Tubeless thickness-unequal weld joint-free integral steel wheel and processing technology thereof

A non-weld, unequal technology, applied in the direction of spoked wheels, wheels, wheel manufacturing, etc., can solve the problems of large processing workload, high cost, loose and leaking welds, etc., and achieve the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

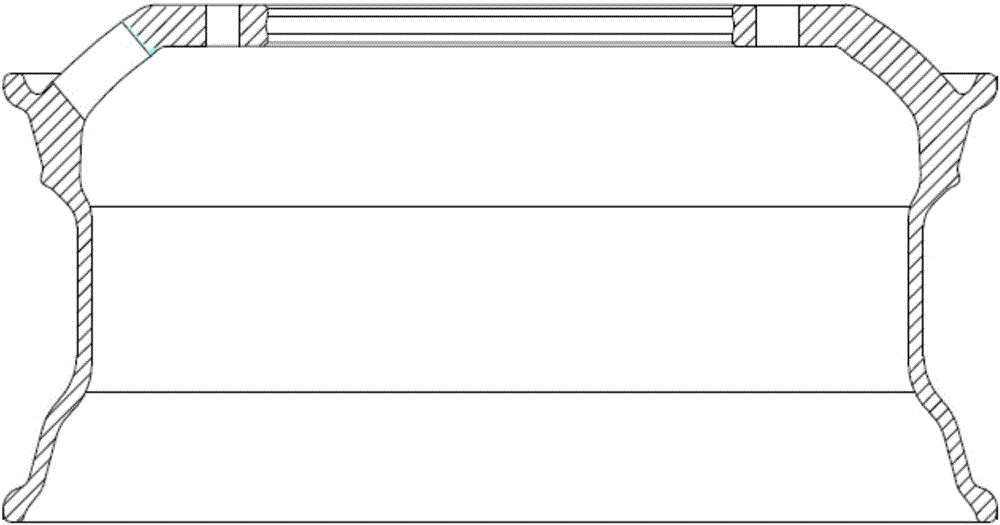

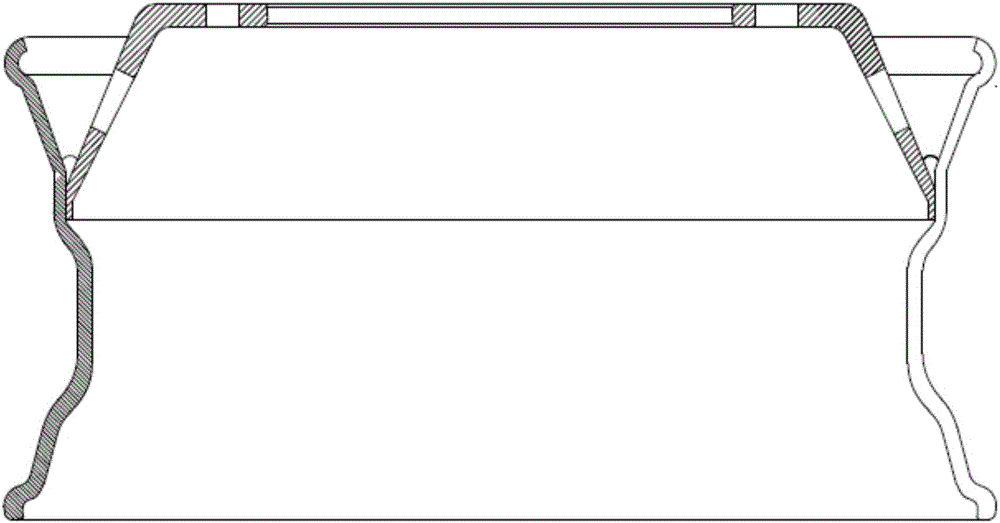

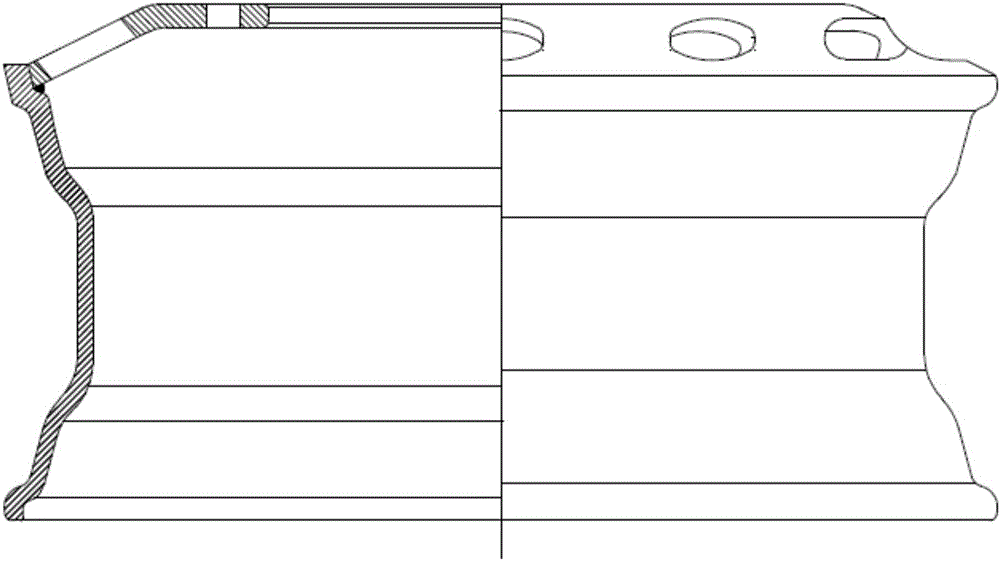

[0031] refer to Figure 4 and Figure 5 . A tubeless integral steel wheel with unequal thickness and no welds, including a rim 1 and a spoke 2, the rim 1 and the spoke 2 are integrally formed and formed by spinning steel plates. The spoke surface 21 of the spoke 2 is one of a flat cone surface, a convex cone surface or a concave cone surface. Designing the spoke surface 21 as a convex cone surface or a concave cone surface can increase the arch force of the wheel.

[0032] refer to Figure 4 , Figure 6 and Figure 7 . A flange 3 is provided at the joint between the rim 1 and the spoke 2, the thickness of the rim is 4-18 mm, and several reinforcing ribs 22 are evenly distributed on the inner surface of the spoke 2, and the reinforcing ribs 22 can increase the strength of the spoke 2.

[0033] refer to Figure 8 , the processing technology of the tubeless unequal-thick non-welded monolithic steel wheel comprises the following steps:

[0034] The first step is to make bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com