High-strength aerated concrete building block produced by using electrolysis manganese residues and preparation method thereof

A technology of aerated concrete and electrolytic manganese slag, which is applied in the fields of ceramic products, climate sustainability, and other household appliances, and can solve the problem of difficulty in raw material processing, lack of obvious advantages in material performance, and few resource utilization methods of electrolytic manganese slag And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

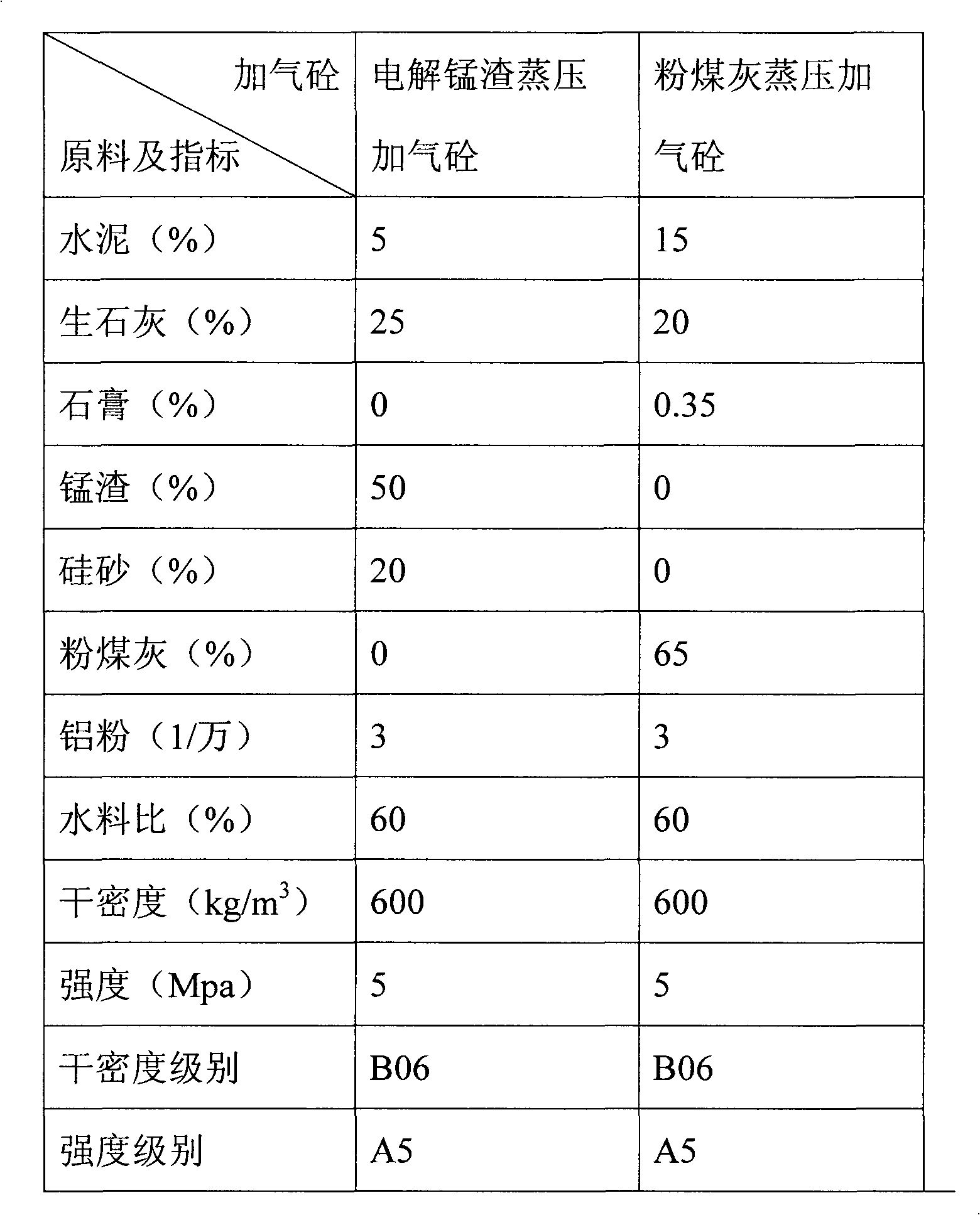

Examples

Embodiment Construction

[0027] Describe in detail the embodiment formula and production process of the present invention below.

[0028] Formula 1: Design density is 400kg / m 3 , the mold volume is V=3.024m 3 (Length, width, height 1.2mx4.2mx0.6m), self-weight is 3.024m 3 x400kg / m 3 =1210kg autoclaved aerated concrete block. According to the proportioning provided by the present invention, the quantity of each component of raw material is as follows:

[0029] Electrolytic manganese slag 48%: weight 580kg; silica sand 20%: weight 242kg; cement 7%: weight 85kg; quicklime 25%: 303kg; aluminum powder 0.92‰: weight 1.11kg; Weight 108.9g; auxiliary agent 0.2%: weight 2.42kg (caustic soda, triglycolaldehyde and polyvinyl alcohol aldehyde glue each 0.807kg); water glass 2%: weight 24kg; water: 726kg.

[0030] Formula 2: Design density is 600kg / m 3 , the mold volume is V=3.024m 3 (Length, width, height 1.2mx4.2mx0.6m), self-weight is 3.024m 3 x600kg / m 3 =1815kg autoclaved aerated concrete blocks. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com