Method for treating garbage leachate

A landfill leachate and treatment method technology, applied in the field of wastewater treatment, can solve the problems of large fluctuations in treatment volume, difficult cleaning, secondary pollution, etc., and achieve the effects of no secondary pollution, good treatment effect, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

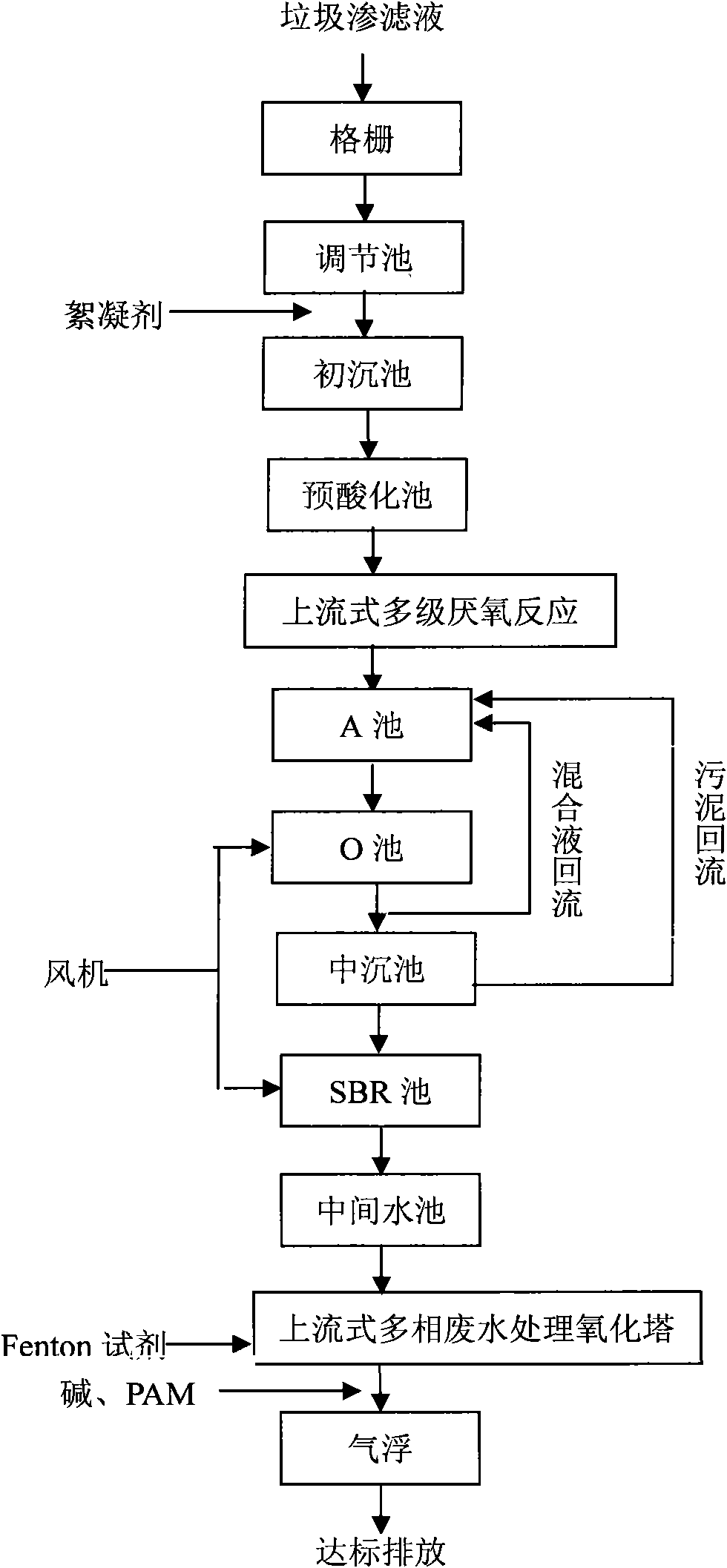

Image

Examples

Embodiment 1

[0017] A pilot test study was carried out on the leachate of a landfill in Guangxi. The raw water CODcr was about 5000mg / L, the hydraulic retention time of the regulating tank was 4h, the flocculants PAC 200mg / L, PAM 2mg / L were added, and the surface load of the primary sedimentation tank was 0.8m 3 / m 2 h, the pre-acidification time is 4 hours, and the pH value of the wastewater is adjusted to about 7 and pumped into the anaerobic reactor. m 3 d, the hydraulic retention time of pool A is 1d, the hydraulic retention time of pool O is 2d, and the volume load of SBR pool is 0.3kBOD / m 3 d. Dissolved oxygen is 2mg / L, sludge concentration is about 3500mg / L, SBR effluent COD is about 380mg / L, the hydraulic retention time of the intermediate pool is 4h, and the effluent of the intermediate pool is pumped into the fenton oxidation tower. The fenton oxidation used in this embodiment The tower is an upflow multiphase wastewater treatment oxidation tower, with fenton reagent H 2 o 2 ...

Embodiment 2

[0019]A pilot test study was carried out on the landfill leachate in Guangxi, the raw water CODcr was about 7000mg / L, the hydraulic retention time of the regulating tank was 4h, the flocculant PAC250mg / L, PAM3mg / L was added, and the surface load of the primary sedimentation tank was 1m 3 / m 2 h, the pre-acidification time is 4 hours, and the pH value of the wastewater is adjusted to about 7 and pumped into the anaerobic reactor. m 3 d, the hydraulic retention time of pool A is 1d, the hydraulic retention time of pool O is 2d, and the volume load of SBR pool is 0.5KgBOD / m 3 d. Dissolved oxygen is 2.5mg / L, sludge concentration is about 4000mg / L, SBR effluent COD is about 500mg / L, the hydraulic retention time of the middle pool is 4h, and the effluent of the middle pool is pumped into the fenton oxidation tower. The fenton used in this example The oxidation tower is an upflow multiphase wastewater treatment oxidation tower, with fenton reagent H 2 o 2 2500mg / L, FeSO 4 1200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com