Method for producing portland cement clinker using domestic waste flying ash

A technology of domestic waste incineration and Portland cement, applied in cement production and other directions, can solve the problems of secondary pollution, high treatment cost and high treatment cost, and achieve the effects of saving production cost, wide application range and low treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

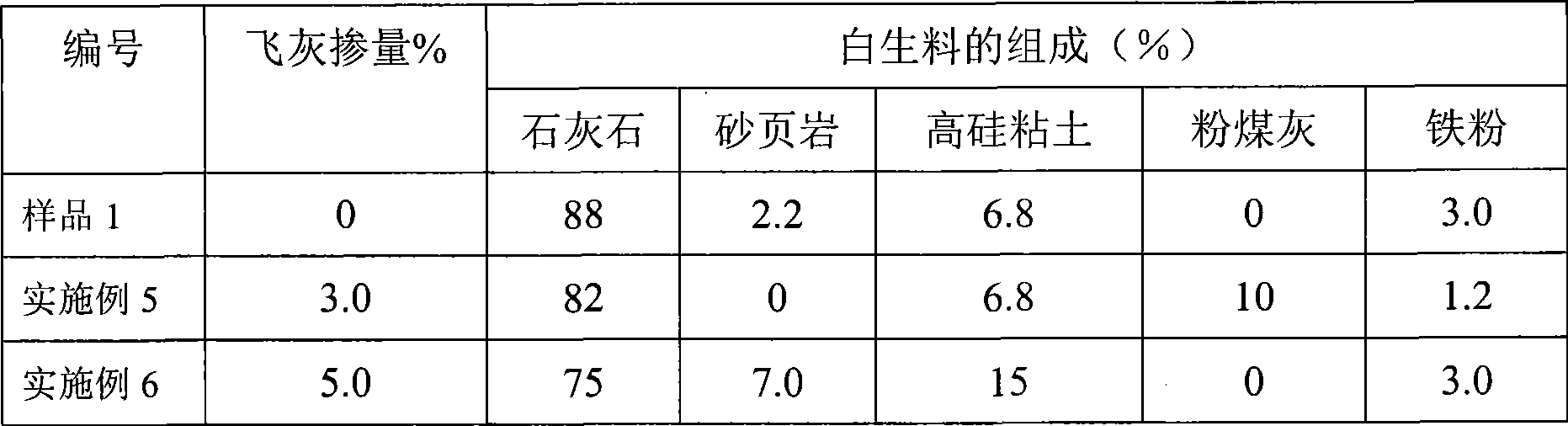

Examples

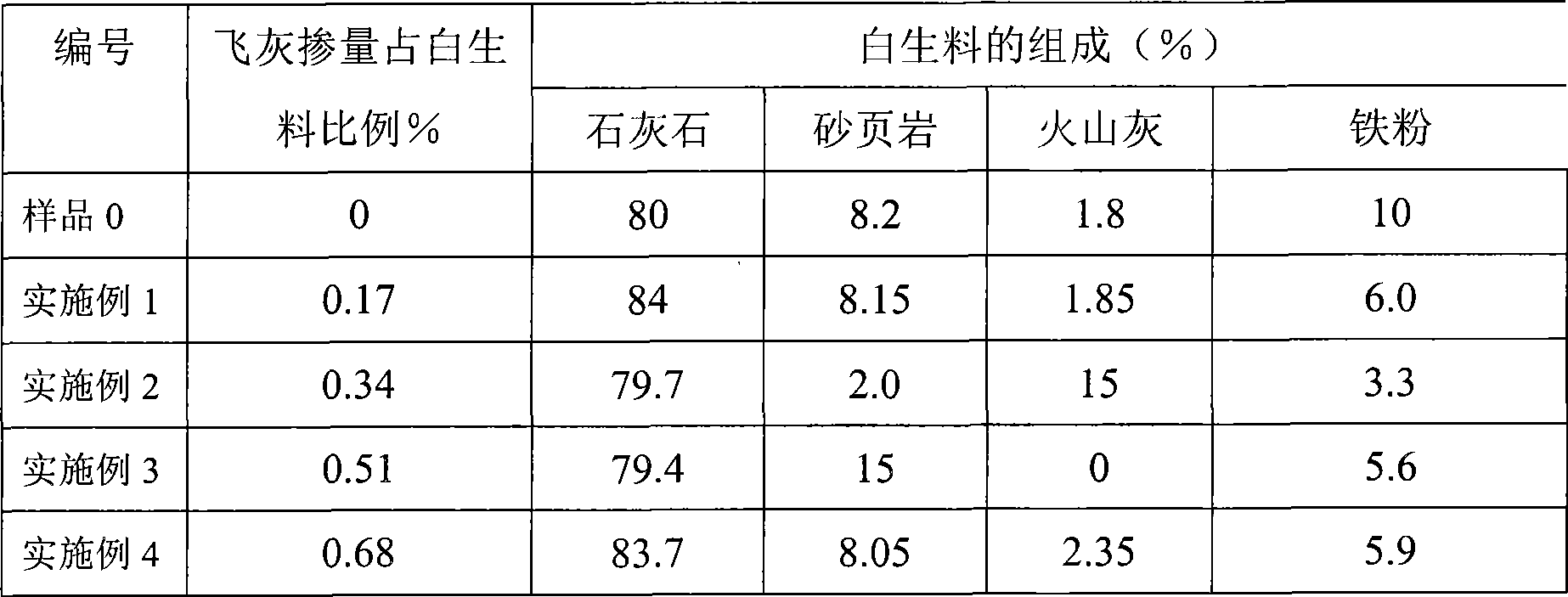

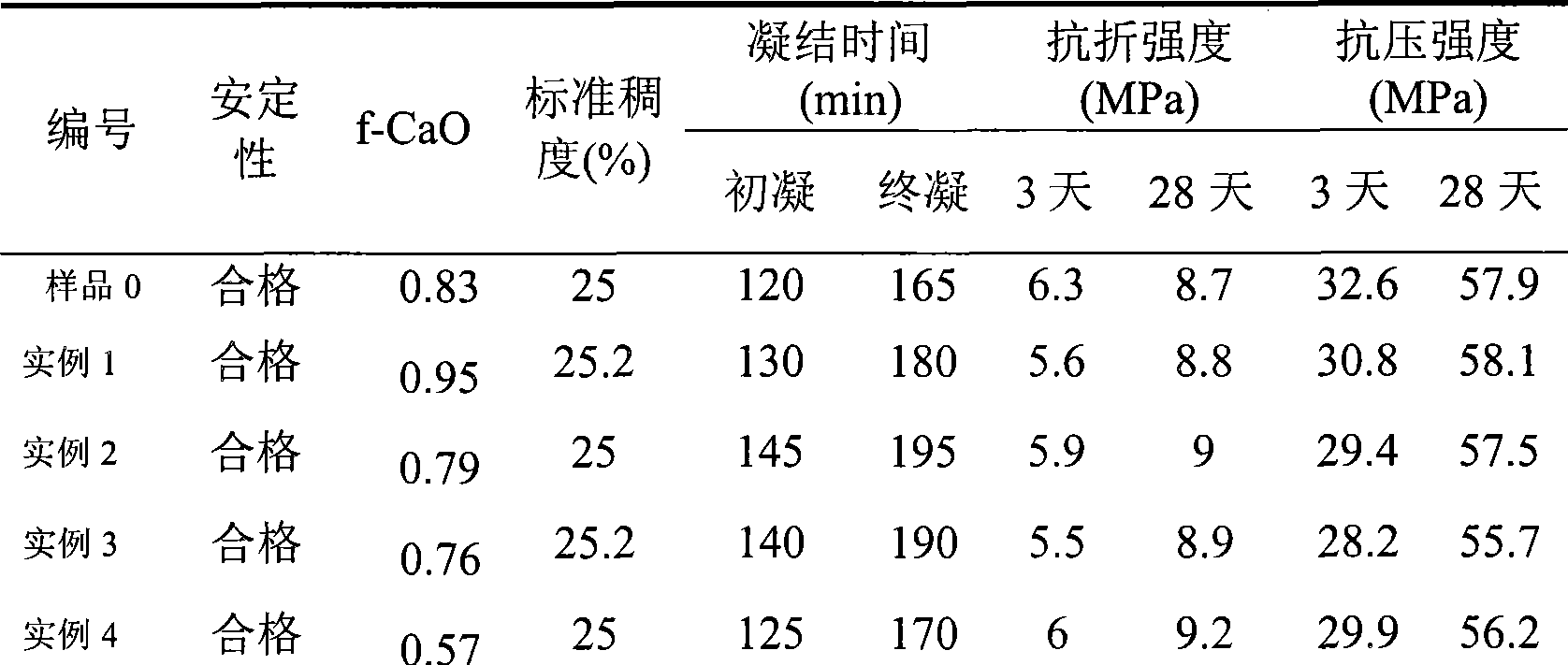

Embodiment 1

[0027] Co-processing in the new dry process kiln production line with double series (kiln train and furnace train) five-stage suspension preheater and FLS spouting type calciner with Φ4.75×75 meters, Guangzhou Likeng waste incineration power plant Fly ash test. The calciner, 5-stage cylinder, kiln tail smoke chamber and smoke chamber ascending flue of the cement kiln are all designed with dust cleaning holes, air cannons and manual cleaning operation platforms. In this embodiment, on the basis of the existing production line, a fly ash sealed storage bin similar to the pulverized coal bin structure and a separate metering device are added near the kiln head coal powder bin. The position (temperature range is 850°C ~ 950°C) has added a bypass air release device. The device is connected with the ascending flue at the end of the kiln through a controllable valve, and is equipped with a coarse powder classifying cyclone, a bag filter and an exhaust fan. Open the valve to make pa...

Embodiment 2

[0029] The basic situation and transformation of the kiln, the storage and feeding methods of fly ash, and the quality level of coal powder are the same as those in Example 1. The amount of fly ash added is 0.34% of the white raw meal, that is, the amount of fly ash sprayed from the kiln head per hour. Ash is 1.08-1.11 tons. Since the fly ash needs to be preheated and the decomposition reaction of some substances needs to absorb heat, in order to maintain the temperature of the firing zone at 1250 ° C ~ 1450 ° C, the proportion of coal used in the kiln head injection is adjusted from 38% when no fly ash is burned to 40%, the length of the firing zone is 24 meters, the temperature of the kiln tail smoke chamber is 1050°C-1150°C, the outlet temperature of the calciner is 870°C-920°C, and the outlet temperature of the first-stage cylinder is about 320°C-340°C. In order to maintain the normal operation of the kiln, the resistance of the high-temperature fan is basically unchanged....

Embodiment 3

[0031] The basic situation and transformation of the kiln, the storage and feeding methods of fly ash and the quality level of coal powder are the same as those in Example 1. Ash is 1.62-1.65 tons. Since the fly ash needs to be preheated and the decomposition reaction of some substances needs to absorb heat, in order to maintain the temperature of the firing zone at 1250 ° C ~ 1450 ° C, the proportion of coal used in the kiln head injection is adjusted from 38% when no fly ash is burned to 41%, the length of the firing zone is 24 meters, the temperature of the kiln tail smoke chamber is 1050°C-1150°C, the outlet temperature of the calciner is 870°C-920°C, and the outlet temperature of the first-stage cylinder is about 320°C-340°C. The workload of manually cleaning the smoke chamber and the skinning of the ascending pipe is 2 times / 8 hours, the frequency of using the air cannon is 4 hours once, and the bypass air is used for 10-20 minutes each time, and the frequency of use is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com