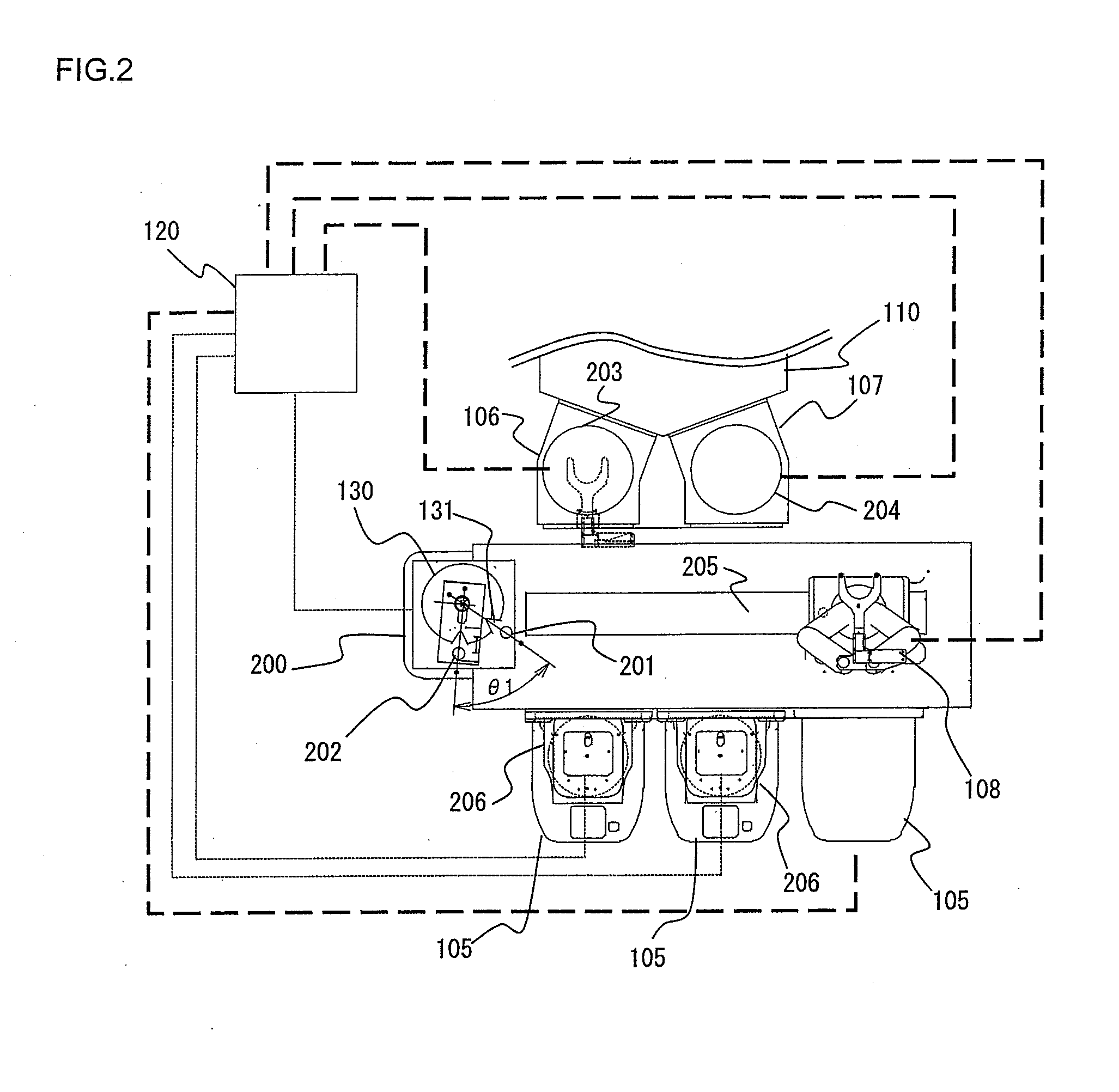

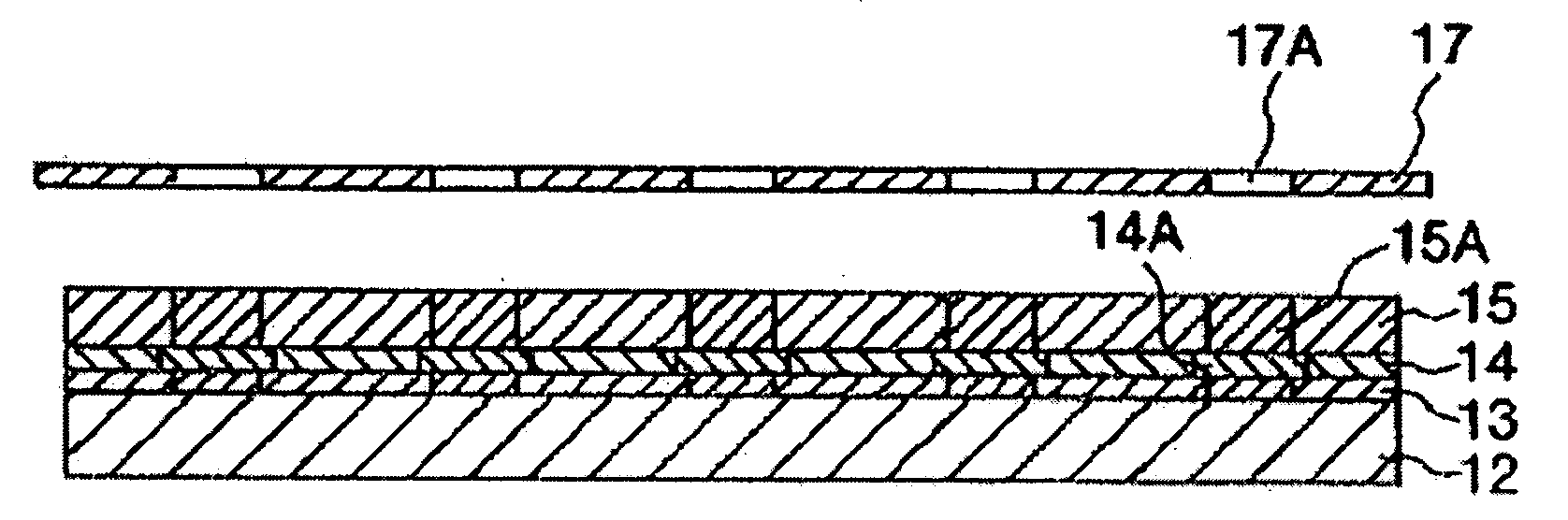

Vacuum processing apparatus

InactiveUS20080112780A1High accuracyHigh production efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringMagnetic tape

The invention provides a vacuum processing apparatus comprising: a plurality of vacuum vessels, each having a processing chamber capable of processing a subject substrate sample placed therein under reduced pressure; a cassette stage for mounting a cassette capable of containing a plurality of the samples; at least one transfer apparatus for transferring the sample from the cassette to the processing chamber in one of the vacuum vessels along a predetermined path and returning the sample processed in the processing chamber to the cassette; and an aligner placed on the path between the cassette stage and the plurality of vacuum vessels for aligning the sample to a predetermined position. The aligner aligns the sample to different positions depending on processings applied to the sample.

Owner:HITACHI HIGH-TECH CORP

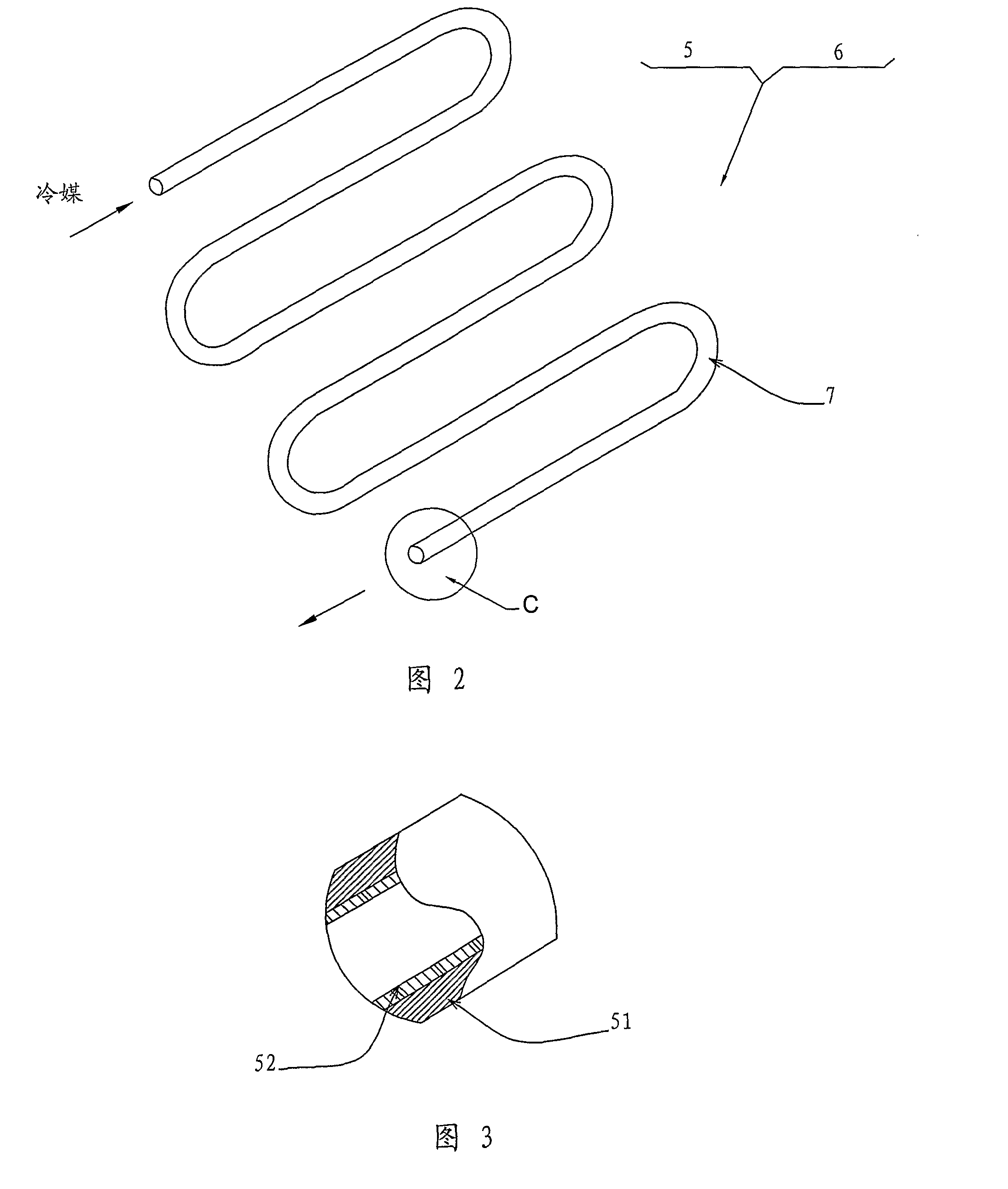

Cu/Al COMPOSITE PIPE AND A MANUFACTURING METHOD THEREOF

InactiveUS20090308481A1Reduce manufacturing processHigh production efficiencyTemperature control deviceMetal rolling stand detailsPercentage reductionRefrigerated temperature

A Cu / Al composite pipe and a manufacturing method thereof are disclosed. The inner layer of the pipe is Cu, and the outer layer is Al. The combinative layer is formed between the two layers due to mutual diffusion of Cu and Al. The raw composite pipe is rolled with single rolling by a planetary rolling machine, wherein the rolling process has the single pass percentage reduction of area of 50%˜95%, an exit rolling speed of 5˜30 m / min, a temperature in the deformation area of 200° C. ˜600° C. The pipe can be used in many fields, such as architecture, refrigeration, air-conditioners, refrigerators, solar energy, water heaters, condensers and radiators, etc.

Owner:JIANGSU XINGRONG HI TECH

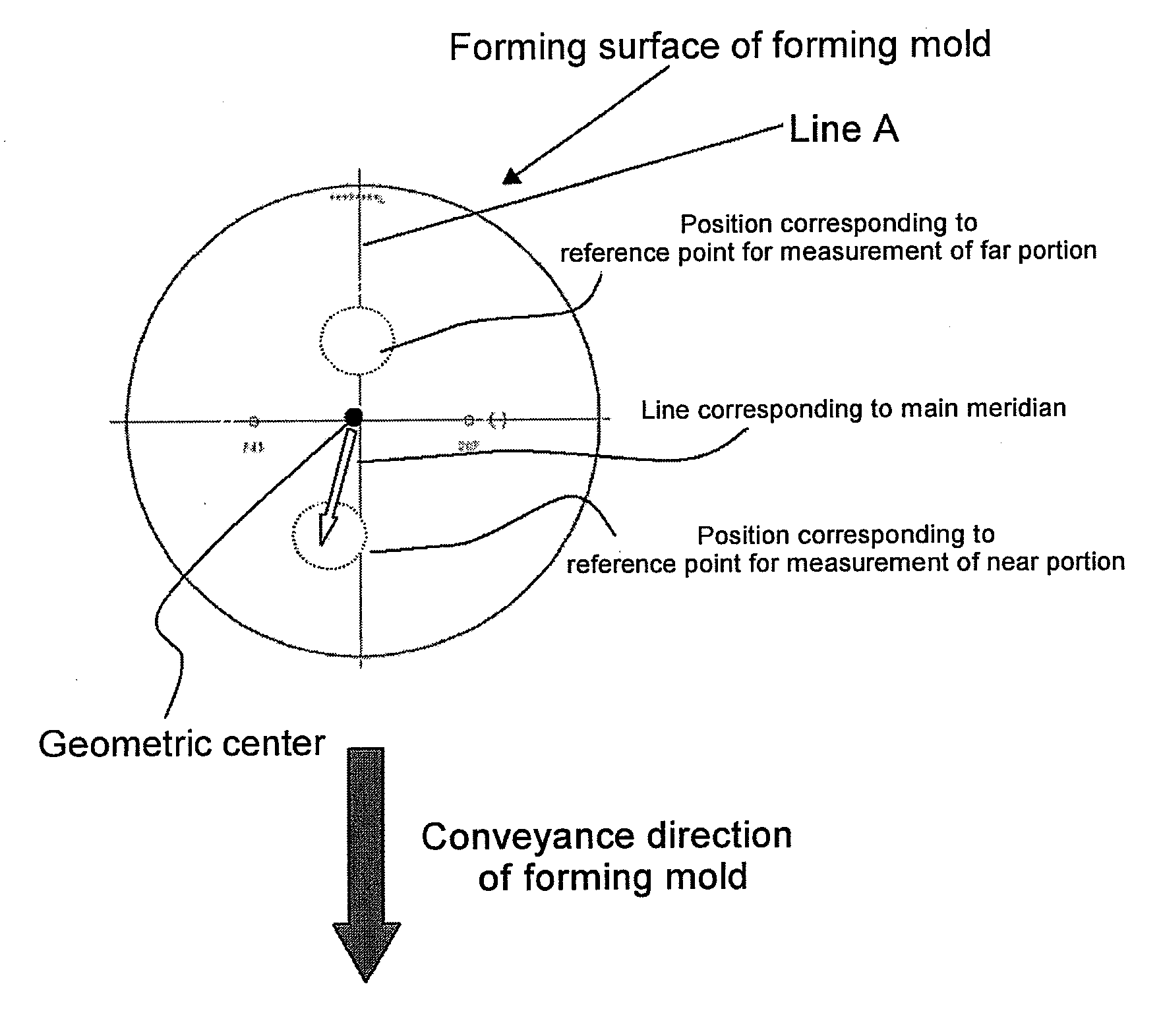

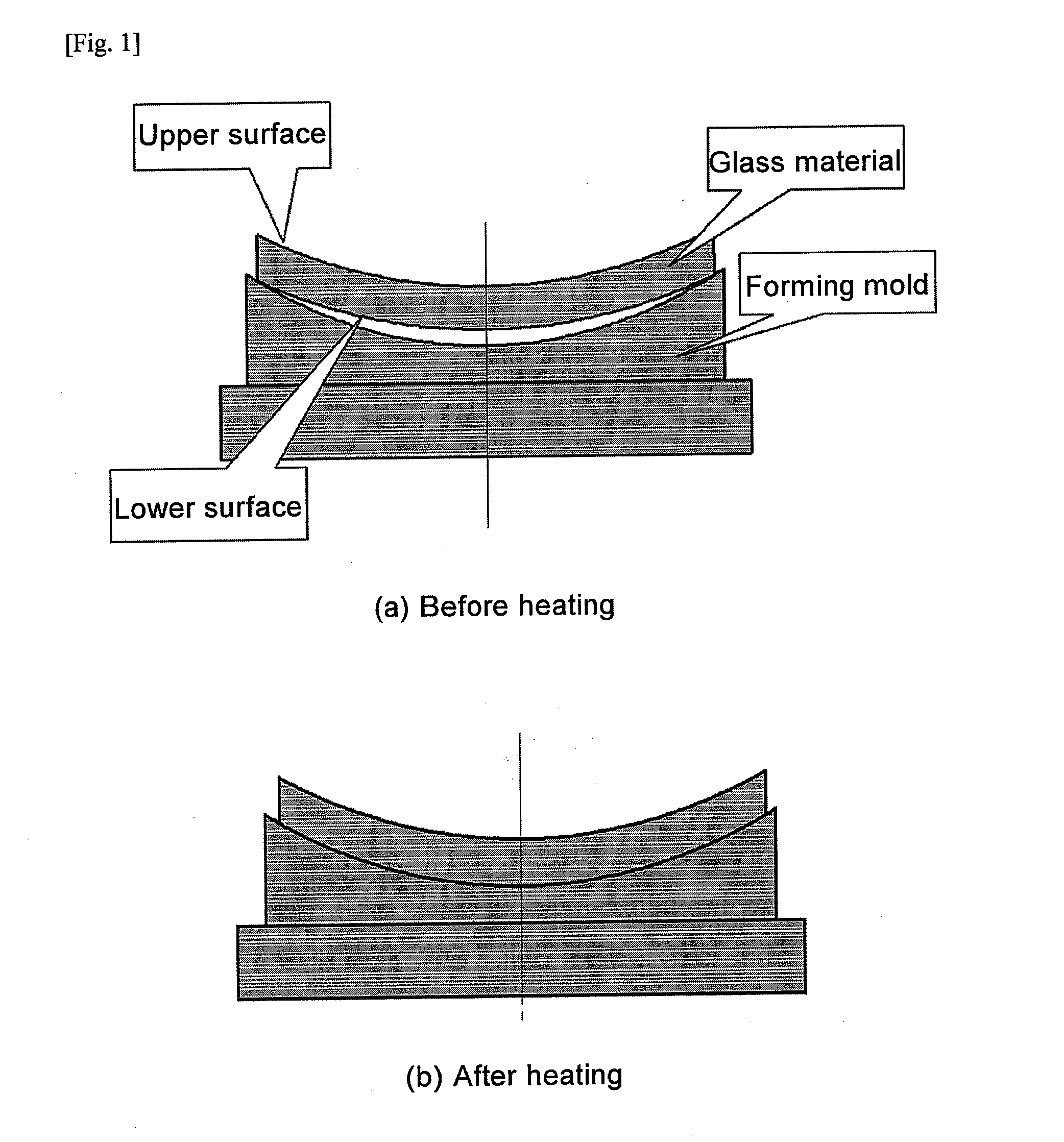

Method of manufacturing lens casting mold

InactiveUS20110304064A1High production efficiencyExcellent wear sensationOptical articlesDomestic articlesThermal treatmentHeating furnace

The present invention relates to a method of manufacturing a lens casting mold by introducing a forming mold, with a forming surface on which is positioned a glass material being formed, into a continuous heating furnace and conducting thermal treatment while conveying the forming mold to form an upper surface of the glass material being formed into a shape of a molding surface for forming a surface comprising a progressive surface. The method of manufacturing a lens casting mold of the present invention comprises controlling a temperature of the continuous heating furnace so that the continuous heating furnace comprises a temperature rising region having a temperature distribution such that the temperature rises in a conveyance direction of the forming mold; utilizing a forming mold having a curvature distribution on the forming surface as the forming mold; and conveying the forming mold in the temperature rising region so that a portion with the largest curvature on the forming surface is comprised in a portion on a side of the conveyance direction as divided in two by an imaginary line, the imaginary line running orthogonally to the conveyance direction of the forming mold and passing through a geometric center of the forming surface.

Owner:HOYA CORP

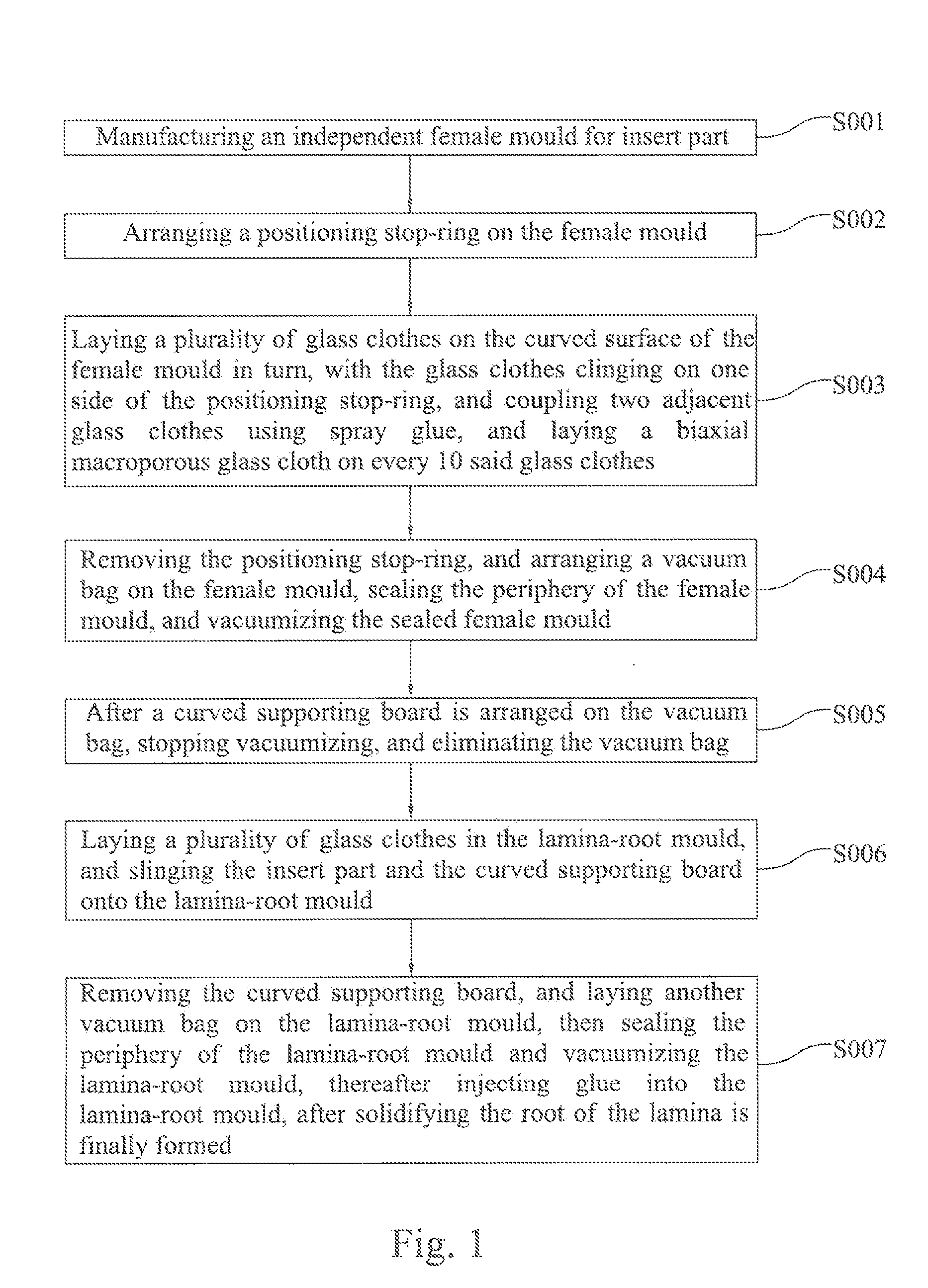

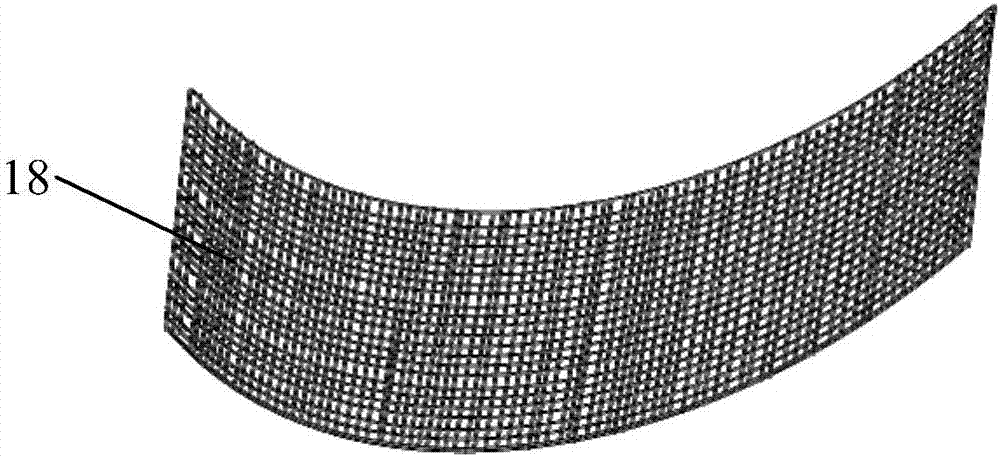

Method of manufacturing root of megawatt wind-turbine blade

InactiveUS20120006473A1High production efficiencyLong operate lifeFinal product manufactureConfectioneryTurbine bladeLeaf blade

A method of manufacturing root of megawatt wind-turbine blade includes the following steps: (1) manufacturing an independent female mould, and arranging a positioning stop-ring on the female mould; (2) clinging on one side of the positioning stop-ring, a plurality of glass fabrics and macroporous glass fabrics are laid on the curved surface of the female mould; (3) after laying the glass fabrics, sealing the female mould using a vacuum bag, and vacuumizing the female mould after a curved supporting board is arranged on the vacuum bag; (4) after laying a plurality of glass fabrics in the blade mould, slinging the prefabricated part and the curved supporting board to arrange them in the blade mould; (5) sealing the blade mould using another vacuum bag, vacuumizing the blade mould, thereafter infusing resin into the blade mould, after curing the root of the blade is finally formed. The method of manufacturing root of megawatt wind-turbine blade increases the production efficiency and production quality of the blade root, and prolongs the operation life of the blade root.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

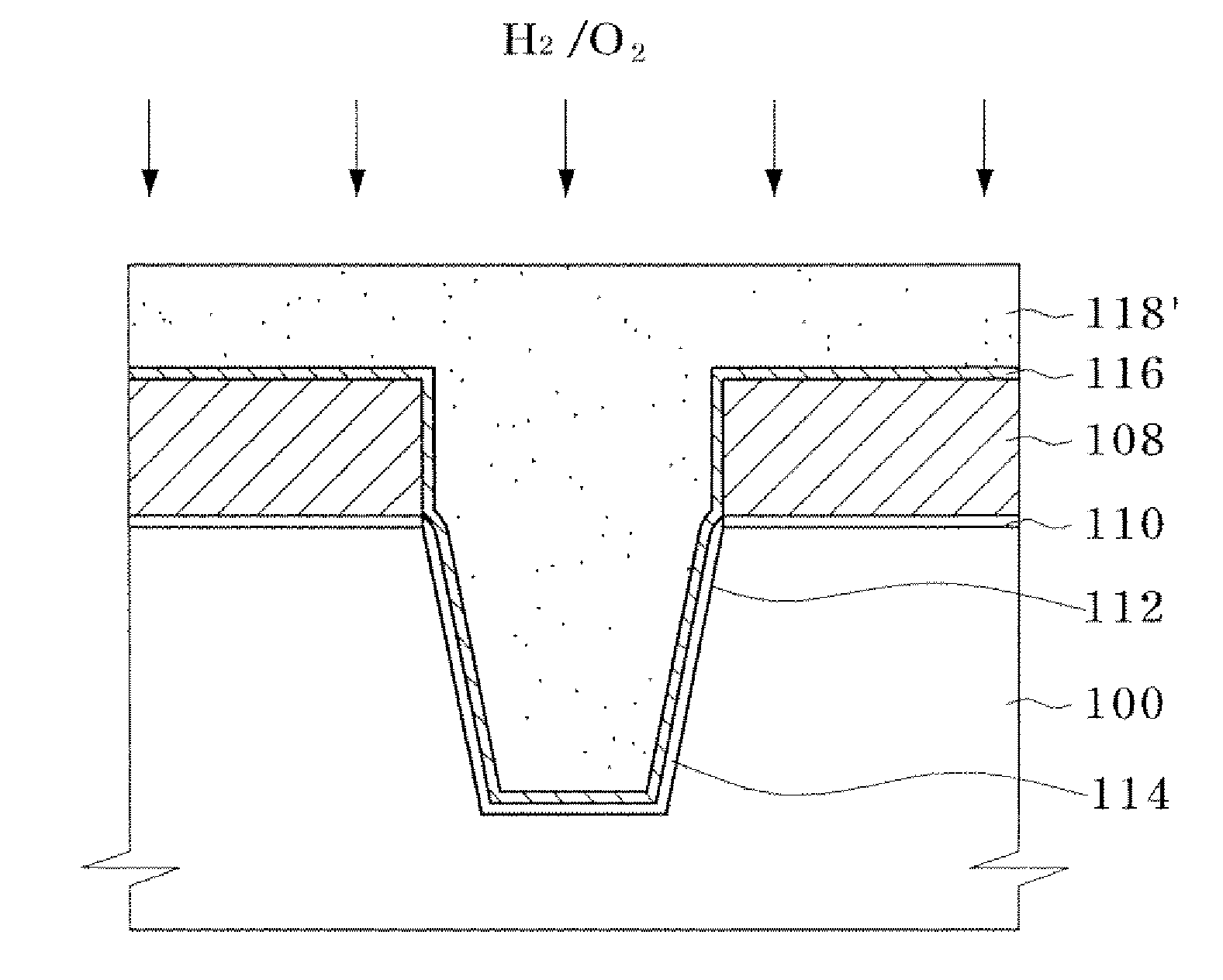

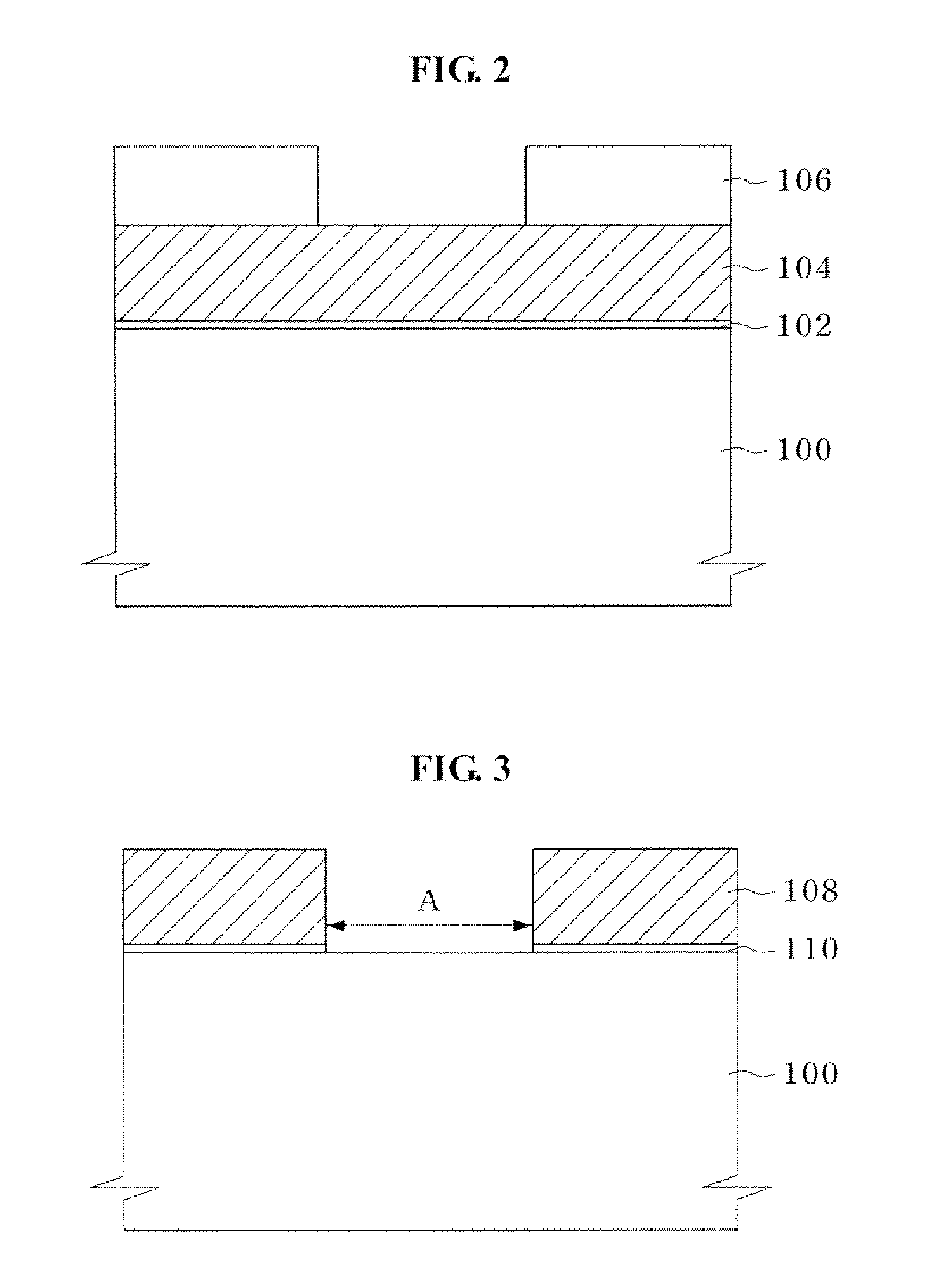

Method for fabricating an isolation layer in a semiconductor device

InactiveUS20080160716A1High production efficiencyImprove curingSemiconductor/solid-state device manufacturingSemiconductorIsolation layer

A method for forming an isolation layer in a semiconductor device includes forming a trench inside a semiconductor substrate, forming a fluid insulating layer over the semiconductor substrate, thereby filling the trench with the fluid insulating layer, curing the semiconductor substrate by plasma oxidation to densify the fluid insulating layer, and planarizing the fluid insulating layer to form an isolation layer.

Owner:SK HYNIX INC

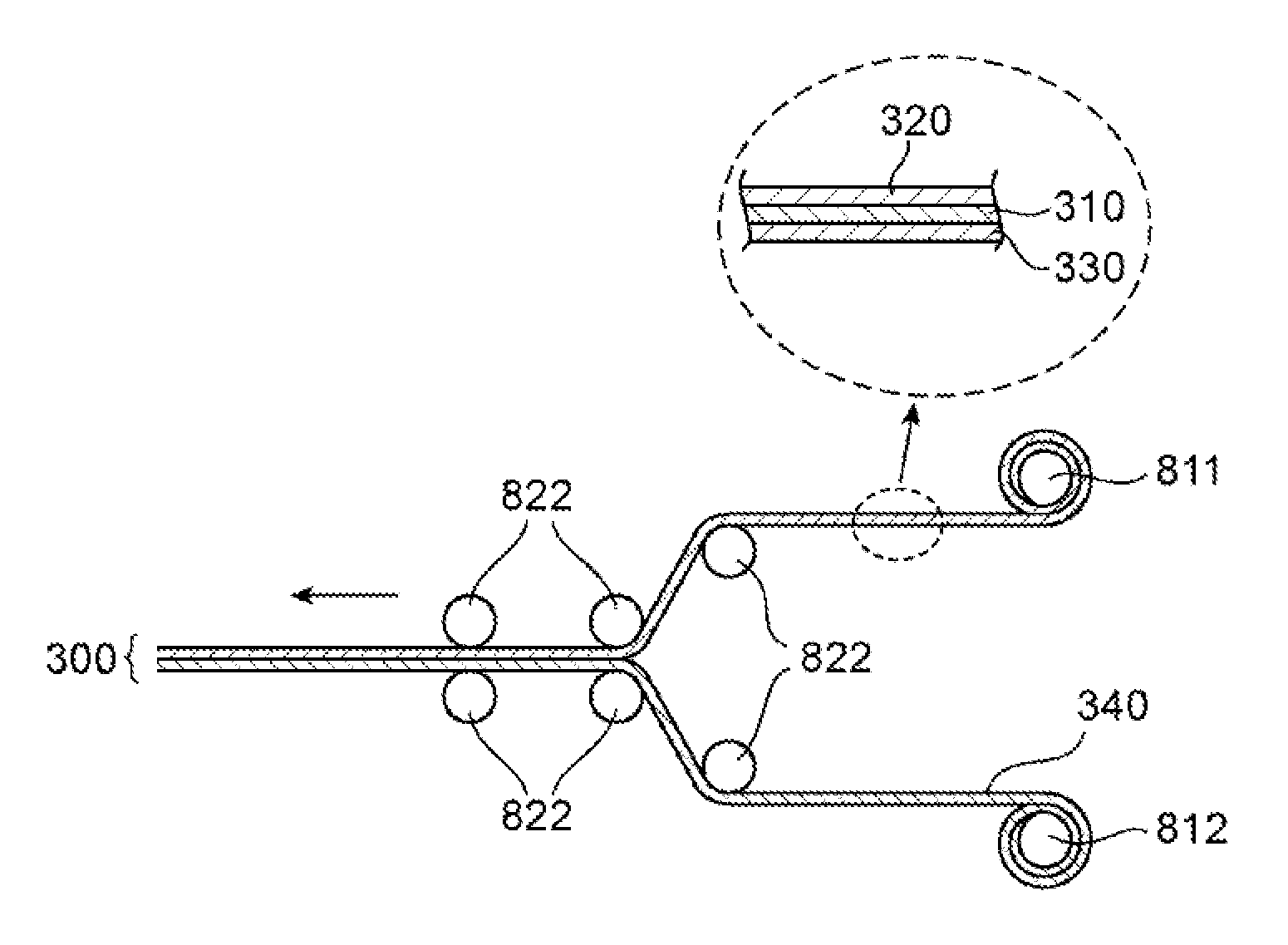

Electronic component production method and electronic component production equipment

InactiveUS20090217515A1High production efficiencyManufacturing cost be reducePrinted circuit assemblingSolid-state devicesInterposerElectron

Manufacturing an electronic component 5 in which an interposer 50 is bonded to a base circuit sheet includes a base circuit forming step for forming a base-side terminal in a continuous base member 610 in continuous sheet form, an arranging / bonding step for arranging the interposer 50 on a surface of the continuous base member 610 in which the base-side terminal is formed and bonding the interposer 50, and a separating step for cutting out the electronic component 5 from the continuous base member 610 to which the interposer 50 is bonded. In this electronic component manufacturing method, for the common continuous base member 610, each of the steps is repeated in parallel while this continuous base material 610 is being advanced.

Owner:HARRIS CORP

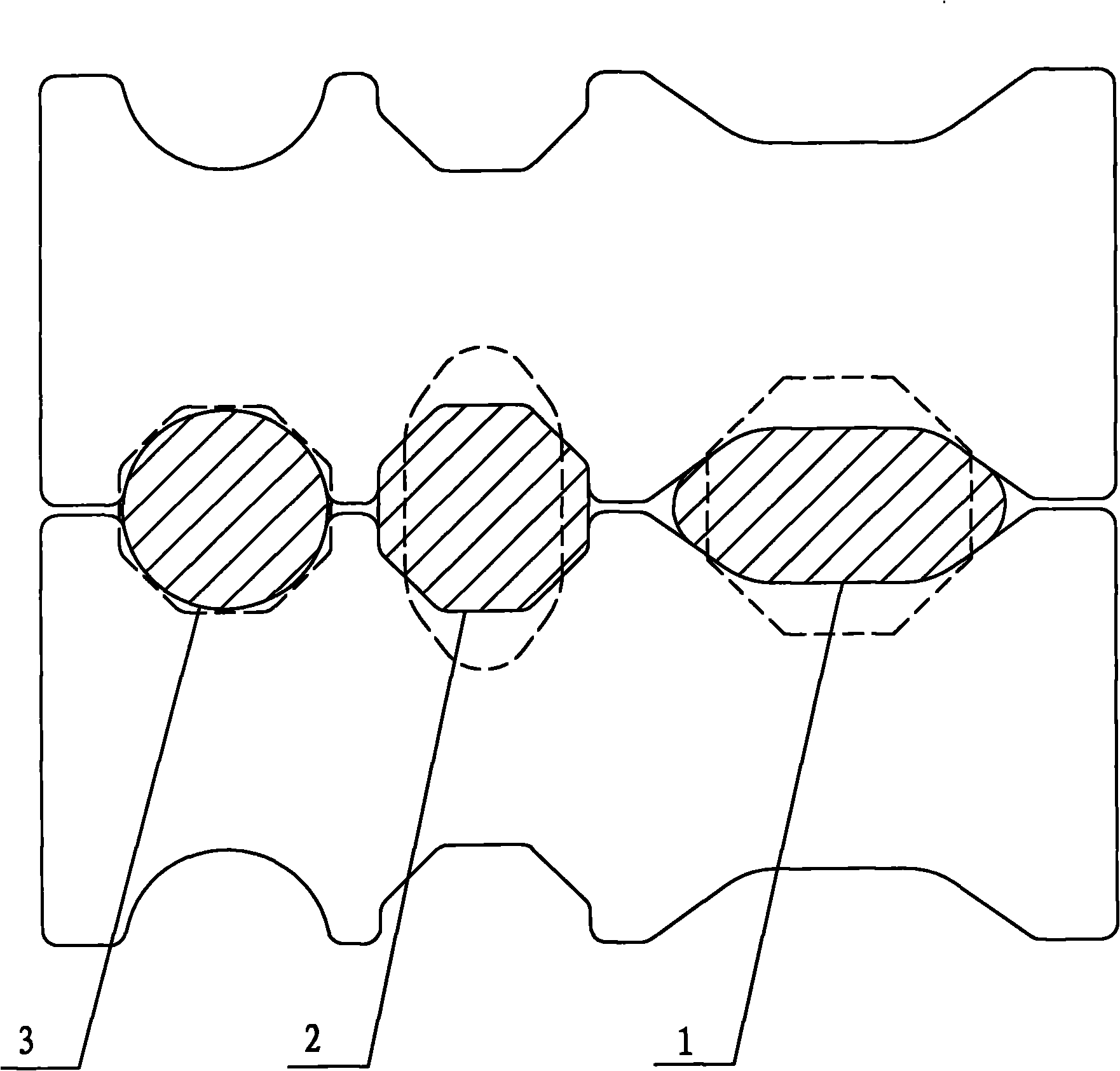

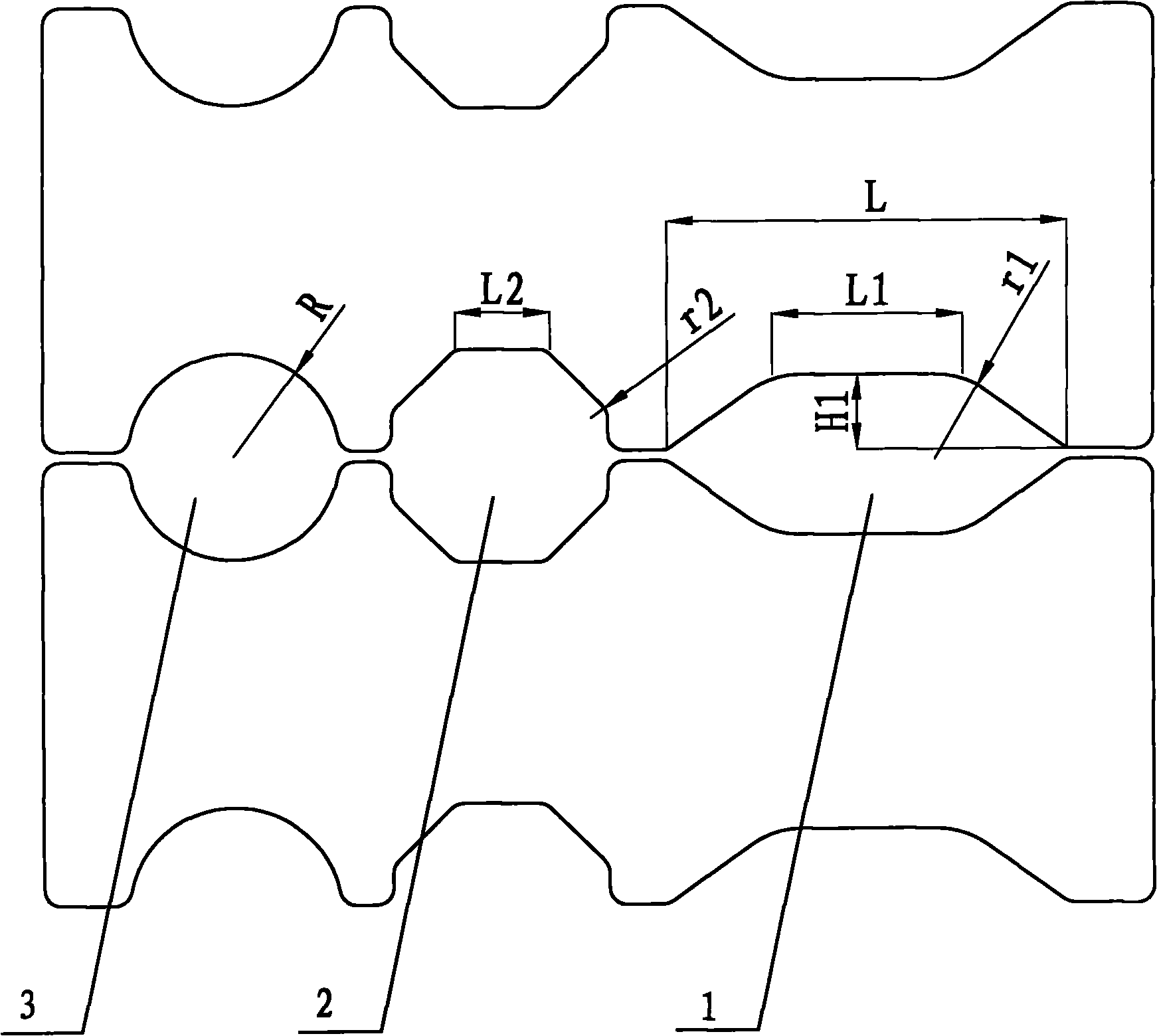

Hole type system and rolling process for super large diameter round steel production

InactiveCN102069090AHigh dimensional accuracyQuality improvementRoll force/gap control deviceRollsMetallurgyManipulator

The invention provides a hole type system and a rolling process for super large diameter round steel production. In the hole type system, three hole types are designed on a pair of rollers, and the three hole types are a flat hexagonal hole type 1, an octagonal hole type 2 and a round hole type 3. The rolling process comprises the following steps: rolling a steel billet with the flat hexagonal hole type 1 and the rolling reduction is 20-90 mm / pass; rolling the billet rolled from the previous step with the octagonal hole type 2, firstly turning the billet 90 degrees with a manipulator, and then placing the billet into the rollers for rolling, wherein the rolling reduction is 30-85 mm / pass; and carrying out finish rolling the billet rolled from the previous steps with the round steel hole type 3, and the rolling reduction is less than or equal to 50 mm / pass. During the three steps, the billet is turned 90 degrees between each two passes. The hole type system and the rolling process provided by the invention have the following advantages: the billet can be rolled to a required dimension through one-time heating with just one large mill; the production process is simple; and the production efficiency is 5 times higher, the production cost is reduced by 50%, and the rolling yield can be increased by 20% through using the rolling process.

Owner:YANGZHOU CHENGDE HEAVY IND CO LTD

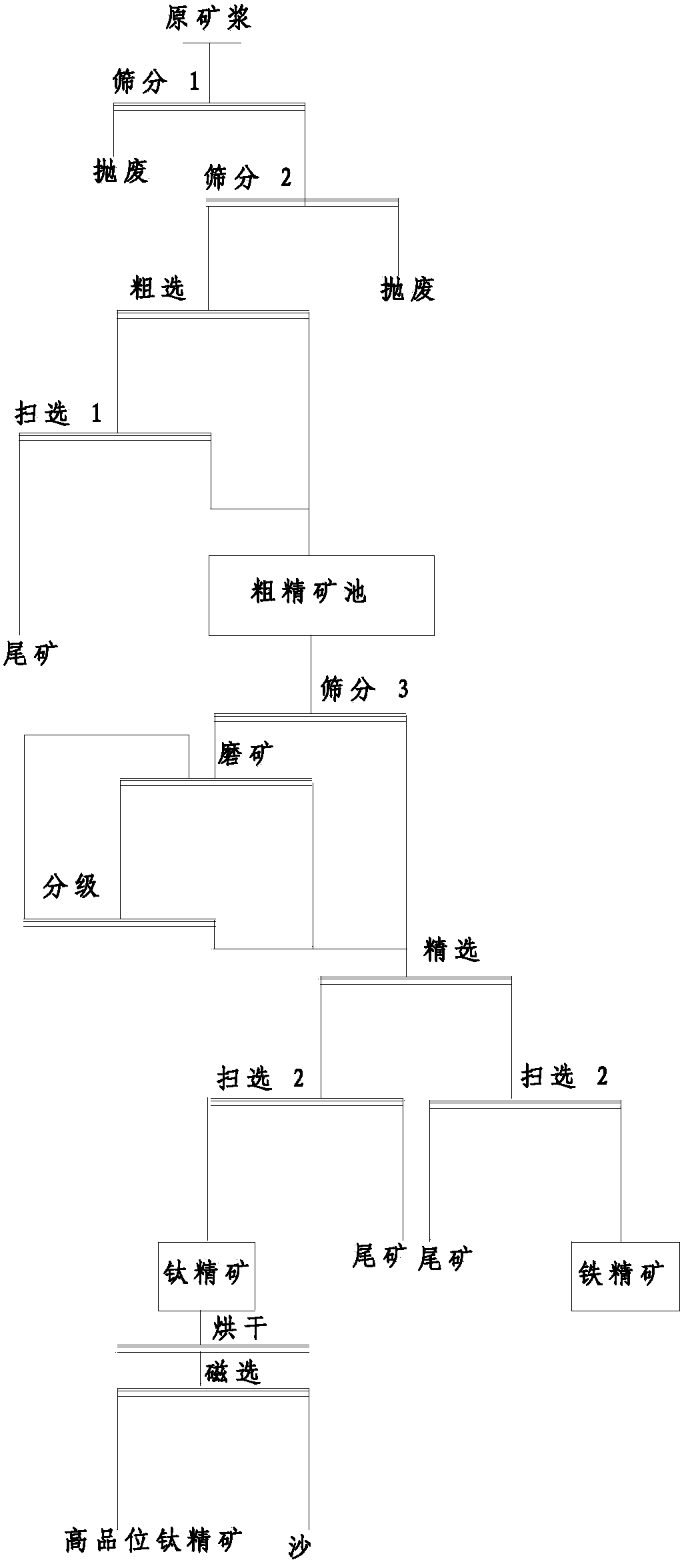

Combined magnetic separation process for selecting weathering sand ilmenite

The invention discloses a combined magnetic separation process for selecting weathering sand ilmenite. A titanium ore concentrate with the grade content of 46-52% and an iron ore concentrate with the grade content of 40-65% are obtained by the steps of pulping, screening and waste discarding, strong magnetic tailing discarding, screening, fine ore collecting, coarse grain regrinding, one-selection and two-scavenging and drying and selection. The process can realize relatively independent production of crude ores, middling and concentrates, can adjust the yields and the grades of a titanium middling and a titanium concentrate, and can separate out refined titanium and refined iron.

Owner:珠海铁建蓝天环保材料有限公司 +1

Super fine titanium carbonitride powder and its preparing method

The superfine titanium carbonitride powder and its preparation process belong to the field of nanometer ceramic material preparing technology. The present invention prepares superfine titanium carbonitride powder with starch or cane sugar as carbon source in 5-30 wt%, titanium hydride as titanium source in 70-95 wt% and nitrogen for the rest, and through the technological process including the steps of compounding material, ball milling, drying, sintering and powdering. The present invention has simple production process, environment friendship, high production efficiency, low production cost and other advantages, and is suitable for industrial production.

Owner:SHENYANG LIGONG UNIV

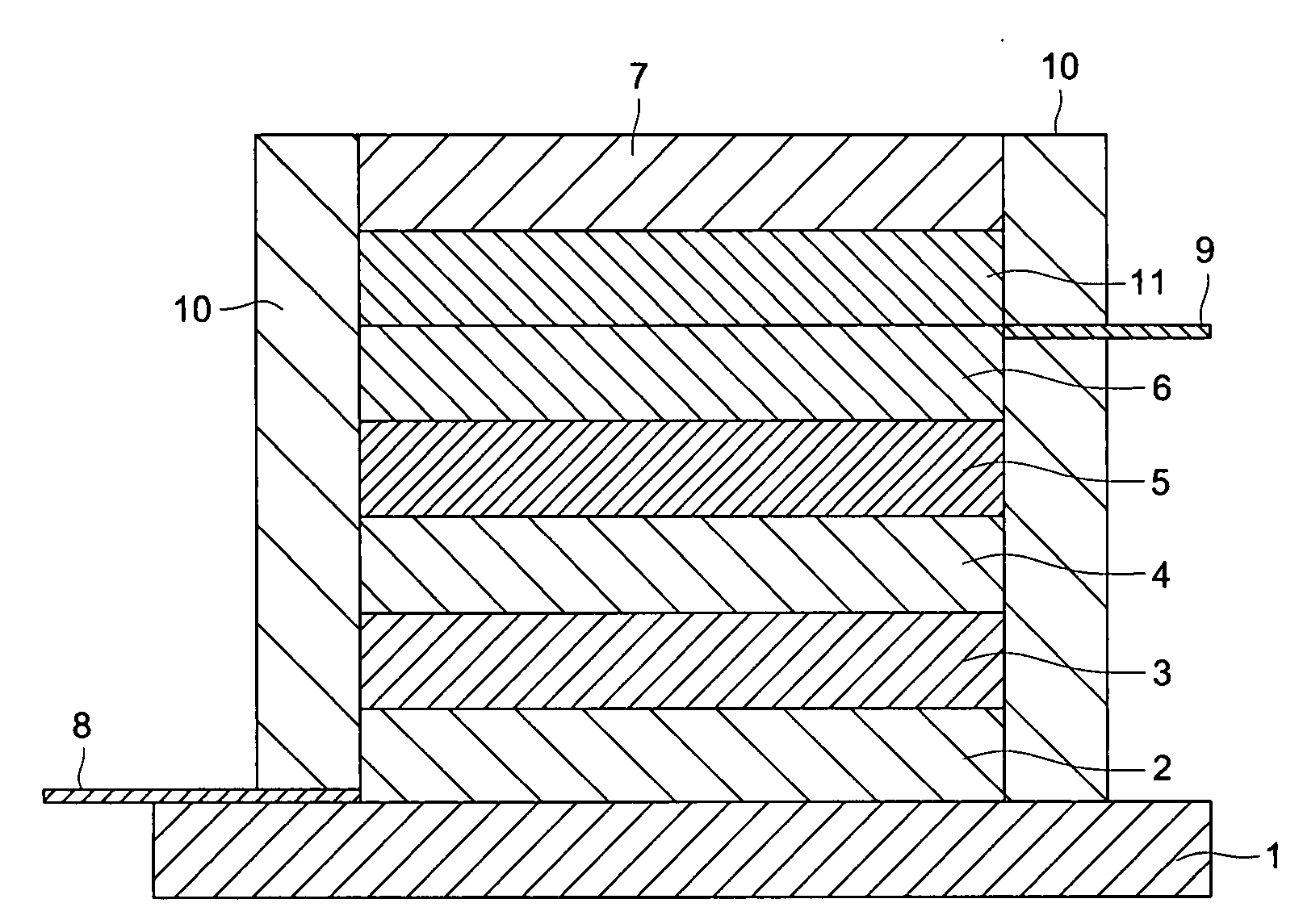

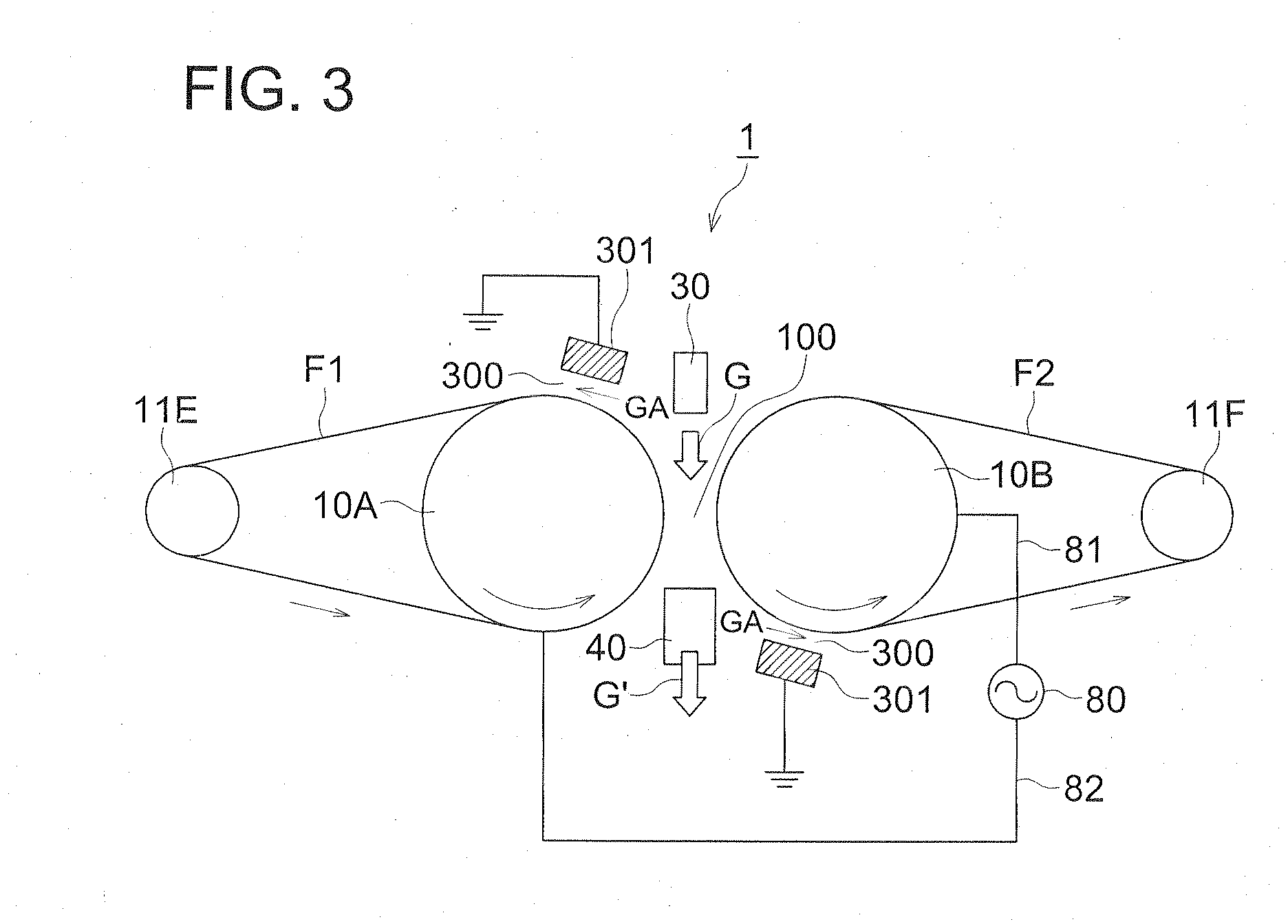

Organic Electroluminescent Element, Production Method of the Same, Display Device, and Lighting Device

ActiveUS20090134778A1High production efficiencyImprove luminous brightnessDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceOptoelectronics

An organic electroluminescent element comprising a laminated body incorporating an anode substrate, an anode, at least one non-light emitting organic layer A exhibiting positive hole transportability, at least one light emitting organic layer B, at least one non-light emitting organic layer C exhibiting electron transportability, a cathode, and a cathode substrate in the sequence set forth, wherein at least 80% by weight of the organic layer A and the organic layer C in the laminated body is formed via a wet process, and the laminated body is made with an adhesion process between the organic layer A and the organic layer B, or between the organic layer B and the organic layer C.

Owner:MERCK PATENT GMBH

Sintered hard alloy base amterial for surface-coated gear cutting tool and surface coated gear cutting tool

InactiveUS20060134466A1High production efficiencyGood performanceMetallic material coating processesNatural mineral layered productsCemented carbideGear cutting

This cemented carbide material for a surface coated gear cutting tool is employed in a substrate for a surface coated gear cutting tool which is obtained by forming a hard coated layer on a surface of the substrate, the cemented carbide material for a surface coated gear cutting tool includes a WC-βt-Co based cemented carbide, wherein a content of Co forming a binder phase of the cemented carbide material is in a range of 12 to 17 wt %, and among components of a βt solid solution forming a hard phase of the cemented carbide material, a content of components excluding WC is in a range of 15 to 20 wt %, and a total content of Ta carbonitride and Nb caronitride is in a range of 5 to 8 wt %.

Owner:MITSUBISHI MATERIALS CORP

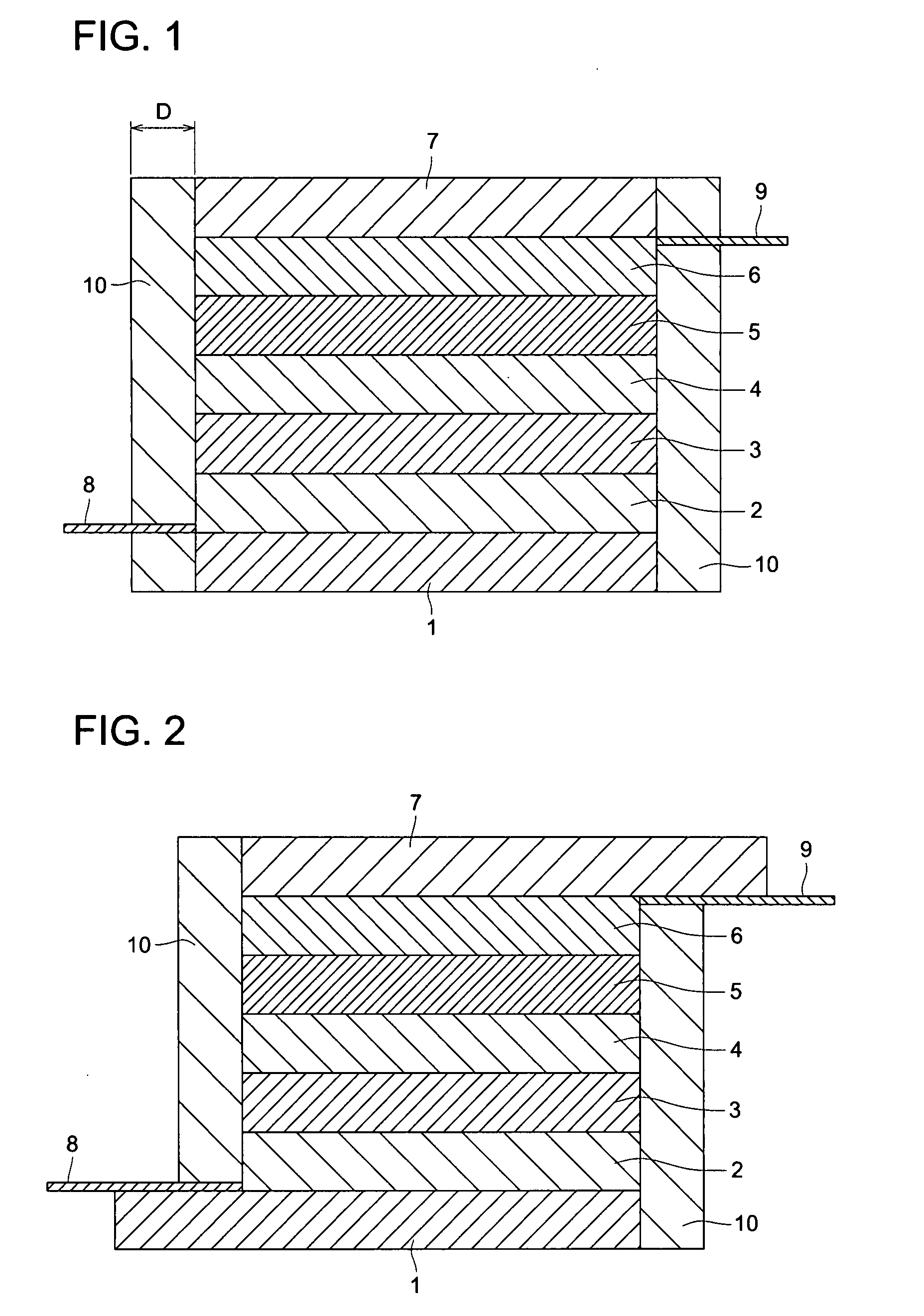

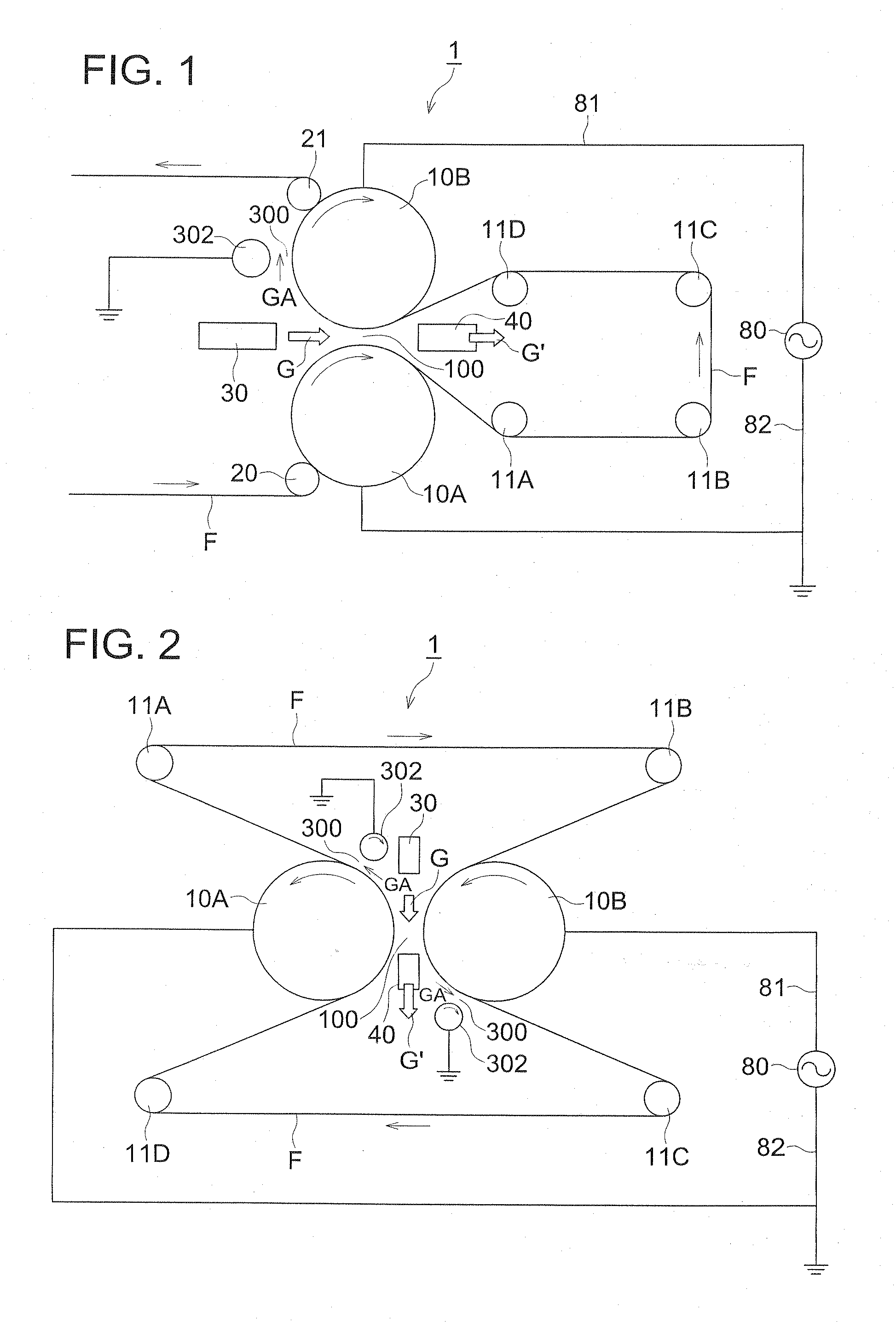

Thin film forming method and thin film stack

InactiveUS20110052924A1High production efficiencyStably formElectric discharge tubesLayered productsElectric fieldForming gas

A thin film forming method by a plasma discharging treatment under atmospheric pressure with a thin film forming apparatus which has a first discharging space for forming a functional thin film on a substrate, and a second discharge space for post-treating the substrate which formed the thin film. The first discharge space has a roller electrodes pair. The thin film forming method includes, a film forming process at the first discharge space which includes the steps of transporting the substrate by the roller electrodes; supplying discharging gas and thin film forming gas into the first discharging space; and generating a high frequency electric field between the roller electrodes. The post-treatment process includes the steps of introducing the substrate on which the functional film is formed; and supplying a discharging gas and post-treatment gas between the facing electrodes; and, generating a high frequency electric field between the facing electrode and the roller electrode.

Owner:KONICA MINOLTA INC

Method for manufacturing color element film-equipped substrate, color element film-equipped substrate, electro-optical device, and electronic device

InactiveUS20060138438A1High production efficiencyEasily formLiquid surface applicatorsDecorative surface effectsSecondary layerEngineering

A method for manufacturing a color element film-equipped substrate includes: forming a bank, in which a first layer and a photo-curing second layer are laminated over a base, and parts of the first layer and the second layer are removed after exposing and developing the first layer and the second layer, with a remainder of the first layer and the second layer serving as a bank; applying a liquid material used for forming a color element film to a region demarcated by the bank; and forming a color element film by curing or solidifying the liquid material applied to the region. The first layer is soluble in a developing liquid during the developing. The second layer is soluble in the developing liquid but dissolves more slowly than the first layer does. The bank is formed with the width of the remainder of the second layer being greater than the width of the remainder of the first layer after the development.

Owner:SEIKO EPSON CORP

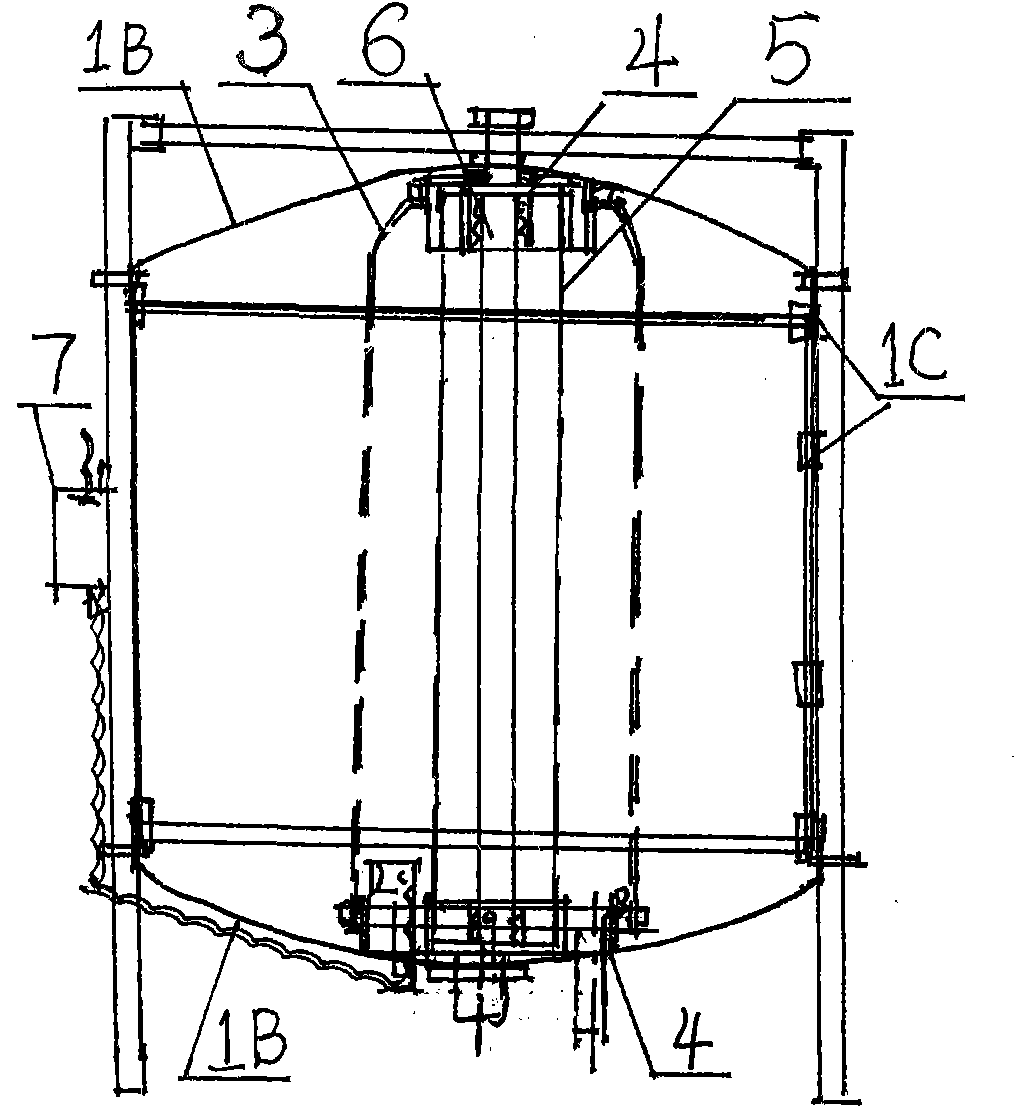

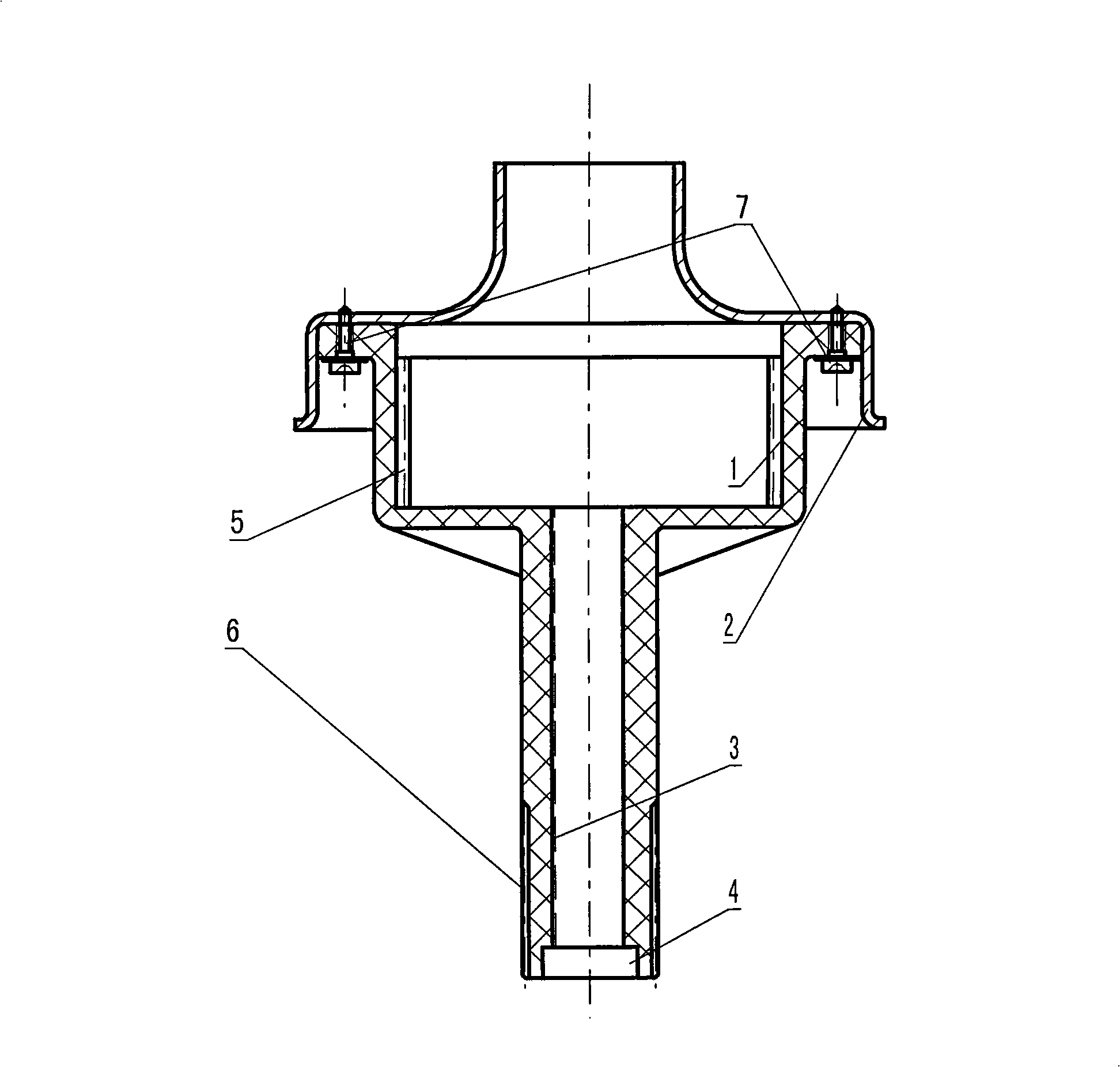

Off-site assembled container manufacturing method, bag-type pressure drain tank and liquid level controller

InactiveCN102001494AReduce areaSimple production equipmentFluid heatersMechanical apparatusWater qualityEngineering

The invention discloses an off-site assembled container manufacturing method, a bag-type pressure drain tank and a liquid level controller. The method for manufacturing the container and the water tank body comprises the following steps of: manufacturing middle containments at least annularly provided with an open edge and corresponding end covers on a production workshop according to the requirement respectively, and overlapping a plurality of middle containments and end covers inside and outside, or packing and storing the middle containments and the end covers; after being transferred to each use destination, connecting the open edge ends and the ends of the middle containments and the end covers or connecting through connecting members to form a container body by assembly; and arranging a fluid storage elastic bag or / and a bag joint, a filter element and / or an inner supporting frame and the liquid level controller consisting of a power supply master controller and a secondary controller connected by a power supply connecting wire on the corresponding positions. The method solves the problems of large storage space occupied by the container body, high cost and the like in the conventional one-time forming production method. The invention provides the bag-type pressure drain tank with strong non-bearing pressure drainage capability, low cost and cleaner water and the liquid level controller with low cost, more reliable and safer performance and the like.

Owner:陈广丰

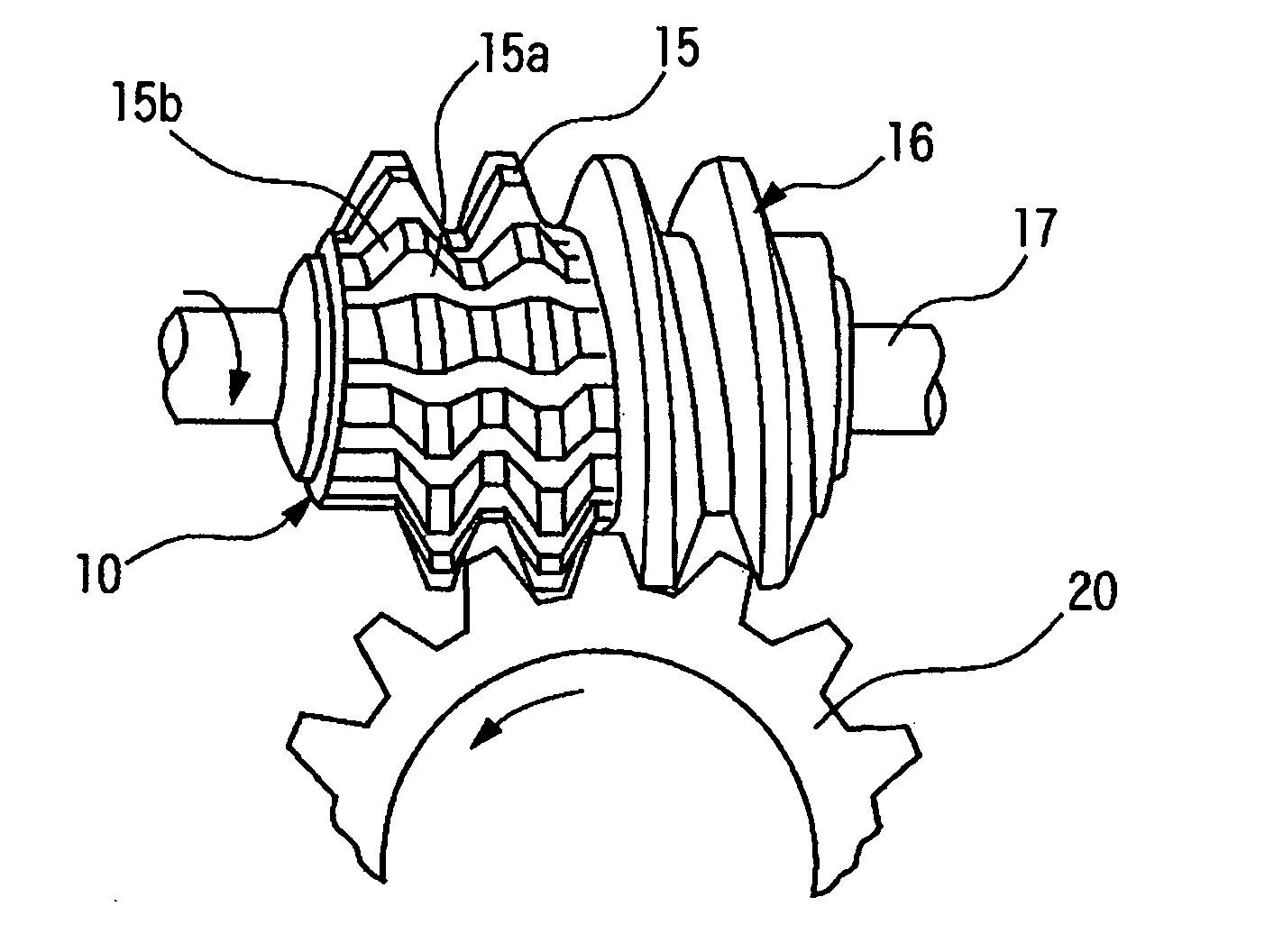

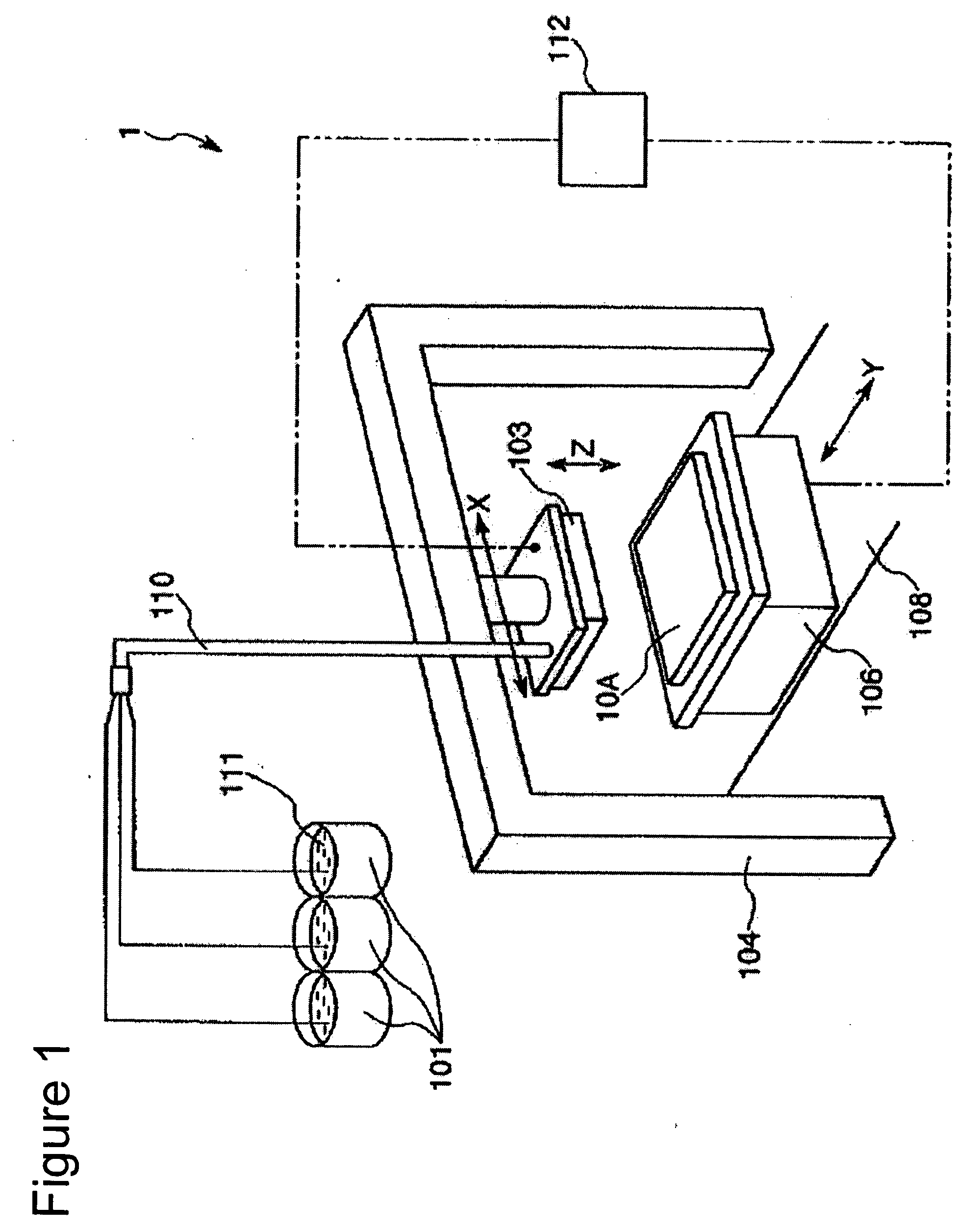

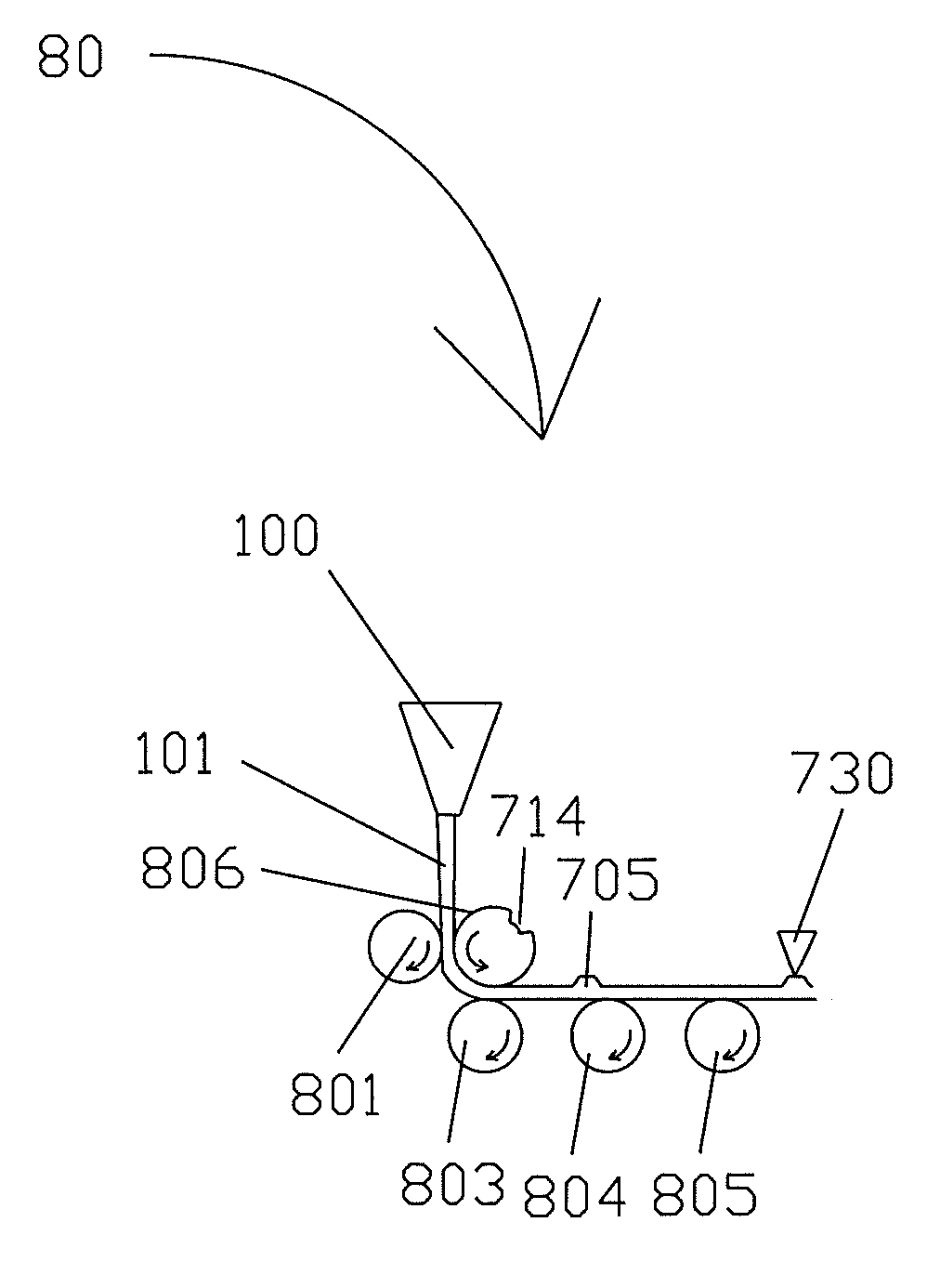

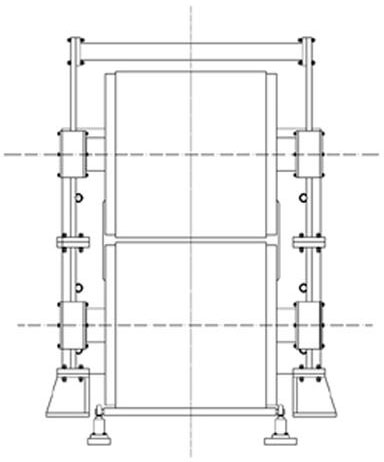

Apparatus for manufacturing light guide plate

InactiveUS20160009011A1Smooth operationHigh production efficiencyMechanical apparatusDough-sheeters/rolling-machines/rolling-pinsLiquid-crystal displayEngineering

The present disclosure relates to the technical field of liquid crystal display. Specifically, it relates to an apparatus for manufacturing light guide plate. The apparatus comprises: a feeding unit having a slit-shaped discharge port, an extrusion unit comprising a conveying roller for conveying the raw material and an extrusion roller for extruding the raw material, and a cutting unit for cutting the light guide plate guided out of the extrusion unit, wherein an elongated recess depressing toward the interior of the extrusion roller is disposed on a roller body of the extrusion roller, in order to manufacture a light guide plate having a varying thickness. The apparatus has the advantages of high production efficiency.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Catalyst for alcohol synthesis, apparatus for producing alcohol and method for producing alcohol

ActiveUS20150284306A1High production efficiencyImprove production efficiencyOrganic compound preparationHeterogenous catalyst chemical elementsOxygen compoundAldehyde

A catalyst for synthesizing an alcohol from a gaseous mixture comprising hydrogen and carbon monoxide, the catalyst being a mixture of catalyst particles α which convert carbon monoxide into an oxygenate, and catalyst particles β which convert an aldehyde into an alcohol.

Owner:SEKISUI CHEM CO LTD

Production method for phase shift film, and production method for circular polarizing plate

InactiveUS20160096312A1High efficiencyHigh production efficiencyPolarising elementsOptical articlesPhase shiftedFilm (photographic)

Provided is a method capable of producing a retardation film suppressed in biaxiality, having a small Nz coefficient, and having a slow axis in an oblique direction with high production efficiency. The production method for a retardation film of the present invention includes: holding left and right side edge portions of a film to be stretched with left and right variable pitch-type clips configured to have clip pitches changing in a longitudinal direction, respectively; preheating the film; reducing, under a state in which a position at which the clip pitch of the clips on one side out of the left and right clips starts to reduce and a position at which the clip pitch of the clips on another side starts to reduce are set to different positions in the longitudinal direction, the clip pitch of each of the clips to a predetermined pitch to subject the film to oblique stretching; and releasing the clips holding the film.

Owner:NITTO DENKO CORP

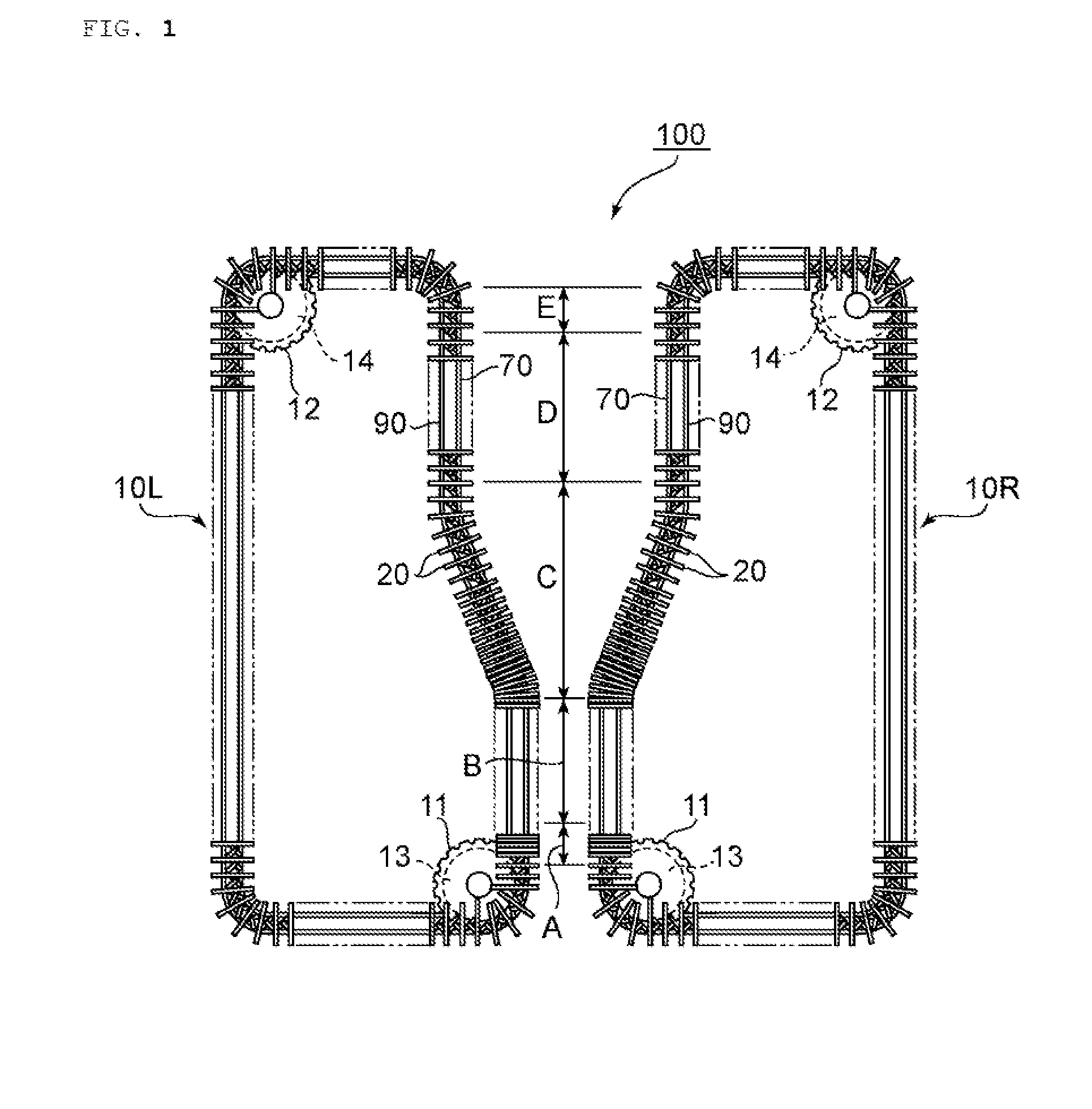

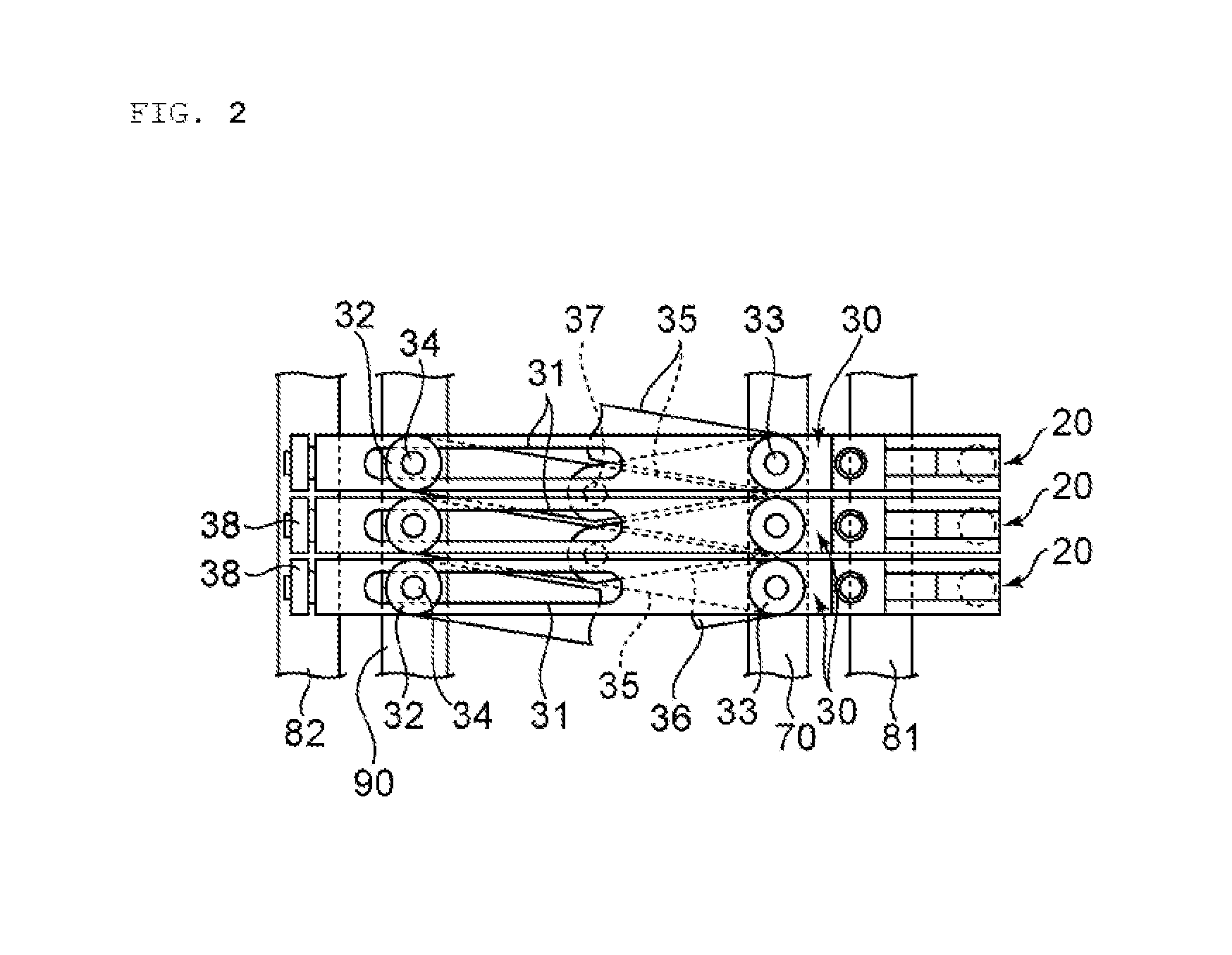

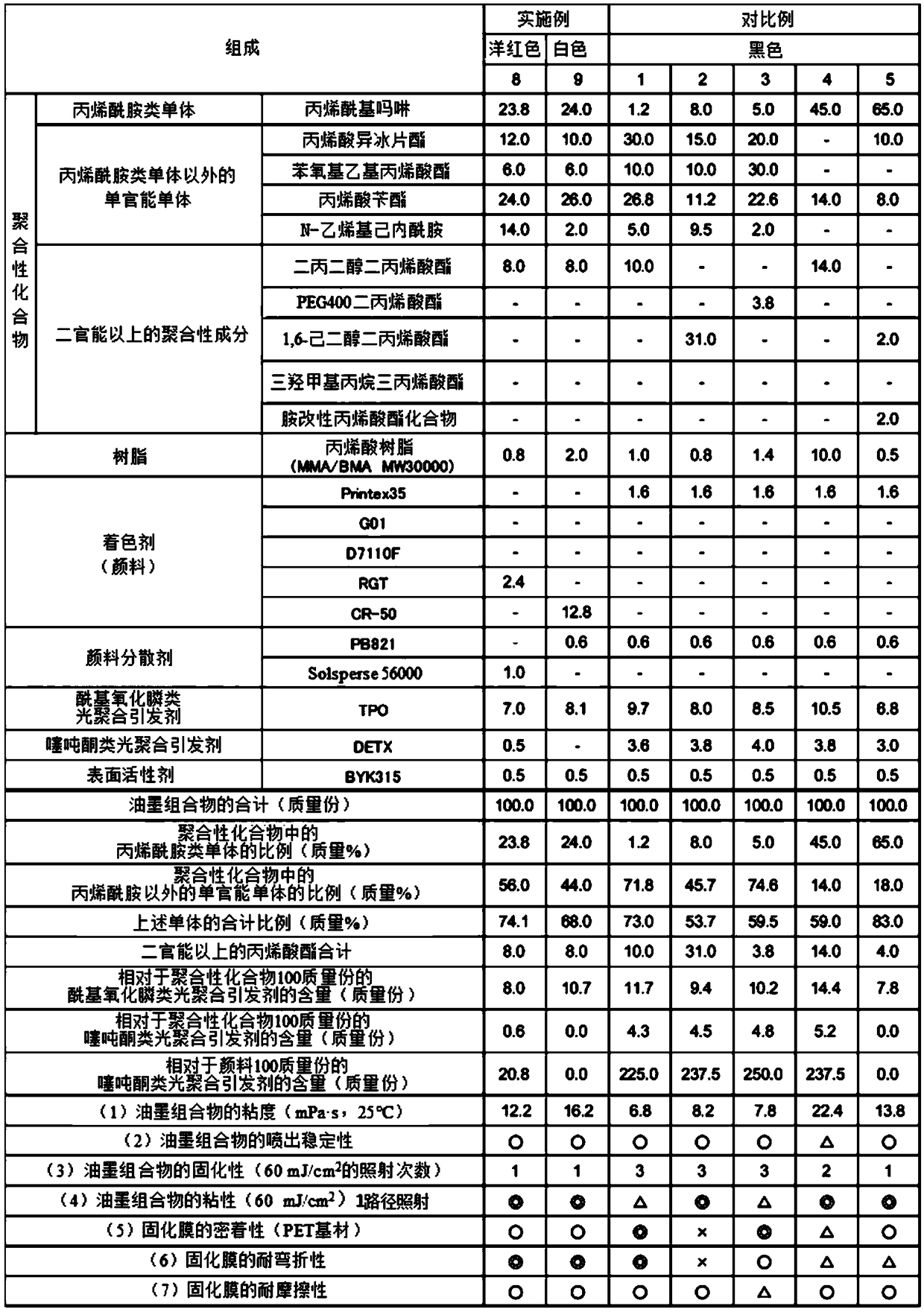

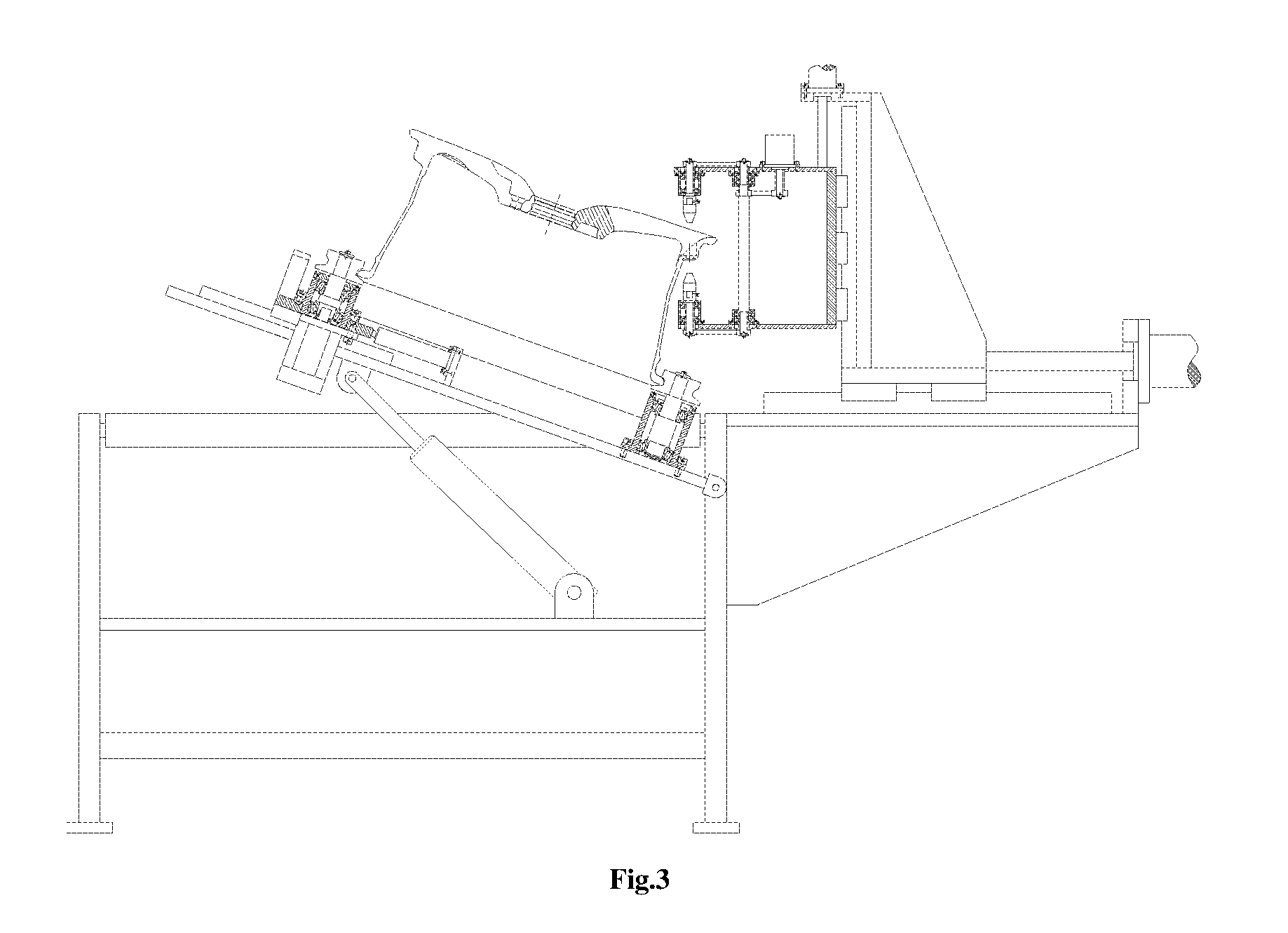

Roller support and hot platen combined segmented continuous flat hot press

ActiveCN102658580AContinuous productionHigh production efficiencyWood working apparatusDomestic articlesFiberEngineering

The invention provides a roller support and hot platen combined segmented continuous flat hot press which comprises an upper driving roll, a lower driving roller, an upper driven roll, a lower driven roller and two steel belts surrounding the rolls. A plurality of groups of upper and lower hot platen components which are disposed on a hot press frame are serially connected, and the rolls drive the upper and lower steel belts to operate between the upper and lower hot platen components, so that the segmented continuous flat hot press is formed. Each group of upper and lower hot platen components consists of upper and lower combined hot platens surrounded by a plurality of rollers, oil circuits in mutual communicated closure are arranged in the hot platens, heated oil enables the hot platens and the rollers to be heated, the steel belts moving up and down drive the rollers to roll and are heated, and fiber materials are fed between the two steel belts to be made into fiber boards by extruding. The roller support and hot platen combined segmented continuous flat hot press is high in production efficiency and product quality.

Owner:SHANGHAI ZHENSEN WOOD WORKING MACHINERY CO LTD

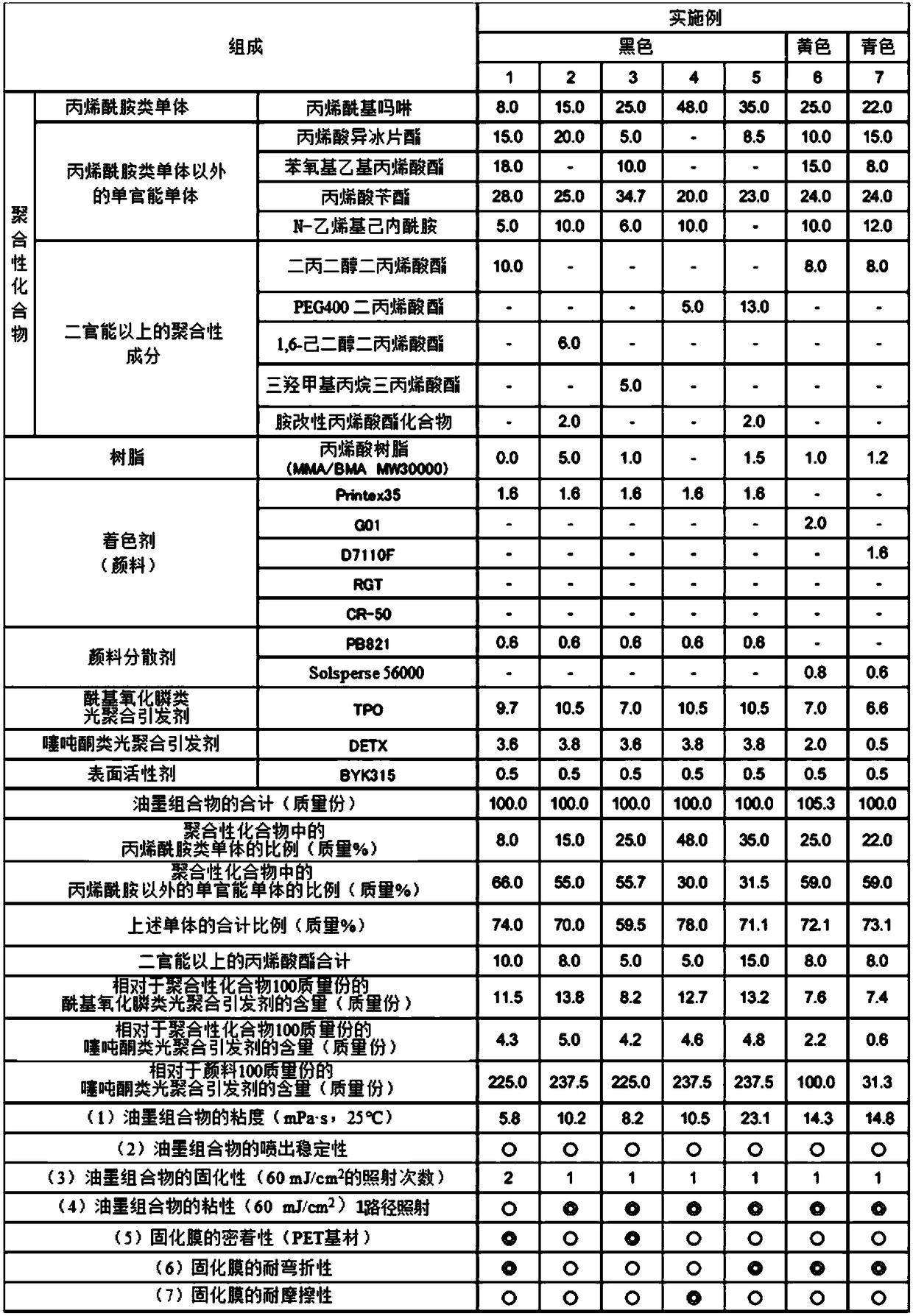

Photocurable ink composition for ink-jet printing

The present invention addresses the problem of providing a photocurable ink composition for ink-jet printing which not only has excellent ejection stability but also is excellent in terms of curability, adhesion, and scratch resistance even when cured by ultraviolet irradiation with a small integrated quantity of light energy and which gives a coating film that is less tacky, has excellent stretchability, and suffers no cracks through post-processing. The above-mentioned problem is solved with a photocurable ink composition for ink-jet printing which contains photopolymerizable compounds and aphotopolymerization initiator. The ink composition contains a. 5.0-50 mass% acrylamide-based monomer, b. 15-70 mass% monofunctional monomer which is not an acrylamide-based monomer, c. 5.0-30.0 mass%polymerizable compound having a functionality of 2 or higher, and d. 0.1-15 mass vinylcaprolactam and / or 0-10 mass% acrylated amine compound having two photopolymerizable functional groups and two amino groups in the molecule, e. the proportion of the monofunctional monomers in the photopolymerizable compounds being 60-99.5 mass%.

Owner:SAKATA INX

Carotenoid Oil Suspension With High Bioavailability And Preparation Method Thereof

ActiveUS20140030419A1High production efficiencyReduce degradationOrganic active ingredientsMetabolism disorderIndustrial scaleChemistry

A carotenoid oil suspension and preparation method thereof are provided. The method includes the following steps: a) mixing carotenoid with organic solvent, heating the mixture to dissolve the carotenoid sufficiently to obtain carotenoid solution; b) introducing the carotenoid solution obtained in step a) into a vegetable oil solution stirred in high speed by spraying, meanwhile recovering the organic solvent generated during spraying under vacuum condition, then, simultaneously completing recycling and spraying, thereafter, obtaining carotenoid oil suspension; wherein, the carotenoid oil suspension comprises a carotenoid crystal with an average particle size of less than 5 μm. The method is applicable in industrial scale with continuous operation and increased efficiency without additional carotenoid crystal grinding processes, and decreases the degradation of carotenoid during the preparation process of carotenoid oil suspension.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Vacuum Forming Method for Leather Product

InactiveUS20130154165A1High emulationHigh production efficiencyLeather articlesVacuum formingMetallurgy

A vacuum forming method for a leather product, comprising the following steps: making a mold; heating a raw material of the leather product to a predetermined temperature and placing the raw material on a surface to form a pattern on the raw material, the pattern formed on the raw material corresponding to a pattern of the mold surface, wherein the raw material is disposed under a vacuum forming condition; and cooling the raw material of the leather product for making the leather product; wherein the predetermined temperature is between 150° C. to 200° C.; the vacuum forming condition is between 350 mmHg-700 mmHg for a vacuum degree. The present invention provides an easy manufacturing technique, which uses an easy-to-produce mold to form the leather product in one process, thereby providing the leather product with high emulation and high production efficiency.

Owner:HSING I PLASTIC

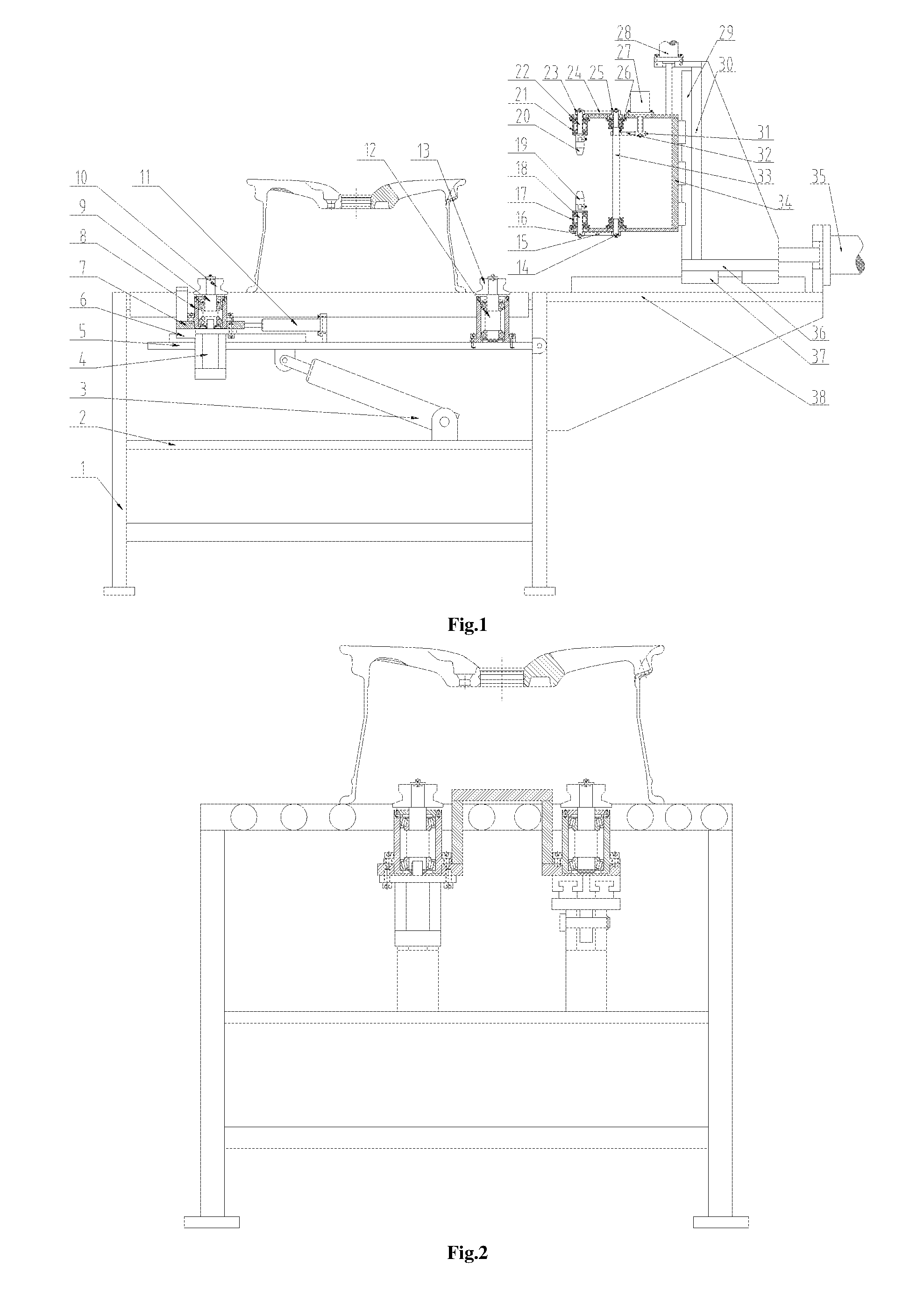

On-line Deburring Device of Wheel Valve Hole

ActiveUS20160354892A1High production efficiencyAdvanced techniqueEdge grinding machinesTyre-inflating valvesElectric machineryHead parts

The present invention relates to an improved on-line deburring device of a wheel valve hole, having a frame, electric cylinders, an air cylinder, grinding heads, a motor, guide rails and a transmission shaft. In use, the present invention can meet the requirements for deburring the wheel valve hole; meanwhile, the device has the characteristics of high production efficiency, advanced technique, high automation degree, stable performance, etc.

Owner:CITIC DICASTAL

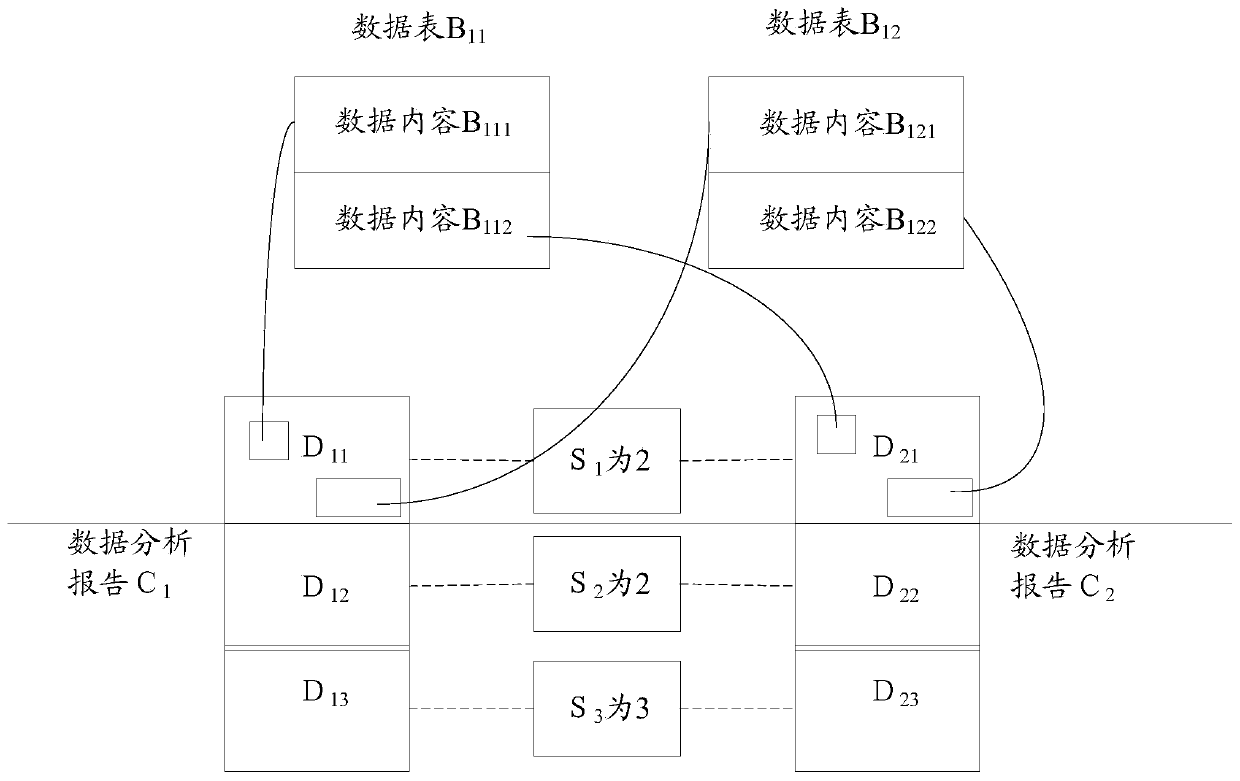

Method for automatically generating data analysis report

ActiveCN110263076AReduce workloadQuick buildVisual data miningStructured data browsingTask demandData source

The invention provides a method for automatically generating a data analysis report, and the method comprises the steps: generating a task demand based on a data analysis report set needing to be generated this time; configuring and managing a data source according to the task requirement; creating a new task template; configuring a task sub-template preview function; and after the task sub-template passes the detection, obtaining a task template capable of generating a data analysis report set meeting the current requirement, and executing the data query statement based on the task template to generate a data analysis report. The method for automatically generating the data analysis report provided by the invention can quickly, accurately and efficiently generate a large amount of data analysis reports of the same series, has the advantage of high generation and manufacture efficiency of the data analysis reports of the same series, and obviously reduces the workload of data analysts.

Owner:海南车智易通信息技术有限公司

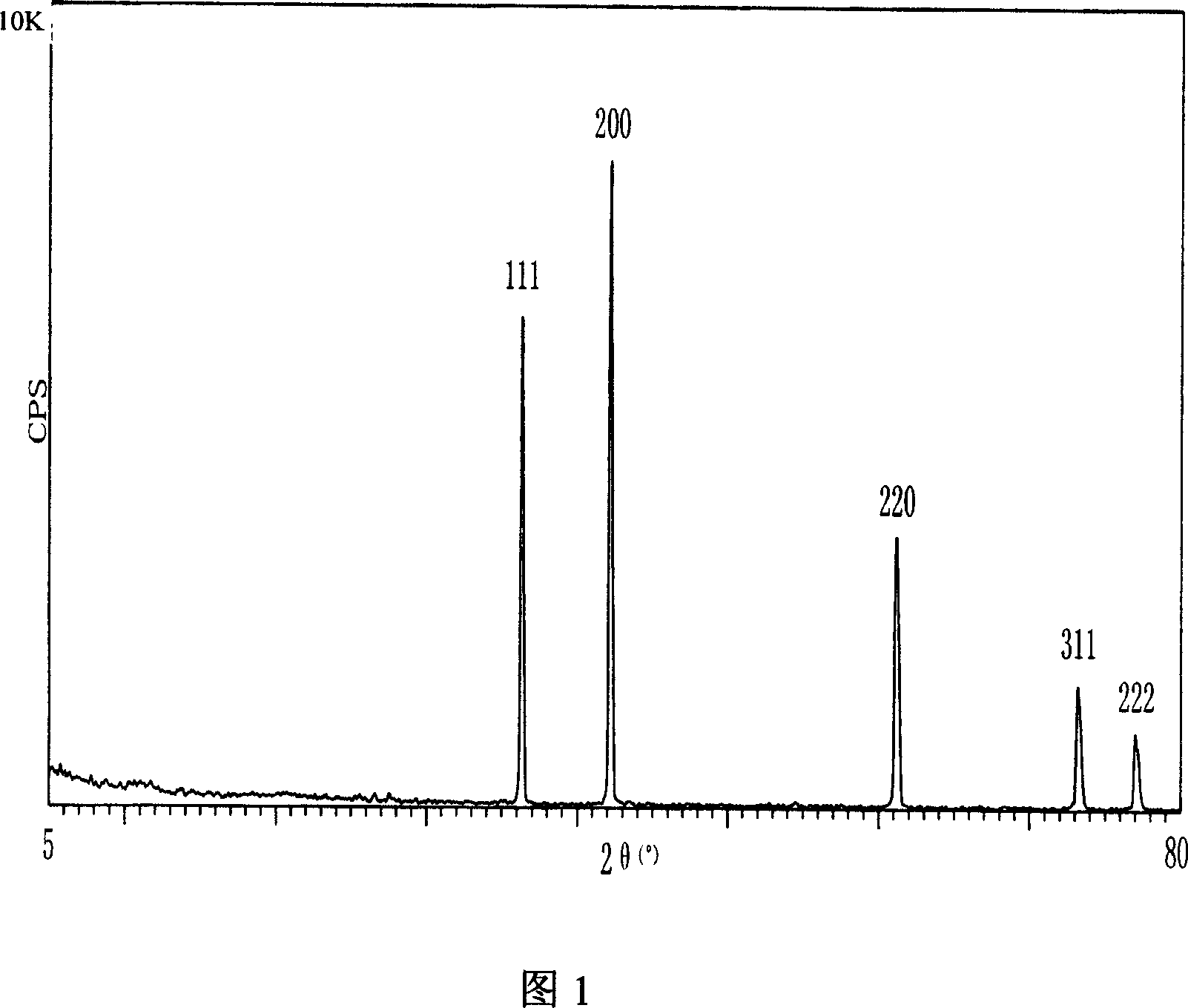

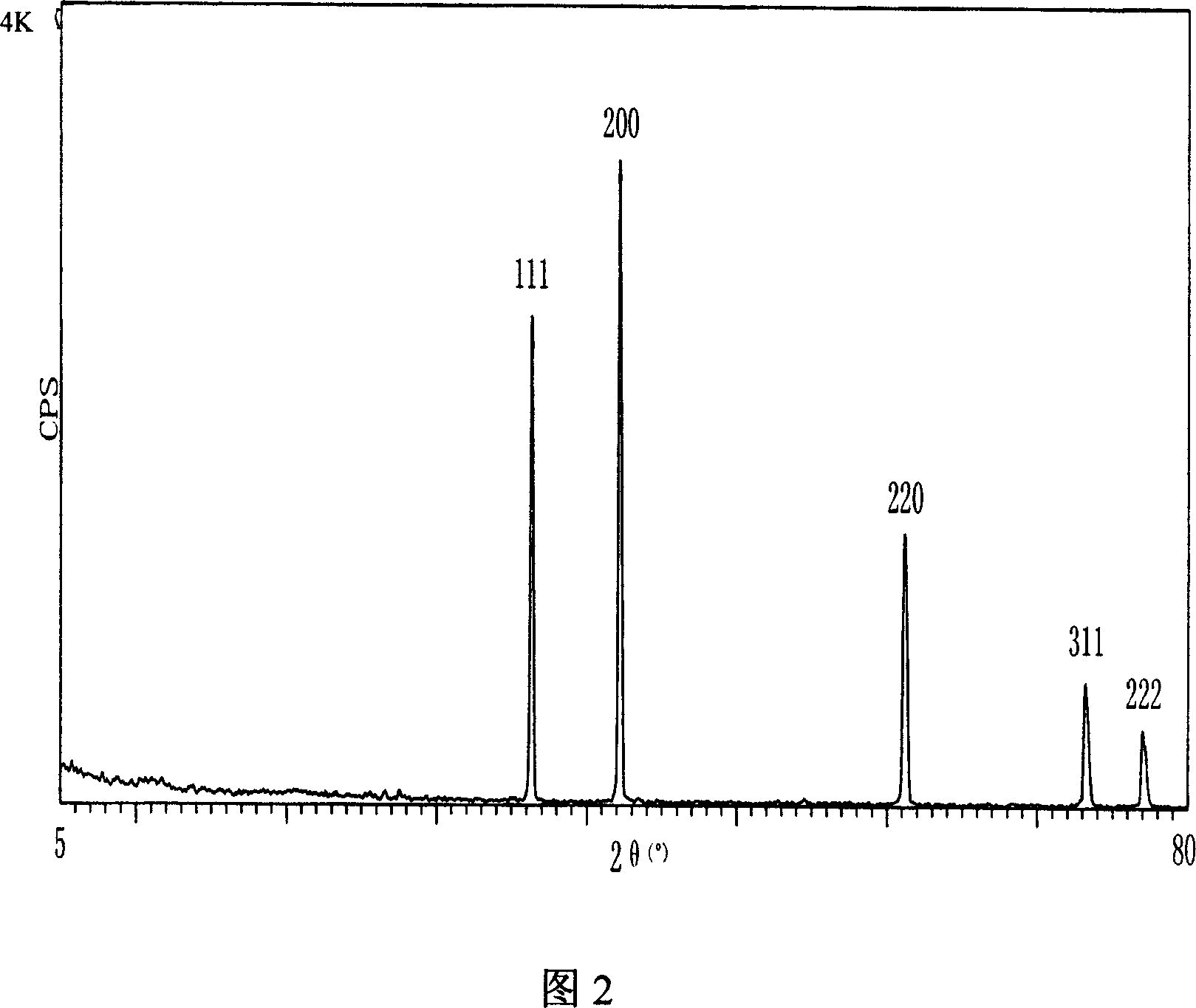

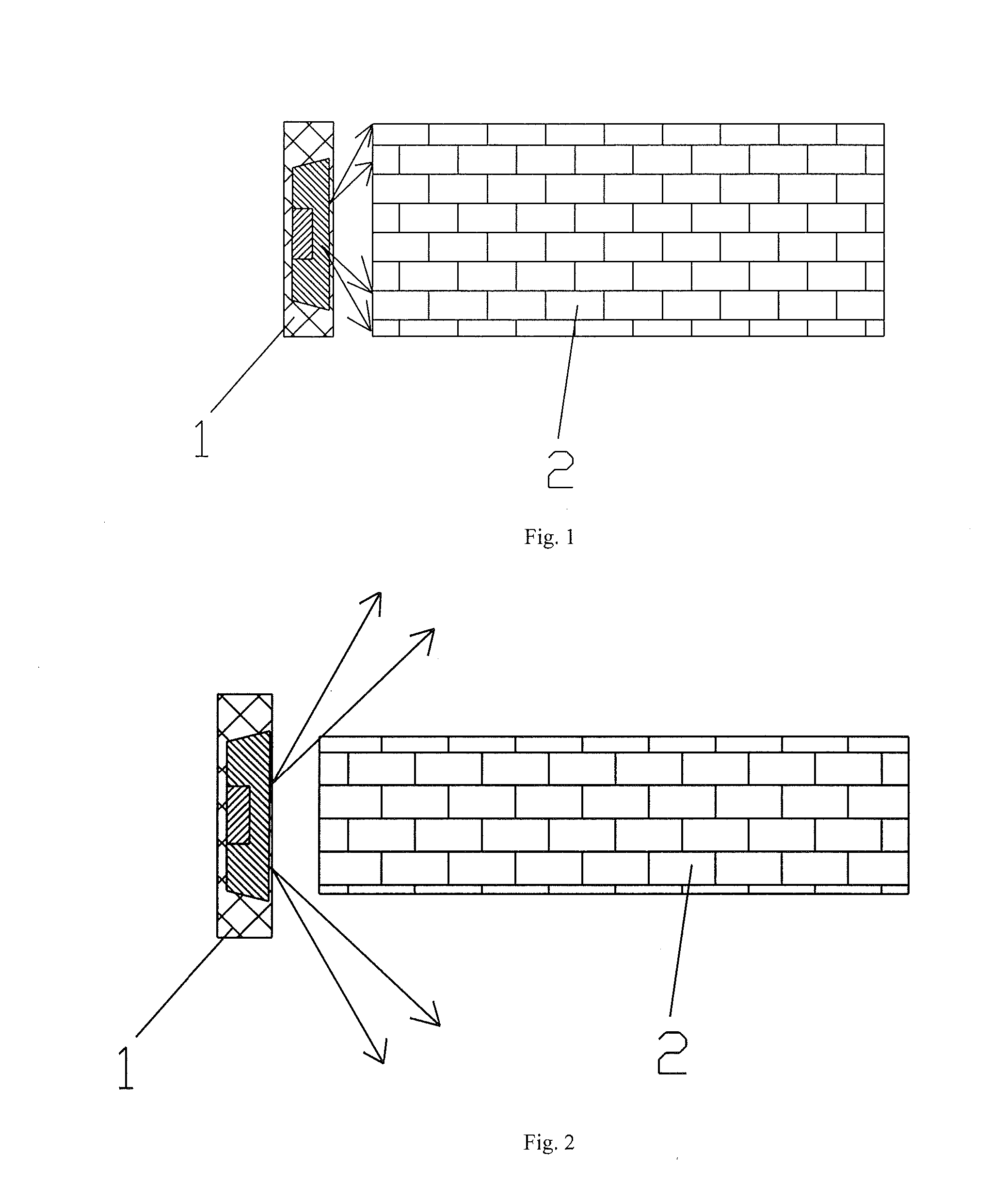

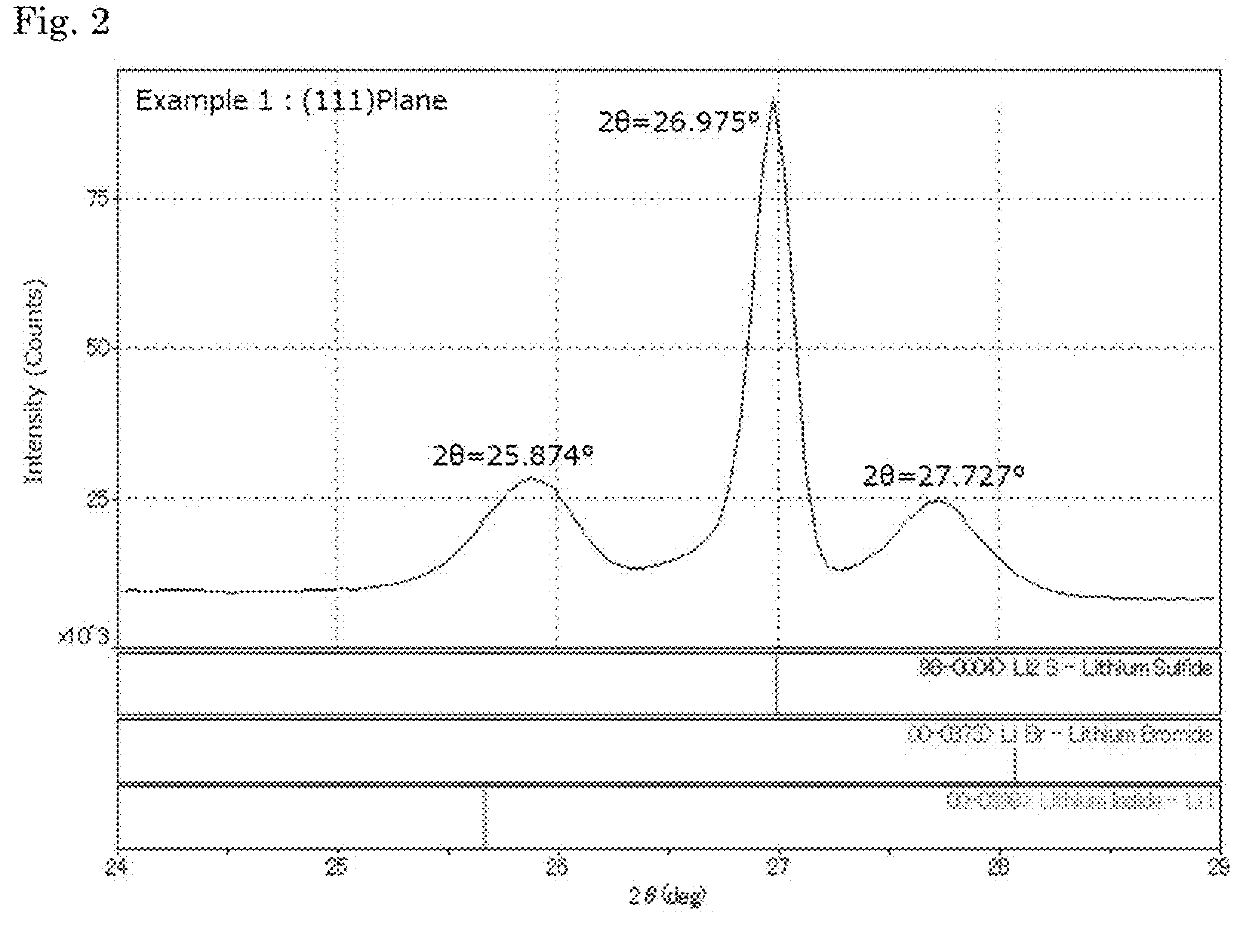

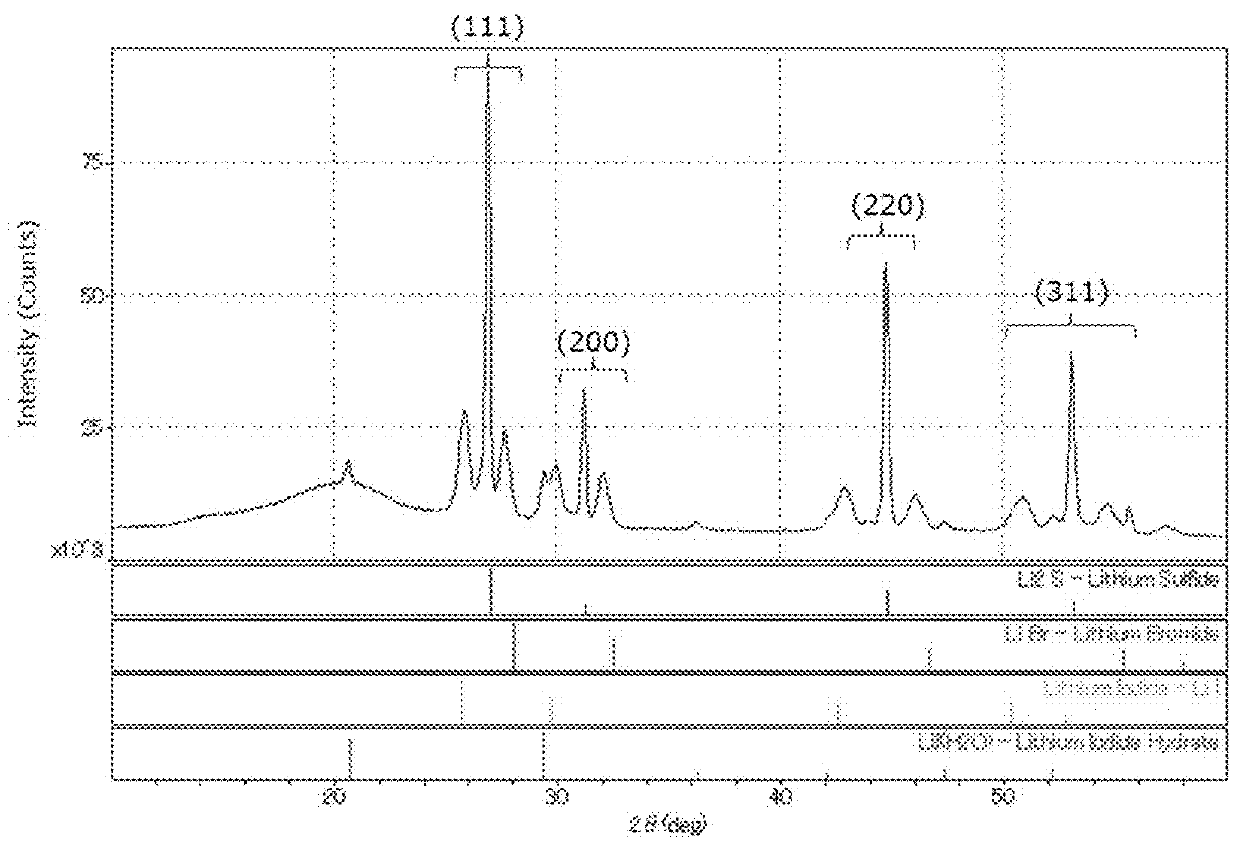

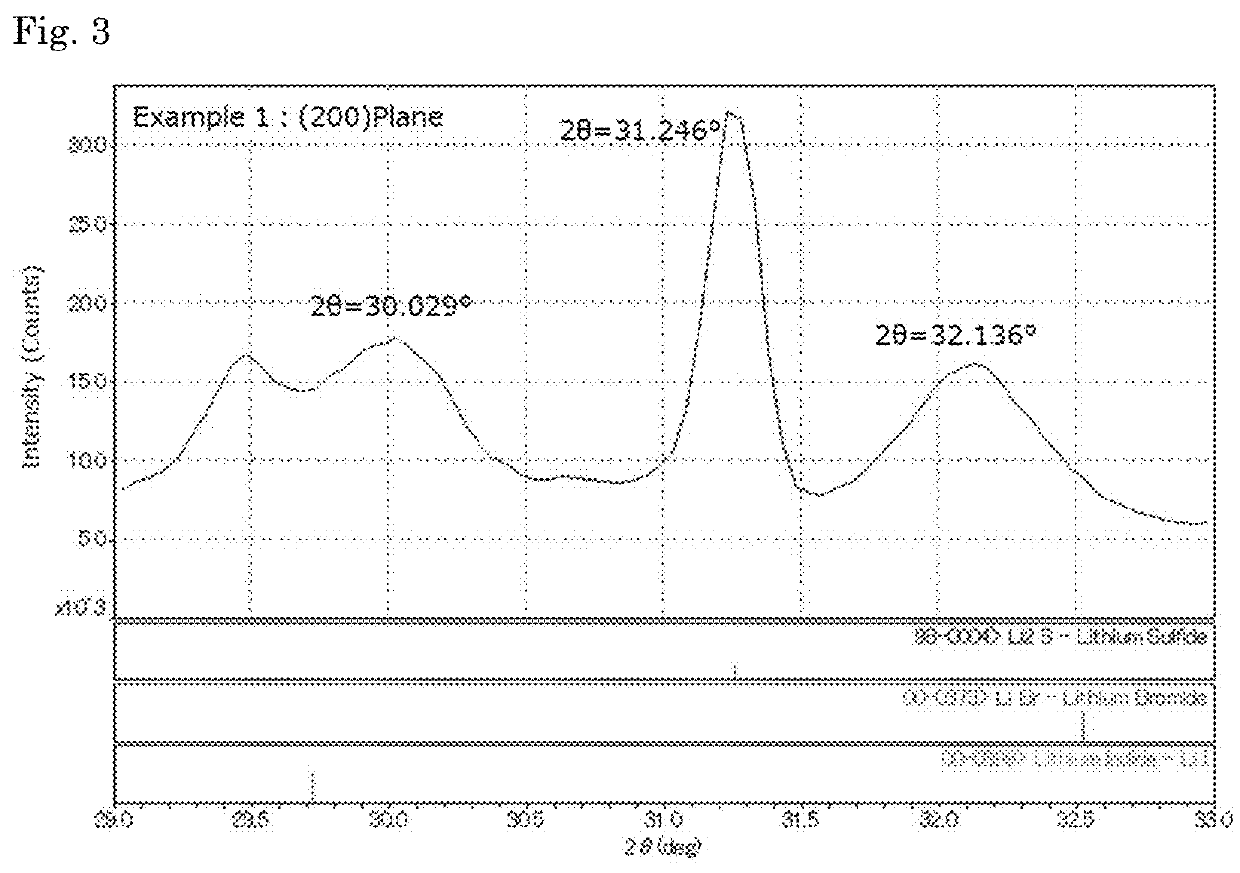

Complex comprising sulfur, a method for manufacturing the same, and a method for manufacturing a solid electrolyte

ActiveUS20180162730A1High production efficiencyImprove production efficiencySolid electrolytesCell electrodesLithium sulfideHalogen

To provide a sulfur-containing complex having few impurities, a method for producing the complex at a higher production efficiency, and a method for producing a solid electrolyte using the complex, a sulfur-containing complex, containing a lithium sulfide and a lithium halide, exhibiting, in X-ray diffractometry using a CuKα ray, the diffraction angle of the peak of lithium halide shifting toward the diffraction angle of the peak of lithium sulfide, and not containing an oxygen-containing lithium halide represented by Li3OX (where X represents a halogen element) is provided. And a production method for a sulfur-containing complex including heating a solution containing a lithium hydrosulfide and a lithium halide in the presence of hydrogen sulfide is also provided.

Owner:IDEMITSU KOSAN CO LTD

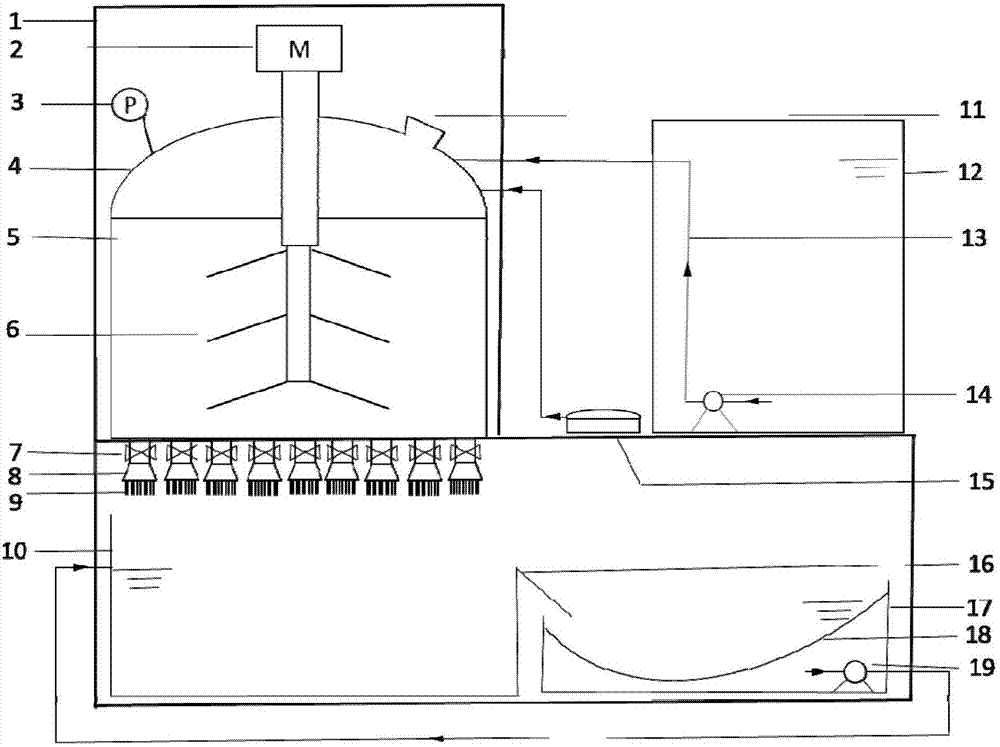

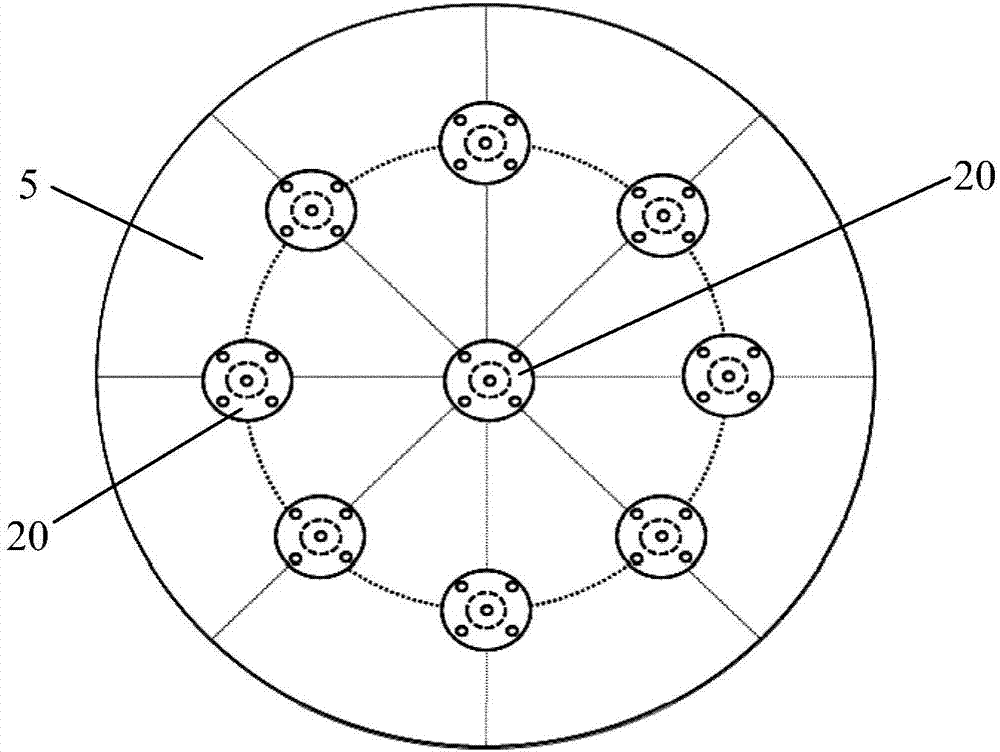

Immobilized microorganism production device and production method

ActiveCN107188306AHigh production efficiencyEasy to shapeTreatment with anaerobic digestion processesSustainable biological treatmentMicroorganismAutomatic control

The invention provides an immobilized microorganism production device and production method. The production device includes a bracing frame, a material stirring barrel, at least two reaction tanks and a water tank. The material stirring barrel and the water tank are arranged at the upper part of a bracing frame, adjacent to each other. The two reaction tanks are arranged at the lower part of the bracing frame, adjacent to each other, and form mutual circulation. The water tank communicates with the material stirring barrel and the reaction tanks, respectively, for water supply and water replenishing. Material discharging pipes capable of being opened and closed are arranged at the bottom of the material stirring barrel and align right with the reaction tanks for dripping of materials. Through uniform stirring of material mixing and material particle forming, automatic control is achieved, the embedding technical process is further simplified, the high yield is increased, and stable operation and the product quality are ensured.

Owner:TONGJI UNIV

Full-automatic cable wiredrawing and continuous annealing production line

InactiveCN111250556AHigh production efficiencyIncrease productivityApparatus for heat treatmentFurnace typesElectrical connectionElectric control

The invention relates to the technical field of cable production equipment, in particular to a full-automatic cable wiredrawing and continuous annealing production line. The full-automatic cable wiredrawing and continuous annealing production line comprises a paying-off machine, a microslip large drawing mill, an annealing machine, a tension controller, a double-disk paying-off machine and an electric control system, wherein the microslip large drawing mill is in butt joint to the paying-off machine; the tension controller is arranged between the annealing machine and the double-disk paying-off machine; the annealing machine is in butt joint to the microslip large drawing mill; the paying-off machine, the microslip large drawing mill, the annealing machine, the tension controller and the double-disk paying-off machine are all electrically connected with the electric control system; and the microslip large drawing mill comprises a base, main motors and a wiredrawing liquid box, whereina plurality of main motors are arranged on the base, each main motor is independently connected with a wiredrawing drum wheel, and the wiredrawing drum wheels are positioned in the wiredrawing liquidbox. The production line is provided with the plurality of main motors, the plurality of main motors realize a purpose of adjusting the wiredrawing slip so as to adapt to various wire rods, the production line disclosed by the invention is suitable for producing a high-quality wire rod product, and automatic double-disk wiredrawing production efficiency is high.

Owner:SHUNDE STRONG MECHANICAL EQUIP

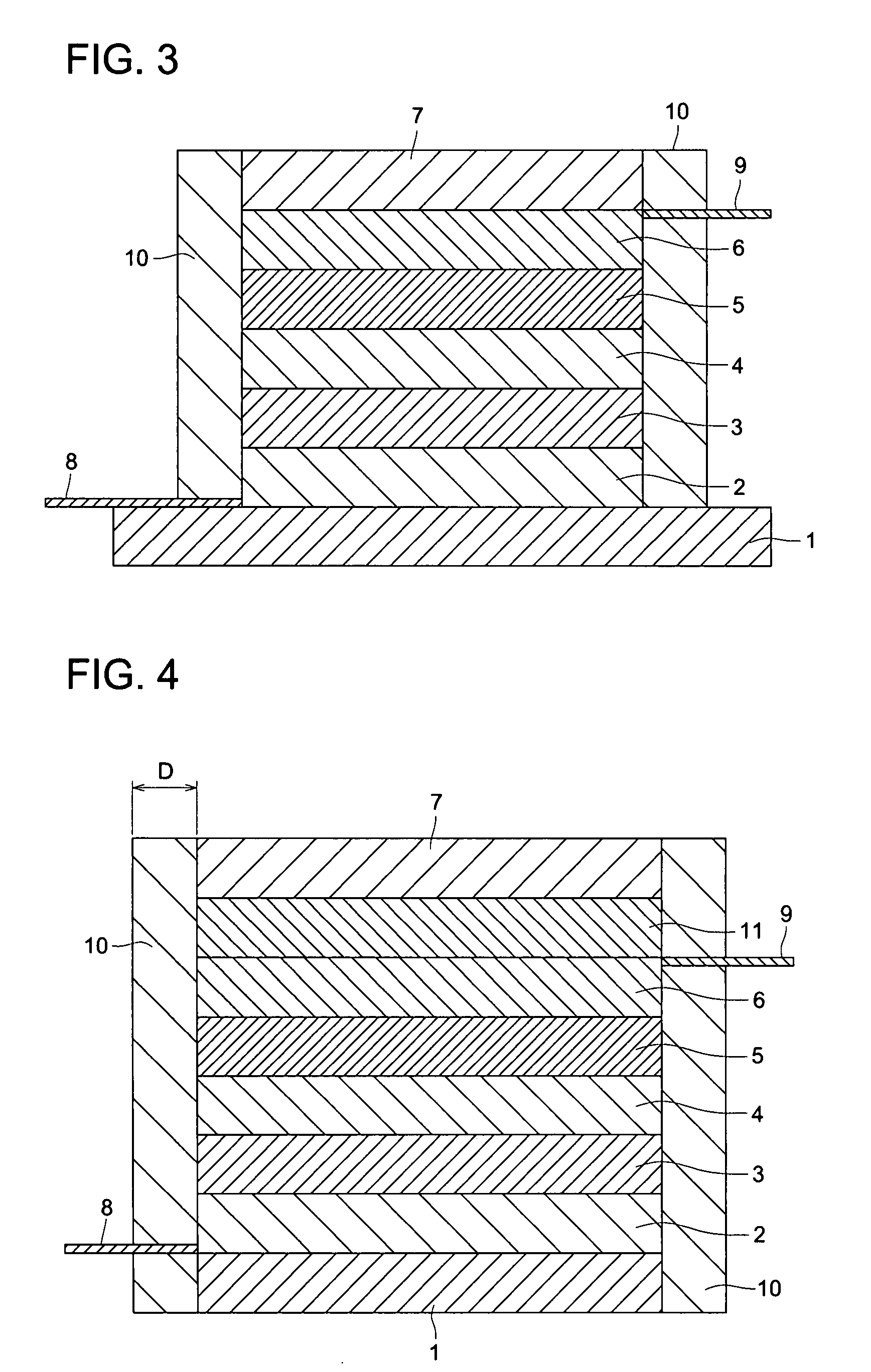

Decelerating casing of decelerating clutch of washing machine

InactiveCN101333756ASimple processing technologyHigh production efficiencyGearboxesOther washing machinesEngineeringGear train

The technical proposal of the invention discloses a decelerating body case for a washing machine decelerating clutch which relates to technical field of the washing machine. The decelerating body case comprises an input shaft cover and a metal drawing brake disc. The input shaft cover is composed of two parts that combine together, in which the diameter of one part is larger than that of the other part, inside of the part with the larger diameter is a cavity that can contain a gear train, and internal teeth are arranged on the internal wall; the brake disc is nested at the end of the part with the larger diameter of the input shaft cover, tightly fixed and hermetically connected. By adopting the technical disposal of the invention, the processing technique is simple, the manufacturing power efficiency is high and the cost is lower; working procedures such as cutting and surface treatment are avoided, materials are saved, and pollution to the environment is reduced; related components are left out which is favorable for the automatic assembly of the washing machine decelerating clutch and manufacturing cost of the washing machine decelerating clutch is further reduced.

Owner:NINGGUO JULONG IND

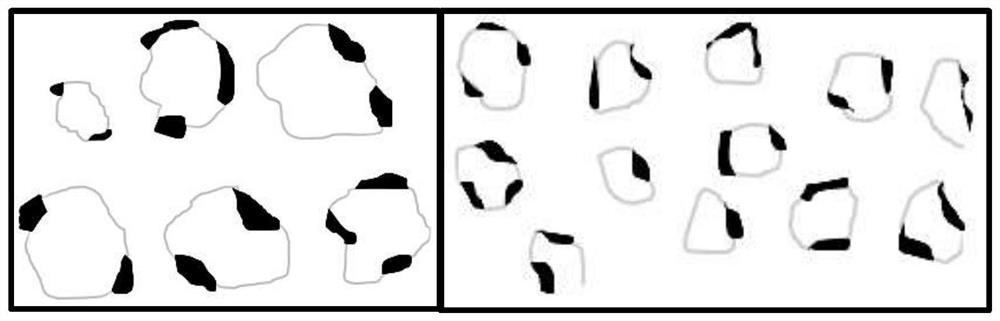

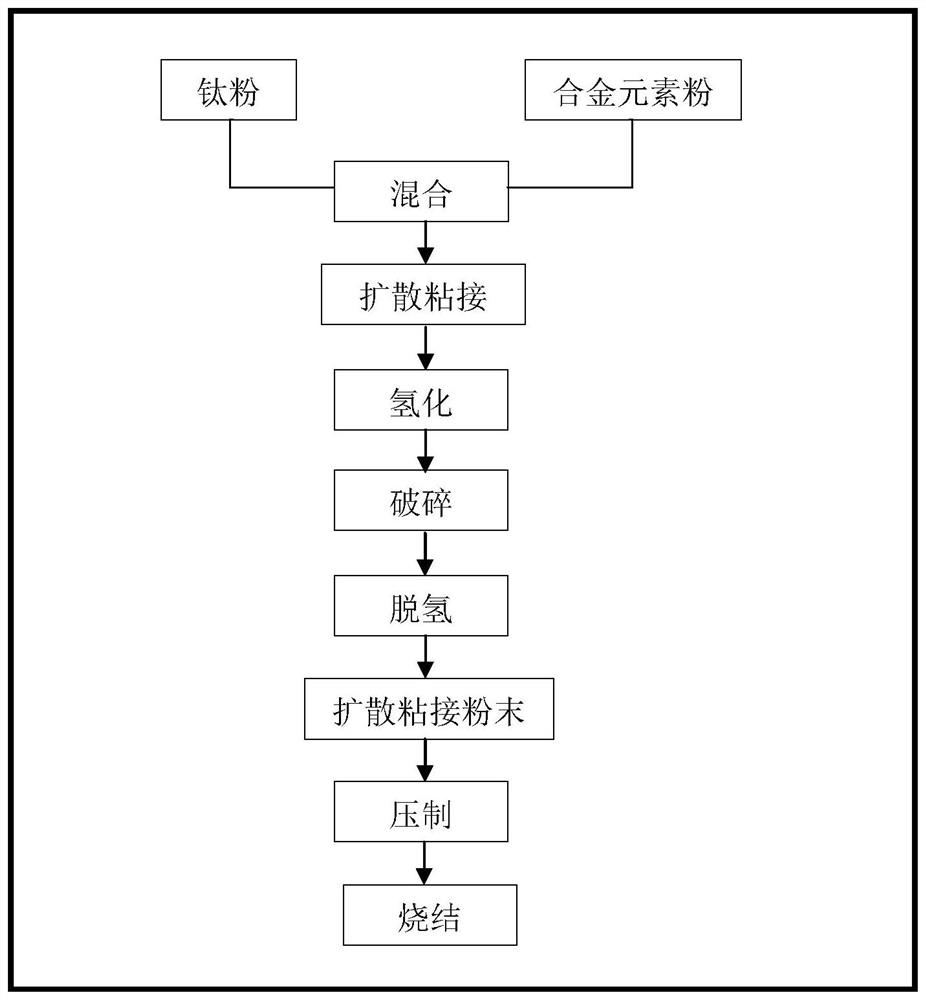

Preparation method of diffusion bonding titanium powders

ActiveCN112453384AReduce oxygen contentPromote fragmentationTransportation and packagingMetal-working apparatusTitanium alloyTitanium powder

The invention relates to a preparation method of diffusion bonding titanium powders, in particular to a method for producing powders for high performance powder metallurgy titanium alloys. The preparation method comprises the following steps that coarse particle titanium powders and elemental powders or alloy powders are used as raw materials to be mixed according to the proportion of required components, obtained mixed powders are subjected to diffusion bonding treatment, and hydrogen is introduced to form titanium hydride; and then the titanium hydride is taken out of a furnace, ball millingand crushing are carried out to obtain powders with the required particle size, and finally dehydrogenating is carried out to obtain the diffusion bonding titanium alloy powders. According to the preparation method, the cost of titanium alloy powders is obviously reduced, and the cost is only 1 / 10-1 / 2 that of the prior art; the preparation method has the advantages of low equipment requirement, less fixed asset investment, high production efficiency and simple and controllable production process; obtained products have low oxygen content and few impurities; and products obtained after sintering have stable performance, low oxygen content and uniform component structures.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com