Constant-temperature transport vehicle for industrial chemicals

A technology of chemicals and transport vehicles, which is applied in the direction of article transport vehicles, vehicles used for freight transportation, transport objects, etc., can solve problems such as high temperature and industrial chemical reactions, and achieve the effect of preventing temperature rise and conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] as attached figure 1 To attach Figure 6 Shown:

[0033] The present invention provides a constant temperature transport vehicle for industrial chemicals, the structure of which includes a bottom bracket 11, wheels 22, side fixing rods 33, a tank body 44, and a headstock 55. The bottom bracket 11 is installed between the wheels 22, The top of the bottom bracket 11 is fixed to the bottom of the tank body 44 , the side fixing rod 33 is welded to the outer surface of the tank body 44 , and the tank body 44 is connected to the headstock 55 .

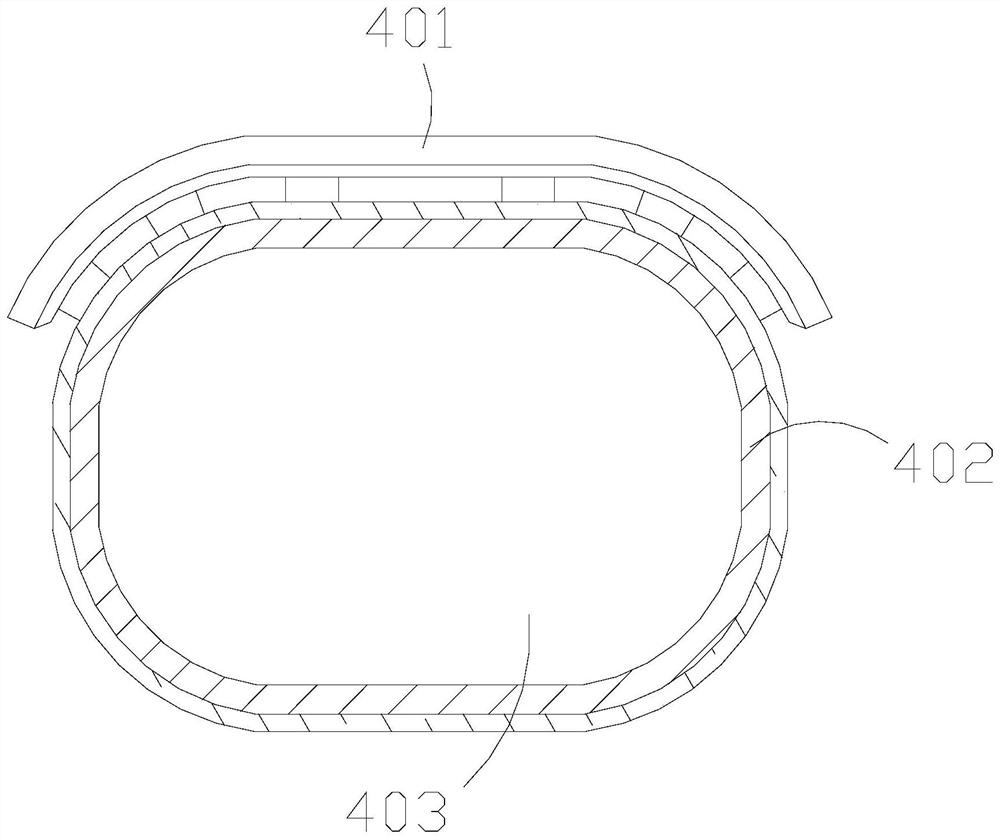

[0034] The tank body 44 includes a cover plate 401 , a sealed tank 402 , and a built-in compartment 403 , the built-in compartment 403 and the sealed tank 402 are of an integrated structure, and a cover plate 401 is installed on the top of the sealed tank 402 .

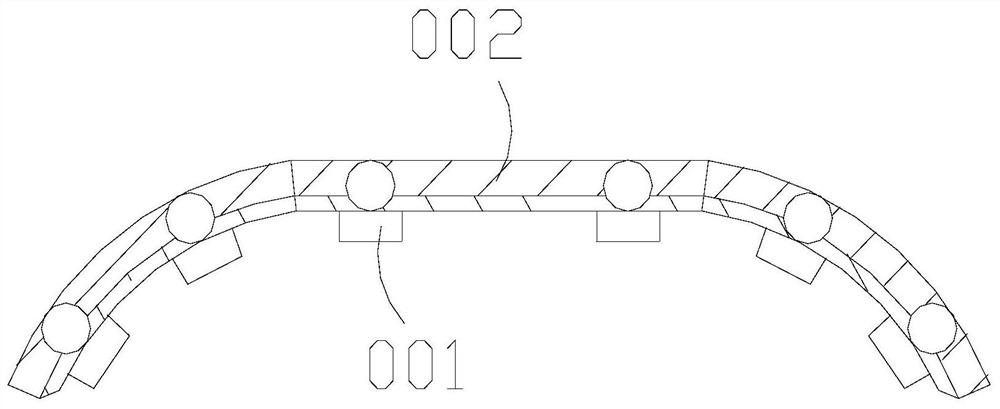

[0035] Wherein, the cover plate 401 includes a spacer 001 and a heat insulation plate 002, the spacer 001 is fixed on the lower end of the heat insulation plate 002, there ...

Embodiment 2

[0042] as attached Figure 7 To attach Figure 9 Shown:

[0043] Wherein, the spacer 001 includes a top spacer g01, a heat insulator g02, and a thermal insulation block g03, the heat separation block g03 and the heat insulation body g02 are an integrated structure, and the top spacer g01 is fixed on the heat insulation body The lower surface of g02, the heat sub-block g03 is an arc-shaped structure, the heat sub-block g03 can collect its heat to a certain extent through its own shape, and the top spacer g01 further separates the temperature from the tank body position between.

[0044] Wherein, the top spacer g01 includes a point contact ball x11, a surface extension block x12, a guide block x13, and a spacer block x14. The surface extension block x12 is attached to the outer surface of the point contact ball x11. The surface extension block x12 is about Both sides are connected with the guide block x13, the outer side of the guide block x13 is attached to the spacer block x1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com