Solid organic waste gasification and melting cycle-treatment process

A technology of gasification and melting of organic waste, applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of low resource utilization rate and environmental pollution, and achieve the effect of high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

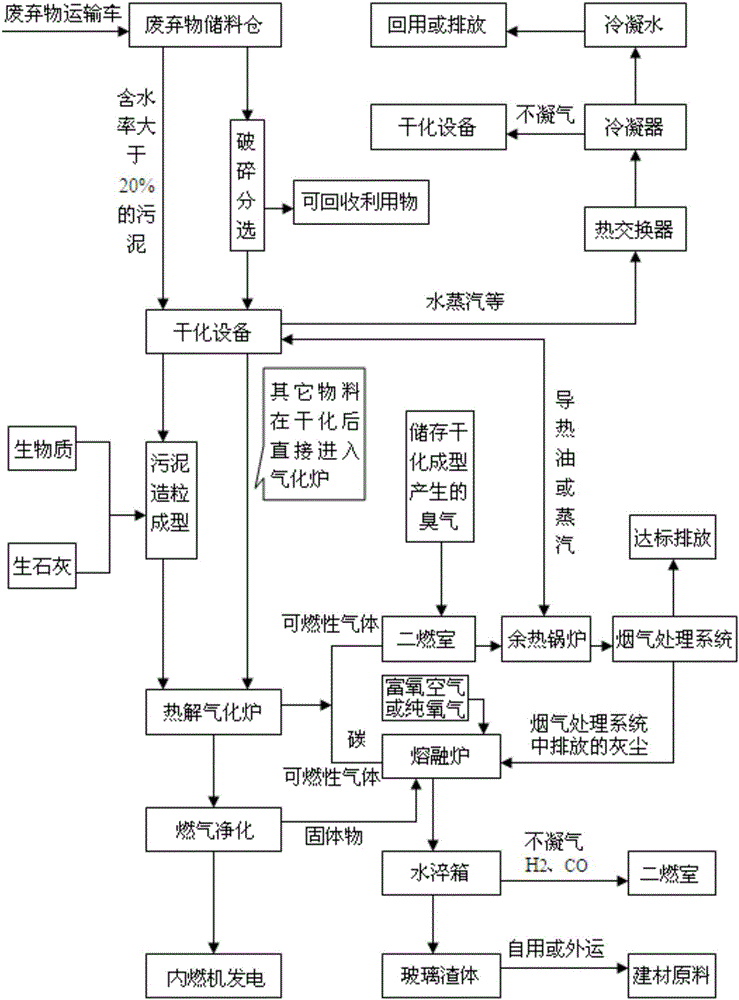

[0017] The invention discloses a cycle treatment process of gasification and melting of organic solid waste, which mainly utilizes the heat contained in the waste itself, reduces the dependence on external energy sources, and provides a safe, efficient, energy-saving and emission-reducing, low-carbon environmental protection, running Processes and systems for low cost, reduction, stabilization, harmless, and resourceful disposal.

[0018] This system is composed of storage system, sorting and crushing system, drying and forming system, gasification and melting system, gas utilization system, flue gas purification system and control system. The process of process realization is as follows.

[0019] ⑴Material storage

[0020] All materials are stored in a closed space, and the waste gas generated is pumped by the fan to the gasification melting furnace for use as a gasification agent. The space is under a slight negative pressure to ensure that the waste gas is not discharged o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com