Method for utilizing municipal sludge as raw material of steel industrial sintering ore

A technology for municipal sludge and iron and steel industry, which is applied in the direction of sludge treatment, chemical instruments and methods, and process efficiency improvement. The effect of high input ratio and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

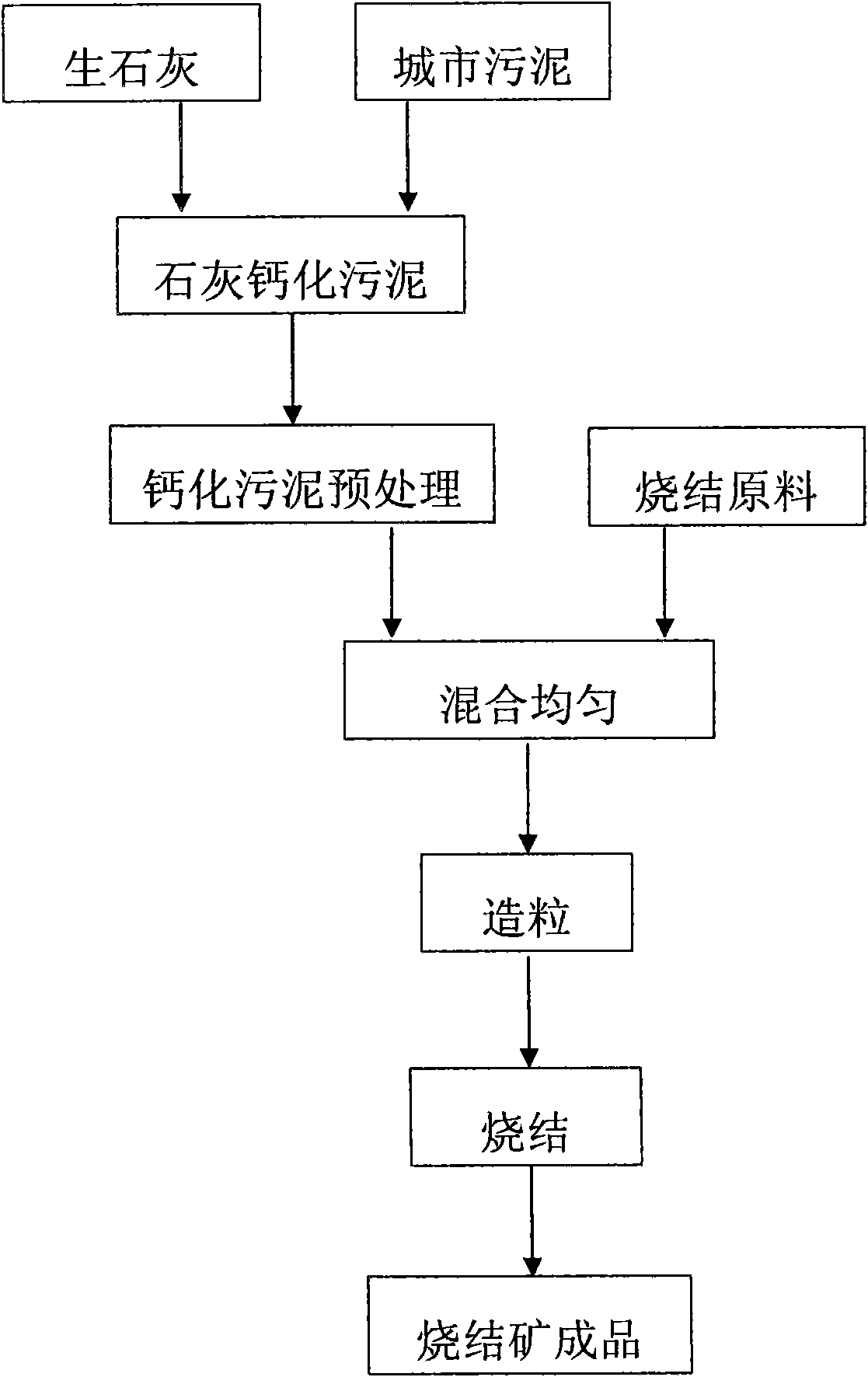

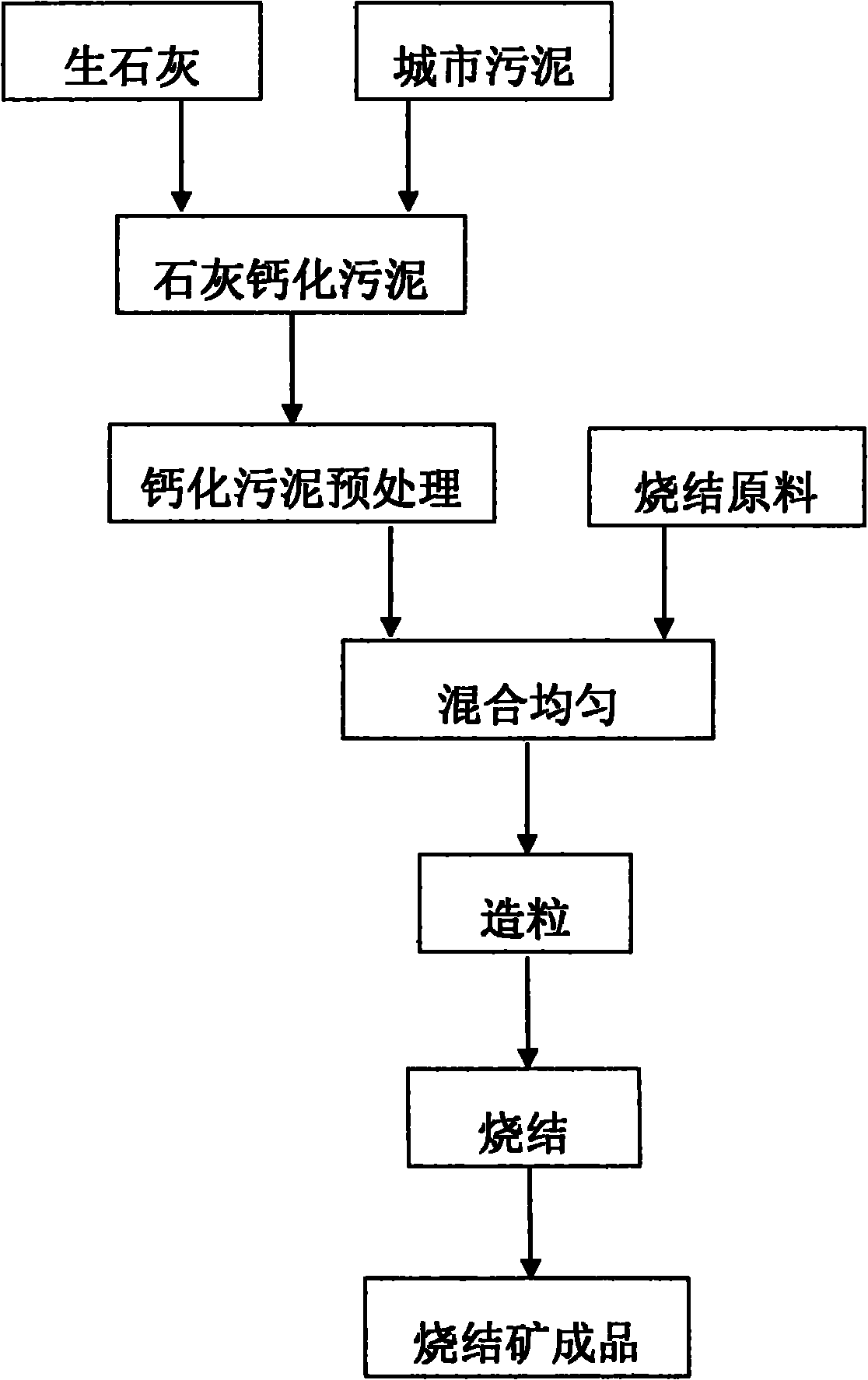

Image

Examples

Embodiment 1

[0021] The calcified sludge after lime drying treatment is naturally air-dried to a moisture content of 10%, then crushed to a particle size of 0.05-1mm, and added to the sintered raw material, and its mass (dry basis) is 2% of the total mass of the sintered raw material. %. The results of the sintering test show that: compared with no sludge particles, after adding lime calcified sludge, the amount of lime added is reduced by 0.8%, the sintering finished product rate is increased by 4.1%, the sintering utilization coefficient is increased by 10.2%, and the solid fuel consumption Reduced by 3.8kg / T, the performance of sintered ore is significantly improved, and the cost of sintering is significantly reduced.

Embodiment 2

[0023] The calcified sludge after lime drying treatment is granulated. After the sludge is granulated, it is naturally air-dried to a moisture content of 2%, and then it is crushed to a particle size of 0.05-1mm, and added to the sintering raw material. base) is 3% of the total mass of sintered raw materials. The sintering test results show that: compared with no sludge particles, after adding lime calcified sludge, the amount of lime added is reduced by 1.2%, the sintering finished product rate is increased by 5.0%, the sintering utilization coefficient is increased by 13.0%, and the solid fuel consumption Reduced by 0.6kg / T, the performance of sintered ore is significantly improved, and the cost of sintering is significantly reduced.

Embodiment 3

[0025]The calcified sludge after lime drying treatment is granulated. After the sludge is granulated, it is naturally air-dried to a moisture content of 10%, and then crushed to a particle size of 0.05-3mm, and added to the sintered raw material. base) is 3.5% of the total mass of sintered raw materials. The sintering test results show that: compared with no sludge particles, after adding lime calcified sludge, the amount of lime added is reduced by 1.6%, and the sintered finished product rate is increased by 1.5%. The sintering utilization coefficient increased by 2.0%, the solid fuel consumption decreased by 0.3kg / T, the performance of sintering ore was improved, and the sintering cost was significantly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com