Novel energy-conserving environment-protecting complete-regeneration coating white cardboard and method for preparing same

An energy-saving and environment-friendly white cardboard technology, applied in papermaking, coating, paper coating, etc., to achieve the effects of reducing pulping pollution, saving wood resources, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

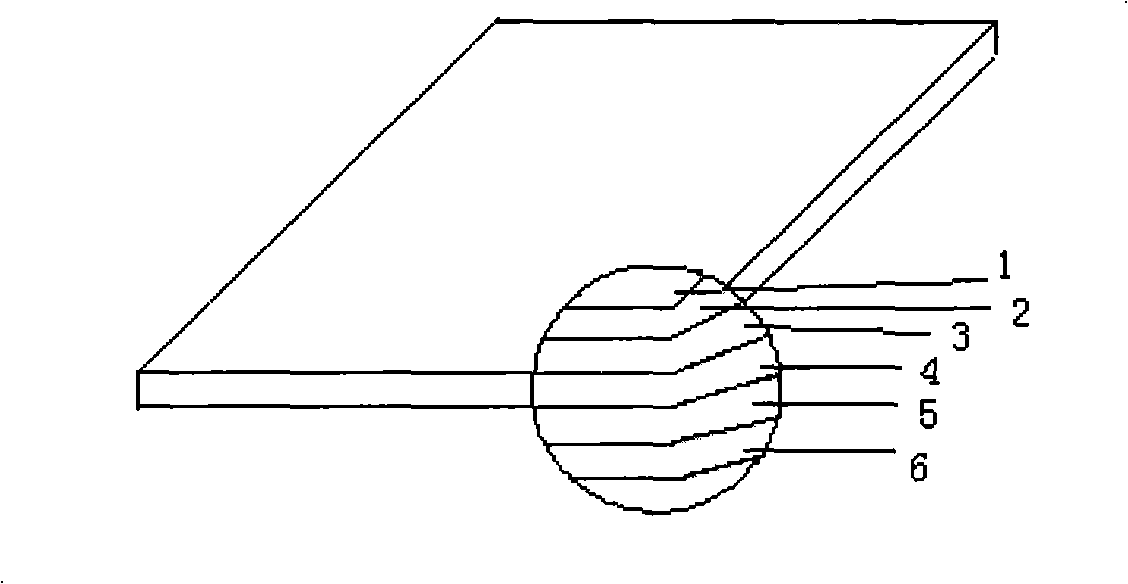

Image

Examples

Embodiment 1

[0028] (1) Specification: 787×1092mm.

[0029] (2) Weight: 300g / m 2

[0030] (3) Process flow:

[0031] a. Flour production (bleached and deinked pulp): use imported mixed office waste paper, and pass through chain conveyor, pulper, intermittent slag cleaner, high-concentration desander, coarse screen, pre-fine screen, Flotation deinking, rotary screen concentration, first thermal dispersion, high-concentration oxidation bleaching, first-stage three-stage fine screening, post-flotation deinking, first-stage four-stage low-concentration desanding, multi-disk filter, second stage Heat dispersion, medium consistency pump, up-flow reduction bleaching pipe, pulp storage tower, pulp distribution box, paper machine pulp tank, white water tank outside the machine (white water pump), four-stage conical desander, pulp pump, tail pulp Groove (the second section of the pressure screen), and finally sent to the headbox; the degree of knocking of the surface pulp is 45-55°SR.

[0032] b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com