Method for catalytically decomposing carbon fiber-reinforced thermosetting epoxy resin composite material

A technology of epoxy resin and composite materials, applied in plastic recycling, recycling technology and other directions, can solve the problems of difficult separation, use, degradation of fiber characteristics, etc., to achieve less by-products, mild reaction conditions, and easily controllable reaction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

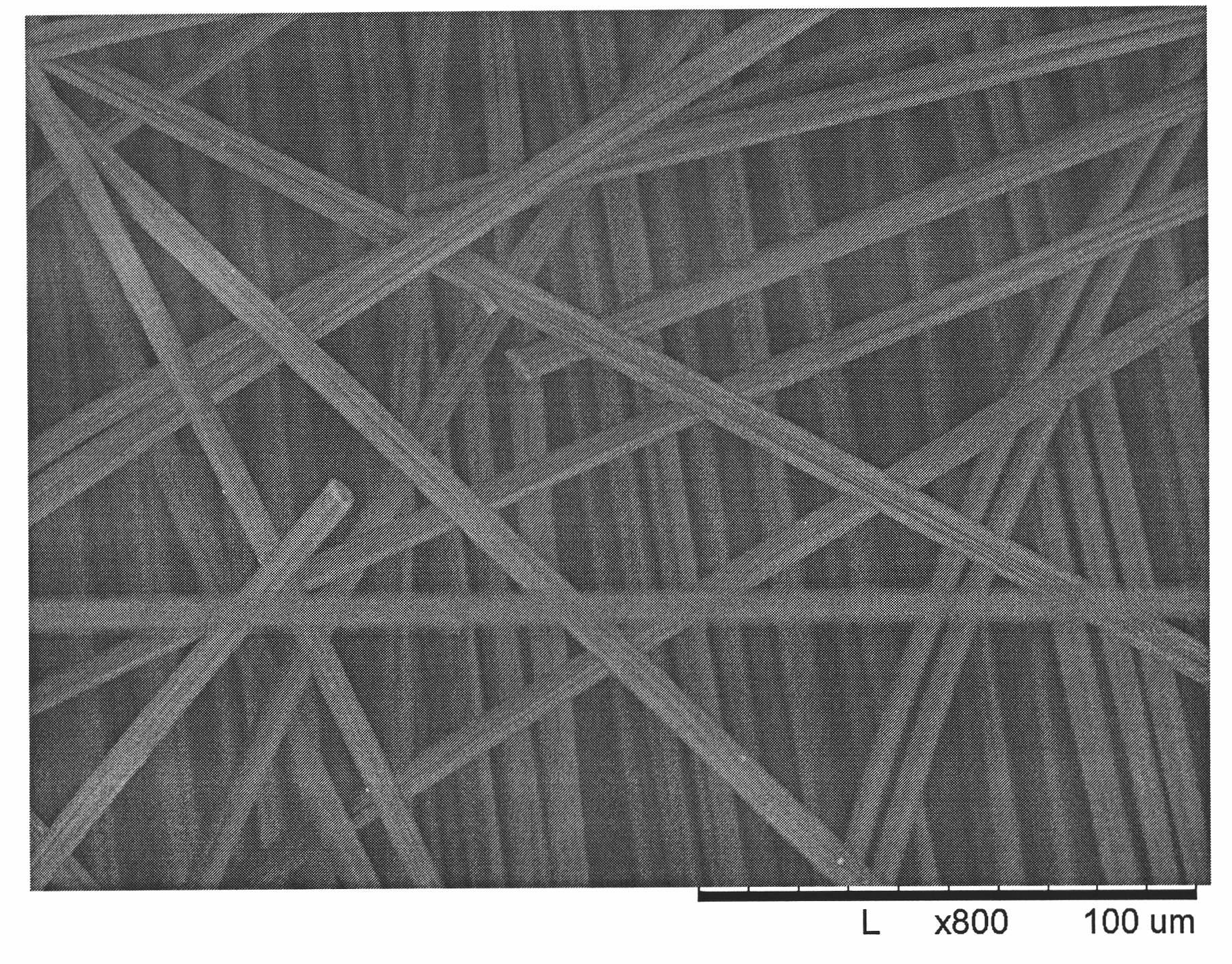

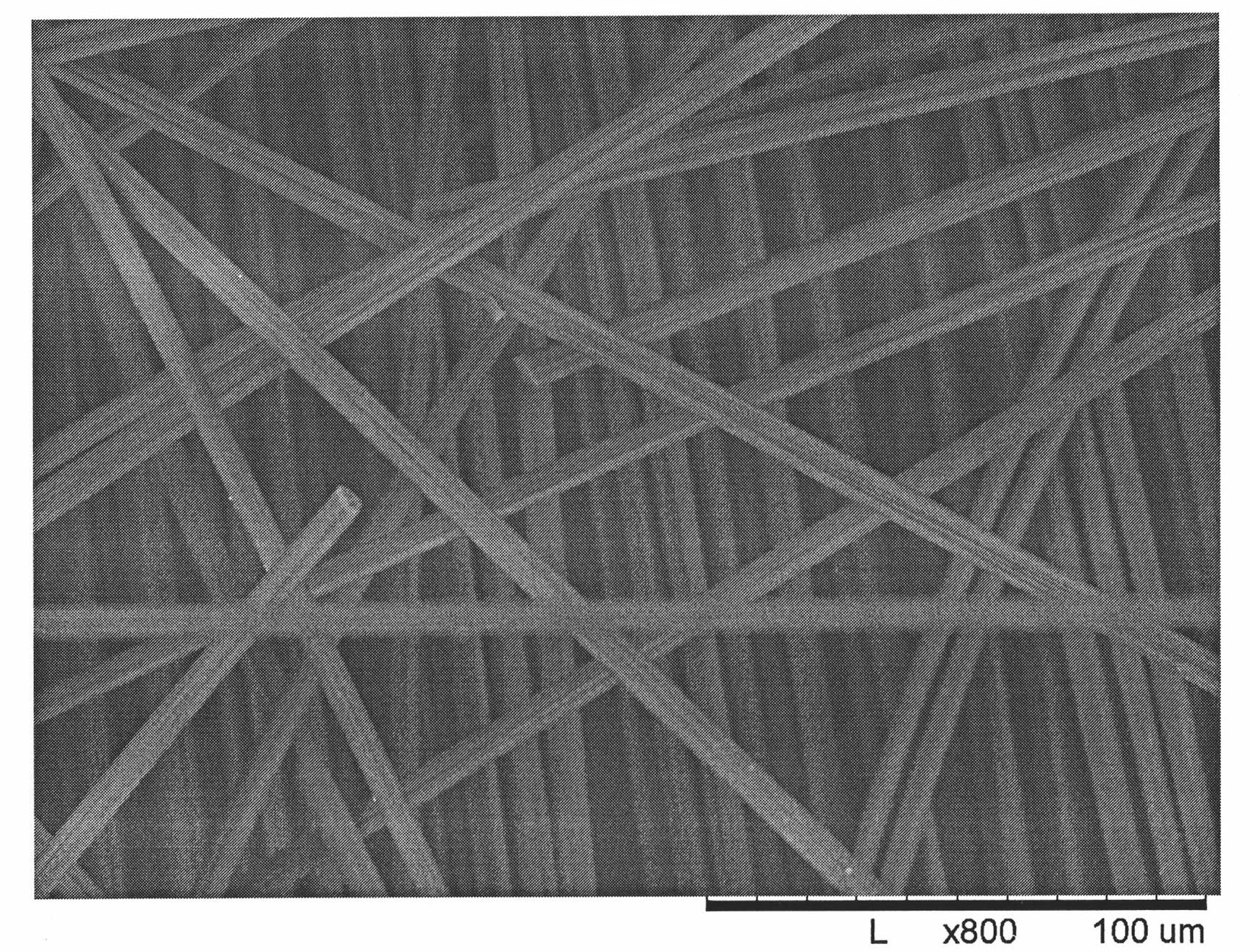

[0028] Add 0.32 g of CF / EP composite material, 0.61 g of solid acid SO into the three-necked flask 4 2- / ZrO 2 , 0.12 g FeSO 4 and 10 milliliters of N,N-dimethylformamide, start the stirrer to stir, and then slowly drop in 20 milliliters of 30% aqueous hydrogen peroxide solution after heating to 50°C in a water bath, then raise the temperature to 80°C for 12 hours, and stop the reaction After cooling, filtering and solid-liquid separation, solid intermediates and liquid intermediates are obtained; the obtained solid intermediates are washed with water, and after drying, clean carbon fibers and reusable solid superacids are separated; the obtained liquid intermediates are decompressed Distillation yields a decomposed reusable thermosetting epoxy residue. Among them, the carbon fiber recovery rate is 95%. The SEM image of the recovered carbon fiber is shown in Figure 1. It can be seen that the surface is basically free of defects and impurities, and can be reused.

Embodiment 2

[0030] Add 0.70 g of CF / EP composite material, 0.80 g of solid acid SO into the three-necked flask 4 2- / Fe 2 o 3 , 0.42 g FeSO 4 and 20 milliliters of ethanol, start the stirrer to stir, after heating to 45 DEG C, slowly drop into 50 milliliters of aqueous hydrogen peroxide solution with a concentration of 30%, then heat up to 70 DEG C and react for 16 hours, cool after stopping the reaction, and filter for solid-liquid separation to obtain Solid intermediates and liquid intermediates; the solid intermediates are washed with water and dried to separate clean carbon fibers and reusable solid superacids; the liquid intermediates are distilled under reduced pressure to obtain decomposed reusable thermosetting epoxy Resin residue. Among them, the carbon fiber recovery rate is 96%, and the surface of the recycled carbon fiber is similar to that shown in Figure 1, basically without defects and impurities, and can be reused.

Embodiment 3

[0032] Add 0.27 g of CF / EP composite material, 0.42 g of solid acid SO in the three-necked flask 4 2- / Fe 2 o 3 , 0.17 g FeSO 4and 10 milliliters of N, N-dimethylformamide, start the stirrer, slowly drop in 40 milliliters of 30% aqueous hydrogen peroxide solution after heating to 50°C, then raise the temperature to 80°C for 10 hours, stop the reaction and then cool , filtering solid-liquid separation to obtain solid intermediates and liquid intermediates; washing the solid intermediates with water, drying and separating clean carbon fibers and reusable solid superacids; distilling the liquid intermediates under reduced pressure to obtain decomposed Reusable thermosetting epoxy residue. Among them, the carbon fiber recovery rate is 96%, and the surface of the recycled carbon fiber is similar to that shown in Figure 1, basically without defects and impurities, and can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com