Industrial chemical mechanical grinding equipment

A chemical mechanical and industrial technology, applied in the field of industrial chemical mechanical grinding equipment, can solve the problems of surface roughness reduction, time-consuming and labor-intensive, micropore volume reduction, etc., and achieve the effect of reducing branch recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

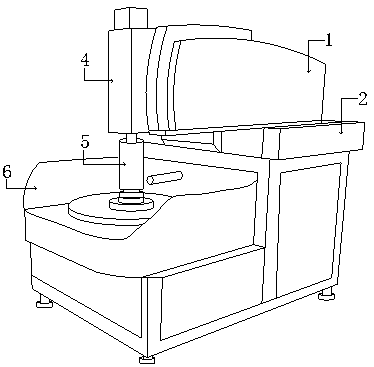

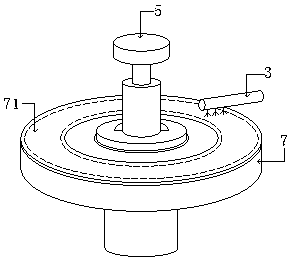

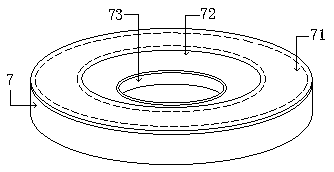

[0027] like Figure 1-Figure 8 As shown, the present invention provides a kind of industrial chemical mechanical grinding equipment, and its structure comprises machine head 1, cabinet 2, abrasive nozzle 3, driving shaft 4, grinding head mechanism 5, shield 6, turntable 7, and described turntable 7 is provided with There is a polishing pad 71, the head 1 is electrically connected to the chassis 2, the upper end of the chassis 2 is fixed with a shield 6, the shield 6 is provided with a turntable 7, and the drive shaft 4 passes through the nose 1 control, the bottom end of the drive shaft 4 is connected to the grinding head mechanism 5, one end of the abrasive spray head 3 penetrates the shield 6 and is connected to the chassis 2, and the other end corresponds to the polishing pad 71, and the turntable 7 also includes an inner chute 72 and the CIMC port 73, the inner chute 72 and the polishing pad 71 are integrated, the polishing pad 71 and the CIMC port 73 are an axis, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com