Immobilized microorganism production device and production method

A technology for immobilizing microorganisms and production equipment, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc. Simple, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

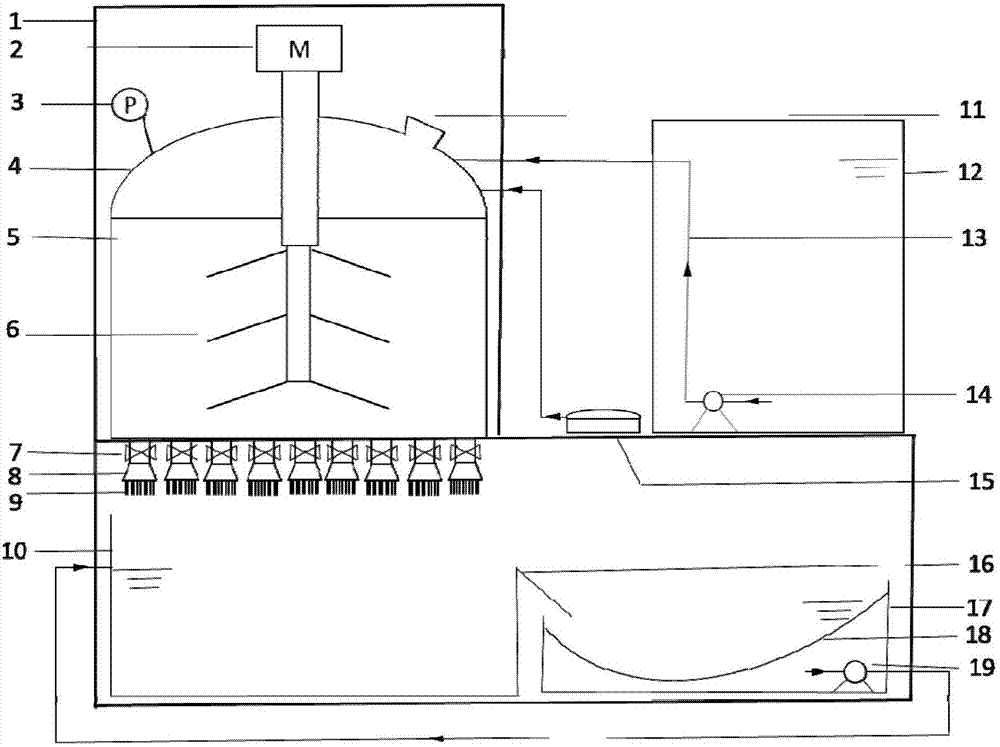

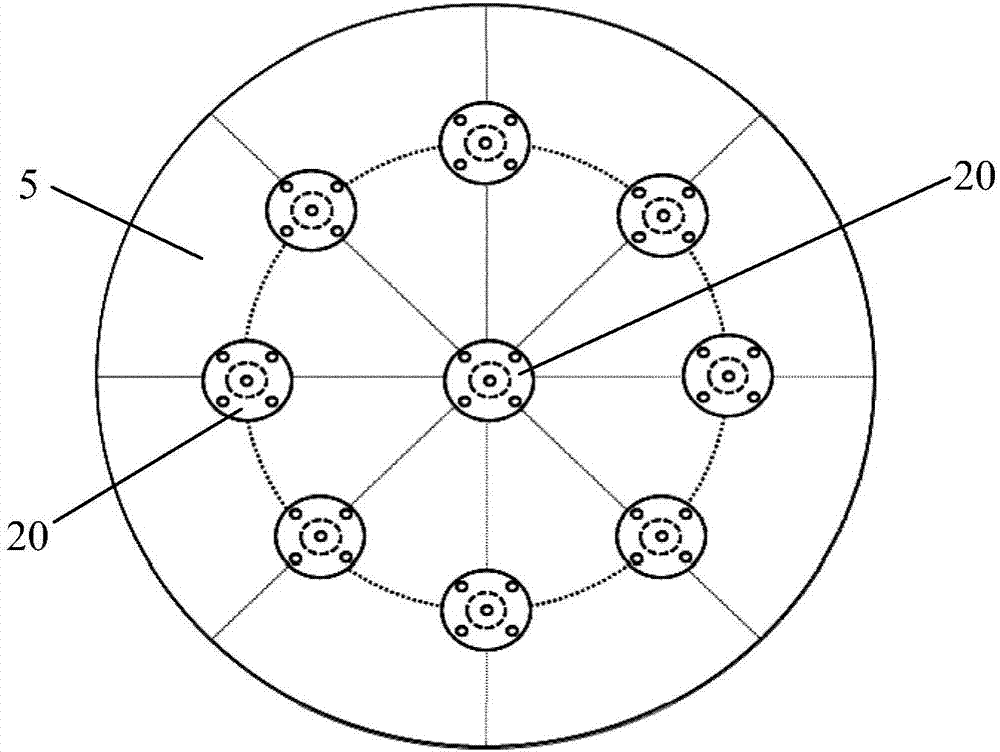

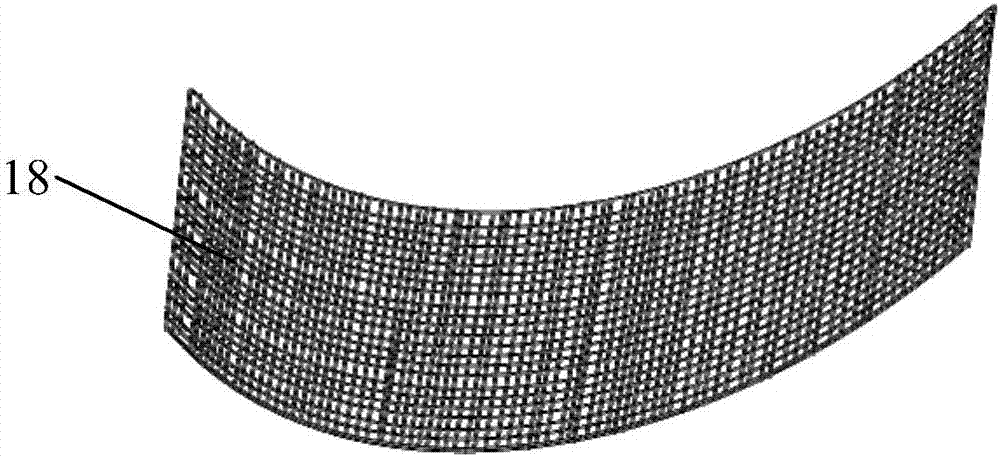

[0049] The present embodiment provides a device for preparing immobilized microorganisms, wherein, 5 barrels of material barrels are 800mm deep, barrels, cylinder wall thickness 20mm, bottom plate diameter 400mm, bottom aperture of material barrel 5 is 28mm, and switching head 8 has a small diameter of 28mm. The maximum diameter is 50mm, the discharge steel pipe is 9 pipes with a diameter of 5mm, and the screen is 30 mesh.

[0050] The specific operation process is as follows:

[0051] (1), open the first submersible pump 14, fill water in the material barrel 5, make the water volume account for 1 / 3 of the material barrel volume, turn on the stirring motor 2, adjust the stirring rate to be 700r / min, then add 5% polyvinyl alcohol , stirring at a rate of 500r / min for 20min until the mixture is uniform;

[0052] (2), continue to add other carrier materials in the material tank, stir for 15min at a stirring rate of 800r / min, until the microorganism immobilized carrier is obtained...

Embodiment approach 2

[0058] The present embodiment provides a device for preparing immobilized microorganisms, wherein, 5 barrels of material barrels are 800mm deep, barrels, cylinder wall thickness 20mm, bottom plate diameter 400mm, bottom aperture of material barrel 5 is 28mm, and switching head 8 has a small diameter of 28mm. The maximum diameter is 50mm, the discharge steel pipe 9 has a diameter of 3mm, and the screen mesh is 30 mesh.

[0059] The operation process includes the following steps:

[0060] (1), open the first submersible pump 14, fill water in the material barrel 5, make the water volume account for 1 / 3 of the material barrel volume, turn on the stirring motor 2, adjust the stirring rate to be 700r / min, then add 5% polyvinyl alcohol , stirring at a rate of 500r / min for 20min until the mixture is uniform;

[0061] (2), continue to add other carrier materials in the material tank, stir for 15min at a stirring rate of 800r / min, until the microorganism immobilized carrier is obtaine...

Embodiment approach 4

[0076] The present embodiment provides a device for preparing immobilized microorganisms, wherein, 5 barrels of material barrels are 800 mm deep, barrels, cylinder wall thickness 20 mm, bottom plate diameter 400 mm, bottom aperture of material barrel 5 is 28 mm, and switching head 8 has a small diameter of 28 mm. The maximum diameter is 50mm, the discharge steel pipe is 9 pipes with a diameter of 5mm, and the screen is 30 mesh.

[0077] The operation process includes the following steps:

[0078] (1), open the first submersible pump 14, fill water in the material barrel 5, make the water volume account for 1 / 3 of the material barrel volume, turn on the stirring motor 2, adjust the stirring rate to be 700r / min, then add 5% polyvinyl alcohol , stirring at a rate of 500r / min for 20min until the mixture is uniform;

[0079] (2), continue to add other carrier materials in the material tank, stir for 15min at a stirring rate of 800r / min, until the microorganism immobilized carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com