Preparation method for preparing Co3O4@CoP composite electrode based on MOF template

A composite electrode and electrode technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of adverse effects, poor electrochemical stability of electrode materials, poor interface binding force, etc., and achieve easy implementation, good electrocatalytic activity, composite The effect of novel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

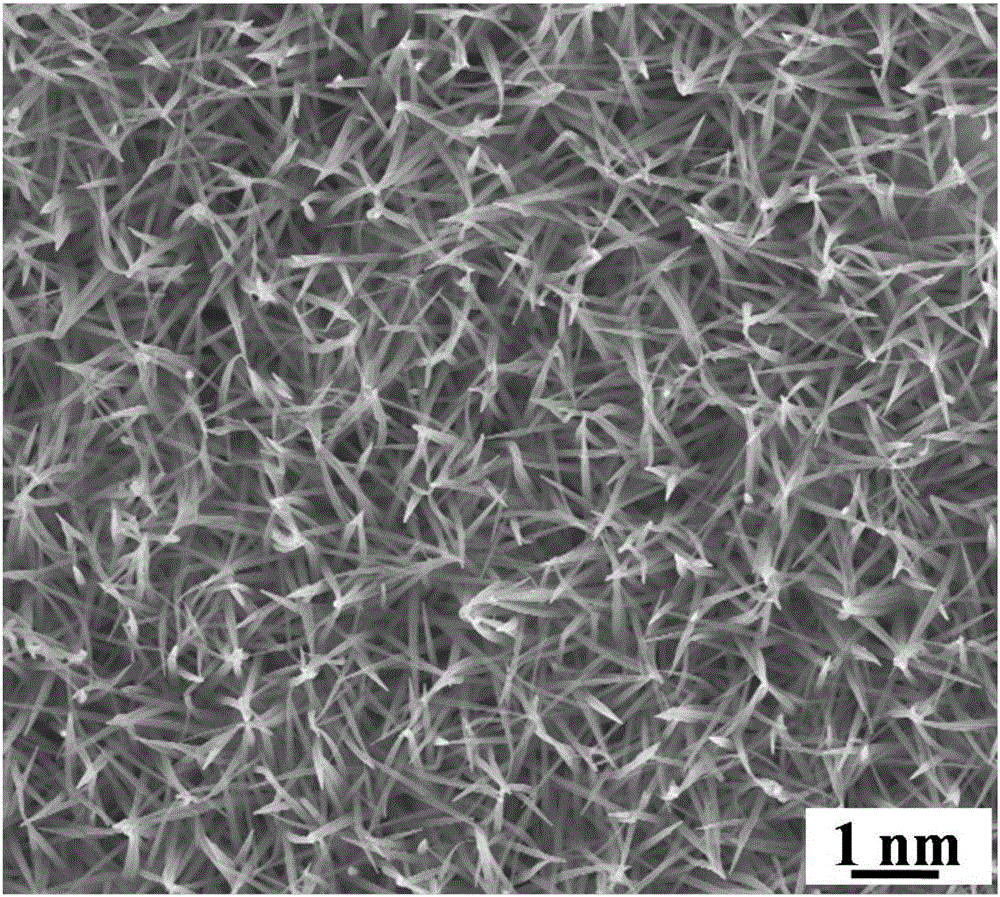

[0020] Step 1: Stir and dissolve 5mmol cobalt nitrate hexahydrate and 25mmol urea in 50ml deionized water, pour the obtained homogeneous solution into the reaction kettle, and immerse the cleaned nickel sheet (length, width and height=2cm×1cm×0.1cm) The above solution was subjected to a hydrothermal reaction at a constant temperature of 8 hours at 100°C, and the Co(CO 3 ) 0.5 OH·0.11H 2 O electrode.

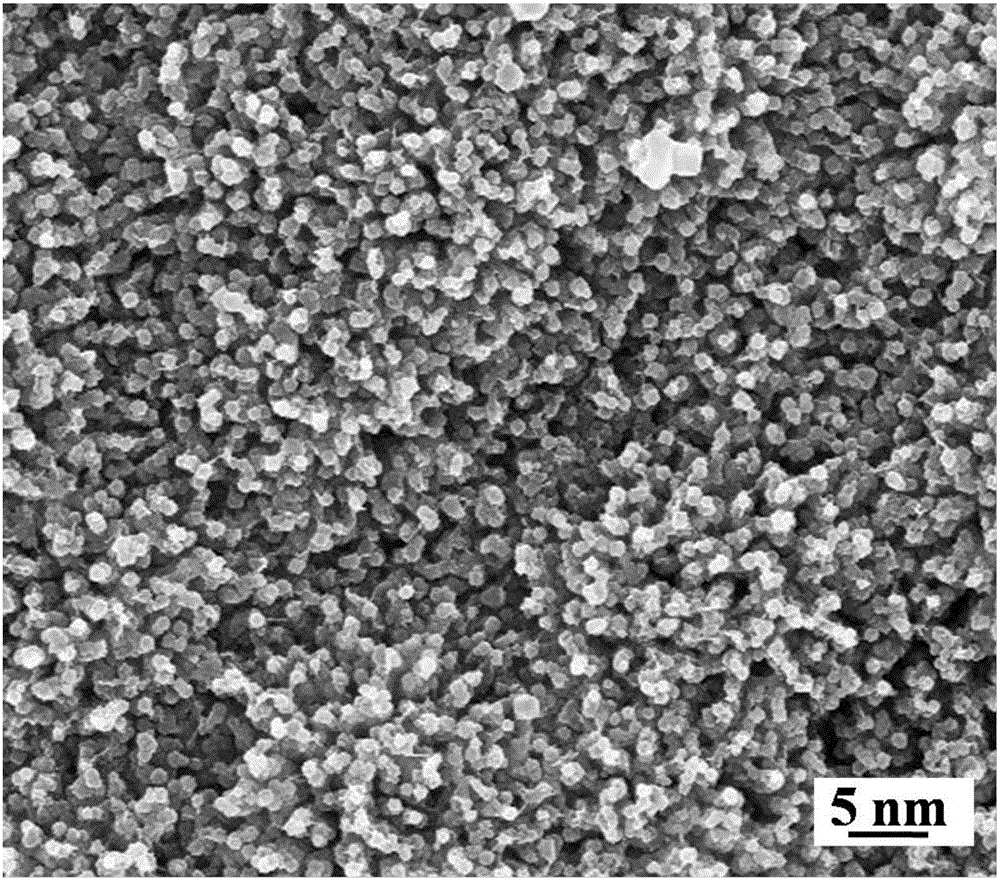

[0021] The second step: 10ml of water was stirred to dissolve 1.25g of 2-methylimidazole, and 1.0ml of triethylamine was added, poured into the reaction kettle and the Co(CO 3 ) 0.5 OH·0.11H 2 The O electrode was immersed and kept at 70°C for 2 hours to prepare Co(CO 3 ) 0.5 OH·0.11H 2 O@ZIF-67 composite electrode.

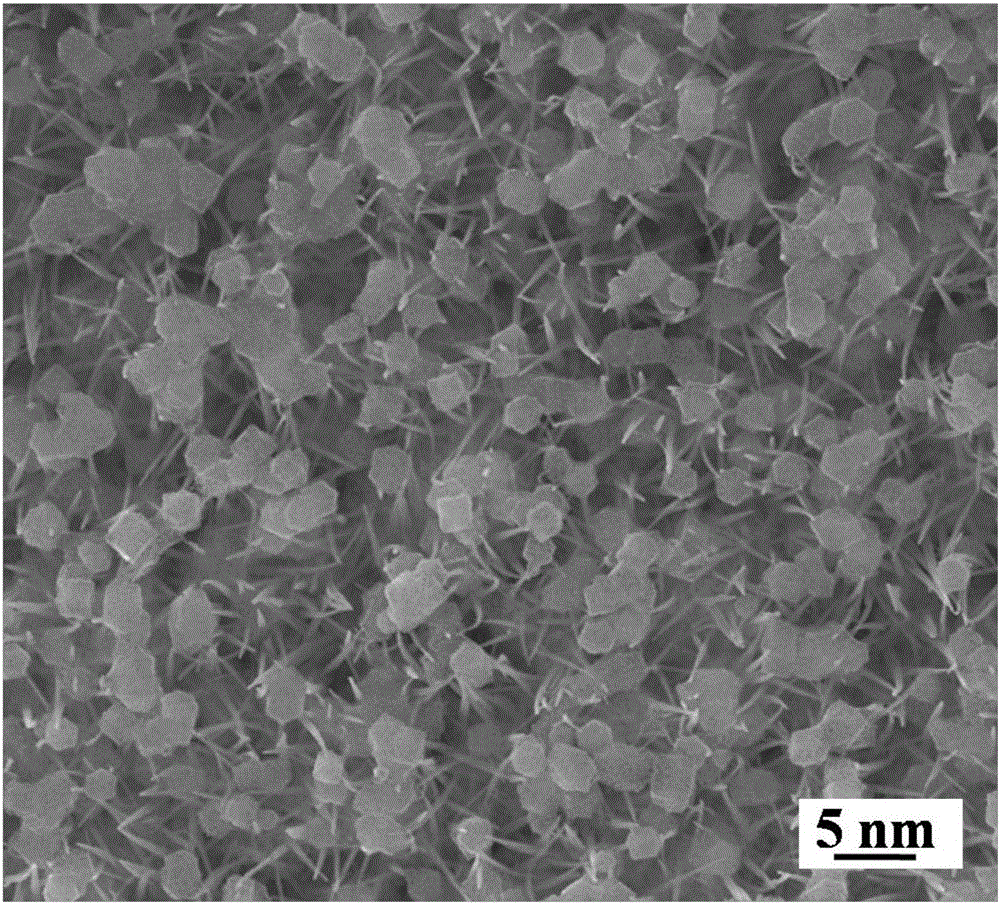

[0022] In the third step, Co(CO 3 ) 0.5 OH·0.11H 2 O@ZIF-67 composite electrode (length, width, thickness = 2cm×1cm×0.1cm) and 0.1g of sodium hypophosphite were placed in a tube furnace porcelain boat for phosphating treatment. The reaction atmosphere is ...

Embodiment 2

[0024] Step 1: Stir and dissolve 5mmol cobalt nitrate hexahydrate and 25mmol urea in 50ml deionized water, pour the obtained homogeneous solution into the reaction kettle, and immerse the cleaned nickel sheet (length, width and height=2cm×1cm×0.1cm) The above solution was subjected to a hydrothermal reaction at a constant temperature of 12 hours at 90°C, and the Co(CO 3 ) 0.5 OH·0.11H 2 O electrode.

[0025] The second step: 10ml of water was stirred to dissolve 1.25g of 2-methylimidazole, and 1.5ml of triethylamine was added, poured into the reaction kettle and the Co(CO 3 ) 0.5 OH·0.11H 2 The O electrode was immersed and kept at 70°C for 2 hours to prepare Co(CO 3 ) 0.5 OH·0.11H 2O@ZIF-67 composite electrode.

[0026] In the third step, Co(CO 3 ) 0.5 OH·0.11H 2 O@ZIF-67 composite electrode (length, width and height = 2cm×1cm×0.1cm) and 0.5g sodium hypophosphite were placed in a tube furnace porcelain boat for phosphating treatment. The reaction atmosphere is Ar a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com