Rock debris annulus reinjection device and control method thereof

An annulus and cuttings technology, used in construction and other directions, can solve the problems of high cost of repairing casing, accelerated corrosion of inner annulus casing, and large economic loss of production shutdown, so as to reduce economic losses, slow down corrosion, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

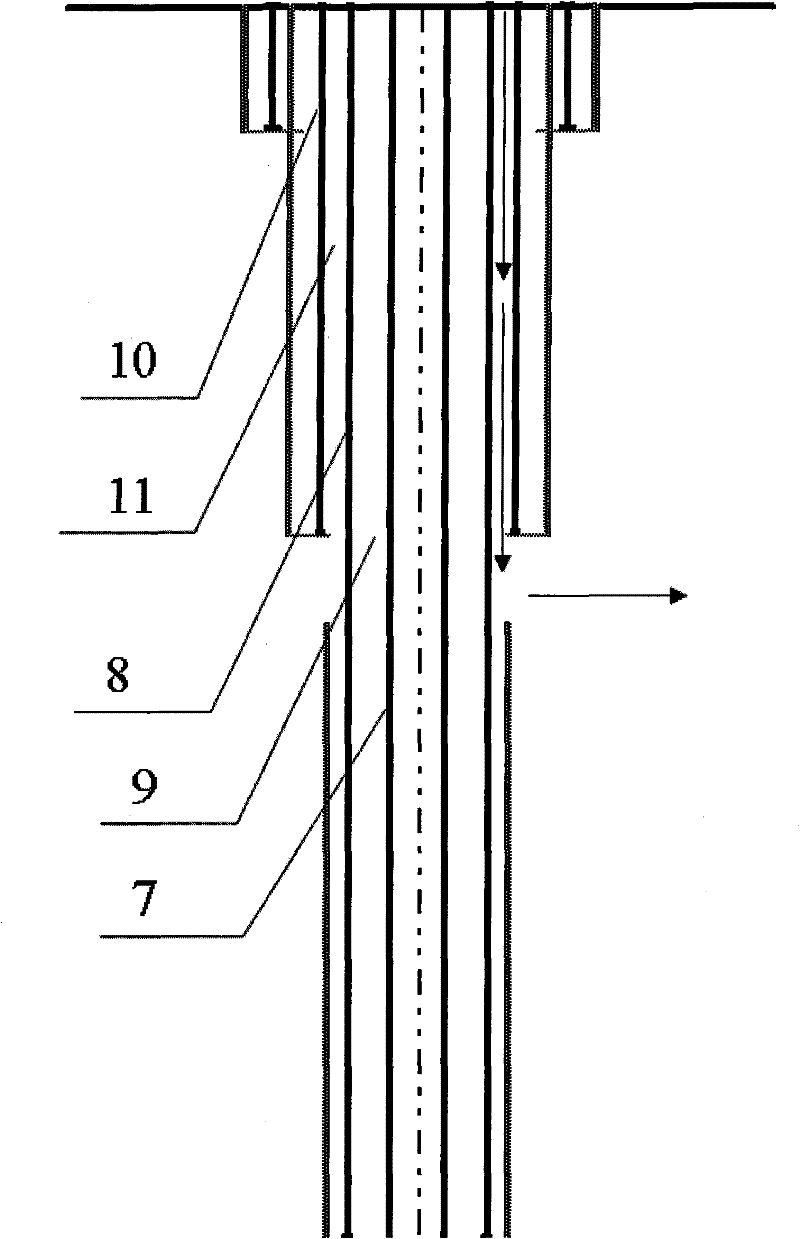

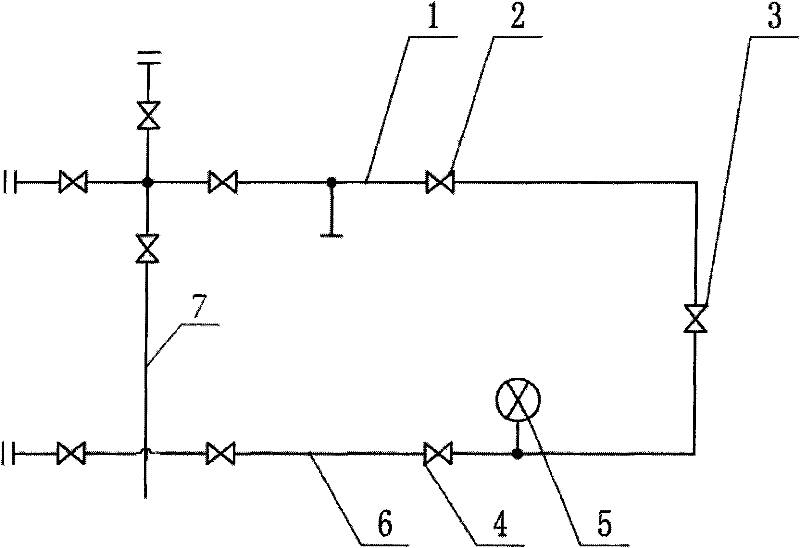

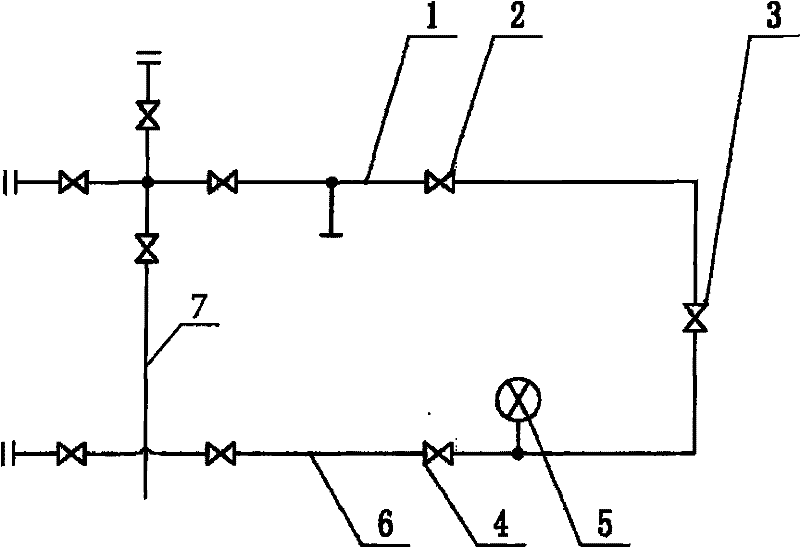

[0023] Example 1, see figure 1 , 2 , the water injection well is selected as the cuttings reinjection well, the water injection pipeline 7 is in the middle, and the inner annular space 9 is formed between the water injection pipeline 7 and the 9-5 / 8" casing 8, and the 9-5 / 8" casing 8 and the The outer annular space 11 is formed between the 13-3 / 8" casing pipes 10, and the water injection pipeline isolation valve 2, the pressure control valve 3, the inner The annulus isolation valve 4 and the inner annulus pressure gauge 5 form a device for cuttings annulus reinjection, and the pressure balance of the inner and outer annulus is realized by adjusting the pressure control valve.

[0024] A control method for cuttings annulus reinjection device of the present invention, during operation, control the cuttings reinjection grout from entering the inner annulus according to the following steps: adopt the above-mentioned installation for cuttings annulus reinjection device; predict t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com