Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Reduce manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

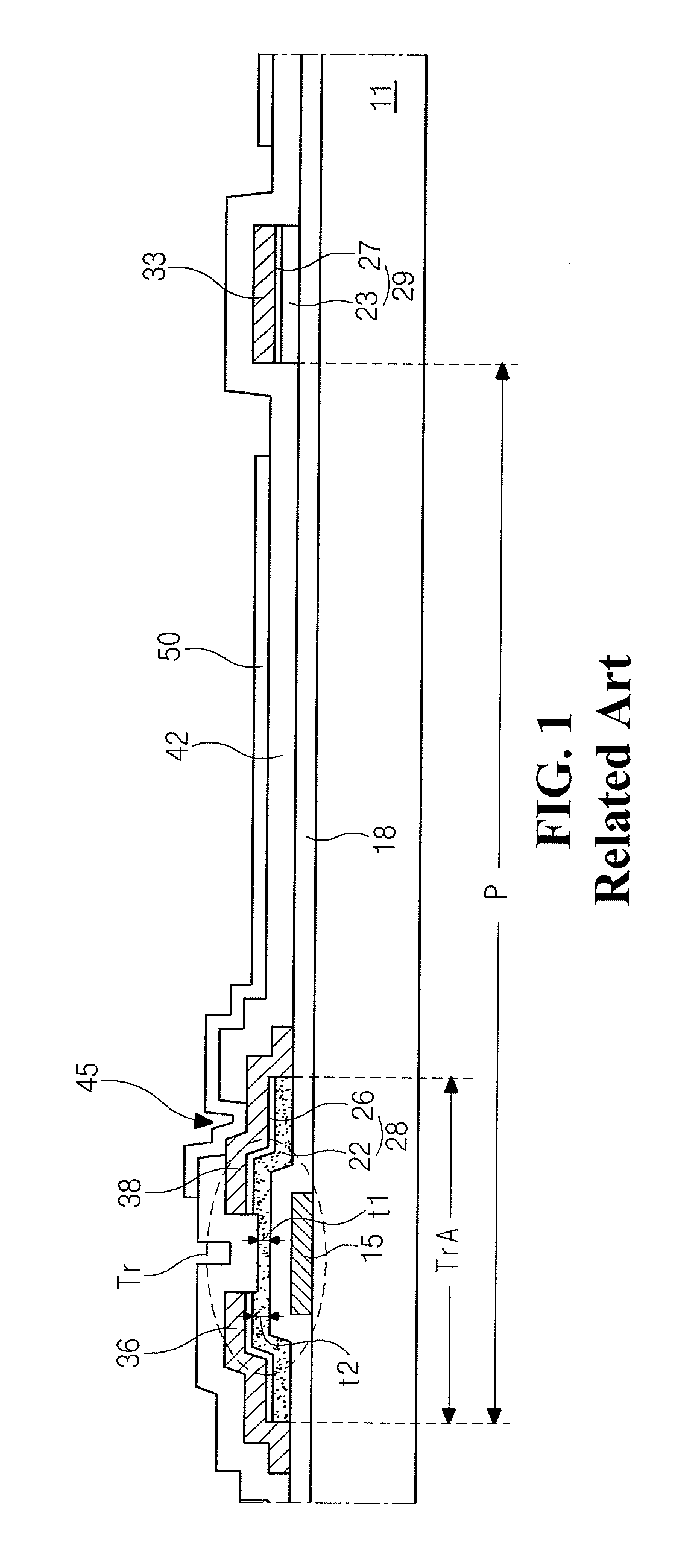

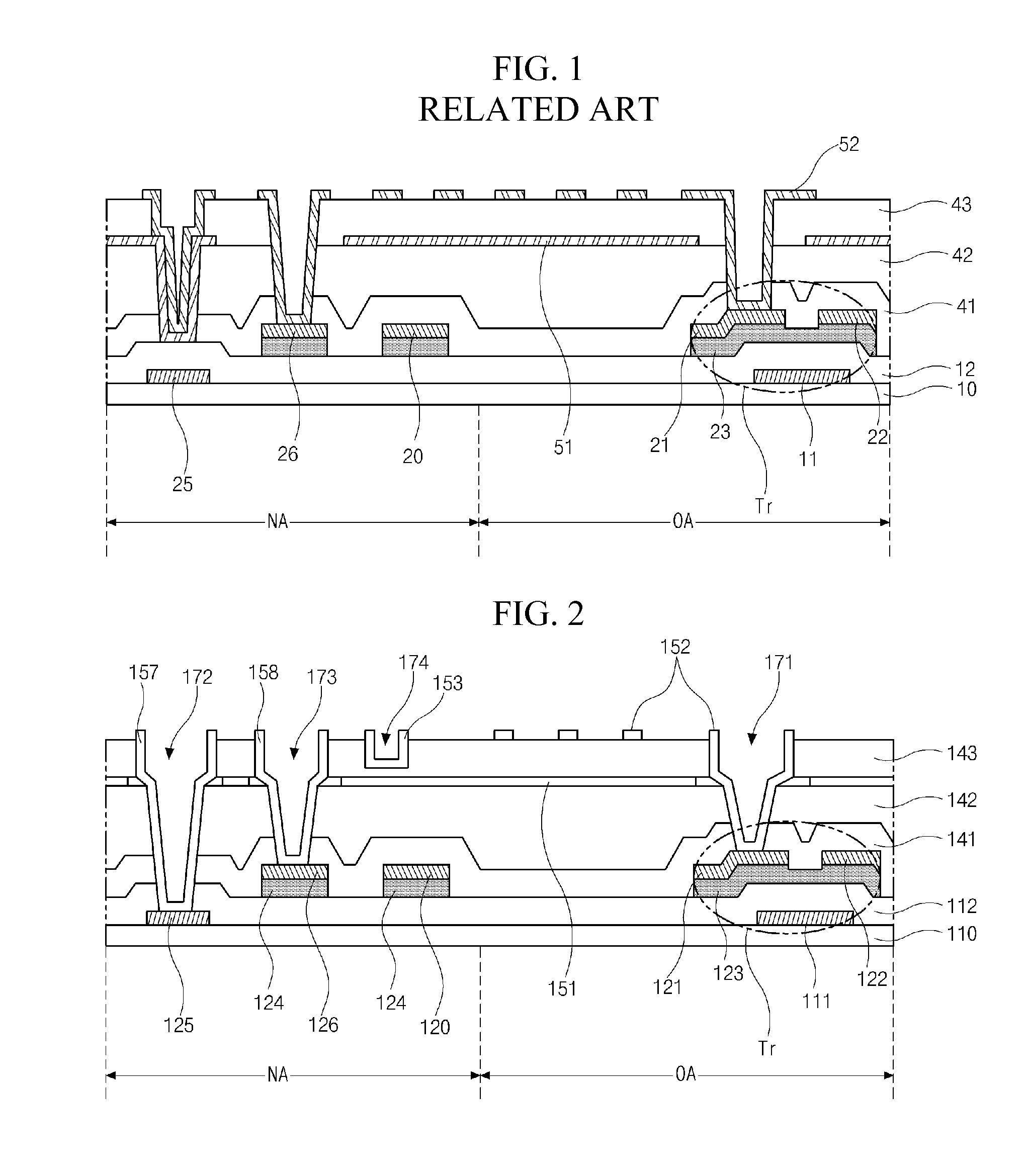

Manufacturing method for a liquid crystal display device

InactiveUS6933989B2Reduce production processReduce manufacturing processTransistorSemiconductor/solid-state device manufacturingLiquid-crystal displayLiquid crystal

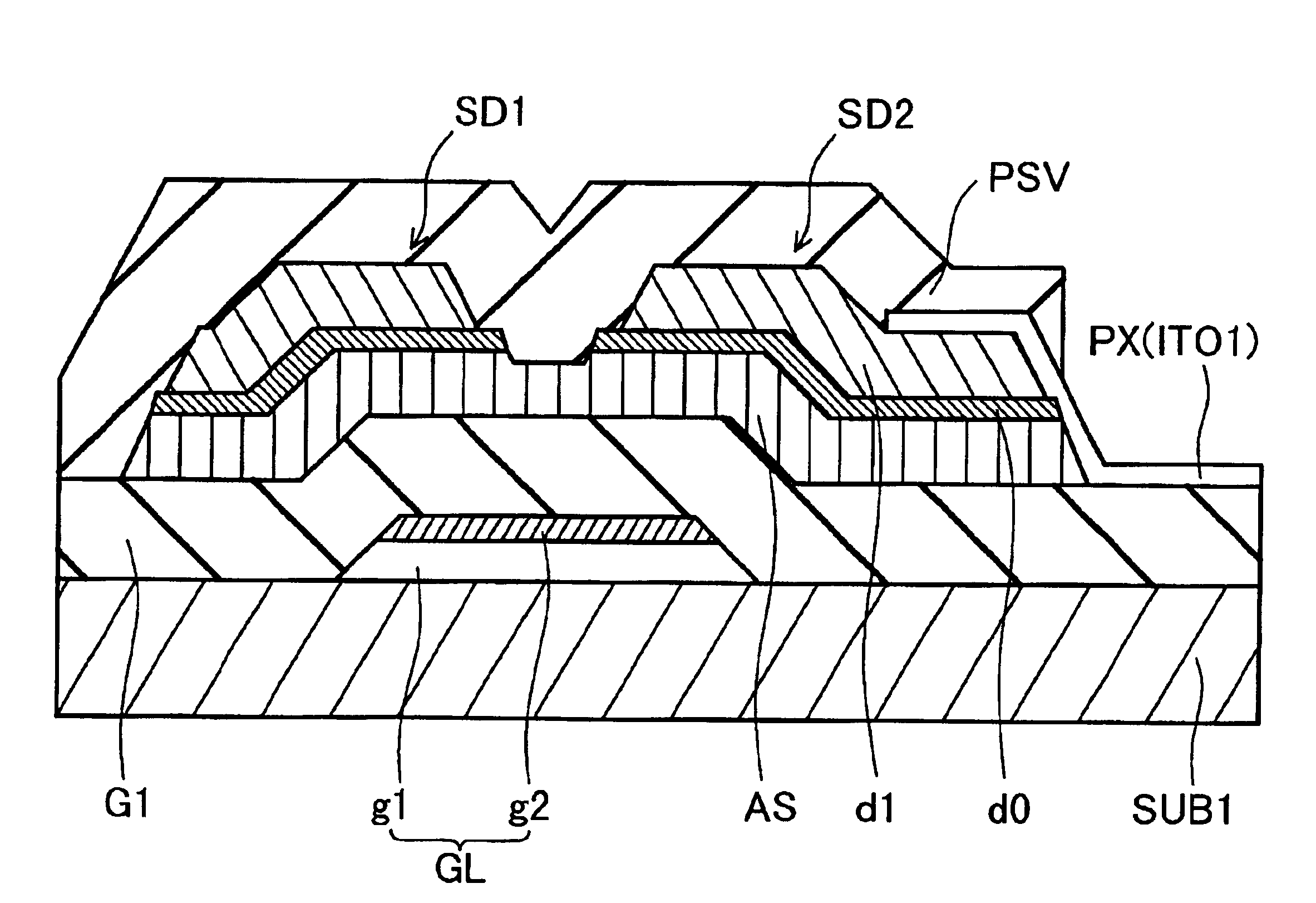

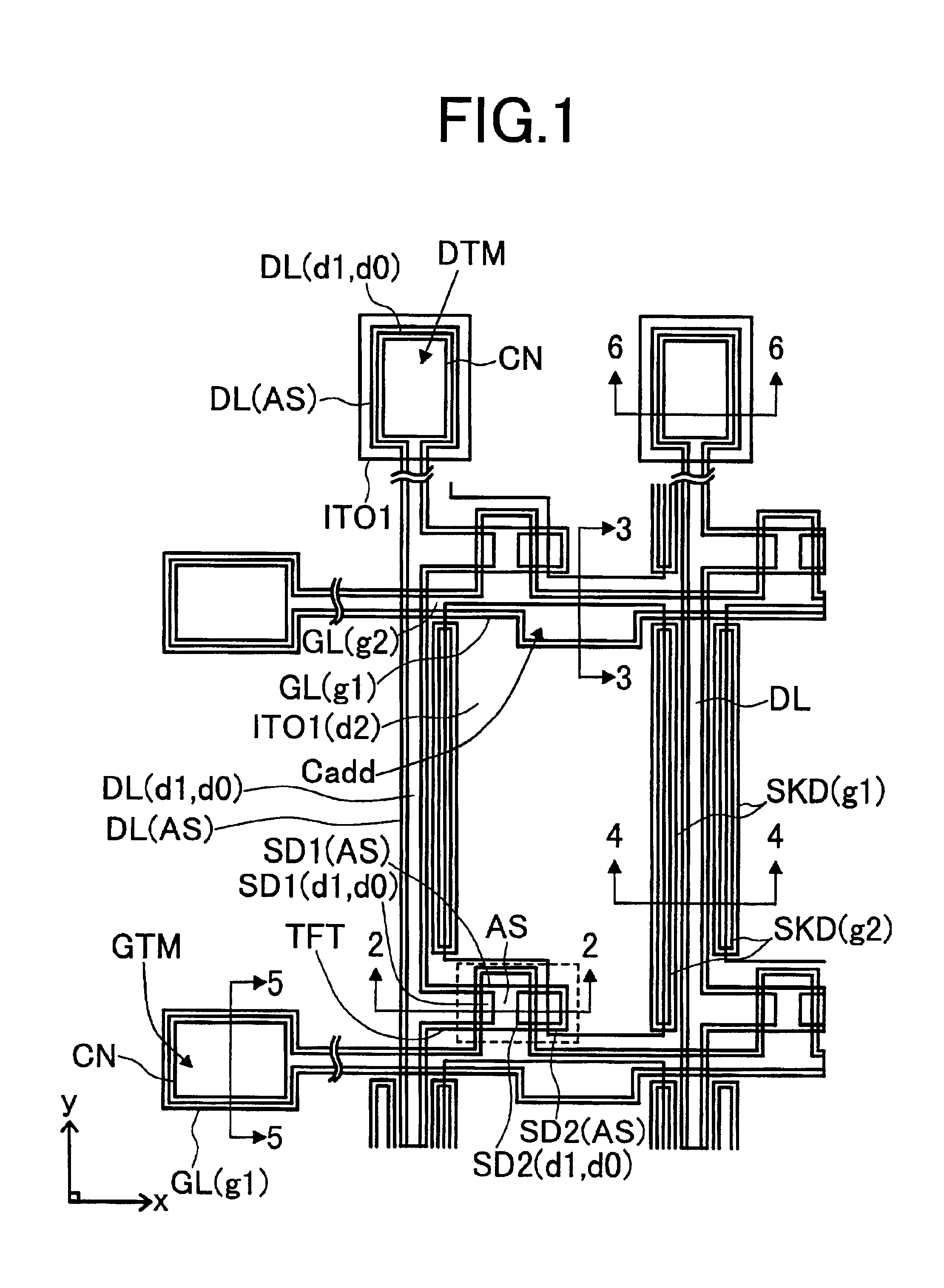

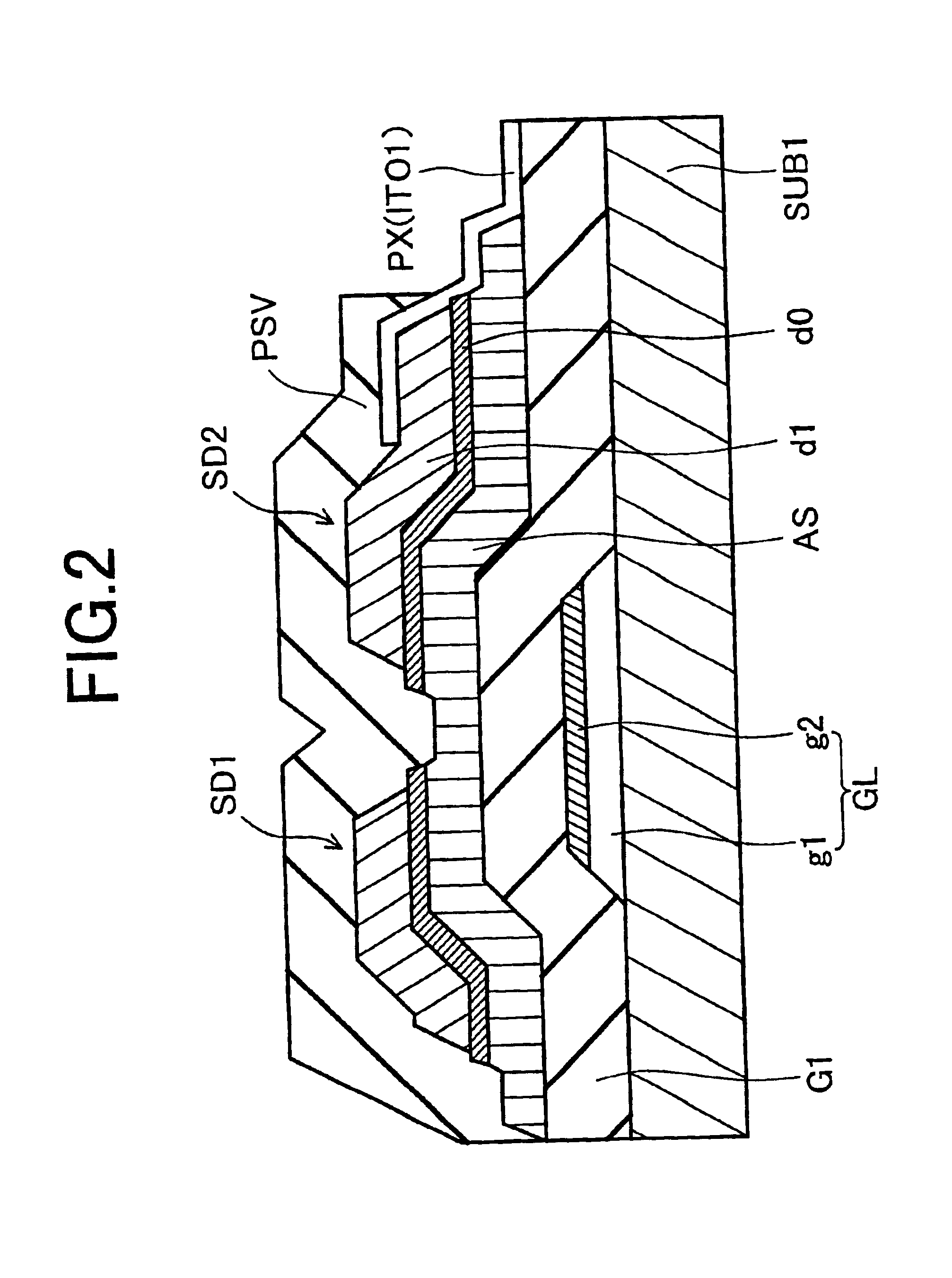

There is provided a liquid crystal display device in which the wiring resistivity of signal lines is reduced. The liquid crystal display device includes substrates disposed in opposition to each other with a liquid crystal interposed therebetween, a thin film transistor to be driven by a scanning signal supplied from a gate signal line, and a pixel electrode to be supplied with a video signal from a drain signal line via the thin film transistor, the thin film transistor and the pixel being provided in each pixel area on a liquid-crystal-side surface of one of the substrates. The gate signal line is made of a multi-layered structure including at least an ITO film formed on the liquid-crystal-side surface and a Mo layer formed to overlie the ITO film.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

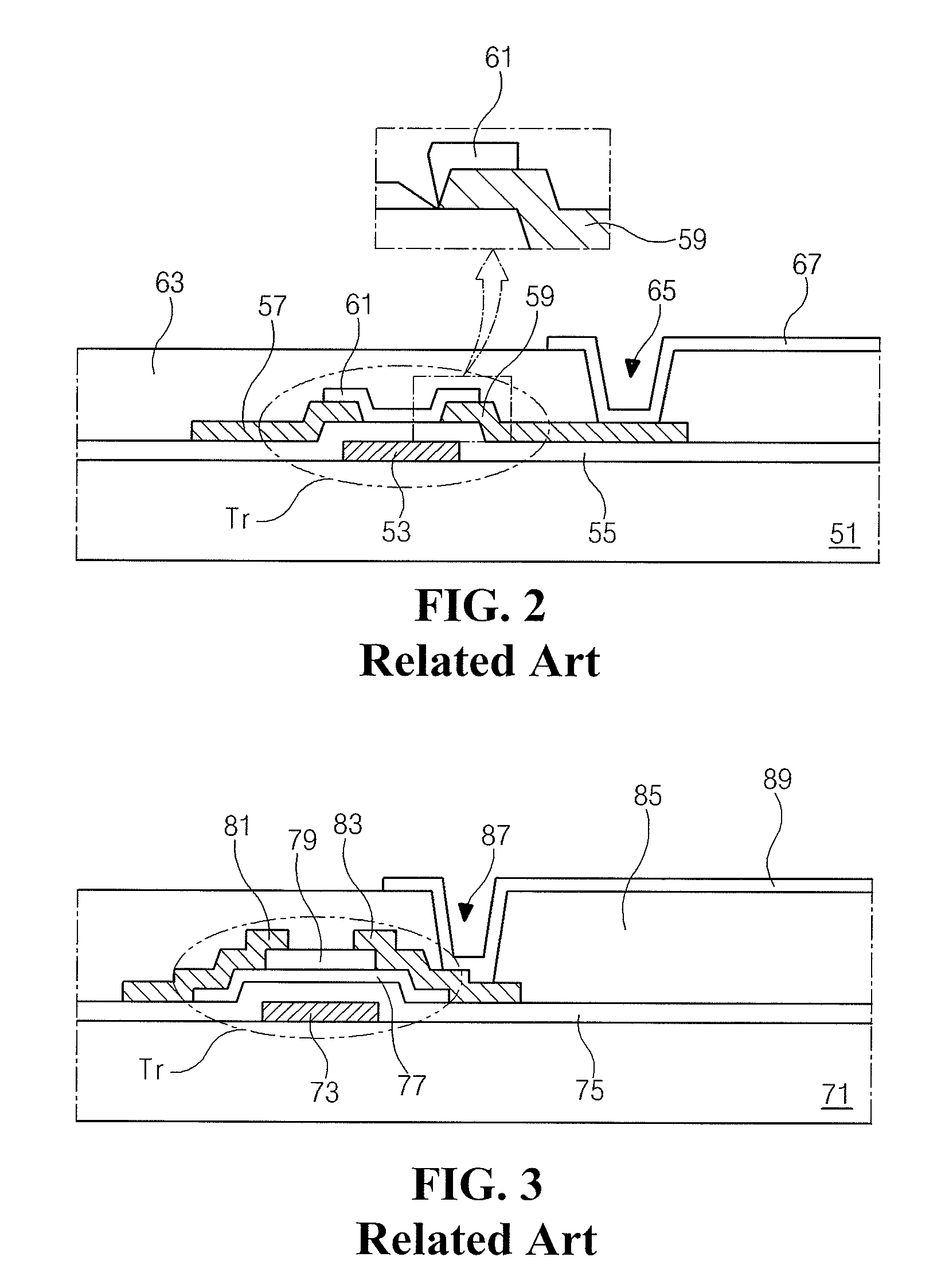

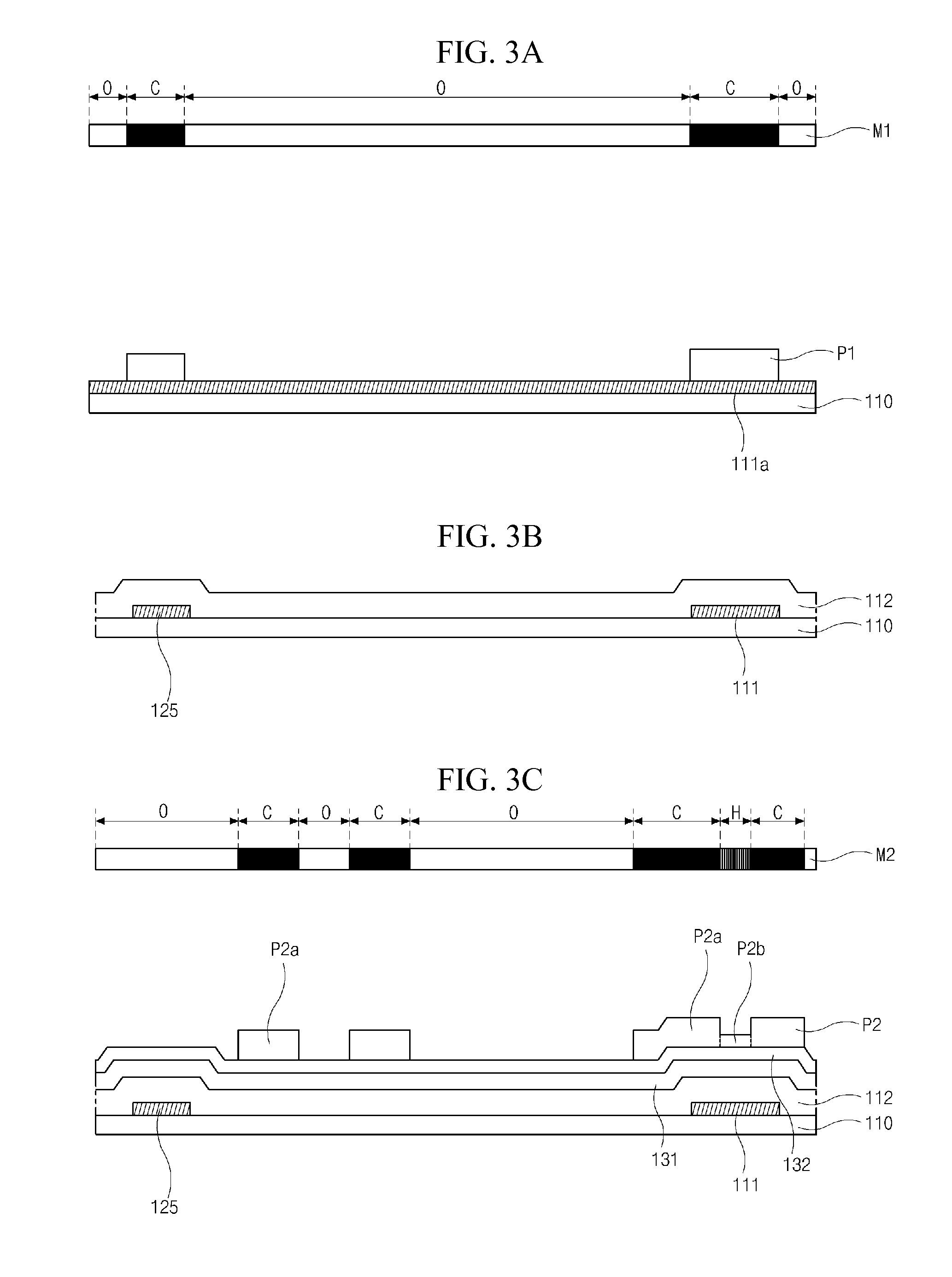

Array substrate and method of fabricating the same

ActiveUS20110291096A1Reduce manufacturing processLow costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSemiconductor

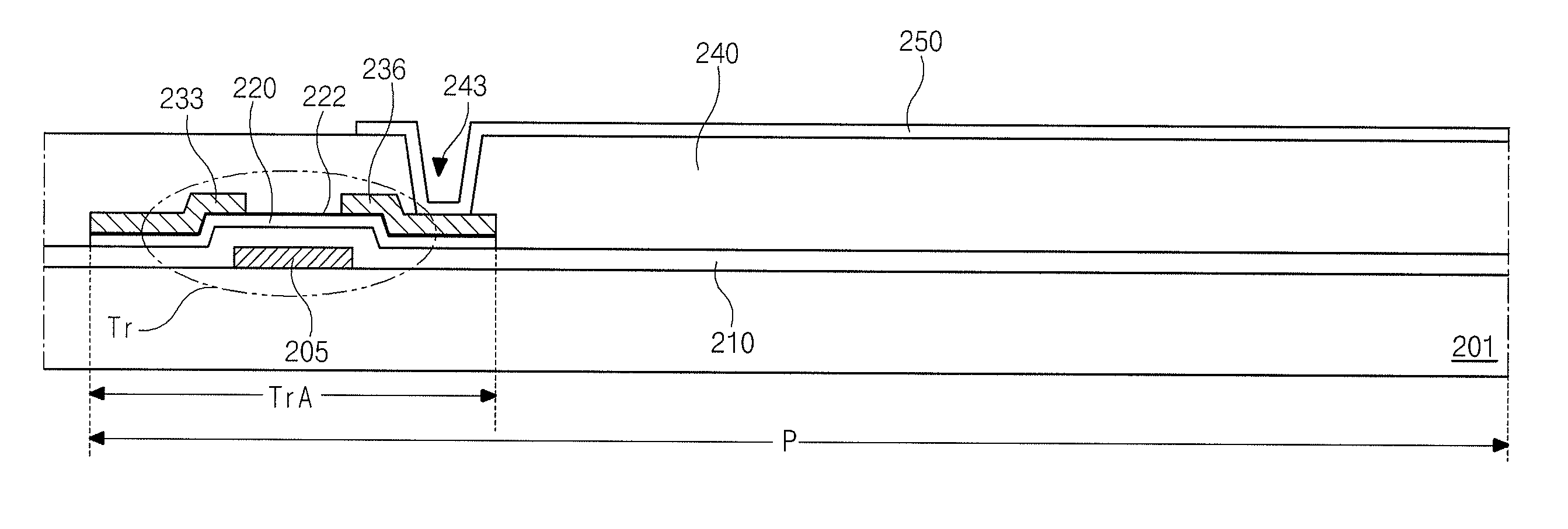

A method of fabricating an array substrate and a display device including the array substrate are discussed. According to an embodiment, the method includes forming a gate electrode on a substrate, forming a gate insulating layer on the gate electrode, forming an oxide semiconductor layer and an etch prevention layer on the gate insulating layer using a single mask, forming source and drain electrodes on the etch prevention layer, and forming a passivation layer including a contact hole on the source and drain electrodes and on the gate insulating layer, and forming a pixel electrode on the passivation layer and through the contact hole.

Owner:LG DISPLAY CO LTD

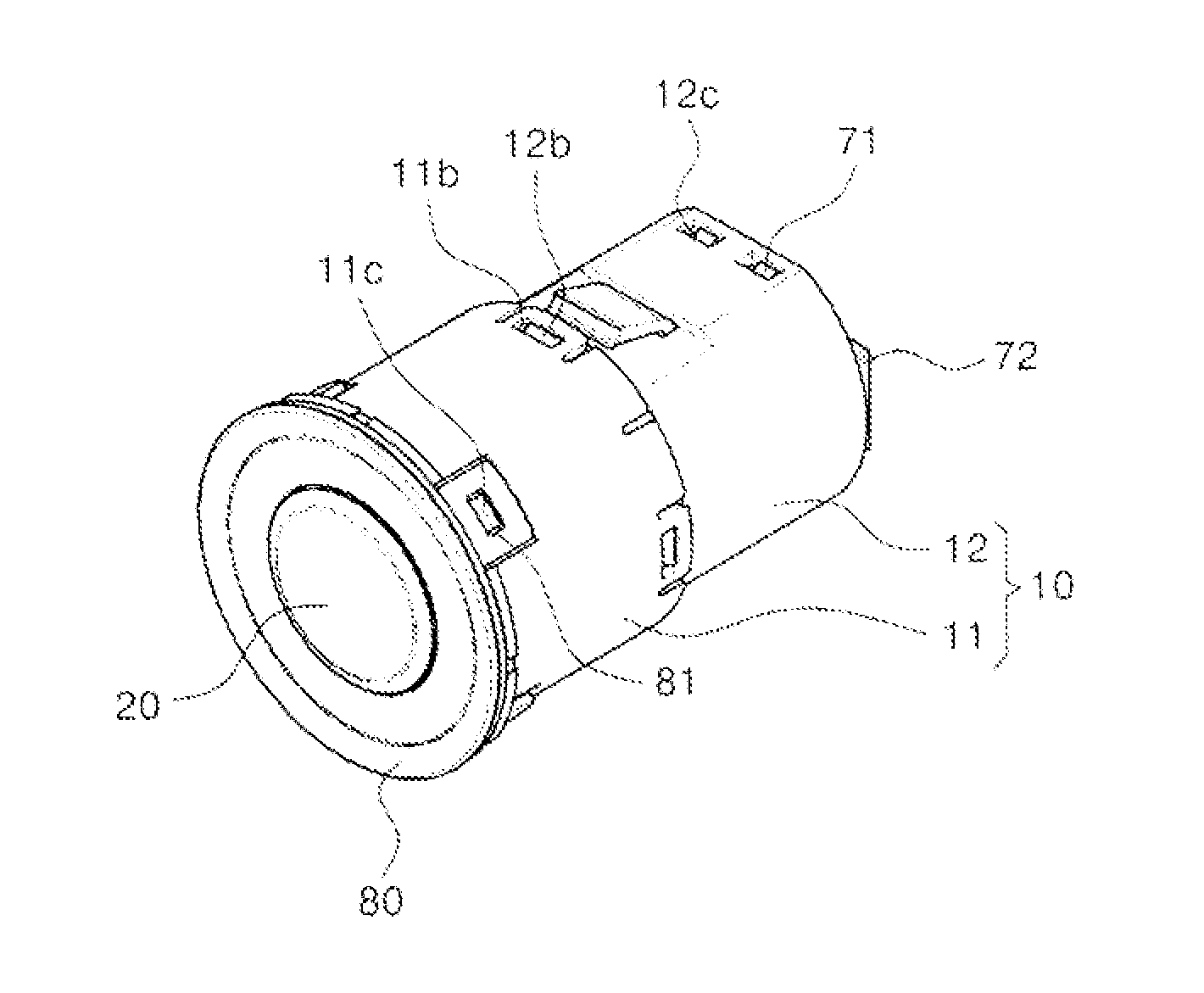

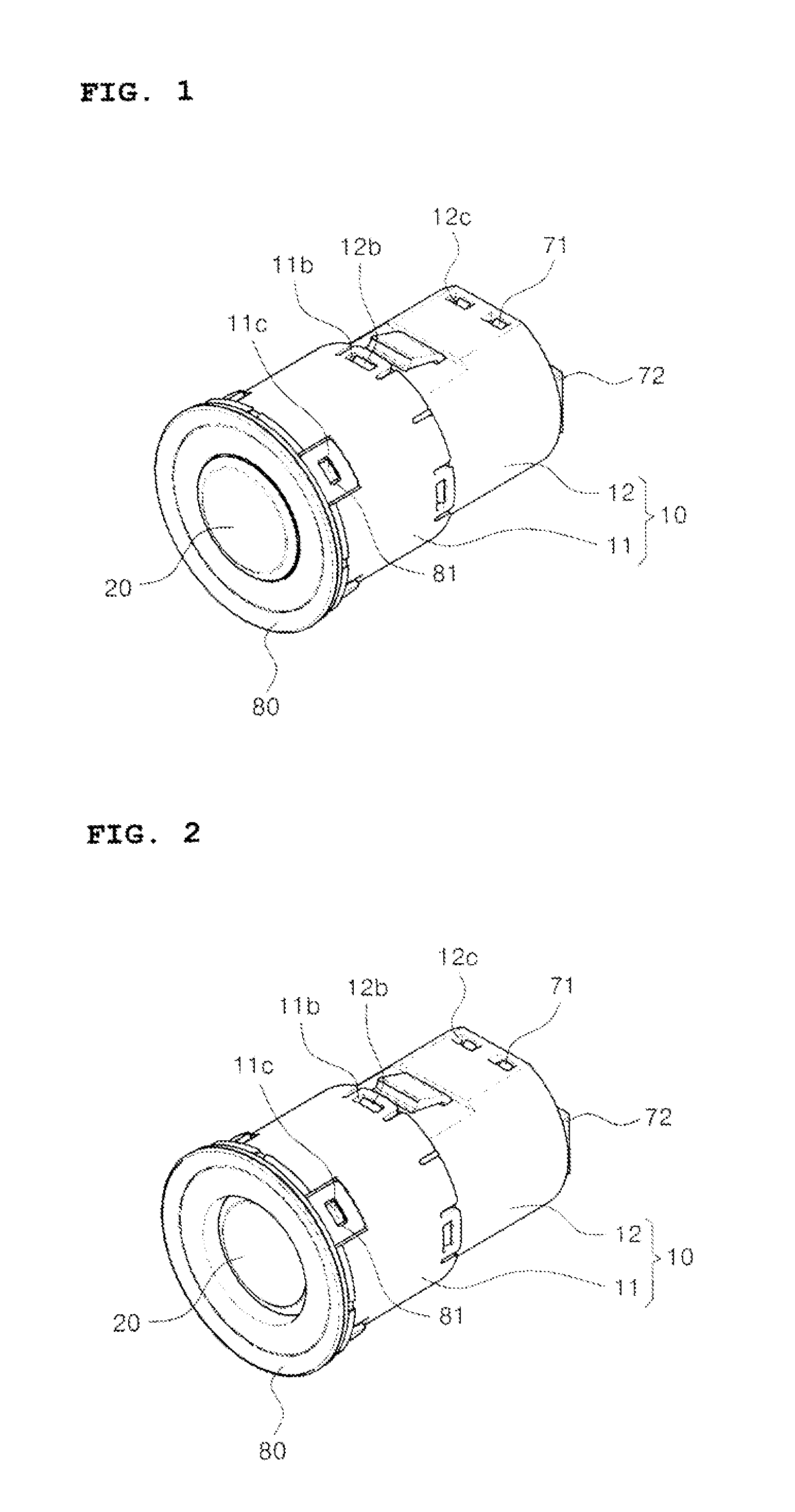

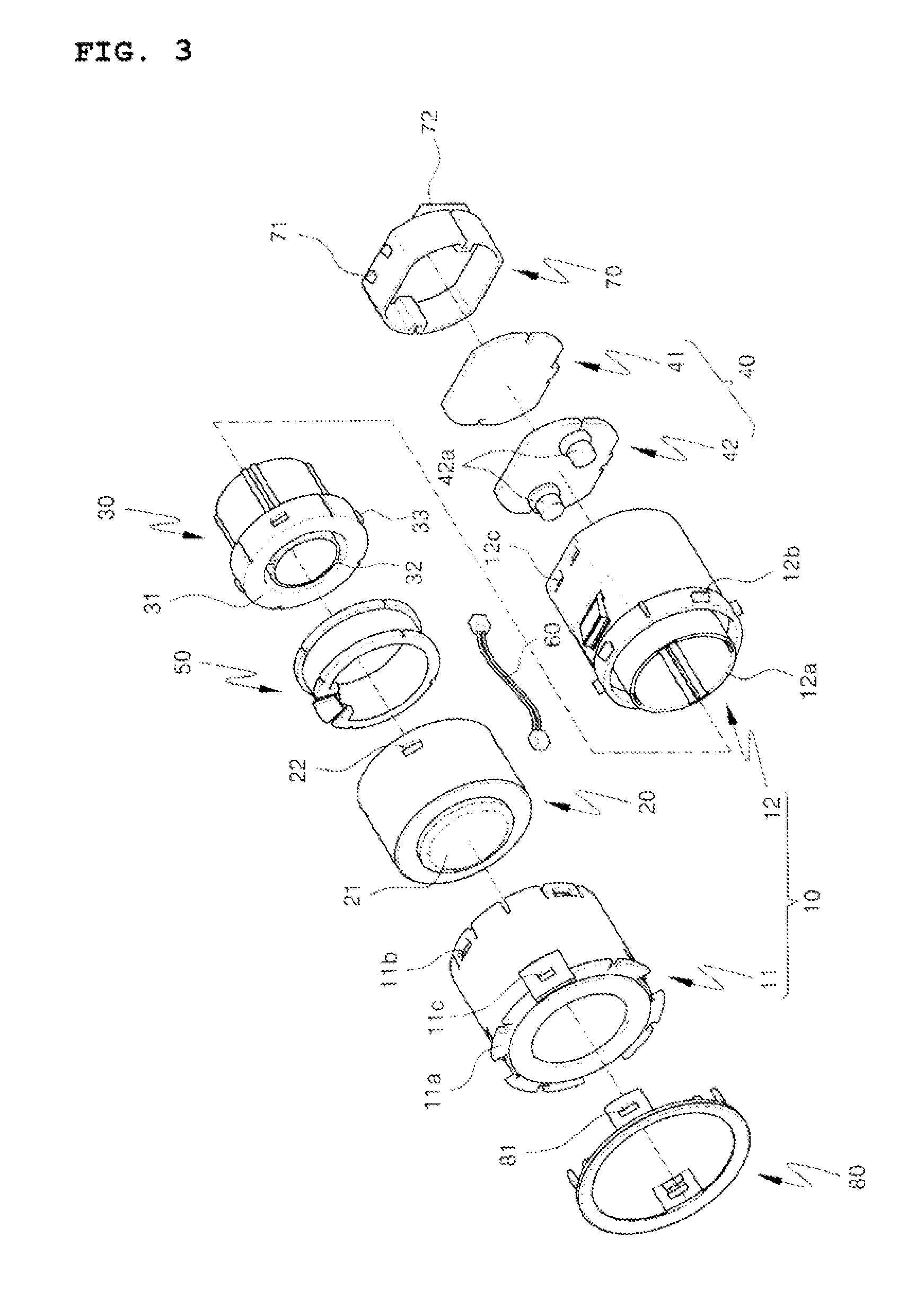

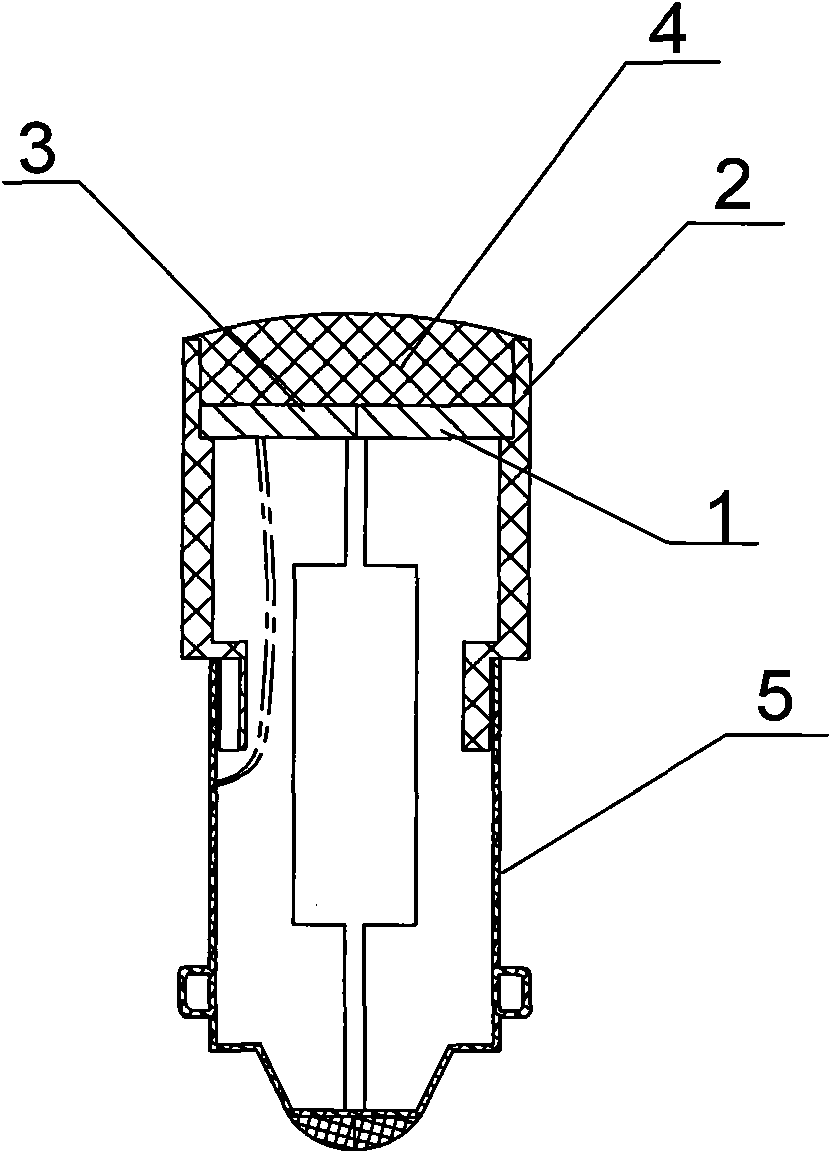

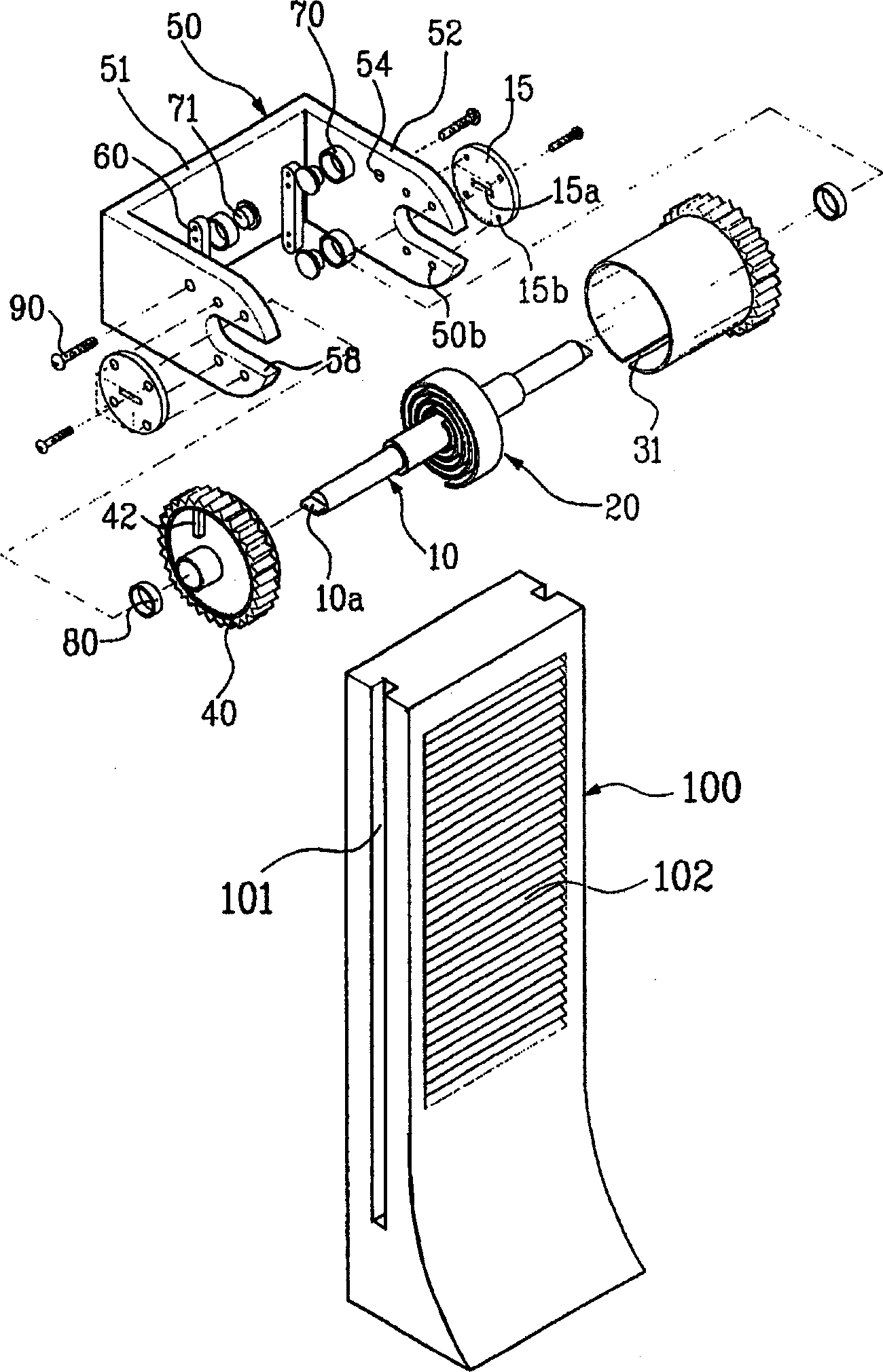

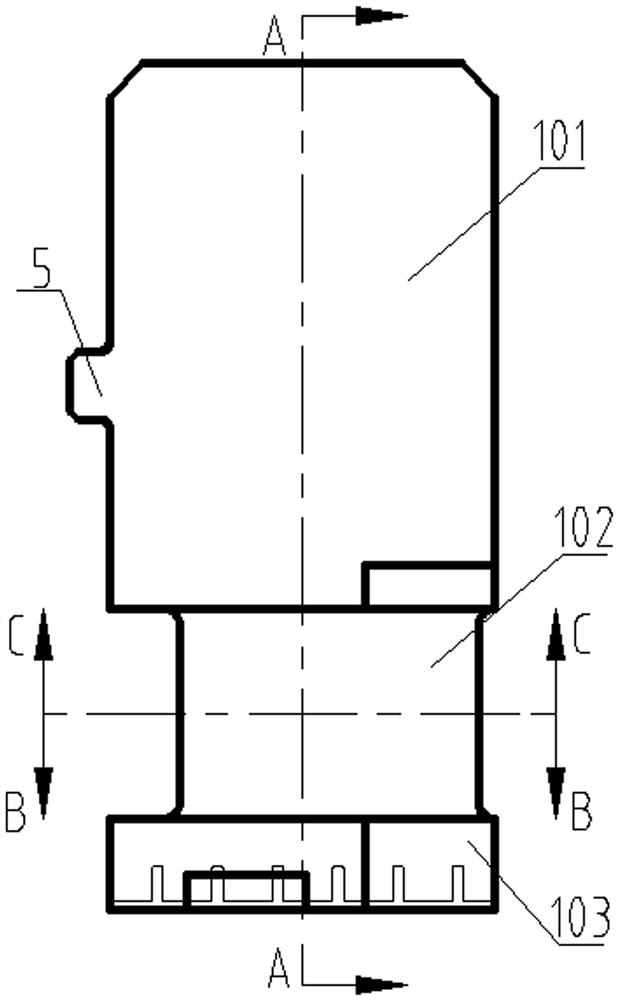

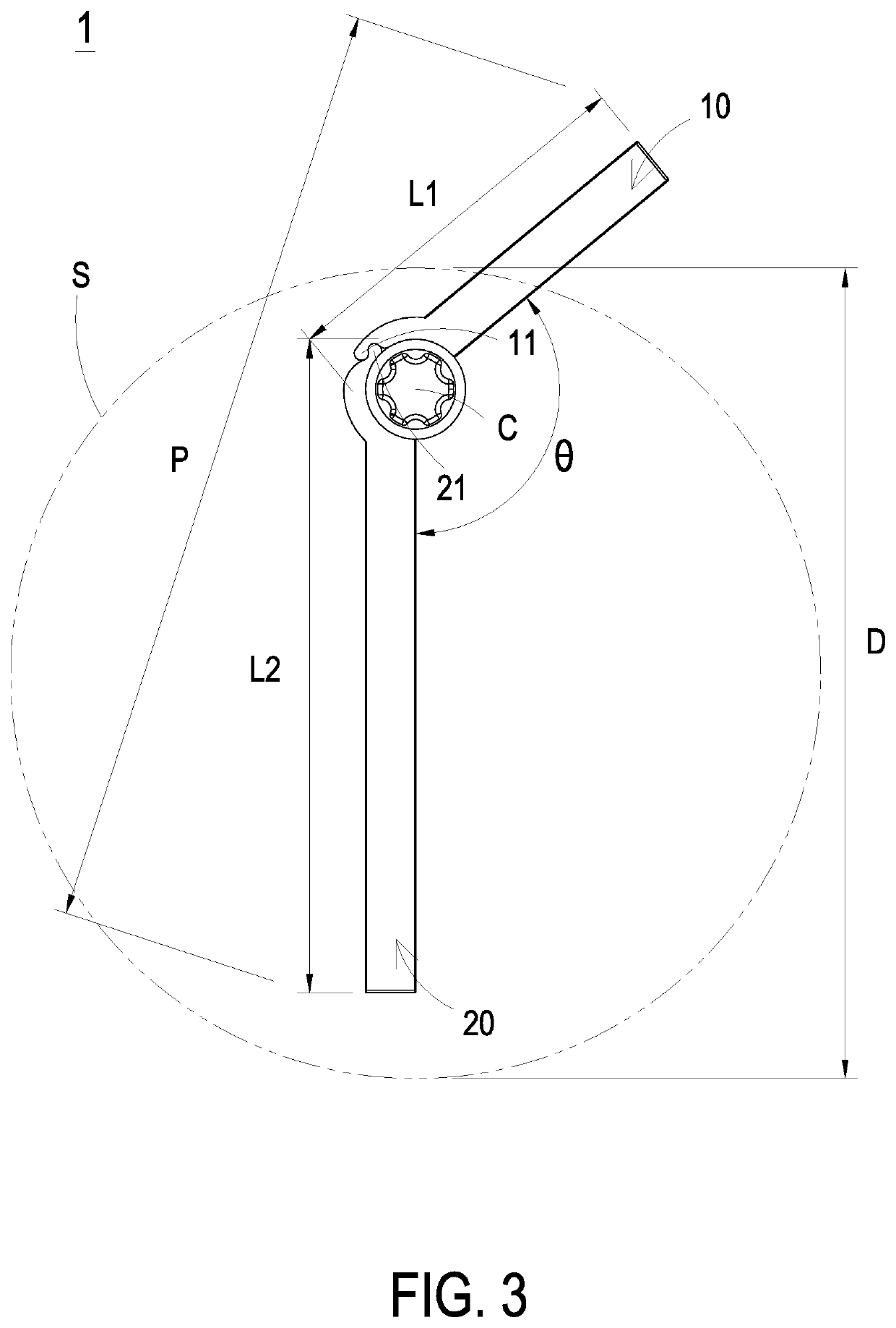

Engine start/stop switch for a vechicle

InactiveUS20120199461A1Reduce manufacturing costReduce manufacturing processPower operated startersAnti-theft devicesDashboardEngineering

An engine start / stop switch for a vehicle is provided, including a housing having one end portion exposed outwardly from a dashboard and the other end portion embedded in the dashboard; a button disposed in the housing and having one end portion exposed outwardly to be pressed to start or stop an engine; a slider disposed at the front end of the button to be slid along the inner peripheral surface of the housing; a circuit unit disposed to closely contact the front end of the slider to be electrified when pressed by the slider and to generate an engine start or stop signal; and a coil antenna interposed between the button and the slider to transmit driving waves to the transponder of a portable device carried by a driver. Further, the housing includes first and second housings detachably coupled to each other to encompass the button. slider and circuit unit.

Owner:ALPS ELECTRIC KOREA

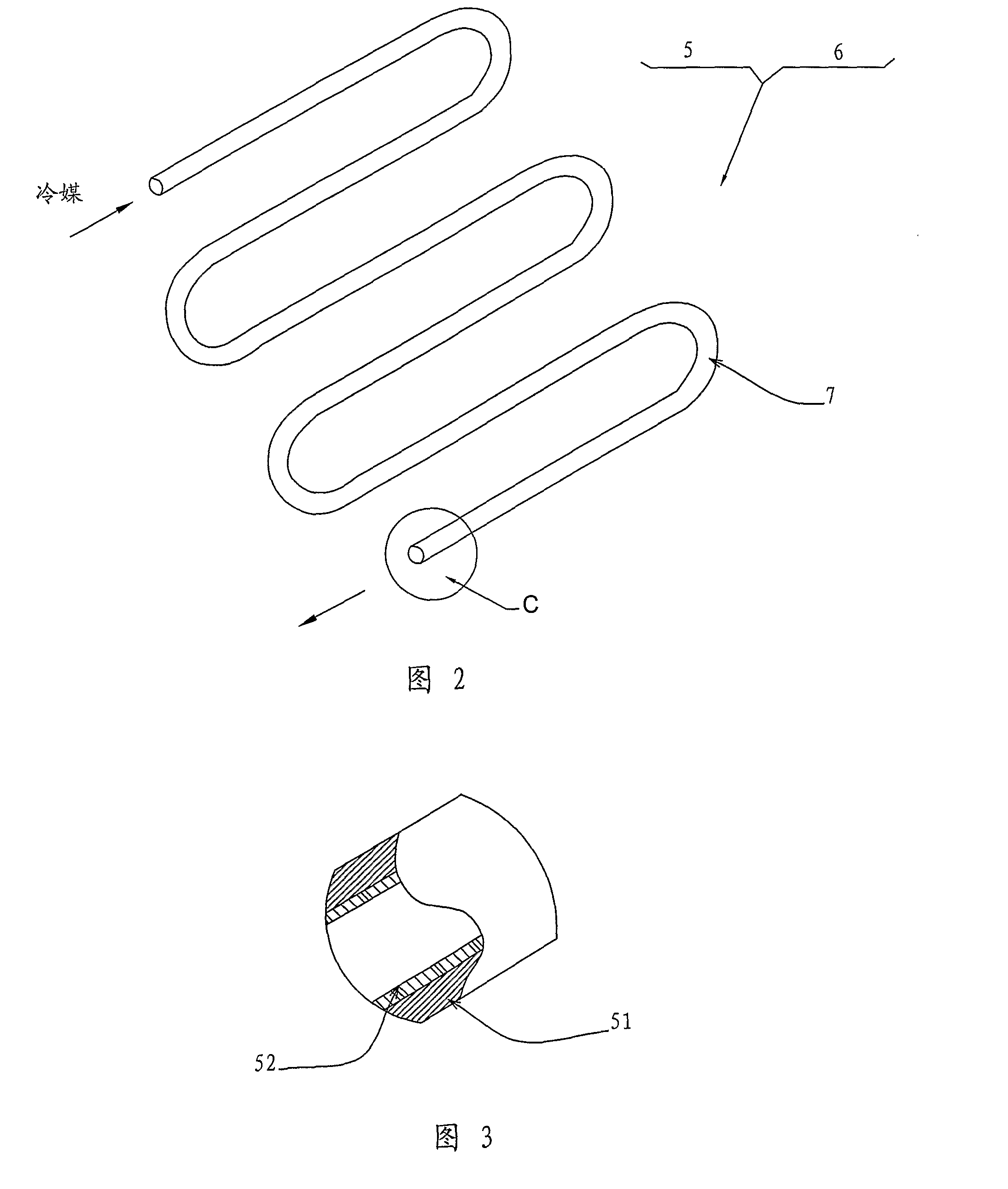

Cu/Al COMPOSITE PIPE AND A MANUFACTURING METHOD THEREOF

InactiveUS20090308481A1Reduce manufacturing processHigh production efficiencyTemperature control deviceMetal rolling stand detailsPercentage reductionRefrigerated temperature

A Cu / Al composite pipe and a manufacturing method thereof are disclosed. The inner layer of the pipe is Cu, and the outer layer is Al. The combinative layer is formed between the two layers due to mutual diffusion of Cu and Al. The raw composite pipe is rolled with single rolling by a planetary rolling machine, wherein the rolling process has the single pass percentage reduction of area of 50%˜95%, an exit rolling speed of 5˜30 m / min, a temperature in the deformation area of 200° C. ˜600° C. The pipe can be used in many fields, such as architecture, refrigeration, air-conditioners, refrigerators, solar energy, water heaters, condensers and radiators, etc.

Owner:JIANGSU XINGRONG HI TECH

Special welding rod used for surfacing reparation of high carbon steel type high-speed railway base tamping pick

InactiveCN102528321AReduce manufacturing processSave raw materials and energyWelding/cutting media/materialsSoldering mediaFerrosiliconSubgrade

The invention discloses a special welding rod used for the hardfacing reparation of a high carbon steel type high-speed railway base tamping pick. The coating of the special welding rod comprises the following chemical ingredients 1-3wt% of titanium dioxide, 25-35wt% of marble, 9-15wt% of fluorite, 2-4wt% of quartz, 2-4wt% of chalk, 5-7wt% of high-carbon ferrochrome, 2-4wt% of high-carbon ferromanganese, 3-5wt% of graphite, 1-3wt% of ferrosilicon, 6-8wt% of ferrotitanium, 5-7wt% of ferromolybdenum, 5-7wt% of cerium oxide, 3-5wt% of metallic nickel, 1-3wt% of ferrovanadium, 3-5wt% of tungsten carbide and 5-7wt% of ferrotungsten, and a core wire is an H08A steel core wire. Through adoption of the welding rod disclosed by the invention, the step of preheating before the welding can be avoided, and low-temperature tempering after welding is used for carrying out surfacing reparation or reproduction for the high-speed railway base tamping pick; because the surfacing metal is high-carbon steel, the surfacing surface has higher abrasion resistance and certain impact resistance and cracking resistance and the special welding rod is very convenient to use on site; the surface hardness range of the high-speed railway base tamping pick after surfacing is HRC (Rockwellhardness) 61-65; and the service life of the repaired high-speed railway base tamping pick is 2-3 times that of the integrally-manufactured tamping pick.

Owner:YANSHAN UNIV

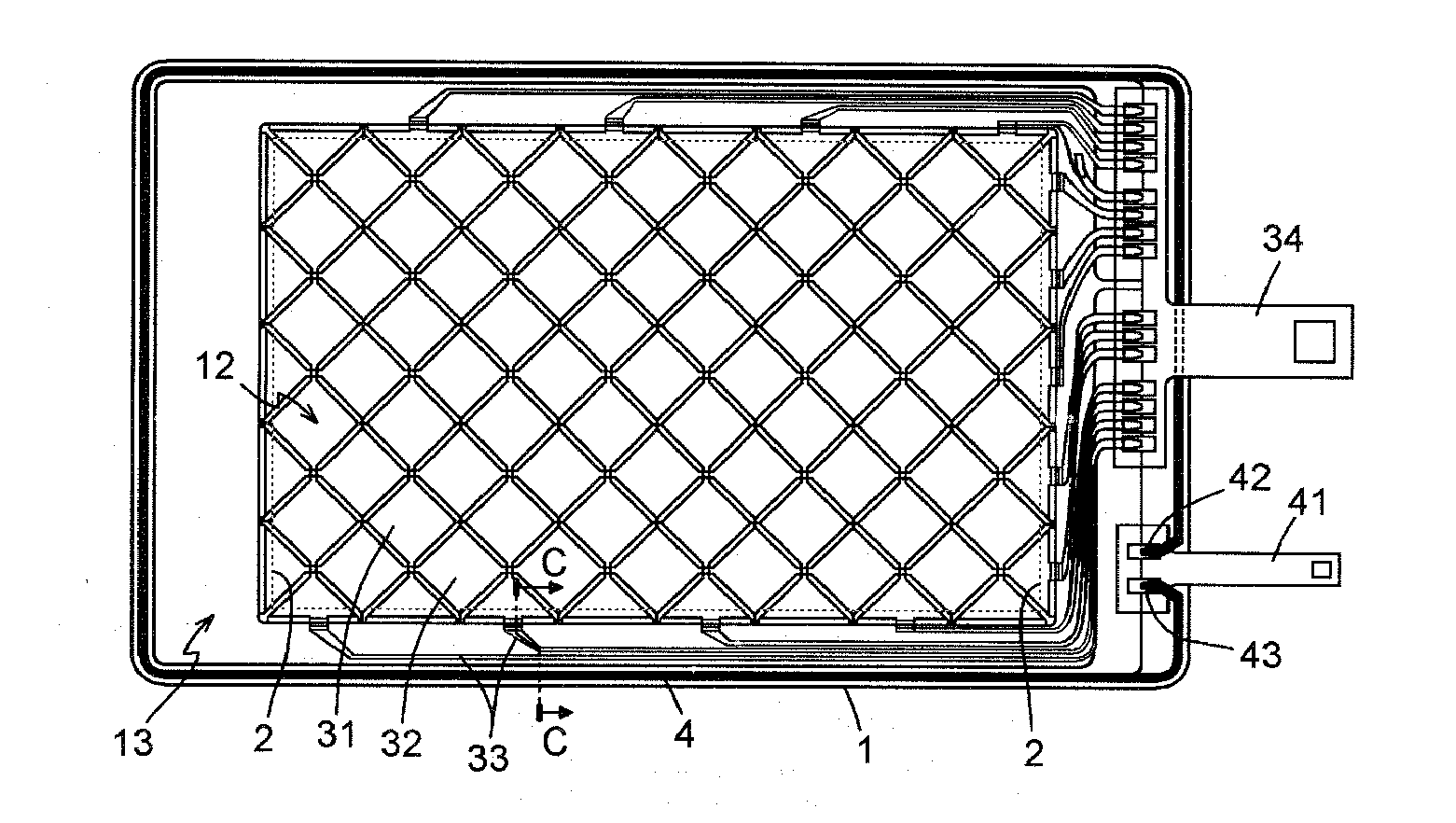

Multi-function touch panel

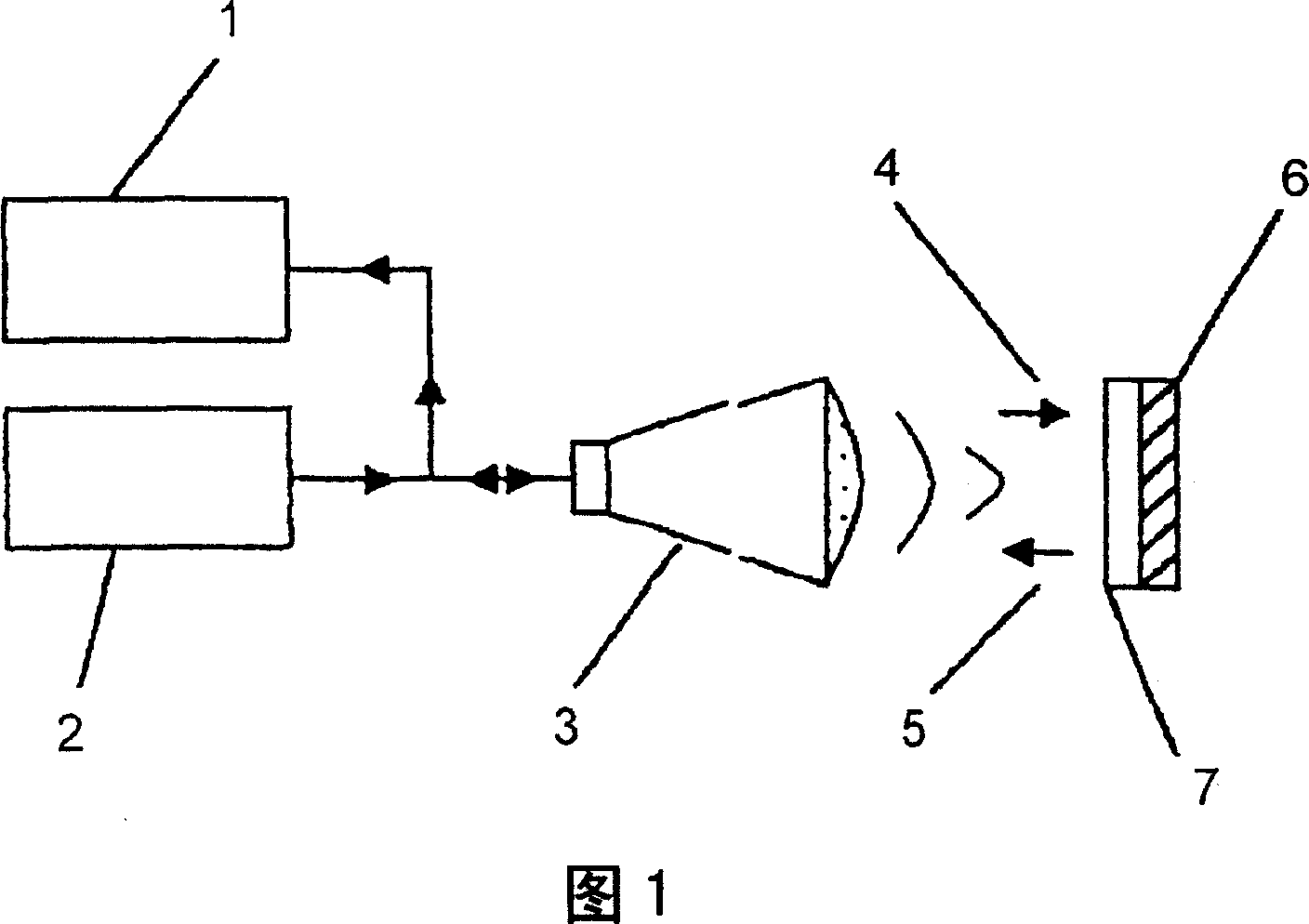

InactiveUS20130043081A1Reduce manufacturing processReduce production processTransmission systemsAntenna equipments with additional functionsTouch panelEngineering

A multi-function touch panel includes a transparent substrate and an opaque color frame formed by an edge of the substrate so as to form a visible area and a shelter area on the substrate. A transparent touch sensing unit is formed to the visible area on a surface of the substrate. A signal wiring under the shelter area is formed around the touch sensing unit. The signal wiring is electrically connected between the touch sensing unit and a first signal bus. A flat antenna is insulatedly formed outside the signal wiring under the shelter area. Two ends of the flat antenna are electrically connected to a second signal bus. The color frame is made of insulated material. The first signal bus and the second signal bus are integrated as one signal bus.

Owner:LUMINOUS OPTICAL TECH

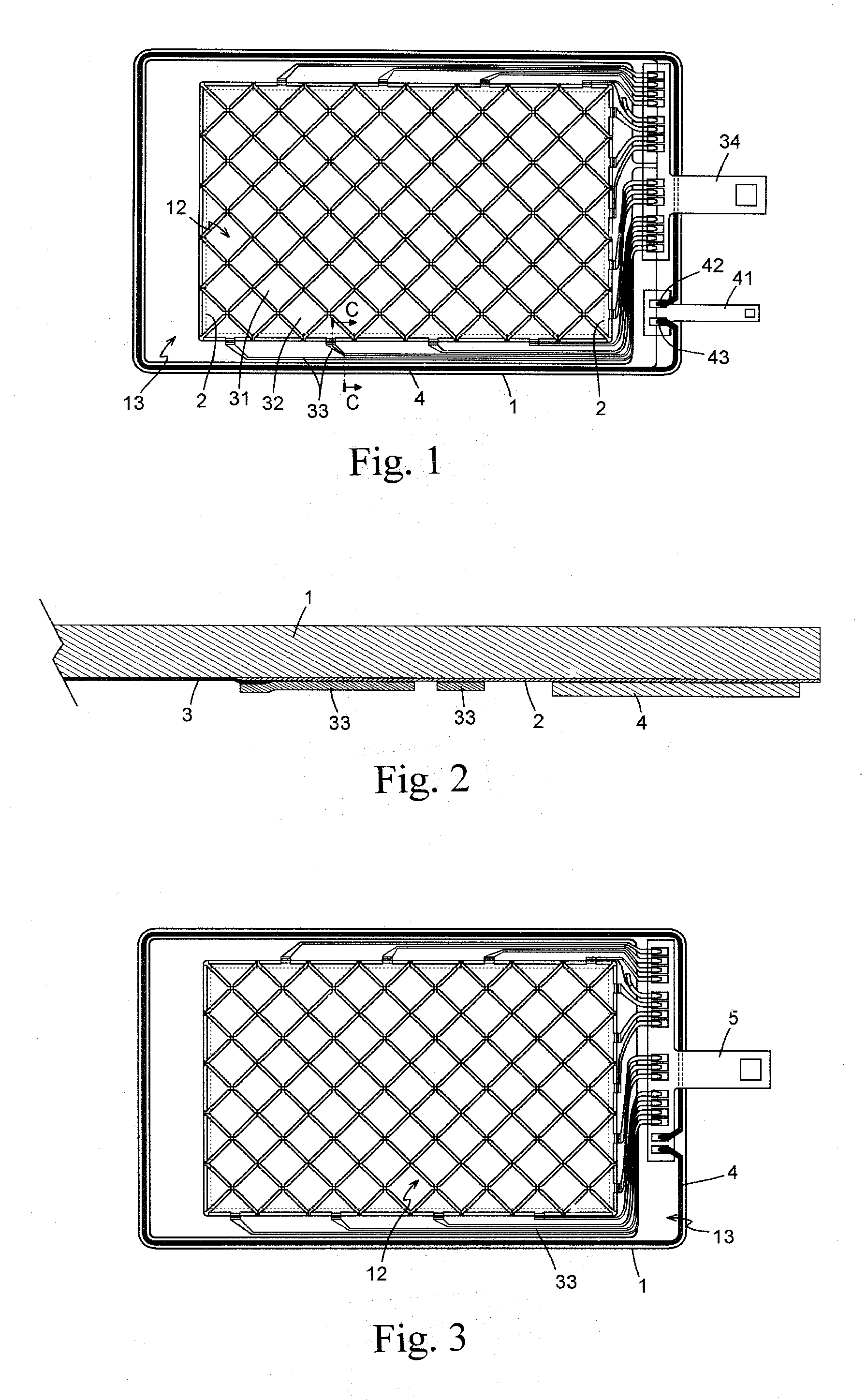

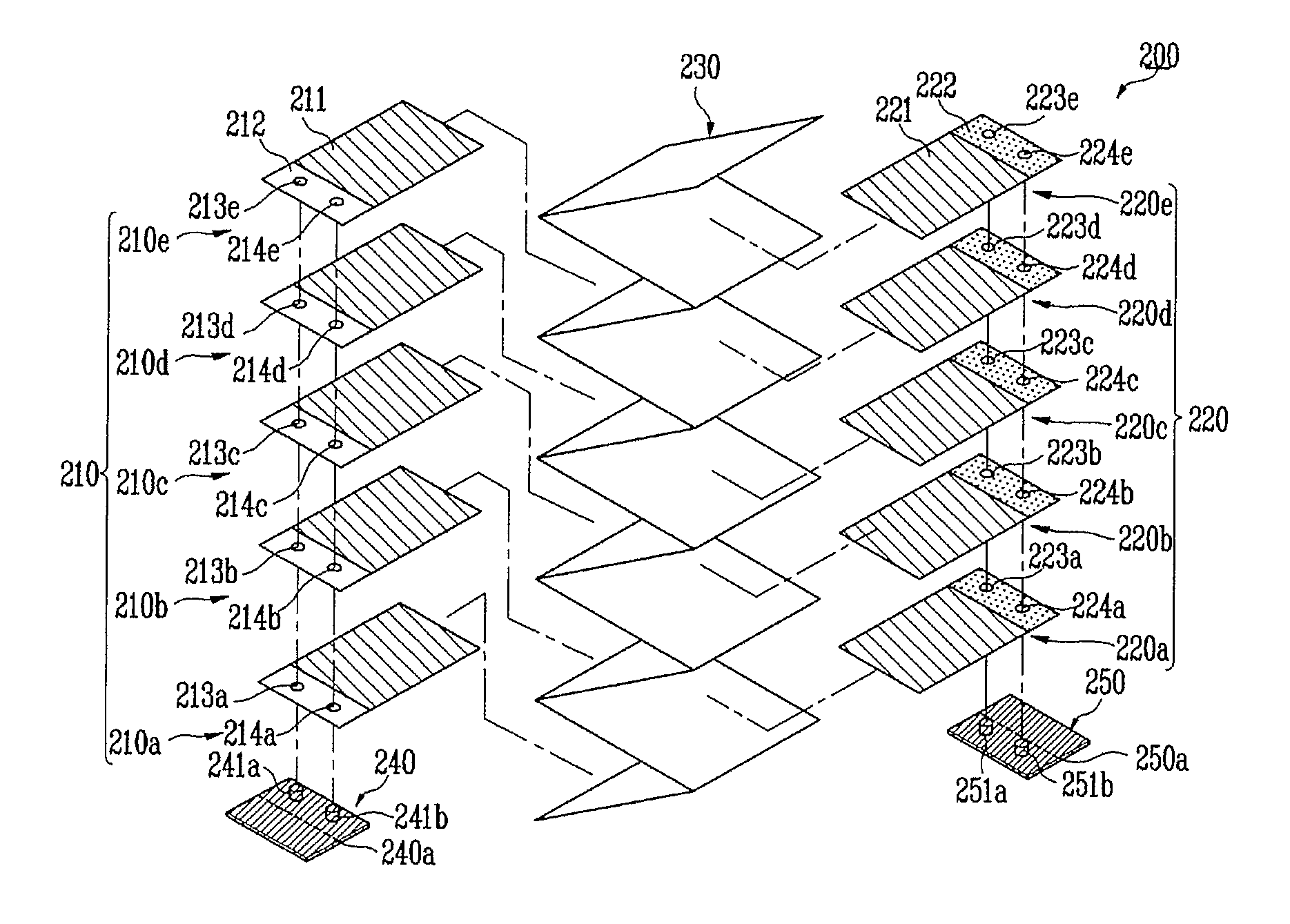

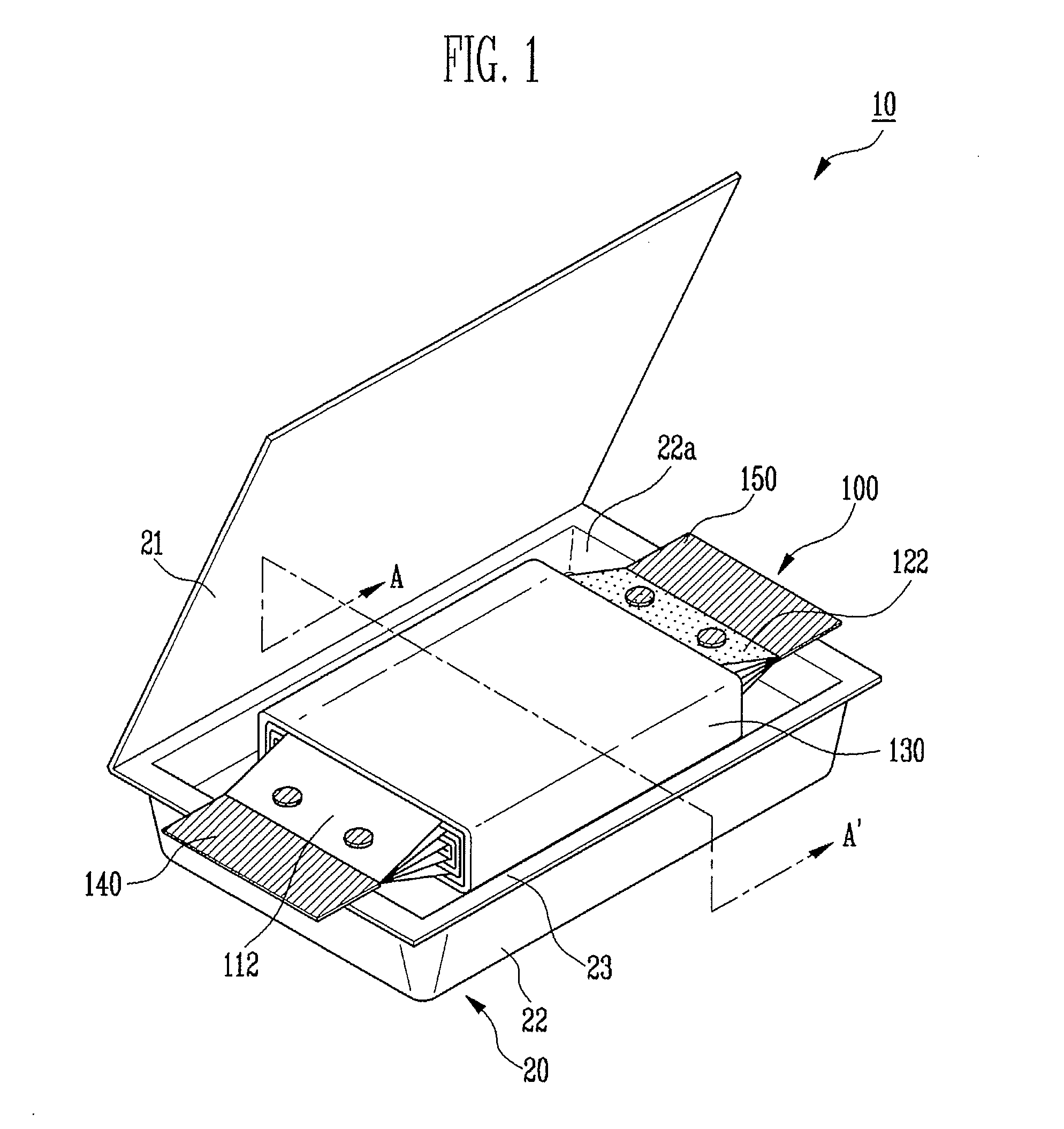

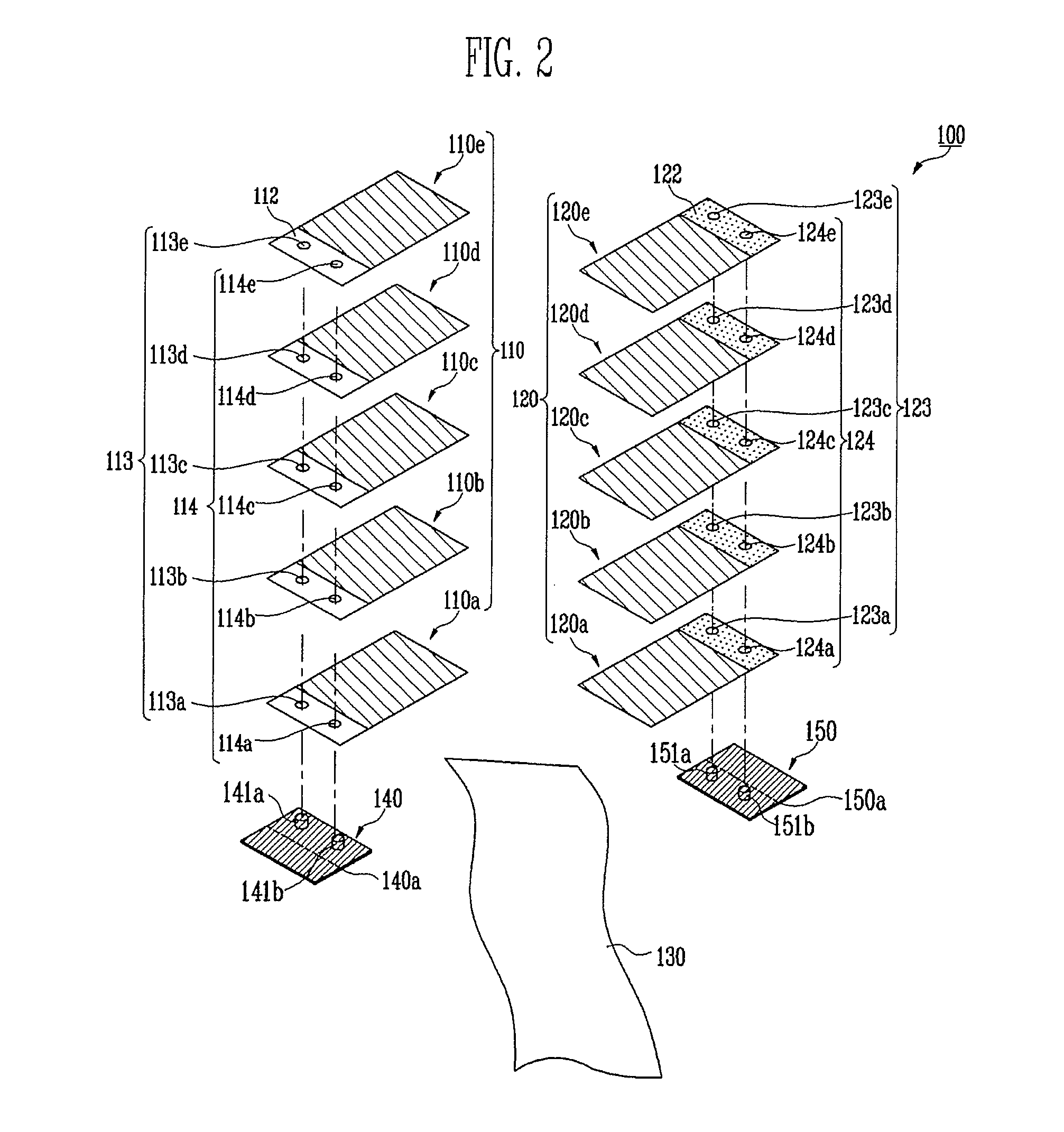

Electrode assembly and secondary battery using the same

InactiveUS20120064382A1Improve reliabilityImprove securityPrimary cell to battery groupingCell seperators/membranes/diaphragms/spacersBiomedical engineeringElectrode

An electrode assembly includes a first electrode member; a second electrode member; a plurality of first guide portions, wherein at least one of the first guide portions is on the first electrode member; a plurality of second guide portions, wherein at least one of the second guide portions is on the second electrode member; and a separator located between the first electrode member and the second electrode member, wherein the electrode assembly has a first region at which the first guide portions are coupled together and a second region at which the second guide portions are coupled together.

Owner:SAMSUNG SDI CO LTD

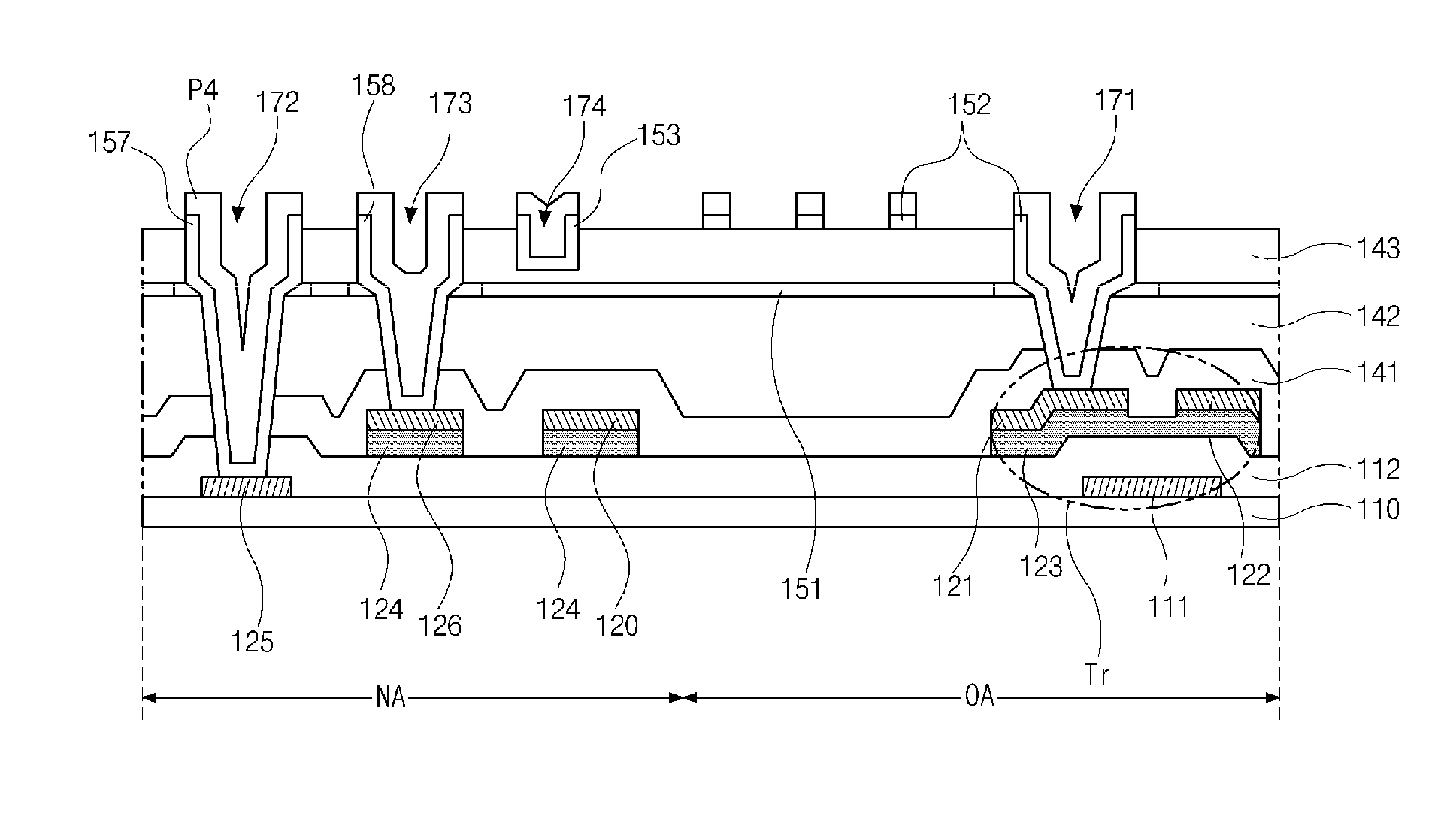

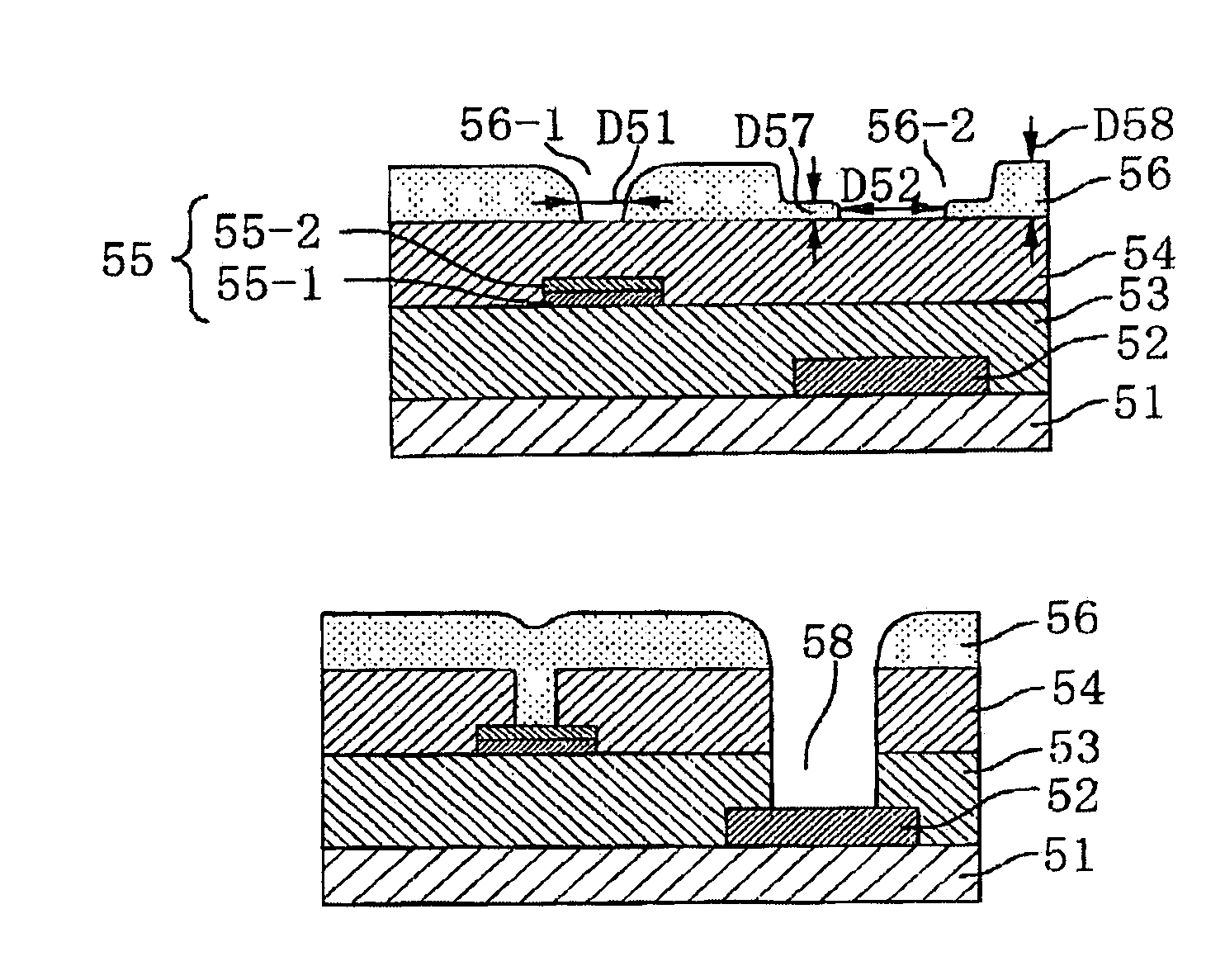

Liquid crystal display device and manufacturing method thereof

ActiveUS20150187817A1Reduce manufacturing processLow costTransistorSolid-state devicesLiquid-crystal displayCommon line

A liquid crystal display device includes a gate electrode; a gate insulating layer on the gate electrode; an active layer on the gate insulating layer corresponding to the gate electrode; source and drain electrodes on the active layer; a first passivation layer on the source and drain electrodes; a common electrode on the first passivation layer; a second passivation layer on the common electrode, covering the common electrode, and having a separate region from the first passivation layer at a thickness of the common electrode; a pixel electrode on the second passivation layer and connected to the drain electrode through a drain contact hole; and a common line at a same layer as the pixel electrode and connected to the common electrode.

Owner:LG DISPLAY CO LTD

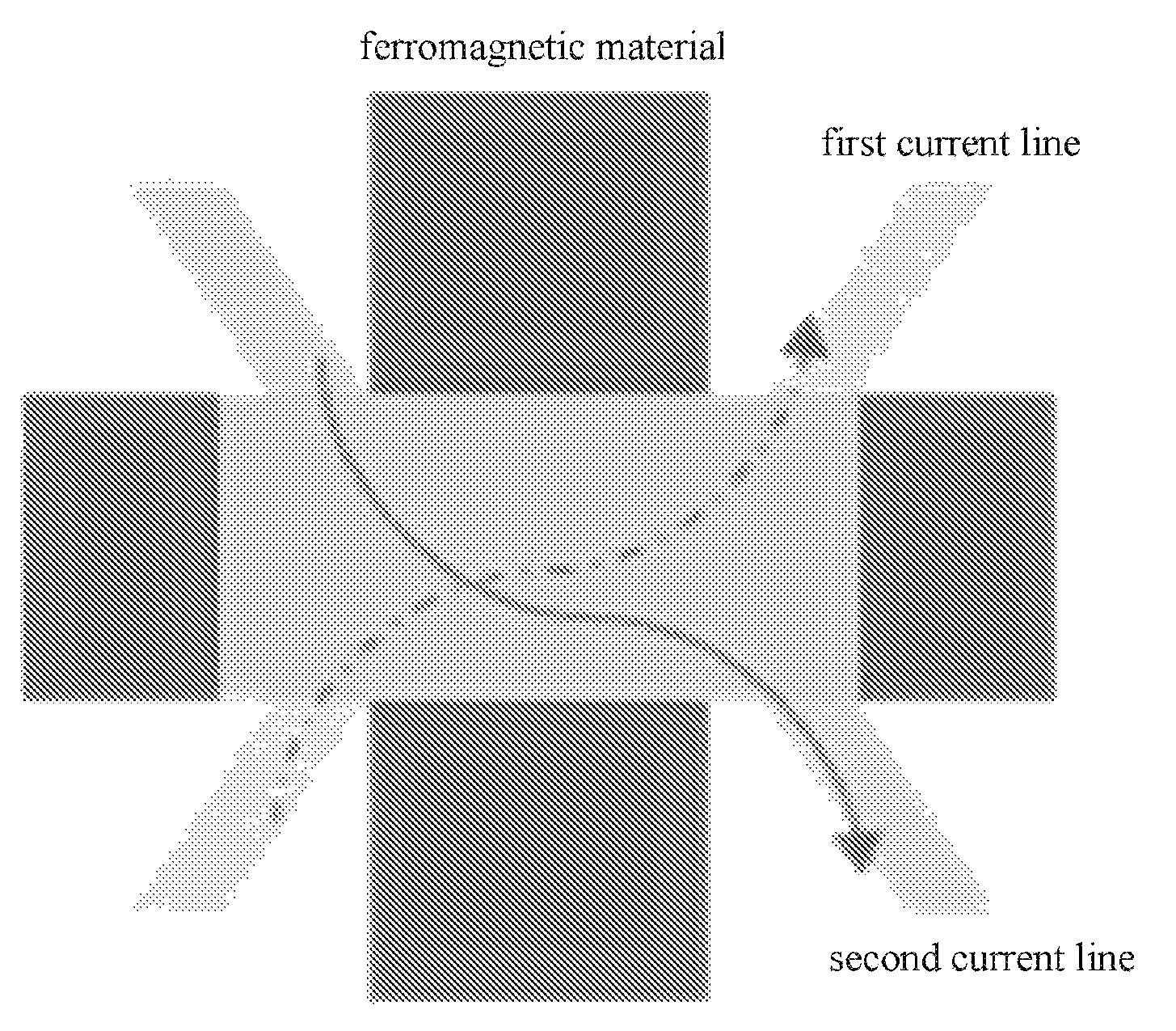

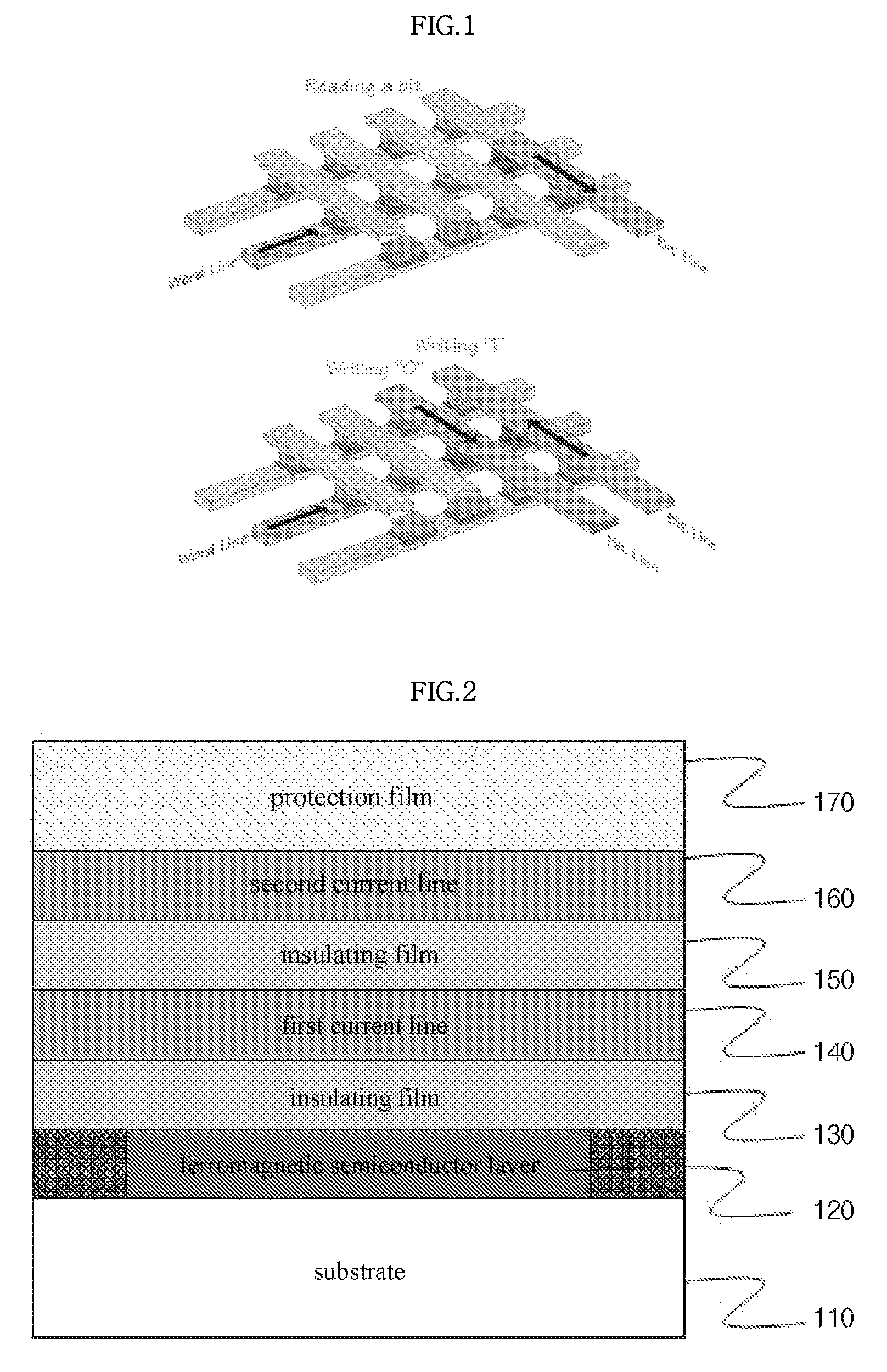

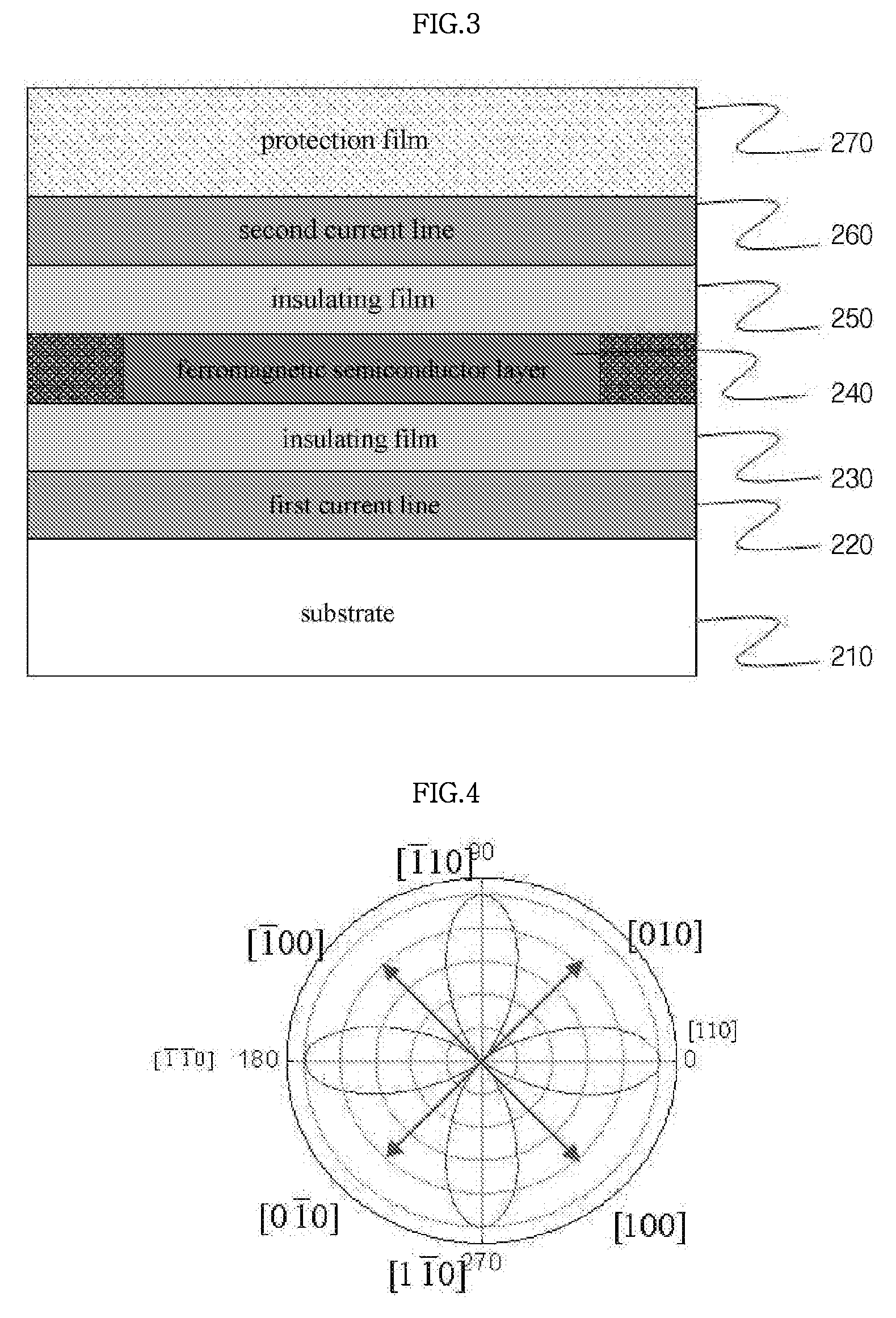

Magnetic memory device using domain structure and multi-state of ferromagnetic material

ActiveUS7742333B2Reduce thicknessReduce production processMagnetic-field-controlled resistorsSolid-state devicesSemiconductor materialsMagnetic memory

Disclosed is a memory device using a multi-domain state of a semiconductor material, and more particularly to a magnetic memory device, in which a ferromagnetic layer for recording magnetic data serves as a sensing layer so as to have a simple structure, shorten a manufacturing process, and reduce the unit cost of production. The planar hall effect or magneto-resistance is used to measure multi-domain states so as to read data stored in a multi-level state.

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND +1

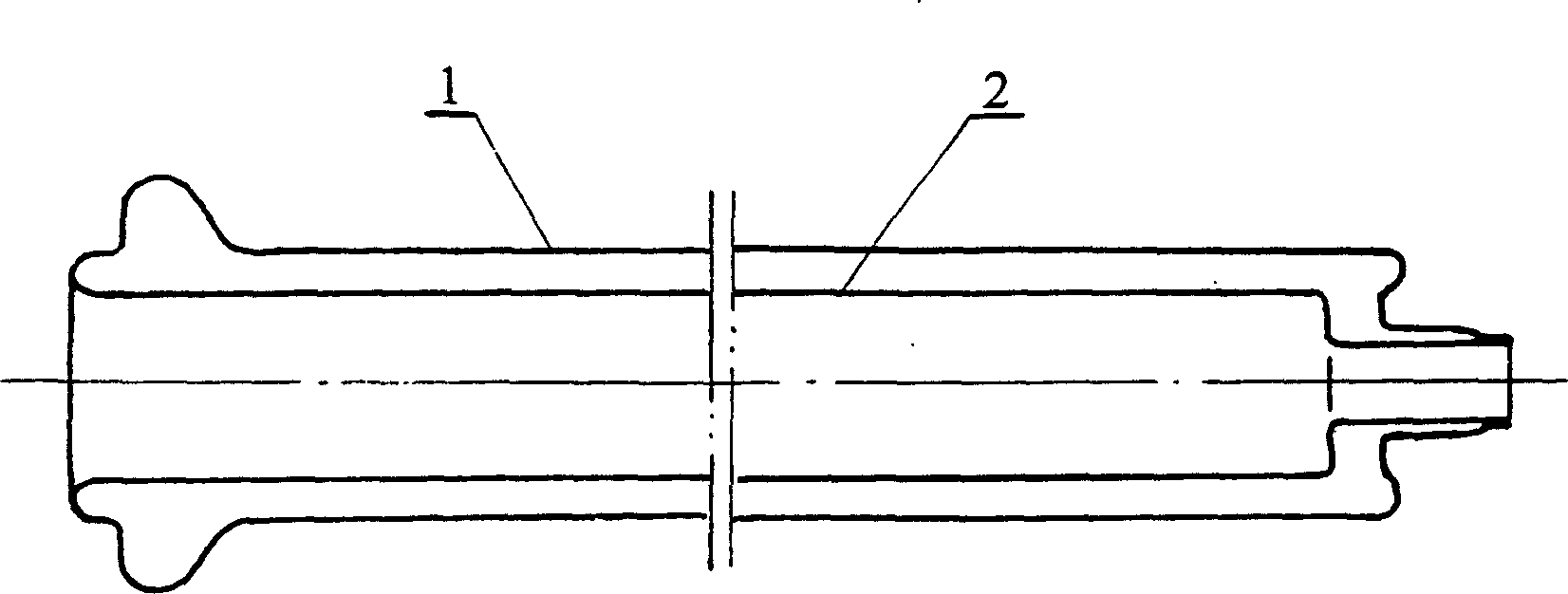

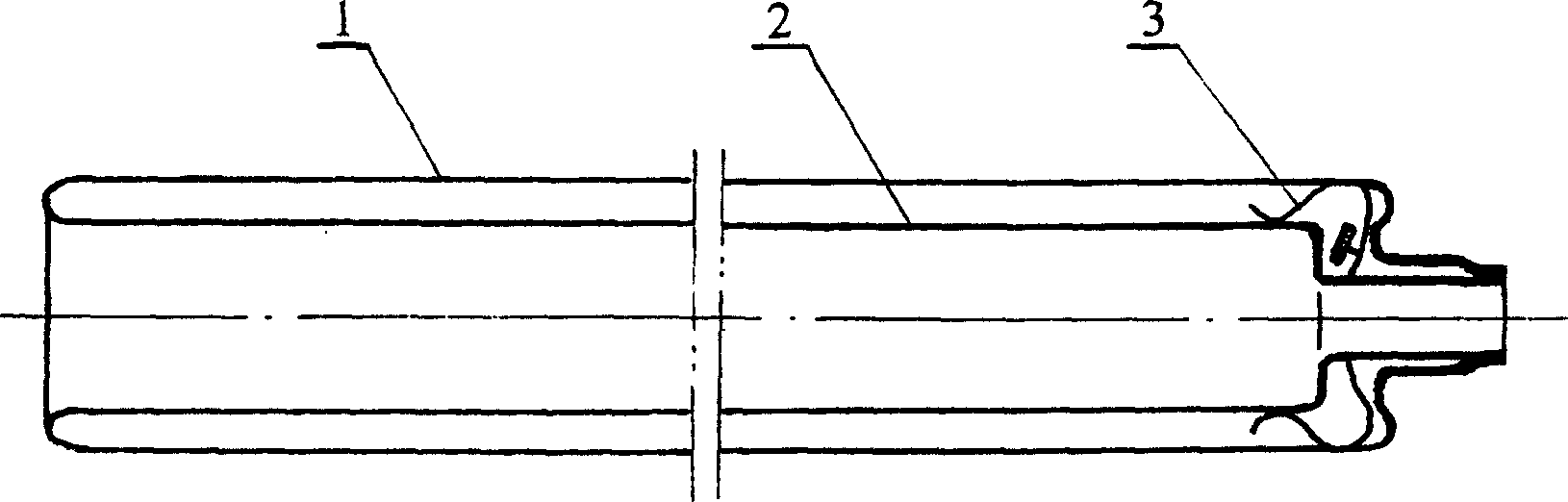

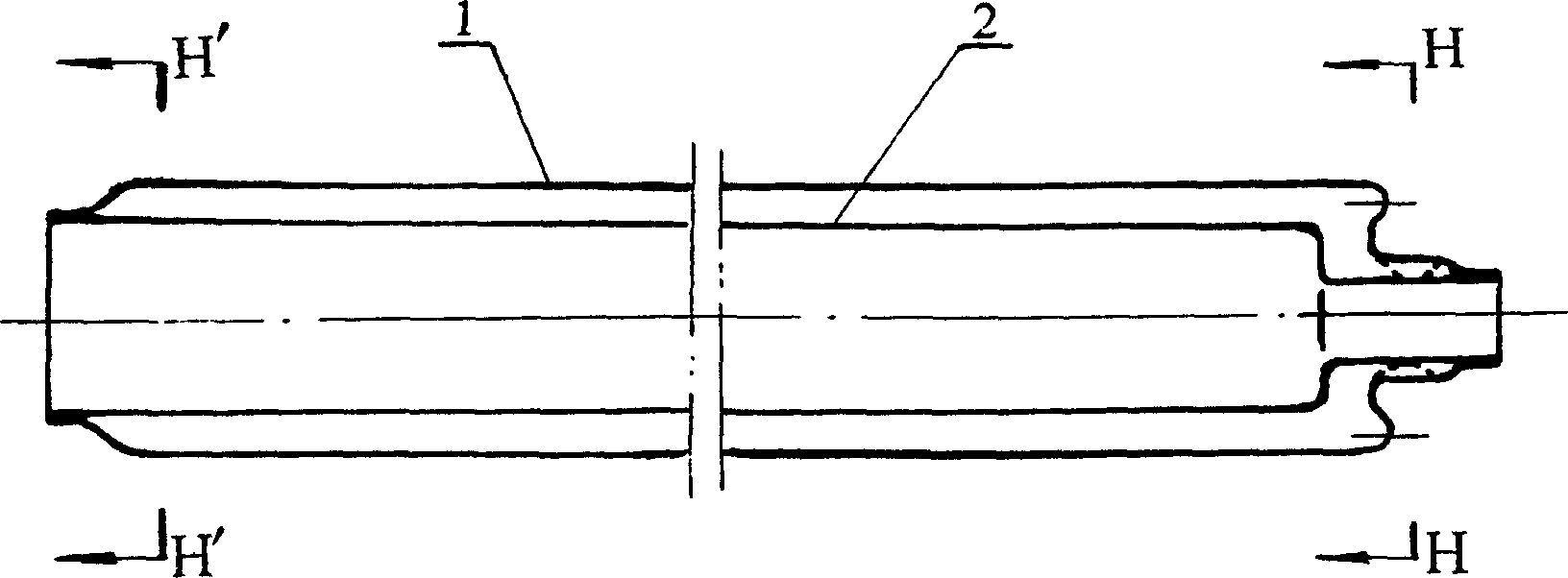

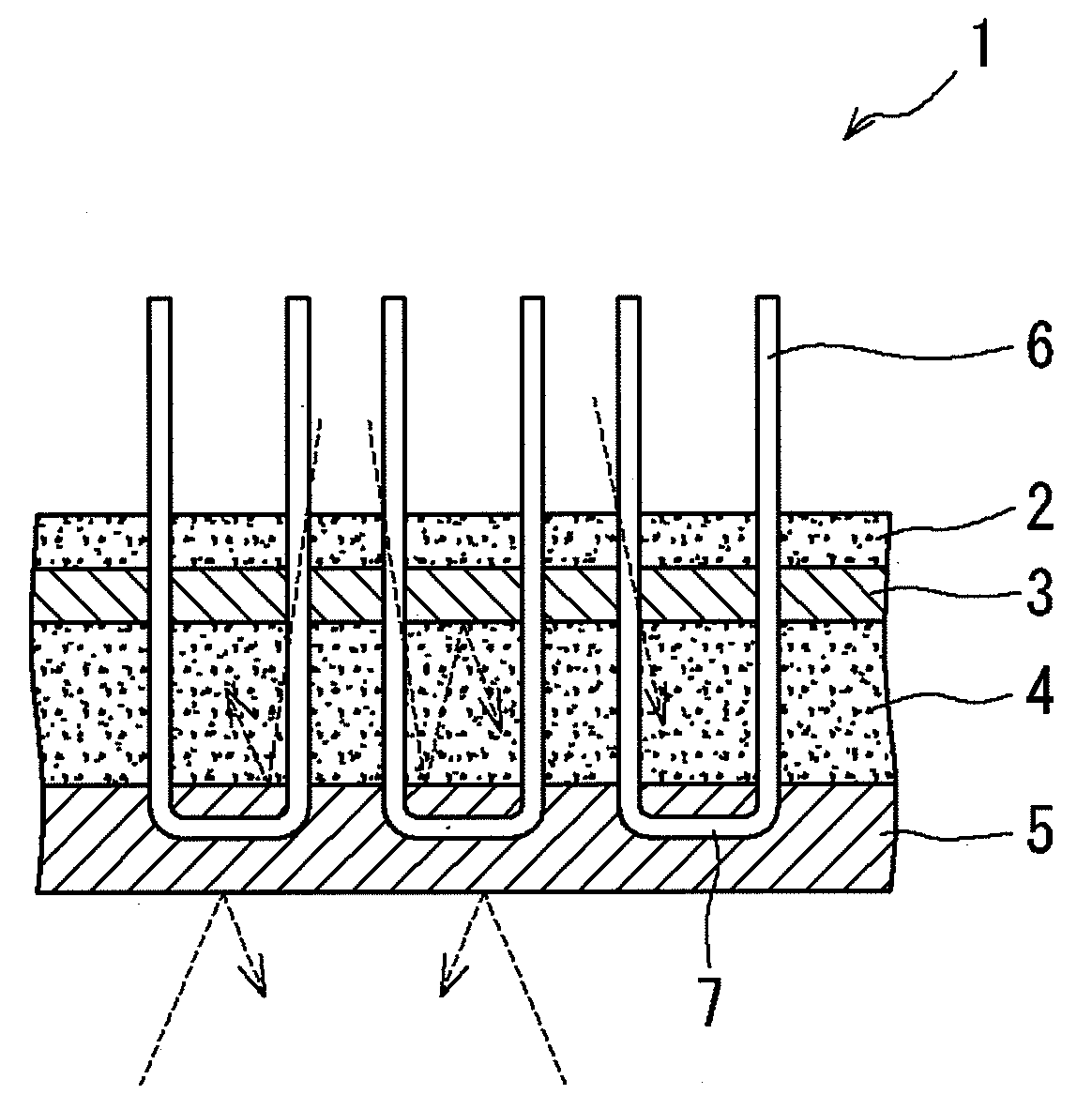

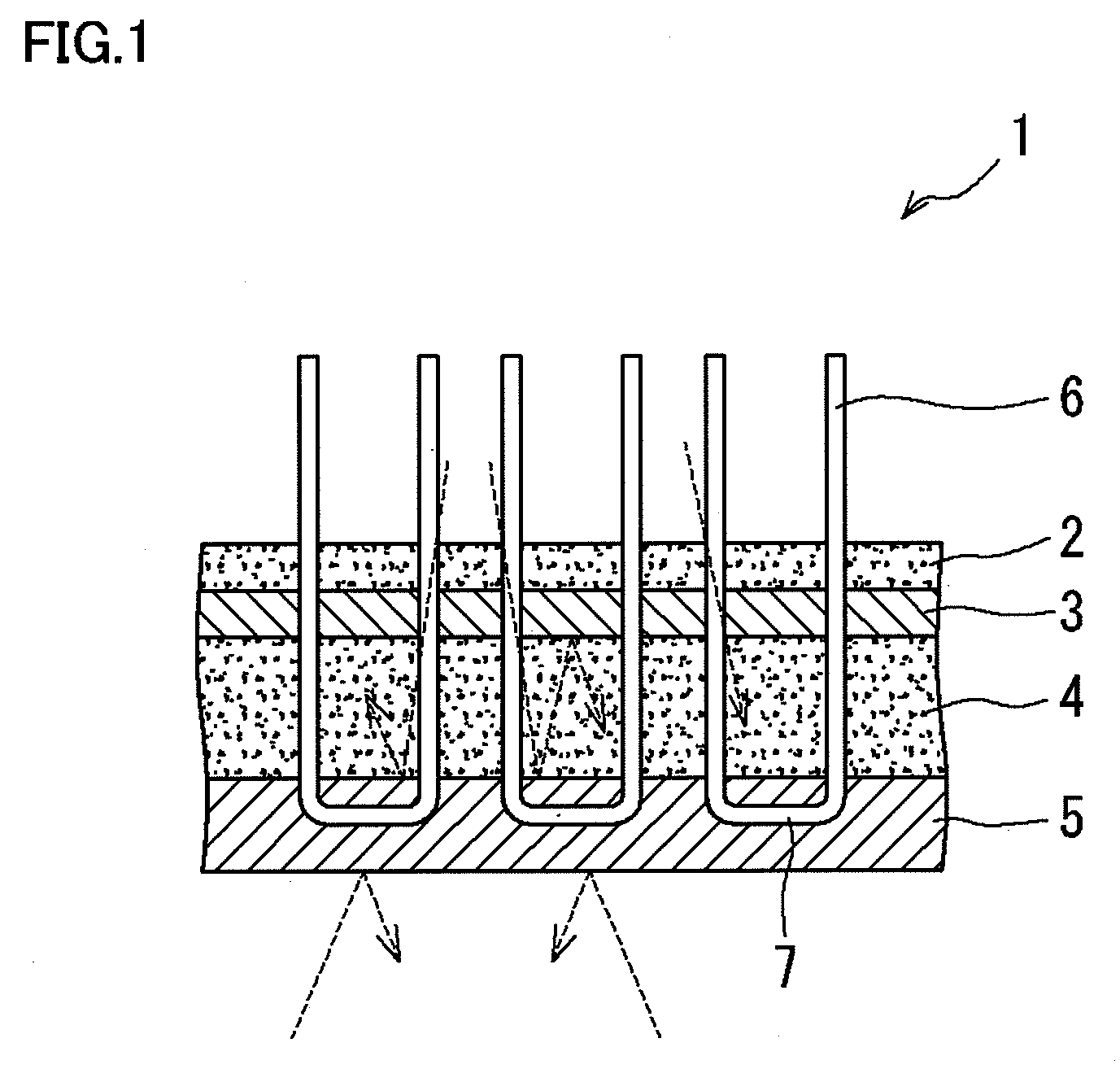

Full-glass vacuum solar heat collection tube and manufacturing technology thereof

InactiveCN1558163ASimple structureReduce manufacturing processSolar heat devicesSolar thermal energy generationSolar waterThin walled

The present invention discloses one kind of novel all-glass vacuum solar heat collecting tube and its manufacture process. The vacuum solar heat collecting tube includes inner and outer glass tube with two end ring sealed, and features that at least one end is specially shaped end comprising inner and outer tubes, rotary deformed transition section and short tube and with at least one thin-wall transition part easy to deform elastically. During the manufacture process, the ring hole in some end between the inner and the outer tubes is used in vacuum deairing and vacuum sealing before being processed into the tube mouth. There are no special deairing tube and no conic sealing joint. The present invention has simple structure, easy manufacture and low damage probability, and may be used widely in various kinds of solar water heater.

Owner:赵宝善 +2

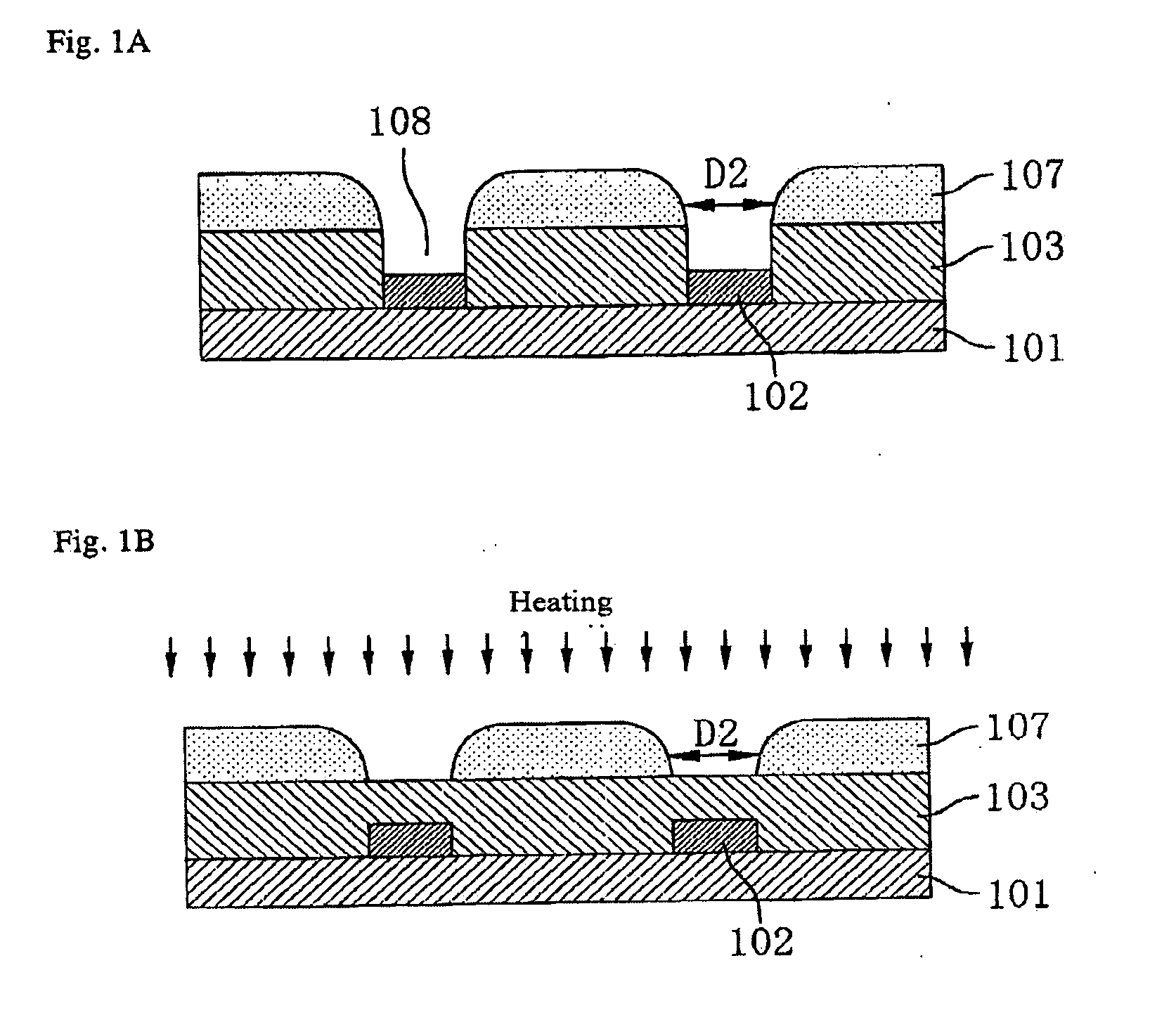

Method for etching and for forming a contact hole using thereof

InactiveUS20060141789A1Reduce manufacturing processIncrease manufacturing costSemiconductor/solid-state device manufacturingOrganic filmOrganic solvent

A method for forming a structure formed by etching which is typified by a contact hole in the semiconductor and a method for manufacturing a display device using the structure. The etching method includes at least, forming an organic mask having a first opening portion and a second opening portion by patterning an organic film which includes either one of an organic film and a film with the addition of organic solvent and is located on a constituent part to be etched, and forming a transformed organic mask by dissolving the organic mask in contact with organic solvent and reflowing.

Owner:VISTA PEAK VENTURES LLC

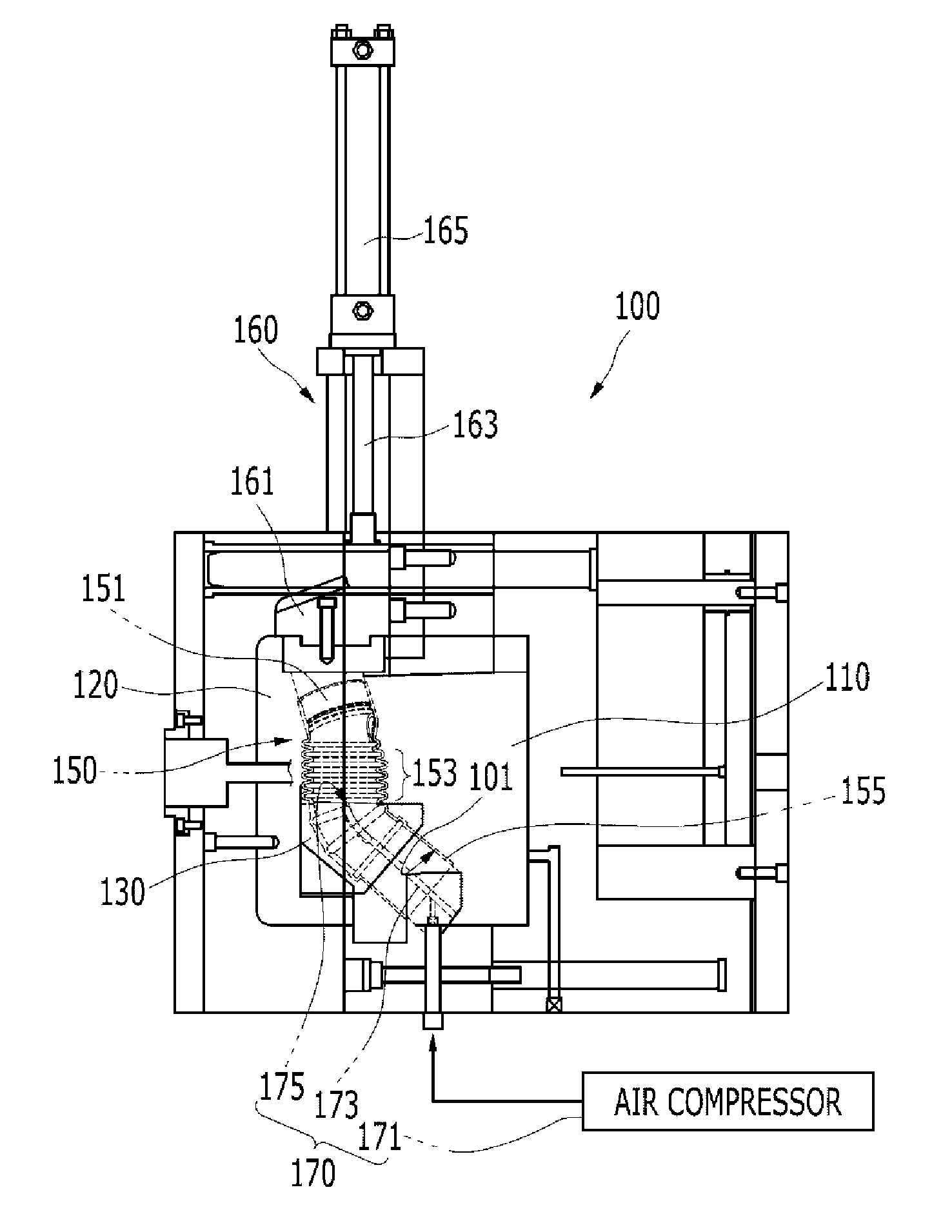

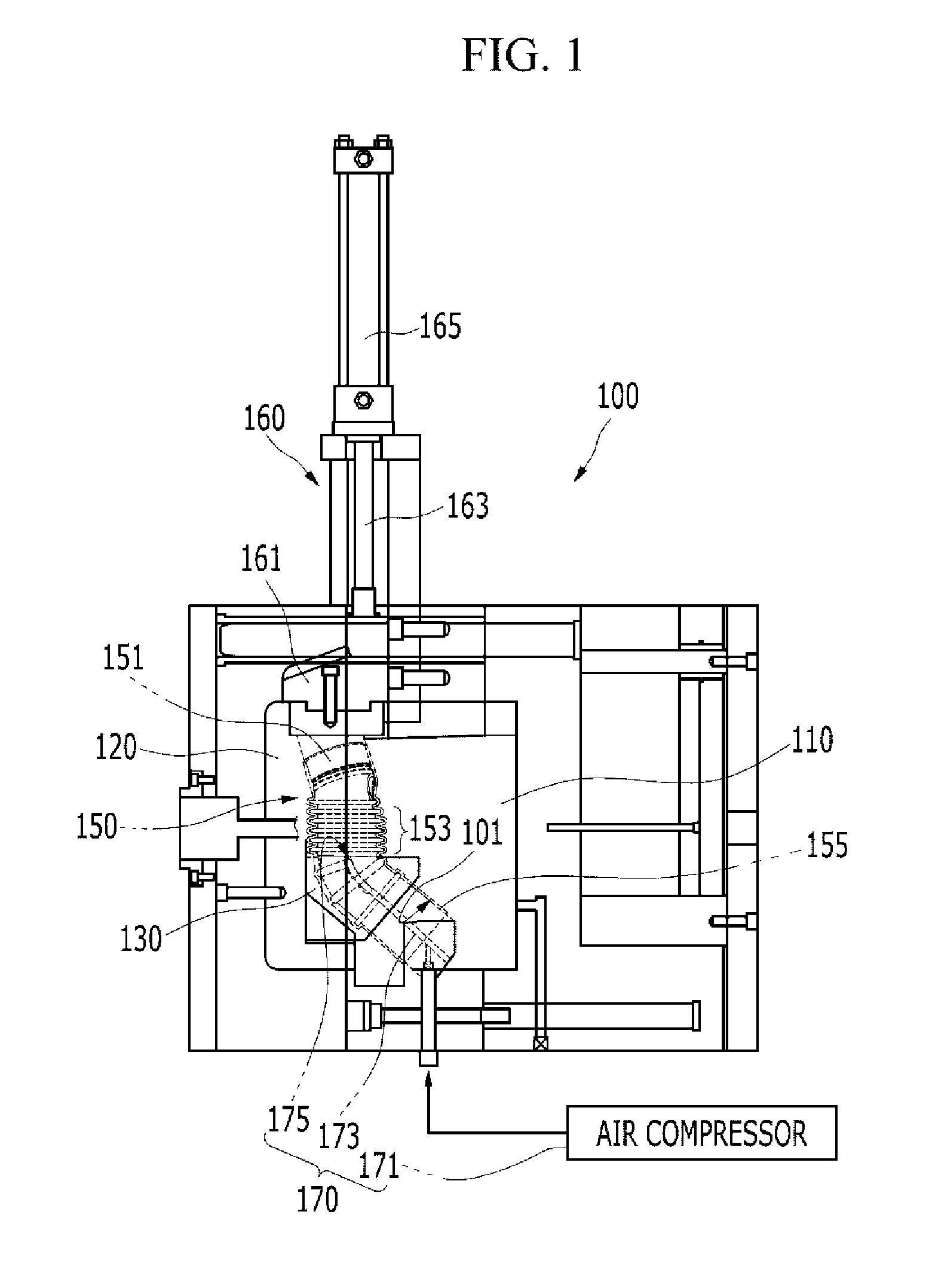

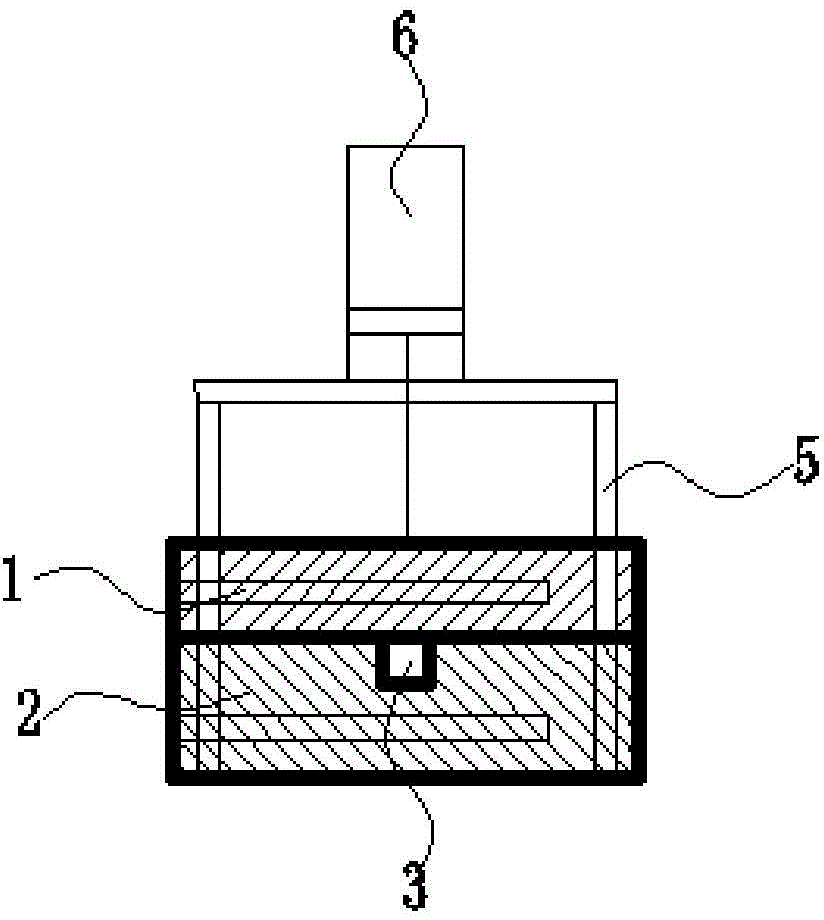

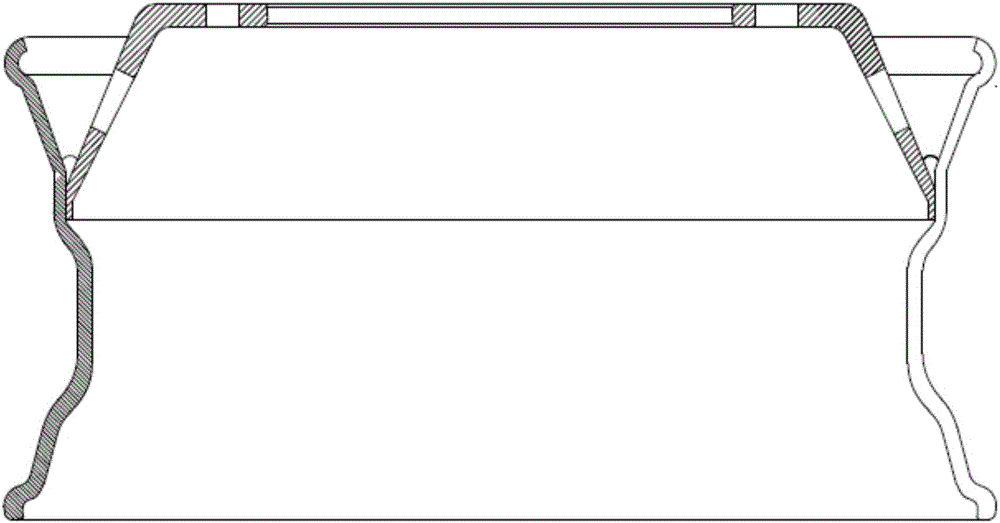

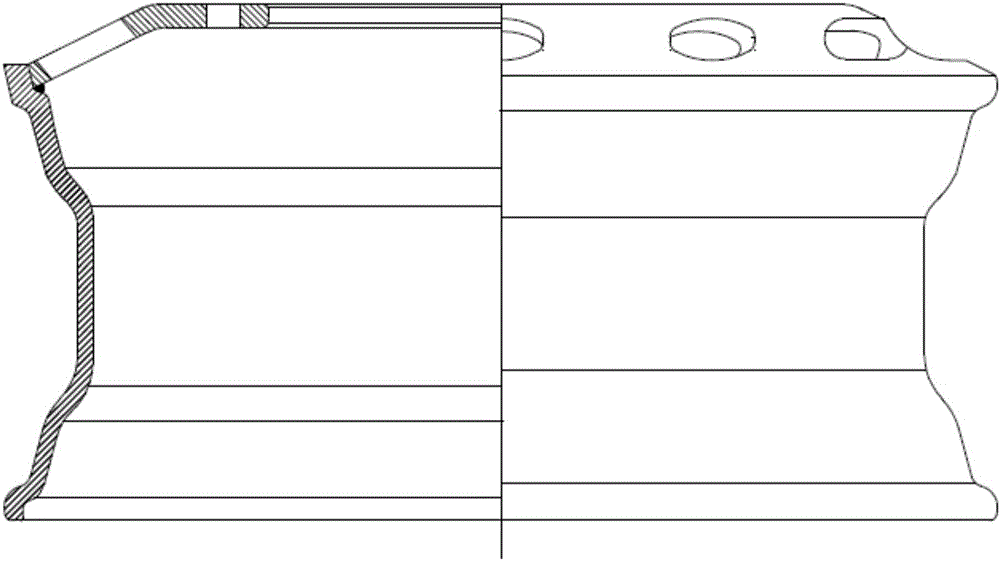

Injection mold for intake hose and intake hose production method using the same

ActiveUS20110316195A1Reduce production processReduce manufacturing costInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringInjection molding machine

An injection mold for an intake hose and an intake hose production method utilizes a main core removably dualized to automatically extract a molding-completed intake hose from the main core after injection molding is completed and an air supplying member supplying compressed air between the main core and the molding-completed intake hose is configured in the main core to automatically extract the intake hose from the main core without an additional extraction equipment, thereby reducing an entire manufacturing process and saving a manufacturing cost.

Owner:HYUNDAI MOTOR CO LTD +1

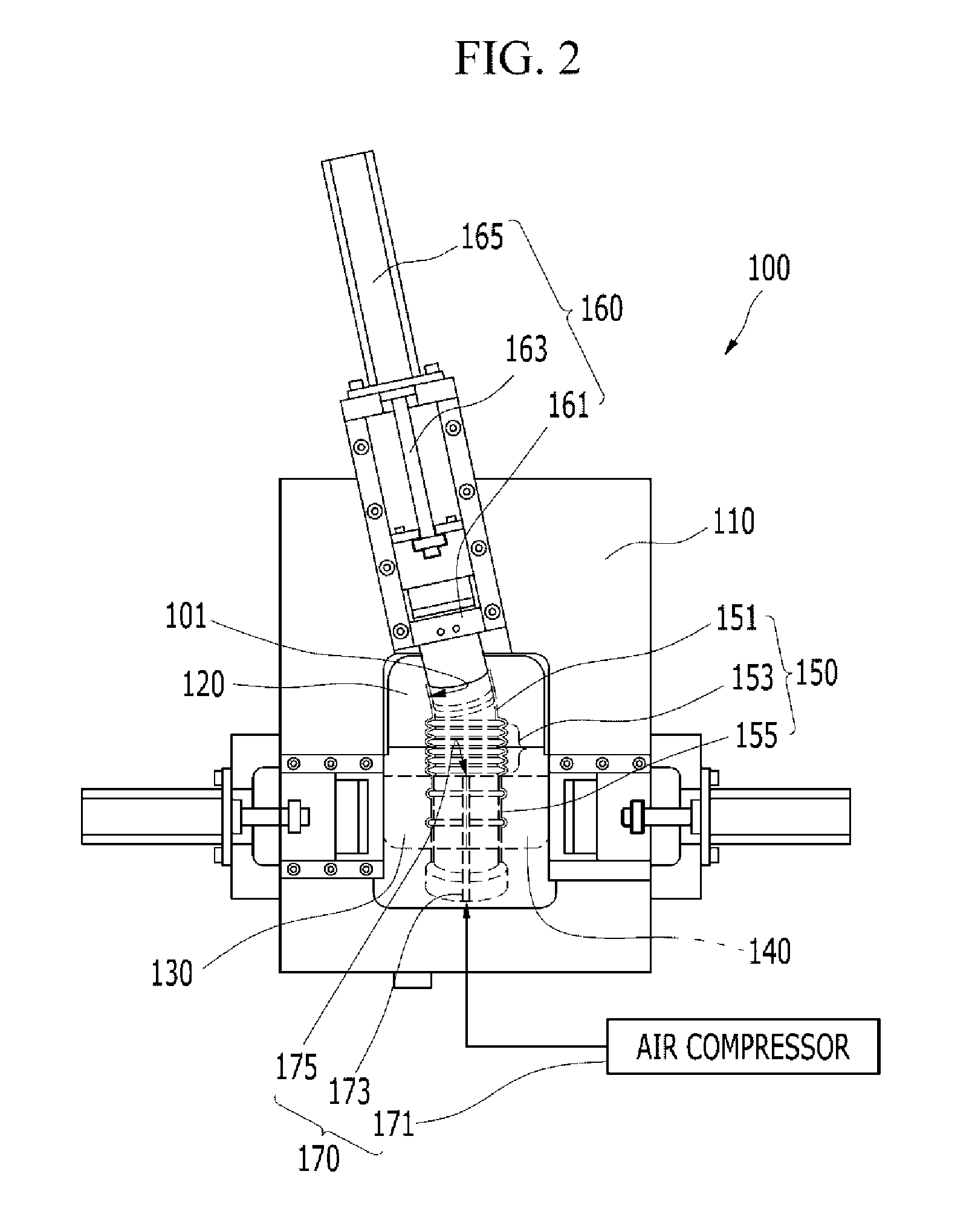

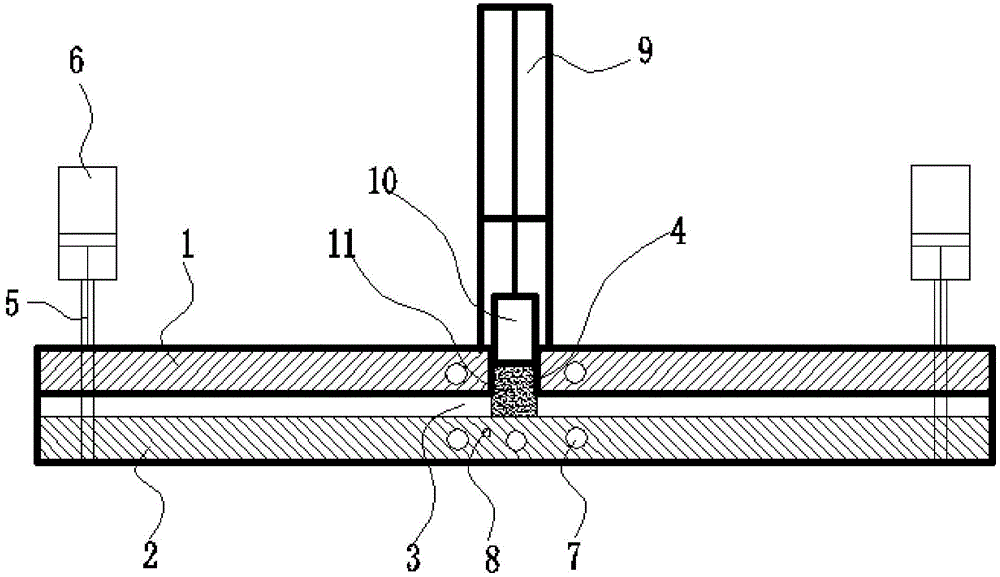

Method for manufacturing LED indicator light

InactiveCN101672434AReduce manufacturing processImprove product reliabilityPoint-like light sourceElectric lightingPrinted circuit boardEngineering

The invention discloses a method for manufacturing an LED indicator light, which comprises the following steps: a. mixing silicon dioxide powder in epoxy resins and stirring evenly to increase the consistency of the epoxy resins; b. smoothly placing a printed circuit board (PCB) 1 with LEDs in a reflection cavity 3 formed by a plastic shell 2; c. injecting the mixed epoxy resins from the front face of the reflection cavity 3 by a glue-pouring device to cover the PCB 1 with LEDs and forming an arc epoxy resins layer 4 at the front face of the reflection cavity; and d. baking to shape. The invention reduces the manufacture procedures of the LED indicator light and enhances the reliability of the LED indicator light. All electronic elements of the invention are sealed in the LED indicator light and are not in contact with the epoxy resins, thereby avoiding that the elements are damaged to cause the failure of the LED indicator light and achieving the purpose of reducing the cost.

Owner:中外合资江苏稳润光电有限公司

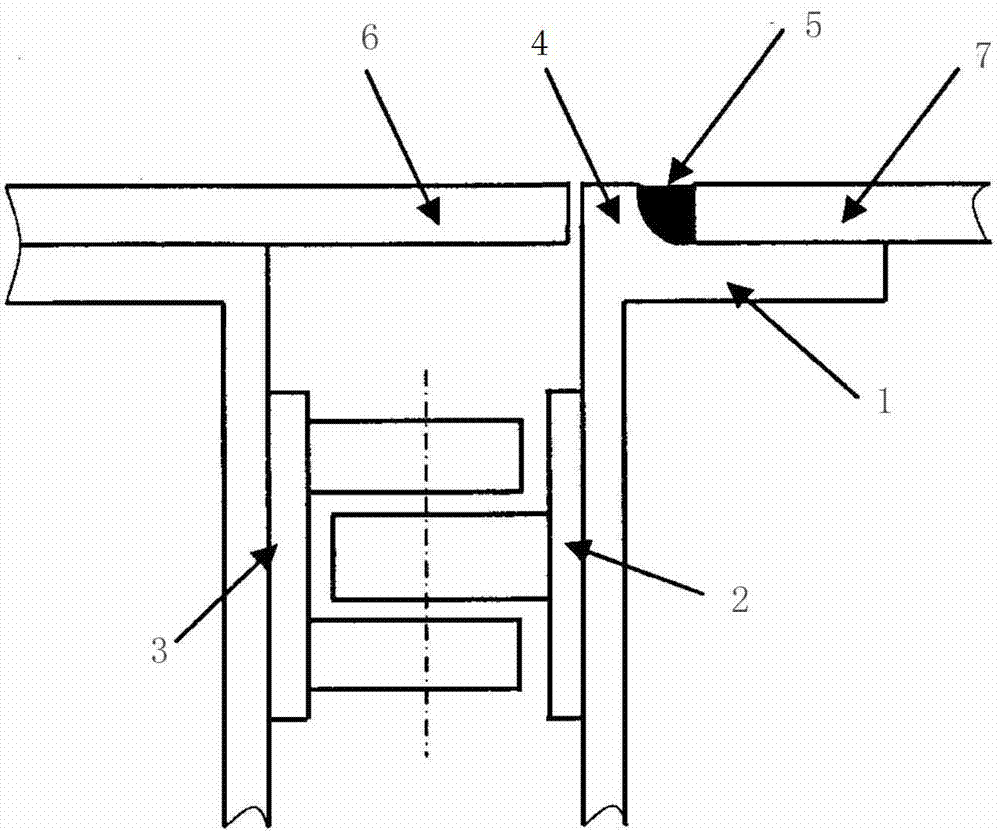

Seat reclining apparatus for vehicle

InactiveCN1982118AReduced parts countReduce manufacturing processMovable seatsRotational axisCushion

A vehicle seat reclining device includes a lock mechanism at each side of the vehicle seat for restricting or allowing a rotational movement of a seat back relative to a seat cushion. The lock mechanism includes a cam mechanism rotating around a rotational axis of the seat back relative to the seat cushion for restricting or allowing the relative rotation between the seat back and the seat cushion. The cam mechanism includes an engagement hole and a first shaft provided at the lock mechanism having an engagement portion engaging with the engagement hole with a clearance The other side lock mechanism includes a second shaft and a connecting portion for connecting the second shaft with the first shaft, wherein the second shaft is connected with the first shaft in such a manner that a rotation position of the second shaft is adjusted to agree with a rotation allowing timing of the relative rotation between the seat back and the seat cushion by the lock mechanisms.

Owner:AISIN SEIKI KK

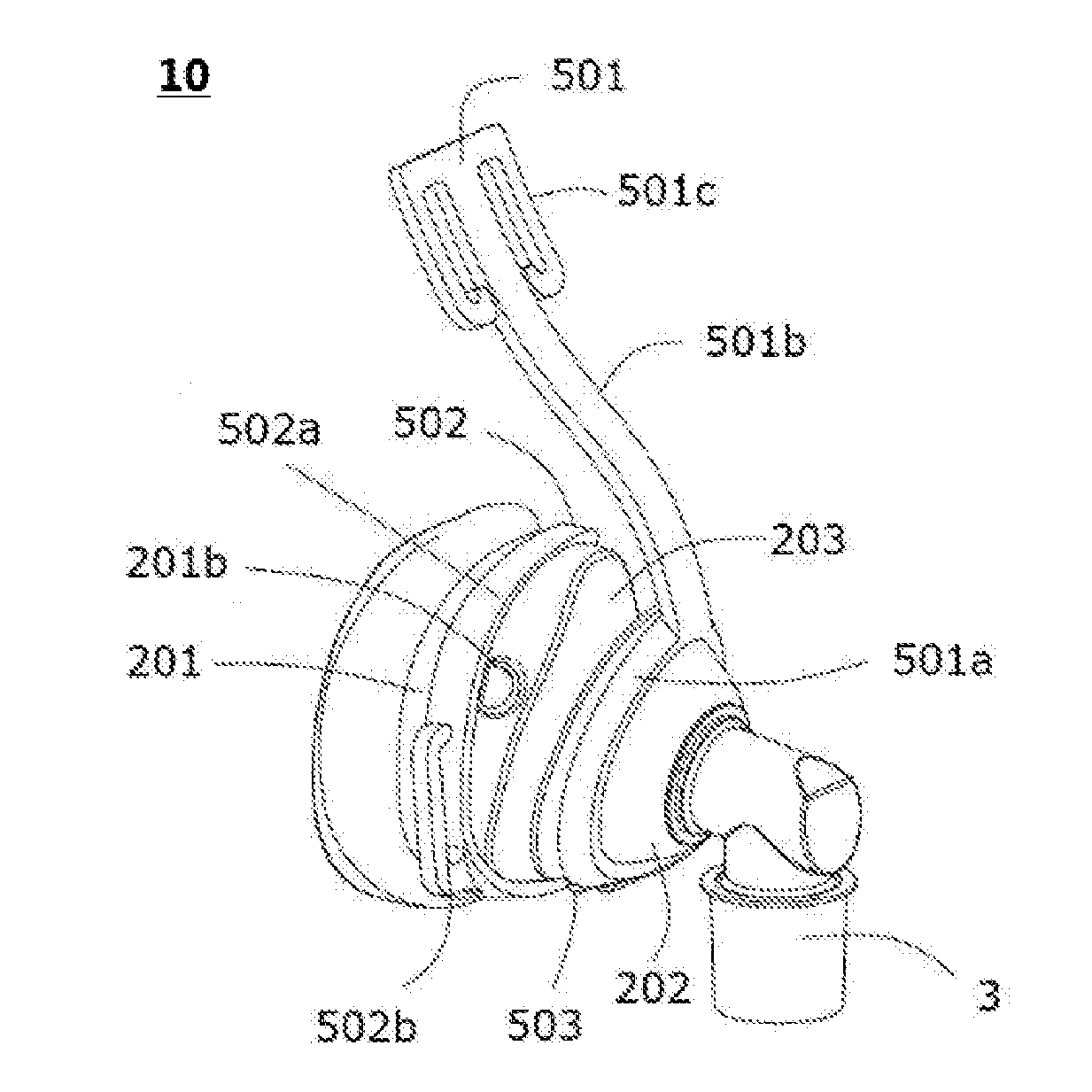

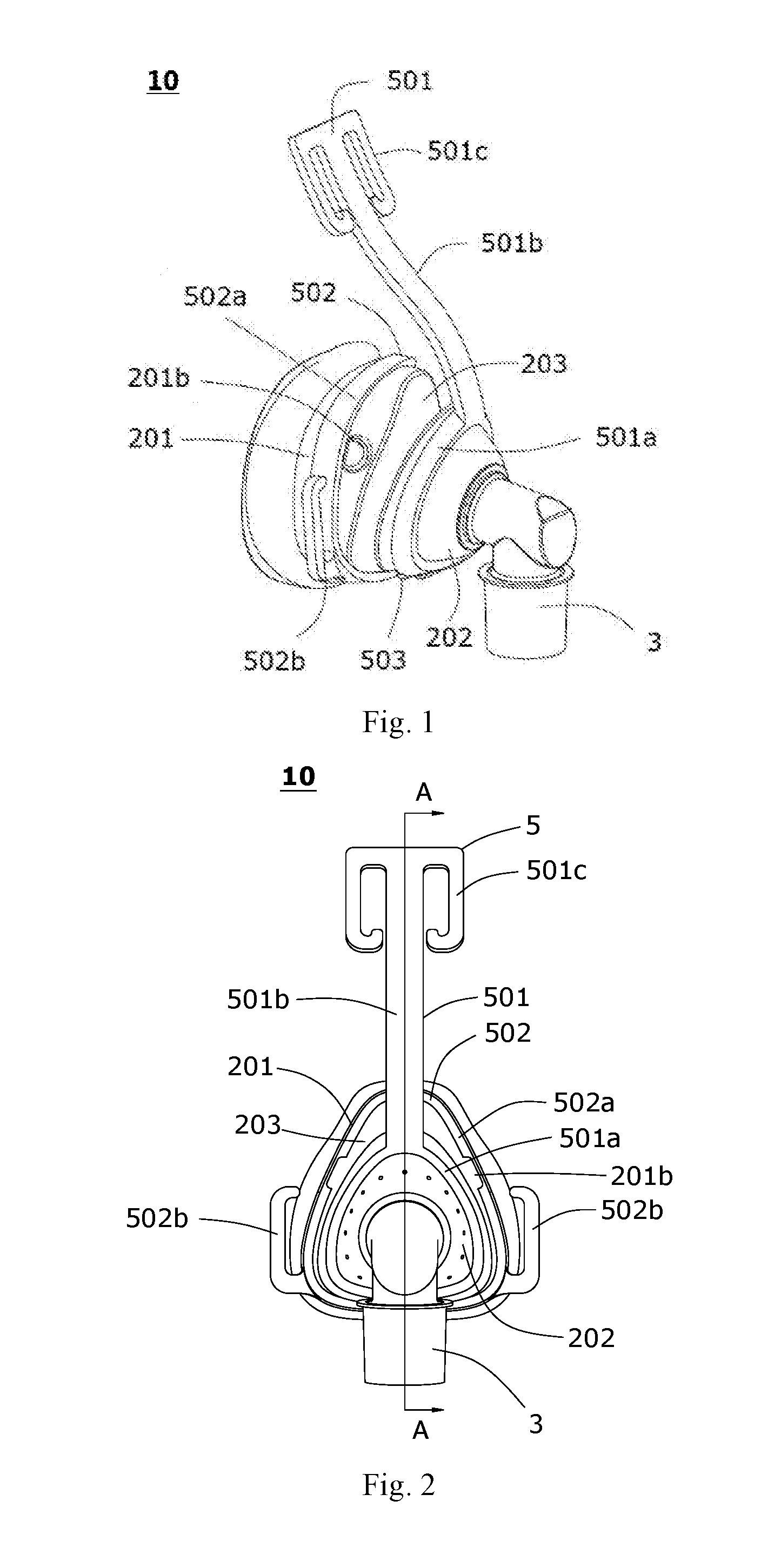

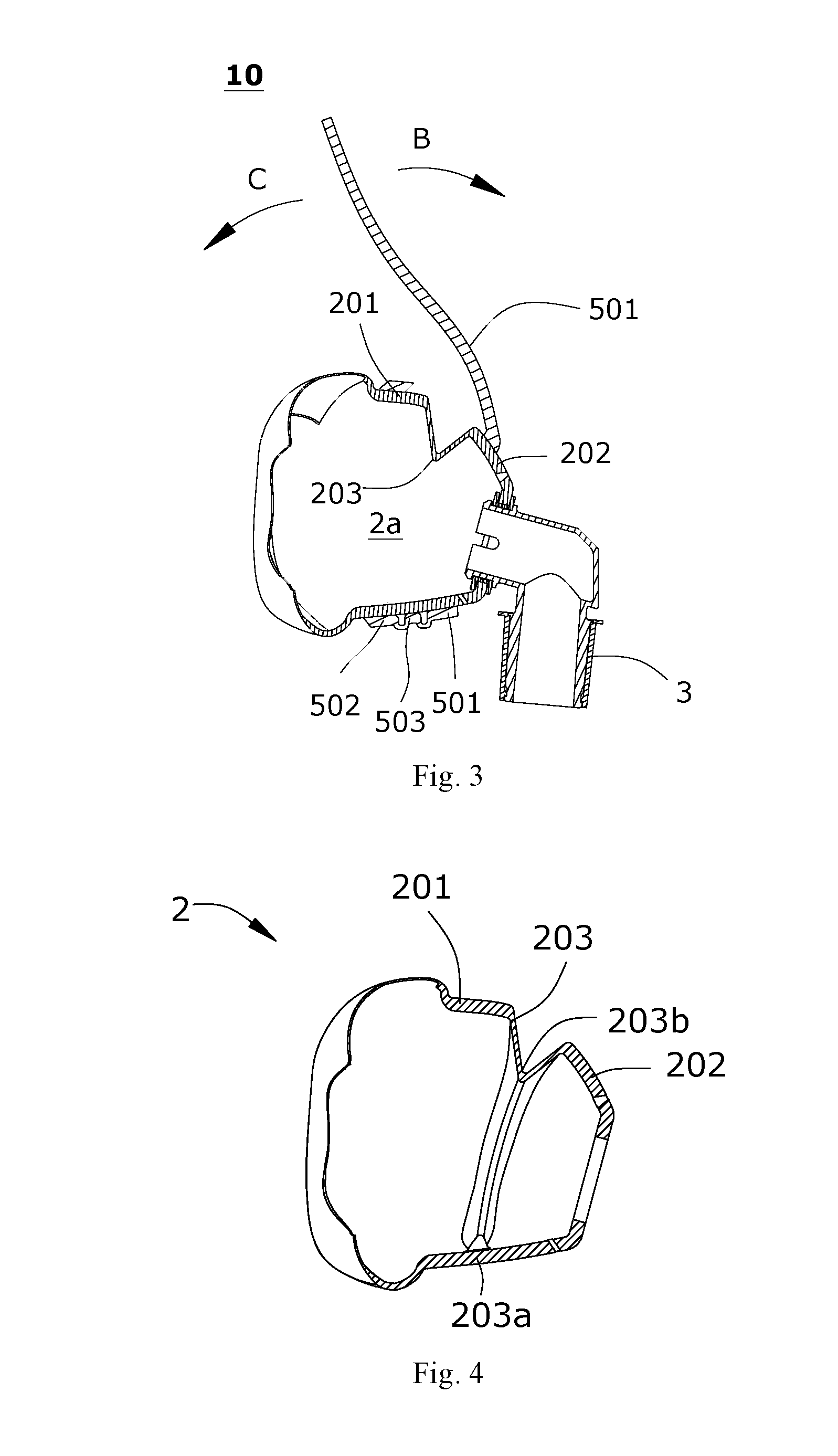

Breathing mask

ActiveUS20160136375A1Realize automatic adjustmentIncrease elasticityBreathing masksRespiratory masksRespiratorEngineering

The present invention relates to a breathing mask for use in a respirator, comprising a receiving cover comprising an engagement portion for engaging a patient's mouth portion and / or nose portion, a connection portion connected to a breathing pipe, and an elastic deformable portion for connecting the engagement portion with the connection portion; a bracket assembly, comprising a forehead support disposed external of the connection portion and a receiving cover fixing frame fixedly disposed external of the engagement portion, and an elastic member for connecting the forehead support with the receiving cover fixing frame from a bottom of the receiving cover. The breathing mask for use in a respirator according to the present invention may achieve automatic adjustment of the forehead support without manual assistant adjustment.

Owner:BMC MEDICAL

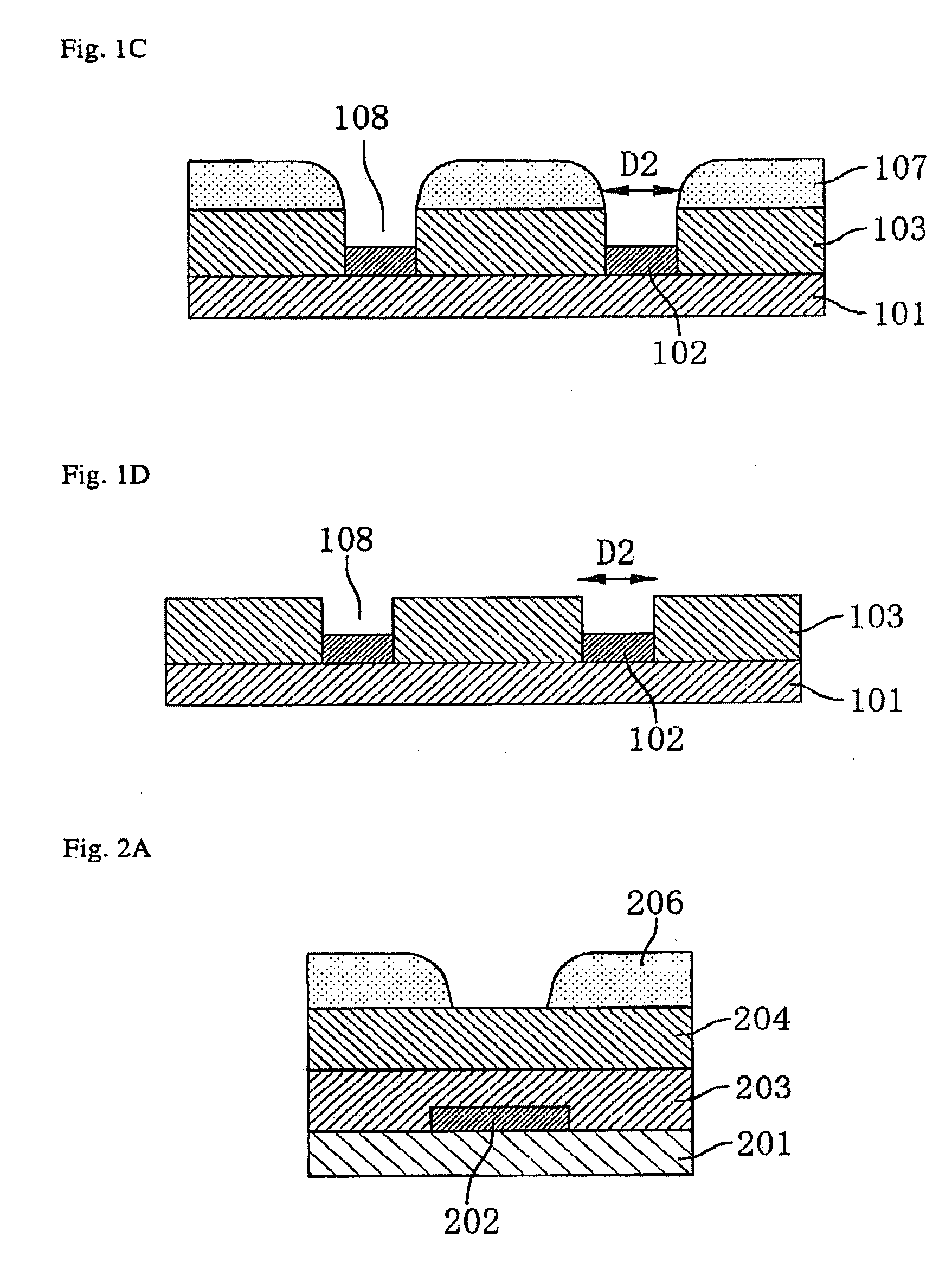

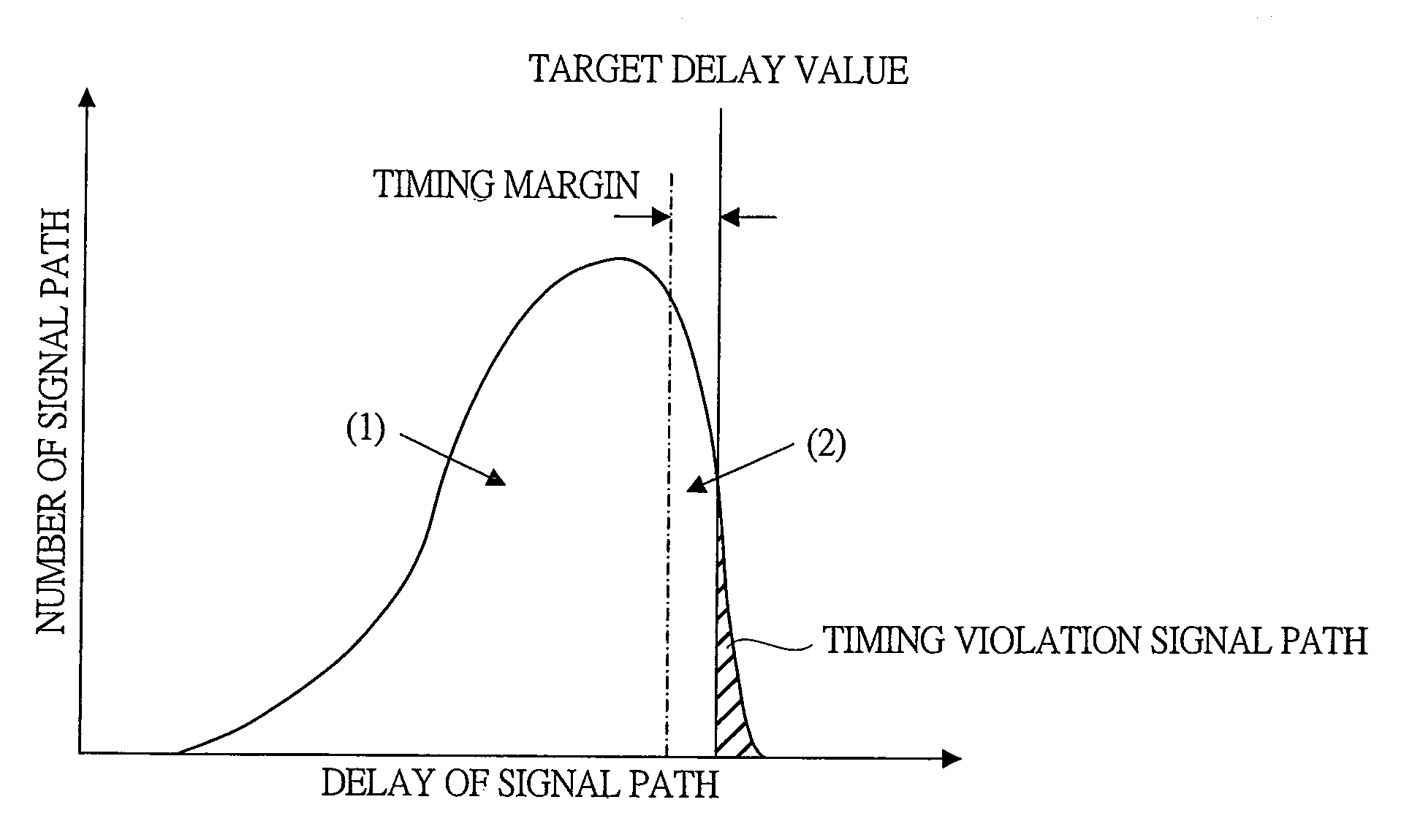

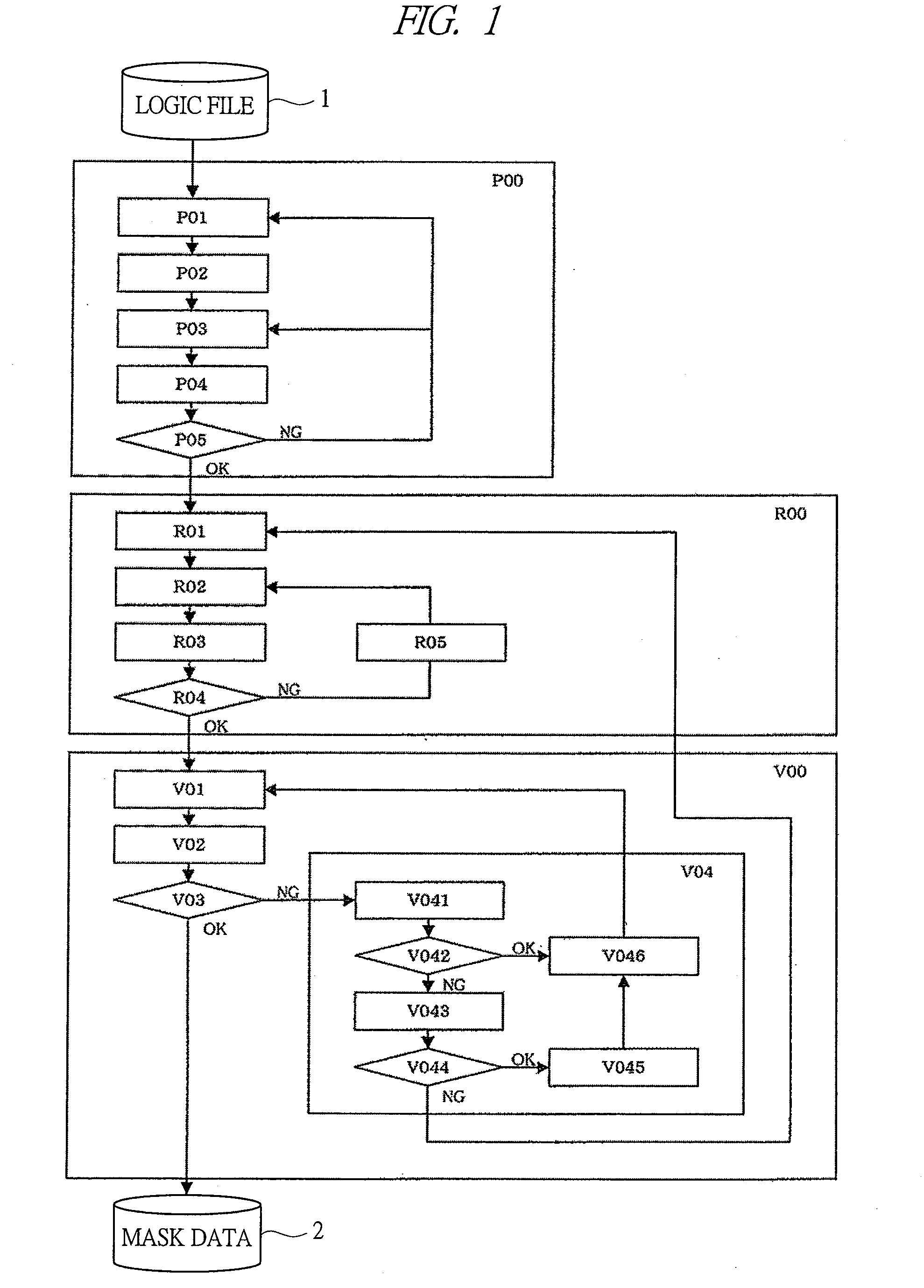

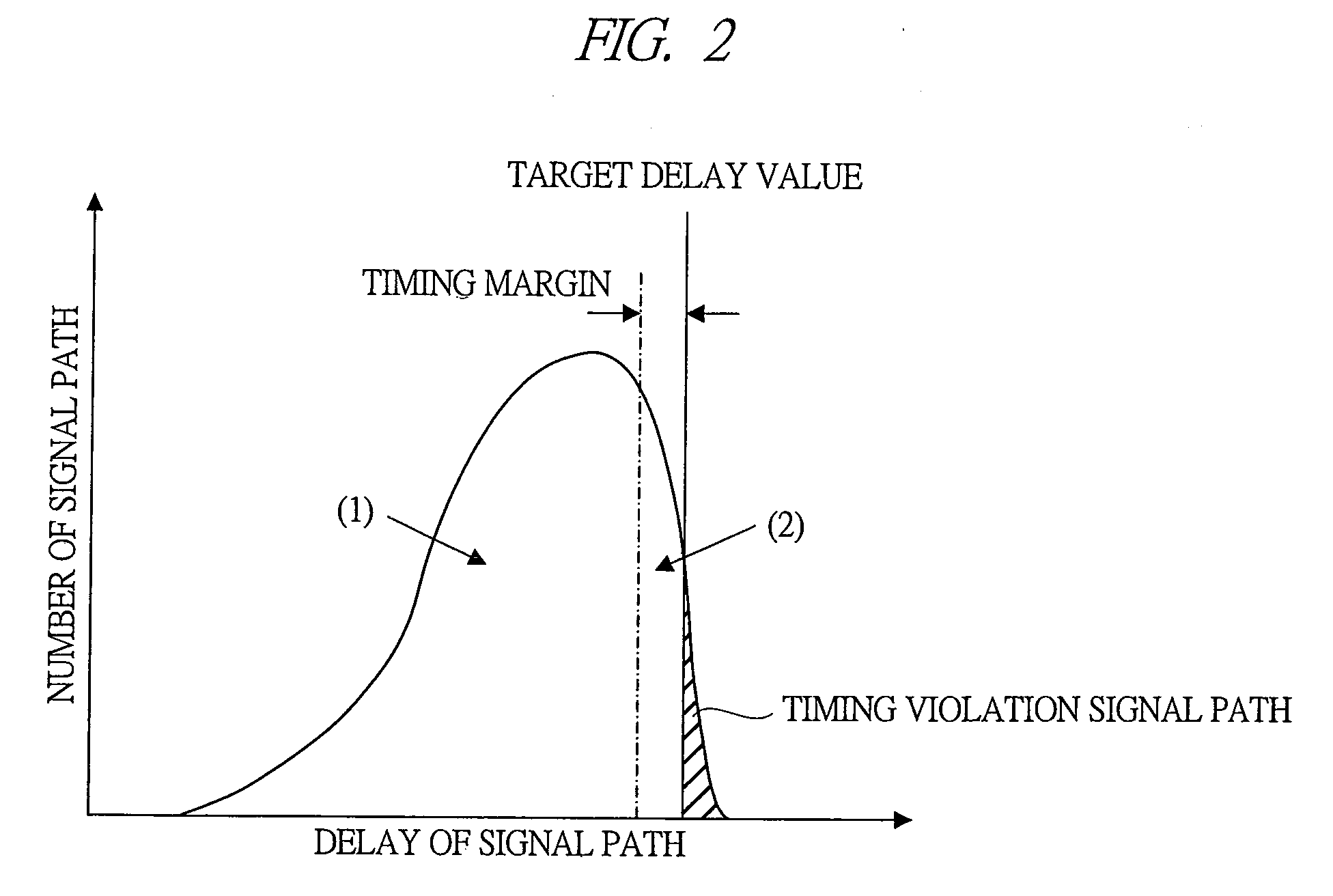

Delay adjusting method and LSI that uses air-gap wiring

ActiveUS20090106718A1Reduce manufacturing processIncrease in costSolid-state devicesSemiconductor/solid-state device manufacturingInhibition zoneDelayed time

Provided is a method for manufacturing a semiconductor integrated circuit device which enables a timing optimization without giving additions to a manufacturing process and increasing cost and TAT. Existence of a timing constraint violation is determined, and when a timing constraint violation is detected, to dissolve the violation, a void formation inhibition zone is set up in a part or all of a spacing (inter-wiring spacing) between an optimization-target wiring which needs a further delay time of a signal and clock and an adjacent wiring adjacent to the optimization-target wiring having a spacing within a specified wiring spacing, and an insulating film is formed in a spacing (inter-wiring spacing) between the optimization-target wiring and the adjacent wiring in the void formation inhibition zone, and voids are formed in a spacing (inter-wiring spacing) between the optimization-target wiring and the adjacent wiring outside the void formation inhibition zone.

Owner:KOKUSA ELECTRIC CO LTD

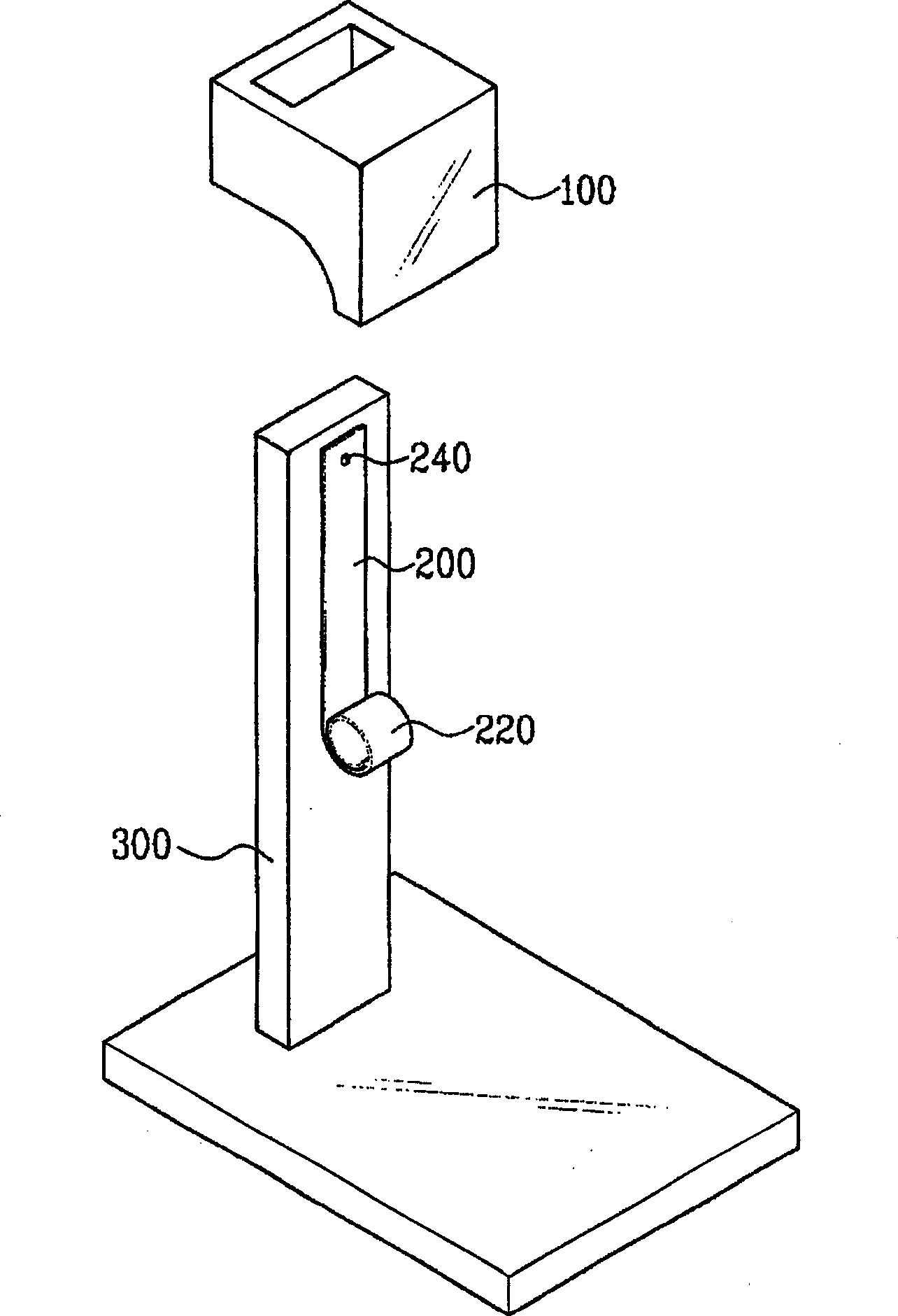

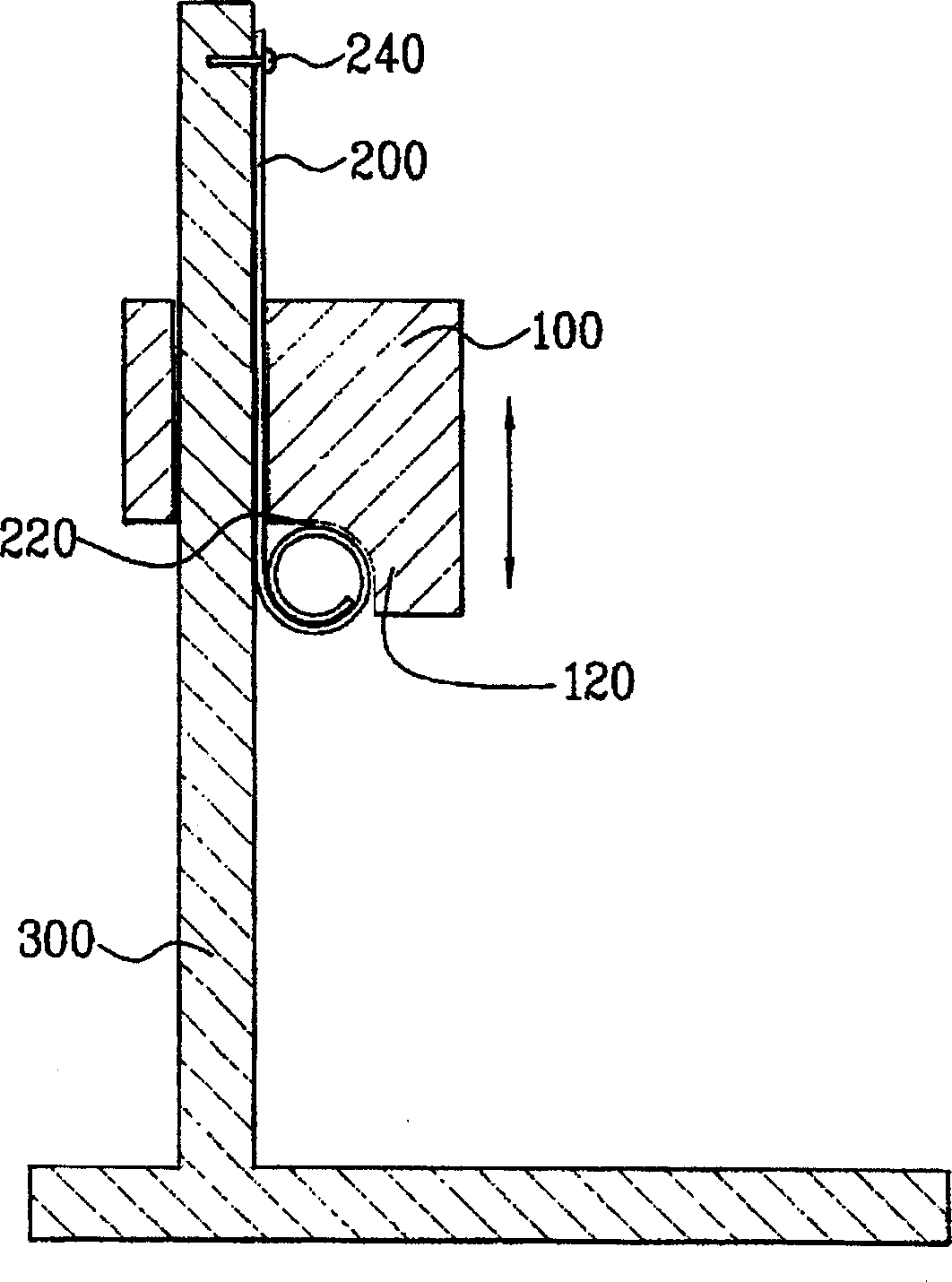

Rack stand in use for display devices

InactiveCN1760988AReduce manufacturing costsReduce manufacturing processInstrument housingStands/trestlesEngineeringSurface plate

The rack stand can fix display device and improves structure for adjusting height of rack stand. The invention reduces fabricating procedures and costs as well as brings the customer convenience on the usage. The rack stand includes following parts: stand as fixed end; connection board movable along the stand up and down and connected to the display device, and movable bracket formed on sides perpendicular to the connection board; two ends of axis supported by two side plates of the movable bracket; rotatable spring casing around the axis; ribbon spring set up inside the spring casing, ití»s one end is fixed on the axis, and the other end is fixed inside the spring casing; the ribbon spring makes the movable bracket suspend at any position of the stand, and the ribbon spring can be moved under proper force; adjusting elastic force as a temporary locking measure for against potation of spring casing.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

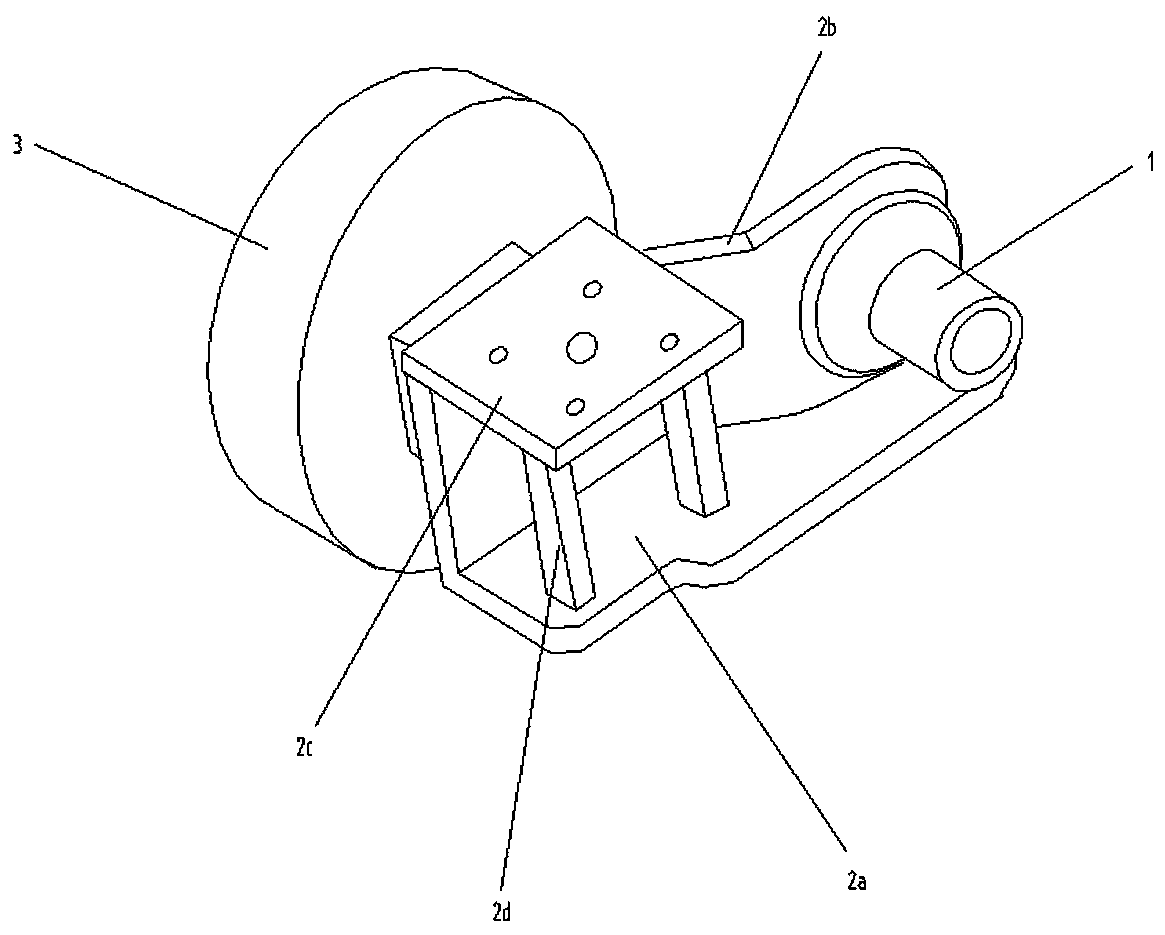

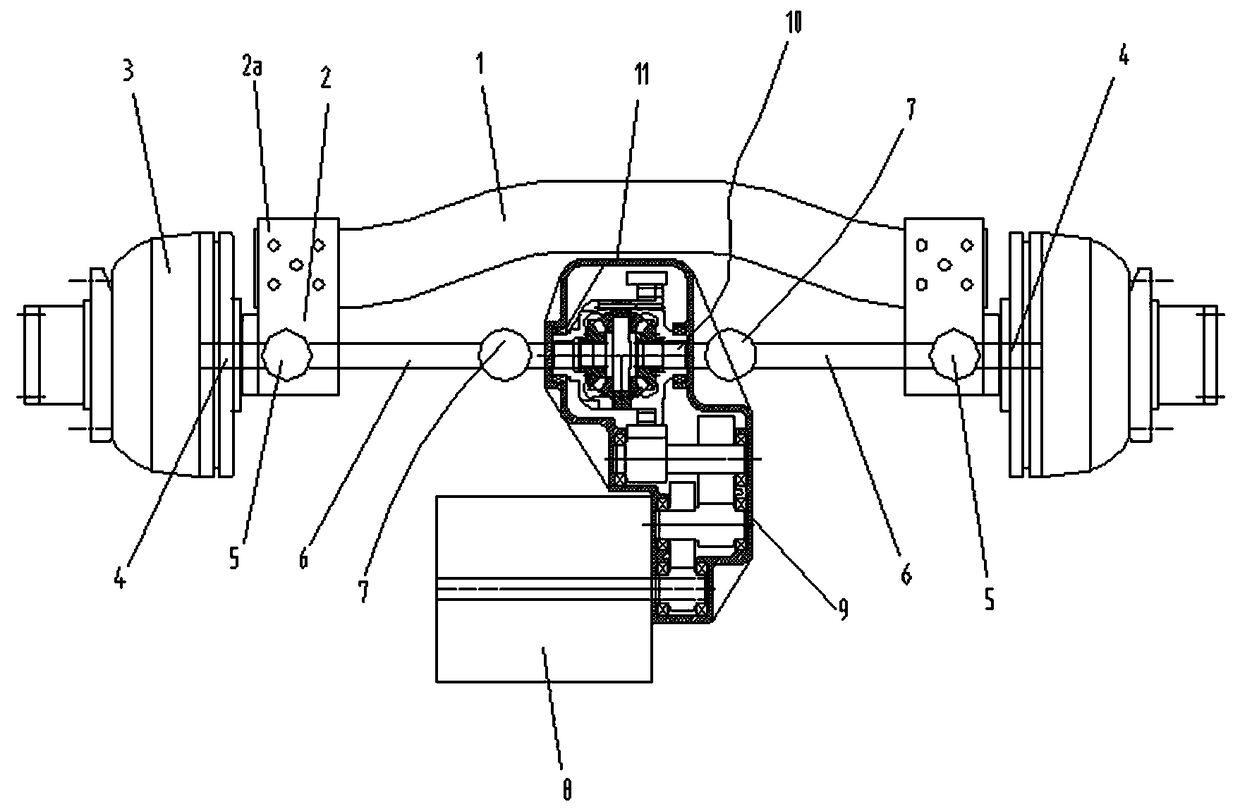

Non-bearing independently driven electric axle

PendingCN109278517AReduce manufacturing processReduced manufacturing and assembly difficultyElectric propulsion mountingAxle unitsElectric driveSteel plates

The invention relates to a non-bearing independently driven electric vehicle axle. The non-bearing independently driven electric vehicle axle is characterized in that a steel bracket (2a) on each wheel end connection bracket (2) is connected with a corresponding steel plate spring on a vehicle frame; each wheel end connection bracket (2) is connected with a corresponding wheel end system (3), andthe two wheel end connection brackets are connected with an integral bearing axle shell (1) which deviates from the axis of the corresponding wheel end system; and the vehicle frame is fixedly connected with a drive motor (8), an integral structural gear box (9) and a differential mechanism (11), and first universal joints (7), oscillating half shafts (6), second universal joints (5) and hub shafts (4) are separately connected to two ends of the differential mechanism. The non-bearing independently driven electric vehicle axle is different from a common electric drive axle structure for a commercial light electric vehicle, an integrated independent electric drive structure and an integral bearing axle shell are adopted, the unsprung mass of a vehicle chassis is effectively reduced, the ground clearance of the electric drive axle is reduced, the advantages of convenient design, manufacture, installation, maintenance and the like are achieved, and in terms of cost economy, an independentsuspension structure with complex use and higher cost due to the use of independent drive is avoided.

Owner:HEFEI AAM AUTOMOBILE DRIVELINE & CHASSIS SYST

Method and equipment for processing polytetrafluoroethylene sealing ring

ActiveCN104527057AImprove processing efficiency and molding accuracyReduce manufacturing processButt jointPTFE - Polytetrafluoroethylene

The invention discloses a method for processing a polytetrafluoroethylene sealing ring. The method comprises the following steps: 1) setting a hot melting mold, wherein the hot melting mold comprises an upper mold and a lower mold, a segment of die cavity is formed between the upper mold and the lower mold, and the end face of the segment of die cavity is matched with the end face of a sealing ring needing to be welded; setting a welding mechanism on the hot melting mold, wherein the welding mechanism comprises a heating device corresponding to the die cavity, a filler area and a material pressing device; 2) putting both ends of a cut sealing strip in the die cavity of the hot melting mold according to the set specification of the sealing ring, and corresponding the butt joint sites at the both ends of the sealing strip to the welding mechanism; 3) putting corresponding modified fillers in the filler area of the welding mechanism, heating the filler area through the heating device, pressing the filler area through the material pressing device after reaching a set temperature, and maintaining the pressure for a period of time until the butt joint sites at the both ends of the sealing strip are fully fused with the modified fillers to form the sealing ring. The invention further discloses equipment for implementing the method.

Owner:广东科雷明斯智能科技有限公司

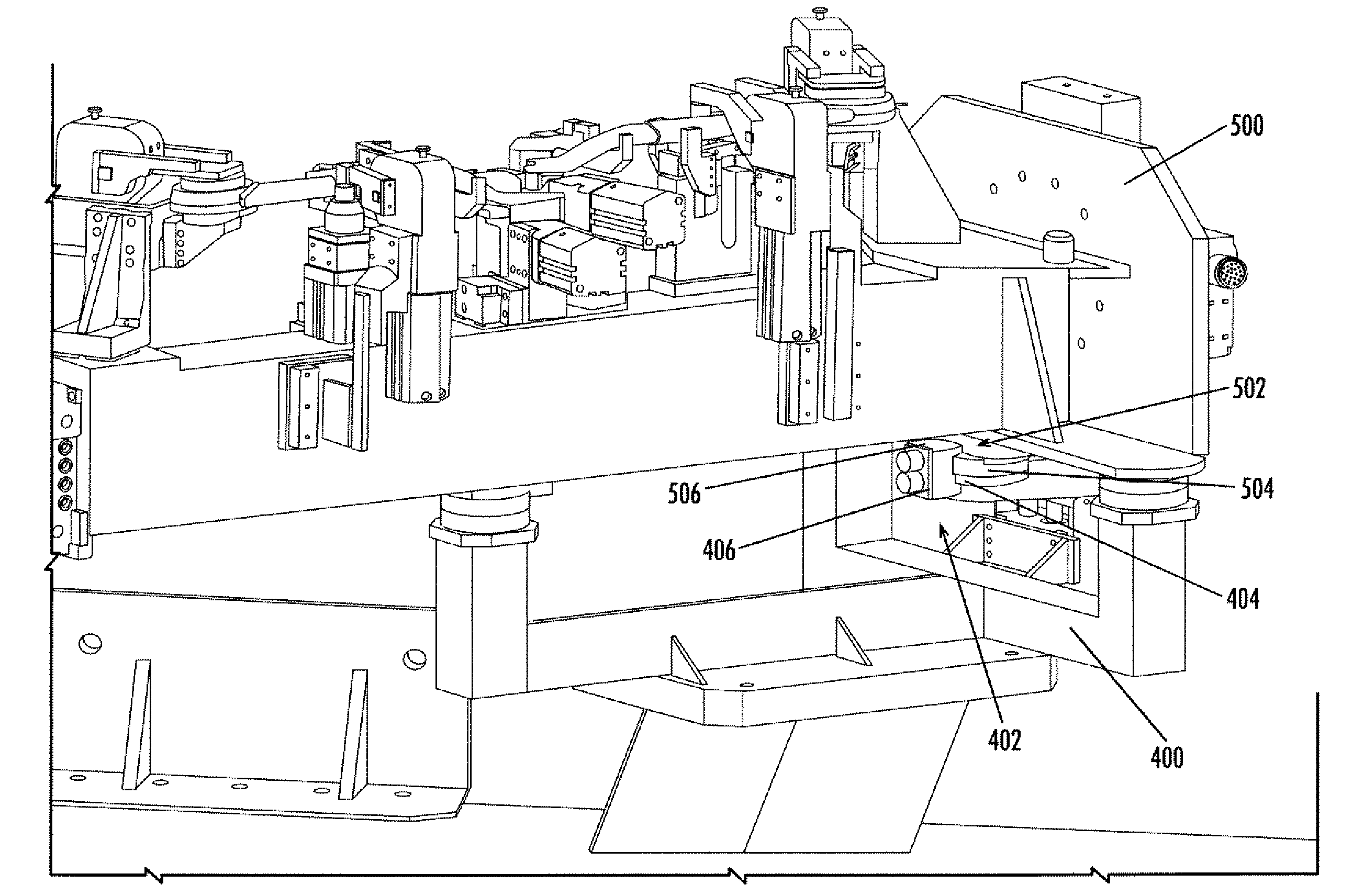

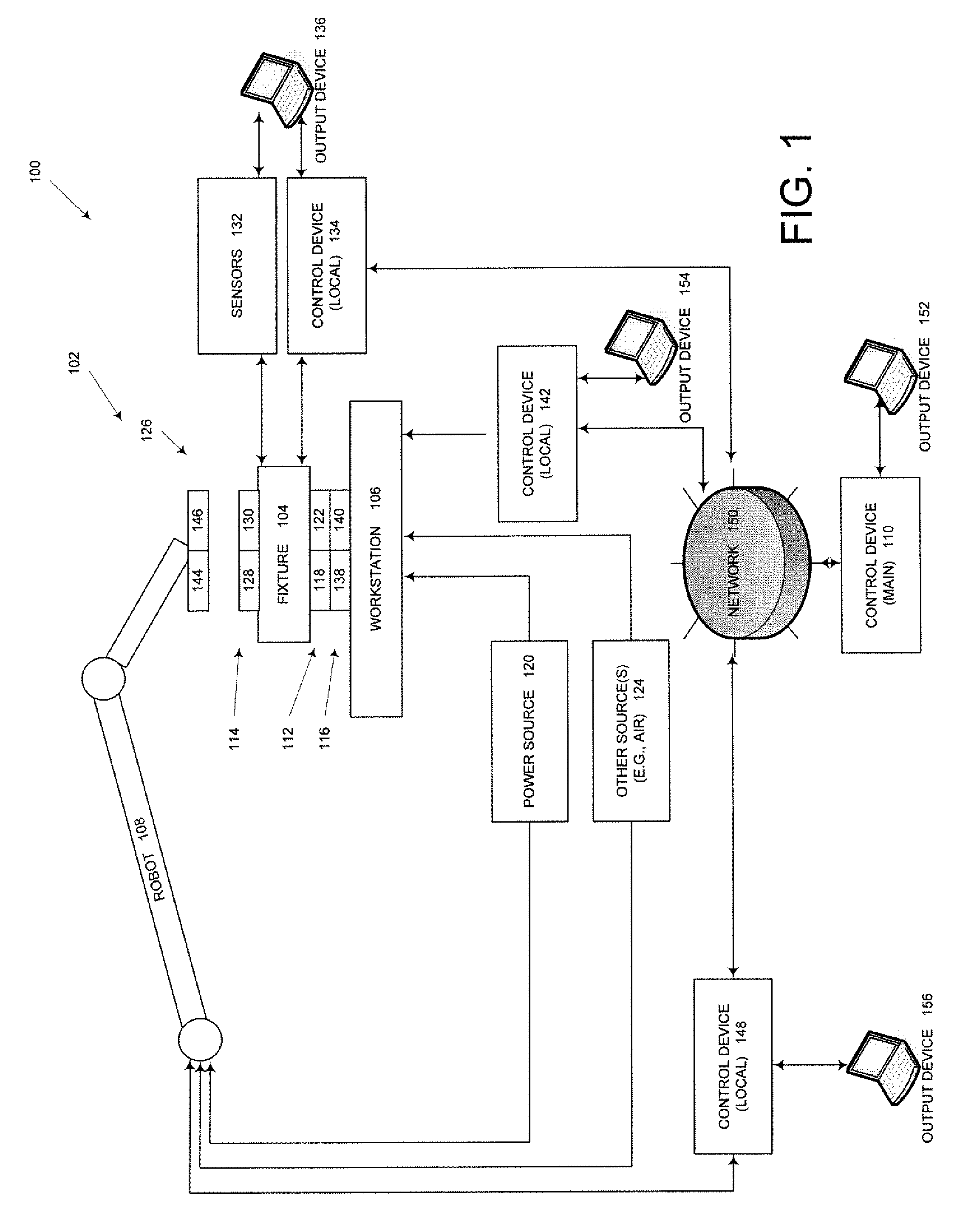

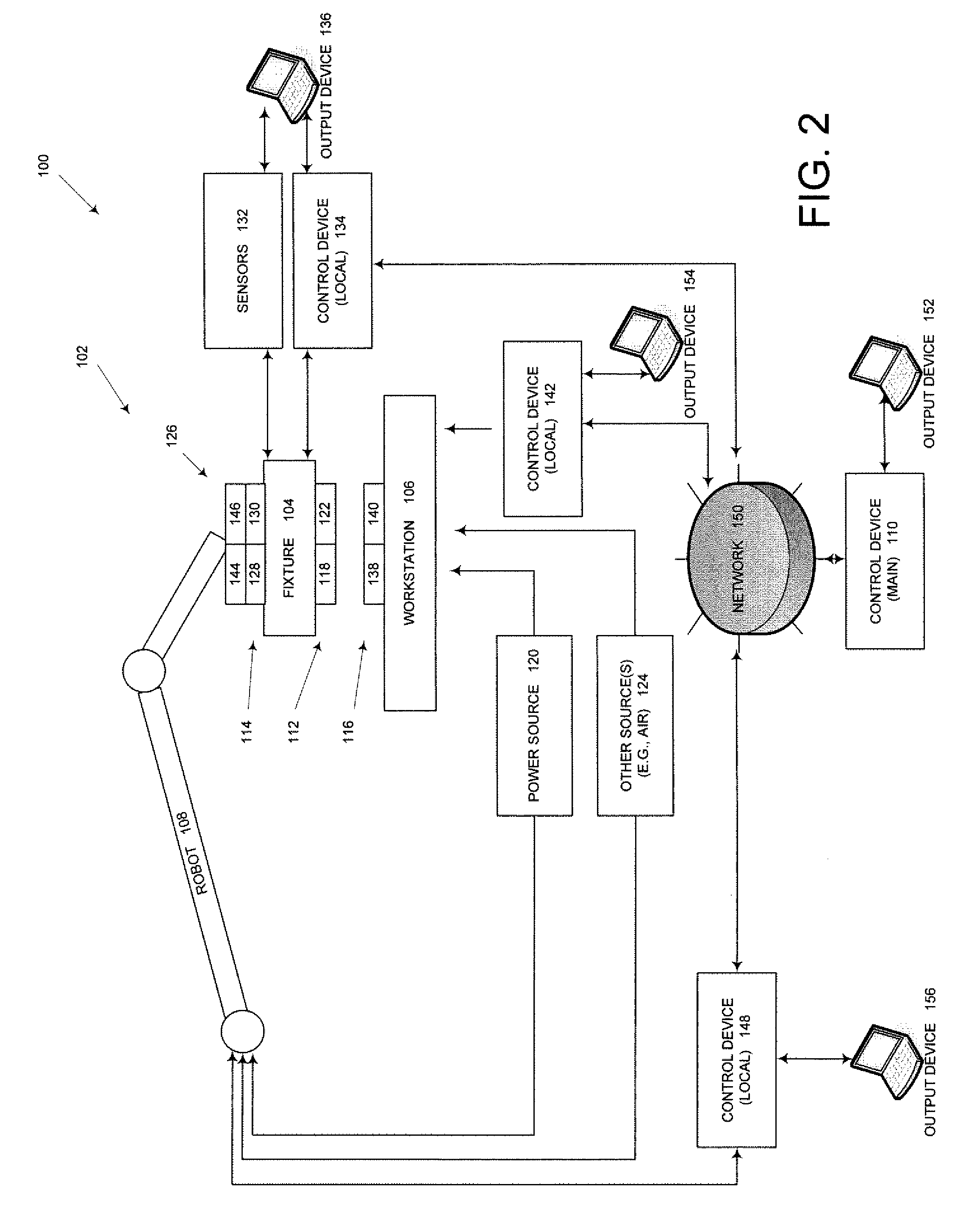

Systems, methods, and apparatus for providing continuous power to a fixture in a manufacturing process

ActiveUS20080163483A1Reduce manufacturing processShorten cycle timeProgramme-controlled manipulatorComputer controlRobotic armWorkstation

Embodiments of the invention are directed to systems, methods, and apparatus for providing continuous power and utilities to a fixture in a manufacturing process. In one embodiment of the invention, a system with robot, such as a robotic arm, and a workstation can be deployed in a manufacturing process. A fixture associated with the manufacturing process can include a mount operable for receiving power from the robot or robot arm, and another mount operable for receiving power from the workstation. An associated control device, such as a programmable logic circuit, can selectively provide power via either mount depending on whether the fixture is mounted to the robot or robotic arm, or to the workstation.

Owner:TENNESSEE RAND AUTOMATION

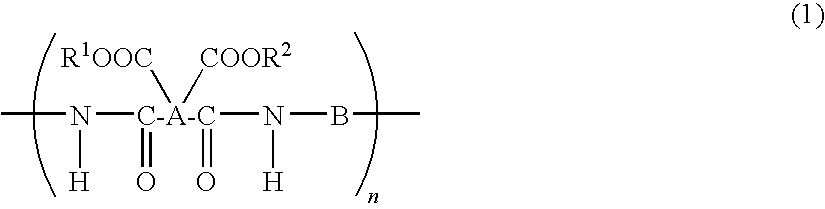

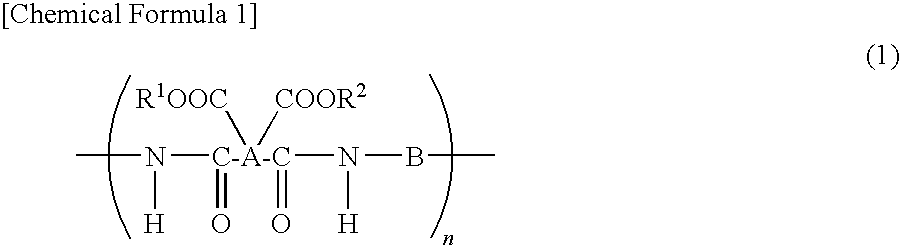

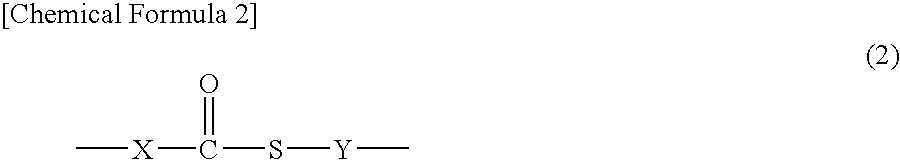

Polyimide precursor, polyimide, and coating solution for under layer film for image formation

ActiveUS20100069569A1High materialReduce processing timeSemiconductor/solid-state device manufacturingPretreated surfacesThiolHydrogen atom

There is provided a polyimide precursor which can alter the hydrophilicity / hydrophobicity of the surface of a cured film formed readily even by a low level of ultraviolet ray irradiation; and a polyimide produced from the polyimide precursor. The polyimide precursor having a structure represented by the following formula (1):(where A represents a tetravalent organic group; B represents a bivalent organic group having a thiol ester bond in its main chain; R1 and R2 independently represent a hydrogen atom or a univalent organic group; and n represents a natural number).

Owner:NISSAN CHEM IND LTD

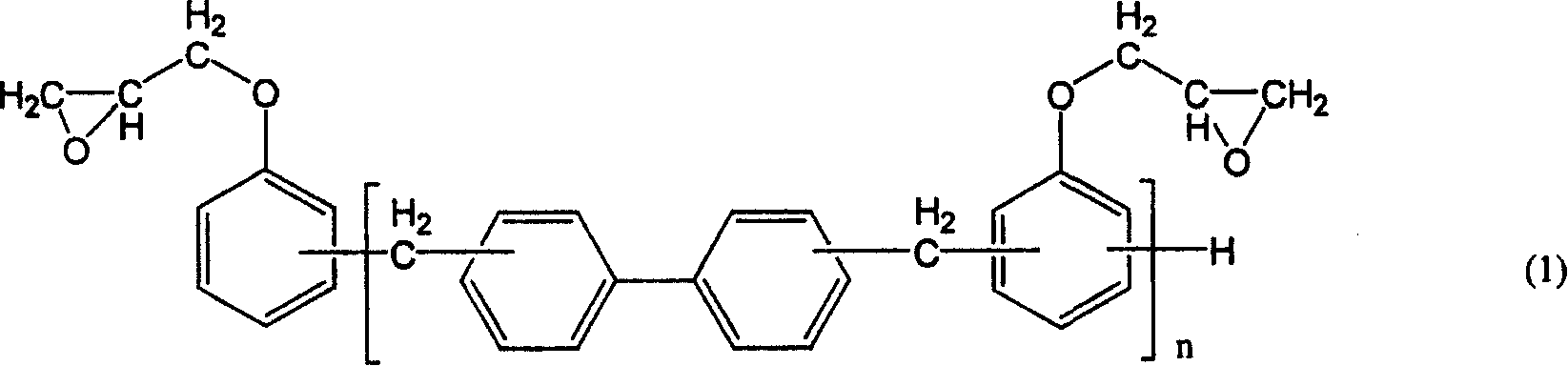

Epoxy resin composition

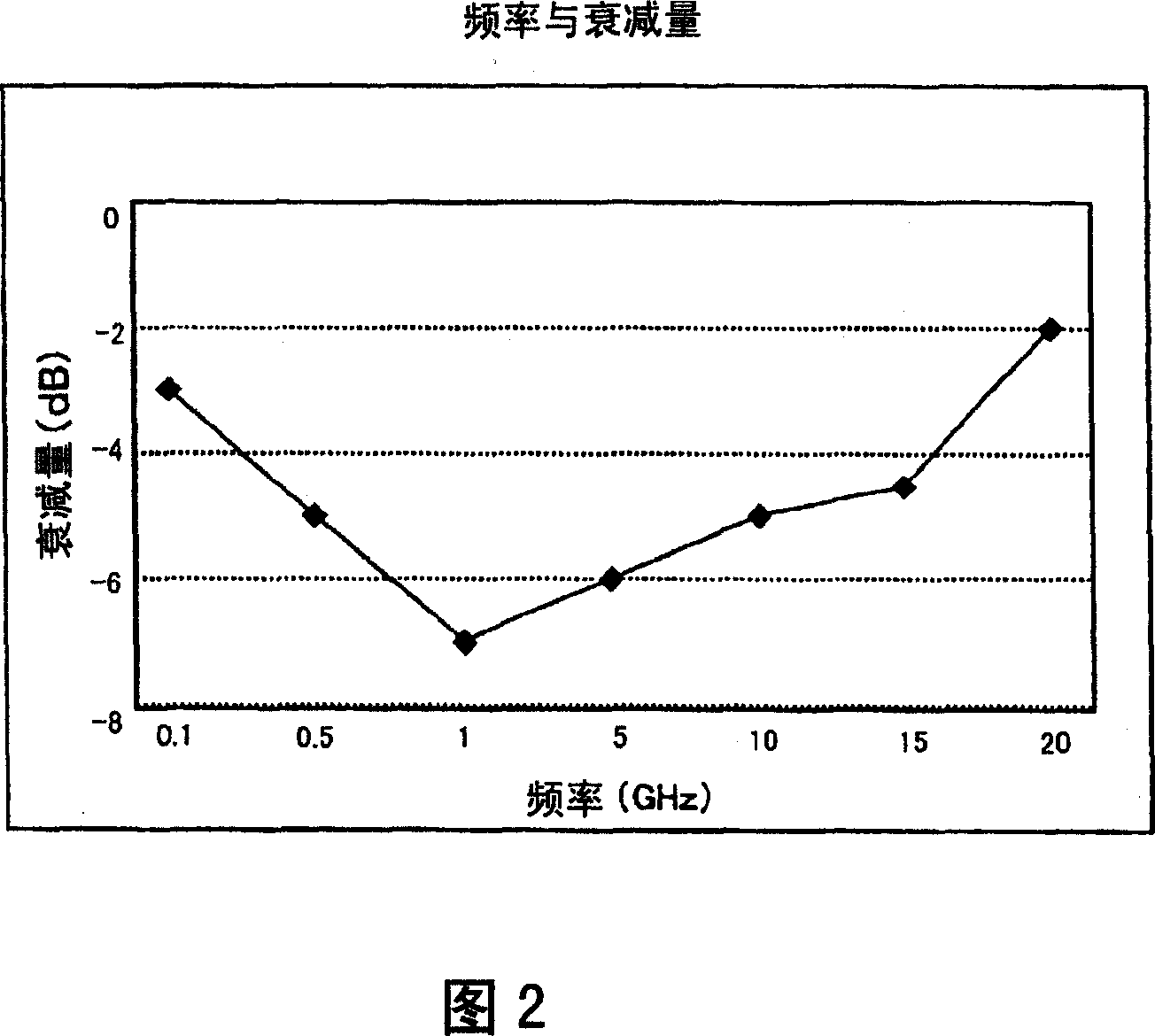

InactiveCN1942502ALow dielectric constantReduce lossSemiconductor/solid-state device detailsPrinted circuit aspectsEpoxyDielectric loss

To provide an epoxy resin composition which can form a cured material having low dielectric constant and low dielectric loss tangent in a radio frequency region, and a film obtained by using the epoxy resin composition. An epoxy resin composition comprising: (A) at least one epoxy resin selected from the group consisting of a novolac epoxy resin having a phenolic skeleton and a biphenyl skeleton, and a bifunctional linear epoxy resin having a weight average molecular weight of 10,000 to 200,000 and having a hydroxyl group; and (B) a modified phenolic novolac having a phenolic hydroxyl group, at least part of which is esterified with a fatty acid.

Owner:NAMICS CORPORATION

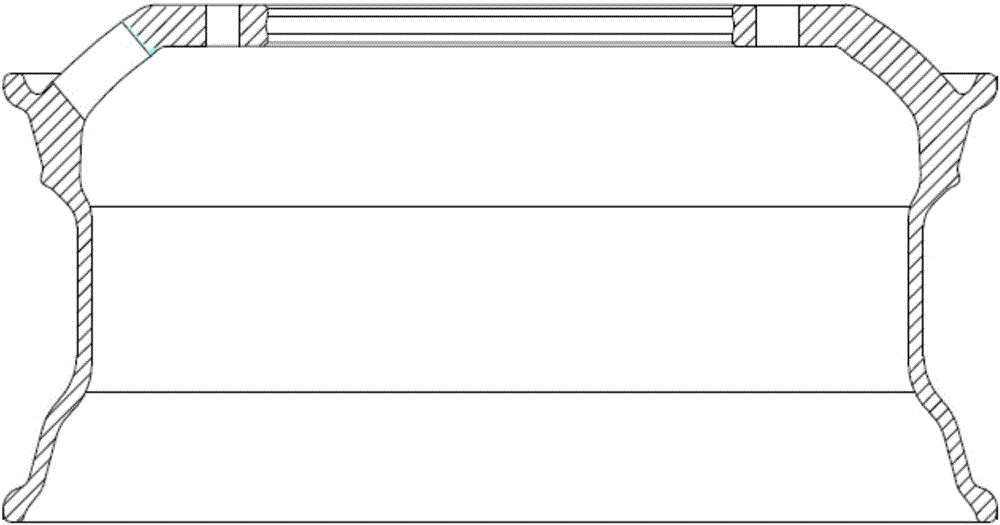

Tubeless thickness-unequal weld joint-free integral steel wheel and processing technology thereof

InactiveCN105904914ATo achieve the purpose of lightweightEliminate inflation leakage problemsWheel manufactureDisc wheelsSheet steelEngineering

A tubeless thickness-unequal weld joint-free integral steel wheel comprises a rim and a spoke. The rim and the spoke are integrally formed and formed by spinning a steel plate. The spoke face of the spoke is one of a flat cone face, a convex cone face or a concave cone face. The tubeless thickness-unequal weld joint-free integral steel wheel adopts the steel plate integral spinning forming technology, the processes that the rim and the spoke of a traditional split type wheel are respectively manufactured, and then assembled and welded are omitted, a seal ring is not used, thus the manufacturing process is decreased and the air inflation leakage problem of the traditional wheel is fundamentally eliminated. The tubeless thickness-unequal weld joint-free integral steel wheel adopts the integral steel spinning forming technology, the problem that a wheel made of an aluminum material is low in strength and poorer in loading capacity when compared with the steel wheel is solved, manufacturing of a finished product of the wheel of which the cross section is unequal in thickness under the condition of equal strength is realized, the bearing capacity is improved and the weight reduction of the wheel is realized.

Owner:泉州市泰智机械发展有限公司

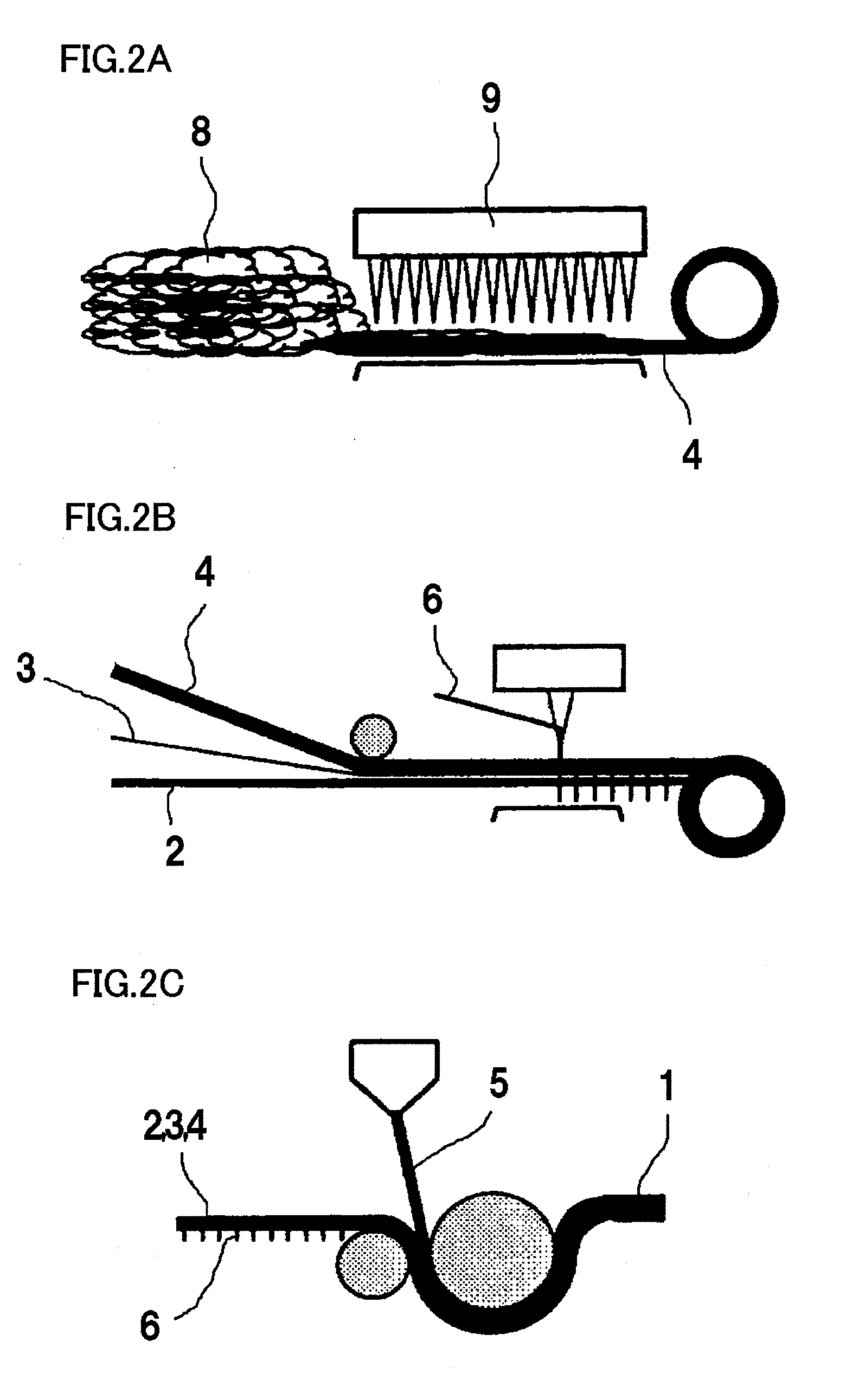

Carpet and method of manufacture therefor

InactiveUS20090304982A1Sound absorbability be improveReduce manufacturing processVehicle arrangementsSynthetic resin layered productsYarnSurface layer

A carpet according to the present invention includes: a first air-impermeable layer (surface layer), a sound absorbent layer provided on a reverse side of the first air-impermeable layer, and a second air-impermeable layer (backing material layer) provided on a reverse side of the sound absorbent layer. In the carpet, a pile yarn is implanted through the first air-impermeable layer and the sound absorbent layer.

Owner:TOYOTA BOSHOKU KK

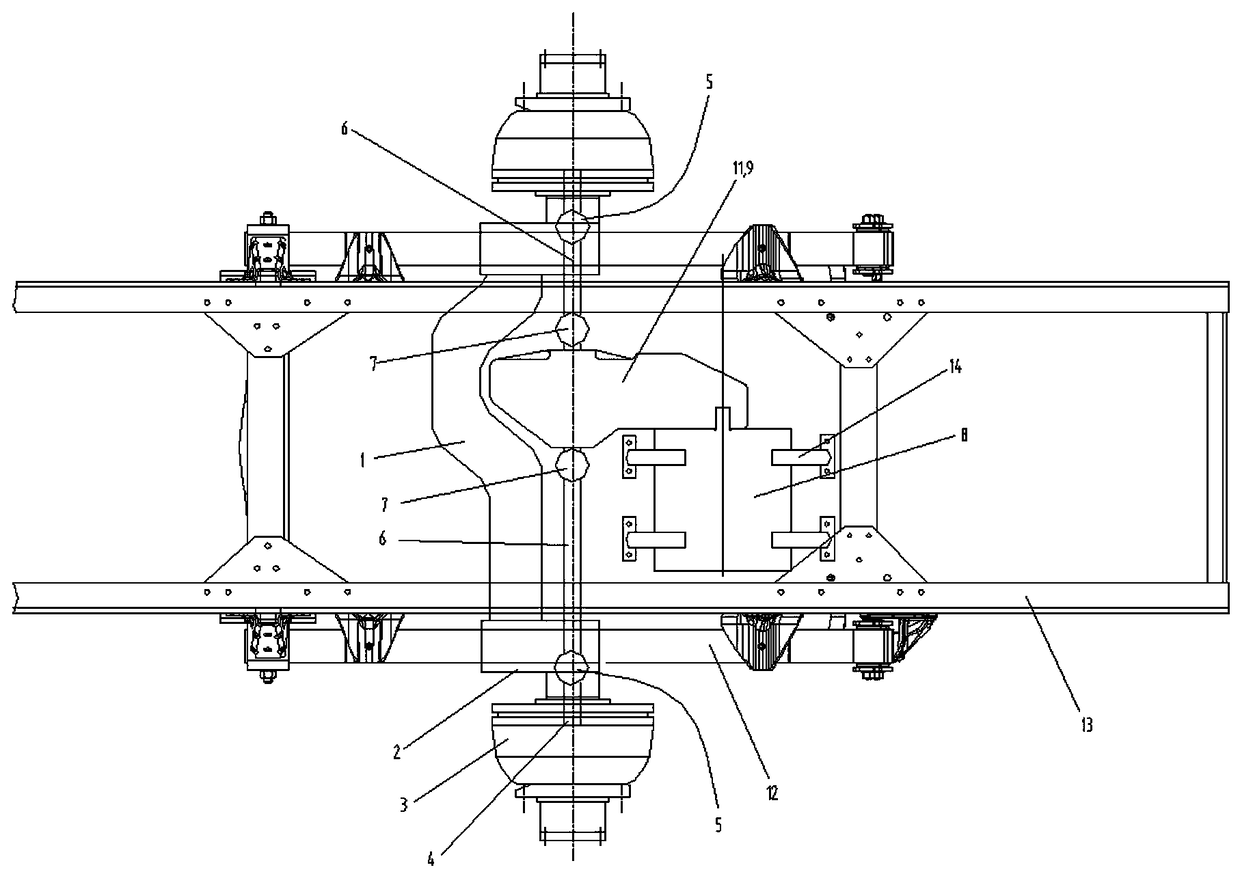

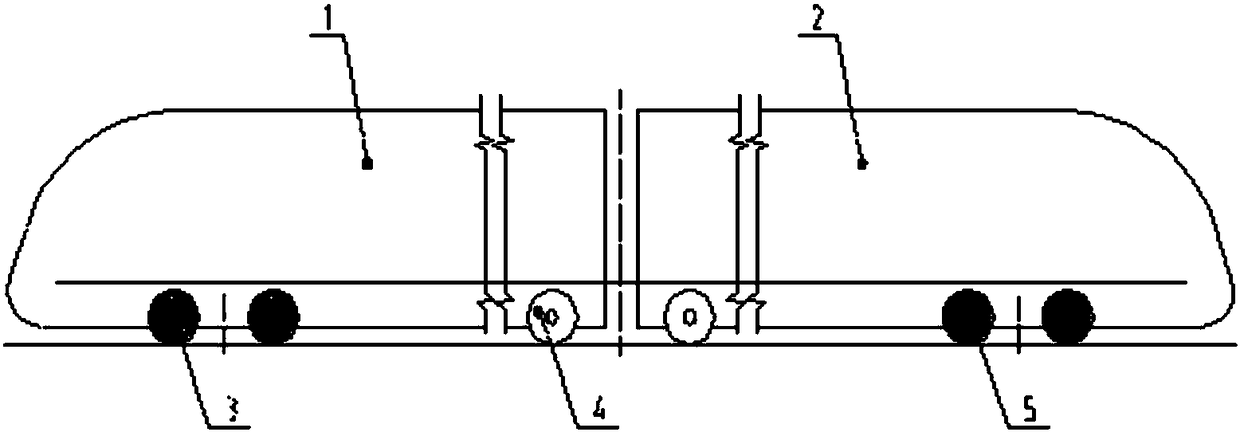

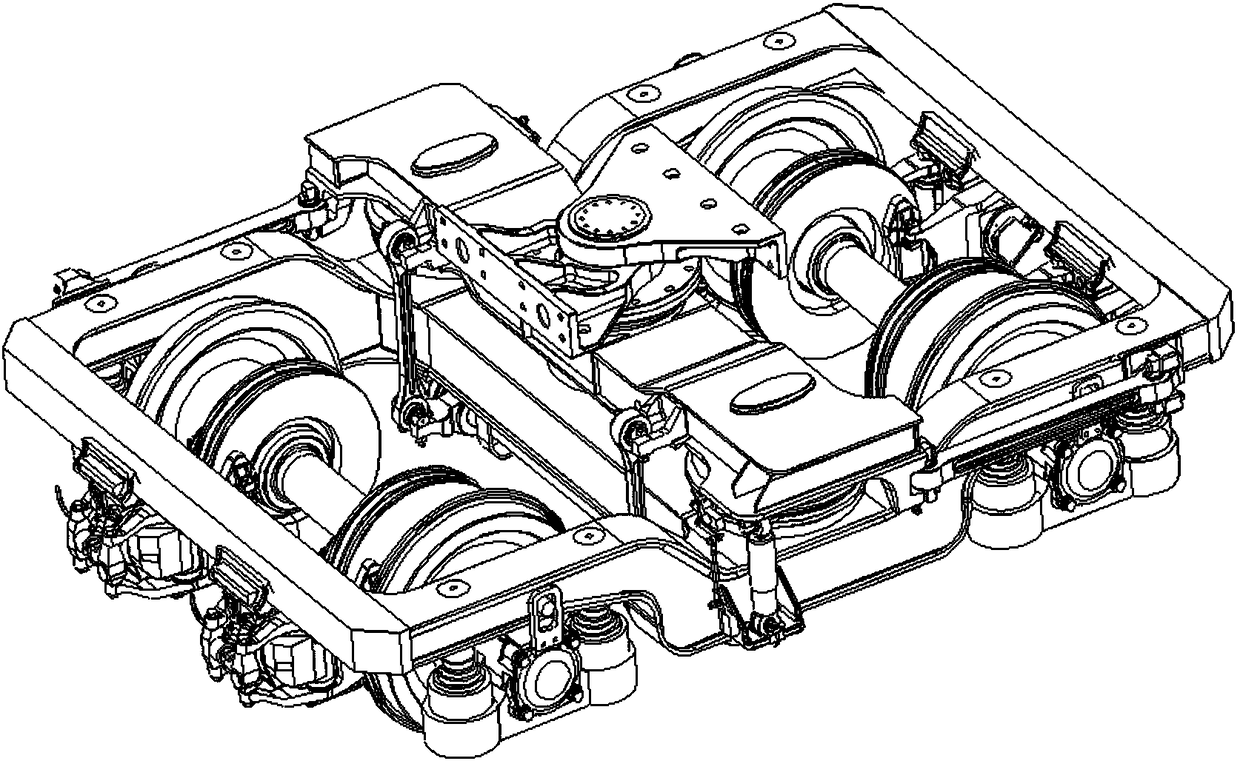

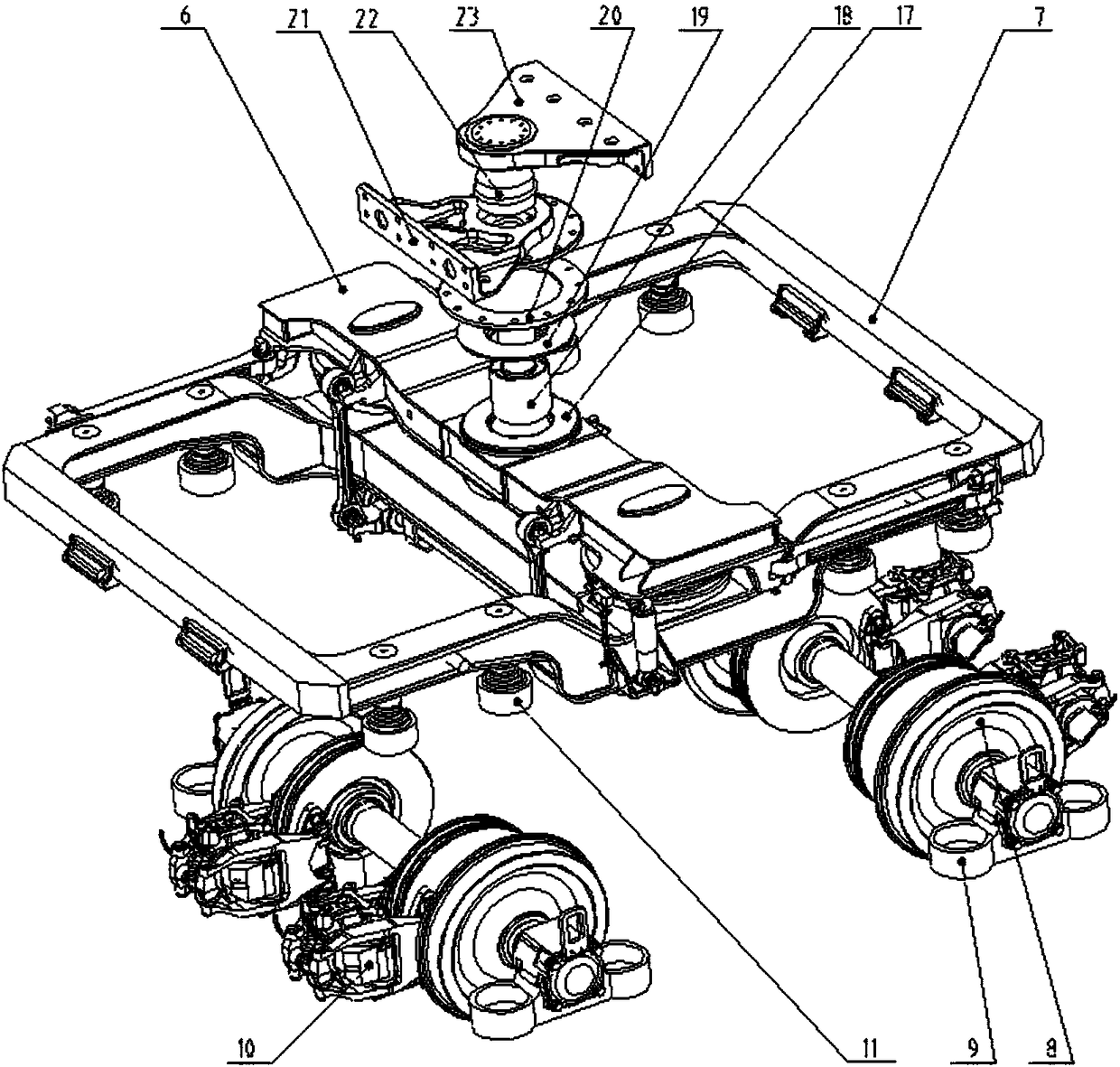

Intermediate articulated bogie with small-curve negotiation capability of six-axle high-floor light rail vehicle

ActiveCN108357510AGuaranteed uptimeImprove securityBogiesBogie-underframe connectionsArticulated bogieLight rail

An intermediate articulated bogie with small-curve negotiation capability of a six-axle high-floor light rail vehicle comprises a bolster device, a framework device, two wheelset devices, axle box devices, basic braking devices and a rotary device, wherein the bolster device is mounted on the framework device; a plurality of primary suspension devices are mounted at the bottom of the framework device; the axle box devices are separately arranged at the end parts of the two wheelset devices; the axle box devices are connected to the primary suspension devices; the basic braking devices are mounted on the wheelset devices; the rotary device is mounted on the bolster device; and the rotary device comprises a center pin rubber sleeve, a lower friction disk and an upper friction disk which arearranged on the center pin rubber sleeve in a sleeving mode, a center pin inserted in the center pin rubber sleeve, a lower articulated device connected to the center pin, and an upper articulated device connected to the lower articulated device through a spherical plain bearing. The intermediate articulated bogie has the advantages of simple structure, light weight, low cost, controllable rotaryresistance and wide application range.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Flame-retardant membrane and preparation method thereof

InactiveCN106147140AImprove flame retardancyShorten the manufacturing processSynthetic resin layered productsFlat articlesPhosphinic AcidsPolyester

The invention relates to a flame retardant film, comprising: a PET base material, a flame retardant layer is provided on both sides of the PET base material, and the thickness of the flame retardant layer is 5-20 μm, wherein the flame retardant layer consists of the following weight Raw material composition: 100‑200 parts of polyester chips, 2‑20 parts of zinc oxide, 0.1‑20 parts of decabromodiphenylethane, 0.5‑5 parts of aluminum hydroxide, 0.1‑4 parts of ammonium phosphate, 1 part of polyvinyl alcohol -10 parts, 1-5 parts of 2-carboxyethylphenylphosphinic acid. The flame-retardant film prepared by the multi-layer composite technology of the present invention has high flame retardancy, environmental protection, transparency, and heat resistance. The preparation method of the present invention shortens the production and manufacturing process, avoids environmental pollution, and has low raw material cost and is non-toxic. Environmentally friendly film.

Owner:周开雄

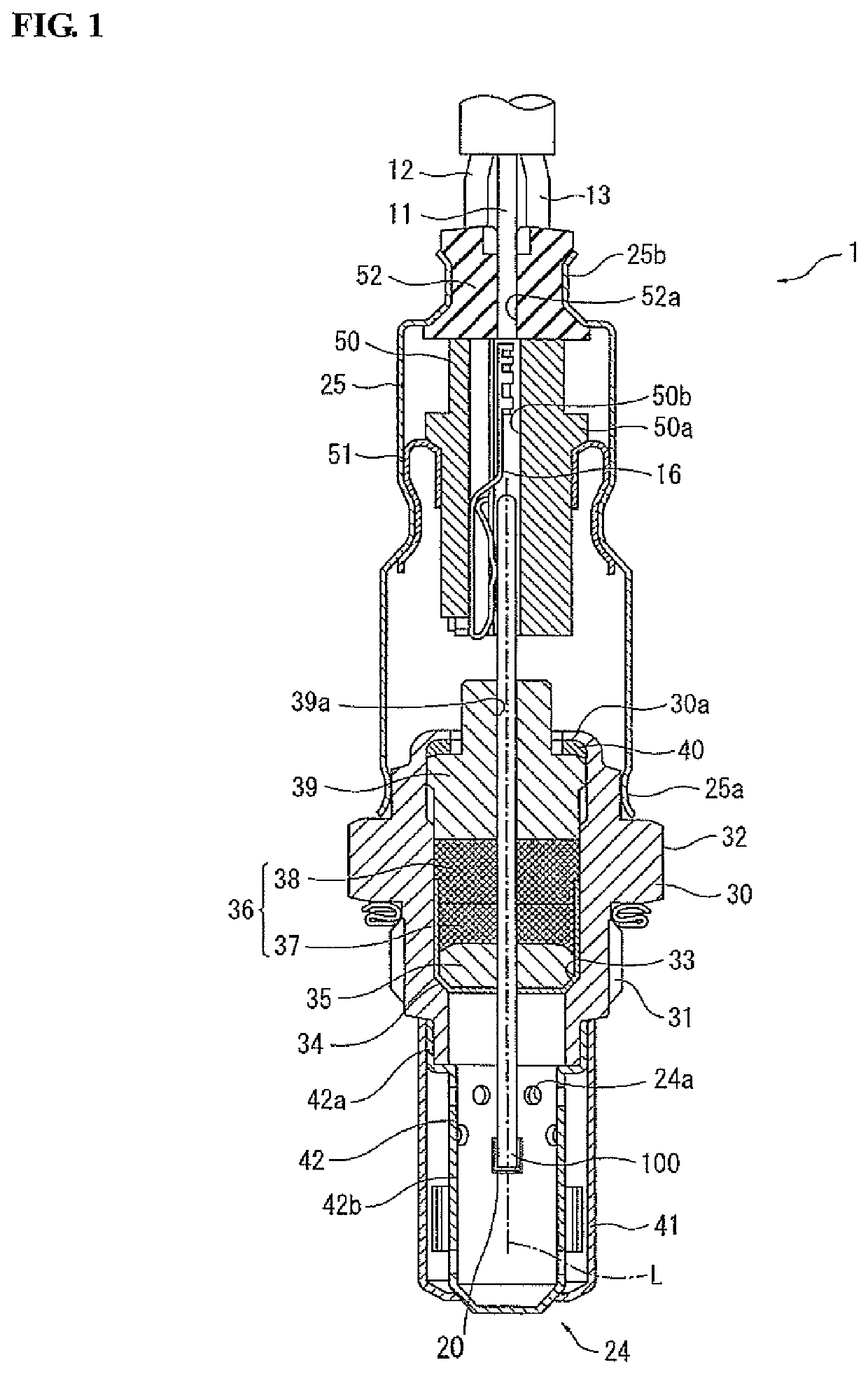

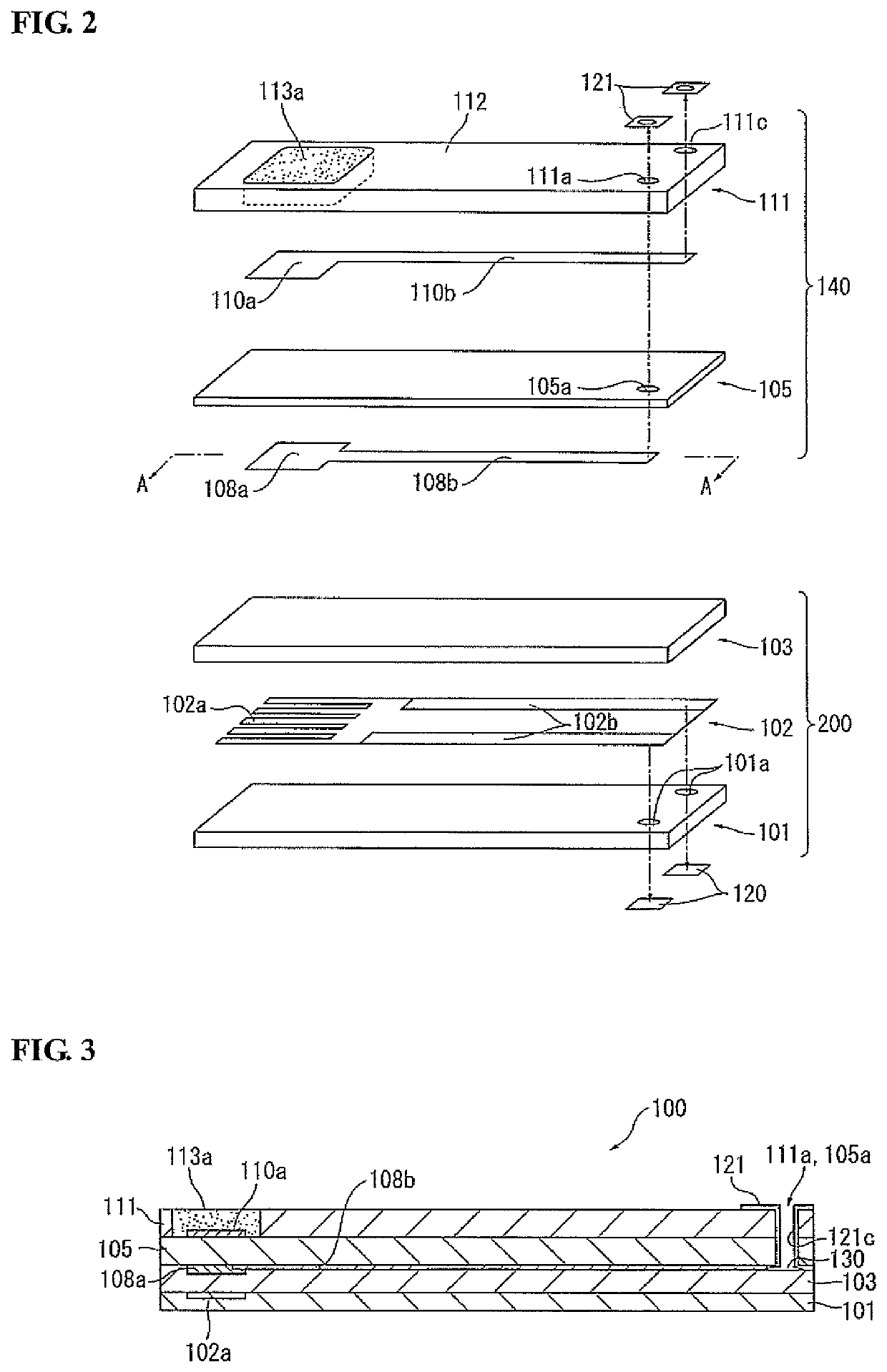

Gas sensor

ActiveUS10876991B2Stable gas detection outputReduce production processMaterial analysis by electric/magnetic meansElectrical conductorReference electrode

Owner:NGK SPARK PLUG CO LTD

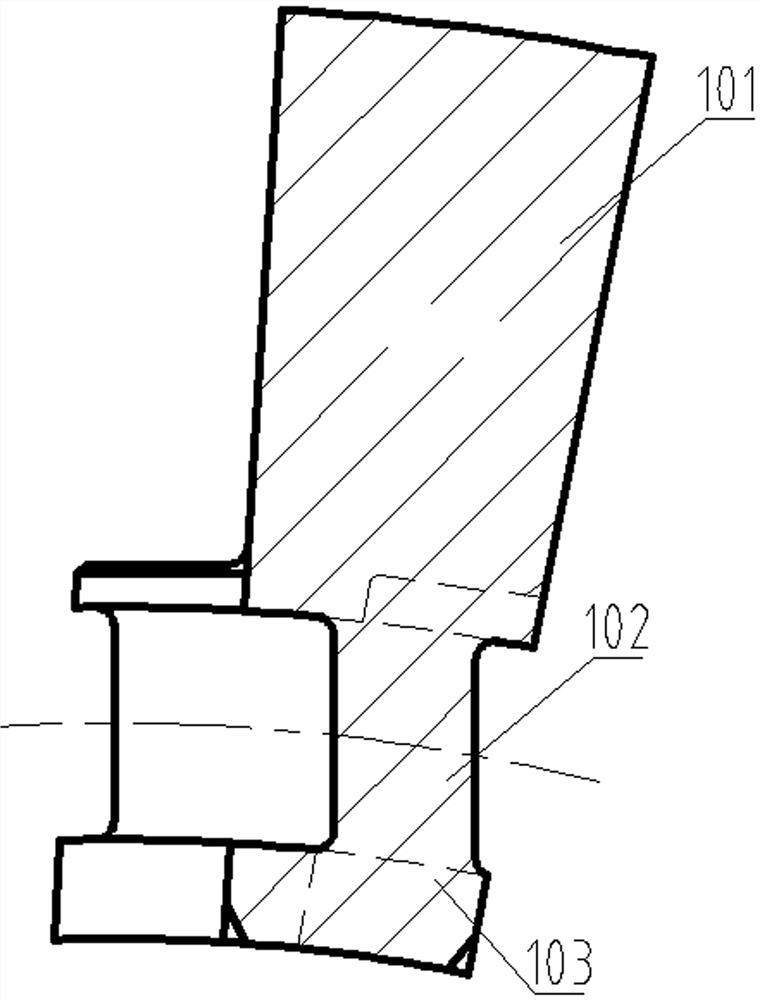

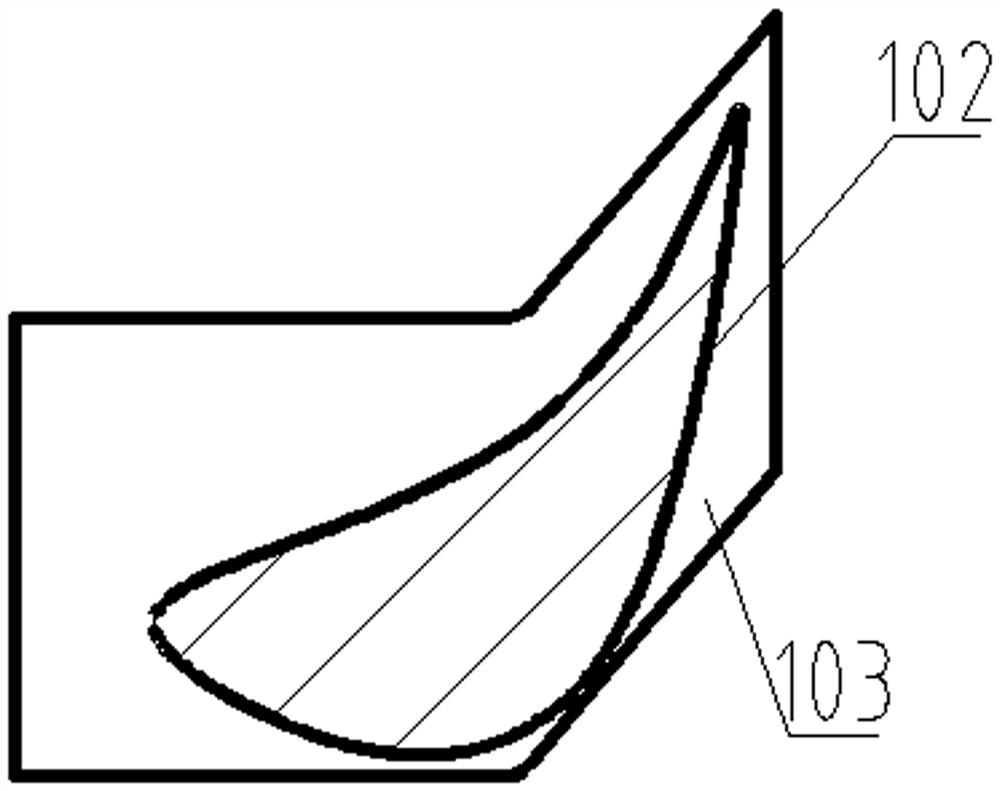

Manufacturing method of assembled stationary blade partition plate of rotary drum steam turbine

ActiveCN112589377AReduce manufacturing processShort cycleStatorsMachines/enginesRadiation raysStructural engineering

The invention discloses a manufacturing method of an assembled stationary blade partition plate of a rotary drum steam turbine. The manufacturing method comprises the following steps: a partition plate sleeve is divided into m assembly groups, a positioning ring is arranged on at least one end surface of an outer ring of each stationary blade, and the circumferential assembly surface of each stationary blade is of a plane structure through which a radiation ray passes; the stationary blades in each assembly group comprise standard stationary blades and thickened-pitch stationary blades, grooves are machined in the front end surface and the rear end surface of the inner circle of the inner ring of the stationary blade to be assembled in the middle of each assembly group, and grooves are machined in the end surface, facing the stationary blades in the same assembly group, of the inner circle of the inner ring of the stationary blade to be assembled at the end of each assembly group; anda plurality of stationary blades are sequentially arranged in each assembly group and are fixed, the stationary blades in each assembly group are welded, and every two adjacent assembly groups are notwelded, so that the assembly of a first-stage partition plate is completed. According to the manufacturing method, tedious and redundant manufacturing procedures can be greatly reduced, the manufacturing period is shortened, the cost is reduced, and the assembly efficiency is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

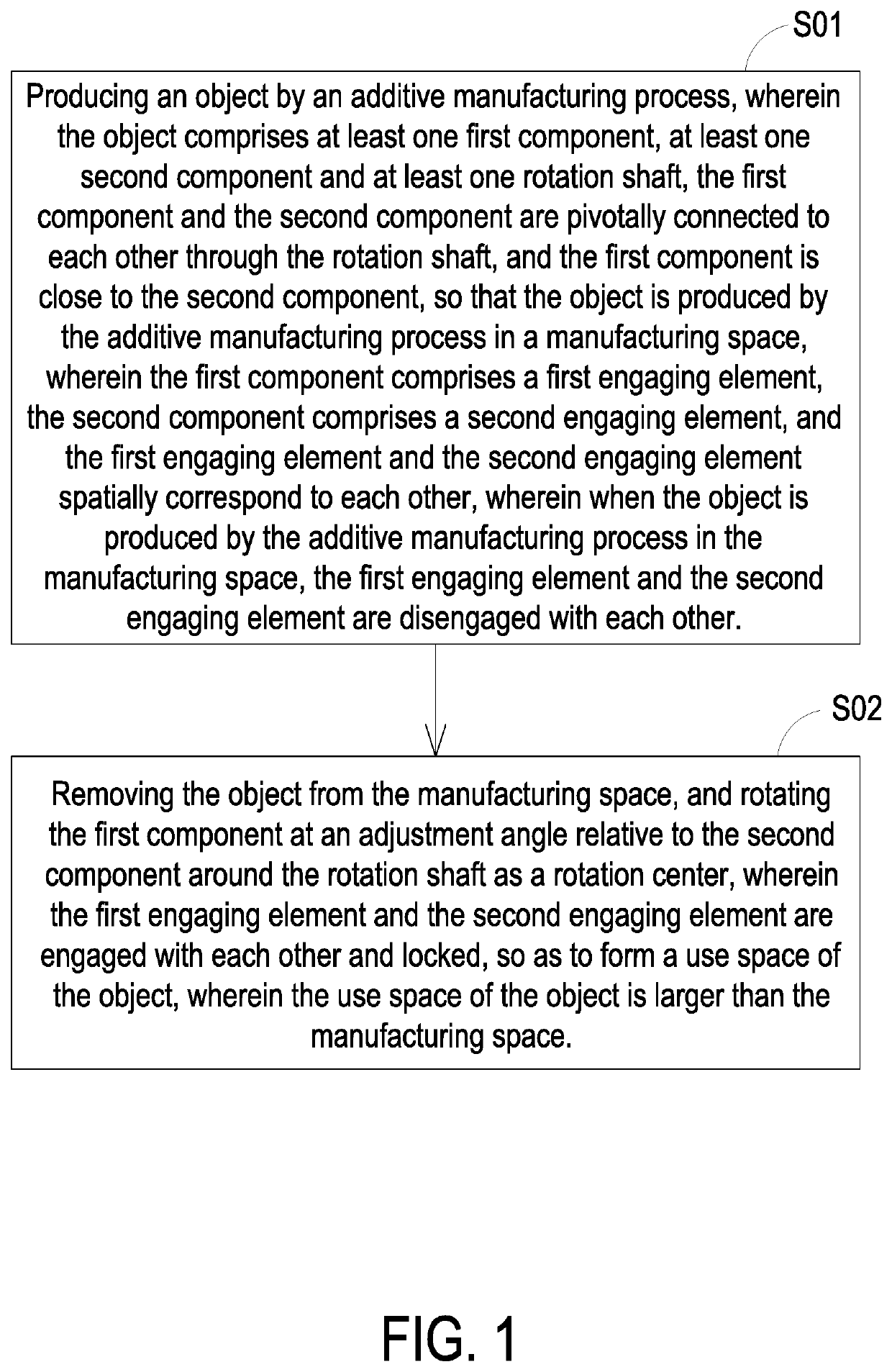

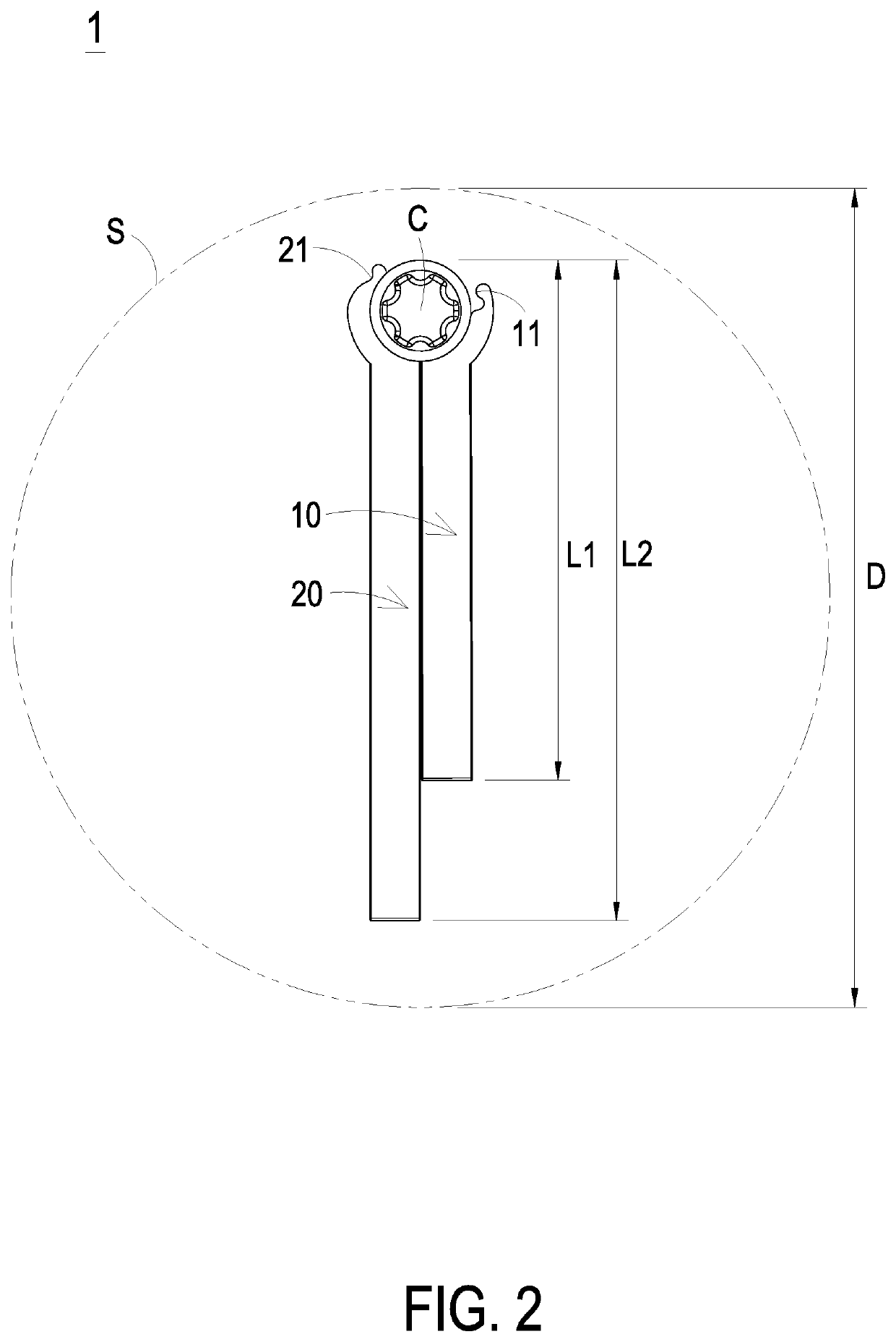

Additive manufacturing method and object manufactured thereby

ActiveUS20210178693A1Manufacturing space can be reducedSimplify the assembly processManufacturing driving meansIncreasing energy efficiencyRotational axisAdditive layer manufacturing

Owner:TECO IMAGE SYST

Annular butt joint structure of fuselage with weatherproof composite skin

InactiveCN104724276AReduce manufacturing processLow manufacturing costFuselage framesFuselage bulkheadsBiomedical engineeringButt joint

The invention relates to an annular butt joint structure of a fuselage with weatherproof composite skin. The annular butt joint structure is characterized in that a front fuselage skin body and a rear fuselage skin body are respectively borne on upper end faces of two metal machining frames, the metal machining frames are in butt joint, a boss structure is arranged at the position of the joint, the fuselage skin bodies are located on the rear side of a boss to form step difference with the boss, and a gap between the boss and the fuselage skin bodies is filled with sealant. The boss is arranged on the upper end faces of the metal machining frames, wind erosion to the end face of the composite skin can be avoided, protection means of the end face of the composite skin is simplified, and assembling cost of final assembly and partial assembly is lowered.

Owner:AVIC SAC COMML AIRCRAFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com