Preparation method of diffusion bonding titanium powders

A titanium powder and bonding technology, which is applied in the field of diffusion bonding titanium powder preparation, can solve the problems affecting the mechanical properties of titanium products, the control of the oxygen content of the original powder, and the high cost of pre-alloyed powder, so as to achieve small investment in fixed assets and uniform composition. , High production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

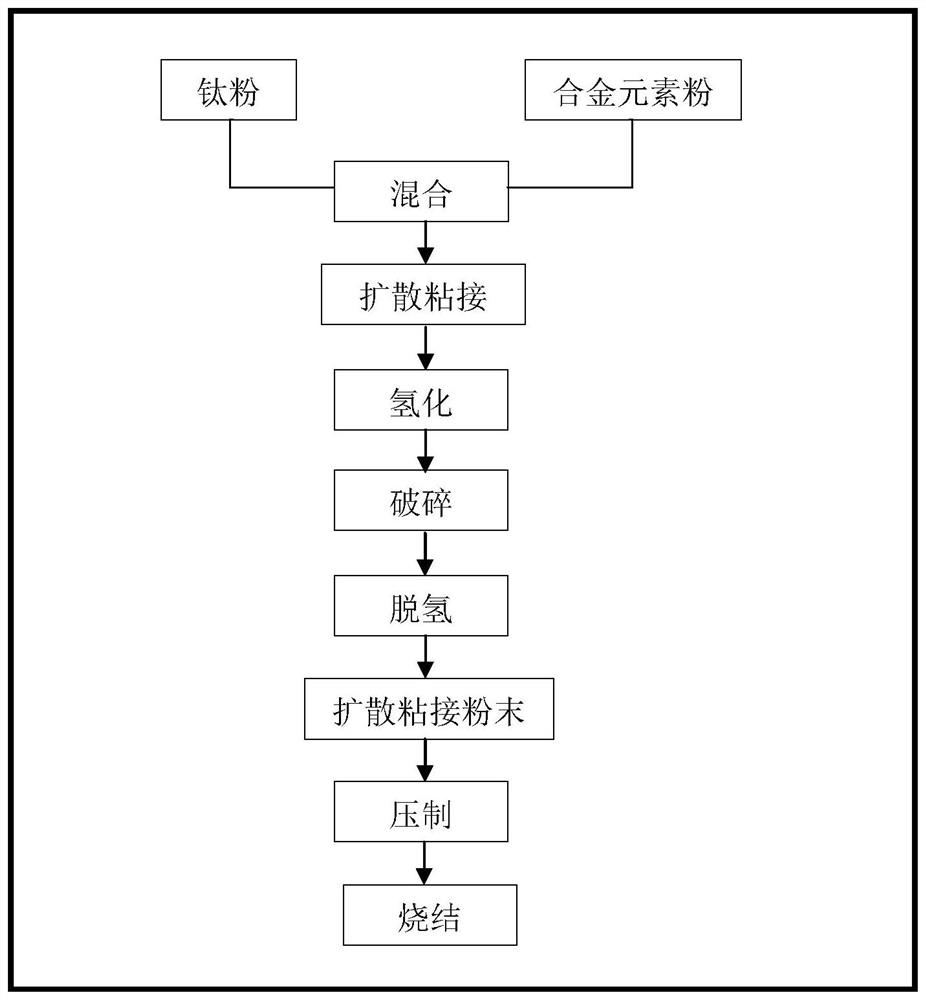

[0045] 1. Mix titanium sponge particles with a particle size of 200 microns, Al powder with a particle size of 40 microns, and V powder with a particle size of 30 microns according to the composition of the Ti-6Al-4V alloy, and put a certain amount of grinding balls into the V-shaped mixture Machine for 1 hour mixing.

[0046] 2. After the titanium alloy powder has been mixed, put it into a hydrogen furnace after standing for 0.5 hours, and in an inert atmosphere, heat up to 650 degrees Celsius, keep the inert atmosphere and keep it warm for 5 hours.

[0047] 3. Stop heat preservation, cool down with the furnace, and feed hydrogen, keep feeding hydrogen until it cools to room temperature.

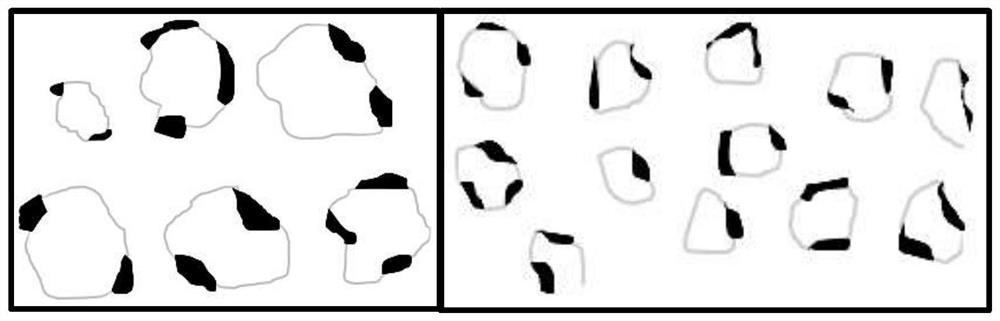

[0048] 4. Turn off the hydrogen, turn on the hydrogen furnace, take out the Ti-6Al-4V alloy powder for cooling and absorbing hydrogen, put it in the ball mill pot together with the grinding balls, and carry out ball mill crushing in an argon or nitrogen atmosphere. After ball milling, Ti-6A...

Embodiment 2

[0055] 1. Proportionate titanium sponge particles with a particle size of 500 microns, Al powder with a particle size of 10 microns, and Fe powder with a particle size of 5 microns according to the composition of the Ti-5Al-2.5Fe alloy, and put a certain amount of grinding balls into the V-shaped mixing The mixer was mixed for 1 hour.

[0056] 2. Put the mixed Ti-5Al-2.5Fe alloy powder into a hydrogen furnace after standing still for 0.5 hour, in an inert atmosphere, heat up to 650 degrees Celsius, keep the inert atmosphere and keep it warm for 5 hours.

[0057] 3. Stop heat preservation, cool down with the furnace, and feed hydrogen, keep feeding hydrogen until it cools to room temperature.

[0058] 4. Turn off the hydrogen, turn on the hydrogen furnace, take out the cooled hydrogen-absorbing titanium alloy powder, place it in the ball mill jar together with the grinding balls, and carry out ball milling and crushing in an argon or nitrogen atmosphere. After ball milling, the...

Embodiment 3

[0065] 1. Mix titanium sponge particles with a particle size of 200 microns and Al-V alloy powder with a particle size of 30 microns according to the Ti-6Al-4V alloy composition, and put a certain amount of grinding balls into a V-shaped mixer for 1 hour mixing , and then add 1.5vol% polyethylene glycol binder and mix well.

[0066] 2. Put the mixed Ti-6Al-4V alloy powder into a hydrogen furnace after standing still for 0.5 hours, raise the temperature to 200 degrees Celsius in an inert atmosphere, keep the inert atmosphere and keep it warm for 8 hours. Continue to heat up to 650 degrees Celsius, keep an inert atmosphere and keep warm for 5 hours.

[0067] 3. Stop the heat preservation, cool down with the furnace, and feed hydrogen (hydrogen pressure 1 bar), keep feeding hydrogen until it cools to room temperature.

[0068] 4. Turn off the hydrogen, turn on the hydrogen furnace, take out the Ti-6Al-4V alloy powder for cooling and absorbing hydrogen, put it in the ball mill po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com