Forming method of variable strength hot stamped piece and die

A forming die and hot stamping technology, which is applied in forming tools, manufacturing tools, vehicle parts, etc., can solve the problems of high manufacturing cost and complicated process, reduce the overall weight, improve the collision energy, and improve the ability to resist side impact deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below according to the accompanying drawings.

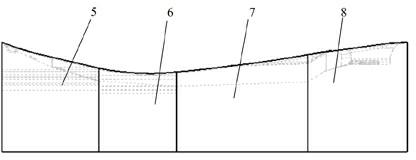

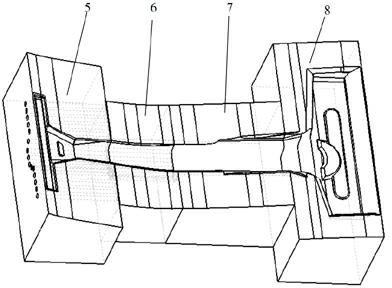

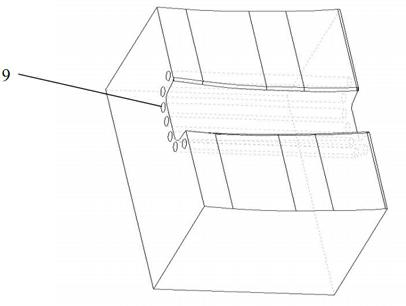

[0023] figure 1 Different parts of the middle B-pillar have different requirements for mechanical properties, which are divided into four levels. The upper end of the B-pillar has the best mechanical properties, as shown in part 1 in the figure, and the tensile strength is above 1500MPa, while the lower end has the worst mechanical properties, as shown in figure 3. , Part 4, the tensile strength is about 650~750MPa or more, and the mechanical properties between the two are next. For part 2 in the figure, the tensile strength is between 1100~1200MPa. According to this requirement, the local cooling hot stamping die is designed, and its die is as follows figure 2 and image 3 As shown, in the hot stamping die, the cooling pipe is arranged in the die block 5, and the cooling pipe is also arranged in the corresponding convex die block; the cooling pipe is arranged in the die b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com