Municipal solid waste extreme decrement and highly resourceful treatment process and municipal solid waste extreme decrement and highly resourceful treatment device

A technology for municipal solid waste and its treatment process, which is applied in the field of extreme reduction and highly resourceful treatment process and equipment of municipal solid waste, and can solve the problems of secondary pollution, thermal efficiency, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

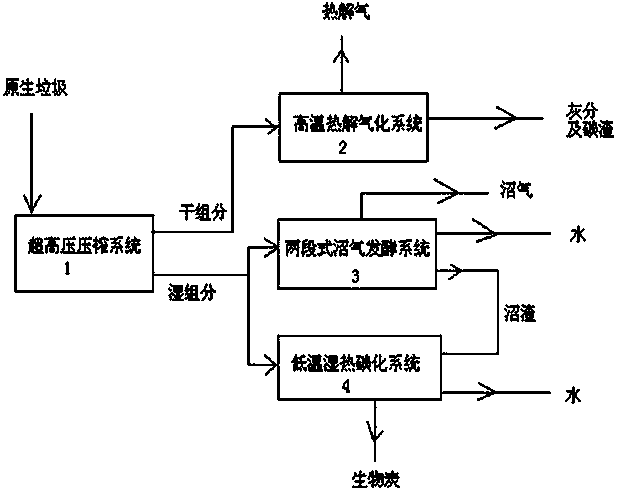

[0031] The municipal solid waste collected by the municipal waste transfer station is put into the waste compactor by the loading equipment (e.g., grab bucket) for ultra-high pressure pressing, and is sorted into dry components with a moisture content below 25% and waste mainly from biomass at one time Wet components composed of material slurry.

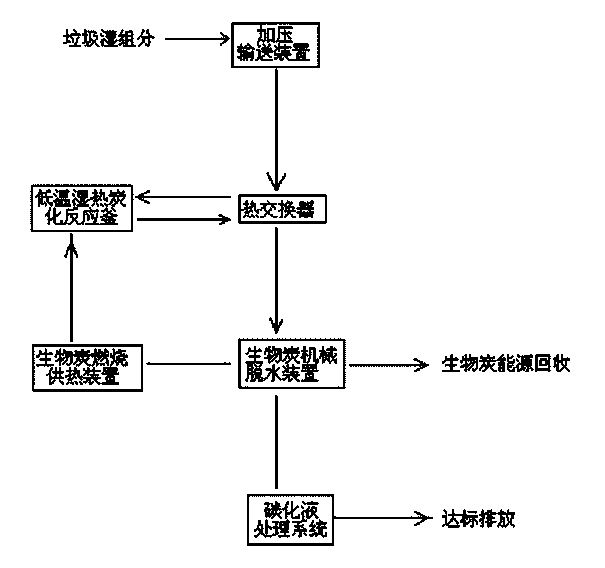

[0032] The wet components enter the low-temperature wet heat carbonization reactor, the temperature is controlled at 200°C, and the residence time in the reactor is 0.5 hours. After the reaction is completed, the material is discharged into the heat exchanger through the pressure relief valve on the top of the reactor, and after heat exchange with the wet component input into the heat exchanger, it is cooled to below 100°C, and then enters the chamber filter press for dehydration to complete solid-liquid separation, thereby Biochar with a moisture content of less than 30% and carbonized liquid containing N, P and other components are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com