Method for preparing charcoal activated carbon flammable gas biological oil by utilizing crop straws

A crop straw and production method technology, applied in the field of processing and production technology, can solve problems affecting aircraft take-off and landing, safety, environmental pollution, hazards, etc., and achieve the effect of increasing economic and social benefits and reducing investment in fixed assets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

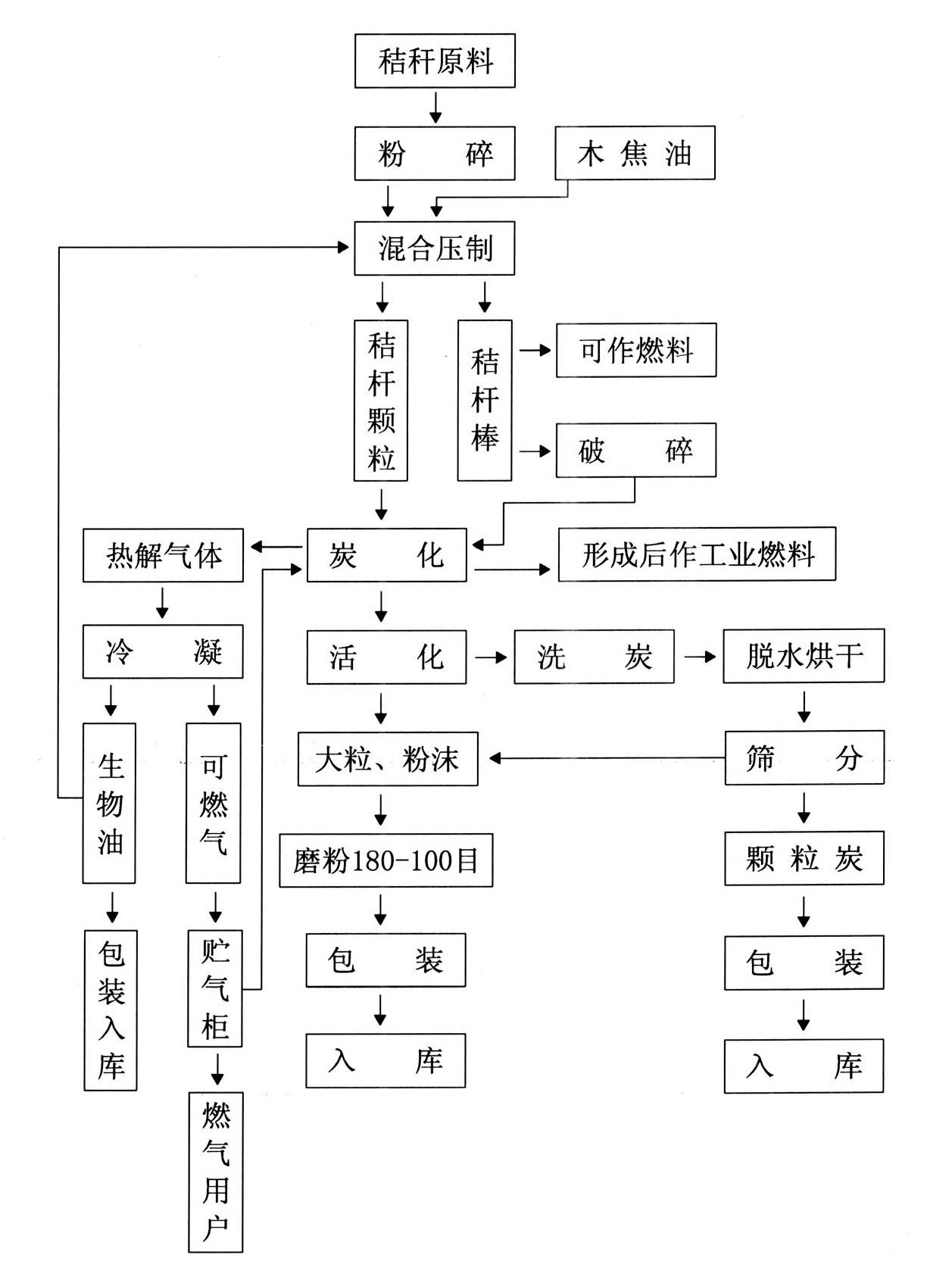

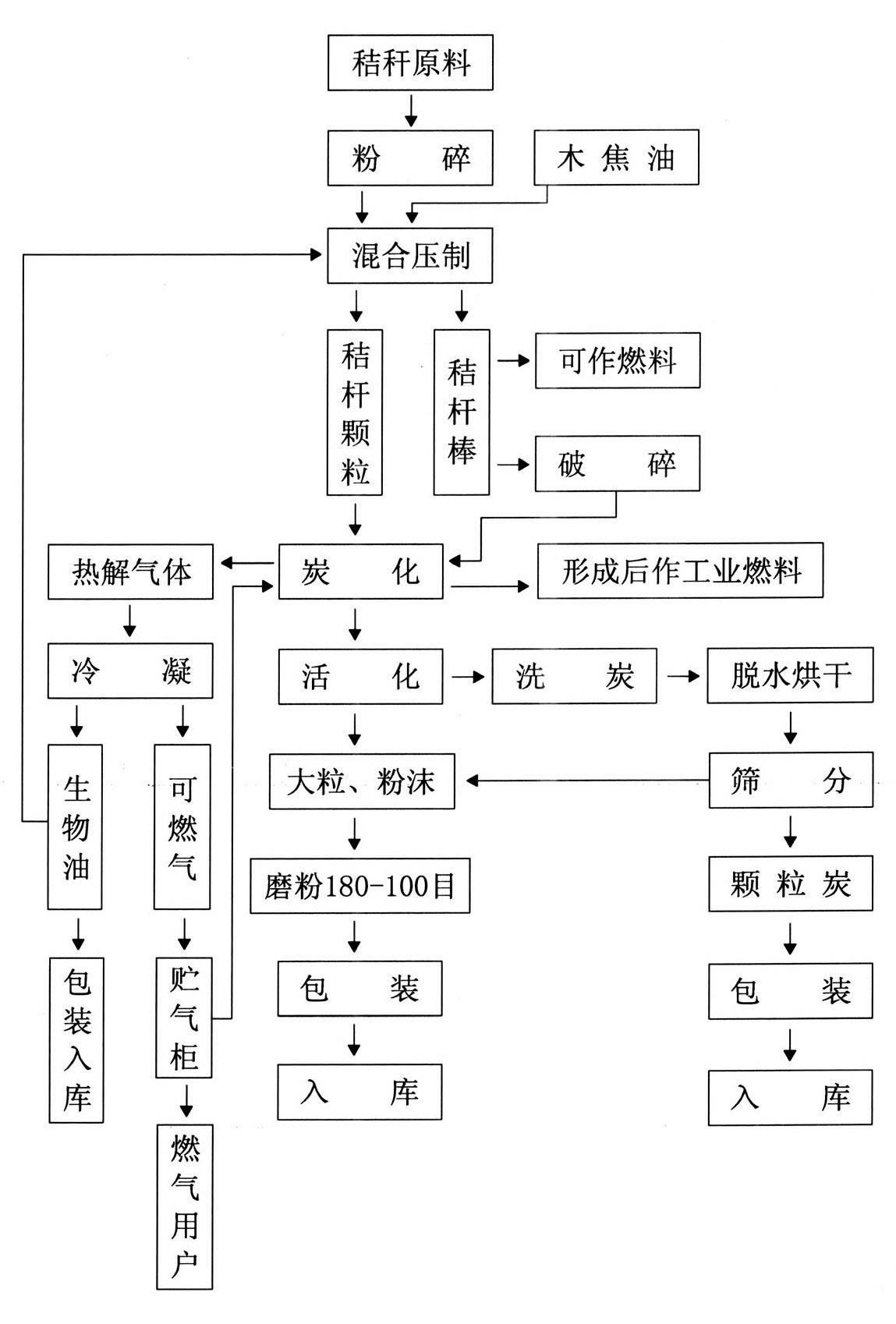

Method used

Image

Examples

Embodiment Construction

[0018] One, preparation method of the present invention, it comprises the following steps:

[0019] 1. Raw material crushing:

[0020] The collected crop stalks are pulverized into straw powder with a particle size of 8-30 mesh with a pulverizer, and the moisture content of the straw is controlled at 10-15%.

[0021] 2. Mixed pressing:

[0022] Add wood tar to the straw powder as a binder, stir and mix evenly, press the screw extruder into straw sticks, and use the straw pellets formed after the straw sticks are broken as carbonization raw materials. The amount of straw powder and wood tar is based on the screw extrusion The hole diameter of the steel flower plate at the outlet of the press is mixed according to the weight ratio as follows:

[0023] ① The hole diameter of the steel flower plate at the exit of the screw extruder is 2-2.2mm, and the weight ratio of straw powder and wood tar is 80-85%: 15-20%;

[0024] ② The hole diameter of the steel flower plate at the exit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com