Purification and graphitization method of graphite material

A graphite material and graphitization technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as inability to meet large-scale production of graphite, graphitization, etc., to reduce power consumption, Avoid heating to generate and transfer heat, the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Purification and graphitization method of the present invention, adopt following steps:

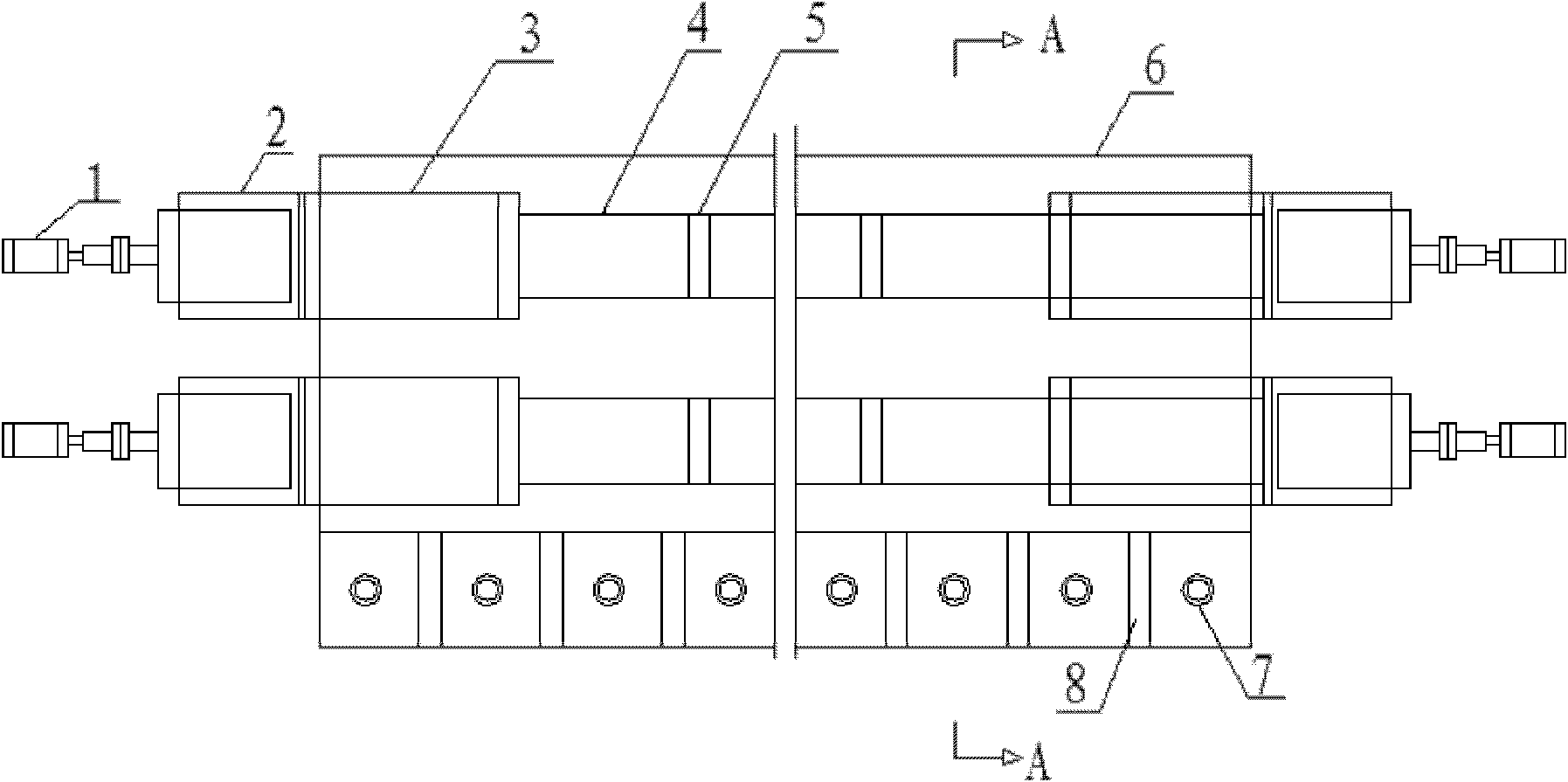

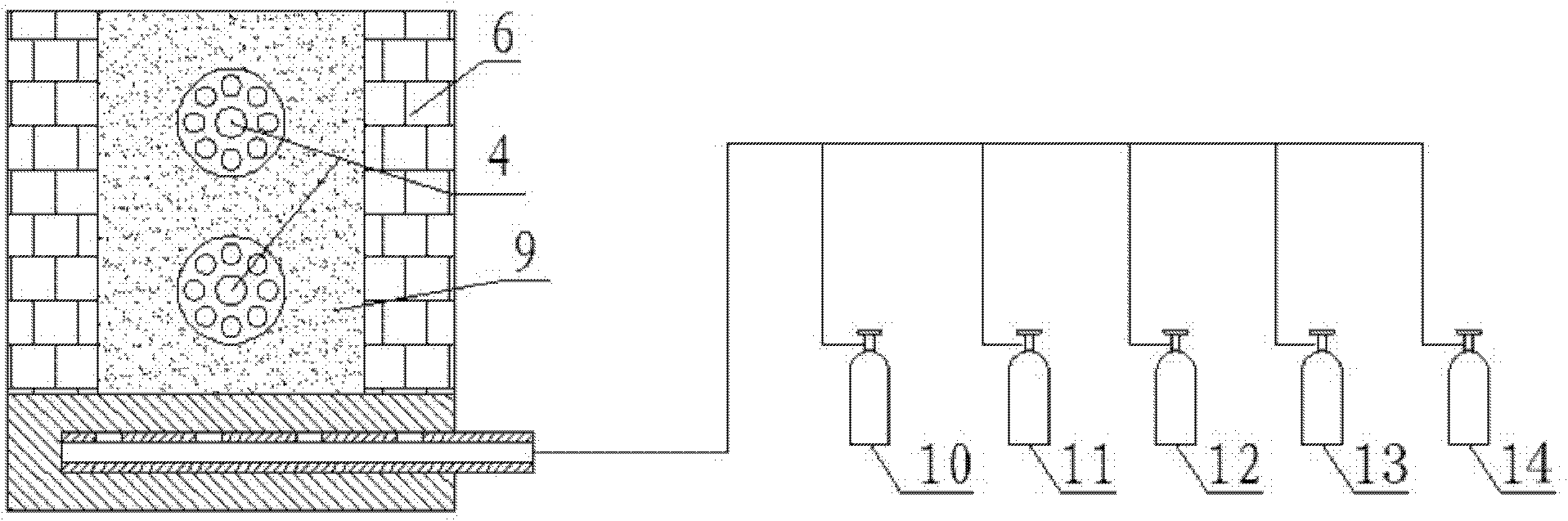

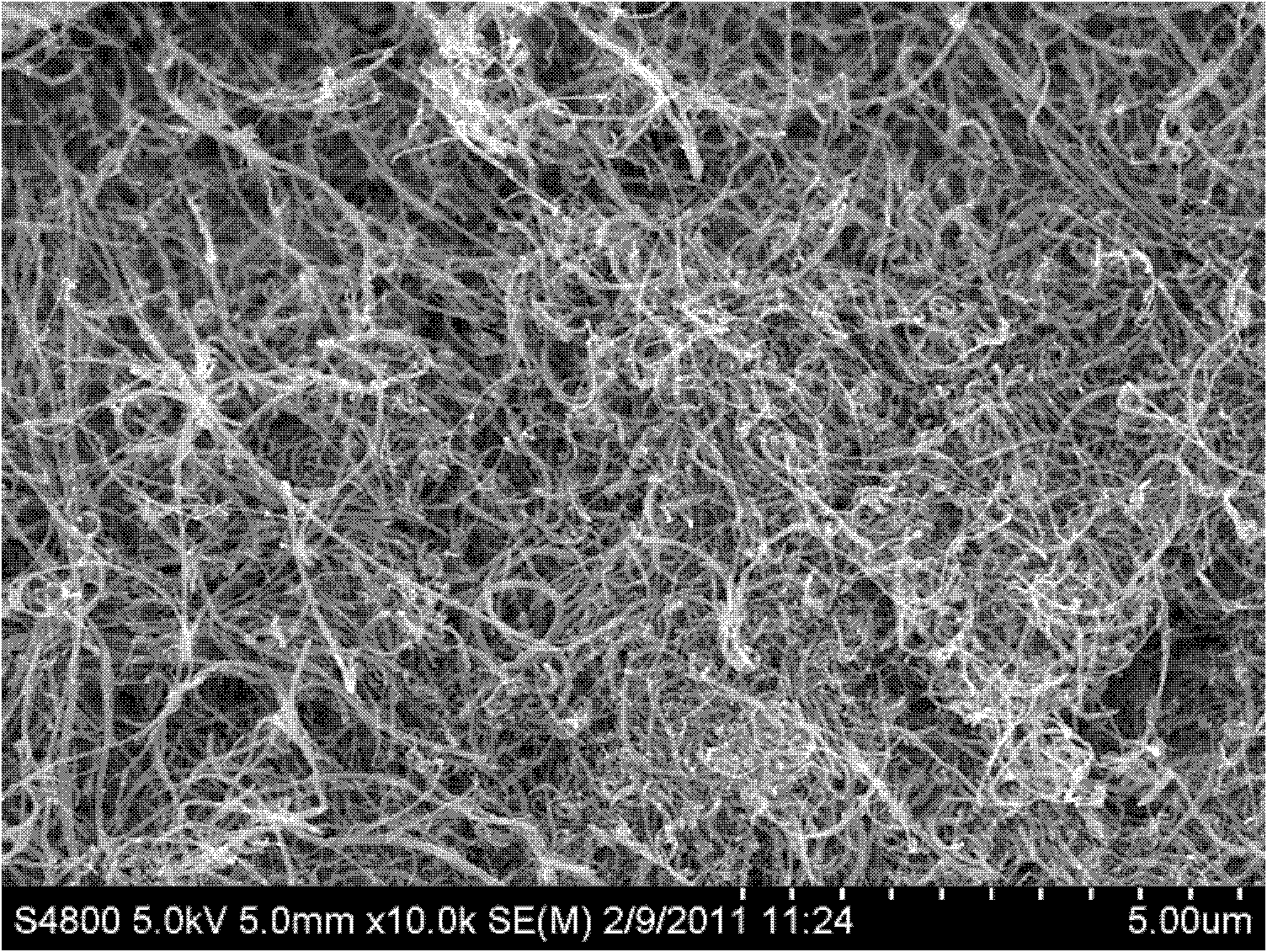

[0019] 1. Put graphite products or carbon products into the graphite crucible in the furnace body. Graphite products are natural graphite powder with a fixed carbon content of more than 85%, artificial graphite powder, microcrystalline graphite powder, coking coal, coke or graphite electrodes, carbon The plain products are carbon nanotubes, carbon fibers, needle coke or petroleum coke with a fixed carbon content of more than 85%. Such as figure 1 and figure 2 As shown, graphite current distribution plates 3 are connected between the furnace end electrodes 2 at both ends of the furnace body, and 30 to 90 graphite crucibles 4 are connected in series between the current distribution plates 3, and the two ends of the furnace end electrodes 2 are pushing devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com