Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Industrial chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

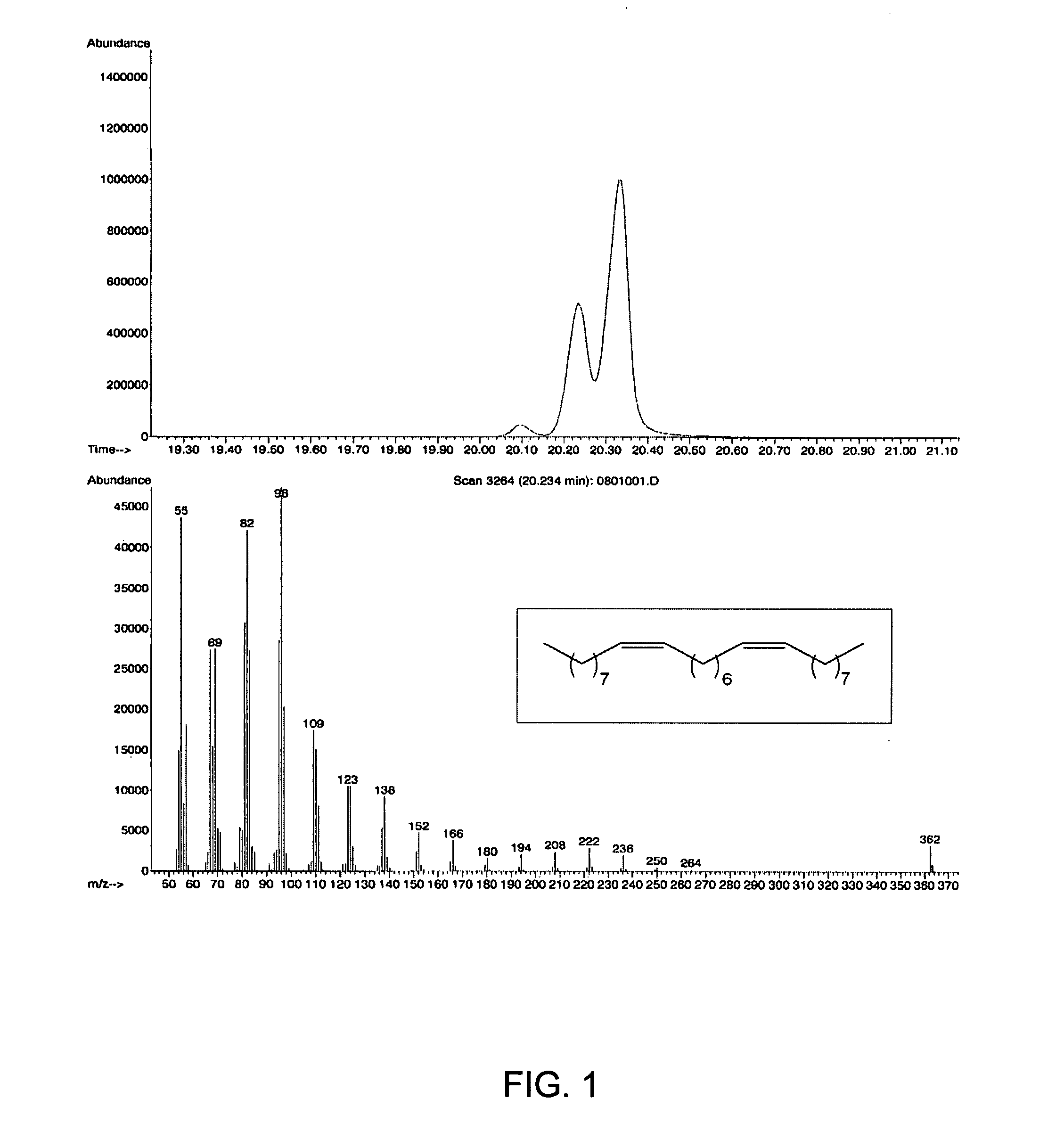

Ring opening cross-metathesis reaction of cyclic olefins with seed oils and the like

ActiveUS20080064891A1Fatty acid esterificationOrganic compound preparationOrganic synthesisRuthenium

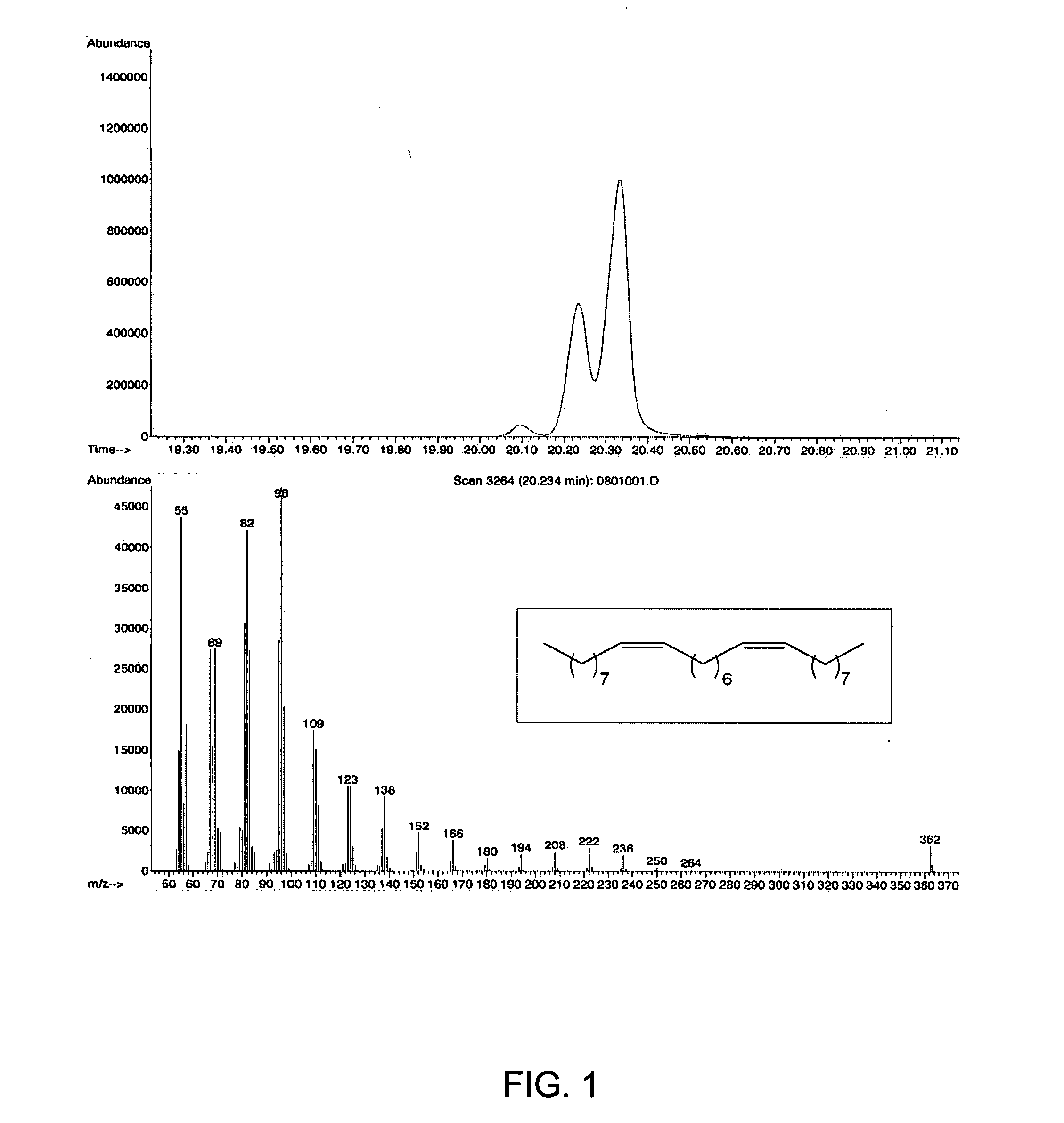

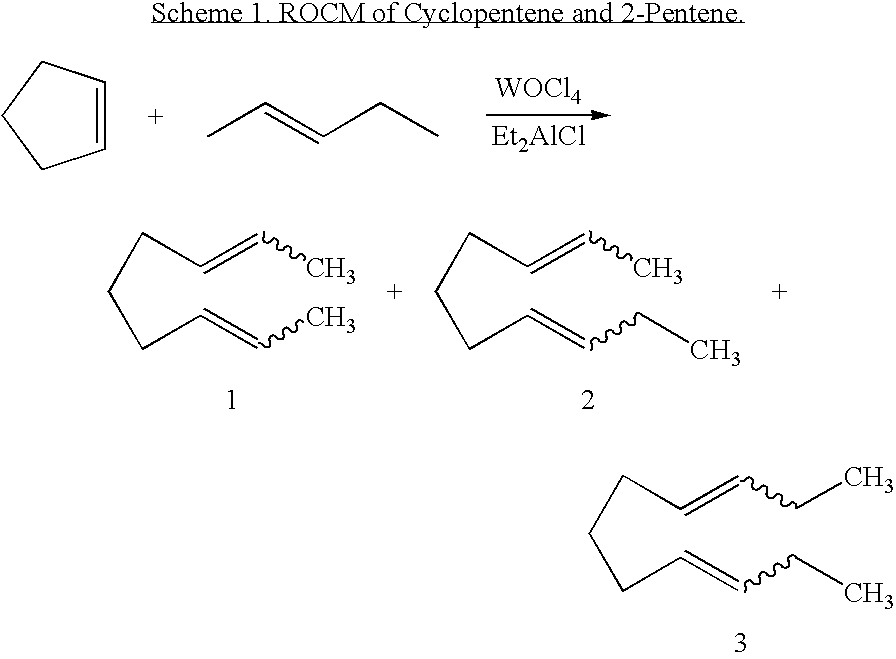

This invention relates generally to olefin metathesis, and more particularly relates to the ring-opening, ring insertion cross-metathesis of cyclic olefins with internal olefins such as seed oils and the like. In one embodiment, a method is provided for carrying out a catalytic ring-opening cross-metathesis reaction, comprising contacting at least one olefinic substrate with at least one cyclic olefin as a cross metathesis partner, in the presence of a ruthenium alkylidene olefin metathesis catalyst under conditions effective to allow ring insertion cross metathesis whereby the cyclic olefin is simultaneously opened and inserted into the olefinic substrate. The invention has utility in the fields of catalysis, organic synthesis, and industrial chemistry.

Owner:WILMAR TRADING PTE LTD

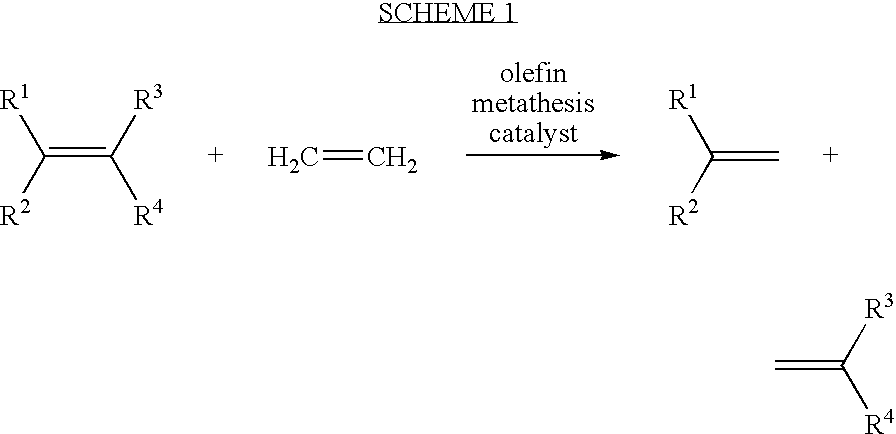

Synthesis of terminal alkenes from internal alkenes and ethylene via olefin metathesis

This invention relates generally to olefin metathesis, and more particularly relates to the synthesis of terminal alkenes from internal alkenes using a cross-metathesis reaction catalyzed by a selected olefin metathesis catalyst. In one embodiment of the invention, for example, a method is provided for synthesizing a terminal olefin, the method comprising contacting an olefinic substrate comprised of at least one internal olefin with ethylene, in the presence of a metathesis catalyst, wherein the catalyst is present in an amount that is less than about 1000 ppm relative to the olefinic substrate, and wherein the metathesis catalyst has the structure of formula (II)wherein the various substituents are as defined herein. The invention has utility, for example, in the fields of catalysis, organic synthesis, and industrial chemistry.

Owner:MATERIA

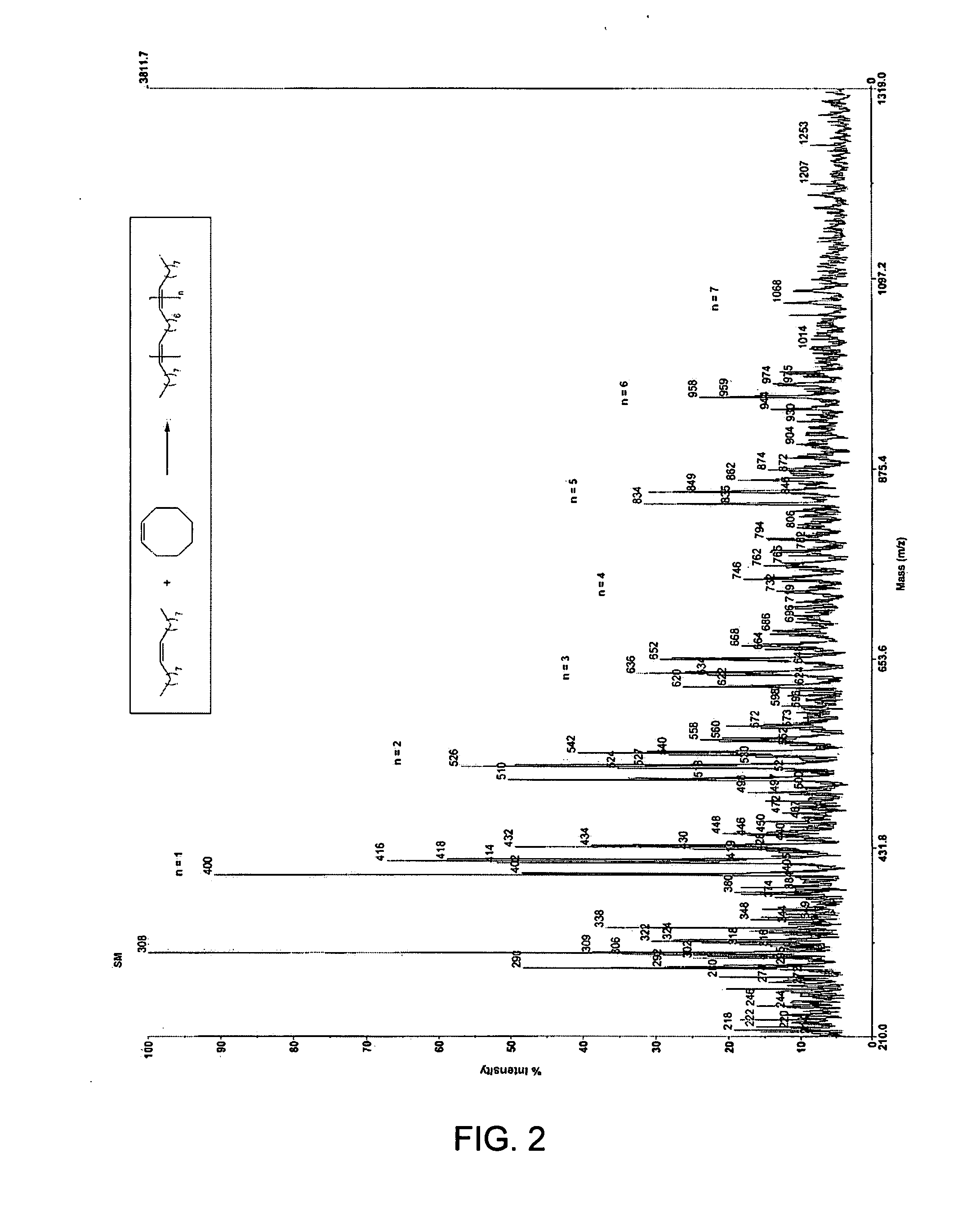

Telechelic olefin metathesis polymers from renewable feedstocks

Olefin metathesis polymerization reactions are disclosed, and more particularly ring-opening metathesis polymerization of cyclic olefins with olefinic compounds, such as are derived from seed oils and the like, to form telechelic polymers. In one aspect, a method is provided for carrying out a catalytic ring-opening metathesis polymerization reaction, comprising contacting at least one olefinic compound with at least one cyclic olefin, in the presence of a ruthenium alkylidene olefin metathesis catalyst under conditions effective to allow ring-opening metathesis polymerization of the cyclic olefin, whereby the cyclic olefin polymer formed is terminated with the olefinic compound. The invention has utility in the fields of catalysis, organic synthesis, polymer chemistry, and industrial chemistry.

Owner:MATERIA

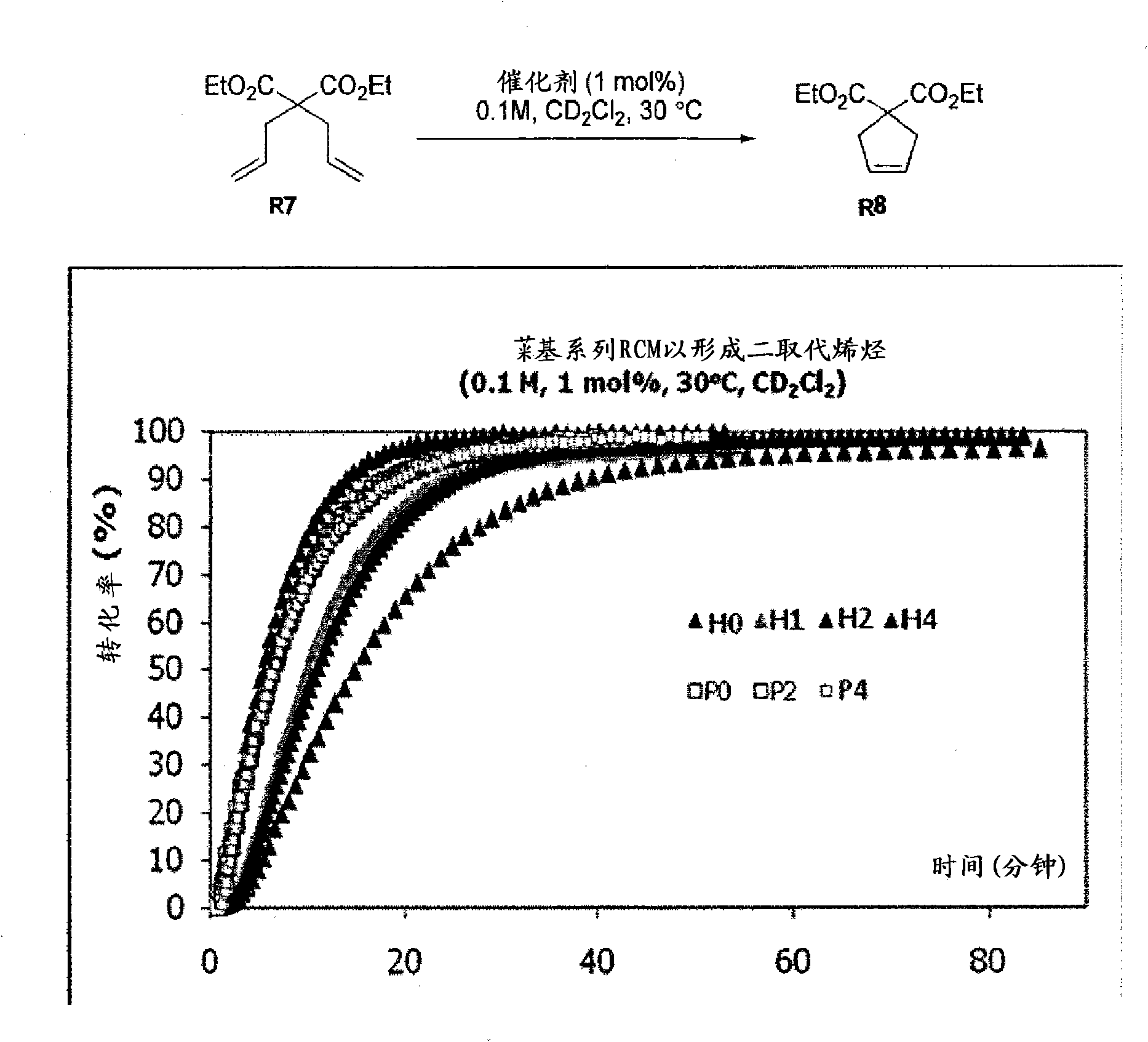

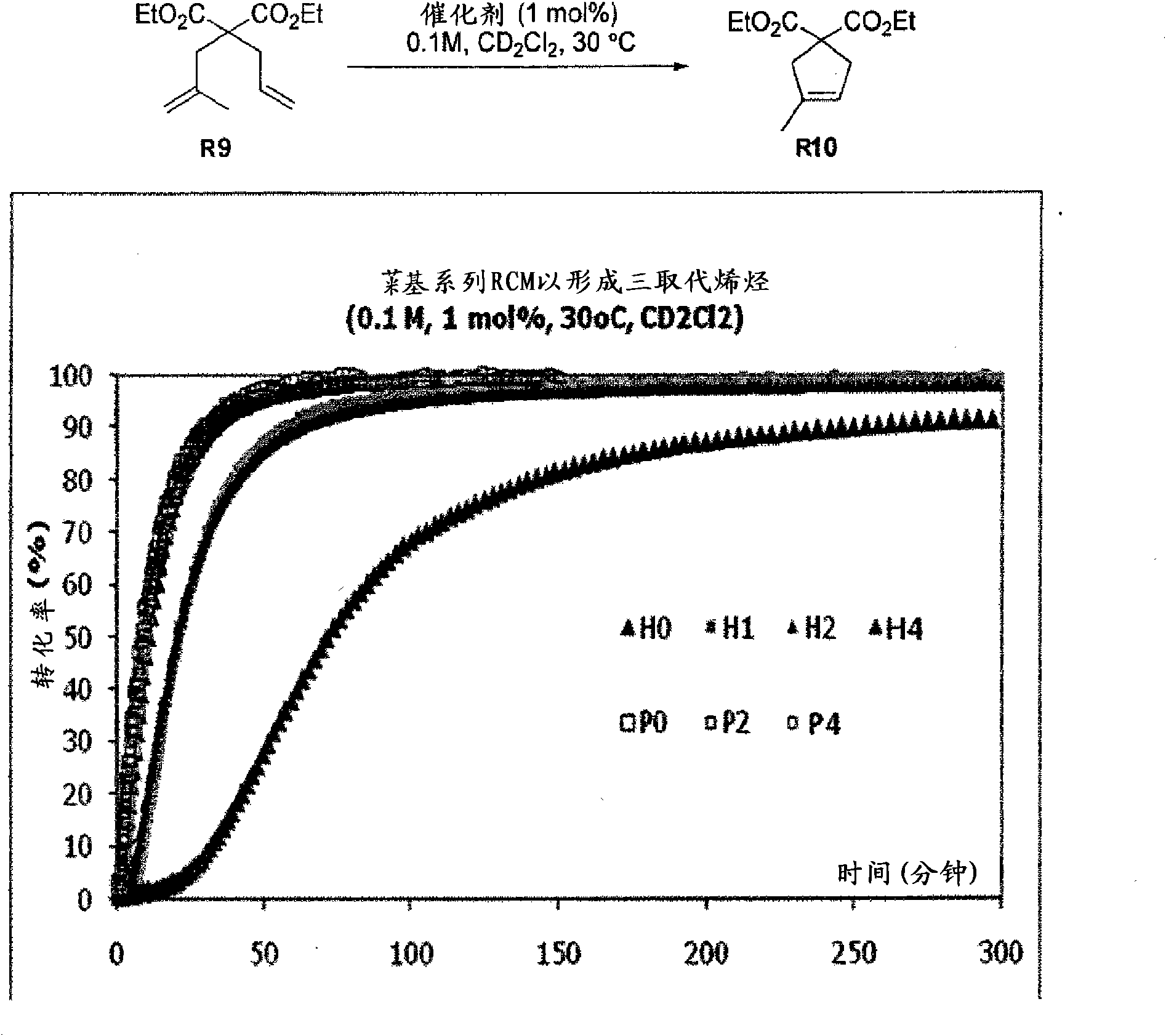

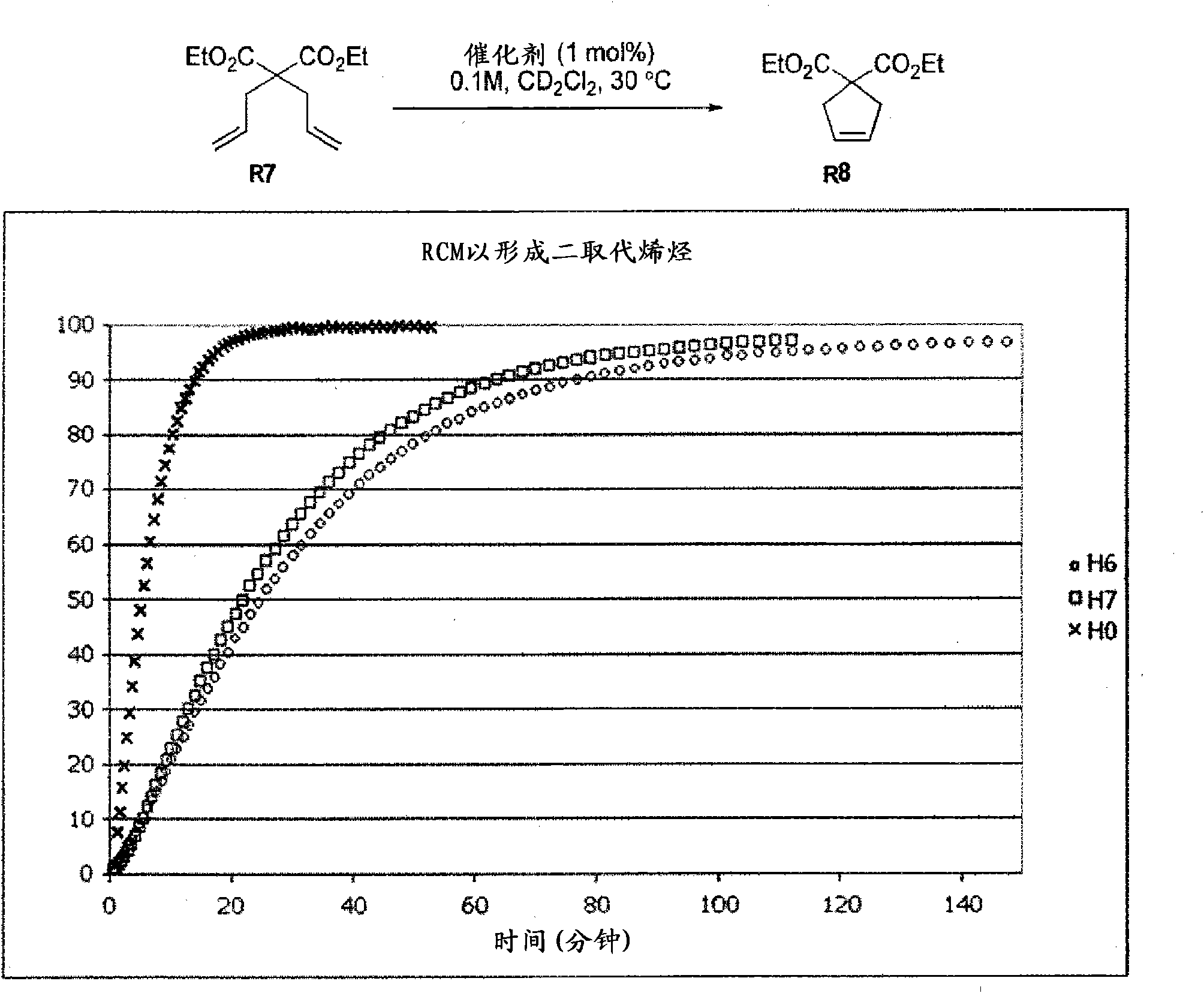

Ruthenium olefin metathesis catalysts bearing N-heterocyclic carbene ligands with substituted backbone

This invention relates generally to olefin metathesis, more particularly, to tri- or tetra-substituted imidazolinium salts which are precursors to N-heterocyclic carbene (NHC) ligands with tri- or tetra-substituted irnidazolinium rings, organometallic ruthenium complexes comprising gem di-substituted imidazoiinium NHC ligands, organometallic ruthenium complexes comprising tri- or tetra-substituted imidazoiinium NHC ligands, and to olefin metathesis methods using them. The catalysts and methods of the invention have utility in the fields of catalysis, organic synthesis, and industrial chemistry.

Owner:MATERIA +1

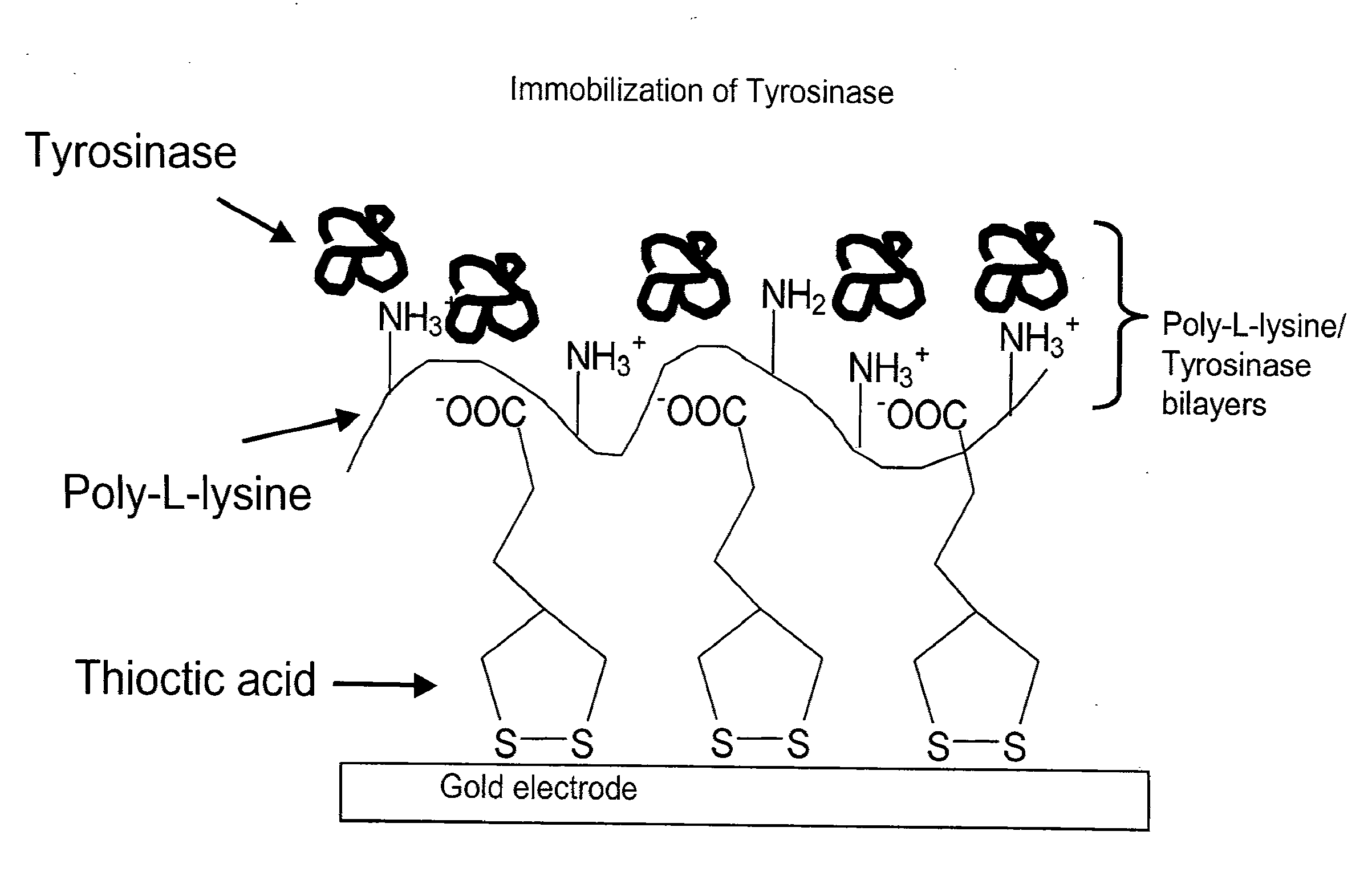

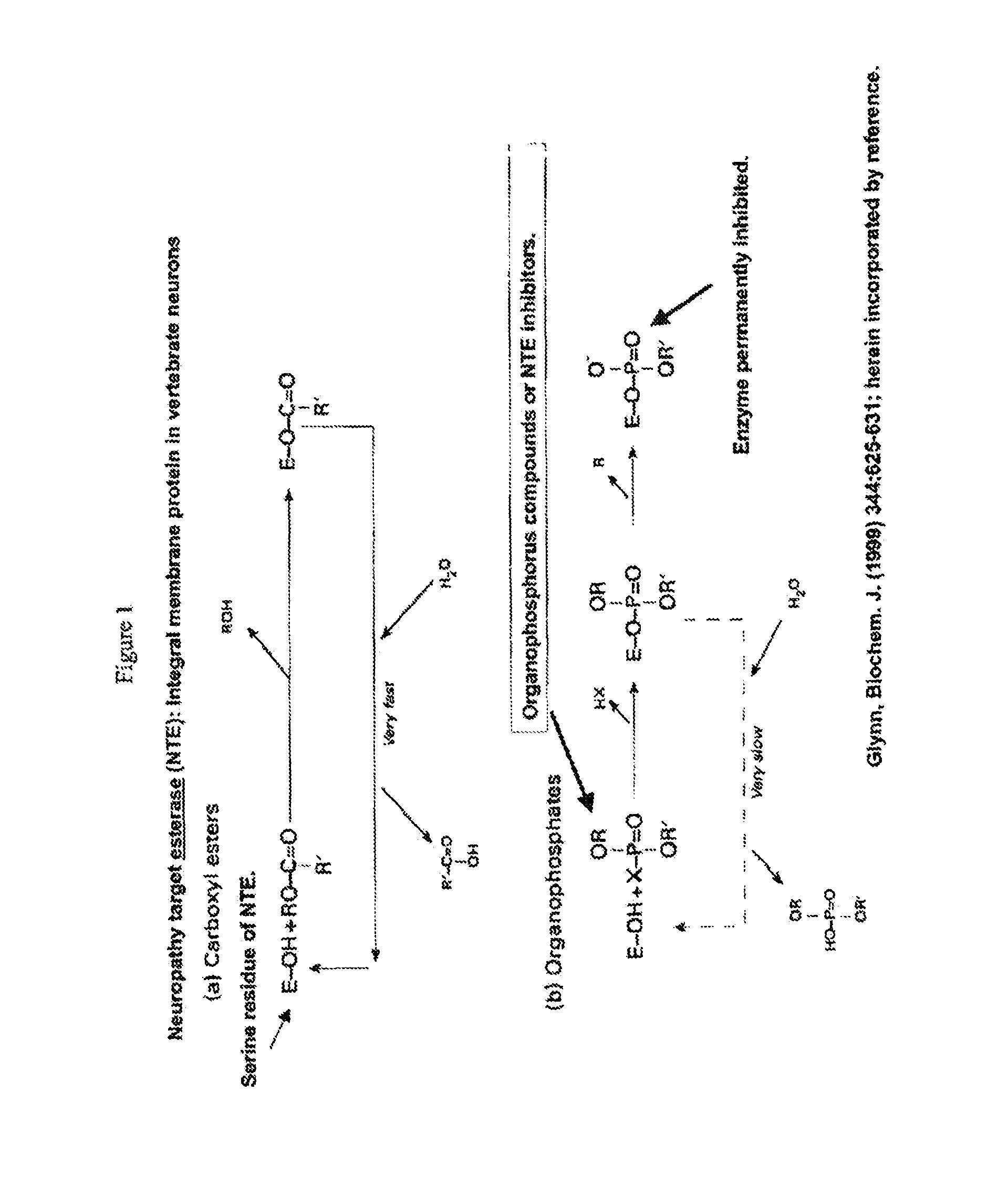

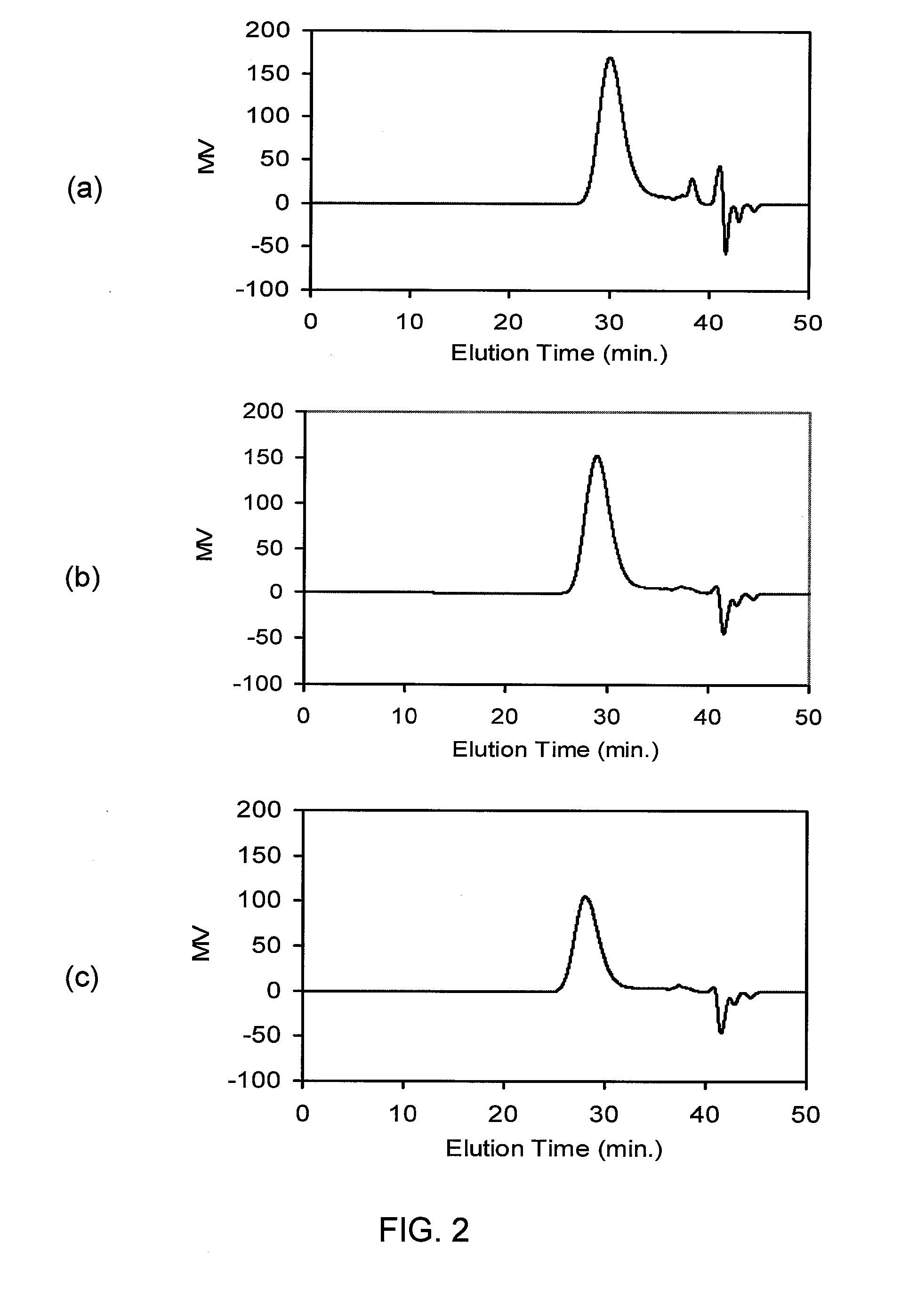

Nanostructured Biosensor Containing Neuropathy Target Esterase Activity

InactiveUS20120160708A1High sensitivityContinuous measurementImmobilised enzymesBioreactor/fermenter combinationsNeuropathy target esteraseHomeland security

The present invention provides compositions, devices and methods for detecting esterase activity. The present invention also provides devices and methods of detecting esterase inhibitors, for example, organophosphates. In particular, the present invention provides a biosensor comprising Neuropathy Target Esterase (NTE) polypeptides. Further, the present invention relates to medicine, industrial chemistry, agriculture, and homeland security.

Owner:MICHIGAN STATE UNIV +1

Self-decontaminating metal organic frameworks

InactiveUS20100081186A1Group 1/11 organic compounds without C-metal linkagesGroup 5/15 element organic compoundsReactive siteMetal-organic framework

A self-decontaminating metal organic framework including an acid linked to a metal producing a metal organic framework configured for the sorption of chemical warfare agents and / or toxic industrial chemicals, the metal organic framework including reactive sites for the degradation of the agents and chemicals.

Owner:FOSTER-MILLER

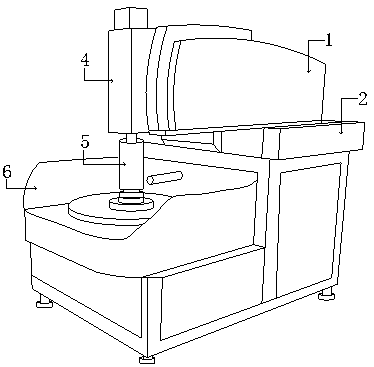

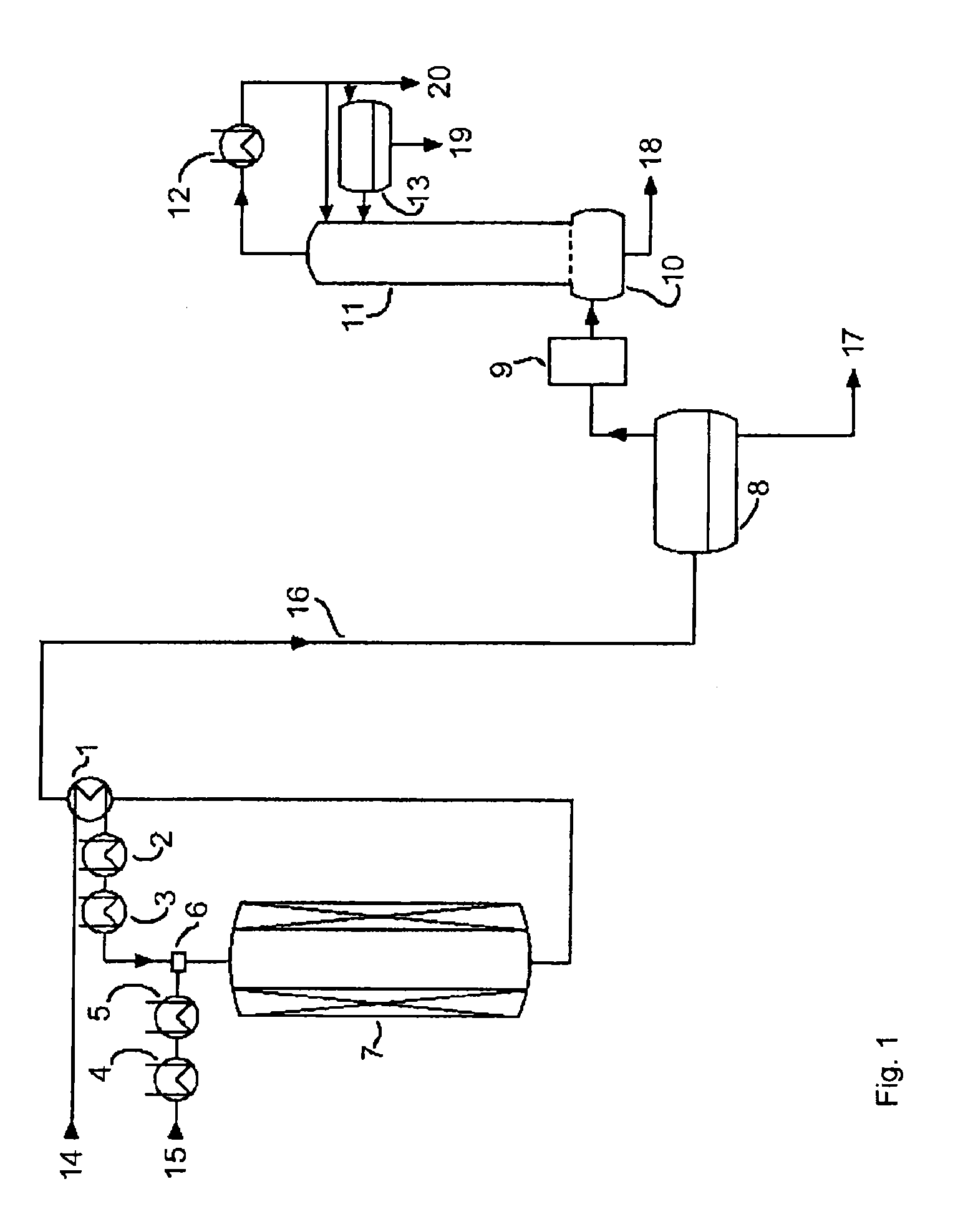

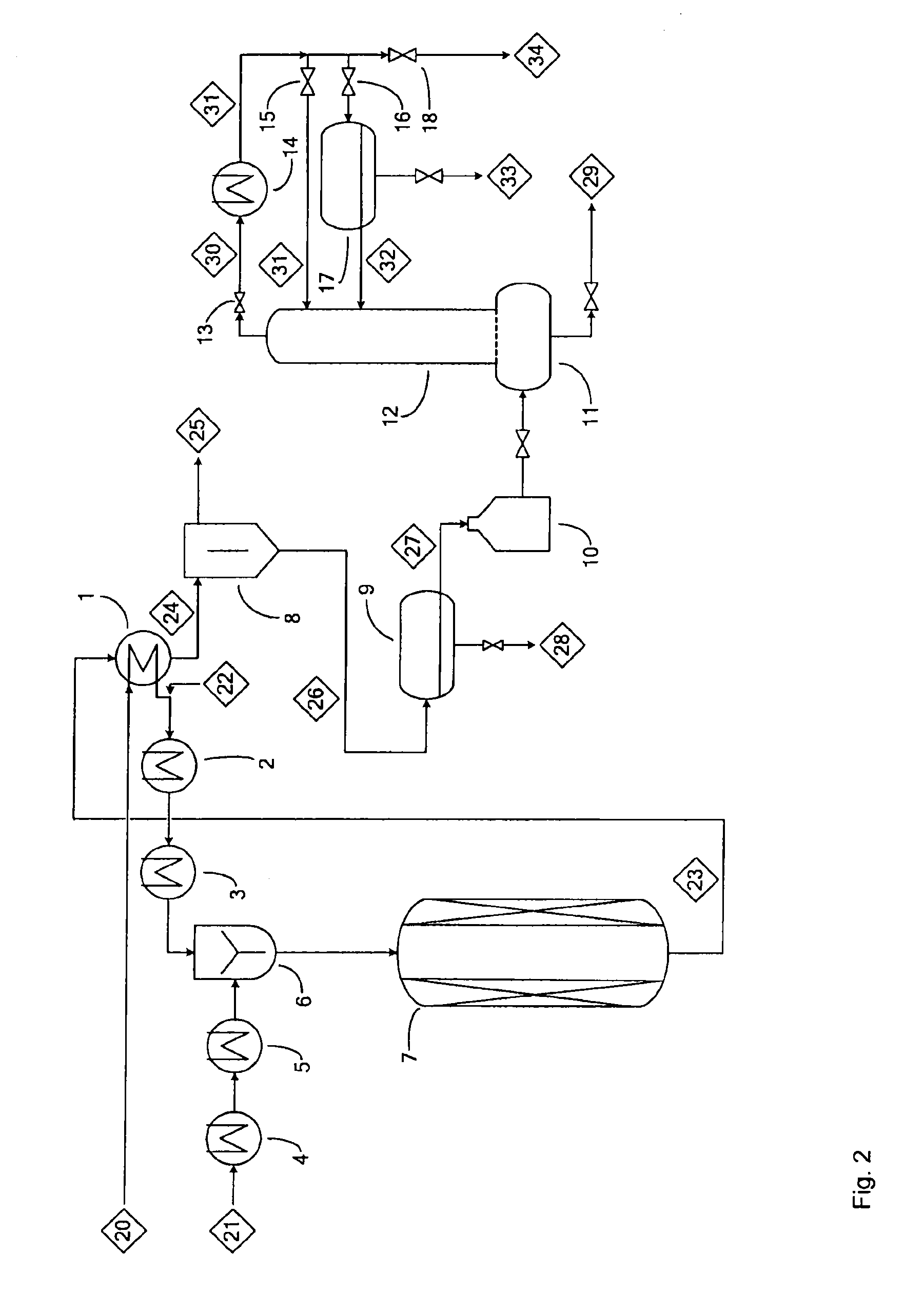

Industrial chemical intelligent titration method and industrial chemical intelligent titration system based on image color information extraction

ActiveCN109342408AAccurate judgmentObjective and accurate responseChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorEmbedded controllerComputer science

The invention provides an industrial chemical intelligent titration method and an industrial chemical intelligent titration system based on image color information extraction, which can intelligentlyjudge a titration end-point and improve the titration efficiency. The method comprises the methods of establishing a rule database, detecting online and updating the rule database. Related parameterssuch as a slow dropping point S are acquired, fitting is performed on the slow dropping point to acquire a slow dropping point curve f(V), and then a slow dropping point prediction titration amount isacquired, thereby accurately judging the titration end-point. The system comprises a chemical titration intelligent processing unit, a titration mechanism and an image acquisition unit. The titrationmechanism comprises a monitoring device, a light blocking plate, an embedded controller, a feeding device, a titration device and a stirring device. the industrial chemical intelligent titration system and the industrial chemical intelligent titration method are higher in the detection efficiency and higher in the detection precision compared with detecting the concentration of a sample with a manual titration method when detecting the sample, improve the titration efficiency and the detection precision, and objectively and accurately reflect the chemical titration result.

Owner:UNIV OF SCI & TECH LIAONING

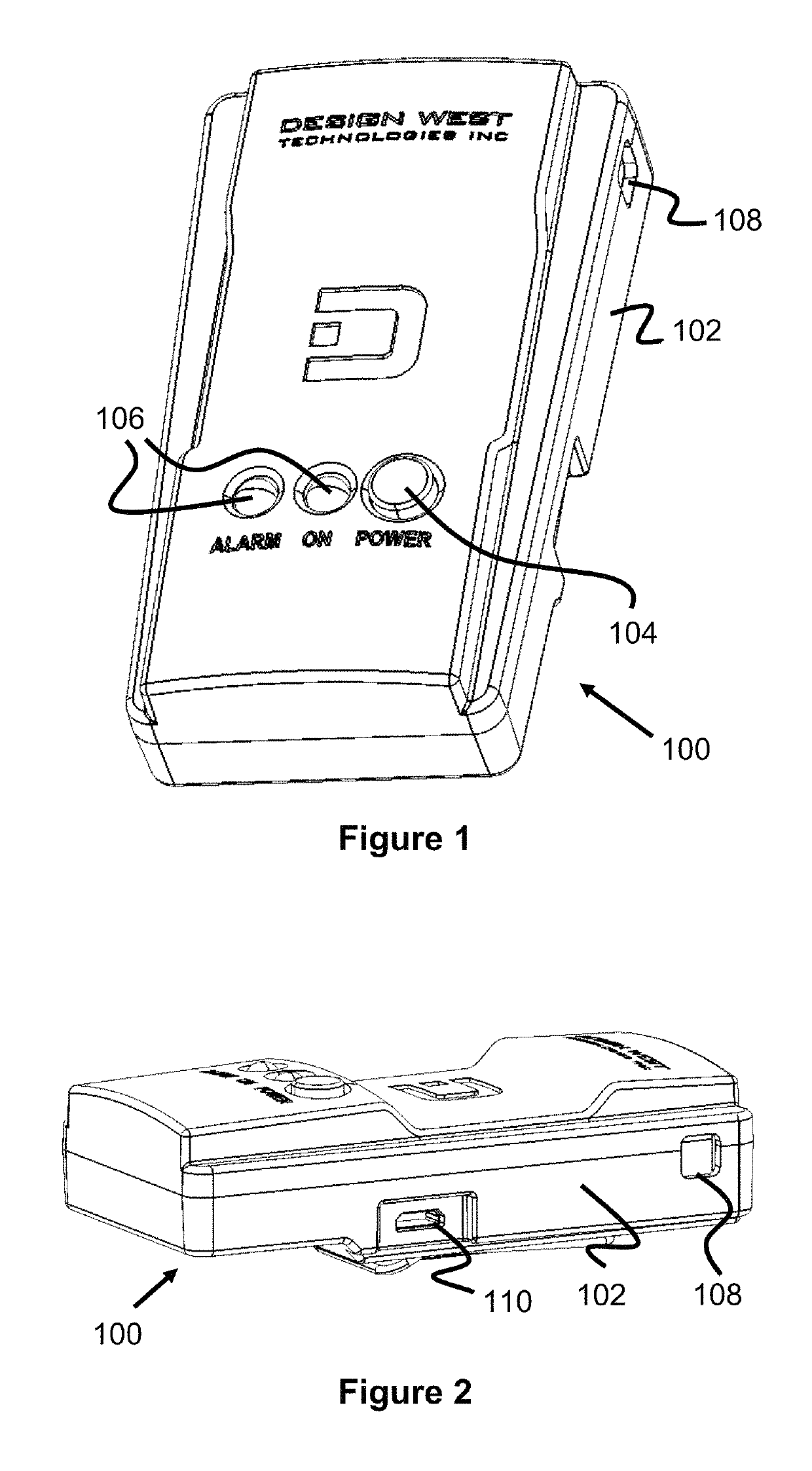

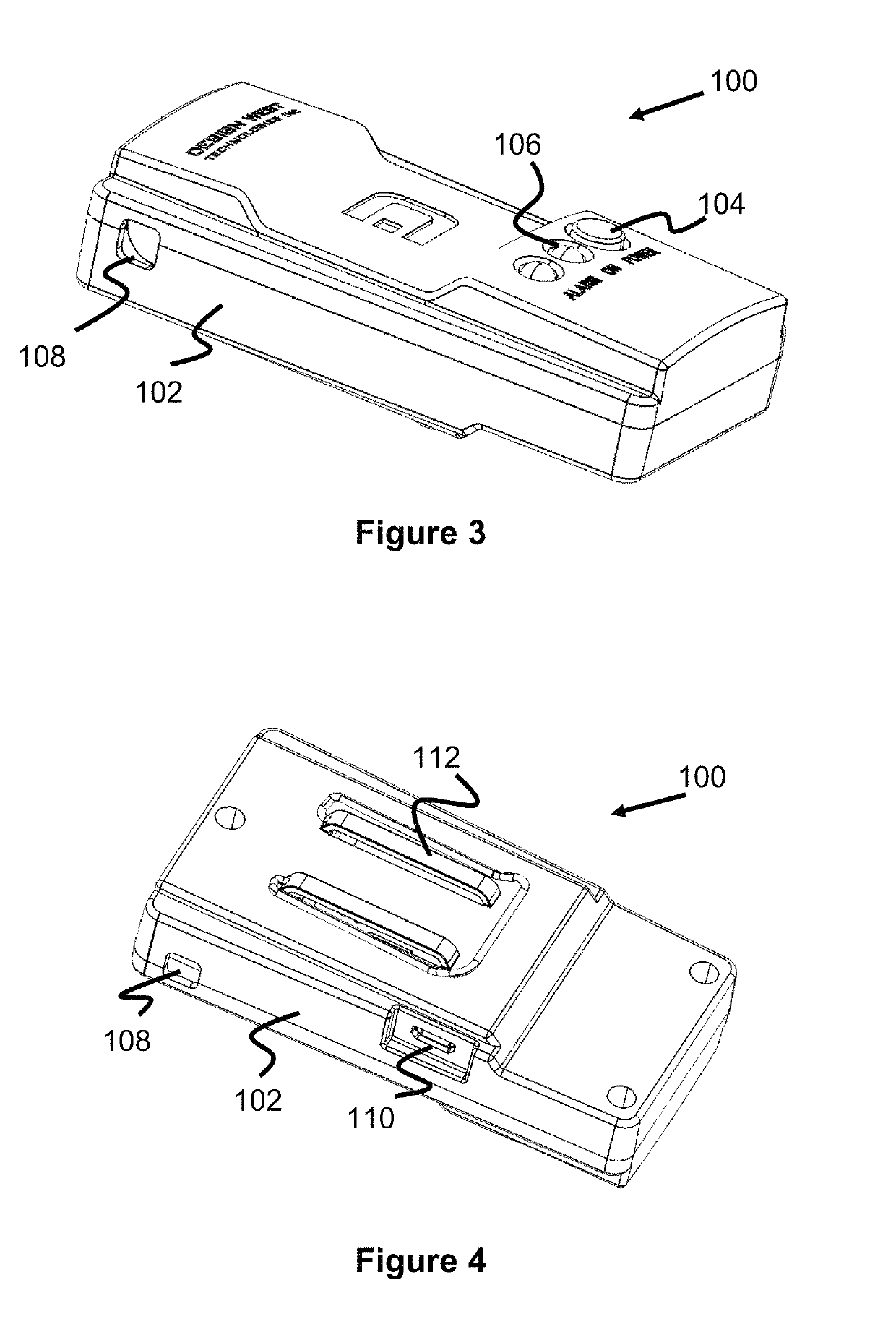

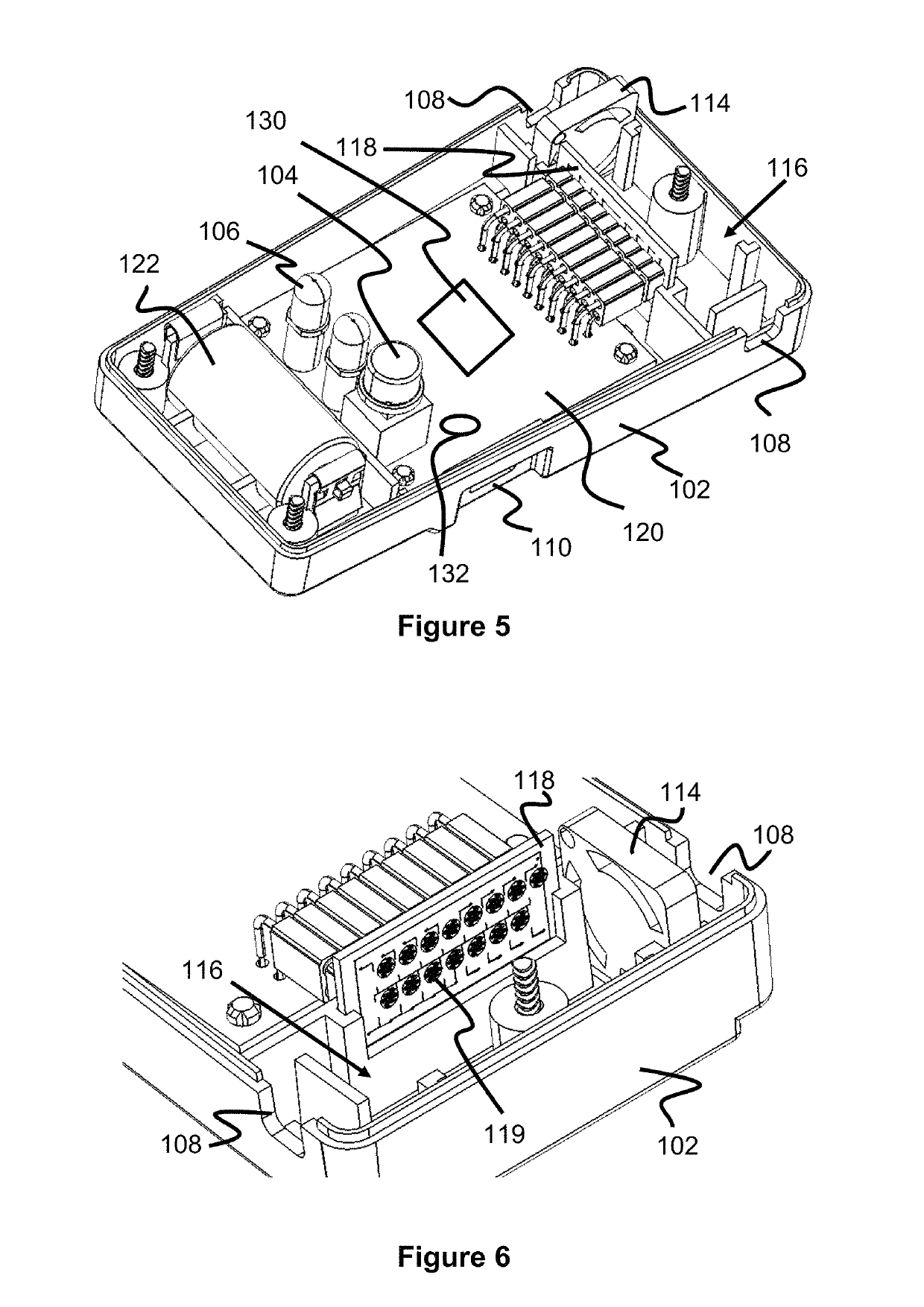

Wearable sensor badge for toxic industrial chemicals

A wearable sensor badge utilizes a carbon nanotube (CNT) sensor array for selective sensing of chemicals from naturally diffused air or by sampling air using a pump / fan for higher sensitivity. An embedded microcontroller monitors the resistance of the sensing elements and by using an advanced detection algorithm the presence of TICs and / or CWAs are identified.

Owner:DESIGN WEST TECH INC

Ring opening cross-metathesis reaction of cyclic olefins with seed oils and the like

Owner:WILMAR TRADING PTE LTD

Nanostructured biosensor containing neuropathy target esterase activity

InactiveUS8623196B2High sensitivityContinuous measurementImmobilised enzymesBioreactor/fermenter combinationsHomeland securityNeuropathy target esterase

The present invention provides compositions, devices and methods for detecting esterase activity. The present invention also provides devices and methods of detecting esterase inhibitors, for example, organophosphates. In particular, the present invention provides a biosensor comprising Neuropathy Target Esterase (NTE) polypeptides. Further, the present invention relates to medicine, industrial chemistry, agriculture, and homeland security.

Owner:MICHIGAN STATE UNIV +1

Single threaded composite fibers and yarns for the degradation of and protection against toxic chemicals and biological agents

ActiveUS11097261B1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationFiberYarn

The present invention relates to single thread composite fibers comprising at least one binder and at least one active catalyst for the capture and degradation of chemical threats such as chemical warfare agents (CWA), biological warfare agents, and toxic industrial chemicals (TIC) and a method for producing the same. The invention fibers are applicable to the fields of protective garments, filtration materials, and decontamination materials.

Owner:UNITED STATES OF AMERICA

Industrial chemical waste liquid copper recovery device

PendingCN111607700AAvoid situations that cannot be dischargedSituations that are not easy to clearProcess efficiency improvementLiquid copperEnvironmental engineering

Owner:成都天智佳网络科技有限公司

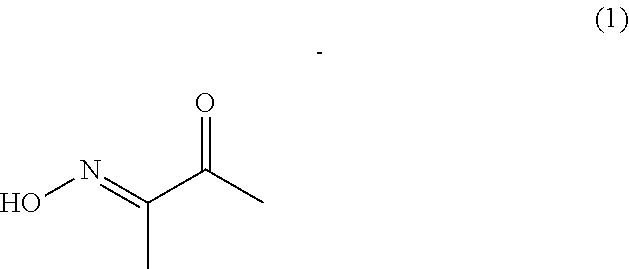

Method and Formulation for Neutralizing Toxic Chemicals and Materials

The present invention is directed to a formulation and associated method for neutralizing one or more toxic chemical and / or materials including toxic industrial chemicals and toxic industrial materials, such as irritants, heavy metals, radioactive metals, acids and acid irritants, pesticides, and various agricultural chemicals, (collectively referred to as toxic chemical, materials, or simply toxins) as well as decontaminating surfaces that have come into contact with these agents. As a result, the formulation of the present invention can be used for neutralizing a broad spectrum of toxic chemicals and materials. In one embodiment, the active ingredient comprises 2, 3, butanedione monoxime (also known as diacetyl monoxime (DAM)), and alkali salts thereof such as potassium 2,3-butanedione monoxime (KBDO). The formulation also typically includes a carrier in which the active ingredient is dispersed. In one embodiment, the carrier comprises polyethylene glycol (PEG); monomethoxypolyethylene glycol(mPEG); and combinations and derivatives thereof.

Owner:EMERGENT PROTECTIVE PROD CANADA ULC

Telechelic Olefin Metathesis Polymers from Renewable Feedstocks

Olefin metathesis polymerization reactions are disclosed, and more particularly ring-opening metathesis polymerization of cyclic olefins with olefinic compounds, such as are derived from seed oils and the like, to form telechelic polymers. In one aspect, a method is provided for carrying out a catalytic ring-opening metathesis polymerization reaction, comprising contacting at least one olefinic compound with at least one cyclic olefin, in the presence of a ruthenium alkylidene olefin metathesis catalyst under conditions effective to allow ring-opening metathesis polymerization of the cyclic olefin, whereby the cyclic olefin polymer formed is terminated with the olefinic compound. The invention has utility in the fields of catalysis, organic synthesis, polymer chemistry, and industrial chemistry.

Owner:MATERIA

Preparation method of supported electro-catalytic nitrogen reduction catalyst MoS2-Fe3O4

Ammonia, as one of the most important industrial chemicals, plays an irreplaceable role in the fields of pesticides, chemical fertilizers, textiles and the like. However, the production of ammonia is a difficult problem troubling the world all the time. The traditional Hobblog method is still adopted in the industry at present, the reaction can only be carried out under the conditions of high temperature and high pressure, and a large amount of fossil raw materials are wasted and the environment is seriously polluted. Scientific researchers find a method for reducing nitrogen into ammonia gas under an environmental condition. The electro-catalytic nitrogen reduction reaction can reduce N2 into NH3 under an external voltage under the environmental condition, the reaction condition is mild, carbon emission is less, and raw materials are easy to obtain, so that more and more attention is gained in recent years. Due to the strong dipole moment of N=N, nitrogen adsorption and serious hydrogen evolution reaction, electro-catalytic nitrogen reduction still faces many difficulties. Therefore, development of a high-activity and high-selectivity electrochemical catalyst is the key of electro-catalytic nitrogen reduction. The invention provides a preparation method for loading Fe3O4 on MoS2 nanoflowers through a hydrothermal method and application of the obtained catalyst to electro-catalytic nitrogen reduction.

Owner:UNIV OF JINAN

Production method of pollution-free garbage treatment and garbage conversion into cycling clean energy

InactiveCN102453582AIncrease savingsIncrease profitWaste processingSolid waste disposalResource protectionEnvironmental engineering

A production method of pollution-free garbage treatment and garbage conversion into cycling clean energy. Garbage resource is treated with cleaning treatment into combustible coalification base-material, which is then treated with energy conversion, substance recombination and optimization to be synthesized into clean energy superior to original coal. The method can increase an original coal saving rate to 65-85%, effectively reduce emission of harmful substance and harmful gas to 65-85% and increase utilization rate of life garbage and industrial garbage to 95-99%; quantity of heat of garbage can be increased from 1500-3500 kilocalorie to an industrial coal standard of 4200-6200 kilocalorie, which completely satisfies requirements of usage of various boilers, industrial generating, industrial chemistry and industrial smelting and civil usage. Pollution-free garbage treatment and effective integral utilization of garbage are great contributions to human kind and have imperative significance for protection of original coal resource, increase of original coal utilization rate, original coal reservation and environmental protection.

Owner:TIANCHANG ZHONGNENG GUOTAI ENERGY TECH

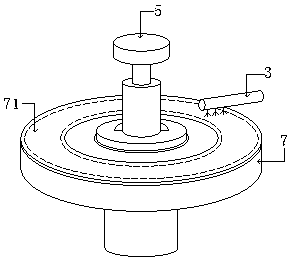

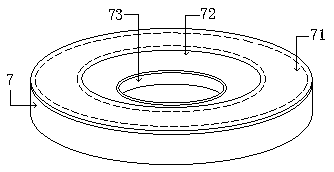

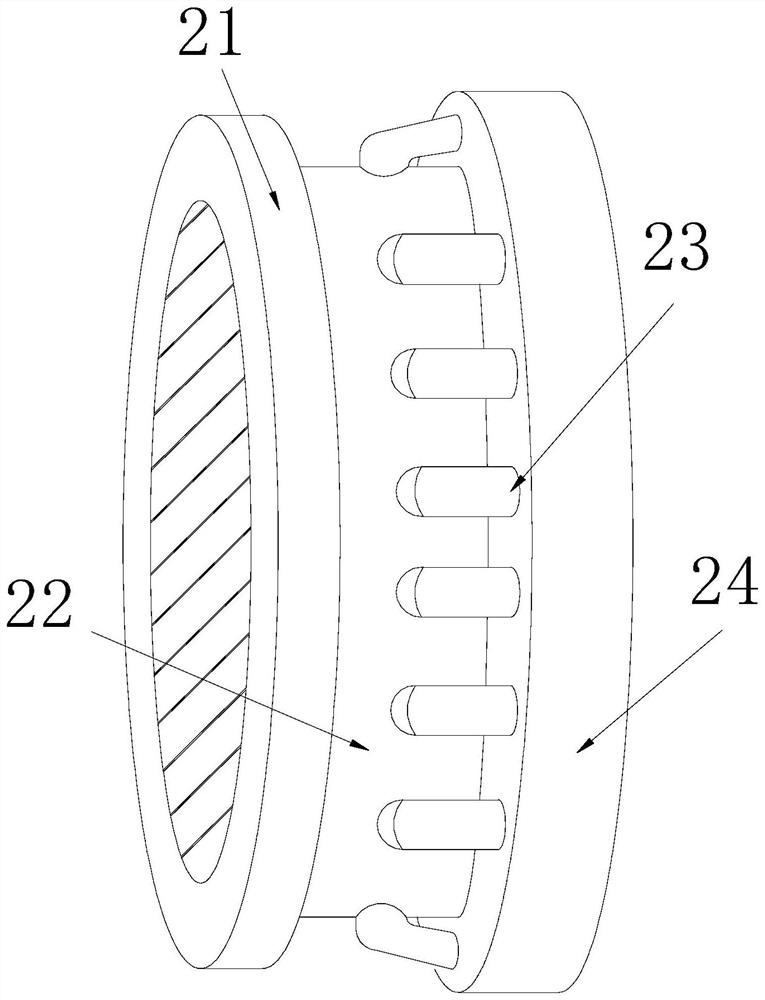

Industrial chemical mechanical grinding equipment

InactiveCN110625515AReal-time replacementReduce branch reorganizationGrinding machine componentsLapping machinesDrive shaftElectrical connection

The invention discloses industrial chemical mechanical grinding equipment which structurally comprises a handpiece, a case, an abrasive spray head, a drive shaft, a grinding head mechanism, a protective cover and a rotary table; the rotary table is provided with a polishing pad; electrical connection is employed between the handpiece and the case; the upper end of the case is fixedly provided withthe protective cover; the protective cover is provided with the rotary table; the drive shaft is controlled by the handpiece; the bottom end of the drive shaft is connected with the grinding head mechanism; one end of the abrasive spray head penetrates through the protective cover and is connected to the case, and the other end corresponds to the polishing pad; the abrasive spray head is added onthe outer side of the polishing pad; the inner side of the polishing pad, an inner chute and a center collection hole perform common action, and an abrasive can be embedded into the polishing pad inthe grinding process and slides downwards into the center collection hole along the slanting surface of the bowl-shaped inner chute; and in the polishing process, the old abrasive is automatically separated from the polishing surface by friction between the polishing pad and a wafer to enable a new abrasive to be exposed, so that the timely replacement phenomenon of the new and old abrasives is realized, branch reconstruction of the surface of a polishing disc is reduced, and a thick glaze layer is prevented from being formed on the surface.

Owner:黄功钢

Protecting adhesive for preventing table corner from being corroded

InactiveCN103666291ANo dry corrosion wearAvoid damageNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveHydrogenAdhesive

The invention relates to the technical field of an industrial chemistry, and particularly relates to a protecting adhesive for preventing a table corner from being corroded. The protecting adhesive comprises the following components in parts by weight: 25-36 parts of butyl acrylate, 14-23 parts of acrylic acid dioctyl and 45-66 parts of sodium hydrogen sulfite. The butyl acrylate disclosed by the invention belongs to a propylene acyl compound, and is insoluble in water; the acrylic acid dioctyl is used as a polymer monomer and applied to a soft polymer, and plays an inner plasticization role in the copolymer; sodium hydrogen sulfite is used as a corrosion remover in general, and the three chemical substances are mixed, and coated on the table corner, so that the table corner can be fully prevented from being abraded by dry corrosion, the damage to the image of the overall table caused by corrosion of the table corner is avoided, and the protecting adhesive is strong in usability.

Owner:西安天嘉蓝环保科技有限责任公司

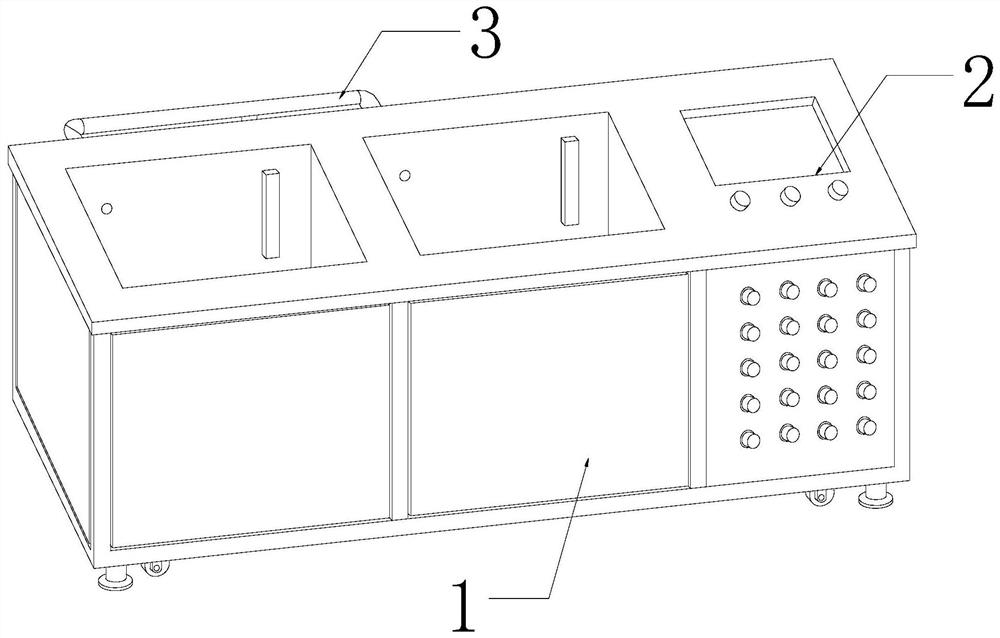

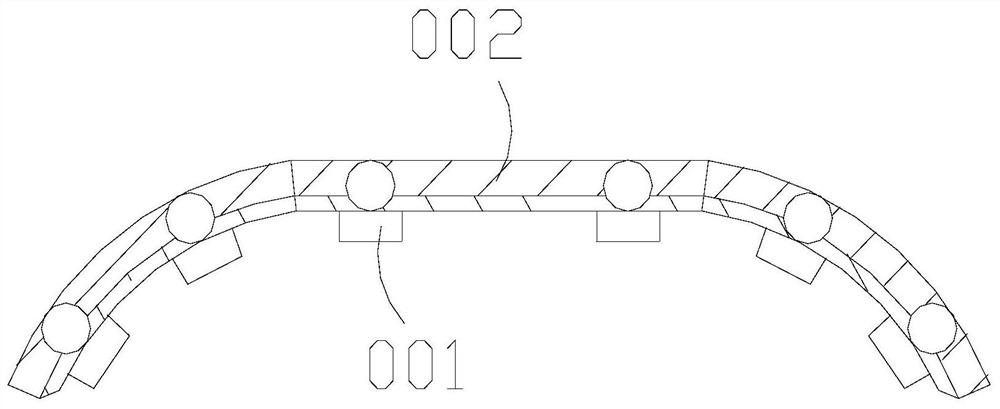

Industrial chemical experiment table

PendingCN111530521APrevent overflowAvoid generatingLaboratory benches/tablesMechanical engineeringElastic rods

The invention discloses an industrial chemical experiment table. The industrial chemical experiment table structurally comprises a placement frame, a detection table, a storage box and a fixed table,the detection table is provided with a stop plate, a drainage mechanism and a connecting pipe; during detection of a reagent bottle, a circular plate is stressed and compressed, uneven stress is prevented, and after the reagent bottle placed on the surface of the circular plate is poured out, liquid flows into a circulation pipeline from the interior of a clamping mechanism, and enters a connecting pipe to be connected with a drain hole, so that the reaction time of the poured liquid and marble is reduced, crystal production is avoided; when the reagent bottle is extruded, a movable mechanismand the upper end of an elastic rod are driven to move, four annular telescopic rings are distributed on the periphery of the reagent bottle to fix the reagent bottle and prevent the reagent bottle from toppling over due to collision, the telescopic rings and the elastic rod are annular, and the outer sides of the telescopic rings are attached to the inner side of a clamping block, so that the poor fixing effect of the telescopic rings on the reagent bottle is avoided, and the clamping stability of the telescopic rings is enhanced.

Owner:成都天智佳网络科技有限公司

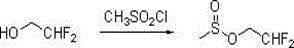

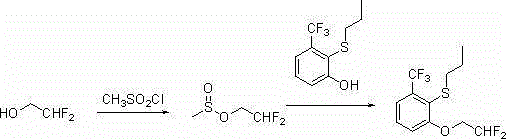

2-(2 ', 2'-difluoro-ethoxy)-6-trifluoromethyl-phenylpropyl sulfur ether synthesis process

InactiveCN105294520ASmooth and efficient introductionReduce generationSulfide preparationMeth-Methanesulfonyl chloride

The present invention discloses a 2-(2 ', 2'-difluoro-ethoxy)-6-trifluoromethyl-phenylpropyl sulfur ether synthesis process. The process is as follows: 2-propyl mercapto-3-trifluoromehtyl phenol, 2,2-difluoroethanol and methanesulfonyl chloride are used as raw materials for two-step reaction to obtain the desired product. The synthesis process uses inexpensive industrial chemicals as the raw materials and reactants for avoiding the use of expensive or highly toxic raw materials, is high in the reaction conversion rate, easy in separation and purification and simple to in process operation, and reduces production costs.

Owner:内蒙古佳瑞米精细化工有限公司

The preparation method of 3,5-dichloro-2-pentanone

ActiveCN109265329BReduce usageSimple processPreparation from heterocyclic compoundsSulfonyl chloridePtru catalyst

The invention relates to the field of fine chemical industry, and discloses a preparation method of 3,5-dichloro-2-pentanone, which is characterized in that the preparation method comprises: contacting α-acetyl-γ-butyrolactone and sulfuryl chloride in a system without a solvent to perform a chlorination reaction, then mixing the material obtained by the chlorination reaction with water, and adding hydrochloric acid dropwise to the obtained mixture to perform a ring-opening reaction. By using cheap industrial chemicals as raw materials, the method realizes a one-pot reaction without organic solvents, simplifies the process operation, reduces three wastes and production costs, and avoids the pollution caused by the use of metal catalysts.

Owner:NUTRICHEM LAB CO LTD

An industrial chemical grinding equipment

ActiveCN111558423BReduce adhesionSpeed up dryingGrain treatmentsHeating arrangementPhosphateElectric machinery

The invention discloses an industrial chemical grinding equipment, the structure of which comprises a motor, a grinding box, a feeding pipe, a mixing pipe, a feeding hopper, and a water inlet pipe. At this time, by cutting off the power of the electromagnetic block, the sliding shaft loses traction. At this time, the sliding shaft slides down inside the slide rail, driving the connecting rod to descend. At this time, the collision plate collides with the upper end of the grinding roller, and the grinding The phosphate rock slurry adhered to the surface of the roller is scraped off by the scraper to reduce the adhesion of the phosphate rock slurry on the surface of the grinding roller, and the rotator is started to rotate, driving the two ropes to pass through for reverse traction. The phosphate slurry is reversed, and the sliding rod is returned by the elasticity of the spring, so that the dial forms a reciprocating movement. After the grinding is completed, the drying of the phosphate slurry is accelerated through the heating of the heating wire and the heat conduction of the arc plate. , to reduce the adhesion of phosphate slurry to the inside of the grinding box.

Owner:辽宁珂思美化妆品有限公司

Phosphogypsum-based environmentally friendly paint

Provided is a phosphogypsum-based acrylic paint, belonging to the field of industrial chemistry. Embodiments provide a phosphogypsum-based acrylic paint, which includes water; wetting agent; dispersing agent; anti-foaming agent; bactericide; sodium nitrite; micronized phosphogypsum; mixing for two minutes all the substances; alkalinizing agent; pigment; butyl glycol; mineral turpentine; and dispersing for 20 (twenty) minutes.

Owner:ESTEVAM DOMINGOS GABRIEL

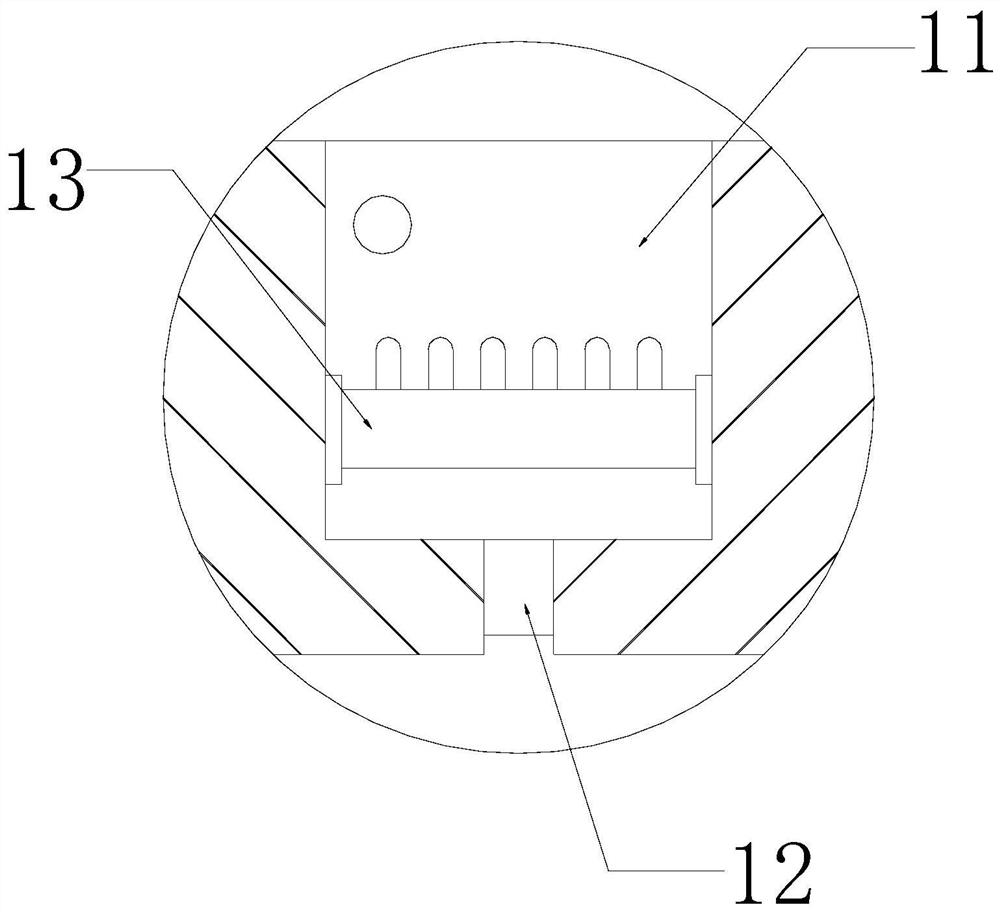

A kind of instrument cleaning equipment for industrial chemistry

ActiveCN112958559BReduce the phenomenon of dissectionEasy to useHollow article cleaningProcess engineeringIndustrial engineering

Owner:山东秋淇分析仪器有限公司

Process for the preparation of dihydropyran

InactiveUS20110087035A1Simple and cost efficient processHigh yieldOrganic chemistryPhotochemistryDihydropyran

The present invention relates to a process for the preparation of 2,3-dihydropyran (DHP, CAS [110-87-2]) and its use in industrial chemistry.

Owner:LONZA LTD

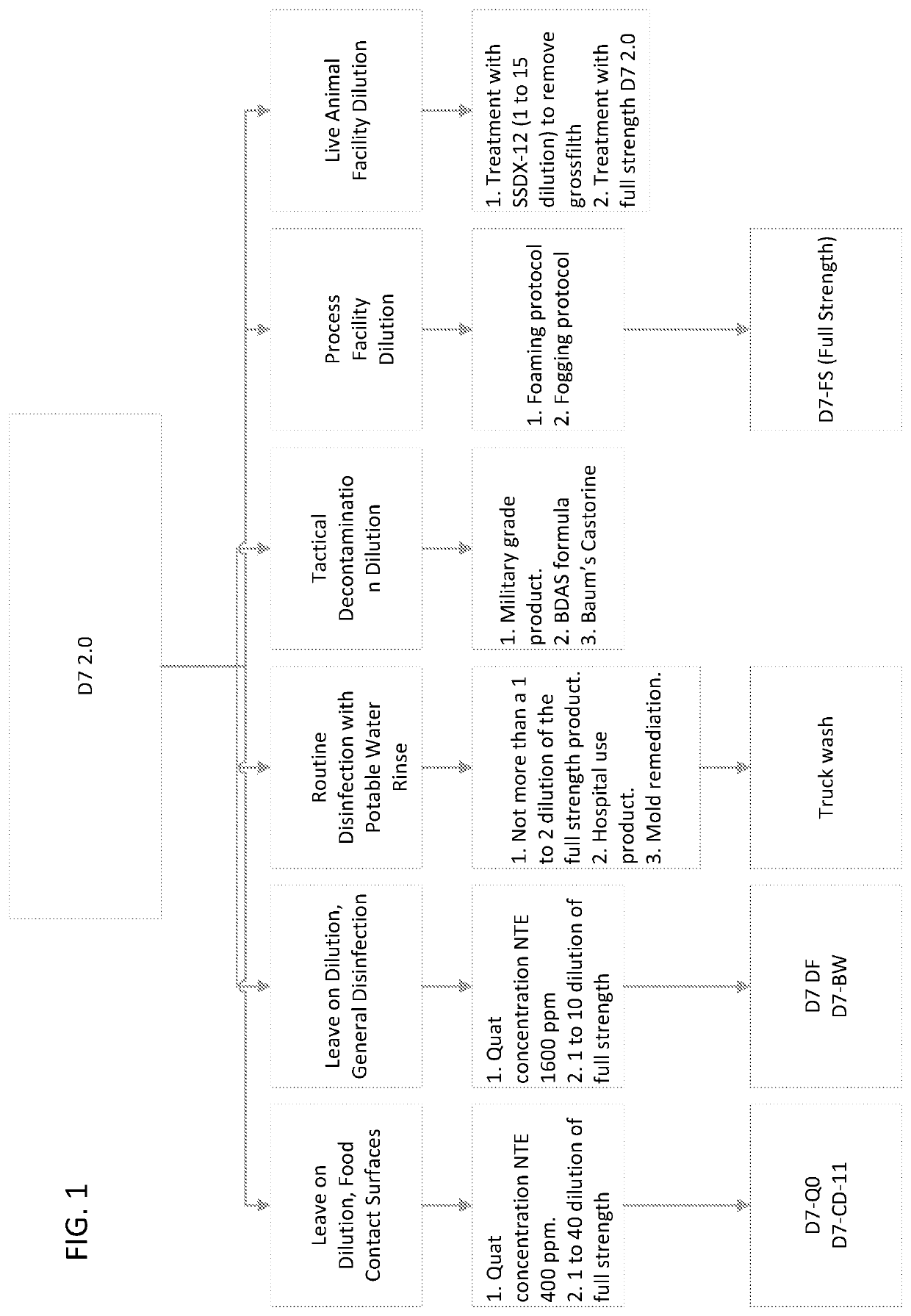

Surface and laundry decontamination formulation

InactiveUS20200345012A1Improve abilitiesOptimized formulaBiocideAnimal repellantsBiotechnologyPlanktonic bacteria

An improved formulation may include an enhanced ability relative to its predicates to destroy toxic threats in the form of sporulated bacteria, bacteria protected by biofilms, planktonic bacteria, fungus, viruses, chemical weapons, toxic chemicals including Fentanyl, its analogs, and a whole host of toxic industrial chemicals. The formulation may include a three part product composed of a buffered detergent chemical system, a hydrogen peroxide chemical system and an accelerator system designed to deliver activated peroxygen species when blended together.

Owner:DECON7 SYST INC

Acyl chloride co-production method

ActiveCN106674000AOrganic compound preparationCarboxylic acid halides preparationChlorideMethyl group

The invention relates to the field of fine chemical materials and especially relates to a novel co-production technology of important industrial chemicals such as 2, 4, 6-trimethylbenzoyl chloride and (methyl)acryloyl chloride.

Owner:SHENZHEN UV-CHEMTECH CO LTD

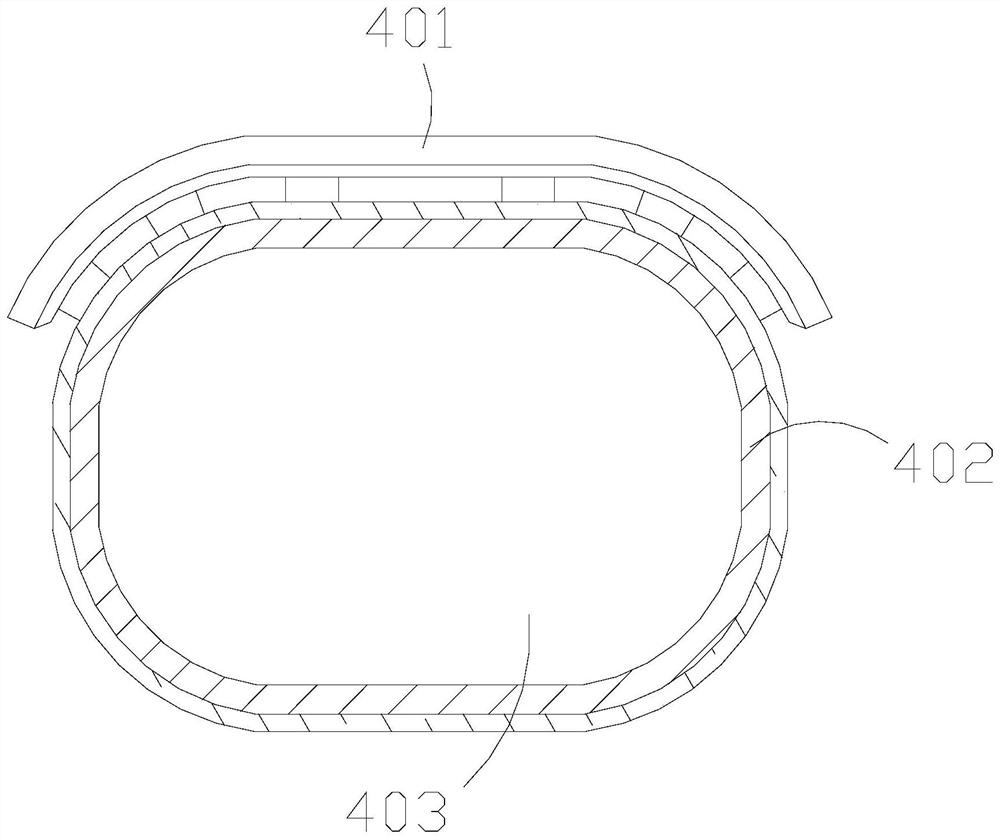

Explosion-proof storage cabinet for storing industrial chemicals

PendingCN112353142AReduce volumeImprove pass rateFurniture partsCabinetsStructural engineeringMechanical engineering

The invention discloses an explosion-proof storage cabinet for storing industrial chemicals, which structurally comprises a cabinet body, a ventilation opening, a storage plate and a cabinet door, wherein the outer side of the cabinet body is fixedly connected with the outer side of the ventilation opening in an embedded mode, after a rotary scraping piece scrapes a layer wall through a rotating rod, a guide-out head rotates along with the rotary scraping piece to enable crystals to be pushed and discharged through an extrusion block, then the layer wall is jacked through a jacking layer, thetop teeth protrude out of a fixing plate, the crystals are continuously jacked and pressed by protruding balls, and marbles hit two protrusions to generate vibration when the main body block continuously rotates, so that the size of the crystals on the inner side of the layer wall is reduced, and the passing rate of air is increased. The crystals pass through a through hole in the middle of a ringbody after being crushed and then are extruded by the jacking layer to push the one-way block to open downwards, then a connecting rod is driven to overturn the lower portion of the one-way block downwards, and the ammonium chloride crystals slide downwards along with the inclined layer and then are discharged out of a guide-out pipe, so that the ammonium chloride crystals left on the inner sideof the ventilation opening layer wall are reduced, and the cleaning efficiency is improved.

Owner:成都宗星柯商贸有限公司

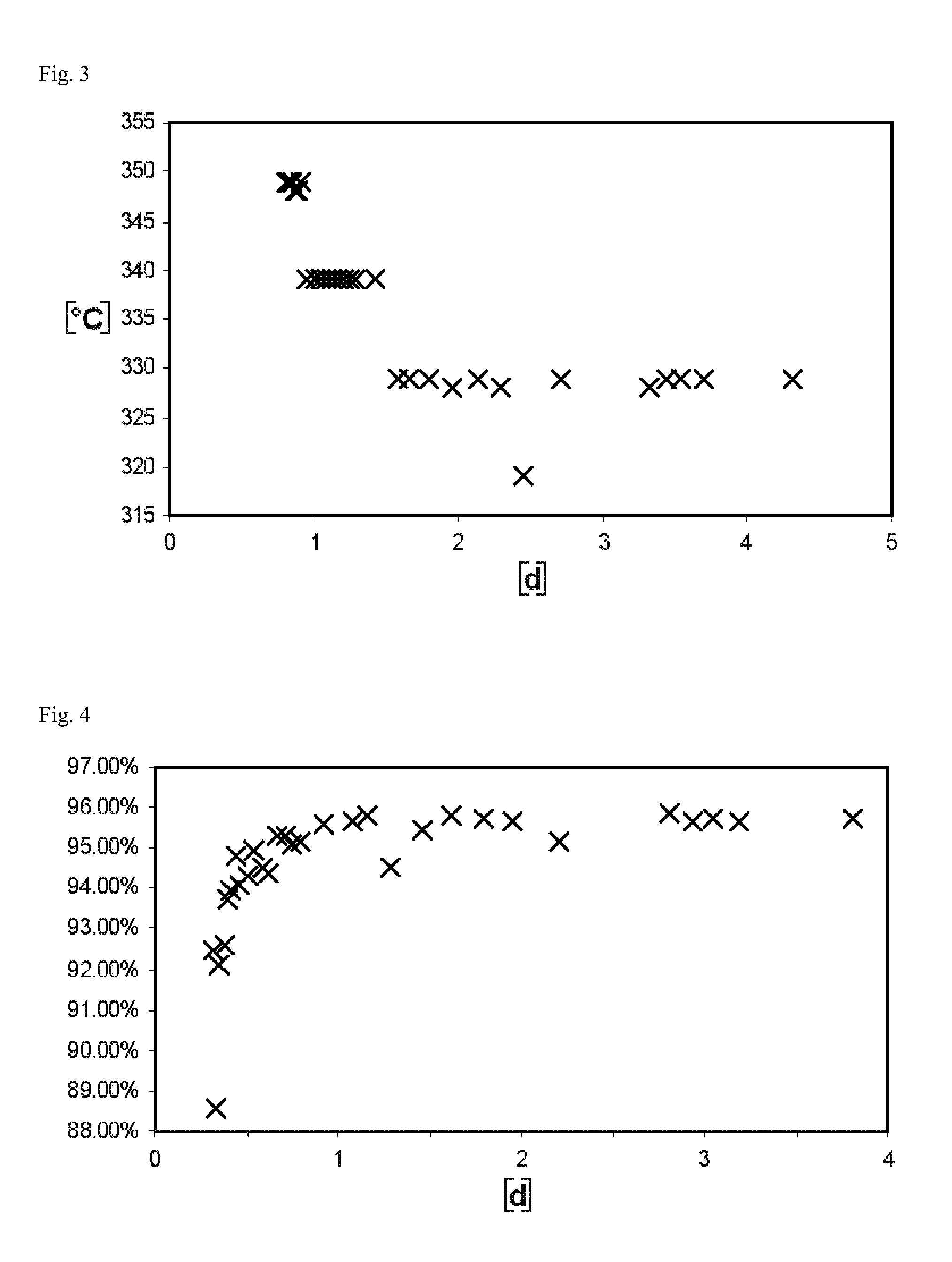

Constant-temperature transport vehicle for industrial chemicals

InactiveCN112937412AAvoid conductionTank vehiclesItem transportation vehiclesProcess engineeringMechanical engineering

The invention discloses a constant-temperature transport vehicle for industrial chemicals. The constant-temperature transport vehicle structurally comprises a bottom supporting frame, wheels, side fixing rods, a tank body and a vehicle head, wherein the bottom supporting frame is installed between the wheels, the top of the bottom supporting frame is fixed to the bottom of the tank body, the side fixing rods are welded to the outer surface of the tank body, and the tank body is connected with the vehicle head; the partition block connected with the heat insulation plate can be supported between the heat insulation plate and the sealing tank, heat is guided and dissipated towards a certain radian, the heat conduction block can disperse and evenly divide the heat when the top is exposed to the sun through the heat borne by the outer protection ball and evenly divided by the partition strip, the heat cannot be directly conducted to the tank body, some residual heat of the heat insulation plate can be conducted to the heat insulation body and the heat distribution block, the contact point of the point contact ball and the tank body is shrunk, the spacer block is made of a non-heat-conducting material, the uniformizing block strip is located in the uniformizing block, the temperature can be dispersed layer by layer again, a small contact surface can be formed at the supporting part between the heat insulation plate and the tank body, and rising conduction of the temperature can be prevented.

Owner:李旭

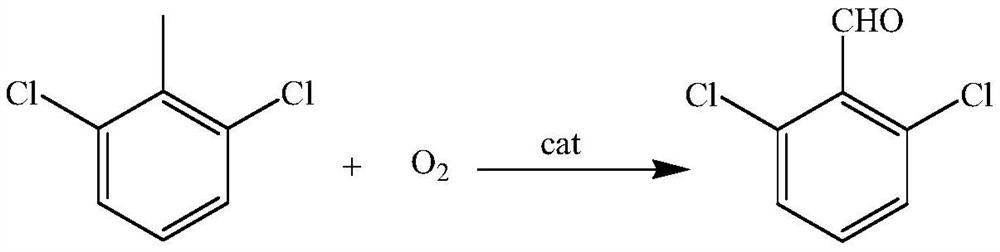

A kind of synthetic method of 2,6-dichlorobenzaldehyde

ActiveCN111004096BAvoid pollutionThe preparation method has few stepsOrganic compound preparationCarbonyl compound preparationPtru catalystSide reaction

The invention discloses a method for synthesizing 2,6-dichlorobenzaldehyde, and belongs to the field of fine chemicals. Using 2,6-dichlorotoluene as a starting material, in the presence of a composite supported catalyst, 2,6-dichlorobenzaldehyde is obtained by intermittently passing oxygen in an autoclave in one step. The synthesis method uses cheap industrial chemicals as raw materials and reaction reagents, adopts supported catalysts, realizes the recycling of solvents and catalysts, and reduces the generation of waste gas and waste water; intermittent oxygen supply improves the production safety factor and avoids the occurrence of side reactions. Thus, production efficiency and reaction yield are improved, energy saving and environmental protection are realized and production costs are reduced.

Owner:DALIAN QIKAI MEDICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com