Photocurable ink composition for ink-jet printing

An ink composition and inkjet printing technology, applied in the directions of inks, applications, household appliances, etc., can solve the problems of bending resistance and other problems, and achieve the effect of high production efficiency and sufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] (Preparation method of ink composition)

[0065] The method for preparing the photocurable inkjet printing ink composition of the present invention is not particularly limited, and it can be prepared by adding all the above-mentioned materials and mixing them with a bead mill, a three-axis roll mill, or the like. And when using a pigment, it is also possible to obtain a concentrated base (conc.base) ink in advance by mixing the pigment, the above-mentioned pigment dispersant, and the above-mentioned photopolymerizable compound, and then add the remaining components of the above-mentioned components to make it a desired one. Composition to prepare.

[0066] (production of printed matter)

[0067] Next, a printing method using the photocurable inkjet printing ink composition of the present invention will be described.

[0068] As the substrate to be printed using the photocurable ink composition for inkjet printing of the present invention, any conventionally known ultr...

Embodiment 1~9 and comparative example 1~5

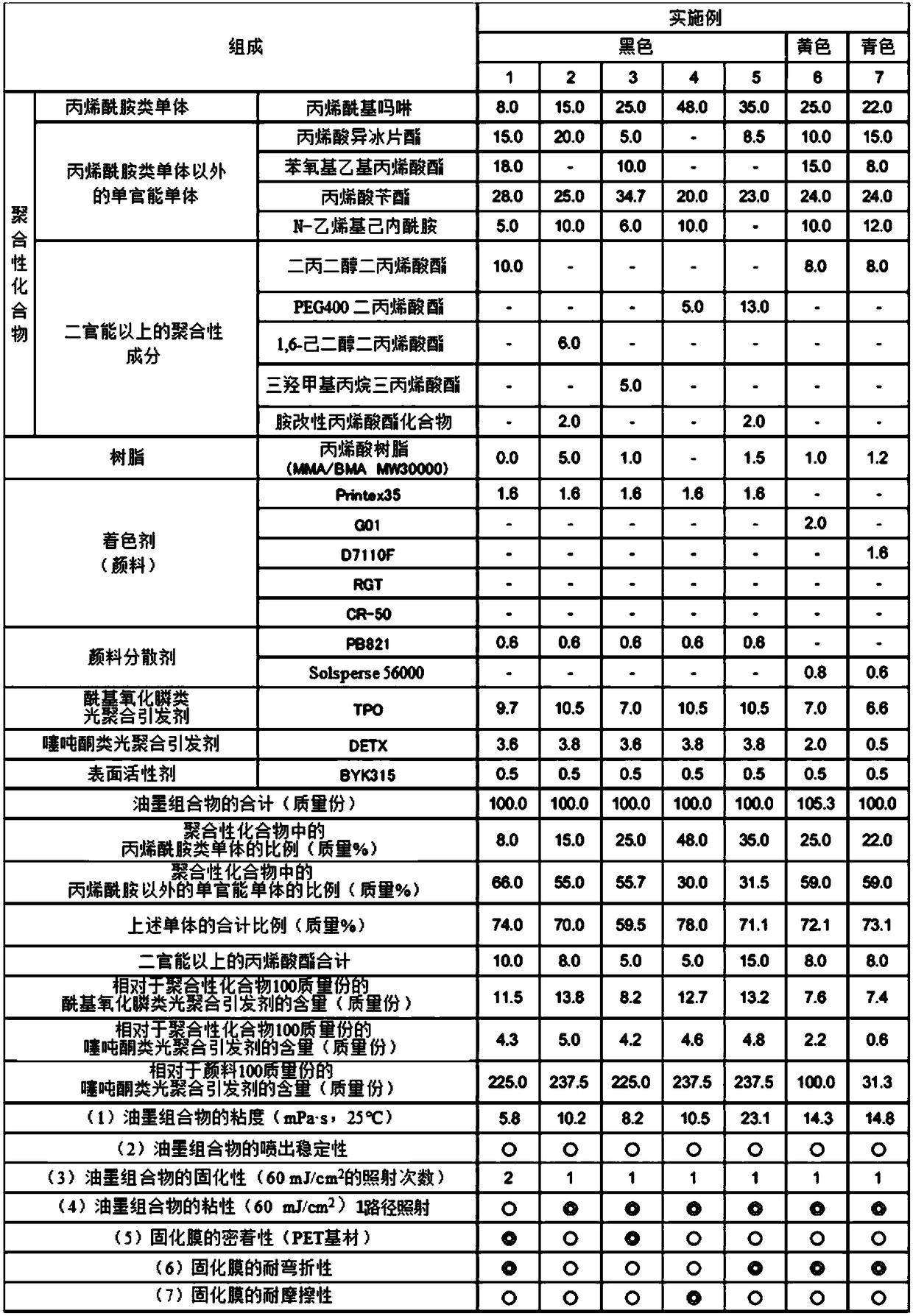

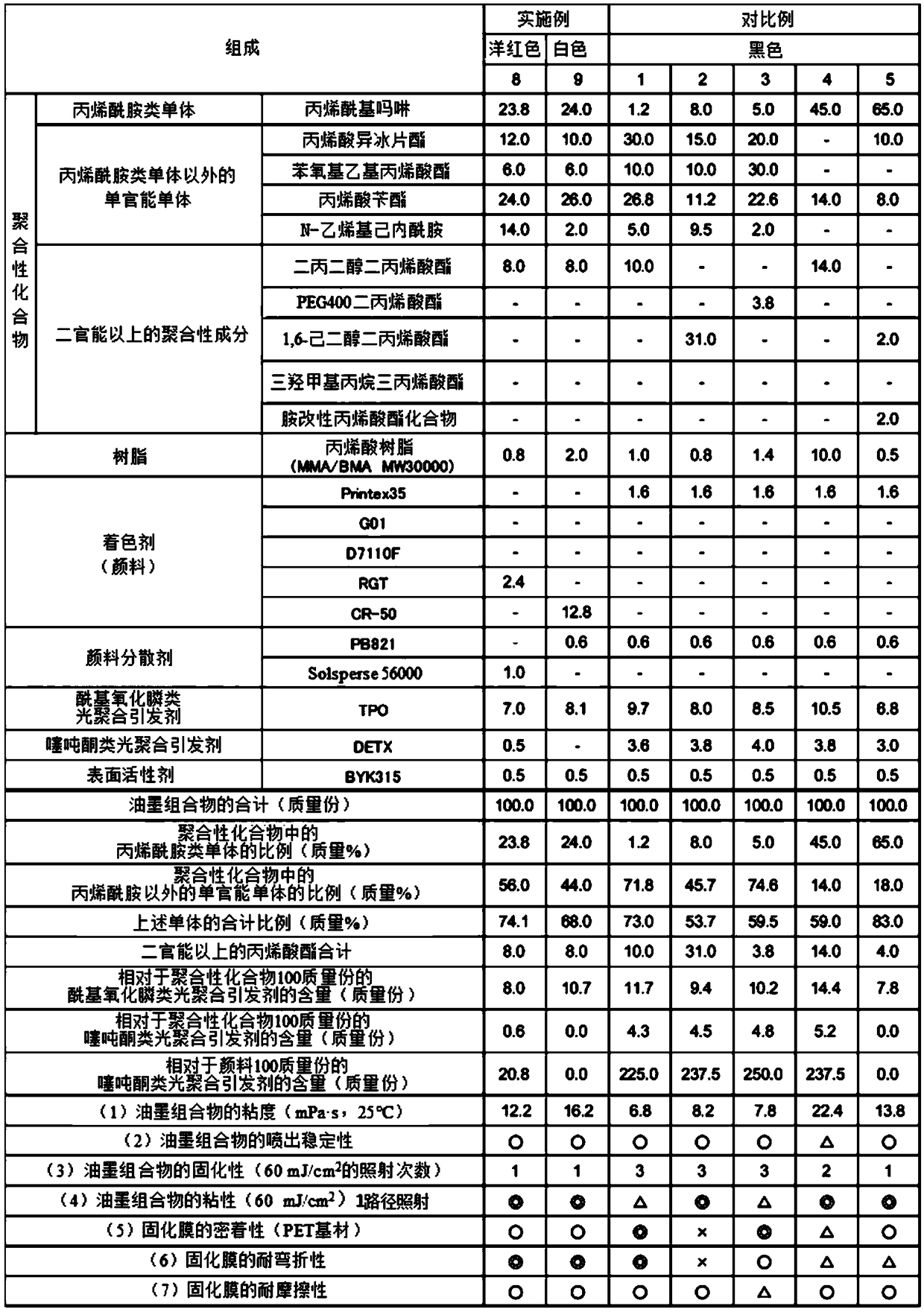

[0099] Preparation of Ink Composition for Photocurable Inkjet Printing

[0100] (Black ink composition)

[0101] Pigment (Pigment Black 7), pigment dispersant (AJISPERPB 821, manufactured by Ajinomoto Fine Techno Co., Ltd.) and photopolymerizable component (benzyl acrylate) were prepared so that the mixing ratio (mass ratio) was 20 / 8 / 72 The blended mixture was dispersed using an Eiger mill (zirconia beads with a diameter of 0.5 mm were used as a medium) to obtain a concentrated base. In the obtained concentrated base, each component was blended so as to have the blending composition (mass %) in Table 1, and stirred and mixed to obtain photocurable inkjet printing of Examples 1 to 5 and Comparative Examples 1 to 5. Composition with black ink.

[0102] (yellow ink composition)

[0103] Pigment (pigment yellow 150), pigment dispersant (Solsperse 56000, manufactured by Japan Lubrizol Co., Ltd.) and photopolymerizable component (benzyl acrylate) were mixed in such a way that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| stripping area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com