Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

276results about How to "To achieve the purpose of lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

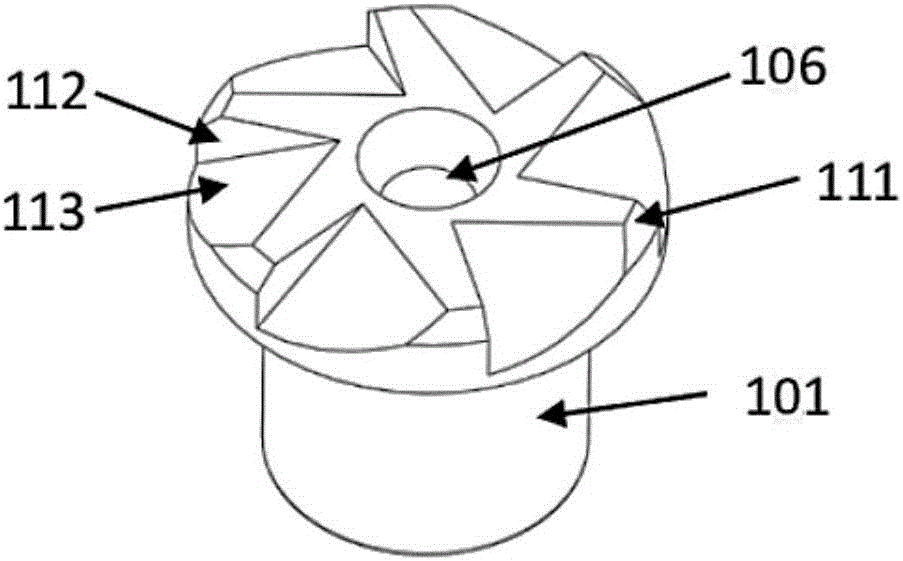

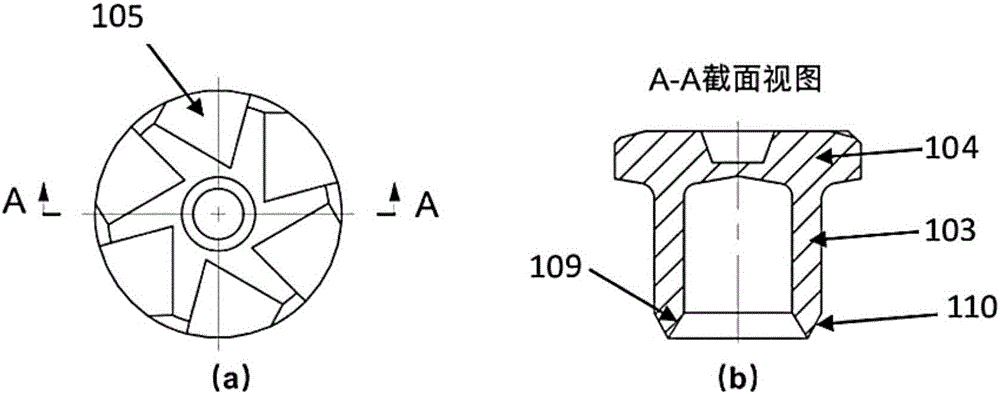

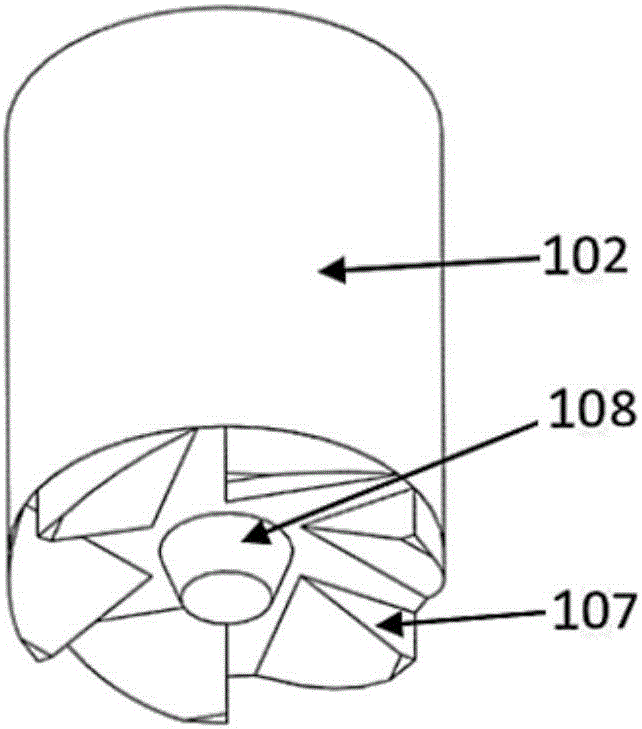

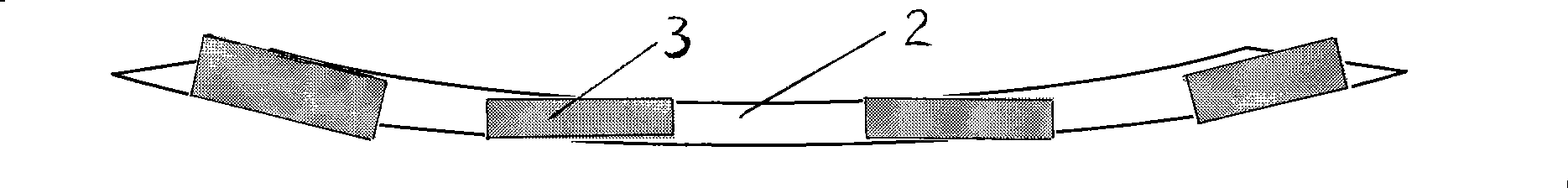

Rivet for friction-self piercing riveting (F-SPR) and F-SPR connecting system thereof

ActiveCN106112543AQuick clampingReduce weightScrewsOther manufacturing equipments/toolsEngineeringRivet

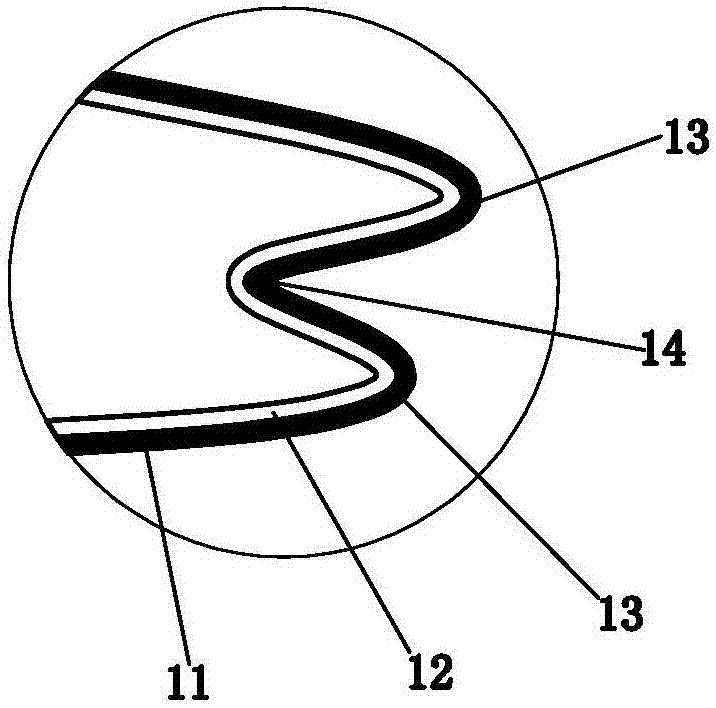

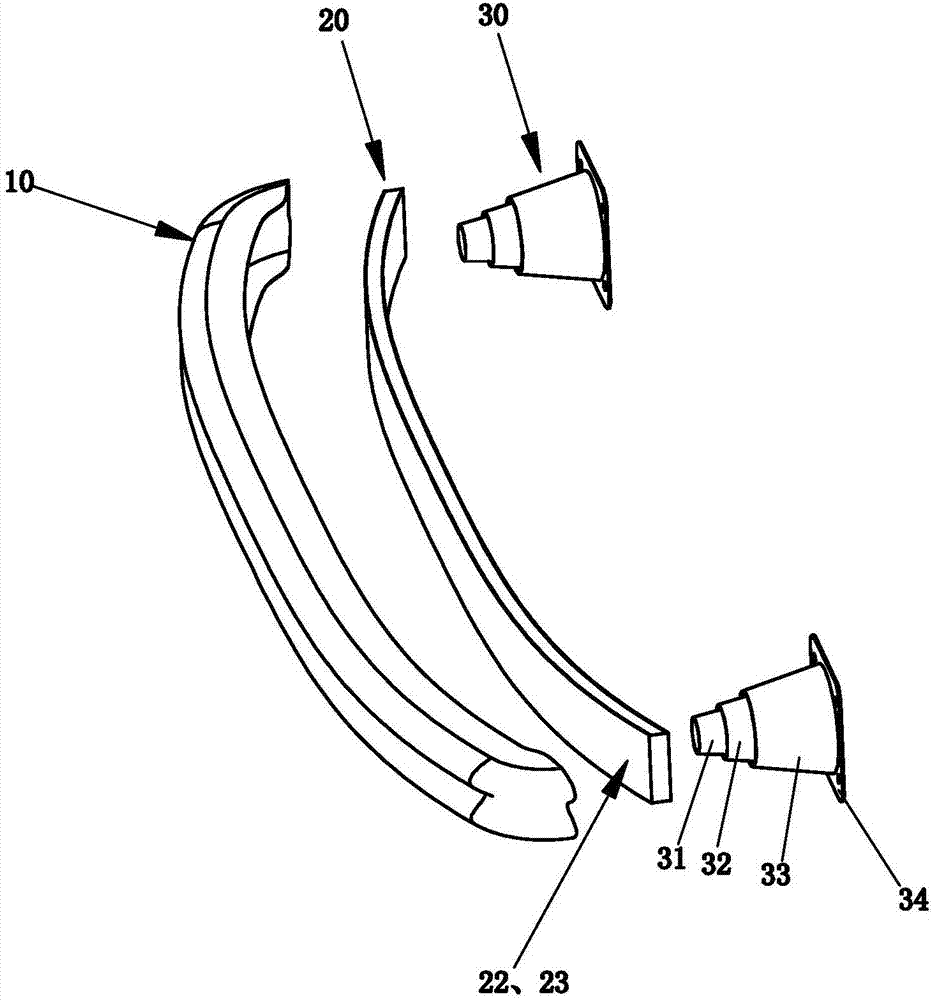

The invention discloses a rivet for friction-self piercing riveting (F-SPR) and an F-SPR connecting system thereof. The rivet comprises a semi-hollow rivet body and a rivet cap, wherein the lower surface of the rivet cap is connected with the semi-hollow rivet body; a wedge-shaped taper corner is arranged at the bottom end of the semi-hollow rivet body; chamfers for assembly and disassembly and a rotating driving structure are arranged on the edge of the upper end of the rivet cap; a locating structure is arranged in the center of the rivet cap; the rotating driving structure is a directed concave surface or a directed convex surface in central symmetry; and the locating structure is a convex surface or a concave surface in central symmetry and mirror symmetry. When the rivet is matched with a driving system for utilization, the driving rigidity and locating accuracy of the rivet during the F-SPR process can be improved, the problems that during the high-speed rotation process of the semi-hollow rivet, the stability is poor and the rivet axis and the rotation axis do not overlap are solved, the probability that a connector loses efficacy is reduced, the problem that a clearance is formed between the rivet and a panel is avoided, and the technological reliability of an F-SPR technology when connecting steel, aluminum, magnesium materials, composites and heterogeneous materials is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

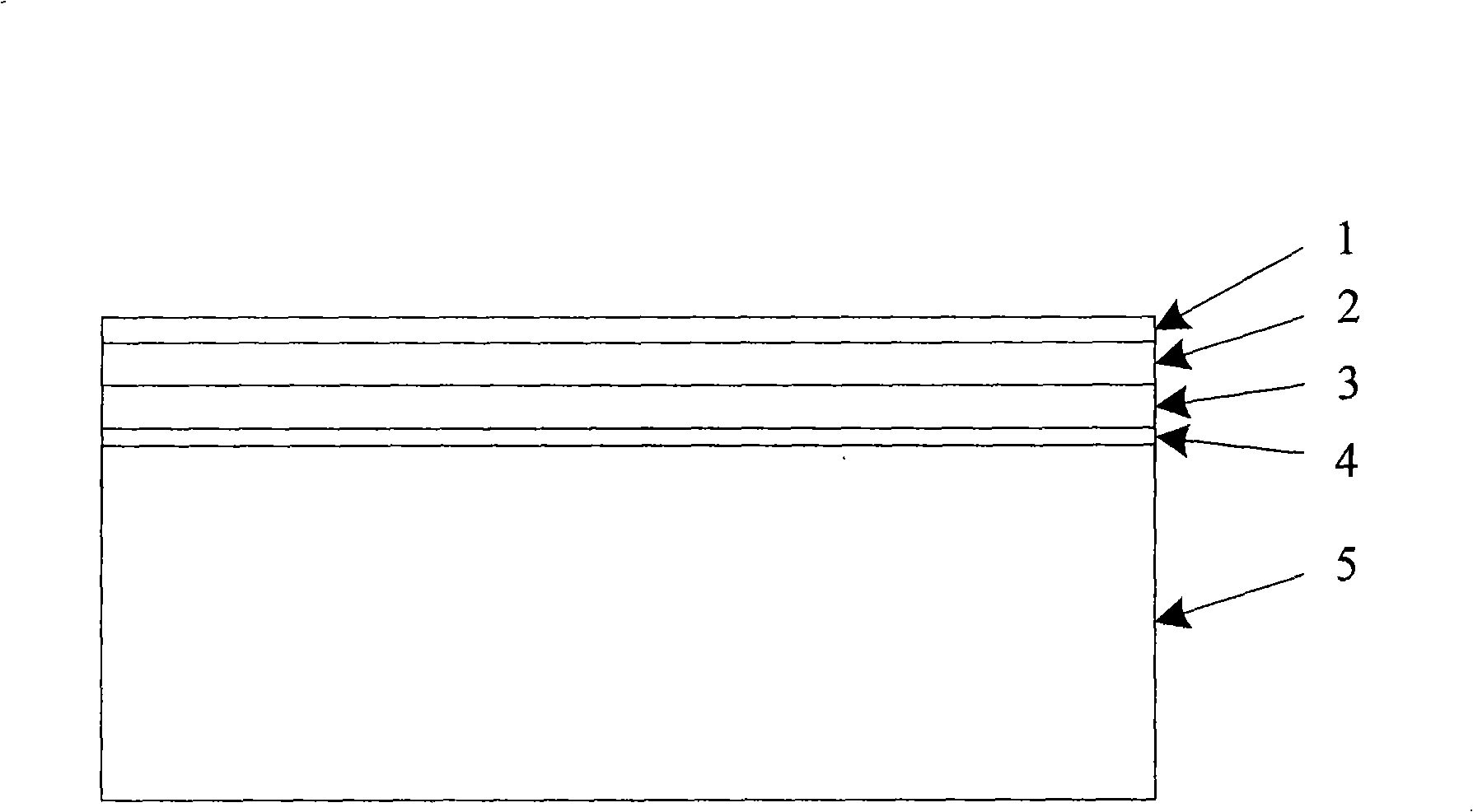

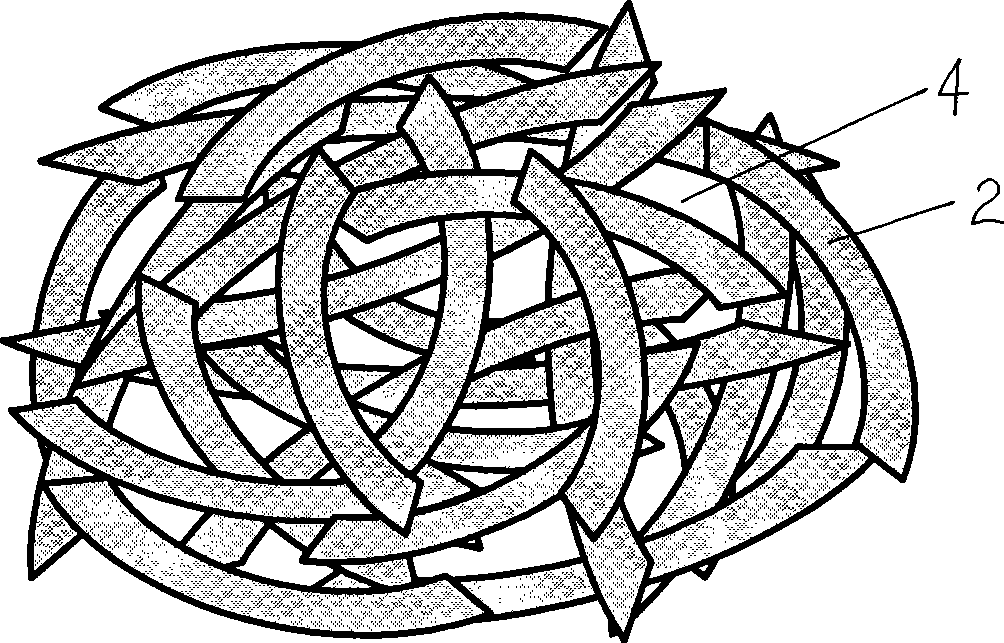

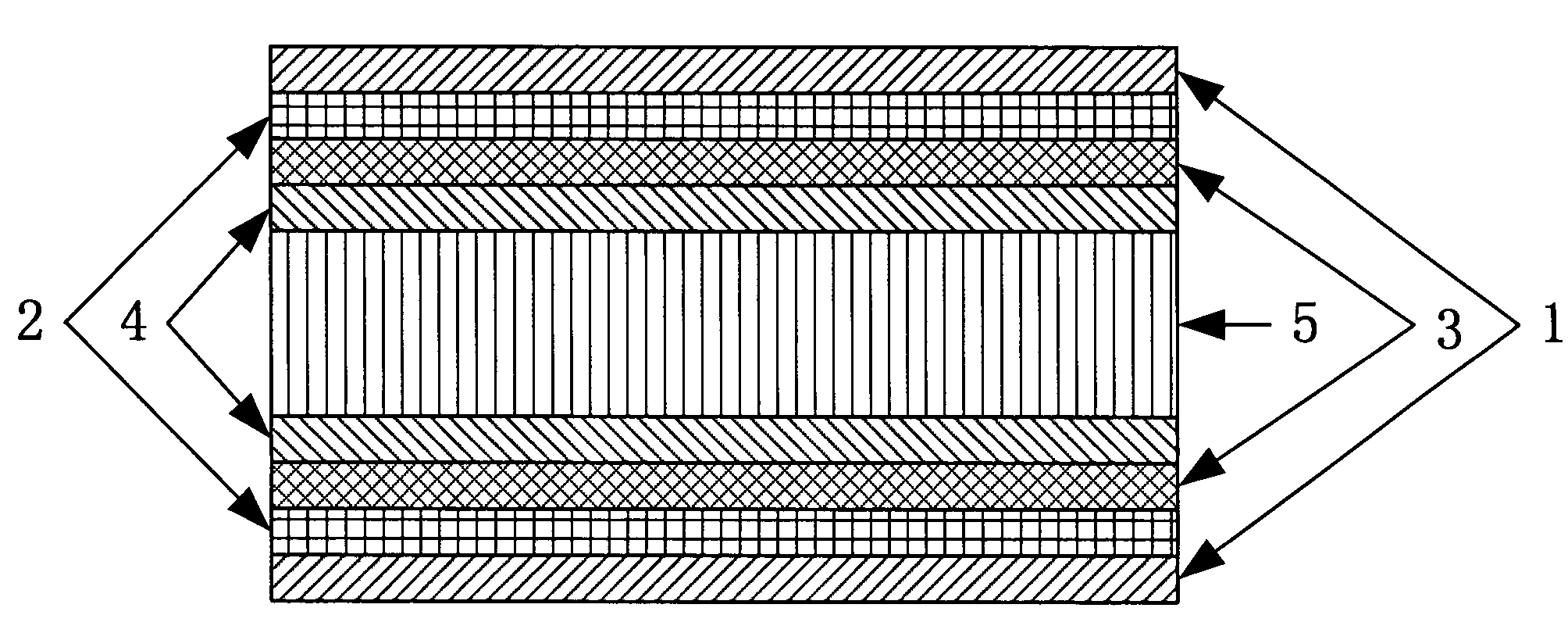

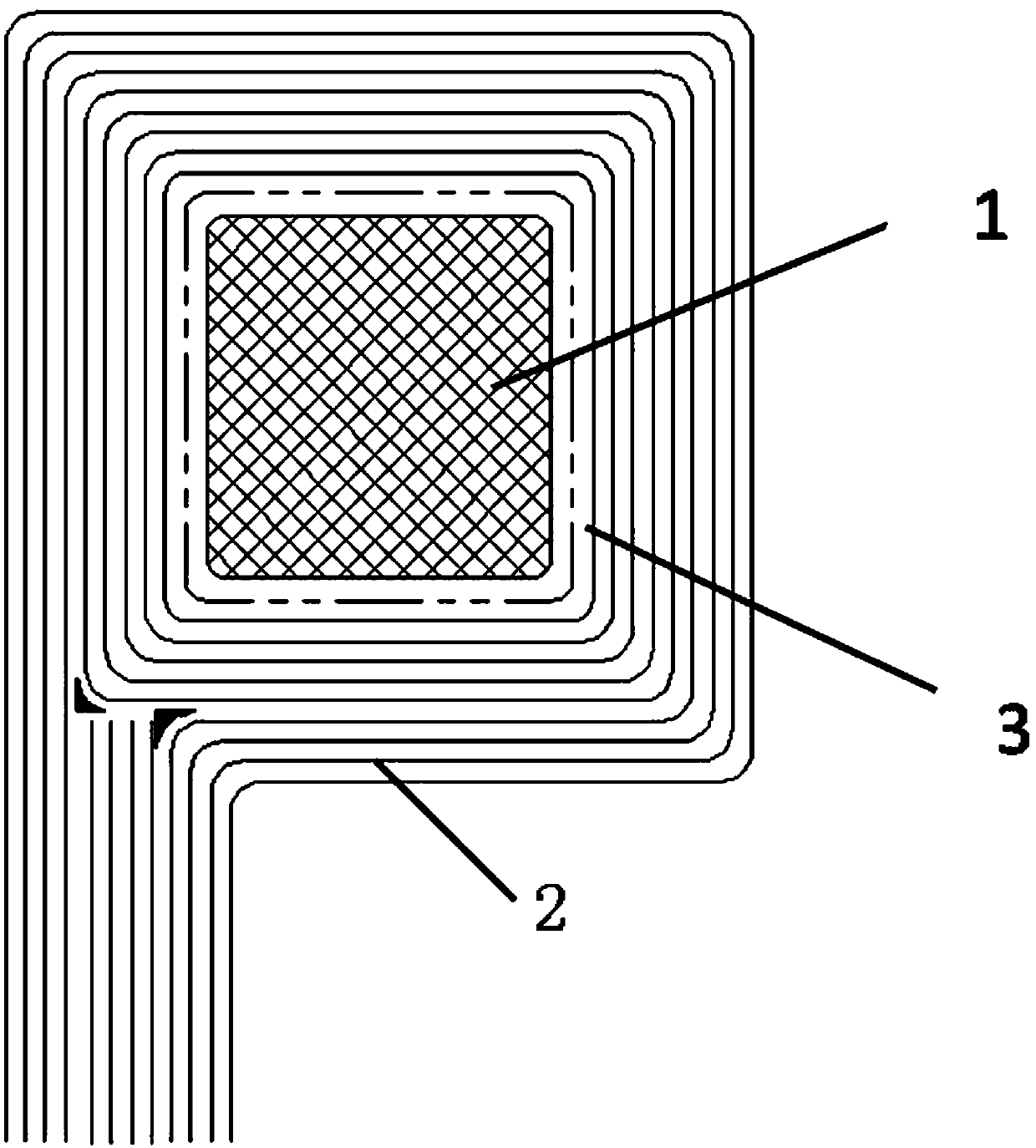

Solar cell module and preparation method thereof

ActiveCN101320760AEfficient outputTo achieve the purpose of lightweightFinal product manufacturePhotovoltaic energy generationFiberStrake

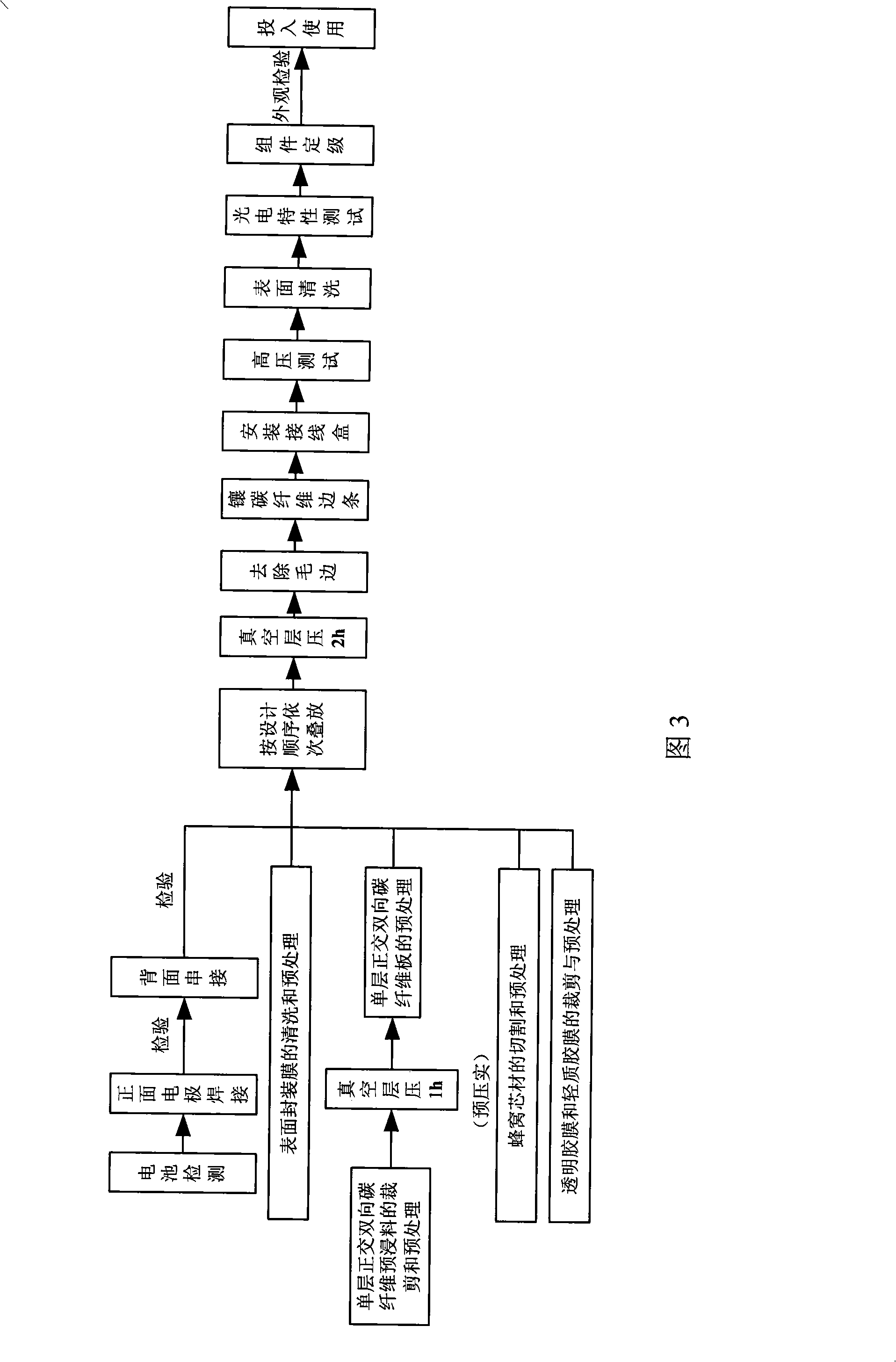

The invention provides a solar module which is composed of a surface sealing film, a transparent adhesive film, a solar cell, a lightweight adhesive film A and an isolated substrate which are stacked from the top to the bottom in order; and the isolated substrate is composed of an isolated film, a carbon-fiber sheet, a lightweight adhesive film B, a honeycomb core, a lightweight adhesive film C and the carbon-fiber sheet which are stacked from the top to the bottom in order, wherein the honeycomb core inside also needs to be appropriately added embedded parts according to concrete operating requirements. The technical scheme of a preparation method of the solar module comprises following steps: (1) making use of an oven to match with a vacuum air pump to process a pre-compacting treatment for a carbon-fiber prepreg; (2) meanwhile, processing a welding sequence of the solar cell; (3) processing a cutting sequence; (4) processing a laminating technology treatment; (5) processing post treatment procedures which in order are: removing raw edges, embedding strakes, arranging a junction box, measuring high voltage, cleaning the surface, measuring photo-electrical output characteristics, classifying components, and examining the appearance. The solar module has the advantages of lightweight, high efficiency and good low-temperature characteristics, and being very suitable to being applied in the stratosphere.

Owner:BEIHANG UNIV

Preparation method of hot-rolled acid-washing high-strength steel for automobile carriage

The invention relates to a preparation method of hot-rolled acid-washing high-strength steel for an automobile carriage. The hot-rolled acid-washing high-strength steel comprises the following major ingredients in percentage by weight: 0.07 percent to 0.1 percent of C, at most 0.05 percent of Si, 1.5 percent to 1.9 percent of Mn, at most 0.015 percent of P, at most 0.01 percent of S, at most 0.005 percent of N, 0.1 percent to 0.2 percent of Mo, 0.04 percent to 0.06 percent of Nb, 0.15 percent to 0.2 percent of Ti, 0.02 percent to 0.04 percent of Al, 0.001 percent to 0.004 percent of B, 0.002 percent to 0.01 percent of Ca and the balance of Fe and inevitable impurities, Ti / B is greater than or equal to 35, and the carbon equivalent Ceq is smaller than or equal to 0.45 percent. The preparation method has the advantages that the ingredients are simple, the production process is simple, the tempering or hardening and tempering treatment is not needed after hot rolling, the surface qualityis good, the obdurability, the welding performance and the cold forming performance are excellent, and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

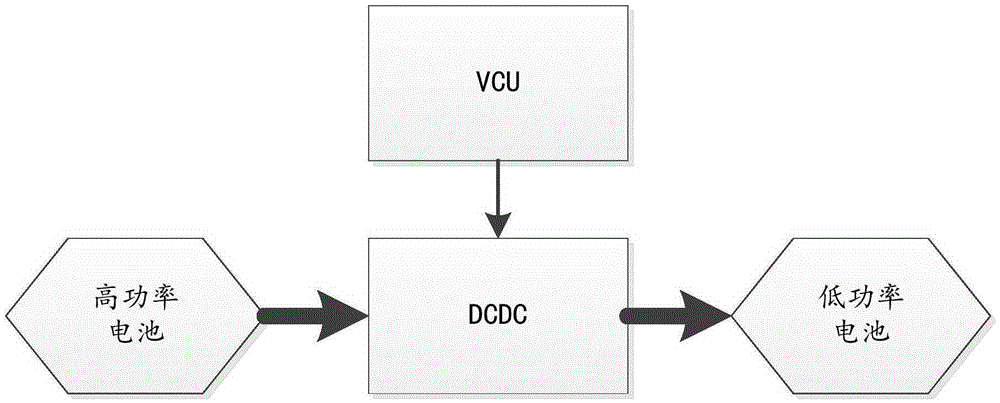

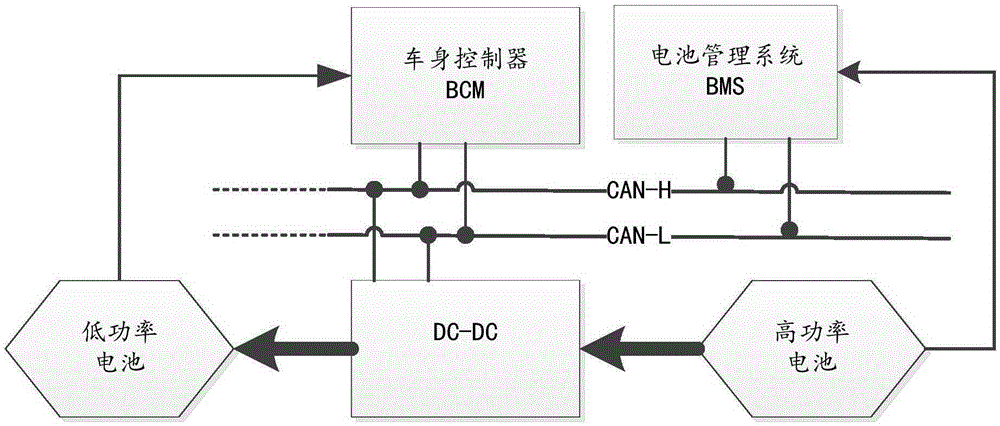

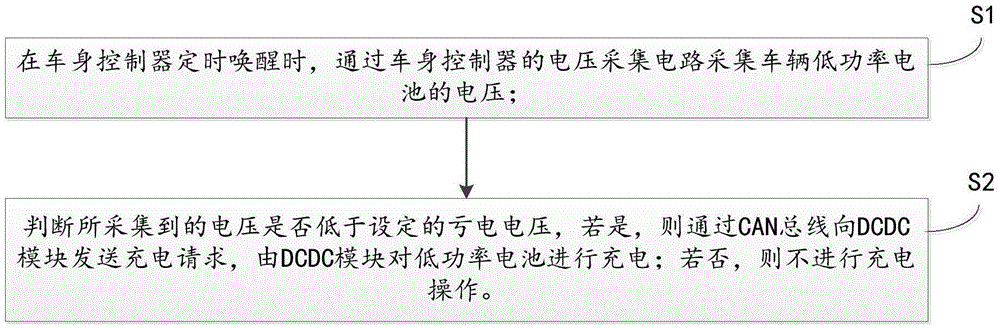

Method and device for controlling low-power battery of electric automobile

ActiveCN105305541AReduce weightTo achieve the purpose of lightweightBatteries circuit arrangementsElectric powerPower batteryElectricity

Owner:FJ MOTOR GRP YUDO NEW ENERGY AUTOMOBILE CO LTD

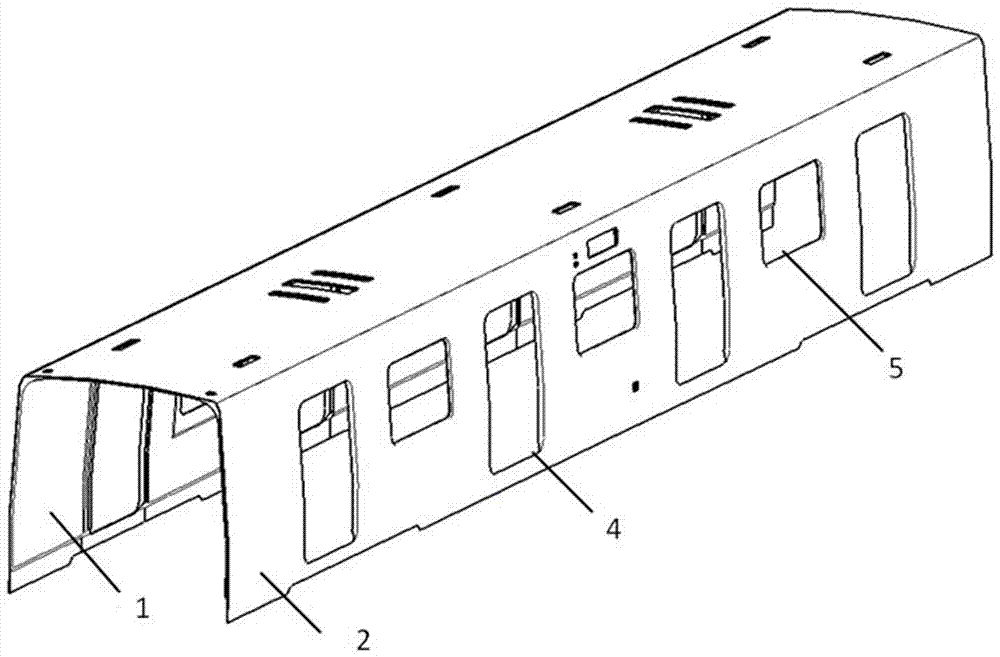

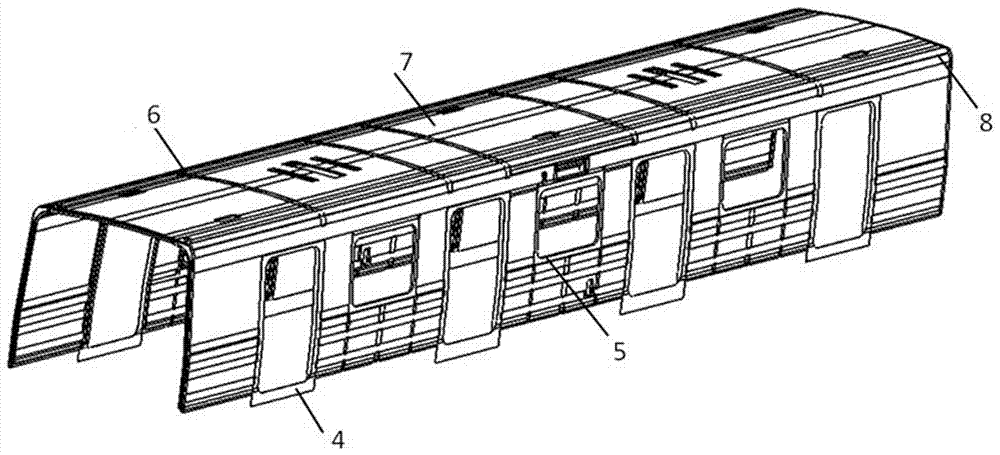

Low-cost technologically-molded carbon fiber composite material subway vehicle body and manufacturing method thereof

InactiveCN107214977AImprove sound insulationReduce in quantityDomestic articlesHoneycombFibrous composites

The invention discloses a low-cost technologically-molded carbon fiber composite material subway vehicle body and a manufacturing method thereof. The subway vehicle body comprises a carbon fiber outer covering, a carbon fiber inner covering, and a sandwich layer paved between the carbon fiber outer covering and the carbon fiber inner covering. The invention also discloses a manufacturing method of the carbon fiber composite material subway vehicle body, which comprises the following steps: (1) paving and adhering carbon fiber fabric prepregs, carrying out OOA technological molding on carbon fiber outer covering; (2) paving honeycombs, foams and pre-modled pre-embedded parts on the carbon fiber outer covering to be used as the sandwich layer, and carrying out OOA technological molding on the sandwich layer; (3) paving and adhering the the carbon fiber fabric prepregs on the sandwich layer, and carrying out OOA technological molding on the carbon fiber inner covering, i.e. integration on the vehicle body. According to the low-cost technologically-molded carbon fiber composite material subway vehicle body and a manufacturing method thereof disclosed by the invention, the weight of the subway vehicle body is effectively reduced, the aim of the lightweight of the vehicle body is fulfilled, the energy consumption of the vehicle body is reduced, and the service life of the vehicle body is prolonged; moreover, by adopting the OOA molding technology with low cost, the cost of the molded carbon fiber composite material subway vehicle body is greatly reduced.

Owner:HENGSHEN

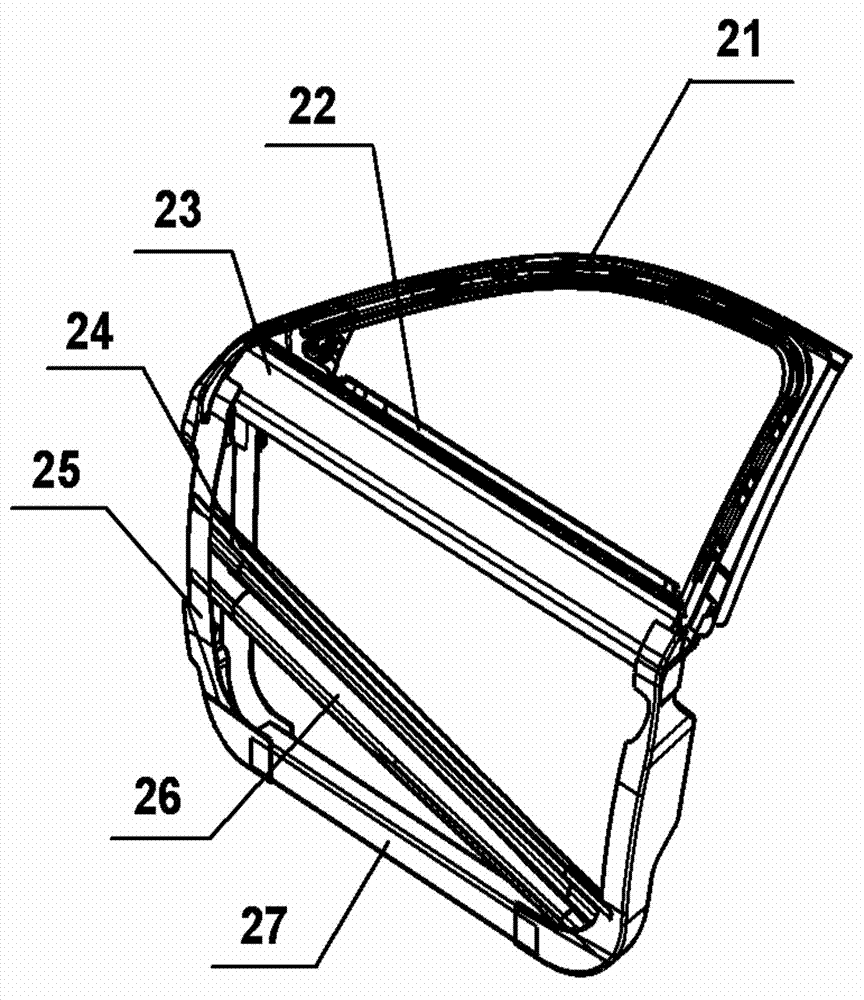

Modularized vehicle door with steel, aluminum and plastic mixed

The invention relates to a modularized vehicle door with steel, aluminum and plastic mixed. Compared with a total complex structure of a traditional vehicle door, according to the modularized vehicle door with steel, aluminum and plastic mixed, the original complex vehicle door structure is modularized, and the vehicle door structure is divided into three functional modules which include a vehicle door outer plate, a vehicle door frame, a vehicle door inner plate and an accessory module. According to the functionality of all parts of the vehicle door, traditional vehicle door modules are functionalized, and good vehicle door manufacturing and assembling manufacturability is achieved. The modularized vehicle door with steel, aluminum and plastic mixed is specifically characterized in that the vehicle door outer plate is not a main stressed part in the vehicle door structure, the strength and rigidity requirements are moderate, and the purpose generally lies in the effect that the functional requirements for meeting external shapes are improved; the vehicle door inner plate is not a main stressed part, either, and can be made of composite materials or plastic. According to the modularized vehicle door with steel, aluminum and plastic mixed, factors in all the aspects of strength, rigidity, appearance and weight are taken into comprehensive consideration, the vehicle door outer plate can be made of thinner metal material plates and aluminum alloy materials, and the aluminum alloy materials are light, small in specific gravity, high in strength, good in ductility, and high in corrosion resistance and meanwhile has good forming performance, machinability and the like.

Owner:HUNAN UNIV

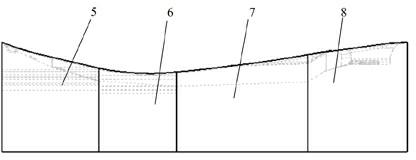

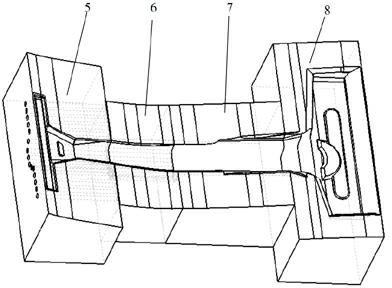

Forming method of variable strength hot stamped piece and die

InactiveCN102319835AImprove the ability to resist side impact deformationEasy to absorbShaping toolsVehicle componentsHot stampingEngineering

An automotive structural component needs high strength to ensure collision safety, and meanwhile, the specific part needs relatively low strength and relatively high toughness to realize high comprehensive performance so as to achieve energy absorption effect and realize good comprehensive protection function. The conventional structural component cannot meet the actual using requirement due to consistent integral performance, or has different implementing performance, complex process and hidden performance worries at the combined position due to an assembled mode. According to different local performance requirements of parts, the invention designs a hot stamping die comprising modules of different cooling efficiency, wherein the die is used for manufacturing body safety protection structural components with high performance, light weight and low cost. Only one specific die insert of the hot stamping die comprises a cooling duct, or the positions, the size and the arrangement of cooling ducts of sub blocks are distinguished and designed according to the performance requirements; and the produced hot formed structural component such as a column B reinforcing plate lightens the integral weight of the original part, promotes the lateral collision deformation resistance of an automobile, and meanwhile can well absorb collision energy.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

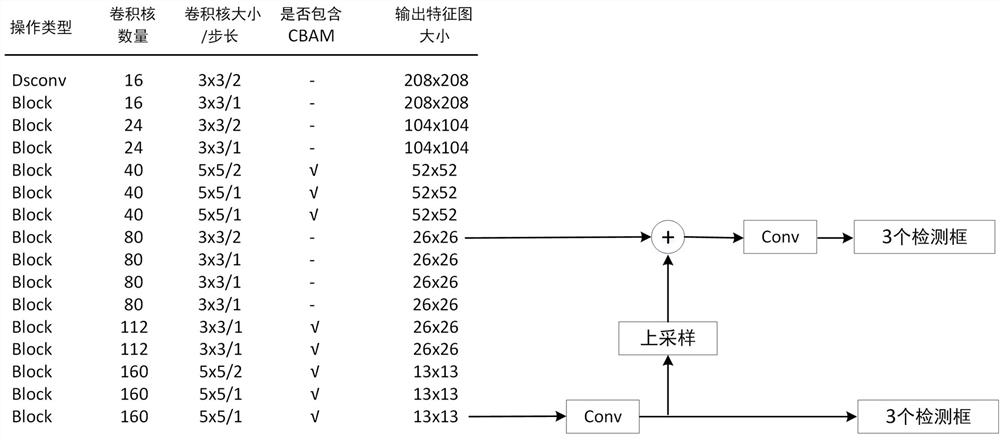

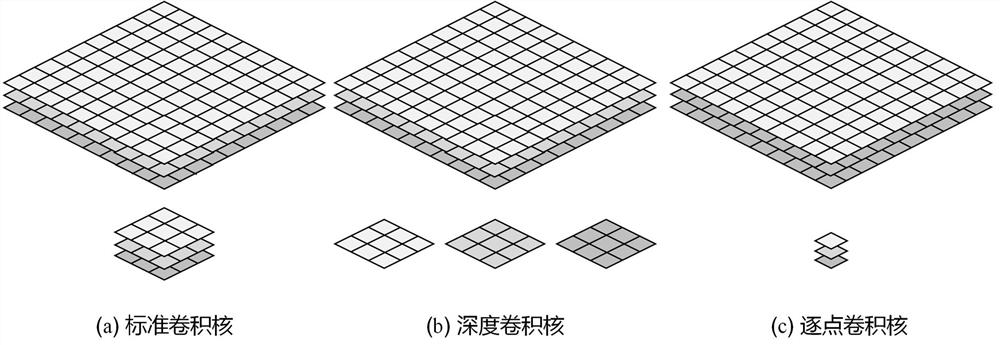

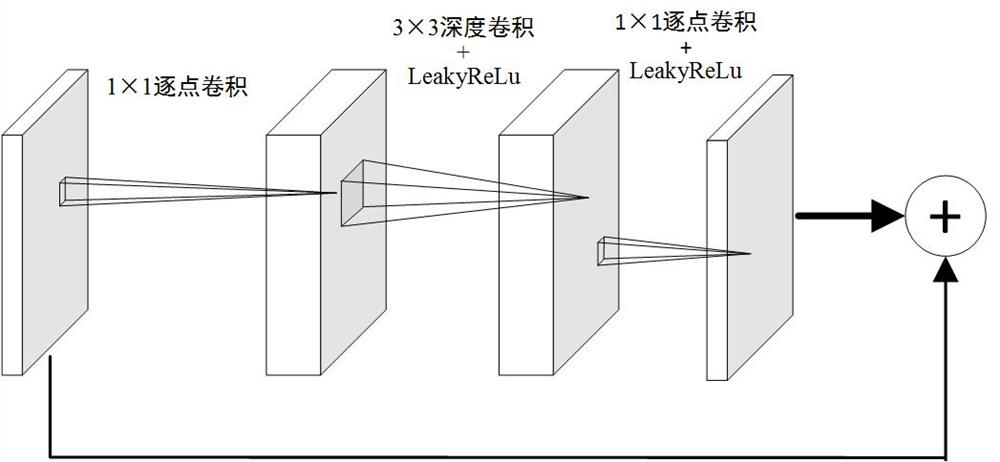

Bridge surface crack detection method based on YOLO v3 and attention mechanism

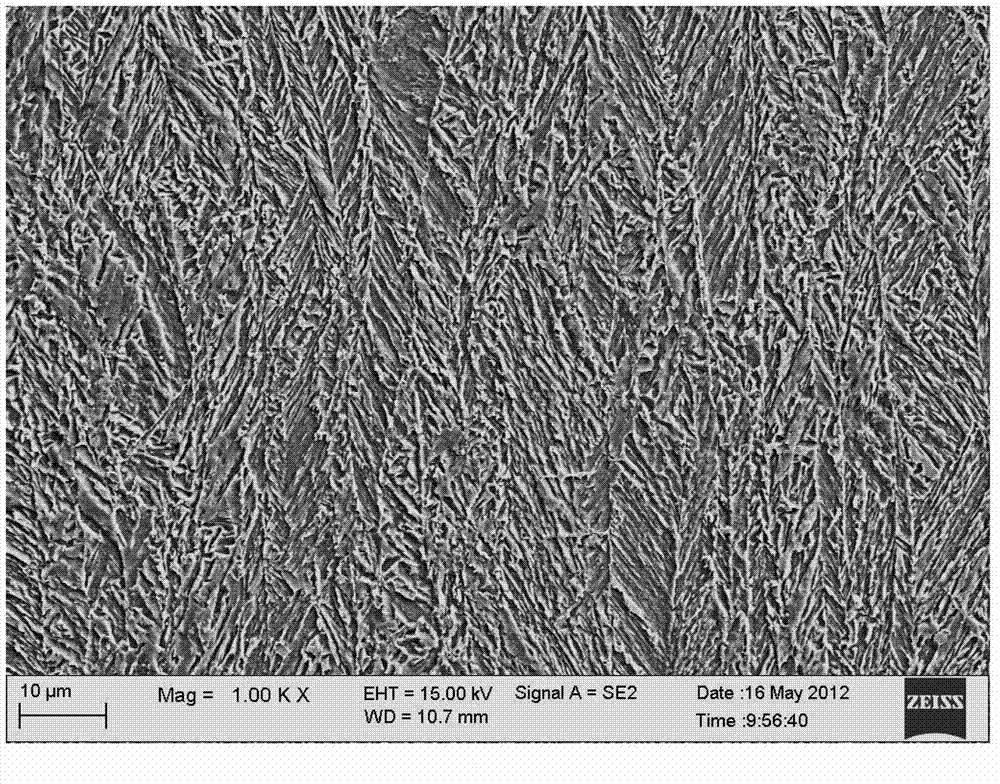

The invention relates to a bridge surface crack detection method based on YOLO v3 and an attention mechanism. The method comprises the following steps: dividing a data set into a training set and a test set; a Crack-YOLO network is constructed, and an output detection box of the network is optimized; training the optimized Crack-YOLO network by adopting the training set, and testing the trained Crack-YOLO network by adopting the test set; and inputting a to-be-tested picture into the Crack-YOLO network passing the test so as to detect cracks on the surface of the bridge. The bridge crack can be accurately recognized and positioned.

Owner:FUZHOU UNIV

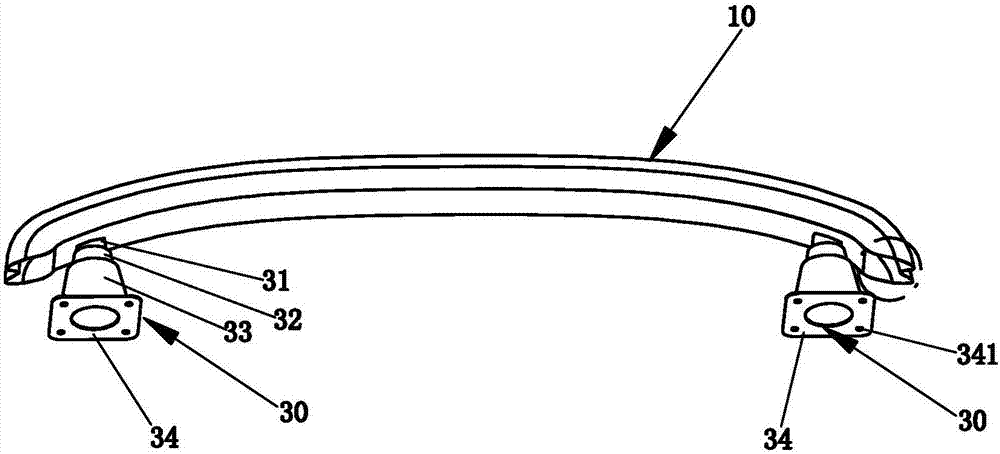

Automobile front anti-collision beam structure and application thereof to automobiles

ActiveCN107985237AObvious graded featuresImprove buffering effectInternal combustion piston enginesBumpersSingle stageThree stage

Disclosed are an automobile front anti-collision beam structure and application thereof to automobiles. The automobile front anti-collision beam structure is composed of a main beam, an inner plate and an energy absorbing device, wherein the inner plate is fixedly connected to the main beam; the energy absorbing device is fixedly connected to the inner plate and at least composed of a bottom plate, a first conical tube, a second conical tube and a third conical tube; the bottom ends of the first conical tube, the second conical tube and the third conical tube are fixedly mounted onto the bottom plate, and the first conical tube, the second conical tube and the third conical tube are gradually nested from inside to outside; the heights of the three conical tubes are gradually reduced from inside to outside, the diameters of the bottom ends of the three conical tubes are gradually increased from inside to outside, the thicknesses of the three conical tubes are gradually increased from inside to outside, and the tapers of the three conical tubes are gradually increased from inside to outside. According to the automobile front anti-collision beam, when collision deformation occurs, crumple of a single stage gradually develops into simultaneous crumple of two stages and then into simultaneous crumple of three stages, plastic deformation can be gradually increased, a regular and stable deformation mode and significant buffer effects can be achieved, and energy absorption can be gradually increased. Therefore, the automobile front anti-collision beam can enhance structural stability and crashworthiness and meanwhile improve the collision angle adaptability.

Owner:HUAQIAO UNIVERSITY

Composite dot-matrix interlayer double-skin cylindrical shell structure with metal liner for bearing inner pressure and preparation process thereof

ActiveCN107891634AHigh precisionReduce defectsSynthetic resin layered productsLaminationWinding machineFiber

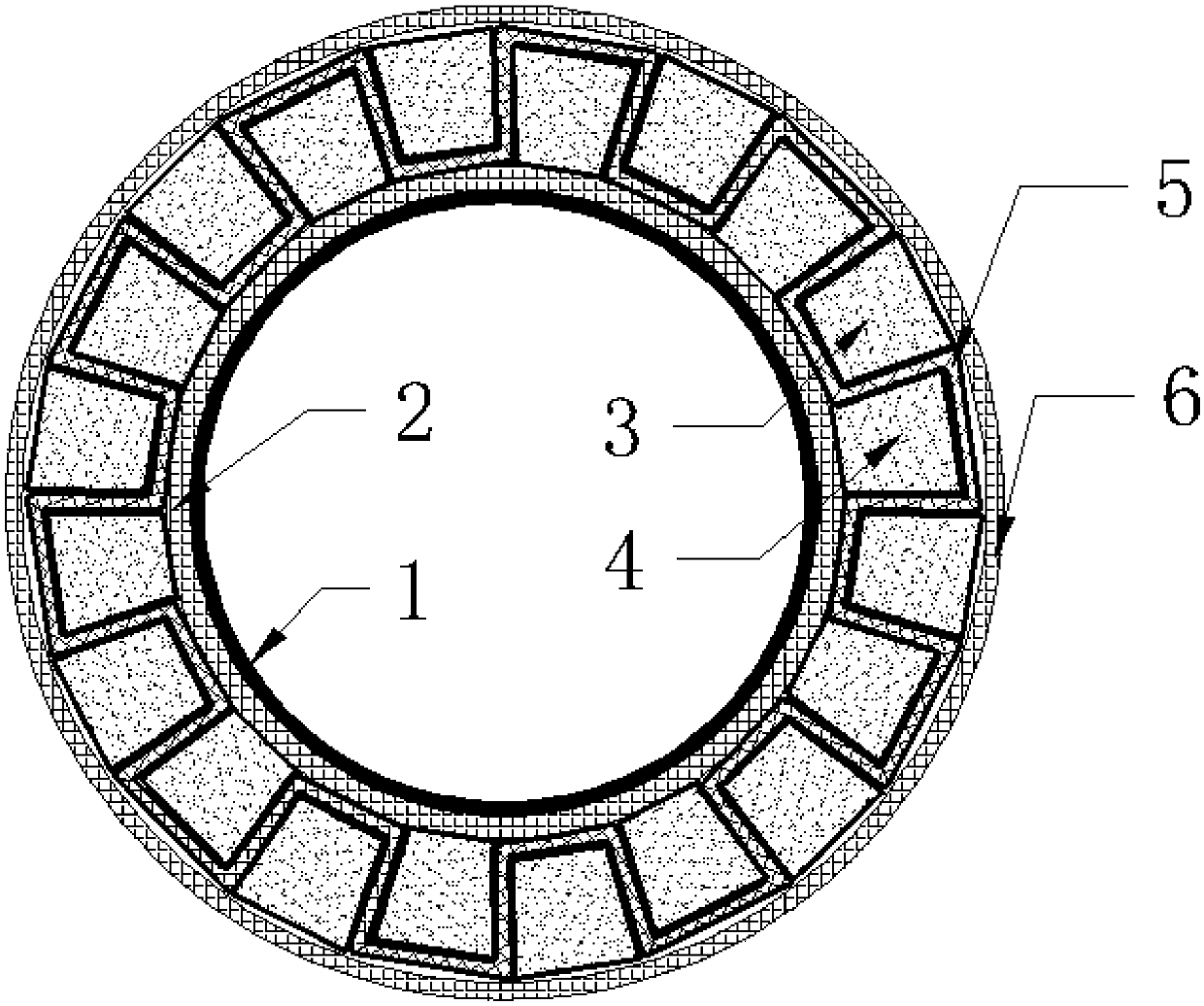

The invention discloses a composite dot-matrix interlayer double-skin cylindrical shell structure with a metal liner for bearing inner pressure and a preparation process thereof, and relates to a preparation process of lightweight pressure bearing containers and pipelines with high automation level and large size. The preparation process of the structure aims at solving the problems that organic integration of high intensity, high rigidity and light weight cannot be well achieved on existing composite cylindrical shells, conventional preparation processes are complex, and batched production oflarge-scale structures is not achieved easily. The adopted preparation process includes the steps that the metal liner is wound with preset cellosilk on a winding machine to form an inner skin; a dot-matrix interlay core containing foam strips and corrugated ribs is laid; the outer wall of the dot-matrix interlayer core is wound with preset cellosilk to form the outer skin; the structure is placed in a solidifying stove for solidification to prepare the composite dot-matrix interlayer double-skin cylindrical shell structure with the metal liner.

Owner:NANJING UNIV OF TECH

Robust automobile body material matching method based on multi-objective continuous orthogonal method

InactiveCN103218500ALow costShorten the overall cycleSpecial data processing applicationsTarget ResponseThree level

The invention discloses a robust automobile body material matching method based on a multi-objective continuous orthogonal method. The method mainly comprises the following steps: creating a collision finite element model through actual collision states and conditions; and then, determining an optimization target, constraint conditions and design variables to be optimized, and creating a three-level orthogonal table; obtaining target response values through numerical simulation calculation, calculating target signal to noise ratios and obtaining correction response values; and finally, reasonably selecting an optimal solution through the determined comprehensive evaluation value, judging the designed target satisfies an iteration judging condition, if not, using the current optimal solution as the initial solution of the next iteration step until the iteration judging condition is satisfied. According to the invention, automobile body design can be further guided reasonably, and the automobile safety performance and lightweight design level are improved.

Owner:HUNAN UNIV

Photo-curing thermoplastic fiber-reinforced epoxy composite material and preparation method thereof

ActiveCN103660310AImprove processing and manufacturing speedRealize mass productionFiberLiquid state

The invention discloses a photo-curing thermoplastic fiber-reinforced epoxy composite material and a preparation method thereof. During preparing, trimethylolpropane triacrylate is taken as a diluent monomer to prepare an epoxy acrylate diluent; the epoxy acrylate diluent and a photoinitiator are mixed and heated into a liquid glue state to obtain liquid photosensitive resin; a piece of thermoplastic fiber-reinforced cloth is coated with the liquid photosensitive resin in a brushing manner, and a piece of prepreg cloth is prepared; and the prepreg cloth is paved on a forming mold and placed on UV(ultraviolet) curing forming equipment for curing forming, so that the thermoplastic fiber-reinforced epoxy composite material is obtained. The thermoplastic fiber-reinforced epoxy composite material can be used for manufacturing a novel electromobile body support frame. The novel photo-curing electromobile body support frame manufactured with the method is good in performance and environment-friendly, and has no harmful influence on a human body and surrounding environment, and simultaneously, the curing effect meets the national standard.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

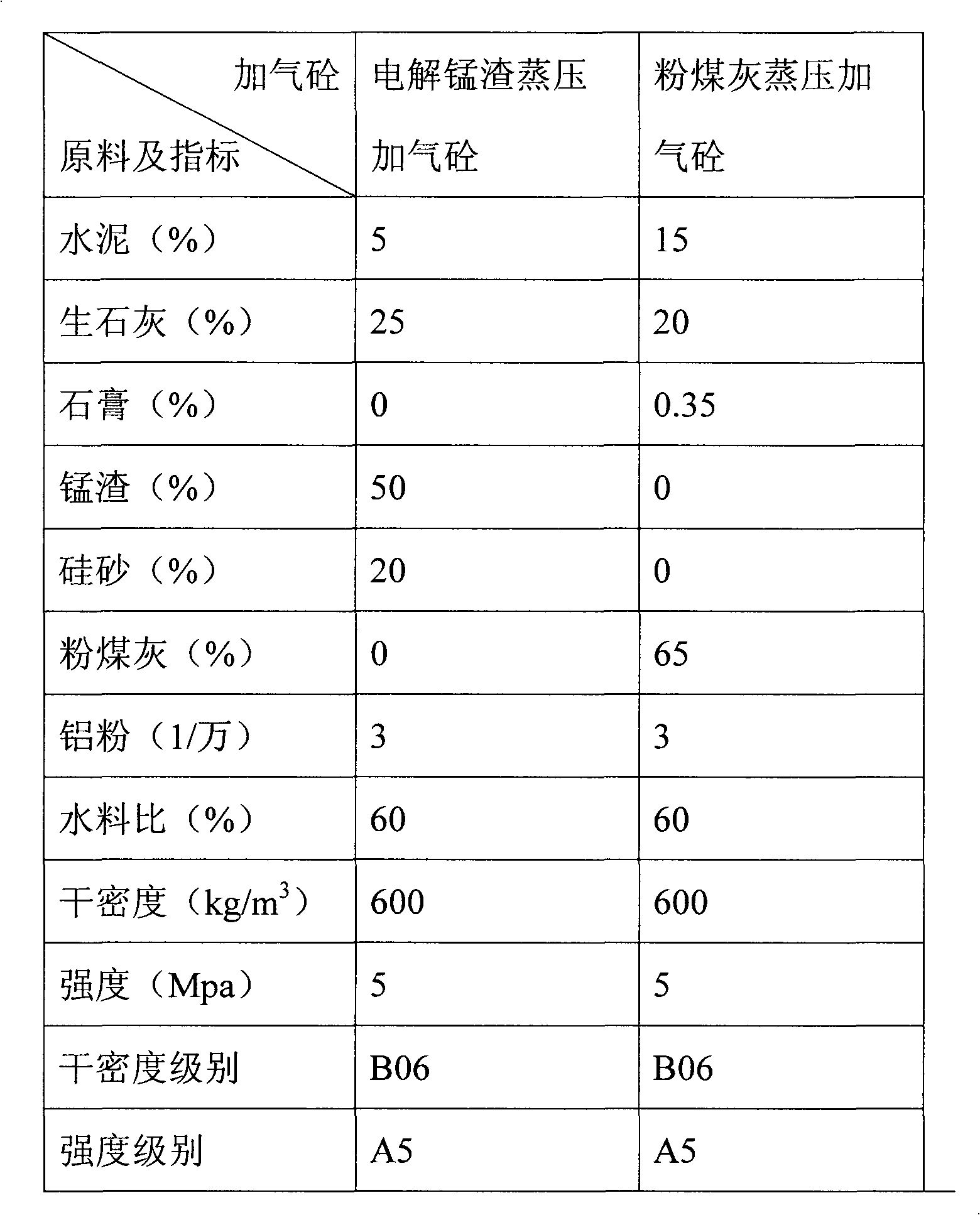

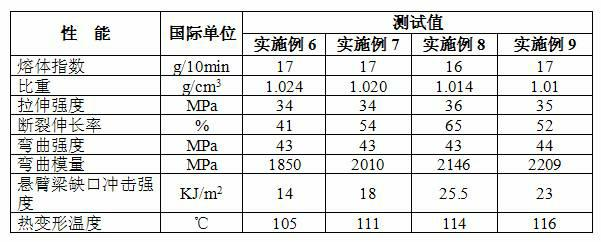

High-strength aerated concrete building block produced by using electrolysis manganese residues and preparation method thereof

InactiveCN102795883AIncrease consumptionSimple processSolid waste managementCeramicwareElectrolysisManganese

The invention discloses a high-strength aerated concrete building block produced by using electrolysis manganese residues and a preparation method thereof. The building block is made of: (1) basic raw materials, (2) additives and (3) a solvent, wherein the basic raw materials include 48-58 percent by weight of electrolysis manganese residues, 20-30 percent by weight of silica sand, 5-10 percent by weight of cement and 15-25 percent by weight of quicklime; based on the total amount of the basic raw materials, the additives include 0.05-0.12 percent by weight of aluminum powder, 1-5 percent by weight of water glass, 0.005-0.01 percent by weight of sodium benzene sulfonate washing powder and 0.1-0.4 percent of an aid; the solvent is water; and the weight ratio of water to a water material of the basic raw materials is 0.6-0.7. The preparation method comprises the following steps of: pretreating the raw materials, and forcibly stirring according to a certain proportion as required to obtain slurry; and standing and performing steam curing with a still kettle to obtain a product. The aerated concrete building block produced with the method has the advantages of low volume weight, high strength, simple process, convenience in operating, freeness from pollution, high electrolysis manganese residue consumption and convenience in mechanical production.

Owner:HUAIHUA YONGGU ENERGY SAVING WALL MATERIAL

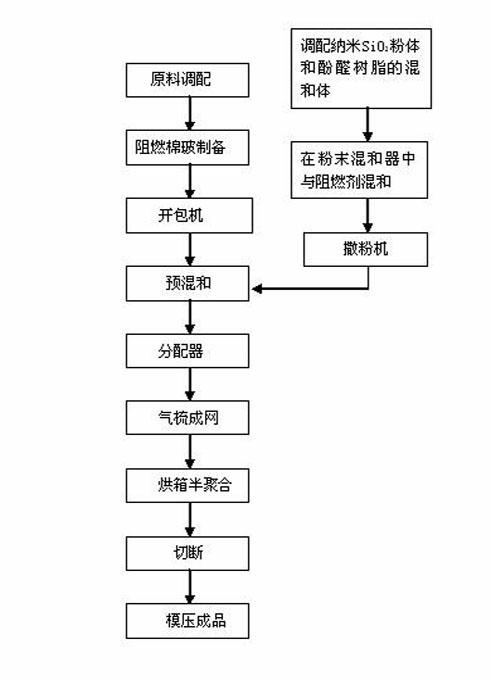

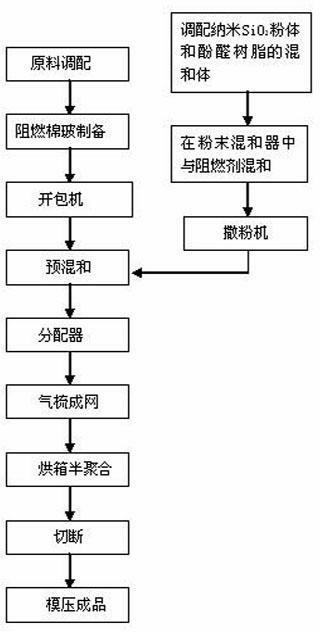

A kind of high flame retardant felt for automobile engine compartment and its manufacturing method

ActiveCN102277686AReduce material weightSmall difference in strengthFibre treatmentNon-woven fabricsChemistryPhenol formaldehyde resin

The invention discloses a highly flame-retardant felt used for automobile engine compartments and a manufacturing method thereof. The highly flame-retardant felt is a mixture of the following materials (accounting for the total weights of raw materials): 44 to 48 percent of blend of regenerated glass fibers and flame-retardant loosened cotton, 39 to 42 percent of blend of nano-sized SiO2 powders and phenolic resin, and 13 to 14 percent of a flame retardant agent. The method comprises the following steps: firstly, preparing an aqueous solution (30 to 35% concentration) of powdery polyammonium phosphate which is used as flame retardant agent and water, uniformly spraying the solution to loosened cotton, and loosening while adding regenerated glass fibers; then, mixing nano-sized SiO2 powders with phenolic resin such that nano-sized SiO2 powders are uniformly dispersed in phenolic resin, and adding the flame retardant agent and thoroughly mixing; and finally, simultaneously feeding the two powdery mixtures to an air-laid netting machine by use of a distributor. By virtue of the process of phenolic resin modification with nanopowders and the special process of fiber flame-retardant treatment, and the composition of flame-retardant loosened cotton, regenerated glass fibers and modified phenolic resin, in addition with an appropriate proportion of flame retardant agent, the best results of being both economic and flame-retardant and satisfying the need for performance improvement are achieved.

Owner:镇江立达纤维工业有限责任公司

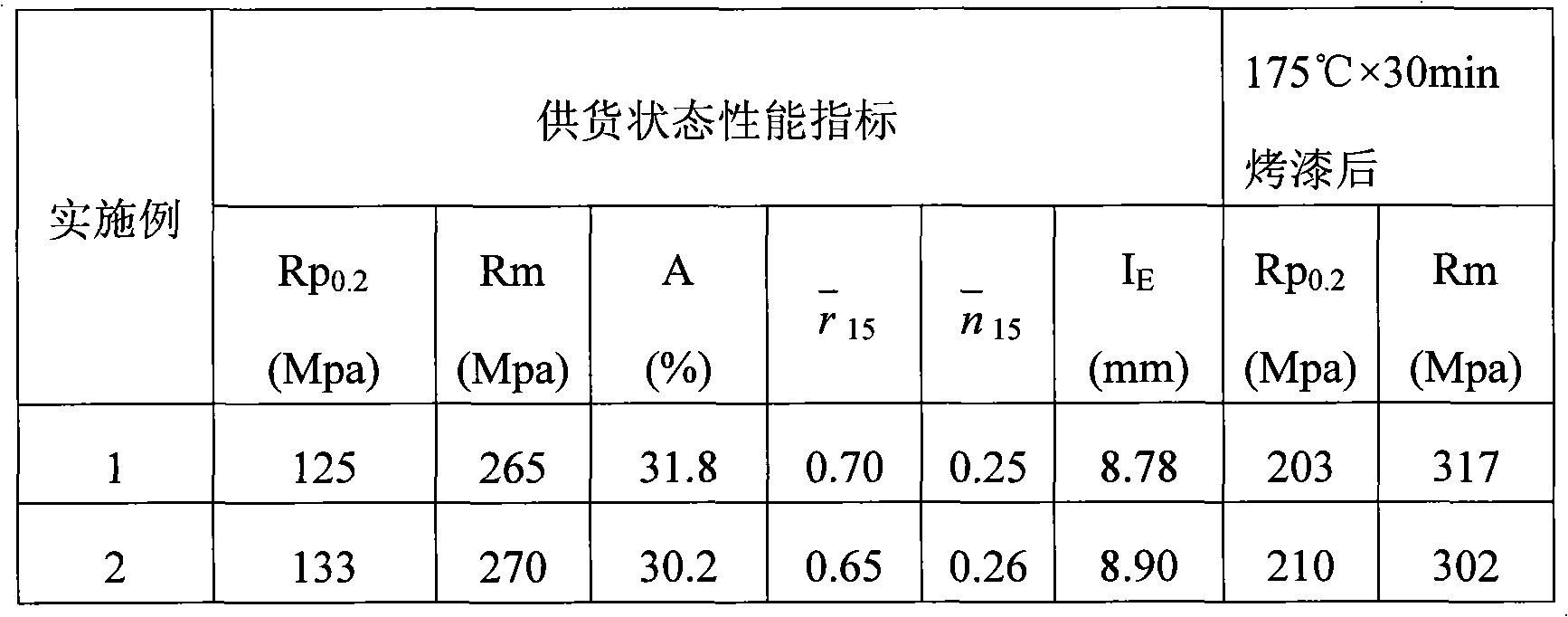

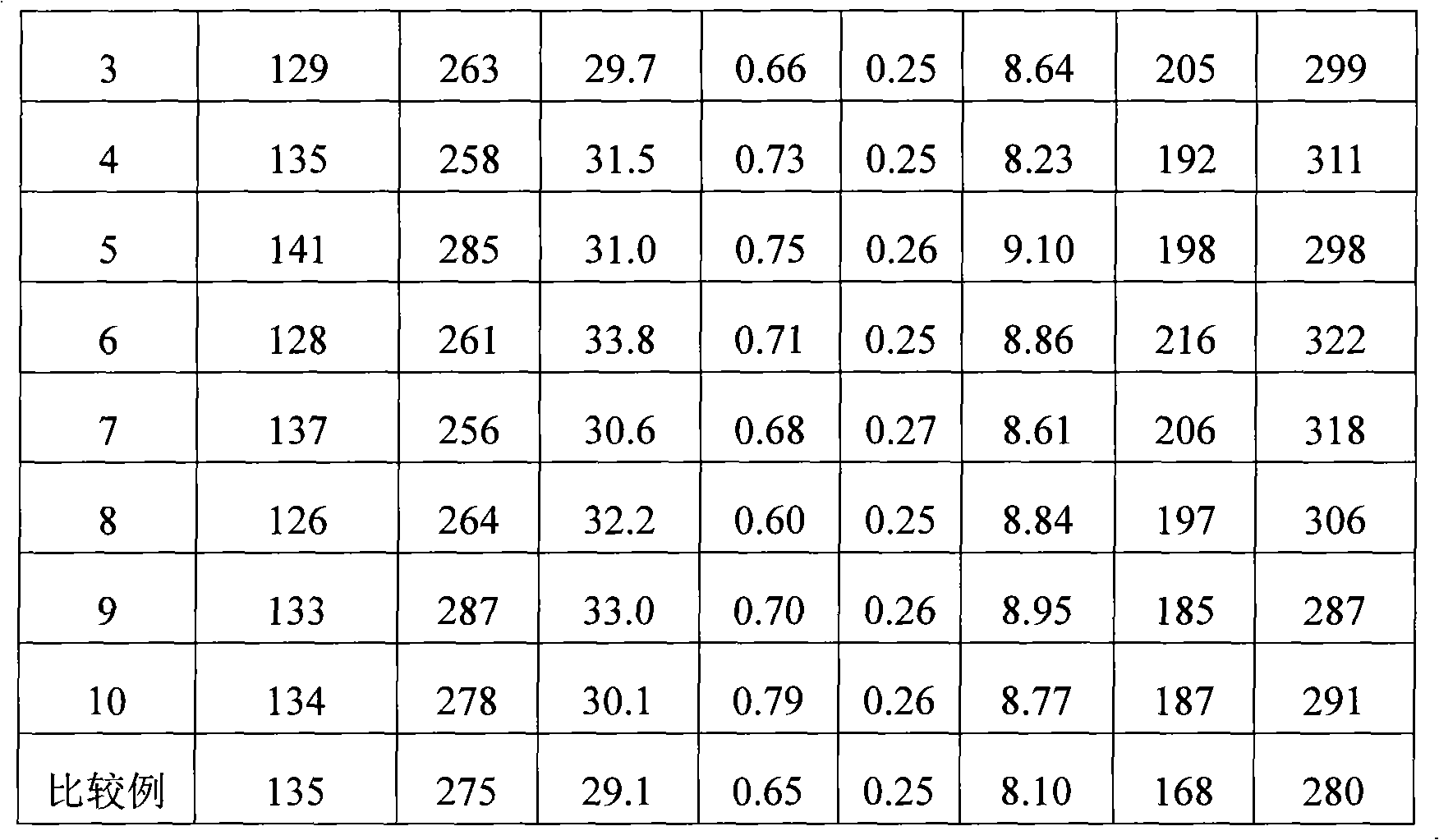

Method for improving baking finish hardenability of AA6022 aluminum alloy sheet

The invention provides a method for improving the harden ability of baking paint of AA6022 aluminium alloy plates, which includes the following steps: after solid solution and water quenching, the AA6022 aluminium alloy plates are subjected to preheating treatment in a week with the preheating treatment temperature of 60 to 100 DEG C and preheating treatment time of 30 minutes to 12 hours. The preheat treatment process effectively improves the intensity of the alloy after the paint is baked and further develops the potential of age hardening of the aluminium alloy; simultaneously, the intensity of materials before stamping is lower, which is beneficial for stamping-forming and further causes automobile factories to broadly adopt the aluminium alloy plates to replace steel plates for producing body stamping parts of automobiles.

Owner:CHINA ALUMINUM INT ENG CORP

Plant breeding substrate and production method thereof

InactiveCN101361454ALight in massHigh courageCultivating equipmentsSoilless cultivationGreeningPlant cultivation

The invention relates to plant cultivation. A plant cultivation substrate is made into a whole by wooden fragments, a soil conditioner and a nutrient particle body. Compared with the like products, the cultivation substrate has the advantages of light self mass, high courage performance and high moister retention: the invention has the best sealing environment to the plant, and does not need the technology experience of the specialists, therefore, the invention not only can realize the greening of roofs, etc., save labor force, and reduce cost, but also is in fixed base type, and can effectively avoid sealing lost and dispersion caused by heavy rain and strong wind.

Owner:大连染谷绿业科技有限公司 +2

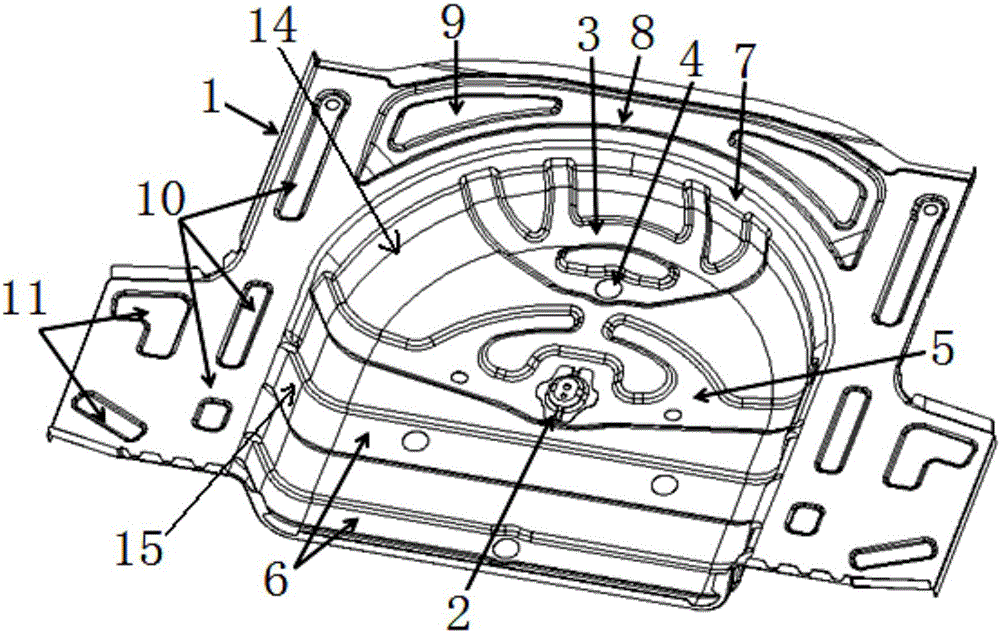

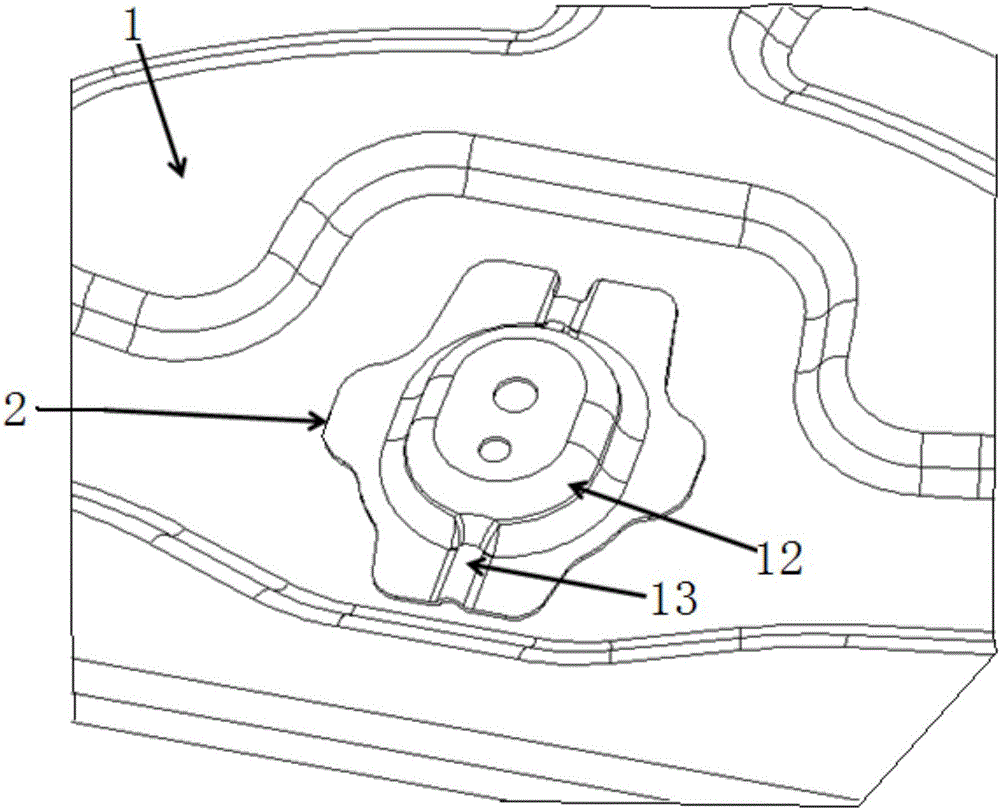

Automobile spare tire installing structure

The invention discloses an automobile spare tire installing structure, which comprises a spare tire pool arranged on a back floor, wherein the spare tire pool comprises a spare tire pool front part and a spare tire pool back part; the spare tire pool front part is of a circular arc structure; the spare tire pool back part extends out in the tangential direction of the circular arc of the spare tire pool front part; the cross section of the spare tire pool back part is in a U shape; an installing support frame used for installing an automobile spare tire is arranged in a connecting position of the spare tire pool front part and the spare tire pool back part; structure reinforcing structures are arranged on the periphery of the installing support frame and at the spare tire pool front part and the spare tire pool back part. The automobile spare tire installing structure has the advantages that the carrying capability is high; the structure is simple; the manufacturing process is simple; good modal stiffness performance is realized; the light-weight requirements can be met.

Owner:CHERY AUTOMOBILE CO LTD

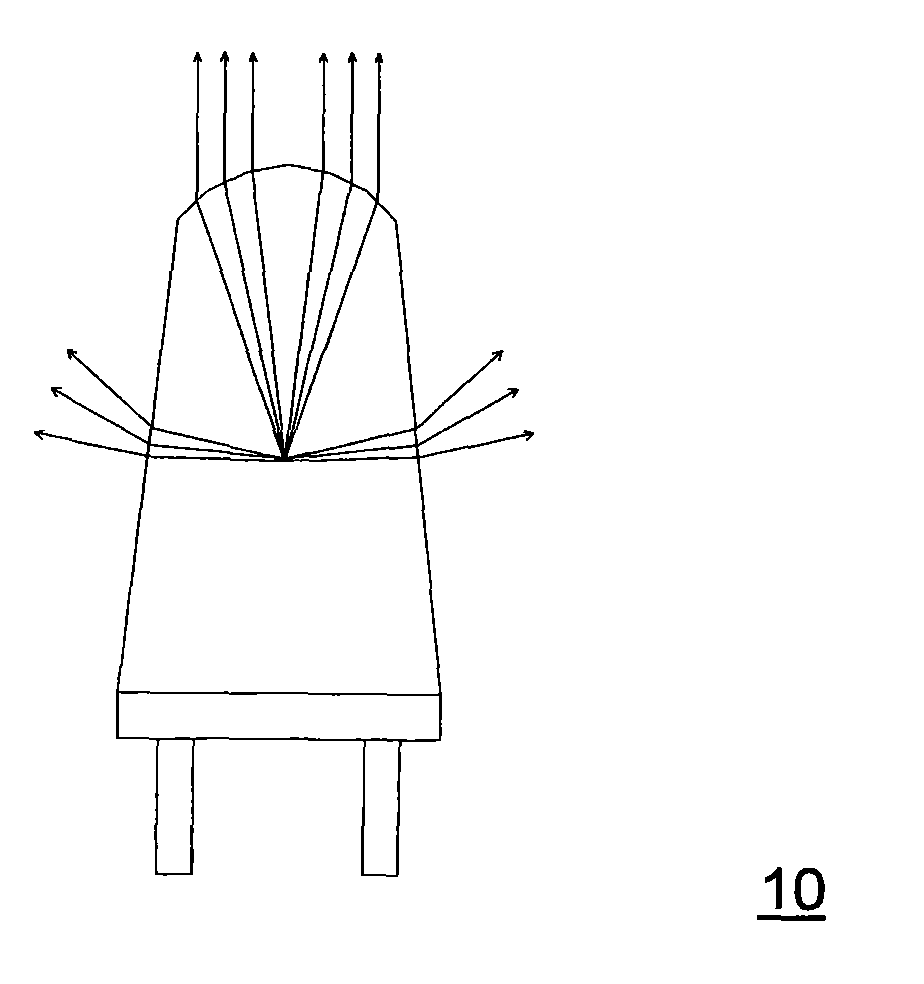

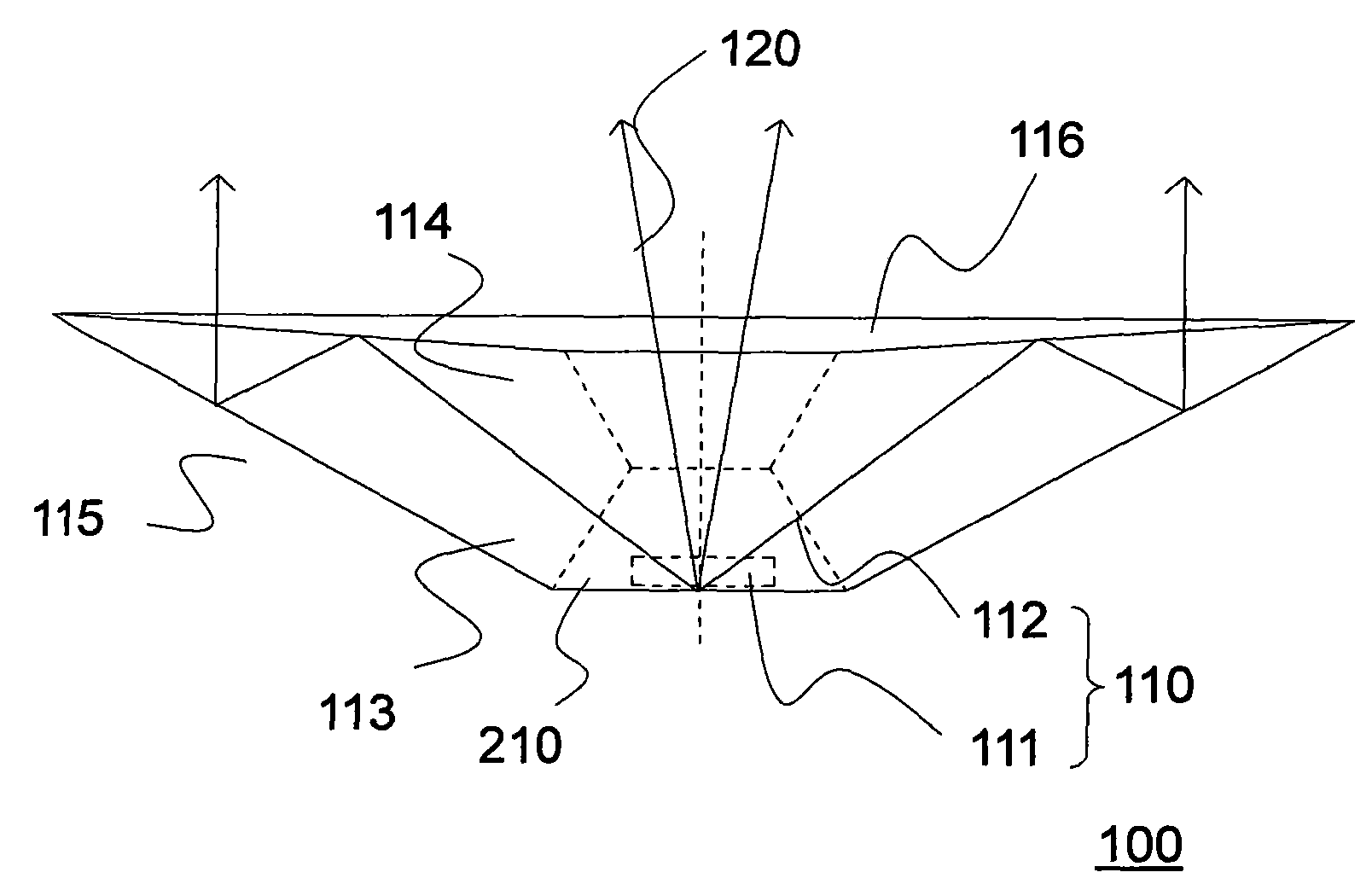

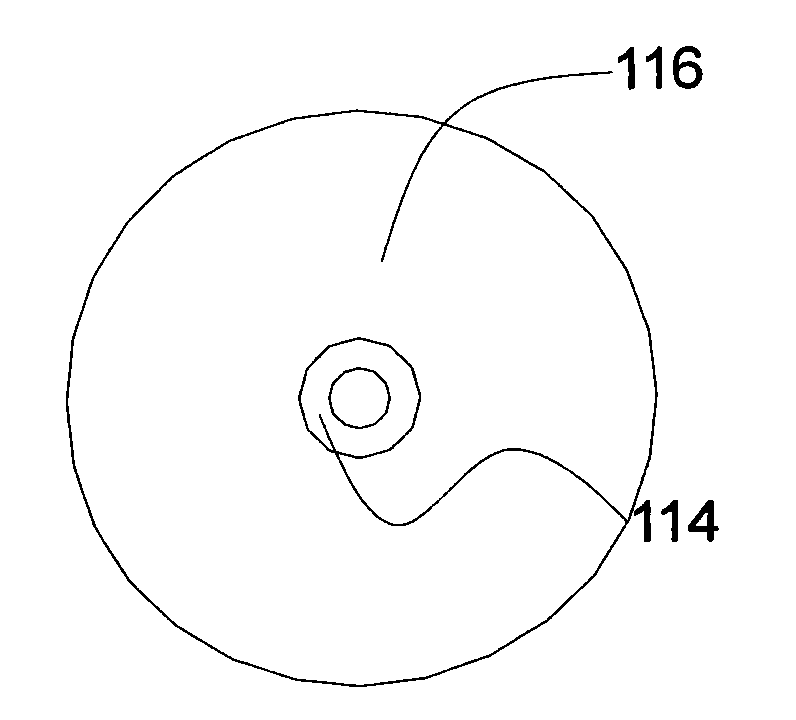

Lighting device and backlight module applying same

ActiveCN101988640AReduce thicknessGood uniform light intensity distributionPoint-like light sourceElectric lightingOptical axisLight guide

The invention relates to a lighting device and a backlight module applying the lighting device. The lighting device comprises a light source capable of emitting a light beam along an optical axis and a lens arranged on the transmission pathway of the light beam. The lens contains a hollow structure and a light guide part, one part of the light beam can penetrate the lens by virtue of the hollow structure along the optical axis, the light guide part is provided with a light emitting surface surrounding the hollow structure, the hollow structure penetrates the light guide part, and the other part of the light beam is transmitted to the light emitting surface to be emitted by virtue of the light guide part. The invention also provides a backlight module applying the lighting device. The invention can obtain good uniform light intensity distribution.

Owner:CORETRONIC OPTICS (SUZHOU) CO LTD

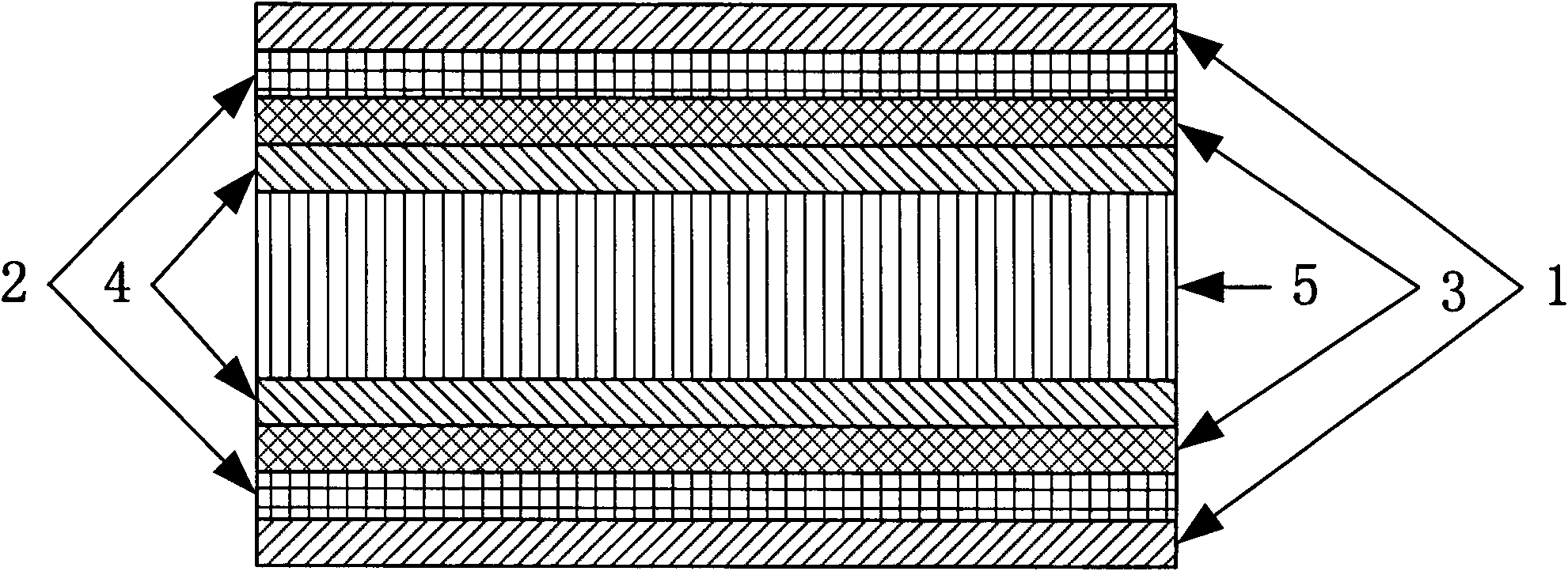

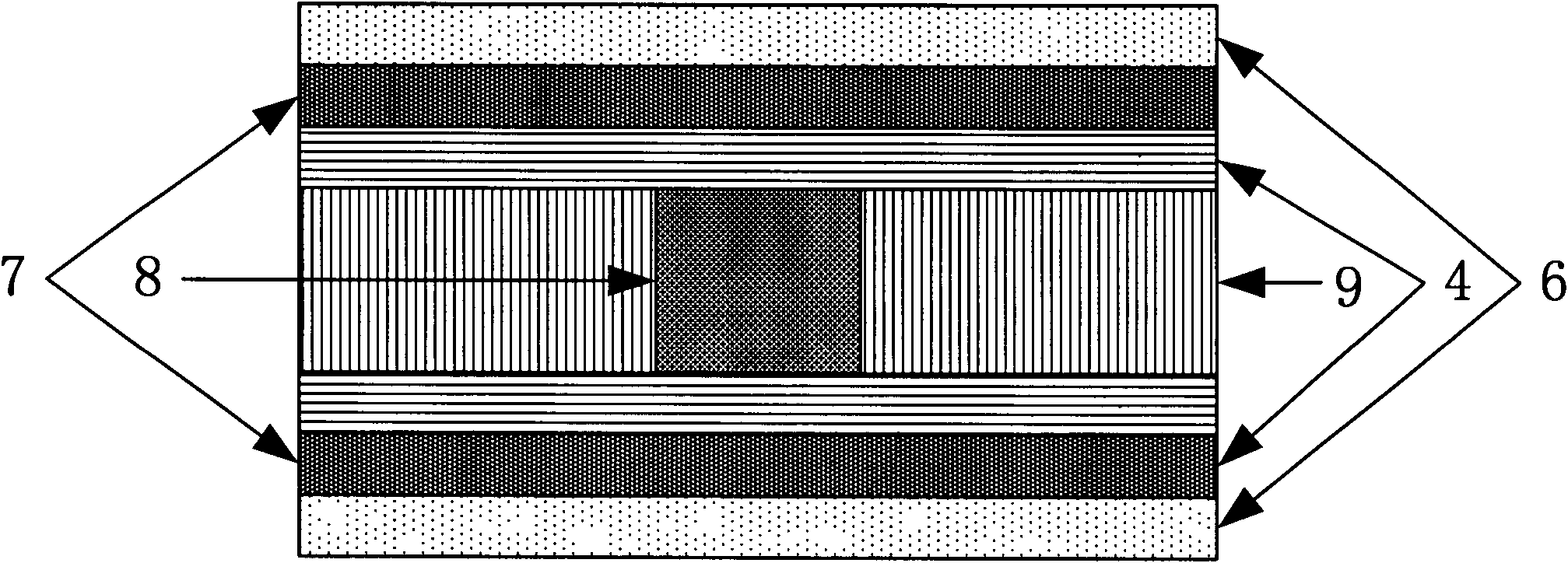

Double-sided solar battery component

InactiveCN102064221AEfficient outputTo achieve the purpose of lightweightPhotovoltaic energy generationSemiconductor devicesHoneycombEngineering

The invention relates to a solar battery component which is formed by sequentially superposing a surface packaging film, a transparent glue film, a solar battery plate, a lightweight glue film, an insulating substrate, a lightweight glue film, a solar battery plate, a transparent glue film and a surface packaging film from top to bottom in close contact without interlayer clearances, wherein the insulating substrate is formed by sequentially superposing an insulating film, a carbon fiber plate, a lightweight glue film, a honeycomb core, a lightweight glue film, a carbon fiber plate and an insulating film from top to bottom in close contact without interlayer clearances; to ensure that the battery component can be connected with related structures, an embedded part is arranged in the honeycomb core; and the specific position of the embedded part is determined by the connecting mode. The double-sided solar battery component has the advantages of light weight, high efficiency and good low-temperature property, makes the most of the solar energy in a limited area, is very suitable for the requirement of long-term regional residency of an aerostat in the stratosphere, and has application value in the technical field of solar photovoltaics.

Owner:BEIHANG UNIV

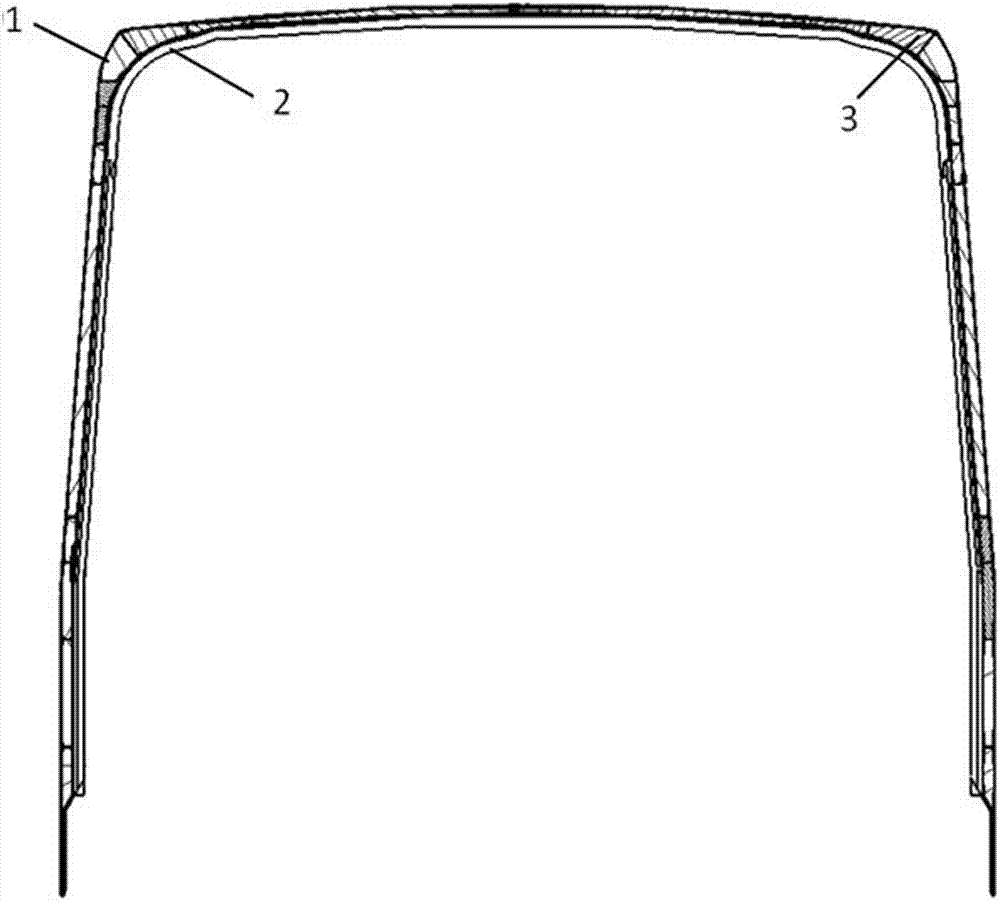

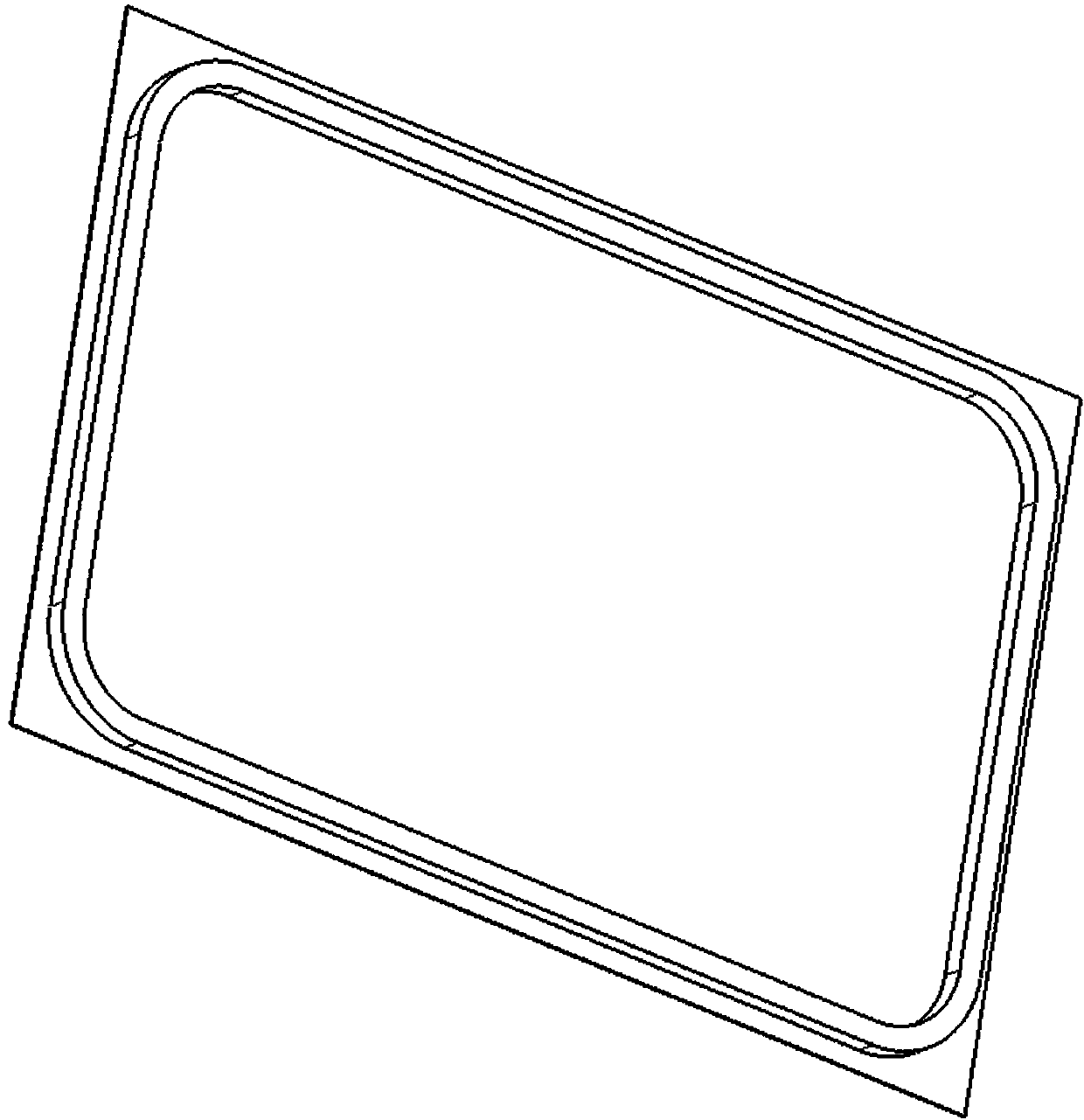

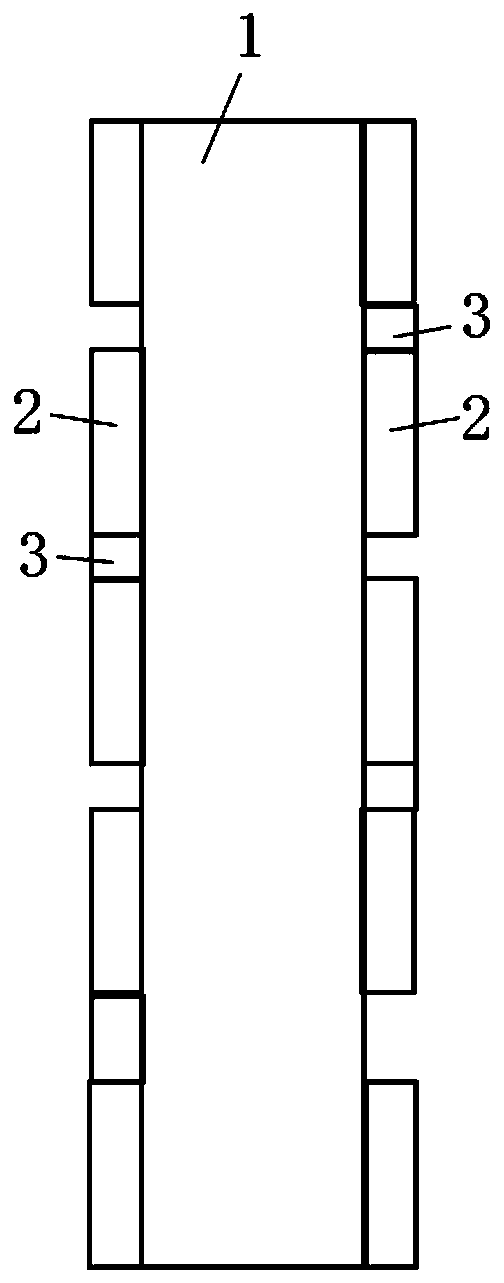

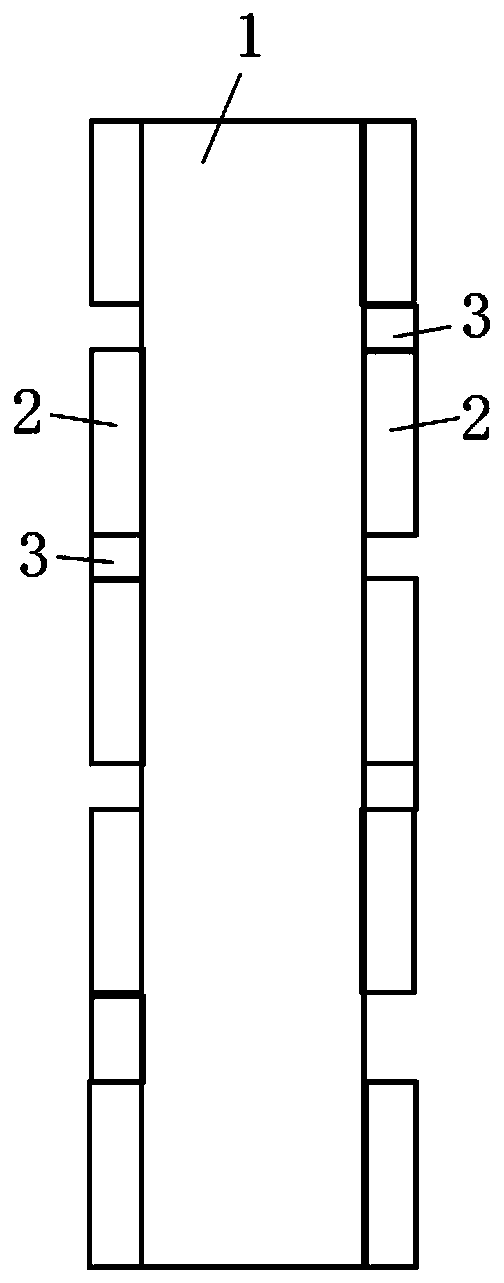

Sandwich structural carbon fiber subway window frame and manufacturing method thereof

InactiveCN107756827ATo achieve the purpose of lightweightReduce in quantityWindow arrangementsMetallic materialsEnergy consumption

The invention is a carbon fiber subway window frame with a foam sandwich structure. The carbon fiber subway window frame includes a foam sandwich core and a carbon fiber skin coated outside the foam sandwich core. The invention also discloses a manufacturing method of the carbon fiber subway window frame. It includes the following steps: (1) Foam sandwich bonding molding; (2) Carbon fiber skin laying; (3) Autoclave process molding. The invention adopts the carbon fiber foam sandwich structure to replace the metal material of the aluminum alloy prototype car, which can not only effectively reduce the weight of the subway window frame, achieve the purpose of light weight, but also reduce energy consumption and prolong the service life.

Owner:HENGSHEN

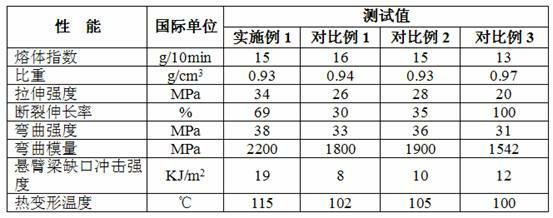

High heat resistance low density high performance auto polypropylene composite and preparation method thereof

ActiveCN102070842AOffset shock performanceCounteracts the negative effects of impact performancePolypropylene compositesSewage treatment

The invention discloses a high heat resistance low density high performance auto polypropylene composite and a preparation method thereof. The polypropylene composite comprises the following components in percentage by weight: 50 to 84.5 percent of PP, 5 to 20 percent of flexibilizer, 5 to 15 percent of crystal whisker, 5 to 15 percent of talcpowder, and 0.5 to 2 percent of coupling agent. The preparation method comprises the following steps of: pre-mixing the components of PP and crystal whisker in a high speed mixer; transporting the mixed raw material into a twin screw extruder; and feeding material at the crystal whisker side into the twin screw extruder and performing fusion, extrusion and granulation to obtain the product. The product is characterized in high heat resistance, low density and high performance, and does not produce environmental pollution during manufacturing and use, thereby reducing the pressure on sewage treatment, and reducing energy consumption. Moreover, the composite neither produces the migration of toxic substance nor contains heavy metals. And the product completely meets the ROSH standard.

Owner:KINGFA SCI & TECH CO LTD +2

Foam concrete produced by electrolytic manganese residue at normal temperature and preparation method thereof

The invention relates to a foam concrete produced by electrolytic manganese residue at normal temperature and a preparation method thereof. The foam concrete is prepared by electrolytic manganese residue, lime, cement, water glass, concrete foaming agent and the like with water under normal temperature. The preparation method comprises the following steps of extracting main pollutants in the electrolytic manganese residue through an inventive technology of a comprehensive utilizing process of electrolytic manganese residue to manufacture chemical products; placing the rest residue slurry in a large-scale preprocessing pool, adding lime with corresponding amount, agitating uniformly to digest and solidify the residual harmful components; treating the electrolytic manganese residue in a harmless way; activating the effective components in the electrolytic manganese residue; discontinuously agitating, and preprocessing for more than 48 hours for later use; getting the slurry with a certain amount when necessary, adding cement with corresponding amount, agitating uniformly as a material A; dissolving and diluting the concrete foaming agent with water in proper amount, placing the concrete foaming agent in a special cement foaming machine to produce foams; adding water glass at the middle and later periods of shaping foams to disperse in the foams as a material B; mixing the material A and the material B in a foam concrete machine to form into foam concrete so as to directly perform pouring construction on the building site; or pouring the foam concrete mixed by the material A and the material B in a die, shaping by cutting in required dimension, and curing at a normal temperature to manufacture building materials of light foam concrete wall blocks.

Owner:卿富安

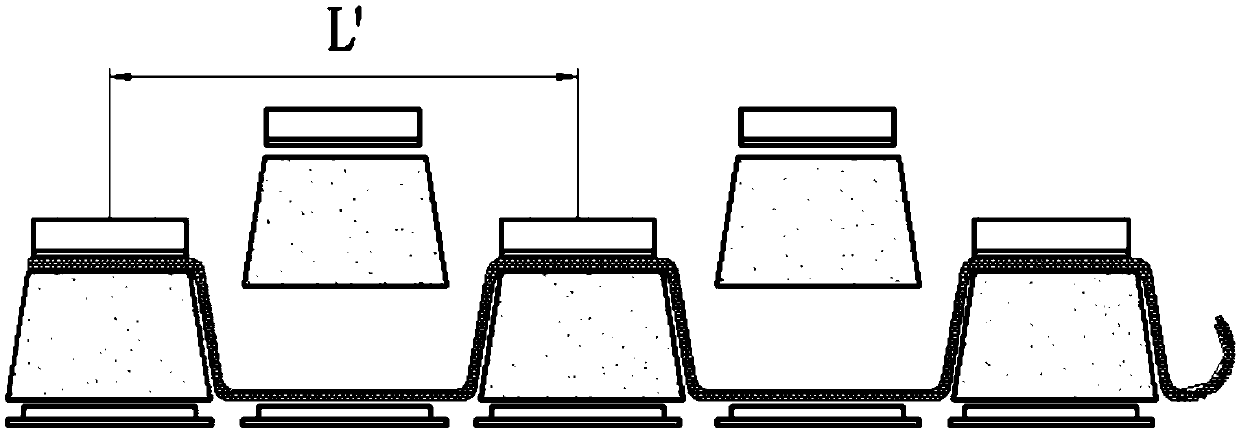

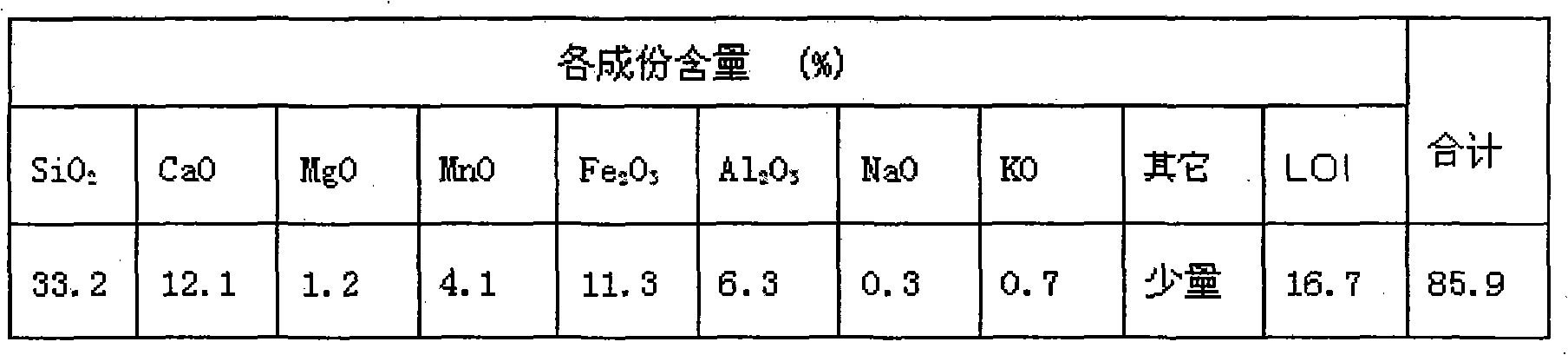

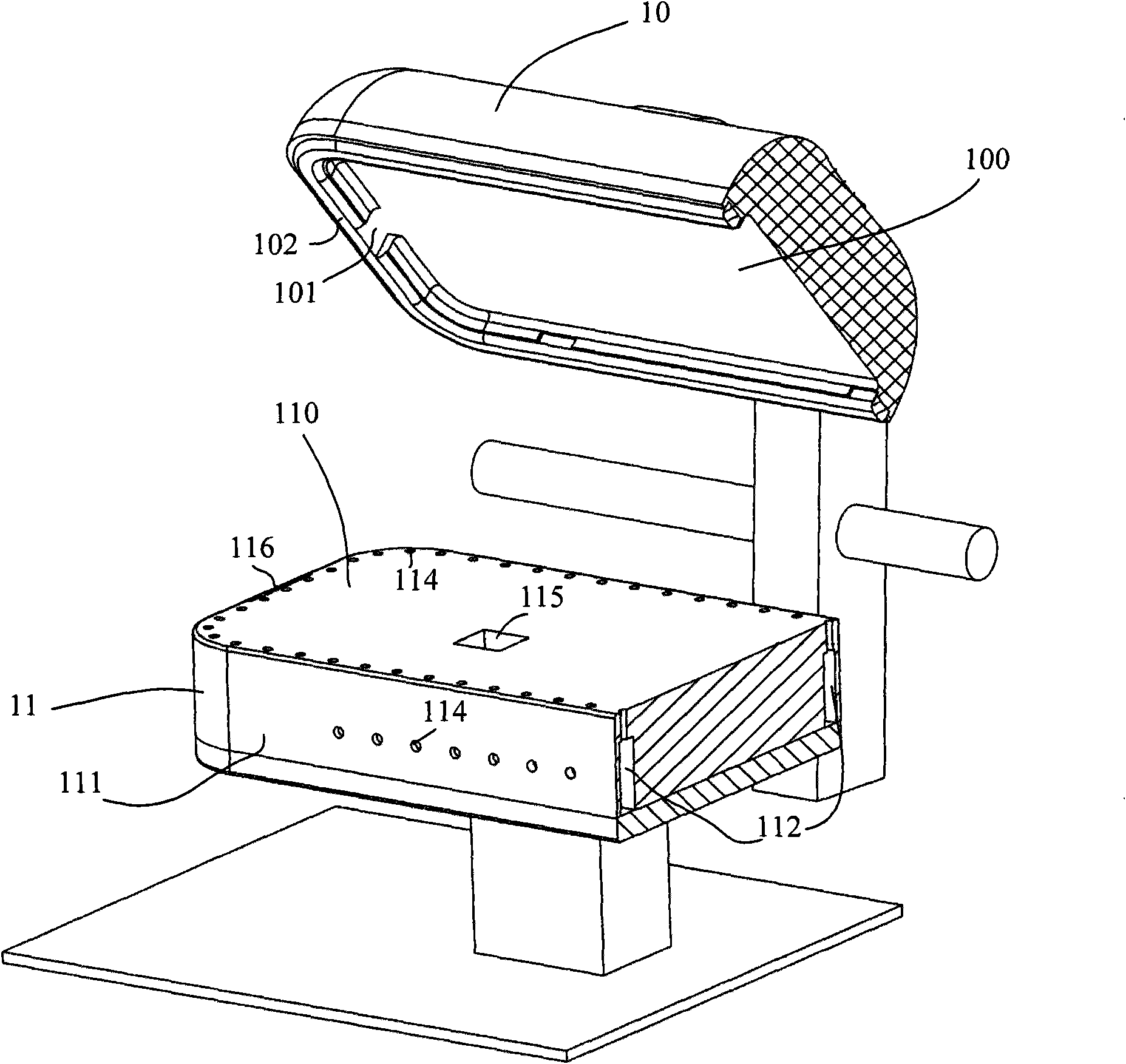

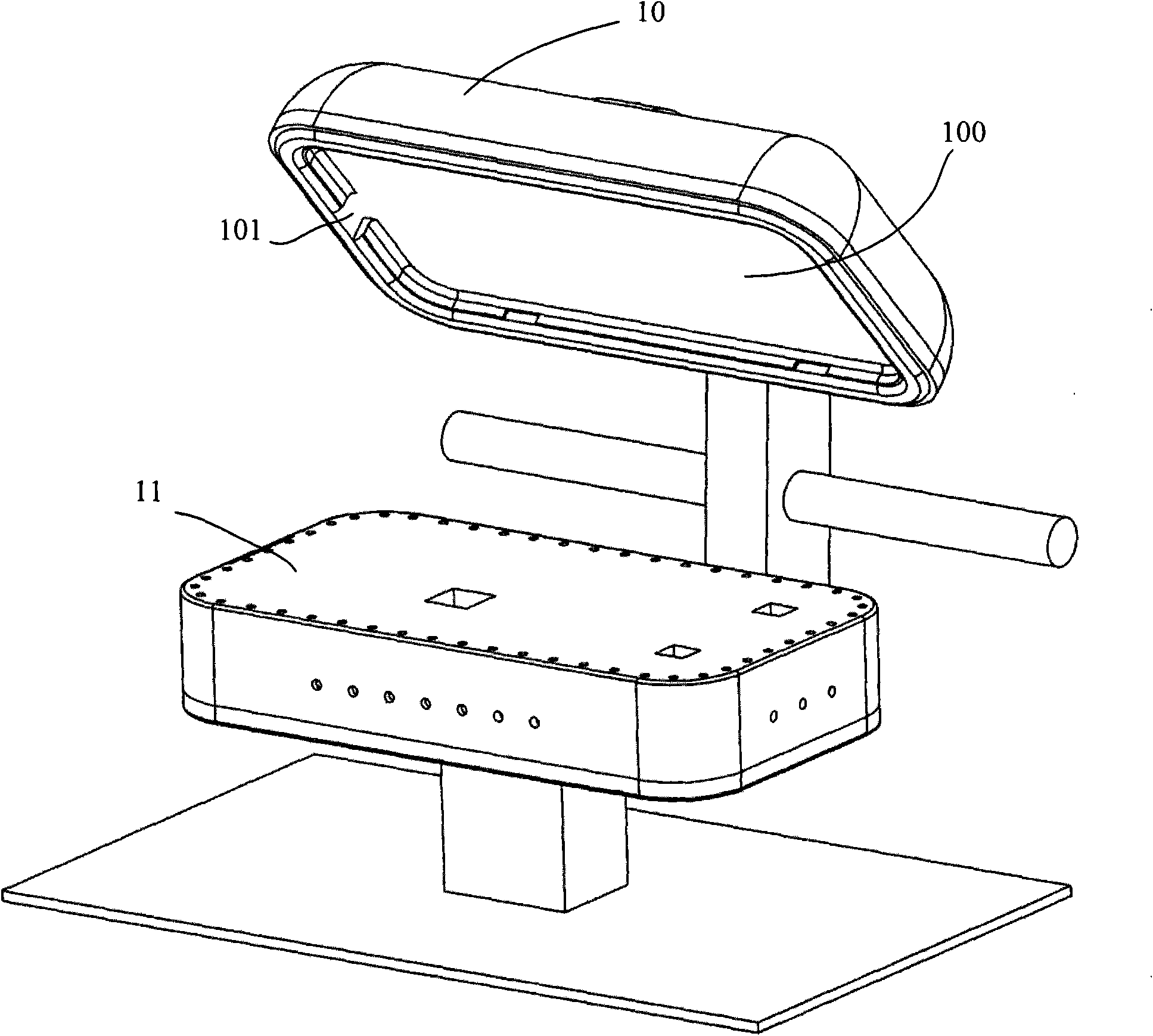

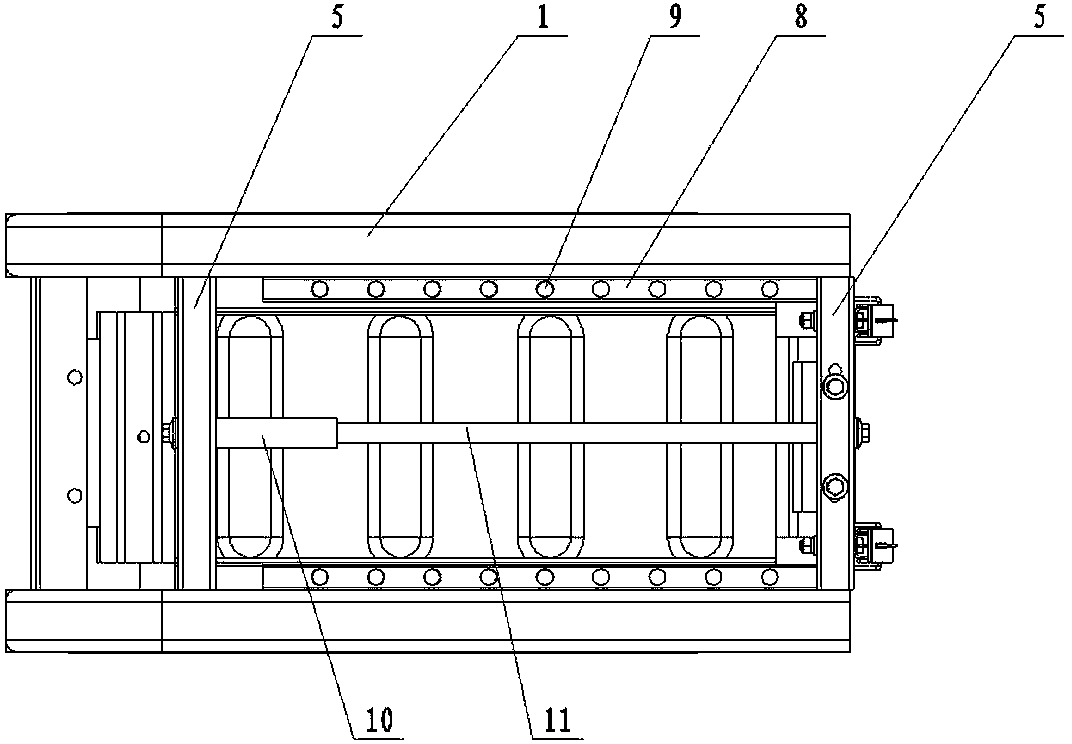

Hot press molding process, molding system and mould group thereof

The invention relates to a hot press molding process, a molding system and a mould group thereof, which can replace the conventional stitching manufacture manner. A first mould is provided with an annular hot press part, a second mould is provided with a hot press surface, a plurality of air absorbing holes are formed in an outer ring of the hot press surface, an air duct is internally arranged in the second mould and is used for connecting an air source, the air absorbing holes are communicated with the air duct, an outer ring cutting sheet is sleeved on the sidewall of the second mould so that a flange of the outer ring cutting sheet faces the hot press surface of the second mould, an air absorbing system is used for absorbing air in the air duct of the second mould so that the flange of the outer ring cutting sheet is smoothly located on the outer ring of the hot press surface depending on the air absorbing holes, the hot press part of the first mould is heated, and the flange of the outer ring cutting sheet is pressed in a hot state by the hot press part so as to enable the flange to be molded; in addition, a central cutting sheet is arranged on the outer ring cutting sheet, and the central cutting sheet and the flange of the outer ring cutting sheet are melted by utilizing the hot press part of the first mould.

Owner:上海华培胶带有限公司 +1

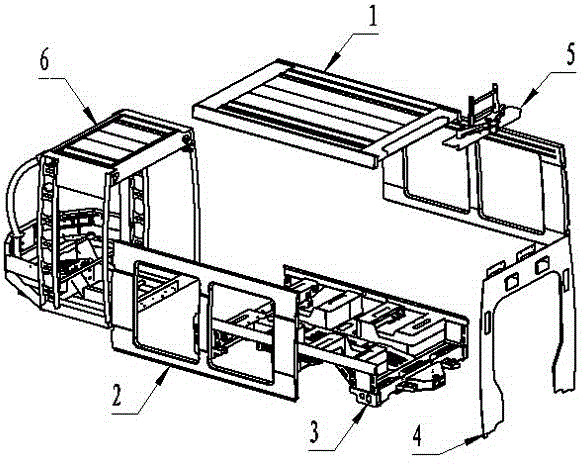

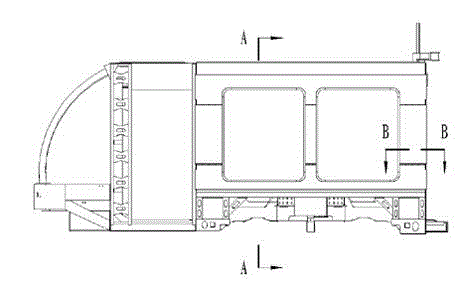

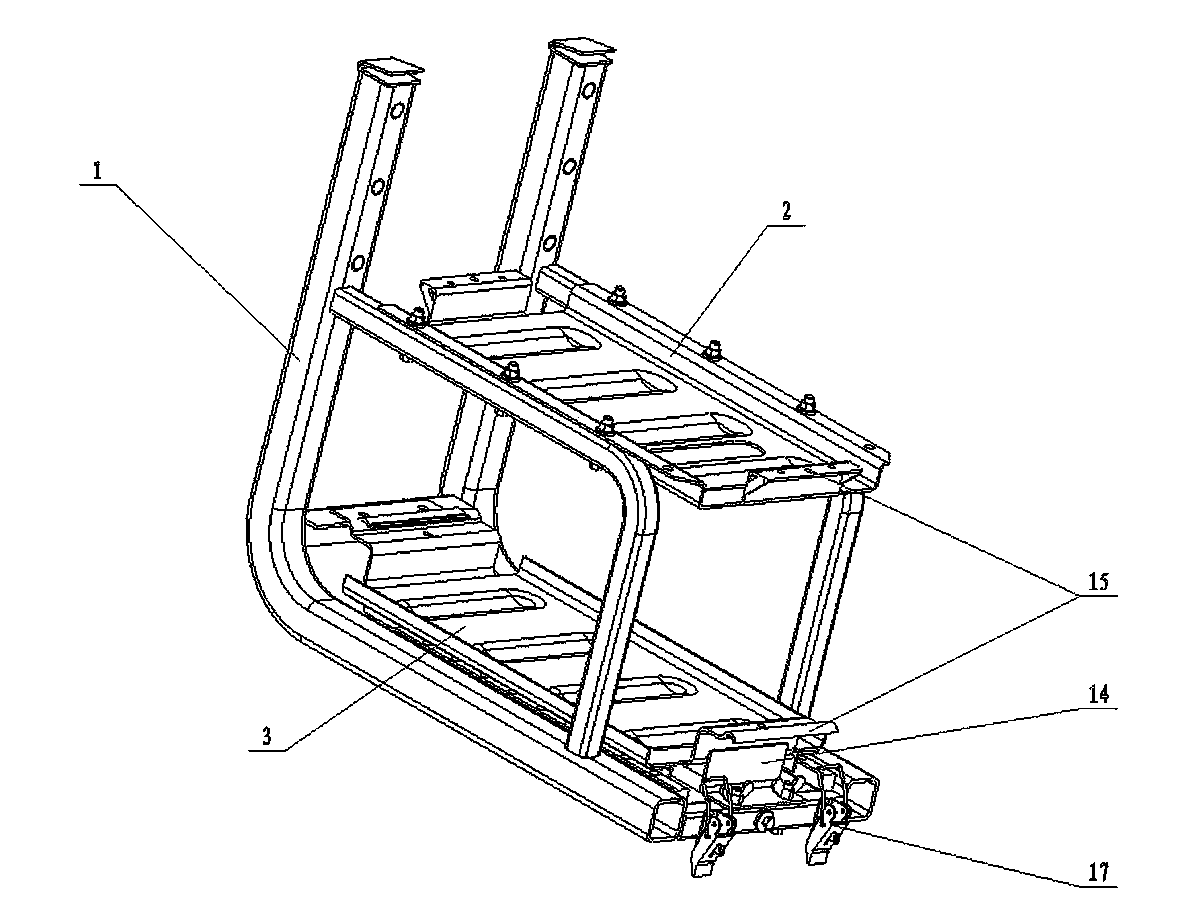

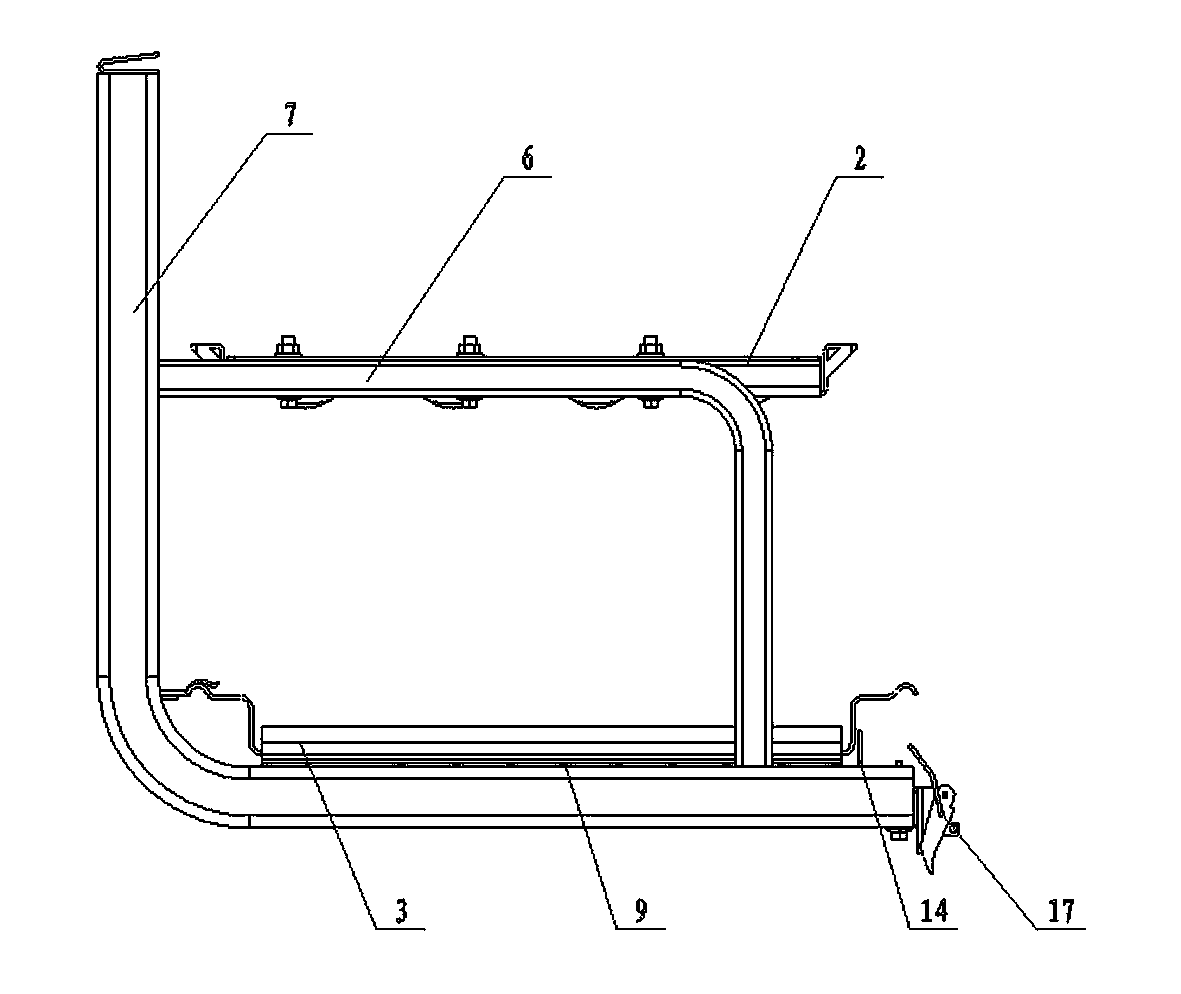

Motor car of 100% low-floor tramcar and assembly method of motor car

ActiveCN104015742AGood production independenceReduce maintenance costsRailway transportAxle-box lubricationAutomotive engineeringHinge angle

The invention discloses a motor car of a 100% low-floor tramcar and an assembly method of the motor car. The motor car comprises a few of large components, such as a top rack, a side wall, a bottom rack, an end wall, an upper hinge component and a cab, wherein the components adopt a riveting mode instead of a traditional welding mode. A car body component adopts a modular design, the components are riveted, each component has good production independence, maintenance universality and interchangeability, and each component can synchronously develop production. Riveting is free of a heat effect, or even coating can be carried out before general assembly, so that the production efficiency is greatly improved, other components of the car body adopt an aluminum profile welding structure except for that the components with large stress adopt a steel structure, the total weight of the car body is greatly relieved in comparison with an all-steel structure, and the lightweight purpose is achieved.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

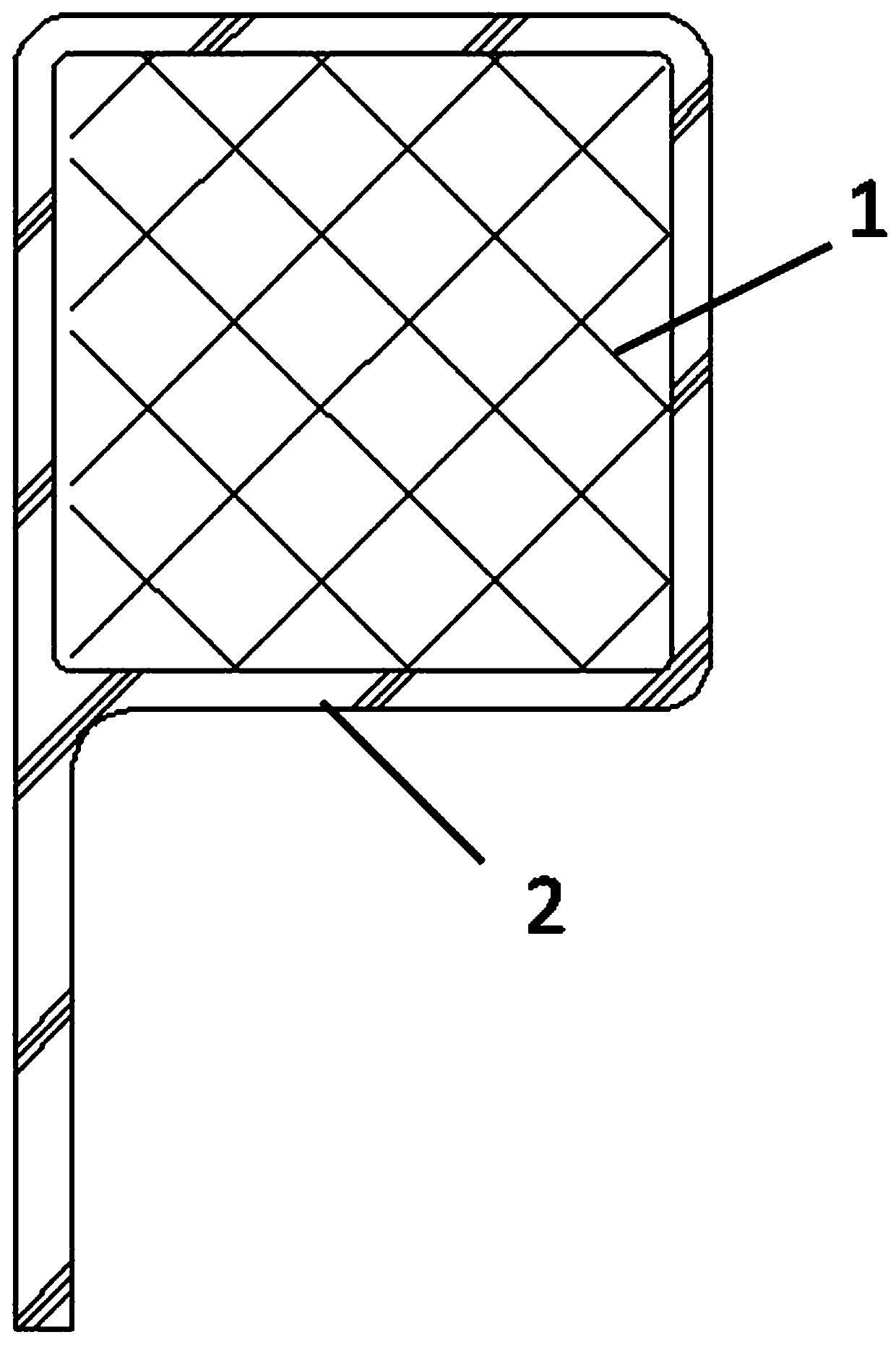

Lithium battery by using lightweight current collector

ActiveCN111129505ALight in massImprove conductivityElectrode carriers/collectorsLi-accumulatorsPhysicsElectro conductivity

The invention discloses a lithium battery by using a light-weight current collector. The lithium battery comprises a positive plate, a diaphragm and a negative plate which are laminated or wound, thepositive plate comprises a positive current collector; the negative plate comprises a negative current collector; the positive electrode current collector and / or the negative electrode current collector are / is composed of a conductive film base layer and a metallized film layer. The thickness of the conductive film base layer is 5-20 [mu]m, the conductivity of the conductive film base layer is 1-100 s / cm, the thickness of the metallized film layer is 0.2-2 [mu]m, the metallized film layer of the positive electrode current collector is an aluminum layer or a nickel layer, and the metallized film layer of the negative electrode current collector is one of a copper layer, an iron layer and a tungsten layer. The positive electrode current collector and / or the negative electrode current collector are / is composed of the conductive film base layer and the metallized film layer, and the conductive film base layer is prepared from the polymer base material, so that the mass of the current collector is effectively reduced while the function of the current collector is realized, and the purpose of light weight of the current collector is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

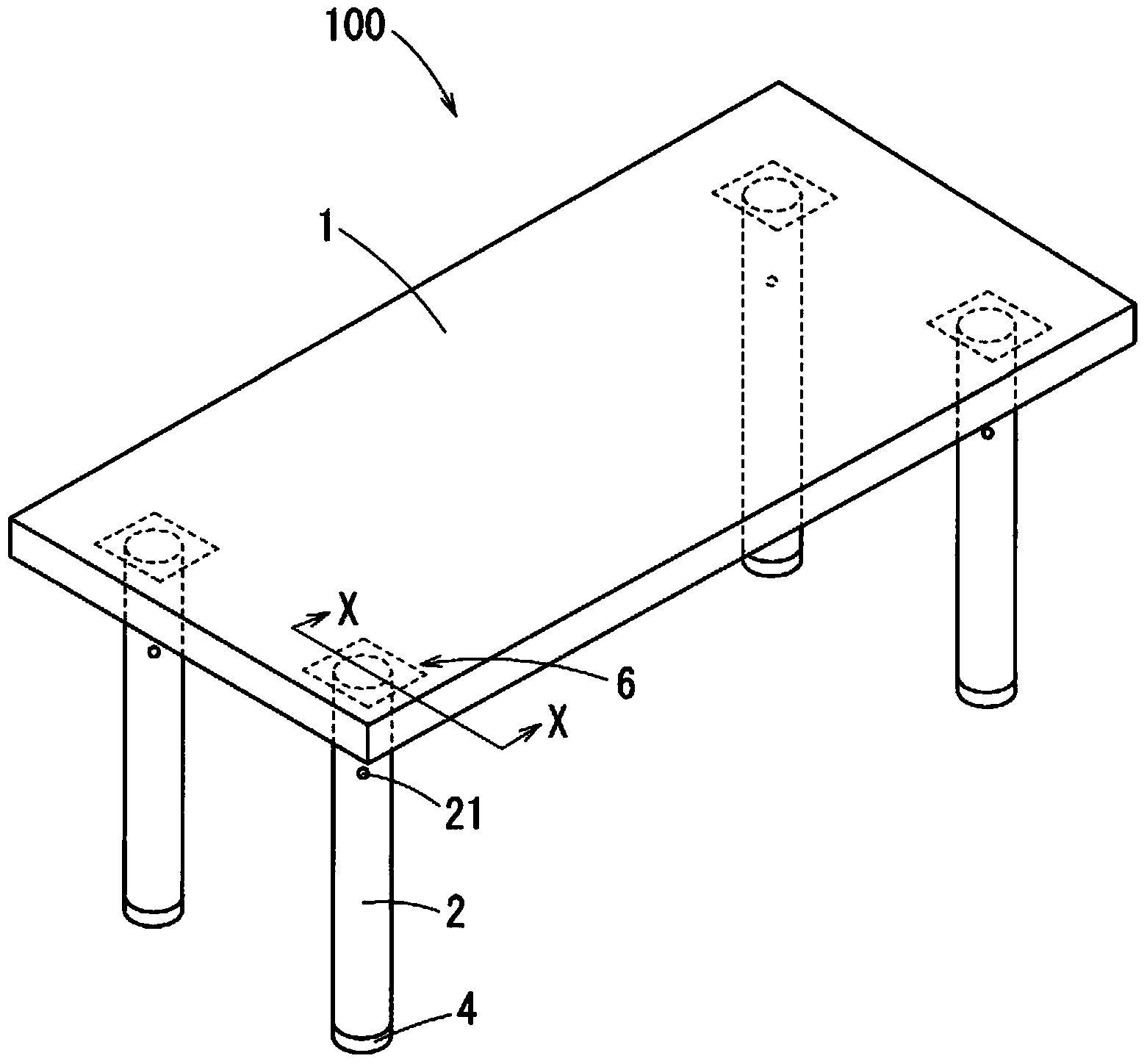

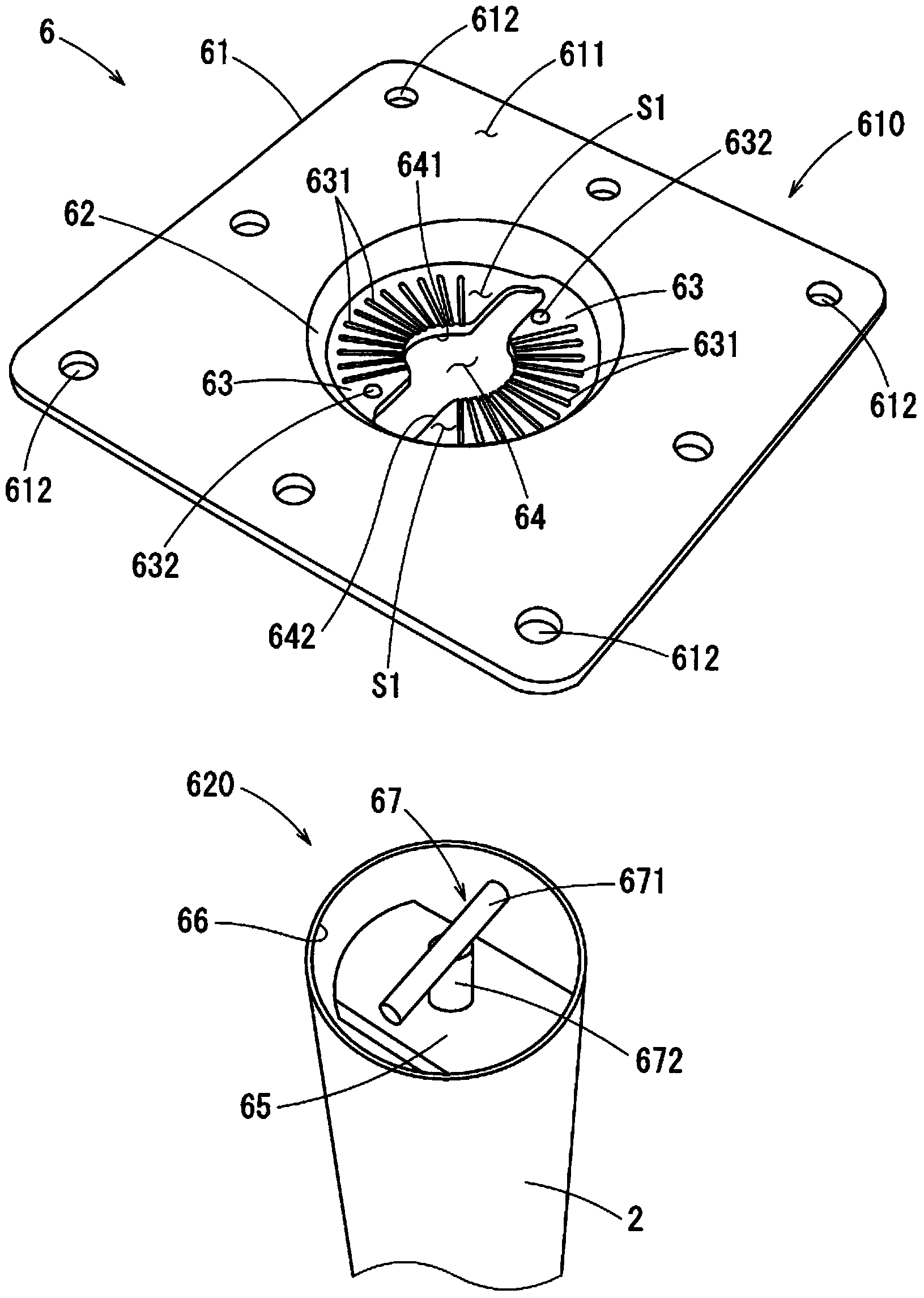

Post structure

InactiveCN104364537AEasy loading and unloadingPrevent looseningFoldable tablesStowable tablesEngineeringMoving parts

[Problem] To design for convenient storage / transport of a table, display case, etc. when not in use by quick removal of posts from the tabletop and / or base plate thereof. [Solution] A post structure in which a rotationally moving part is fitted into a stationary part wherein: a base configuring the stationary part is fastened to the table top and / or base plate, a short cylindrical interlocking projection juts out from the base, an insertion hole is drilled in the bottom face of the interlocking projection and helical surfaces that each slope gently are formed on both sides of the insertion hole; meanwhile, the moving part is fixed on the end of the post, a cross plate is made to bridge the post in the diameter direction almost at the end thereof, and a T-shaped locking rod is provided to stand substantially at the center of the cross plate; and by inserting the interlocking projection of the stationary part into the inner circumference of the post of the rotationally moving part while inserting the fastening rod of the T-shaped locking rod in the insertion hole of the bottom face and turning the post around the axis, the fastening rod is tightened onto the helical surface while the rotationally moving part is fastened to the stationary part. Grooves are provided on the helical surface at equal angular intervals in a radiating pattern.

Owner:KYOSHIN SANGYO

Double-deck storage battery box body

The invention discloses a double-deck storage battery box body which comprises a main body bracket, an upper fixed plate and a lower fixed plate, wherein batteries are placed on the upper fixed plate and the lower fixed plate respectively; a sliding plate is fixed on the inner side of the bottom end of the main body bracket; a plurality of holes are formed in the upper surface of the sliding plate, balls are mounted in the holes, and the lower surface of the lower fixed plate is in contact with the balls to enable the lower fixed plate to adopt a withdrawable structure; the fixed sleeve of a regulating mechanism is fixedly connected onto the bottom of the lower fixed plate, and the two ends of an adjustment lever are fixed onto a front end beam and a rear end beam; a limiting plate is fixed at the front end beam of the main body bracket and positioned at the front end of the lower fixed plate; a baffle plate is fixed on the lateral surface of the support frame of the main body frame. According to the invention, the arrangement of the lead-acid storage batteries for starting is changed to a stacking manner from a parallel manner, so that the arrangement space is effectively saved, the arrangement flexibility is improved, the distance between shafts is shortened at the same time to fulfill the purpose of light weight, and the center of gravity of a storage battery box body assembly is dispersed to reduce the bending moment to a fixed point so as to reduce the use of bolts.

Owner:DAYUN AUTOMOBILE CO LTD

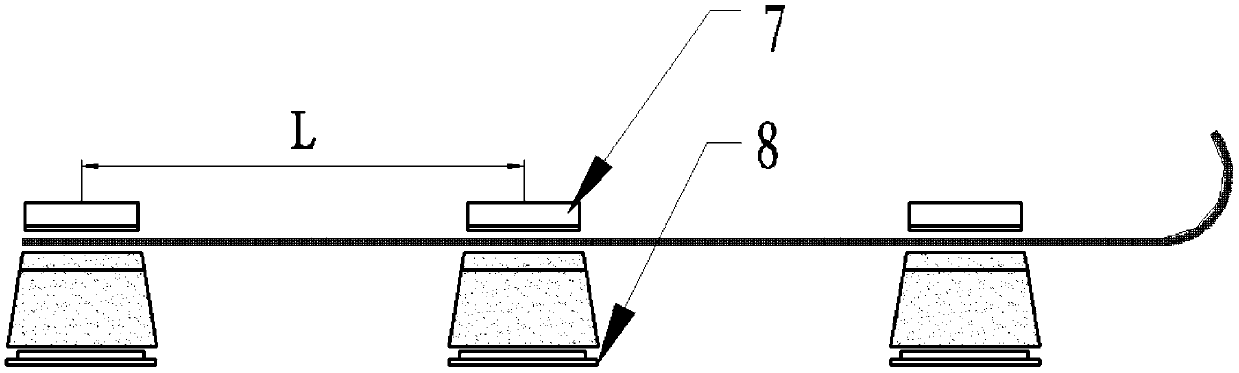

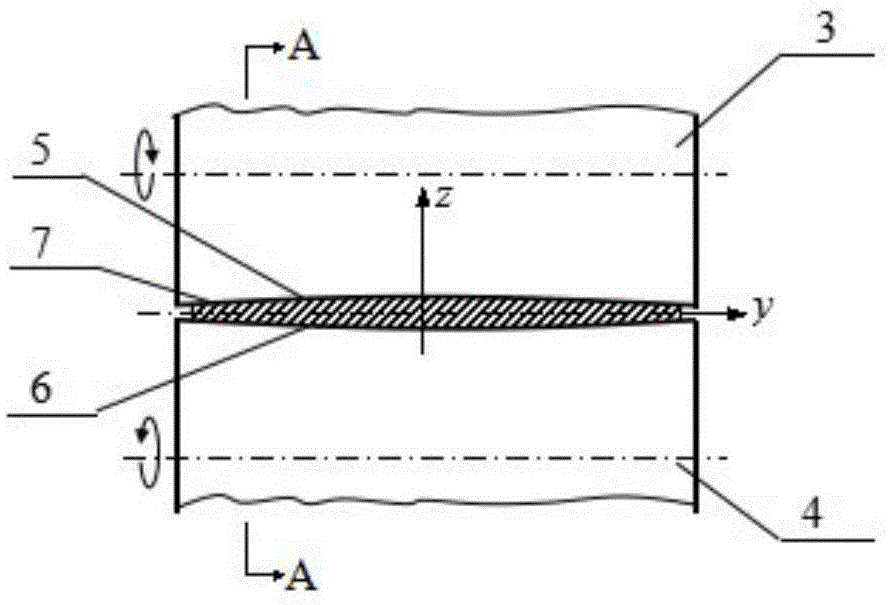

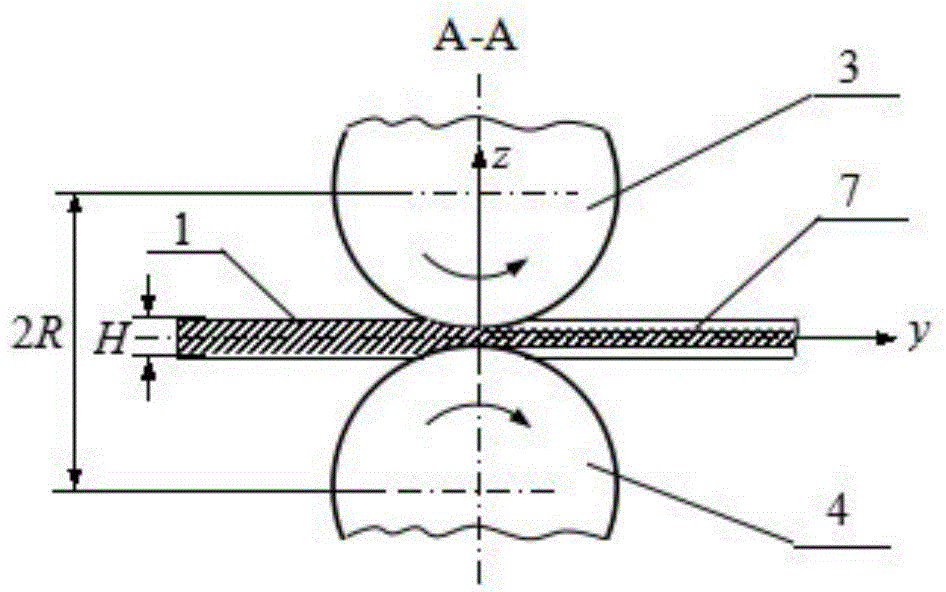

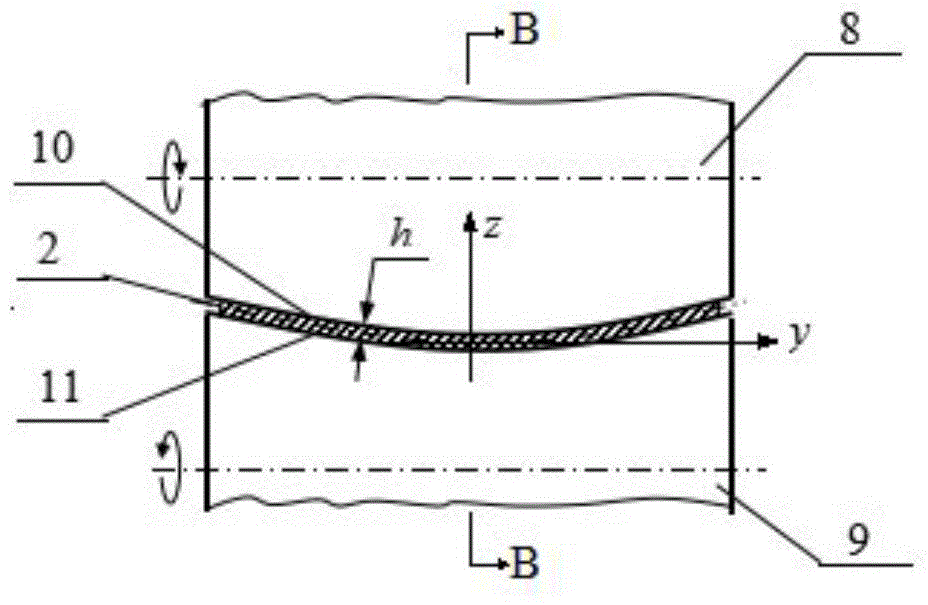

Continuous roll-forming method of constant-thickness curved surface

InactiveCN104438493AGuaranteed StrengthTo achieve the purpose of lightweightVariable thicknessRoll forming

The invention provides a method of forming a constant-thickness three-dimensional curved surface part by a plate material, and belongs to the field of metal plastic processing. The method comprises the following steps: forming the constant-thickness three-dimensional curved surface part by performing two-pass rolling on the plate material by virtue of a convex (concave) working roll, wherein the first-pass rolling is completed by a pair of upper and lower working rolls with convex (or concave) roll outlines, a straight roll seam with a varied clearance in the transverse direction is formed between the upper and lower working rolls, and the plate material is changed into a variable-thickness pre-formed flat plate after being subjected to the first-pass rolling, the second-pass rolling is completed by a pair of upper and lower working rolls with concave and reverse roll outlines, an arc-shaped roll seam with an equal clearance in the transverse direction is formed between the upper and the lower working rolls, and the variable-thickness flat plate subjected to the first-pass pre-forming is changed into the constant-thickness three-dimensional curved surface part after being subjected to the second-pass rolling; controlling the longitudinal bending deformation of the finally formed three-dimensional curved surface by virtue of transverse distribution of the first-pass rolling roll seam clearance, and controlling the transverse bending deformation of the finally formed three-dimensional curved surface by virtue of the outline shape of the second-pass rolling arc-shaped roll seam.

Owner:JILIN UNIV

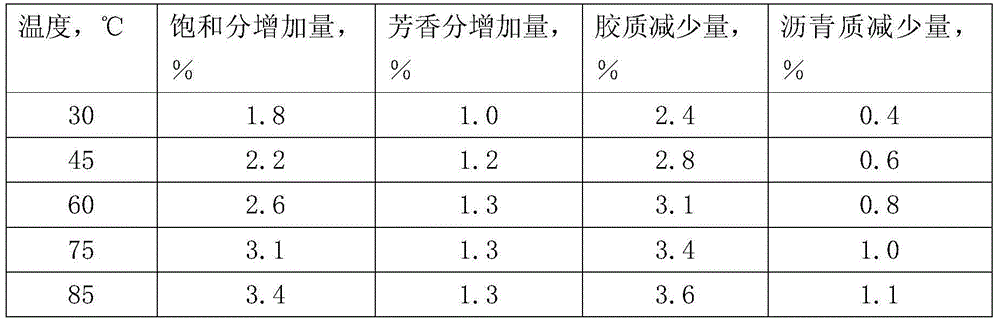

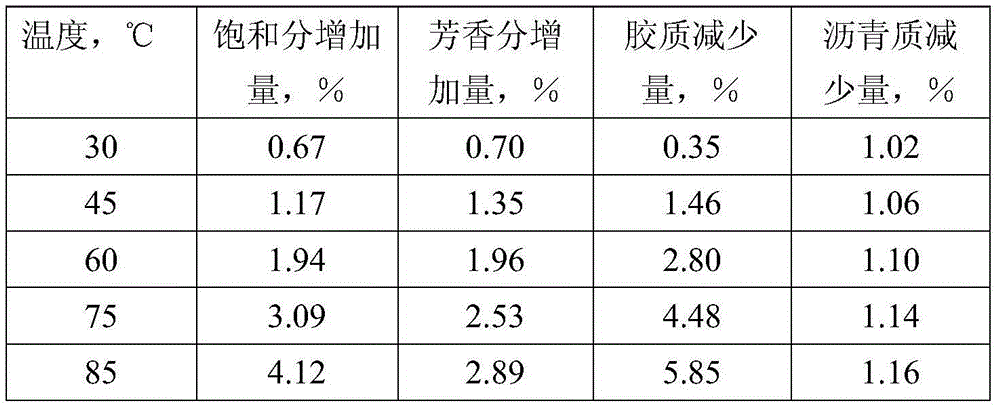

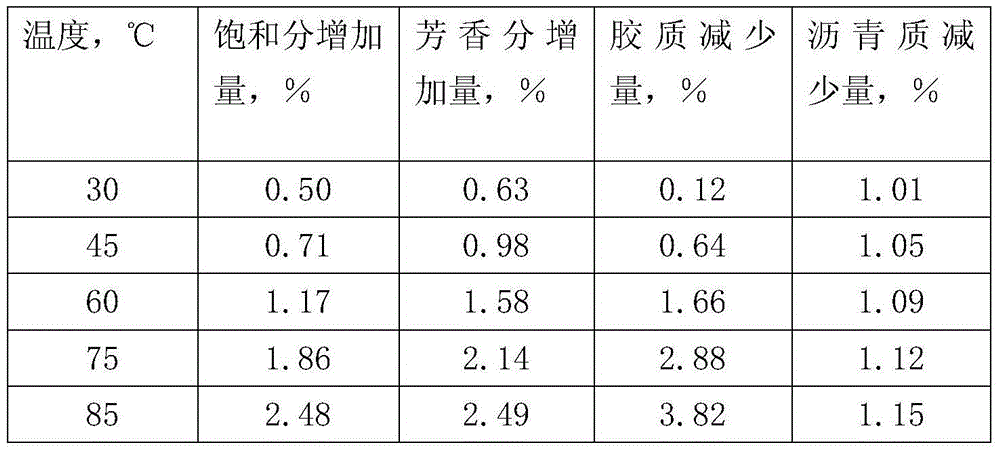

Method for improving residual oil component distribution by using hydrogen donor under action of ultrasonic waves

InactiveCN104449816AQuality improvementChange compositionEnergy based chemical/physical/physico-chemical processesHydrocarbon oils refiningUltrasound - actionHydrogen

The invention discloses a method for influencing content of four components of residual oil by adding a hydrogen donor under the action of ultrasonic waves. The method comprises the following steps: (1) adding the hydrogen donor in the residual oil according to a specified proportion, stirring and fully mixing; (2) putting a uniformly mixed oil sample in an ultrasonic wave generator to apply ultrasonic waves to the oil sample; (3) performing four component separation on the oil sample after being subjected to the ultrasonic wave treatment, weighting the separated four components, and comparing the masses of the separated four components with original four components of original un-treated residual oil to obtain the mass change. By utilizing the method provided by the invention, the four component distribution of the residual oil can be remarkably changed, the contents of saturated phenol and aromatics in the residual oil are increased, and the contents of colloid and asphalt are reduced. The residual oil is pretreated by the method so that the treatment difficulty of the residual oil is reduced.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

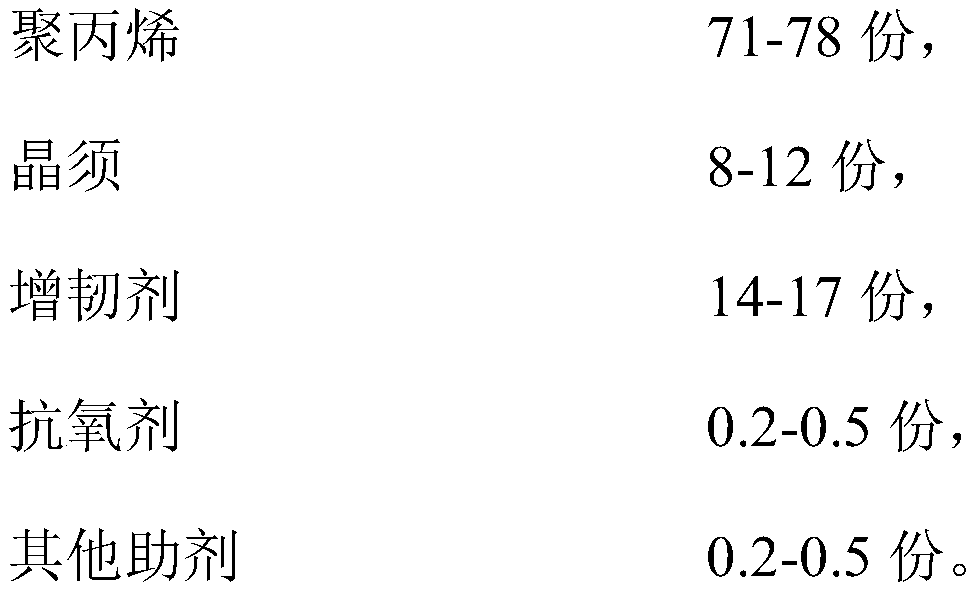

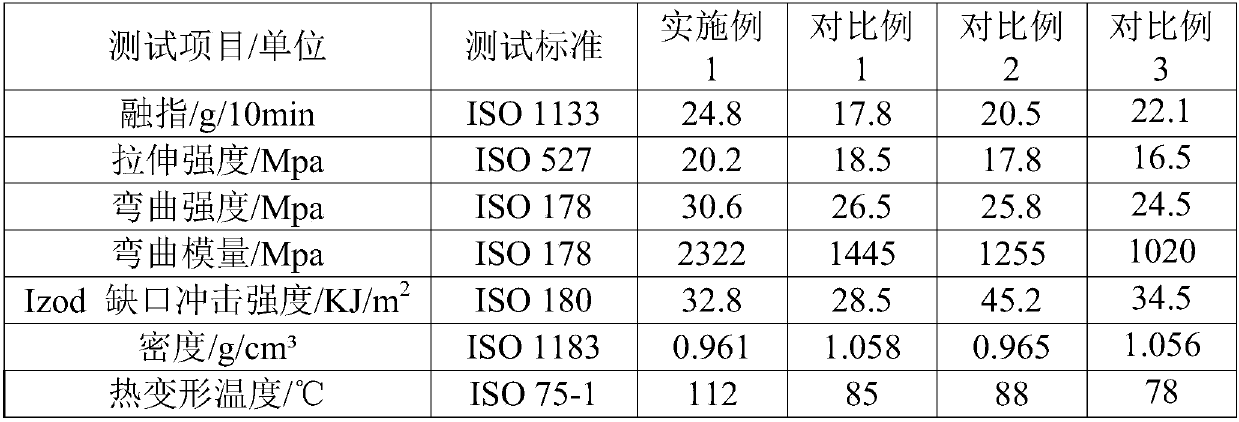

High-rigidity high-toughness low-density polypropylene composition and preparation method thereof

The invention discloses a high-rigidity, high-toughness and low-density polypropylene composition and a preparation method thereof. The high-rigidity, high-toughness and low-density polypropylene composition is prepared from 71-78 parts by weight of polypropylene, 8-12 parts by weight of whiskers, 14-17 parts by weight of a toughening agent, 0.2-0.5 part by weight of an antioxidant and 0.2-0.5 part by weight of other assistants through mixing, extrusion and granulation. According to the preparation method of the high-rigidity, high-toughness and low-density polypropylene composition, high-crystallinity co-polypropylene is used as a base material; whisker with a certain length-diameter ratio is used for enhancing modification; it is ensured that the prepared composition has high strength; meanwhile, the impact strength of the composition is improved with the toughening agent with a high melt index; the prepared polypropylene has high rigidity and high toughness, and the addition amountof the whiskers is only 8-12%, so that the density of the product is controlled at 0.96 g / cm<3> and is 8-10% lower than the density of the conventional PP+EPDM-T20, the lightweight purpose is achieved; the polypropylene composition disclosed by the invention is simple in preparation process, simple and convenient to operate and relatively low in raw material cost.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com