Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Catalytic growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

Method for preparing single-layer graphene

The invention discloses a method for preparing single-layer graphene. The method comprises the following steps of: 1) preparing an alloy substrate; and 2) in the hydrogen and inert atmosphere, catalyzing to grow graphene on the surface of the alloy substrate obtained in the step 1) by a chemical vapor deposition method, thereby finishing the preparation of the single-layer graphene. The method makes use of the characteristics of two or more alloy metals in the alloy substrate, realizes control on the decomposition, diffusion and precipitation processes of a carbon source, simply and efficiently restrains the precipitation process of carbon dissolved in the metal substrate to enable the graphene to be capable of growing in a surface catalytic manner to obtain the single-layer graphene withuniform layer distribution, and is suitable for industrial production and particularly for the controllable preparation of single-layer or few-layer graphene.

Owner:PEKING UNIV

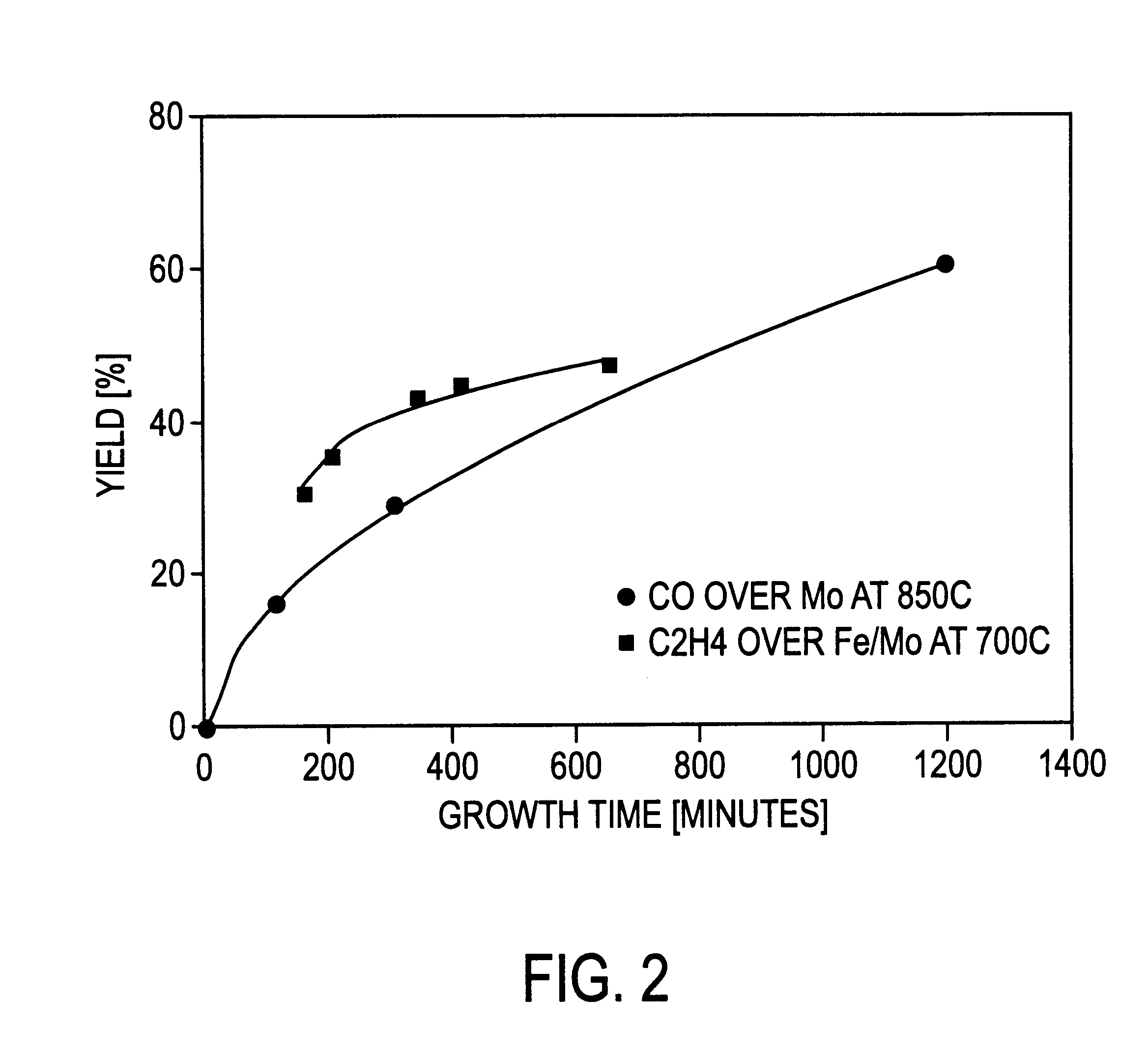

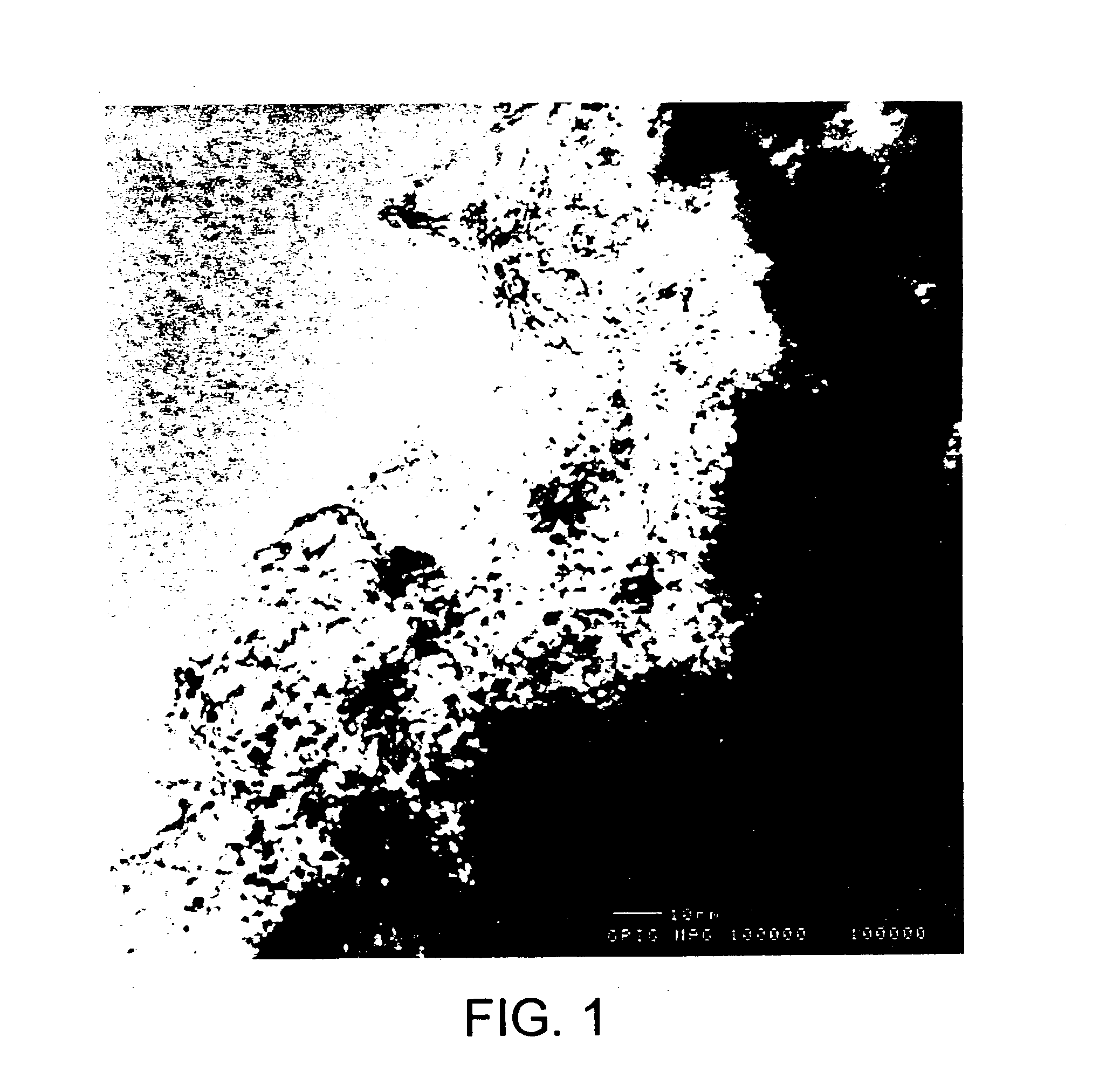

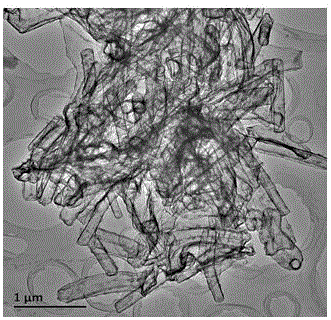

Catalytic growth of single- and double-wall carbon nanotubes from metal particles

InactiveUS7125534B1Improve productivityImprove scalabilityMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

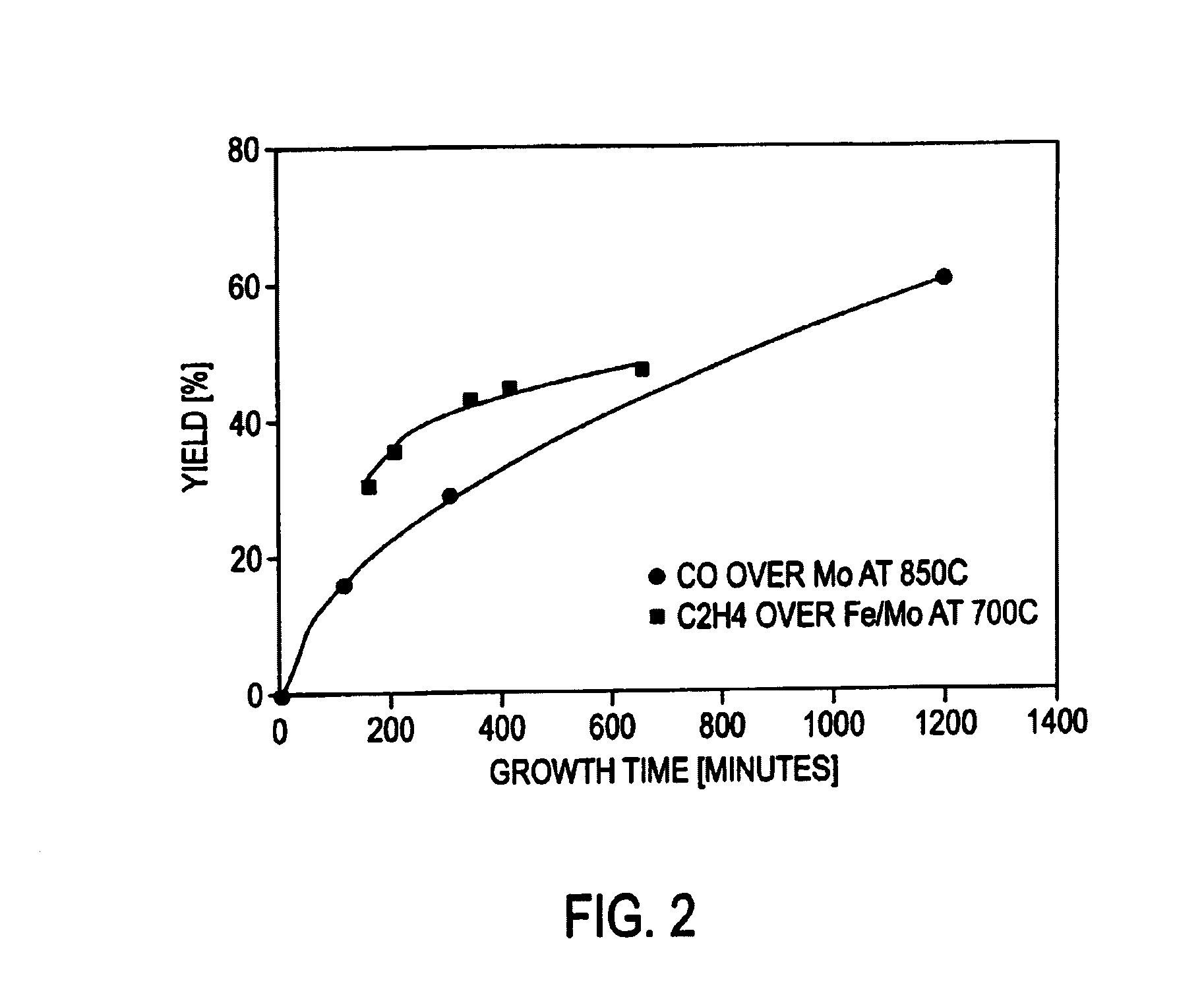

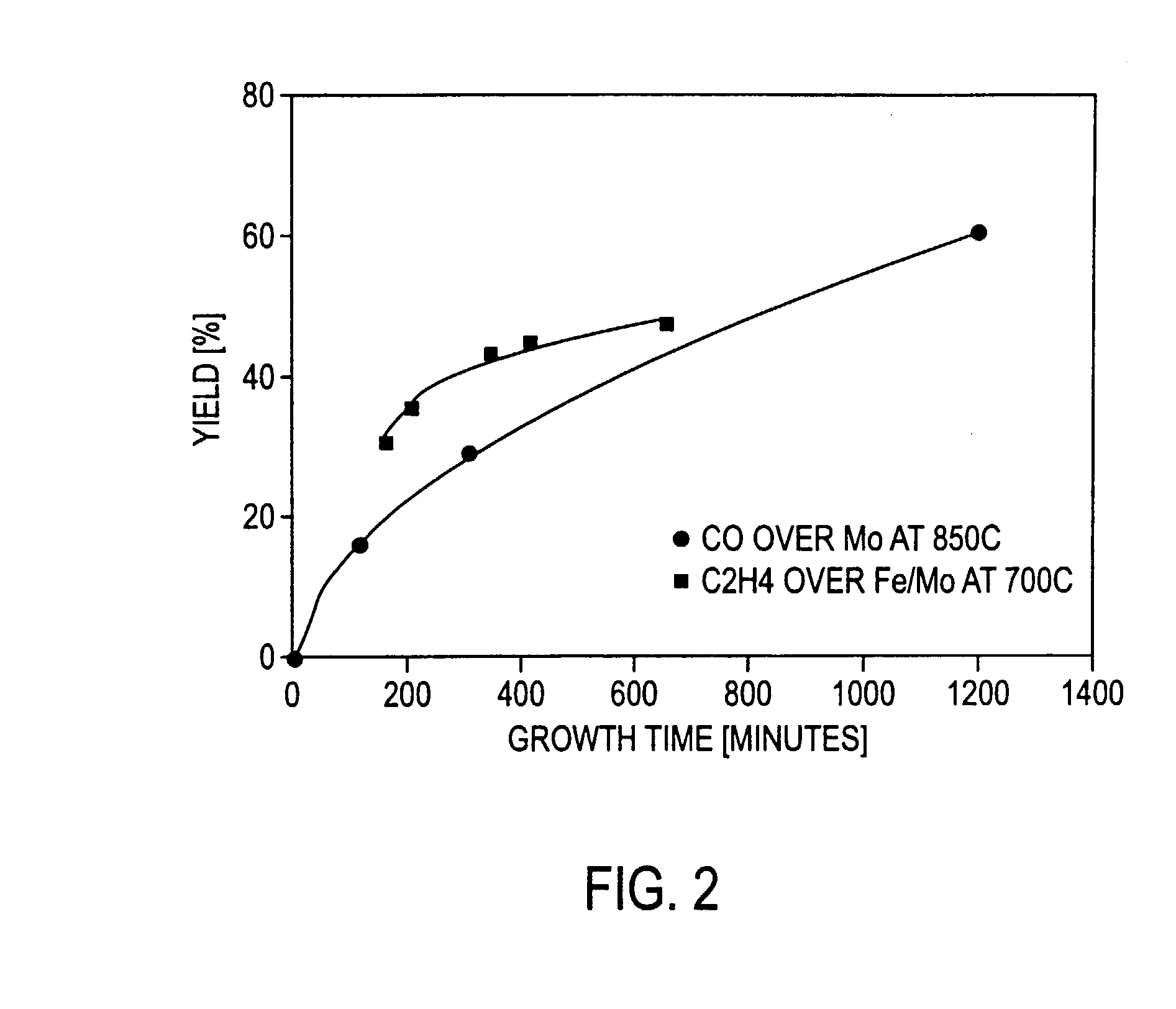

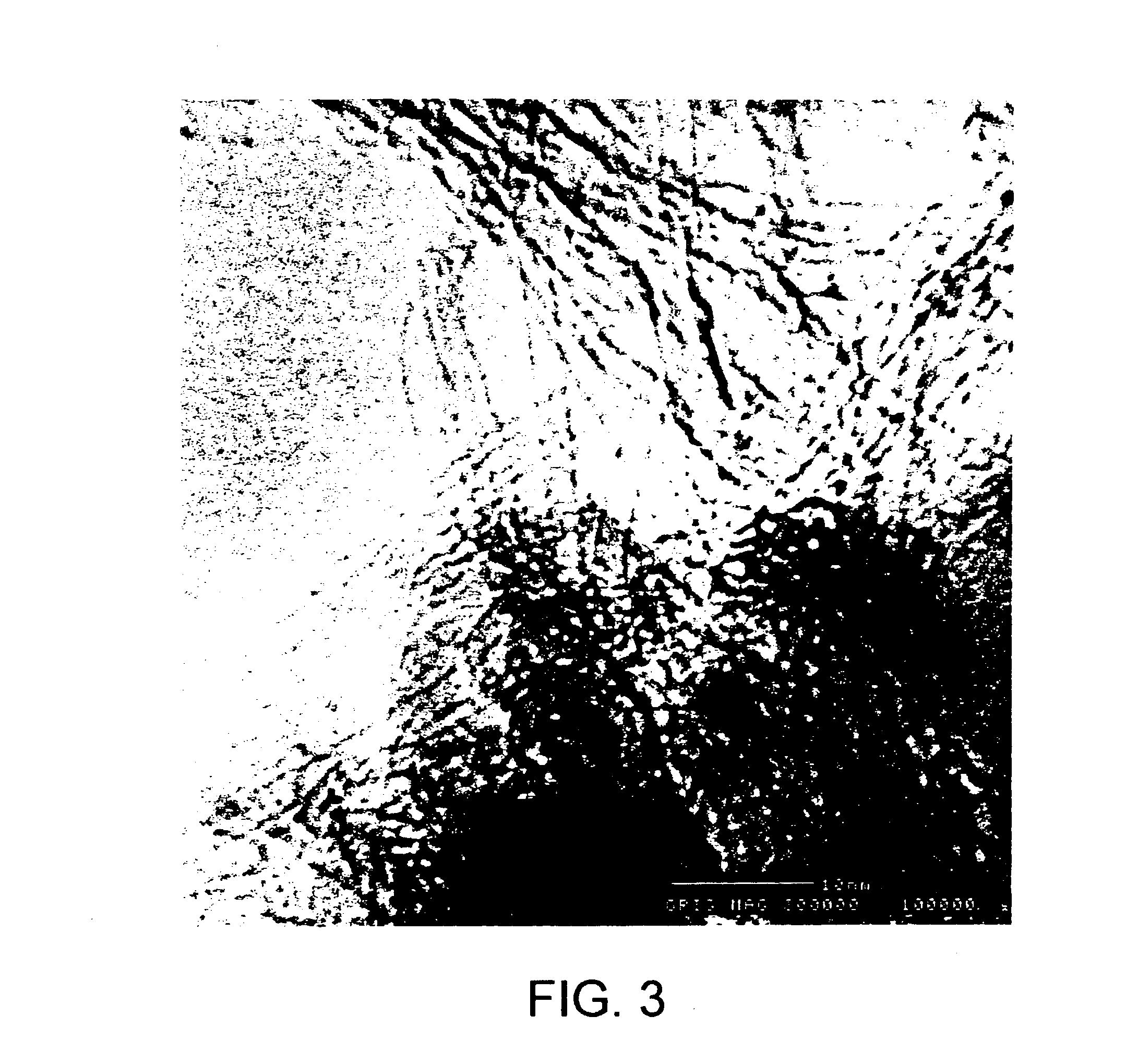

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst. The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

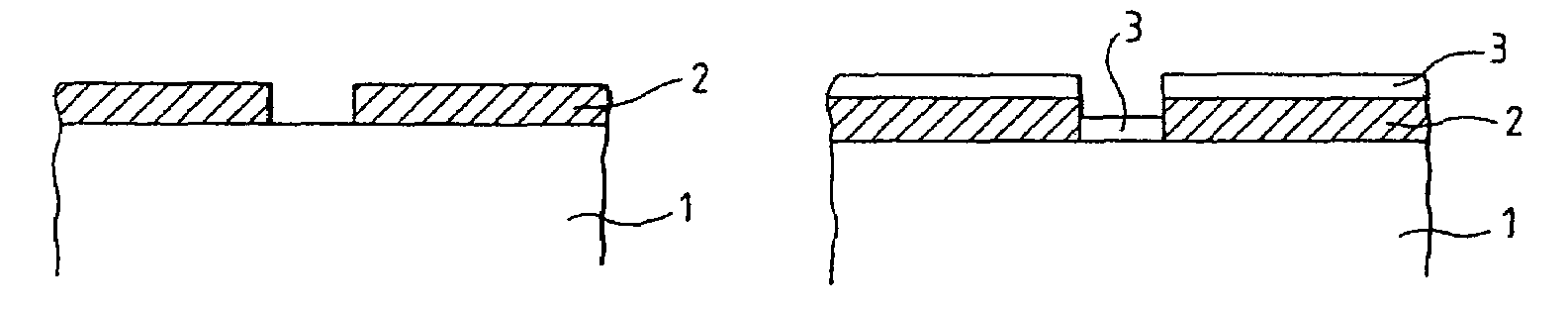

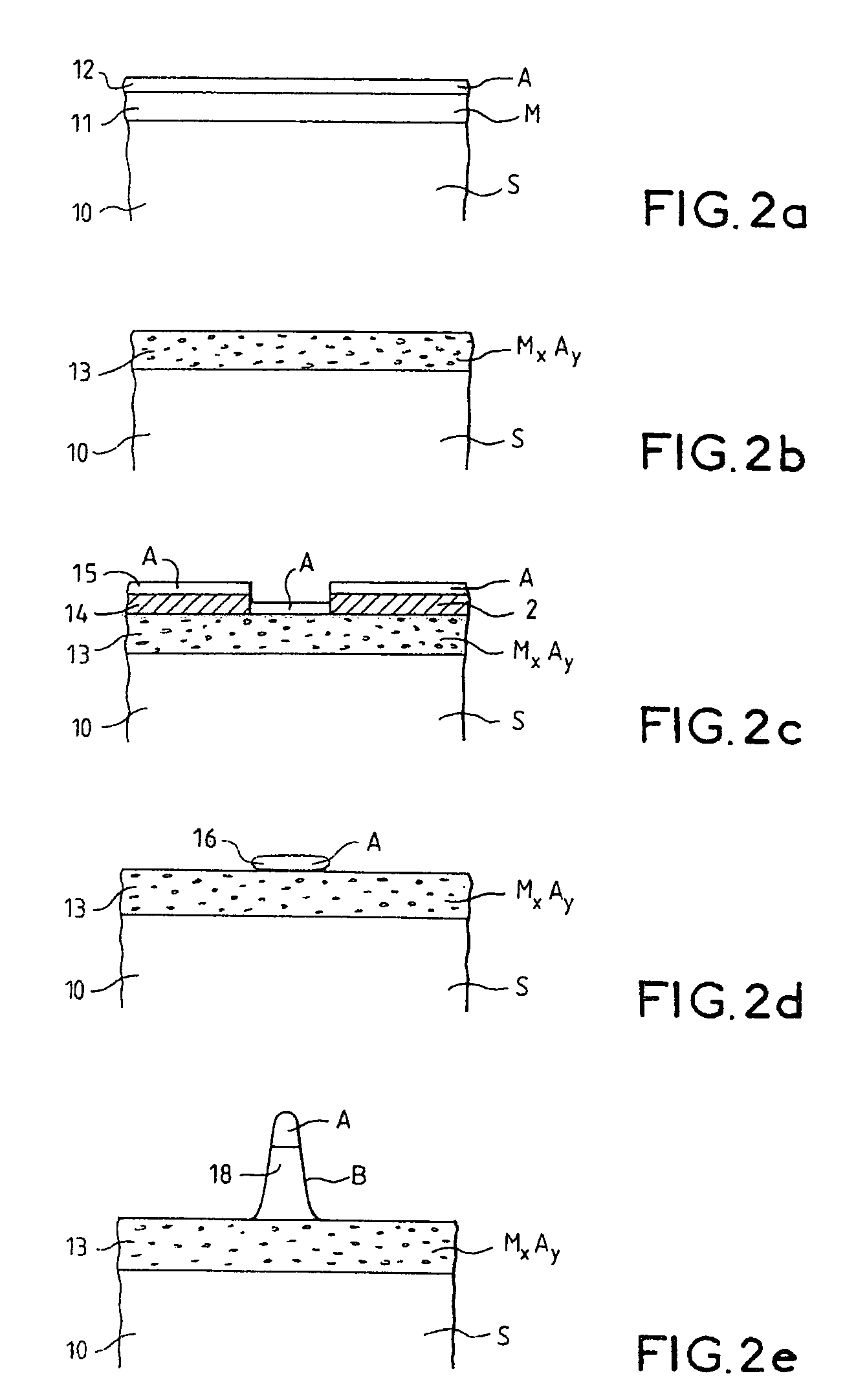

Method for catalytic growth of nanotubes or nanofibers comprising a NiSi alloy diffusion barrier

InactiveUS7491269B2Efficient growth processMaterial nanotechnologyPolycrystalline material growthFiberNanofiber

The invention relates to a process for the growth of nanotubes or nanofibers on a substrate comprising at least an upper layer made of a first material, wherein: the formation, on the surface of the upper layer, of a barrier layer made of an alloy of the first material and of a second material, said alloy being stable at a first temperature; the formation of spots of catalyst that are made of the second material, on the surface of the alloy layer; and the growth of nanotubes or nanofibers at a second temperature below said first temperature. The alloy layer allows effective growth of nanotubes / nanofibers from catalyst spots on the surface of said alloy layer. This is because the alloy layer constitutes a diffusion barrier preventing the catalyst from diffusing into the growth substrate, which barrier is stable at the catalytic nanotube / nanofiber growth temperature.

Owner:THALES SA

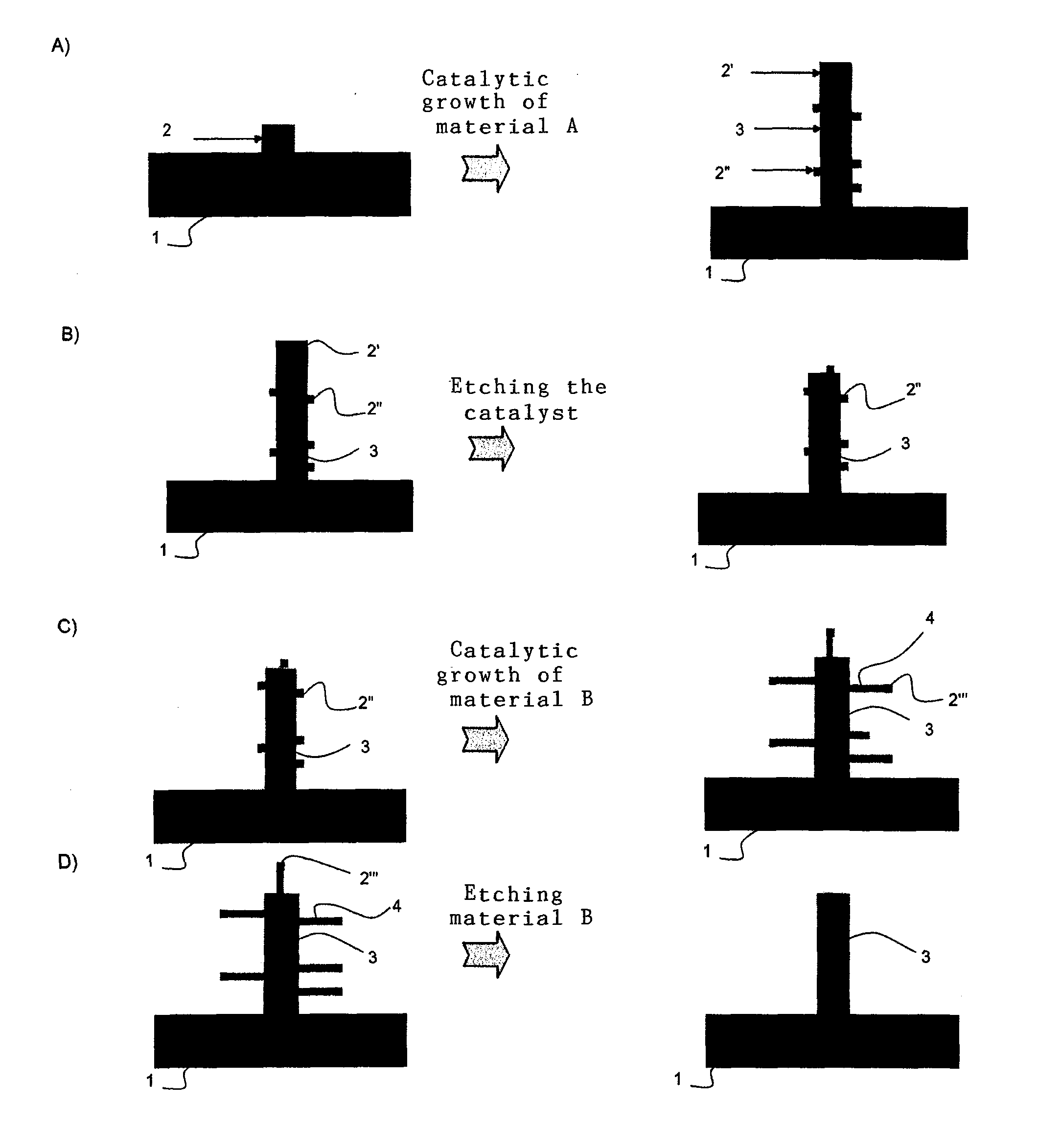

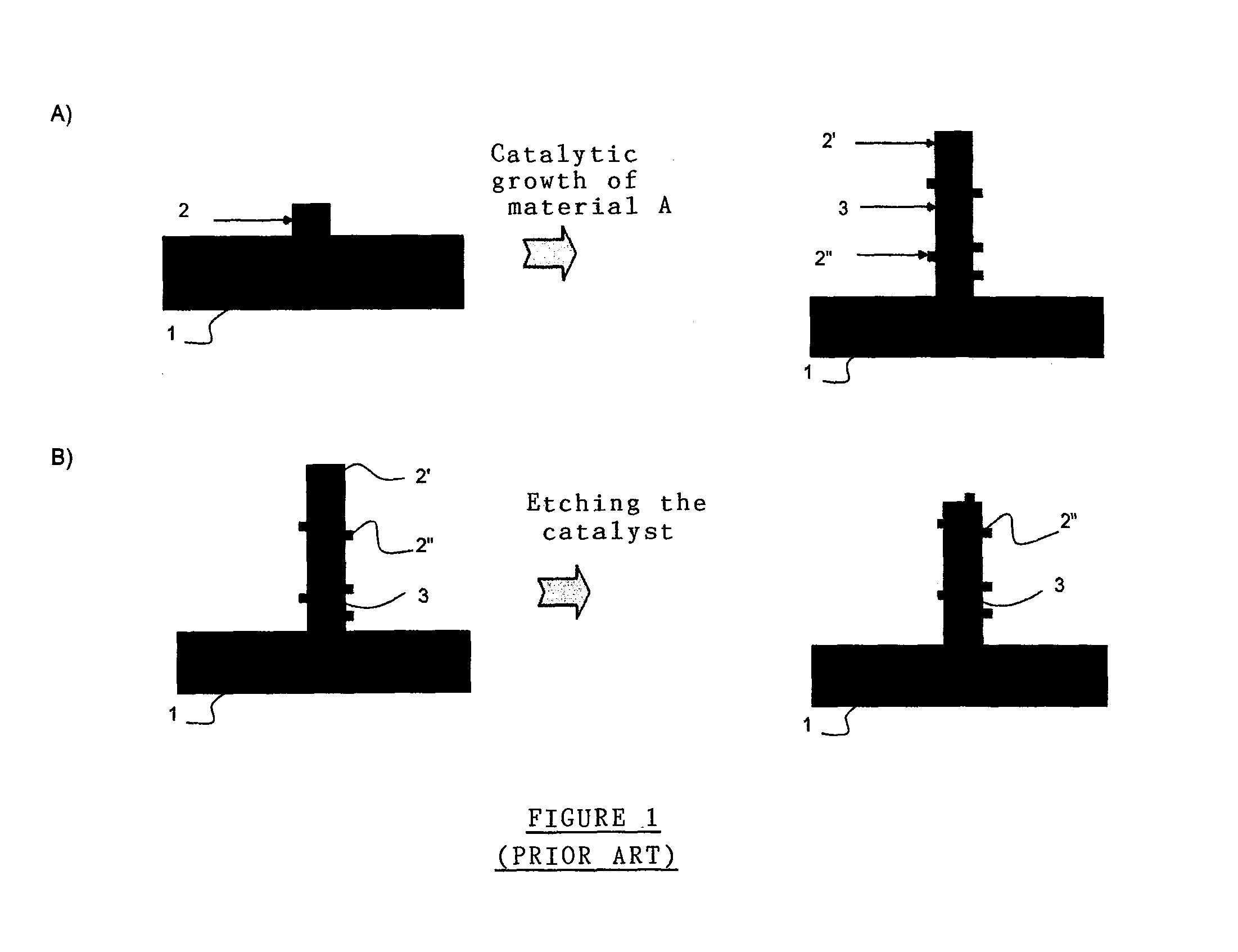

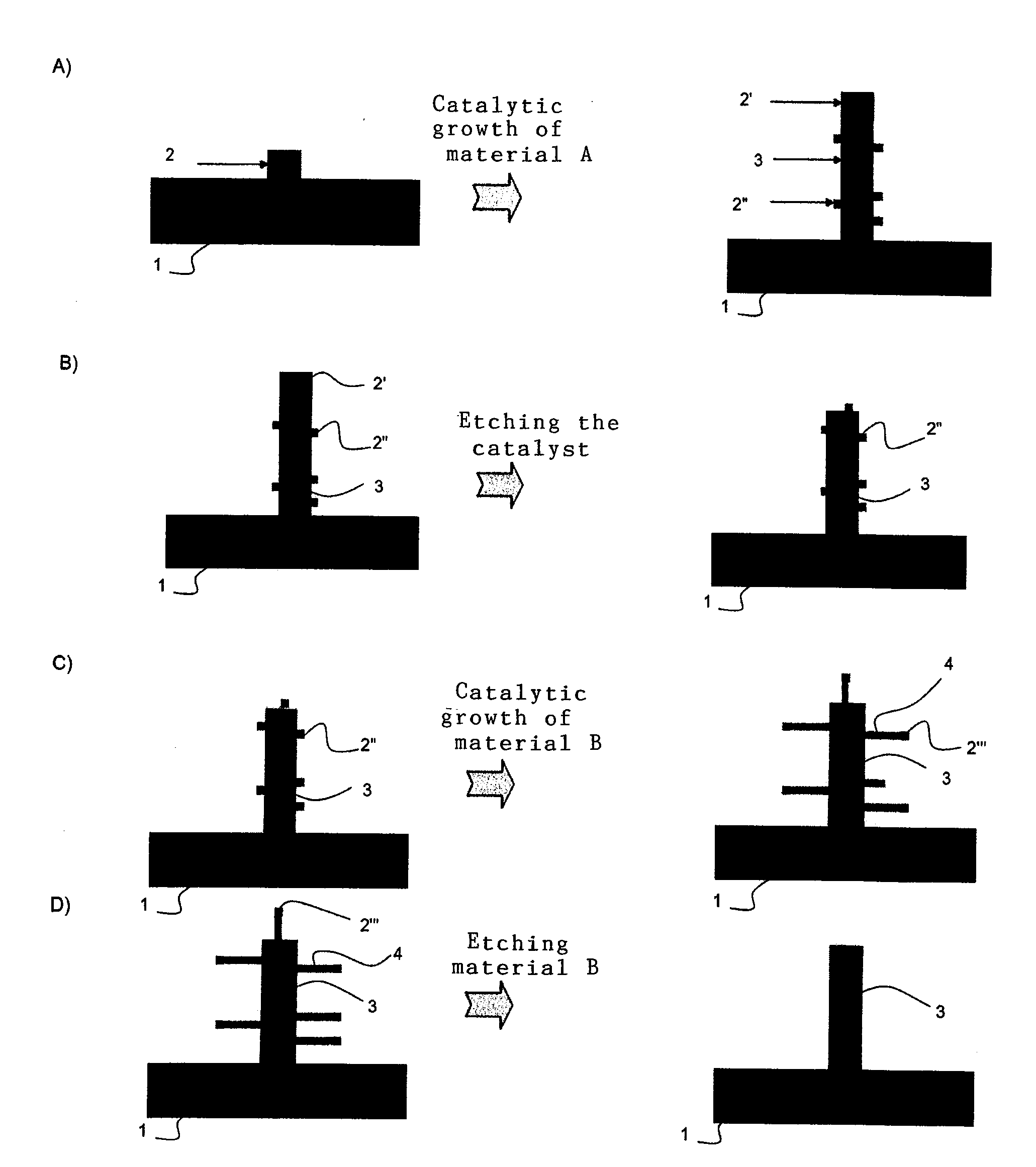

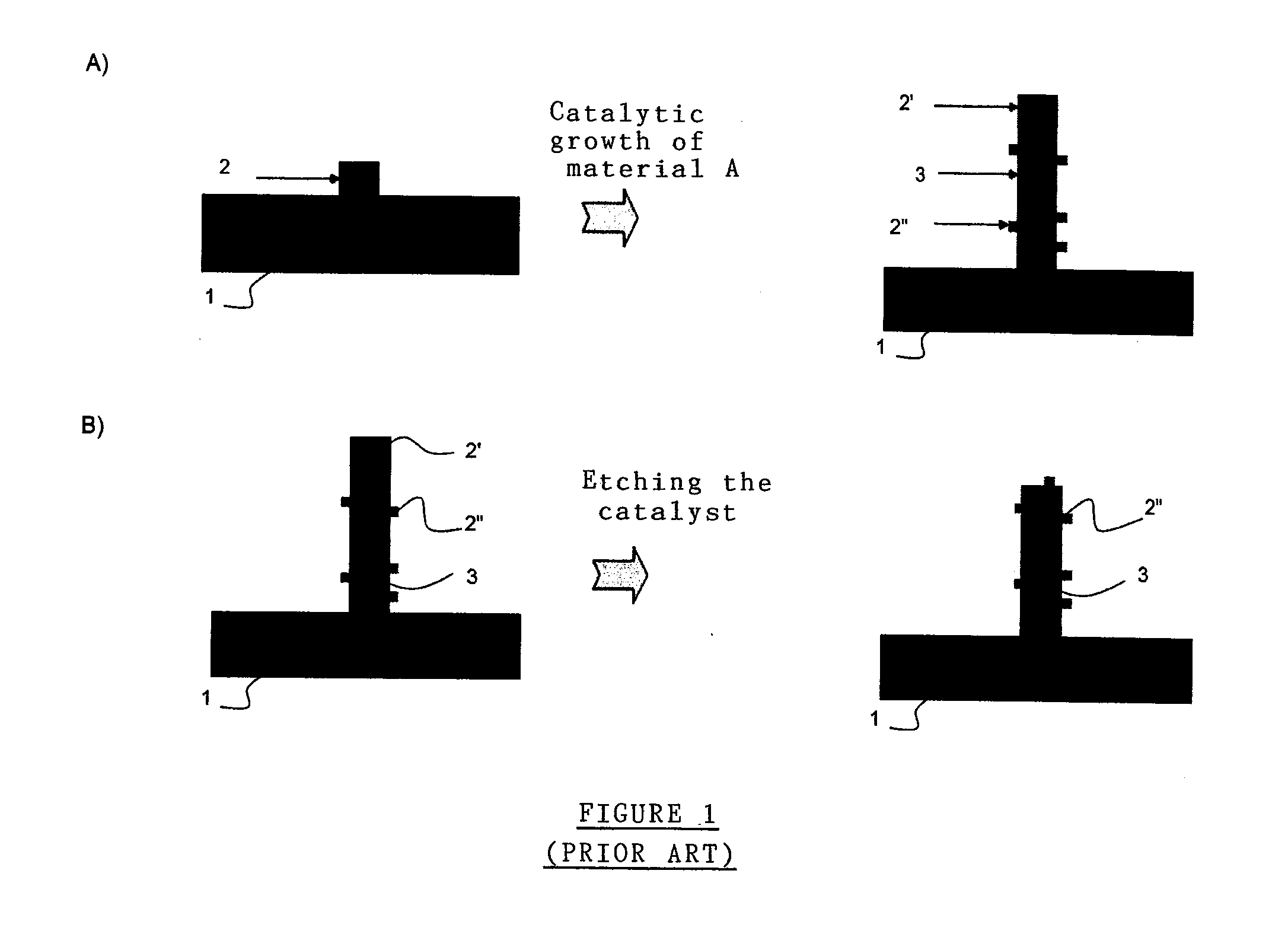

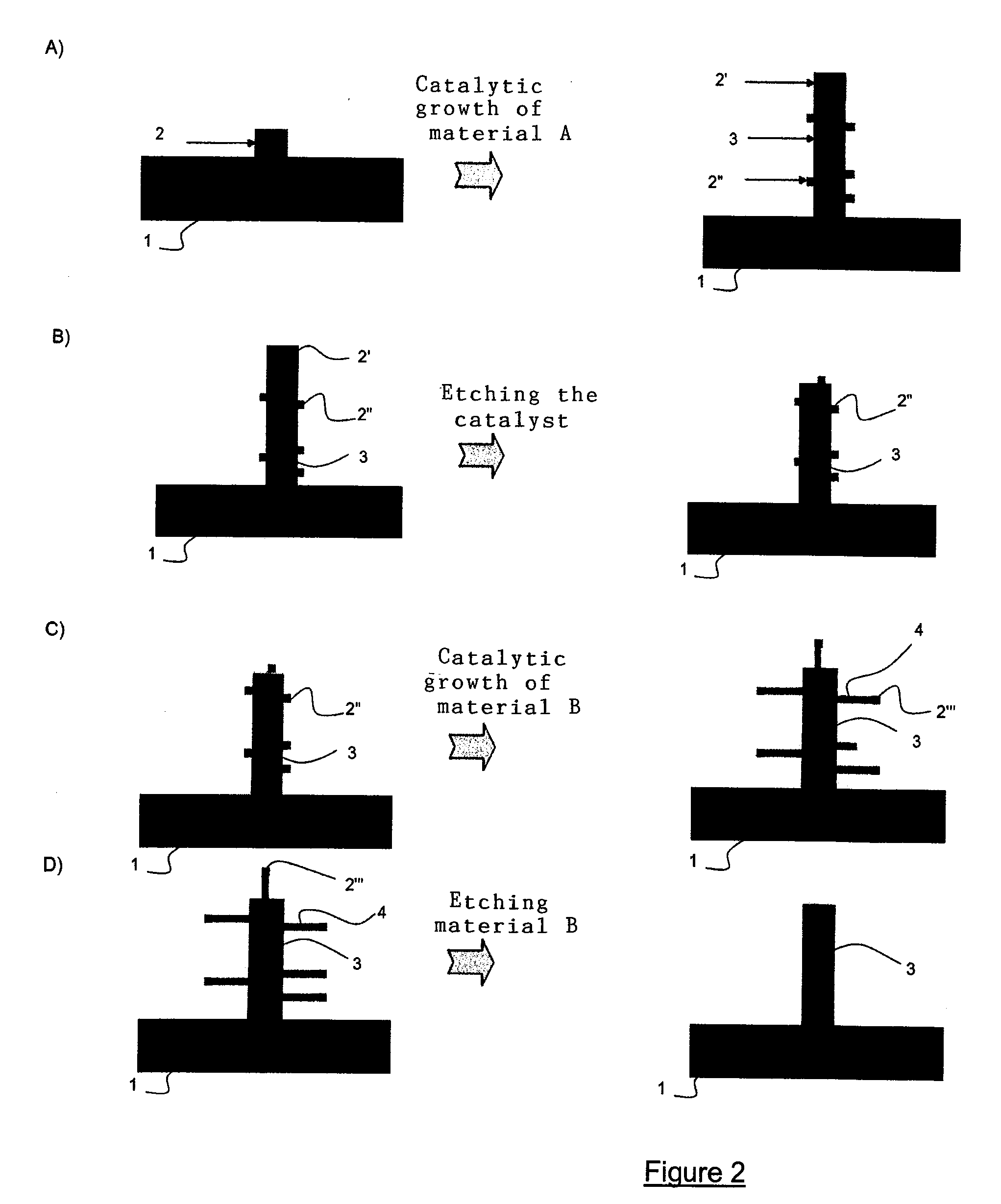

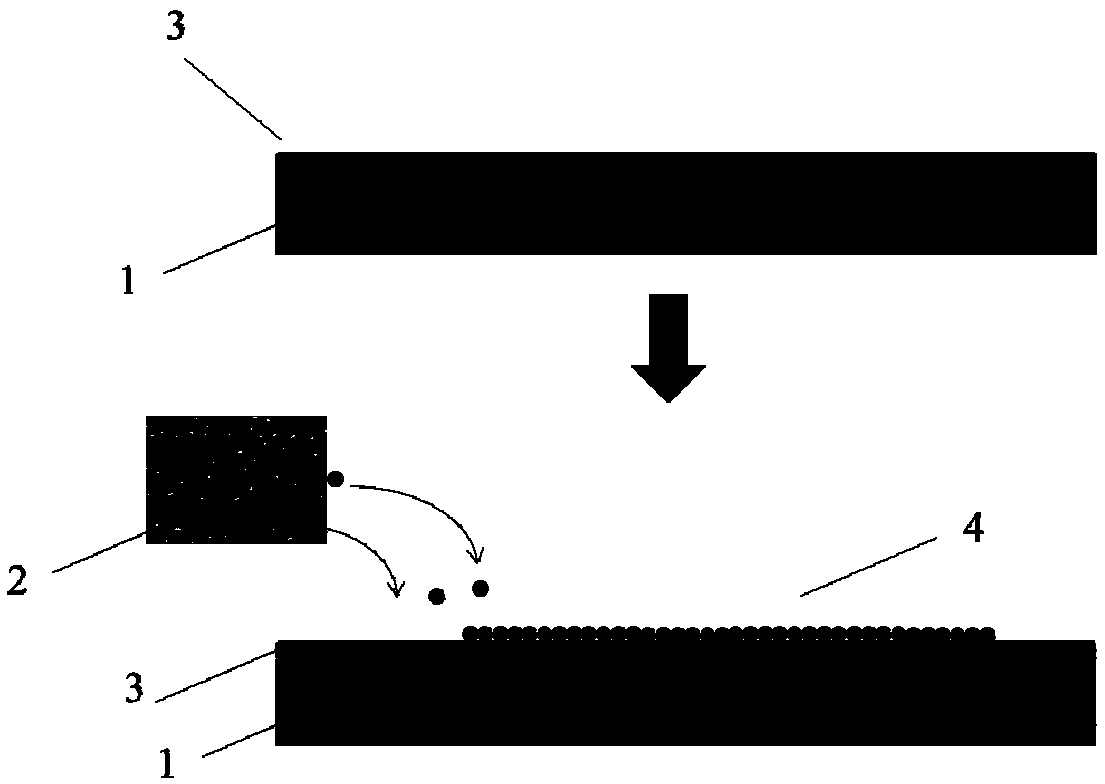

Method for eliminating the metal catalyst residues on the surface of wires produced by catalytic growth

InactiveUS8669171B2Individual molecule manipulationSemiconductor/solid-state device manufacturingMetal catalystSolid structure

A method is provided for eliminating catalyst residues that are present on the surface of solid structures. The solid structures are made from a first material and are obtained by catalytic growth from a substrate. The method includes the following steps: catalytically growing, from the catalyst residues, solid structures made from a second material; and selectively eliminating the solid structures made from the second material, thereby eliminating the catalyst residues.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

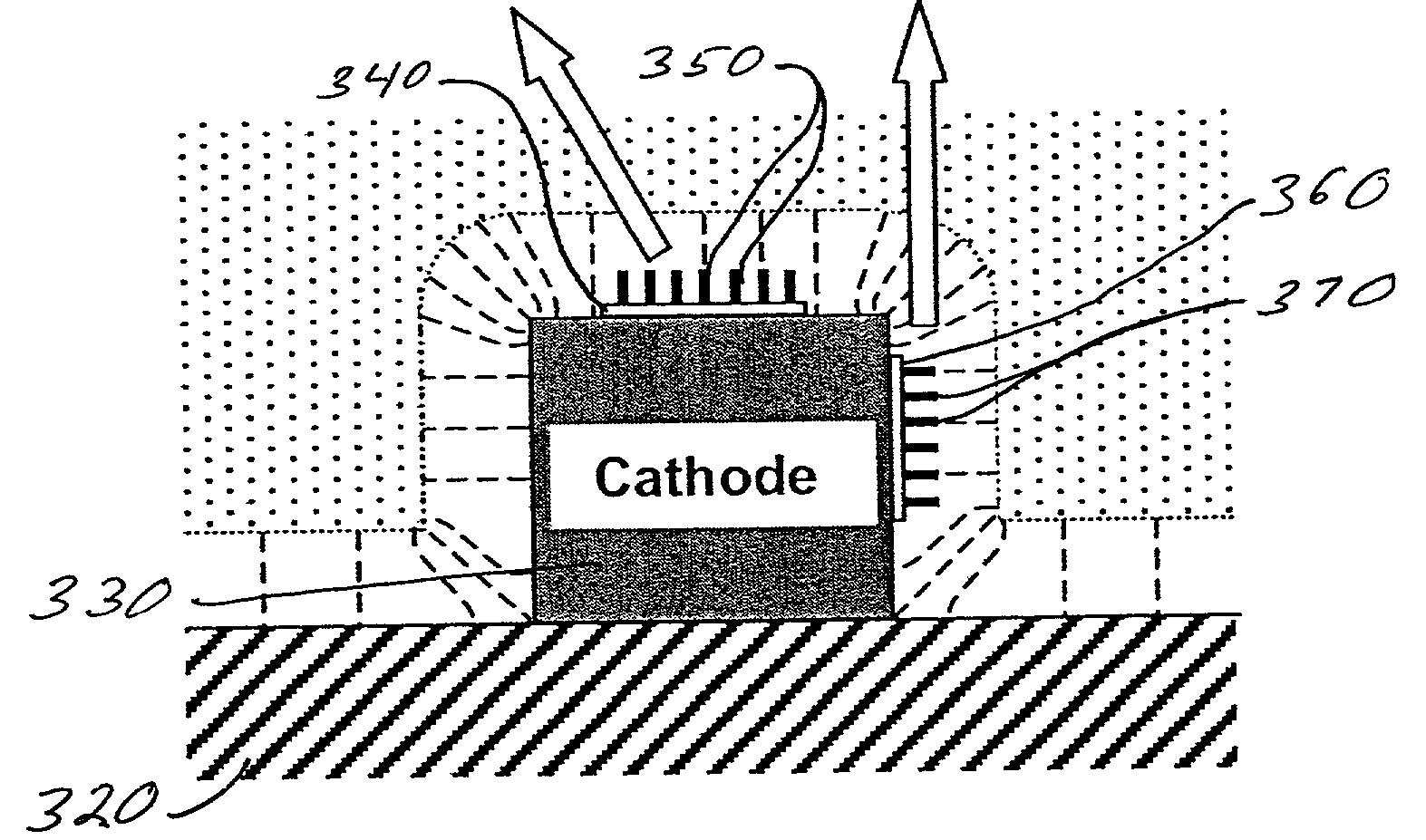

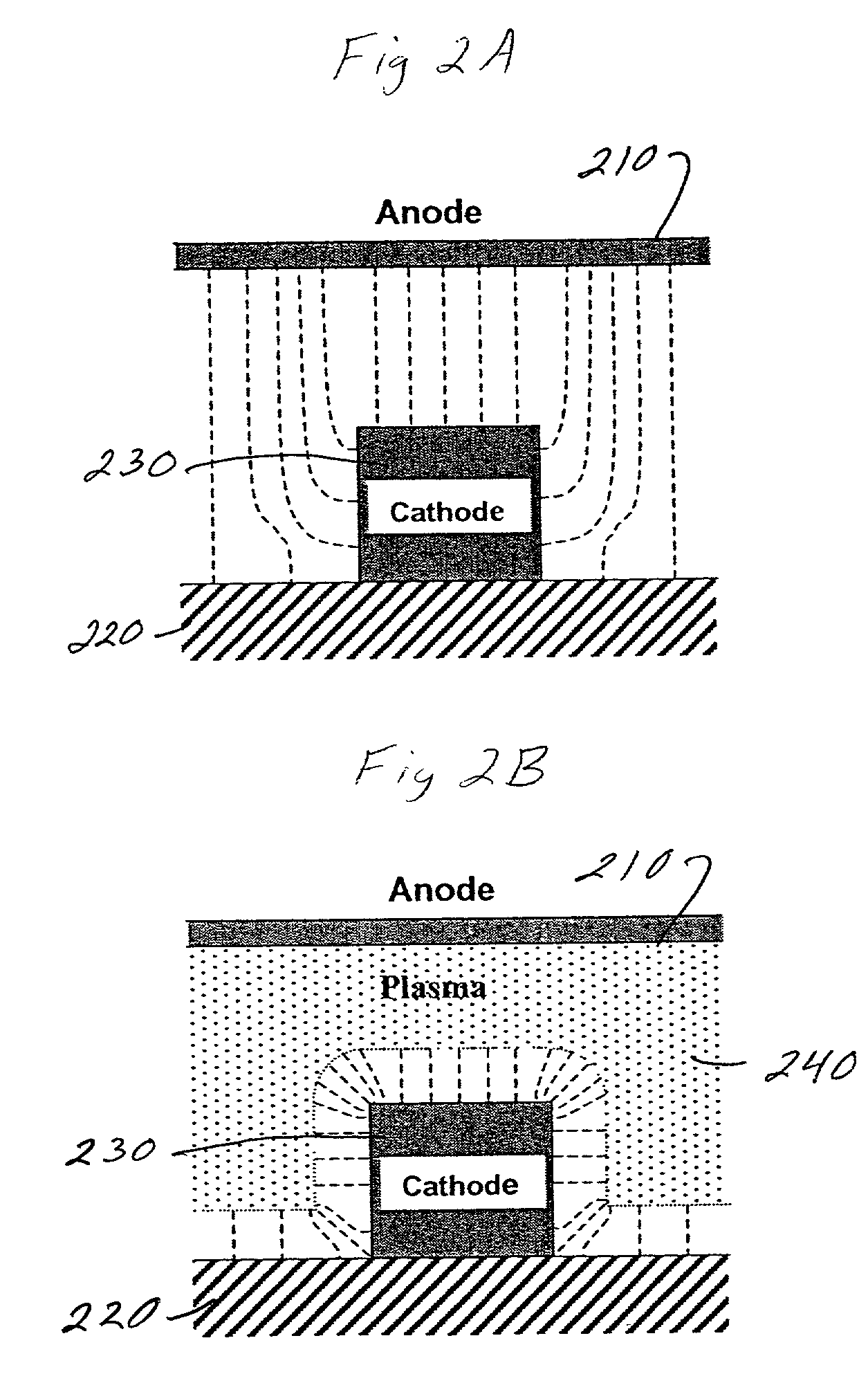

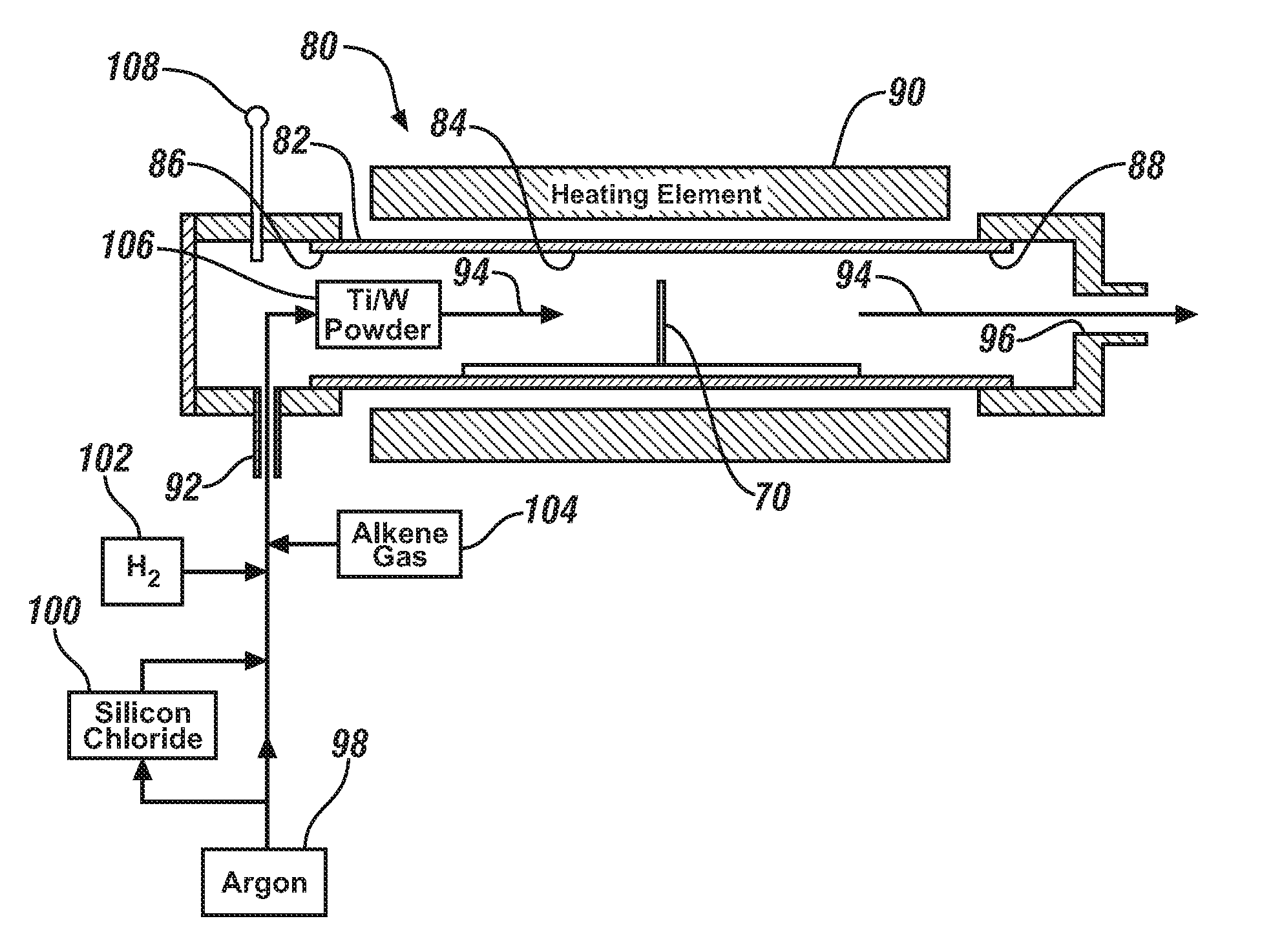

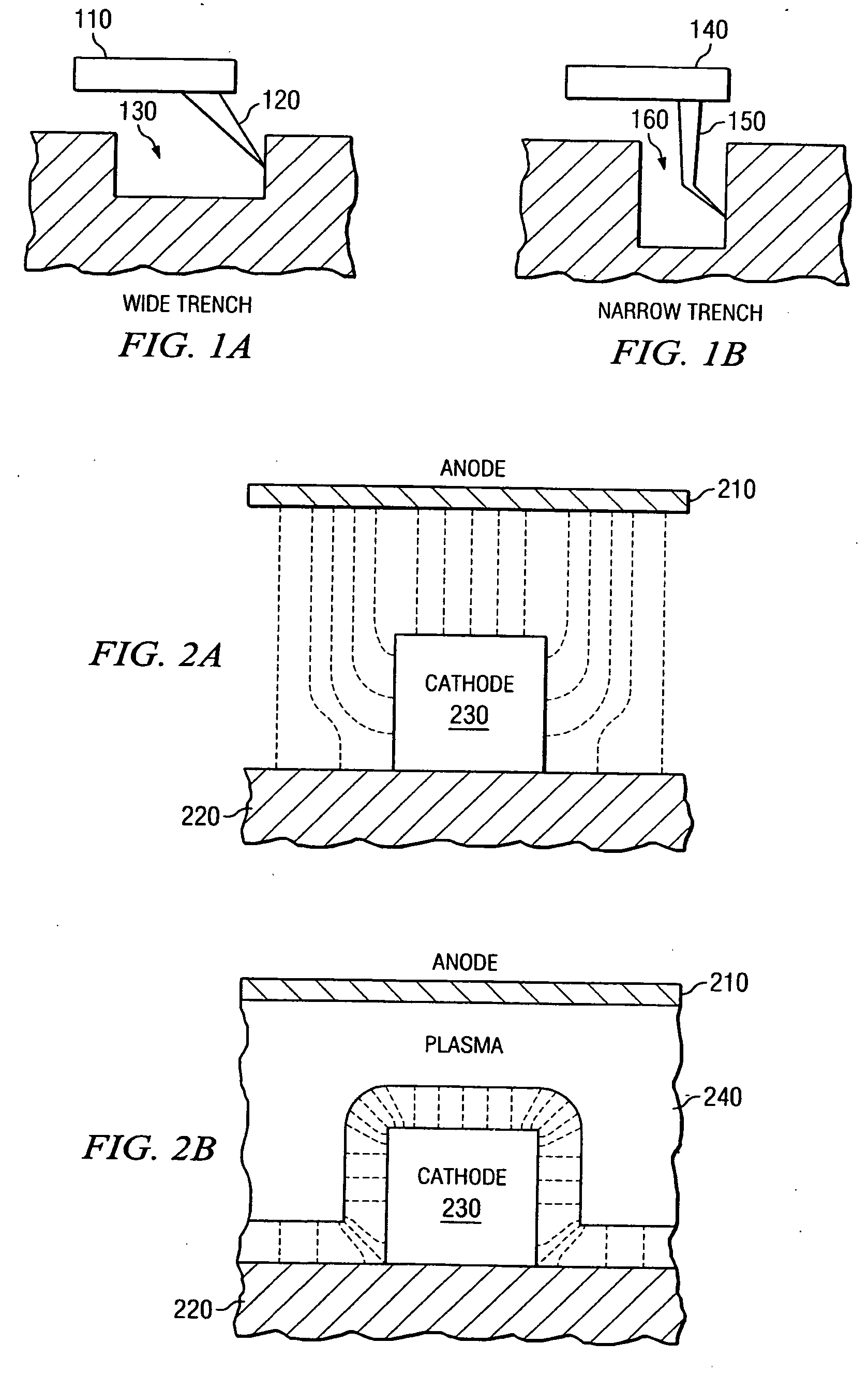

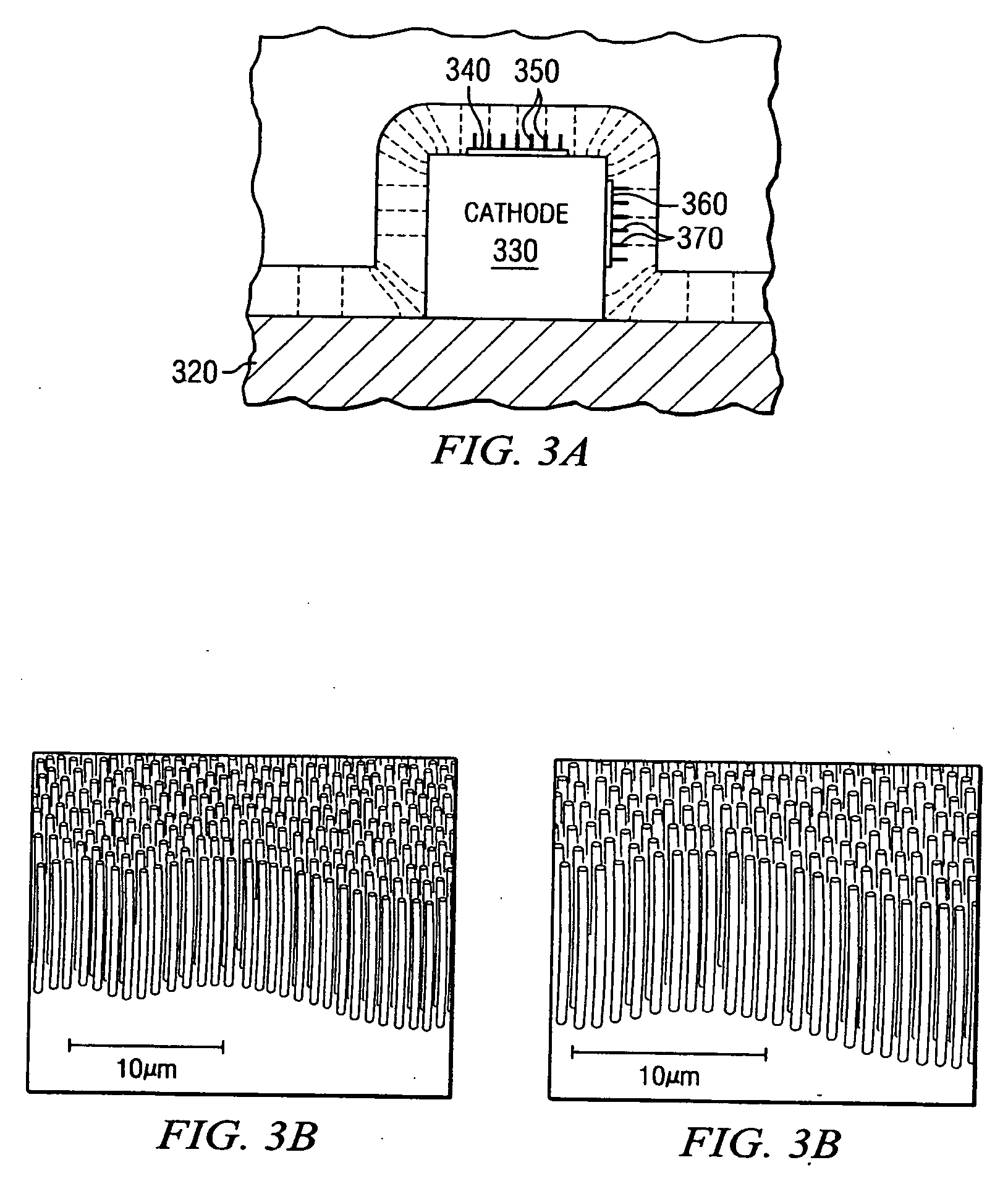

Controlled alignment of catalytically grown nanostructures in a large-scale synthesis process

InactiveUS20030148577A1Cost effectiveQuality improvementPowder deliveryMaterial nanotechnologyProcess systemsNanostructure

Systems and methods are described for controlled alignment of catalyticaly grown nanostructures in a large-scale synthesis process. A method includes: generating an electric field proximate an edge of a protruding section of an electrode, the electric field defining a vector; and forming an elongated nanostructure located at a position on a surface of a substrate, the position on the surface of the substrate proximate the edge of the protruding section of the electrode, at least one tangent to the elongated nanostructure i) substantially parallel to the vector defined by the electric field and ii) substantially non-parallel to a normal defined by the surface of the substrate.

Owner:UNIV OF TENNESSEE RES FOUND +1

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS20030175200A1Less pollutionNarrow size distributionMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

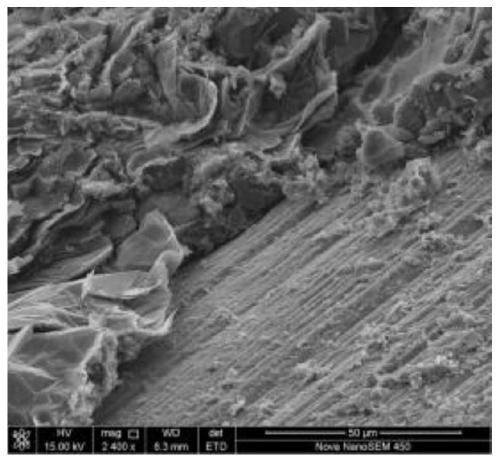

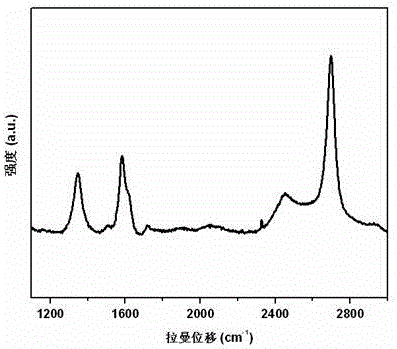

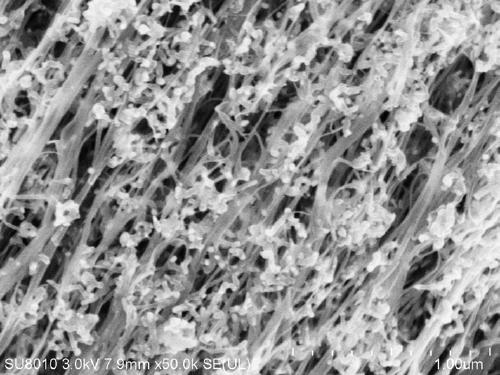

Preparation method and application of carbon-based metal organic frame (MOF) compound derivative material

The invention discloses preparation method and application of a carbon-based metal organic frame (MOF) compound derivative material, and belongs to the technical field of preparation of a functional nanometer material. The preparation method comprises the steps of placing a carbon fiber / polyacrylonitrile (PAN) thin film in an MOF precursor solution, achieving self-assembly of different morphologies of an MOF on different substrates at a room temperature, mixing the obtained product and an appropriate amount of melamine, and then performing thermal reduction on in-situ catalytic growth carbon nanotube (CNT) in an inert atmosphere to obtain the carbon-based MOF derivative material. The function nanometer material prepared by the method has the physical characteristics of high conductivity, rapid ion transmission passage, good flexibility, favorable self-support structure and the like and shows long service lifetime, high-capacity electric storage performance and excellent electrochemicalstability during energy storage and conversion; and the preparation process of the whole material is simple, no toxic product during reaction is generated, and the material is green and environmental-friendly and is suitable for industrial production on a large scale.

Owner:NANJING UNIV OF TECH

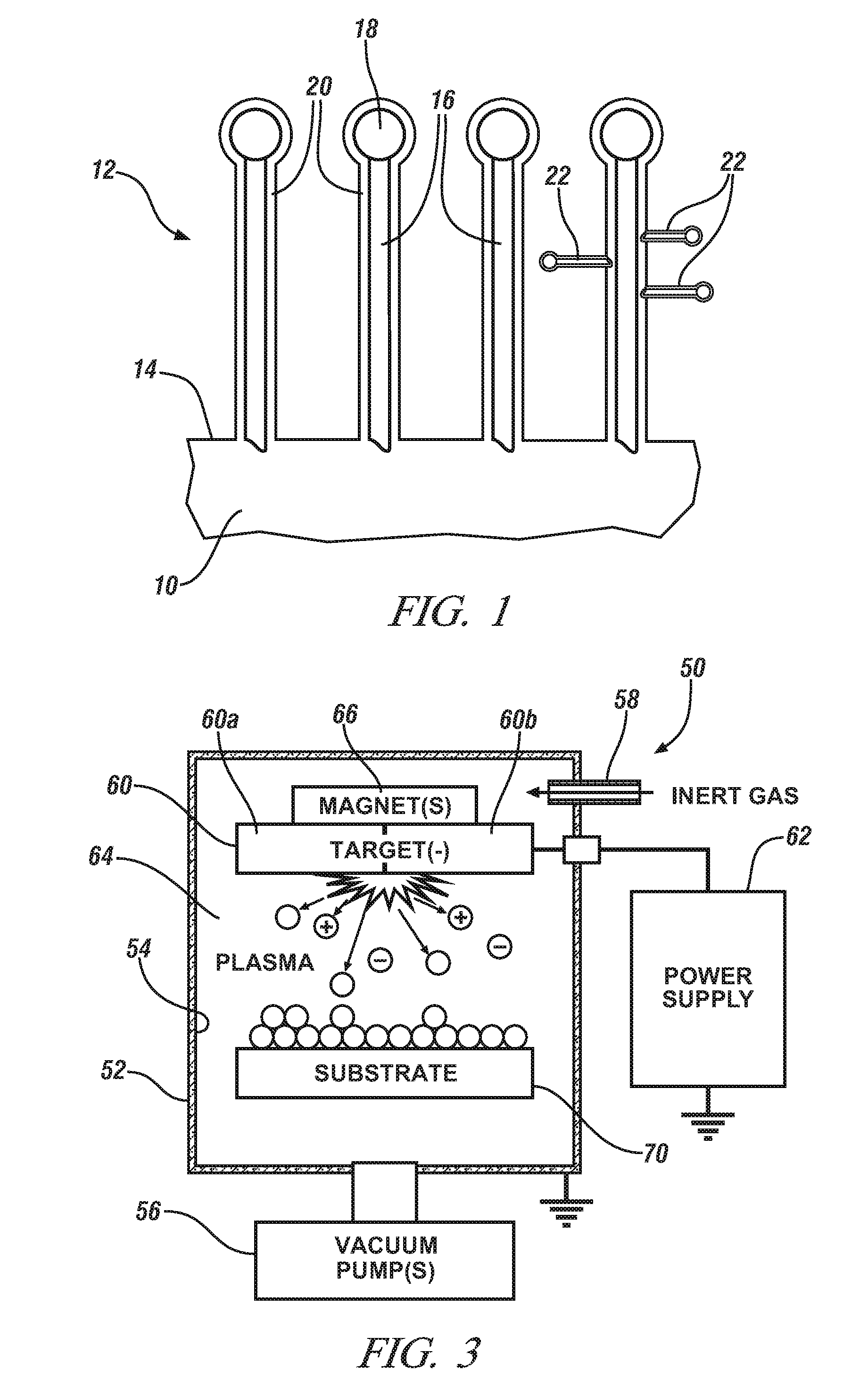

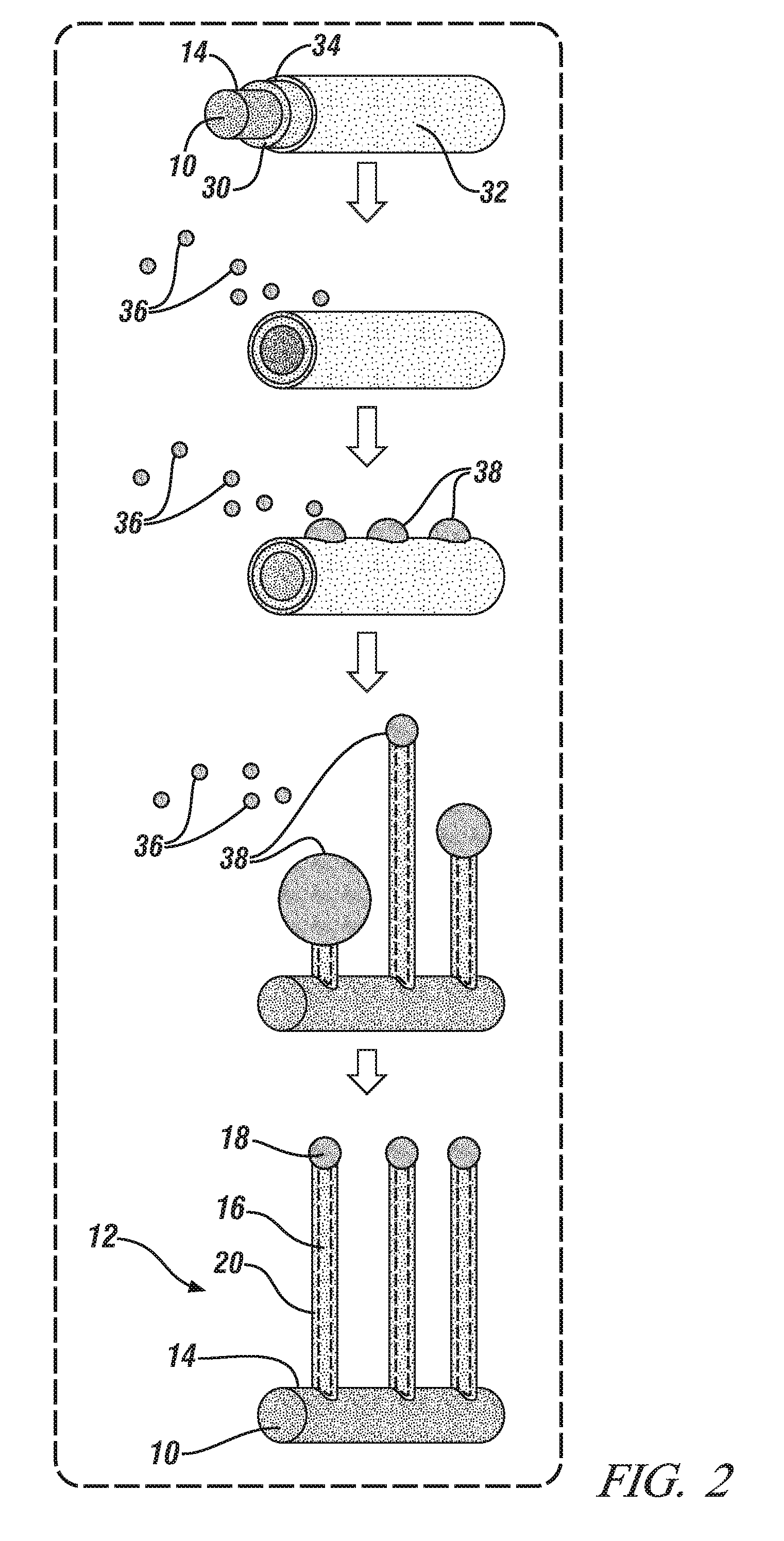

Microfiber supported metal silicide nanowires

ActiveUS20120241192A1Improve featuresReduce the overall diameterMaterial nanotechnologyNon-insulated conductorsGold particlesMetallurgy

An arrangement of elongated nanowires that include titanium silicide or tungsten silicide may be grown on the exterior surfaces of many individual electrically conductive microfibers of much larger diameter. Each of the nanowires is structurally defined by an elongated, centralized titanium silicide or tungsten silicide nanocore that terminates in a distally spaced gold particle and which is co-axially surrounded by a removable amorphous nanoshell. A gold-directed catalytic growth mechanism initiated during a low pressure chemical vapor deposition process is used to grow the nanowires uniformly along the entire length and circumference of the electrically conductive microfibers where growth is intended. The titanium silicide- or tungsten silicide-based nanowires can be used in a variety electrical, electrochemical, and semiconductor applications.

Owner:UNIV OF WESTERN ONTARIO +1

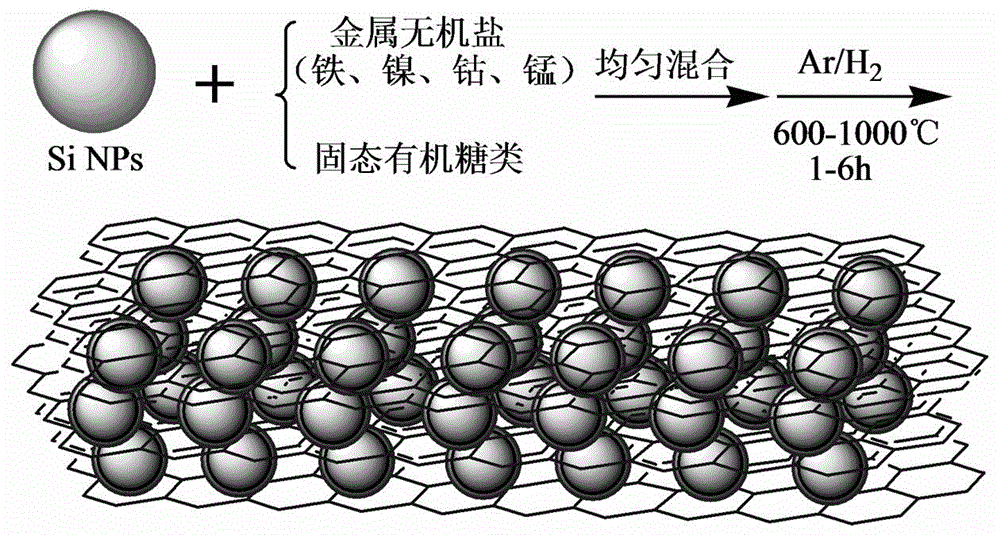

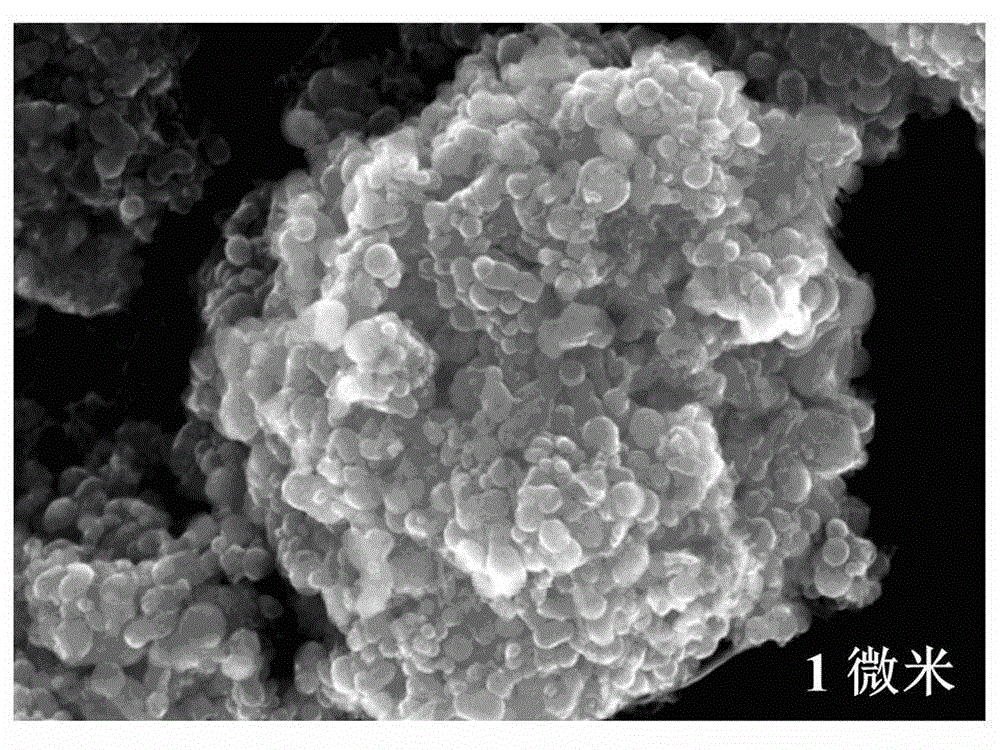

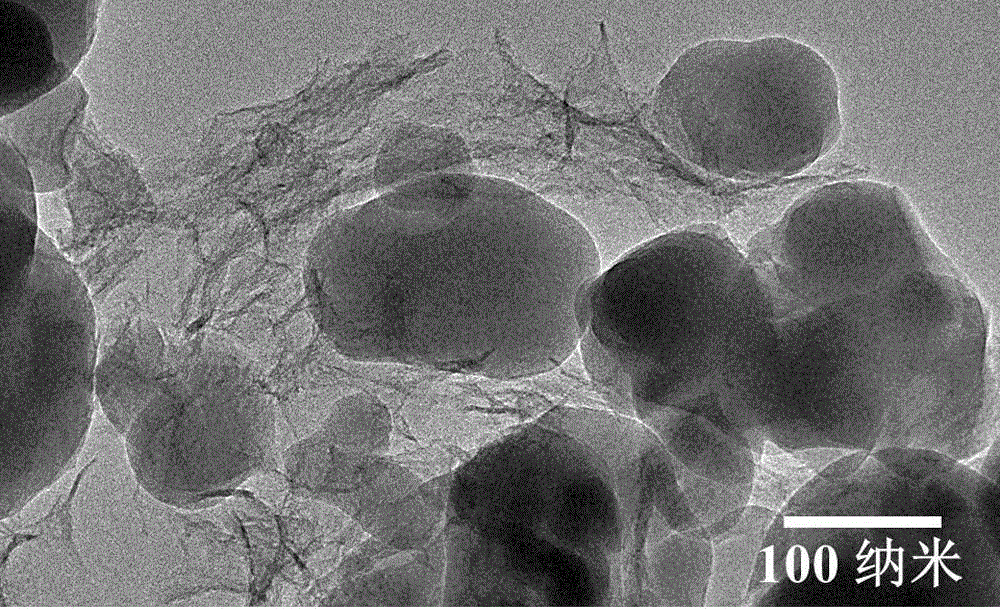

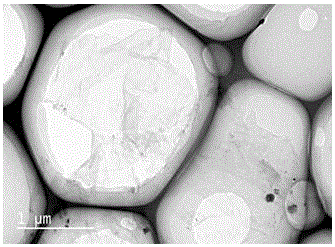

In-situ solid-phase synthesis method of silicon-graphene spheroidal composite material with multilevel structure and application thereof

InactiveCN104934573AAvoid volume effectImprove electronic conductivityCell electrodesFinal product manufacturePtru catalystElectronic conductivity

The invention brings forward a novel low-cost in-situ solid-phase preparation method. By the method, a silicon-graphene spheroidal composite material with a multilevel structure can be synthesized by one step. The composite material can be used as a high specific energy anode material to be applied in a lithium ion battery. Low-cost organic carbohydrate and inorganic transition metal salt which are respectively used as a carbon source and a metal catalyst precursor are selected to be uniformly mixed with a silicon nano-material; by a tube furnace heating method, in-situ catalytic growth of a graphene coated network happens on the surface of silicon nano-particles; and through the bridging effect of the graphene network, spheroidal micro-scale particles with a nanometer fine structure is self-assembled. The silicon-graphene spheroidal composite anode material with the multilevel structure has an advantage of high specific capacity. In addition, two main bottleneck problems such as poor electronic conductivity of a silicon anode material and severe volume effect during the cyclic process can be overcome simultaneously, and multiplying power and cycle performance of silicon anode can be raised greatly.

Owner:SUZHOU GREEN POWER TECH CO LTD

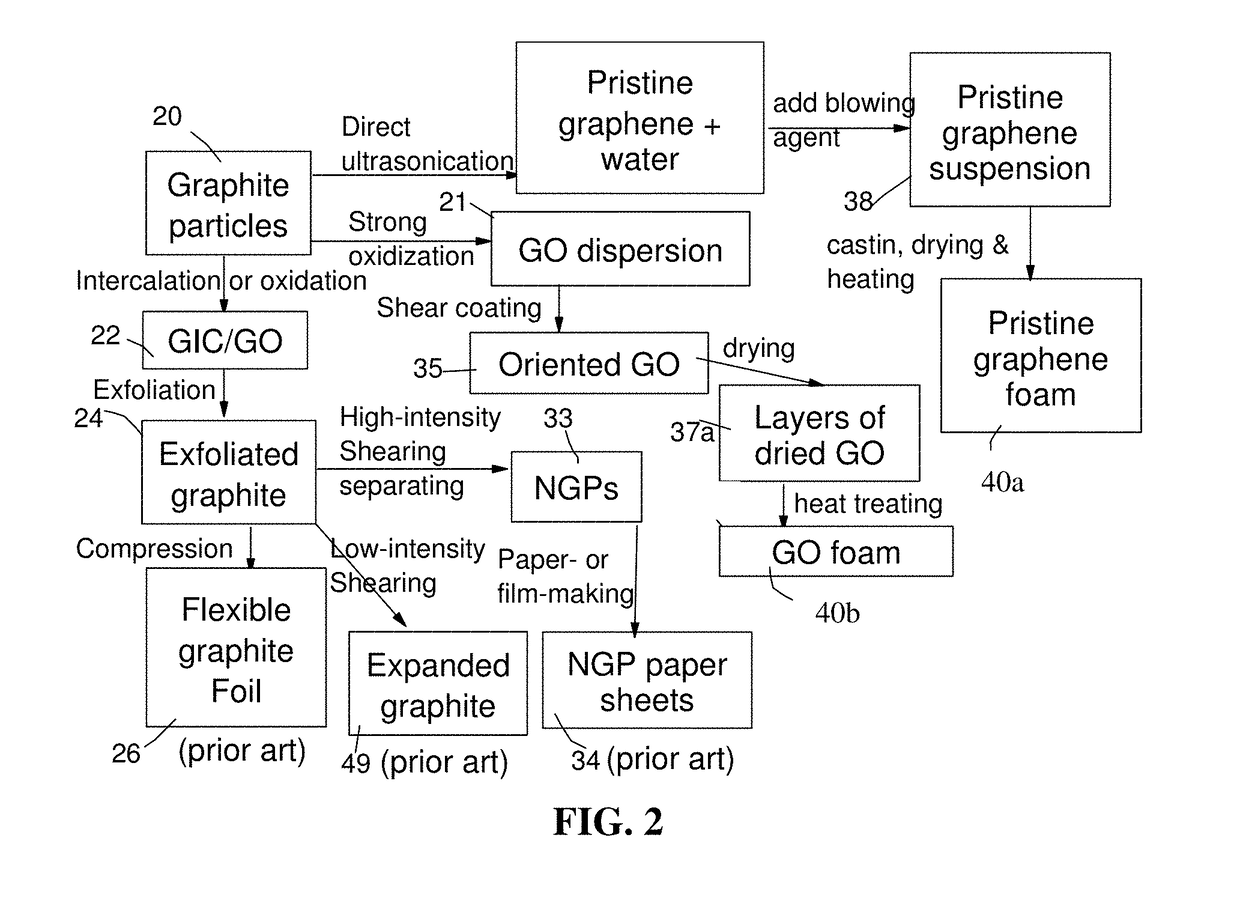

Process for producing graphene/silicon nanowire hybrid material for a lithium-ion battery

ActiveUS20200227734A1Increase flexibilityFast shippingElectrode thermal treatmentSecondary cellsPtru catalystLiquid medium

A process for producing a graphene / Si nanowire hybrid material, comprising: (a) dispersing catalyst metal-coated Si particles, graphene sheets, and an optional blowing agent in a liquid medium to form a graphene / Si dispersion; (b) dispensing and depositing the dispersion onto a supporting substrate to form a wet layer and removing the liquid medium from the wet layer to form a dried layer of graphene / Si mixture material; (c) exposing the dried layer to a high temperature environment, from 300° C. to 2,000° C., to induce volatile gas molecules from graphene sheets or to activate the blowing agent for producing the graphene foam and to enable a catalyst metal-catalyzed growth of multiple Si nanowires emanated from Si particles as a feed material in pores of the foam to form a layer of the hybrid material; and (d) operating a mechanical breaking means to produce the Si nanowire / graphene hybrid material in a powder mass form.

Owner:GLOBAL GRAPHENE GRP INC

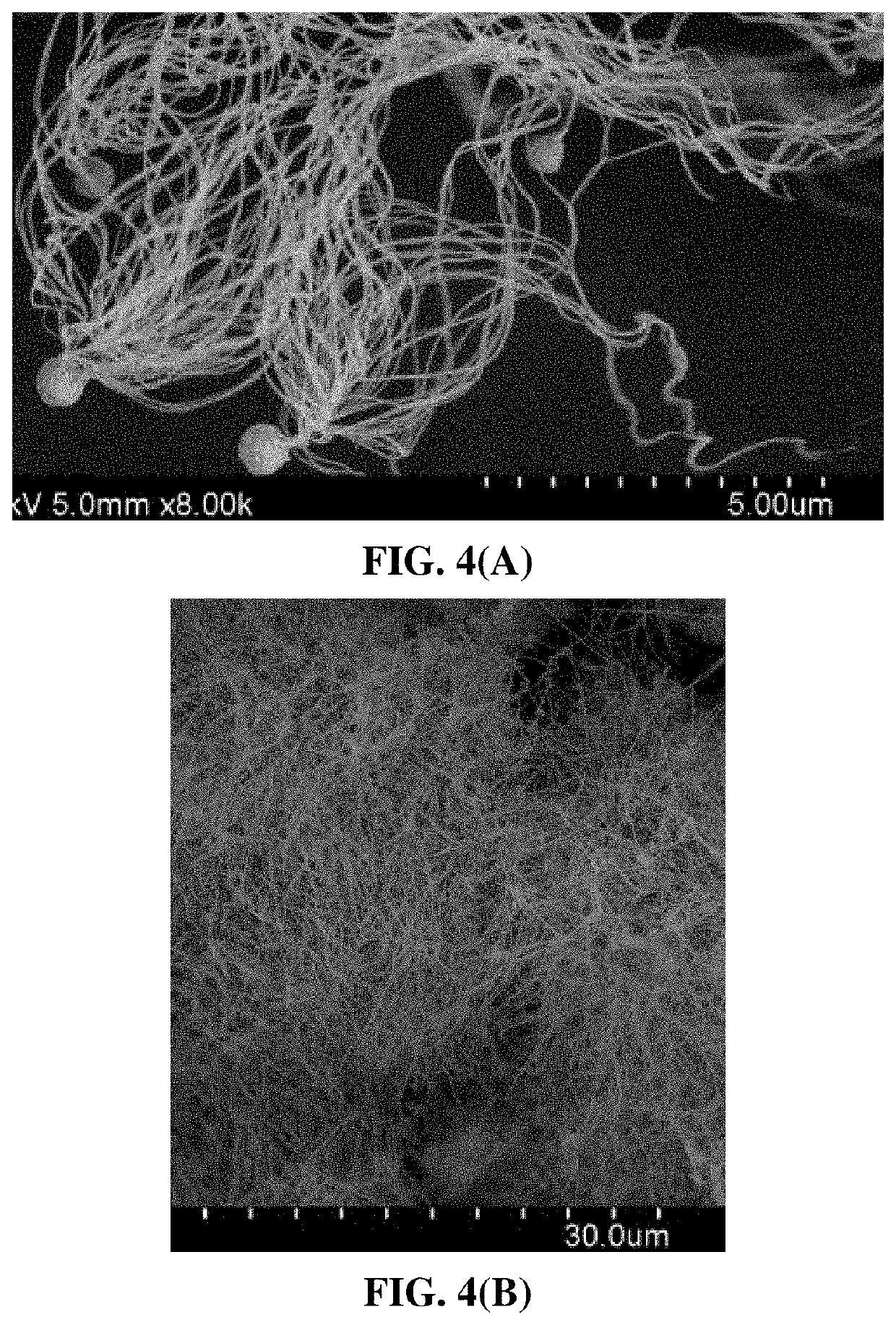

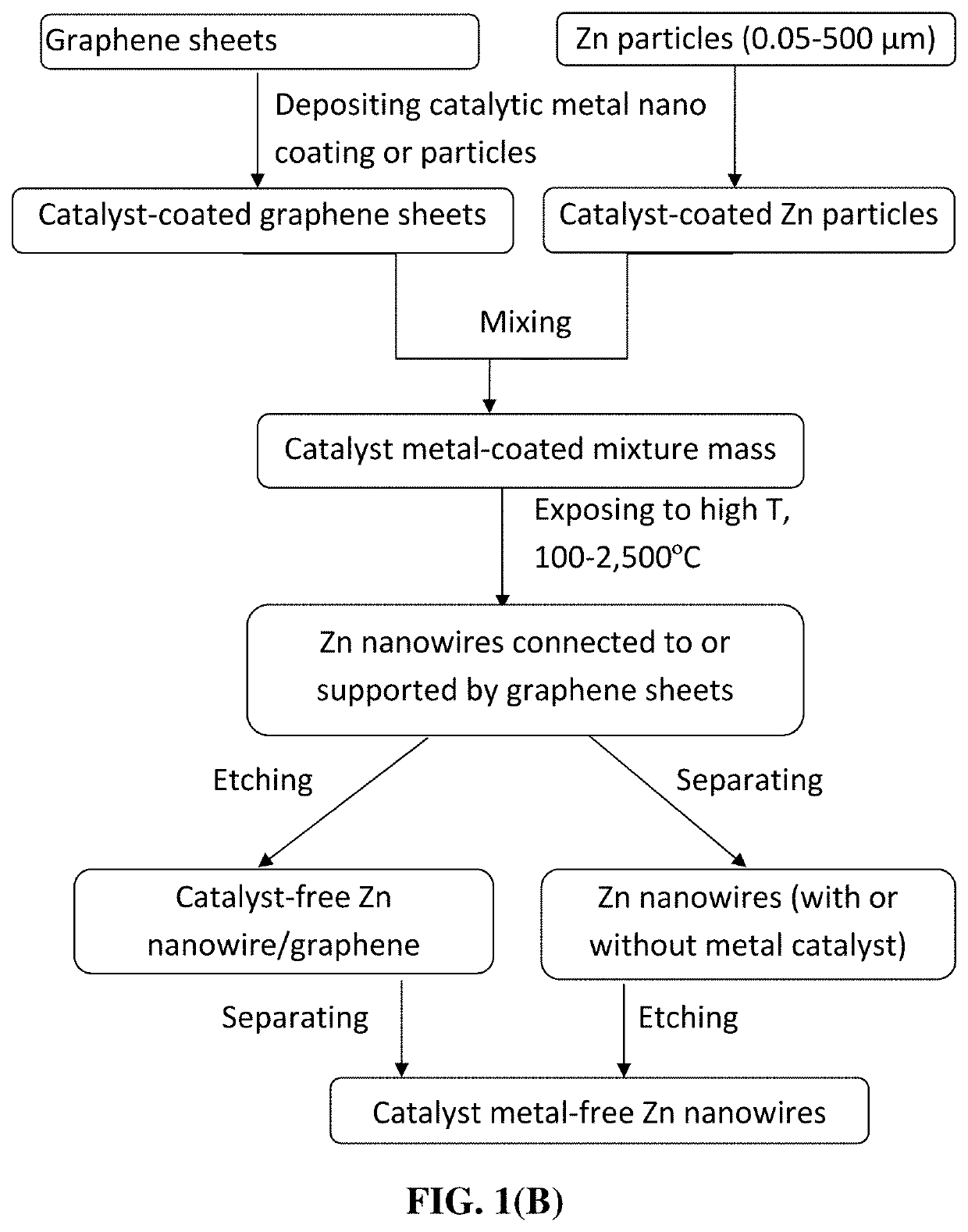

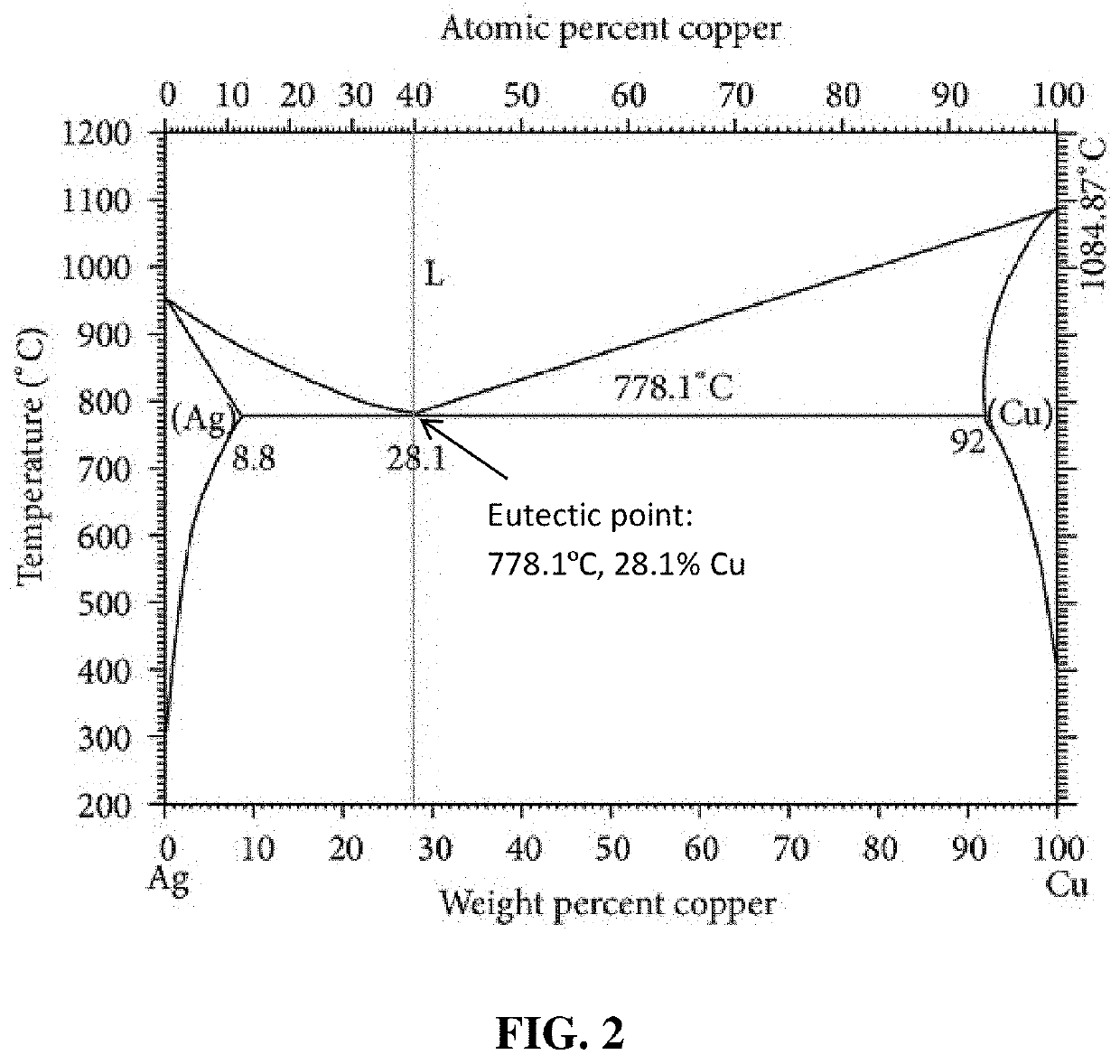

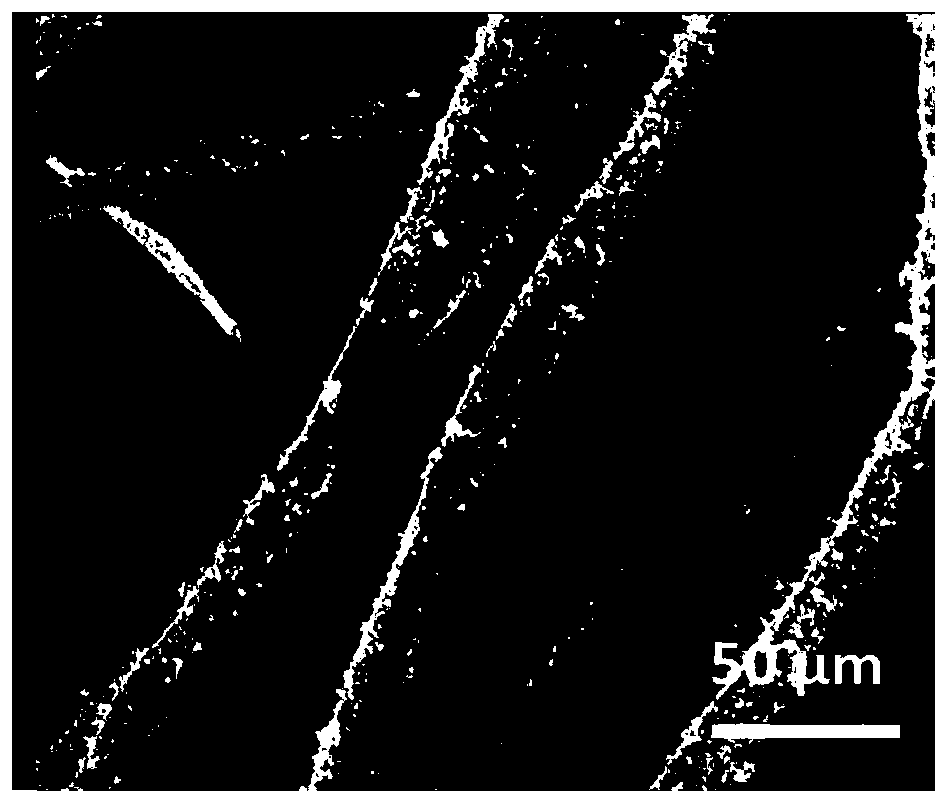

Process for producing metal nanowires and nanowire-graphene hybrid particulates

Disclosed is a process for producing graphene-metal nanowire hybrid material, comprising: (A) preparing a catalyst metal-coated mixture mass, which includes mixing graphene sheets with source metal particles to form a mixture and depositing a nanoscaled catalytic metal onto surfaces of the graphene sheets and / or metal particles; and (B) exposing the catalyst metal-coated mixture mass to a high temperature environment (preferably from 100° C. to 2,500° C.) for a period of time sufficient to enable a catalytic metal-catalyzed growth of multiple metal nanowires using the source metal particles as a feed material to form the graphene-metal nanowire hybrid material composition. An optional etching or separating procedure may be conducted to remove catalytic metal or graphene from the metal nanowires.

Owner:GLOBAL GRAPHENE GRP INC

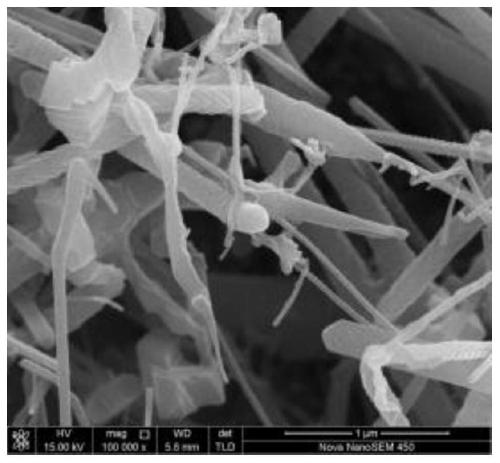

Hierarchical structure hollow CNTs/Co/C fiber wave-absorbing material and preparation method thereof

ActiveCN110938407ACoated evenlySolve reunionOther chemical processesCarbon nanotubesFiberPolymer science

The invention discloses a hierarchical structure hollow CNTs / Co / C fiber wave-absorbing material and a preparation method thereof, and belongs to the technical field of radar wave-absorbing materials.The method takes cotton fibers and Co-containing zeolite imidazole structure metal organic framework ZIF-67 nanoparticles as raw materials. ZIF-67 nanoparticles with a regular dodecahedron microstructure grow and coat the surfaces of the cotton fibers in situ, cotton fibers are carbonized into hollow carbon fibers through a high-temperature carbonization process in a reductive H2 / Ar mixed atmosphere, the pyrolysis of the ZIF-67 metal organic framework nanoparticles and the catalytic growth of the carbon nanotubes are realized so that the hollow CNTs / Co / C fiber wave-absorbing material with themicron carbon fiber-nanotube hierarchical structure is obtained, and under the conditions that the density is 0.02 g / cm<3> and the thickness is 2 mm, the maximum absorption intensity of electromagnetic waves at 14 GHz reaches -59.5 dB, and the effective absorption frequency band width reaches 6.2 GHz (11.8-18 GHz). The technical problems that a traditional wave-absorbing material is high in density, low in absorption strength and narrow in frequency band are solved.

Owner:HARBIN INST OF TECH

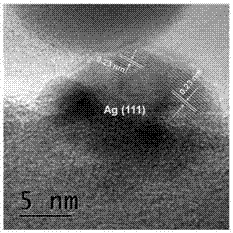

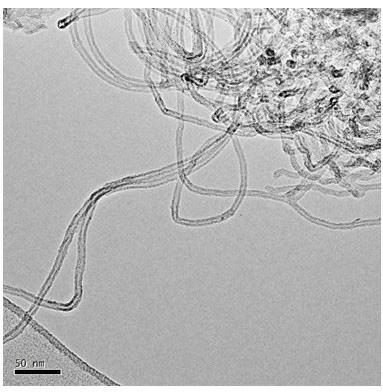

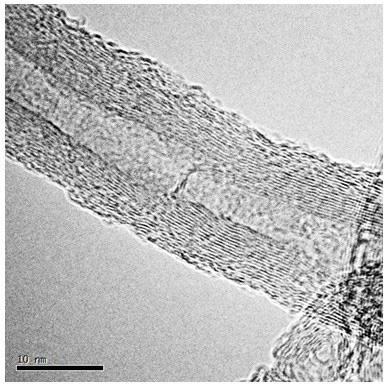

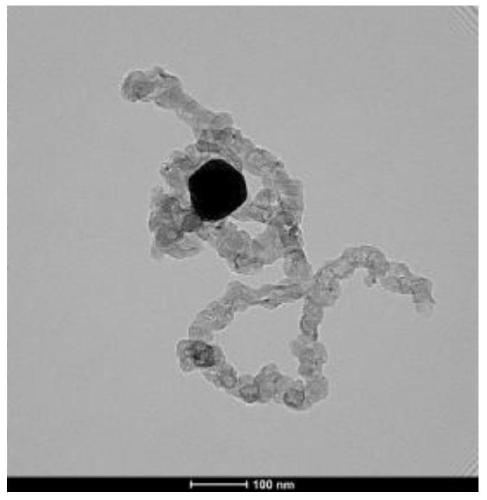

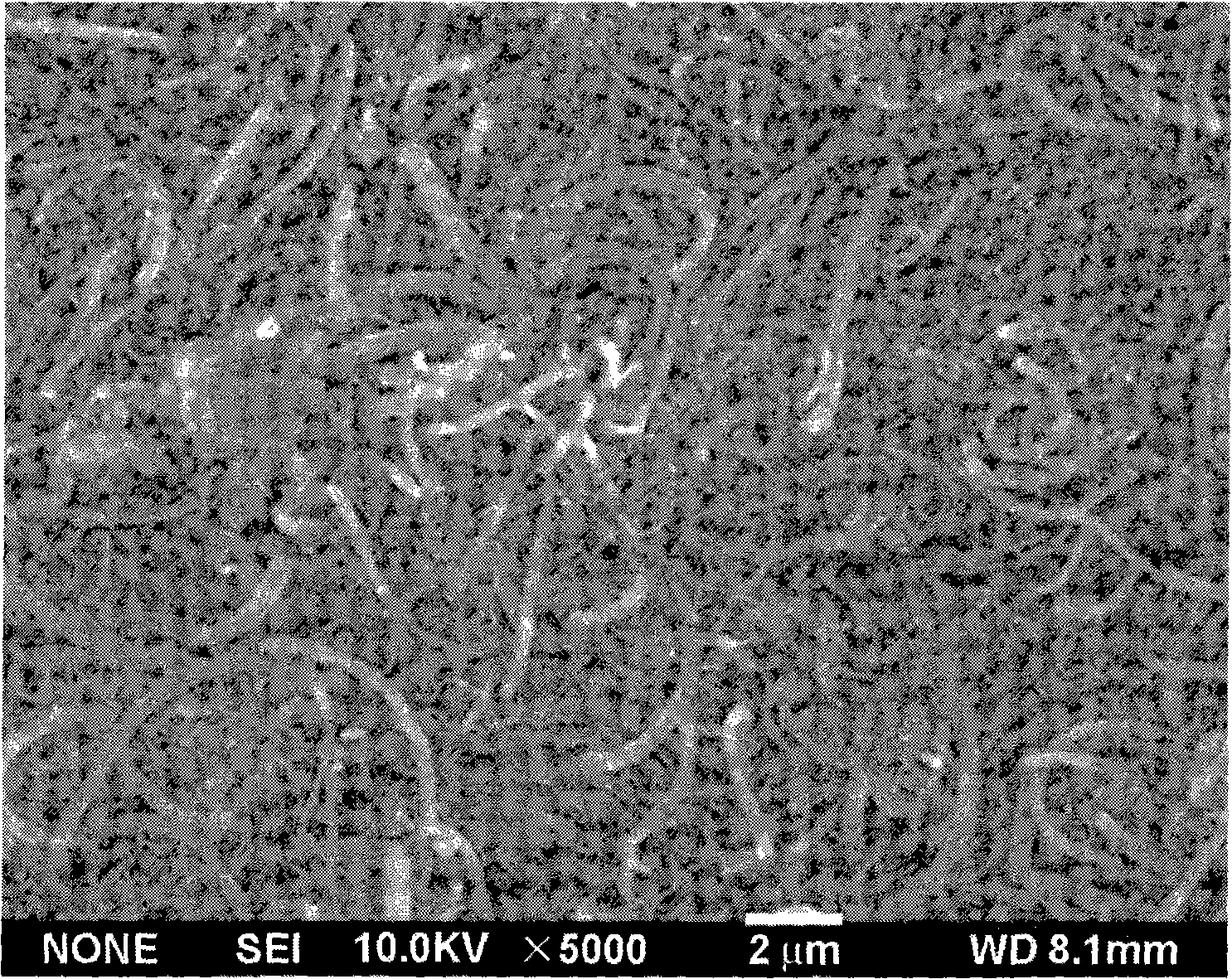

Ag-carbon nano fiber composite material as well as preparation method and application thereof

ActiveCN107511149AIn situ catalytic growthMild conditionsWater/sewage treatment by irradiationWater treatment compoundsFiberCarbon nanofiber

The invention provides an Ag-carbon nano fiber composite material as well as a preparation method and application thereof. The preparation method provided by the invention adopts a one-step method and has moderate conditions; special instruments and equipment are not needed, high temperature and high pressure are not needed, the operation is simple and feasible and the efficiency is high; hydrothermal reaction does not need a template; a monosaccharide is used as a carbon source and reduction reaction between the monosaccharide and a catalyst precursor Ag3PO4-AgCl is realized; the in-situ catalytic growth of carbon nano fibers is realized, Ag nanoparticles are highly dispersed in situ and loaded on the carbon nano fibers and Ag nano-wires are filled into cavities of the carbon nano fibers in situ. A result of the embodiment shows that the Ag-carbon nano fiber composite material is used for photo-catalytically degrading an organic pollutant methylene blue under visible light; after the methylene blue is adsorbed for 2h under a dark state, the concentration of the methylene blue is reduced to 55 percent of initial concentration; after the methylene blue is photo-catalytically degraded for 2h under the visible light, the removal efficiency of the methylene blue can reach 95 percent or more.

Owner:JIANGXI NORMAL UNIV

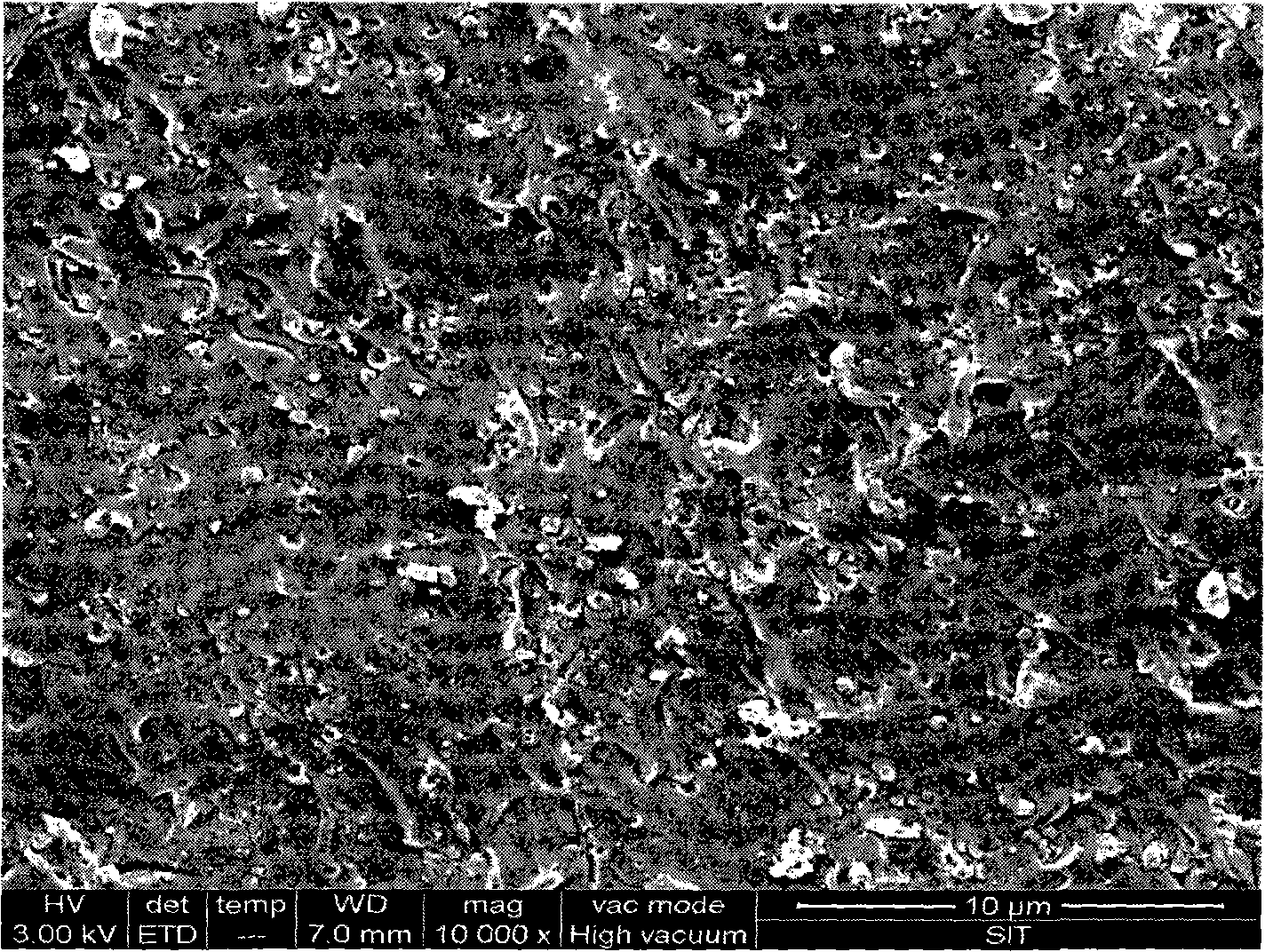

Preparation method of carbon nanotube reinforced Al-matrix composite

The invention discloses a preparation method of a carbon nanotube reinforced Al-matrix composite. The method comprises the following processes of: coating lamellar aluminum powder by using polyvinyl alcohol or a mixture of polyethylene glycol and citric acid; adhering the lamellar aluminum powder for coating a polymer to catalyst precursor particles dissolved in a solution; then, calcining, reducing, pyrolyzing a high polymer and carrying out catalytic cracking on a carbon source to grow a carbon nanotube; and finally, carrying out a powder metallurgy process to obtain the carbon nanotube reinforced Al-matrix composite. The preparation method has the advantages that a catalyst is uniform in dispersing, not easy to agglomerate, high in catalytic activity, simple in preparation, not high in matrix appearance requirement and high applicability; the process reaction is mild, the damage degree for a carbon nanotube structure is low, the yield of carbon nanotubes growing through catalysis is continuously adjusted, and the prepared composite has excellent performance.

Owner:TIANJIN UNIV

Low-carbon ultra-low-carbon carbon-containing refractory material containing in-situ peeled two-dimensional micro-nano graphite flake phenolic resin composition, and preparation method thereof

PendingCN110240466AImprove high temperature bending resistanceImproved thermal shock stabilityMicro nanoWater baths

The invention discloses a low-carbon ultra-low-carbon carbon-containing refractory material containing in-situ peeled two-dimensional micro-nano graphite flake phenolic resin composition. The low-carbon ultra-low-carbon carbon-containing refractory material containing in-situ peeled two-dimensional micro-nano graphite flake phenolic resin composition comprises magnesium carbon, aluminium carbon, and magnesium aluminium carbon refractory material; a fireproof aggregate and a flaky carbonization matter are taken as the main raw materials of the refractory material, a small amount of an antioxidant and high temperature asphalt powder are added, phenolic resin is taken as a binding agent, and a nitrate is taken as a catalyst. A preparation method comprises following steps: the carbonization matter, phenolic resin, and an alcohol solution of the nitrate are full mixed, and three-roller grinding peeling is adopted so obtain a micro-nano graphite flake containing mixture; water bath heating is carried out, the mixture is subjected to mixing, moulding, and baking curing with the fireproof aggregate, the antioxidant, and the high temperature asphalt powder so as to obtain a finished product. The low-carbon ultra-low-carbon carbon-containing refractory material containing in-situ peeled two-dimensional micro-nano graphite flake phenolic resin composition is capable of realizing catalytic growth of carbon nanotube, SiC, and MgAl2O4 whisker under service conditions; and the carbon content of prepared products are reduced greatly with maintained or increased strength, slag corrosion resistance, and thermal shock resistance.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for directly growing graphene on insulating substrate through remote catalysis of copper particle

The invention discloses a method for directly growing graphene on an insulating substrate through remote catalysis of copper particles. Specifically, the method comprises the following steps: uniformly coating a high-temperature-resistant insulating substrate of silicon dioxide, aluminum oxide, aluminum nitride, magnesium oxide, zirconium oxide, boron carbide or silicon carbide with cupric acetate in a steeping manner, and by using a chemical vapor deposition method, implementing remote assistant in-situ catalytic growth of graphene by using copper nanoparticles generated from the cupric acetate at high temperature, thereby preparing a graphene composite conductive material. By adopting the method, continuous, large-scale and low-defect graphene can be generated, complex transfer procedures are avoided, the graphene can grow along the structure of a substrate in a full-wrapping manner, duplication of the substrate structure can be achieved by using the graphene, and the prepared material can be used in multiple fields such as the photovoltaic industry and the electric conduction industry.

Owner:EAST CHINA NORMAL UNIV

Apparatus for controlled alignment of catalytically grown nanostructures

Systems and methods are described for controlled alignment of catalyticaly grown nanostructures in a large-scale synthesis process. An apparatus includes an electrode including: a protruding section defining an edge; and a nonprotruding section coupled to the protruding section, where the edge is adapted to deflect an electric field generated with the electrode and at least one section selected from the group consisting of the protruding section and the nonprotruding section is adapted to support a substrate for the growth of elongated nanostructures.

Owner:UT BATTELLE LLC

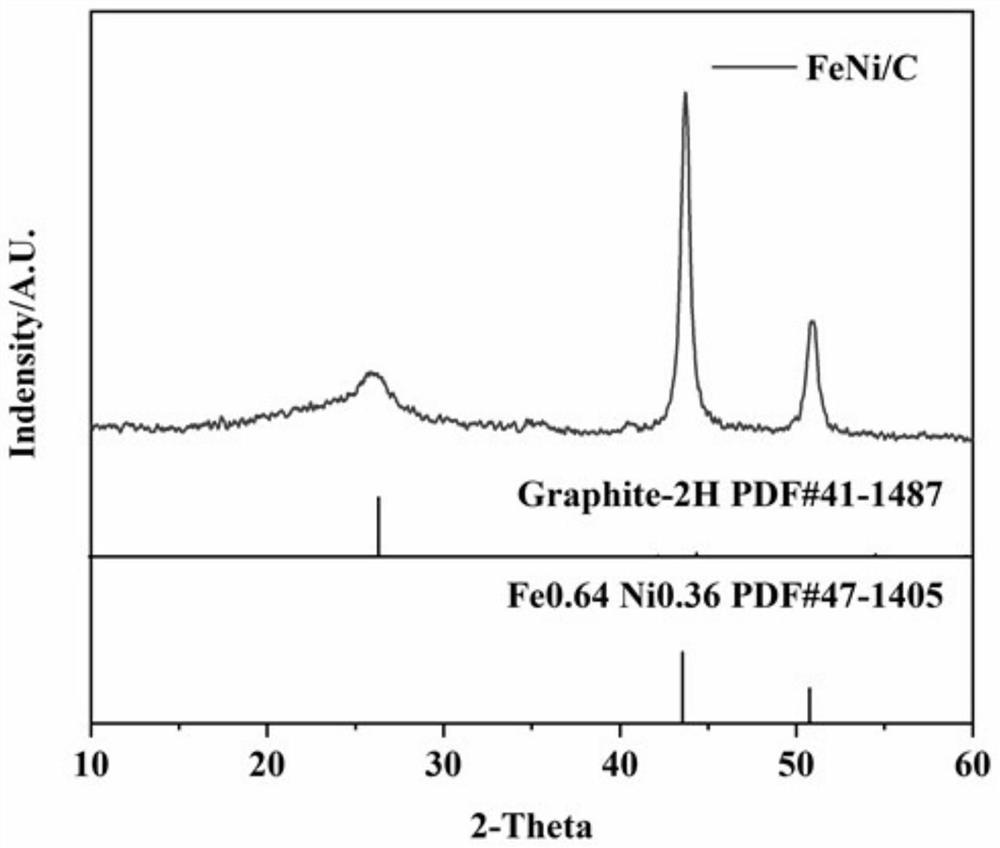

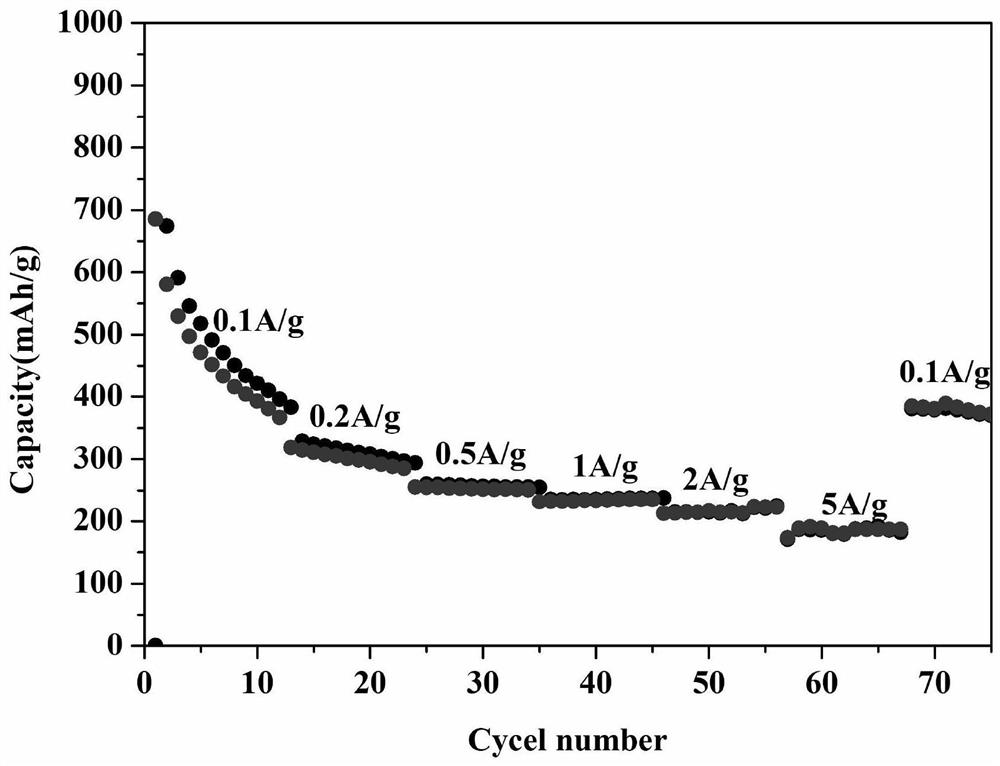

Method for preparing FeNi alloy catalytic growth carbon nanotube material through electromagnetic induction heating method

PendingCN112909259AIncrease load capacityExcellent sodium ion storage performanceMaterial nanotechnologyPositive electrodesTemperature controlCrucible

The invention discloses a method for preparing a FeNi alloy catalytic growth carbon nanotube by an electromagnetic induction heating method. The method comprises the following steps of: 1, weighing an iron source, a nickel source and a carbon source in proportion, fully mixing and grinding; 2, in an induction alternating magnetic field environment and an inert gas atmosphere, placing the mixture in a crucible, cutting magnetic induction lines of the material, generating induction current, heating, controlling the temperature at 300-700 DEG C, naturally cooling a product, and collecting the product; 3, standing the product obtained in the step 2 in nitric acid, corroding 70% of the FeNi alloy, separating out residual solids, and drying; 4, mixing the product obtained in the step 3 with selenium powder in proportion, placing the mixture in a reaction kettle in a sealed glove box under the inert gas atmosphere, heating the mixture to 100-300 DEG C in a homogeneous reaction instrument, and keeping the temperature for 6-12 hours to obtain a product FeNi(at)Se / C. The nanotube has excellent sodium ion storage performance, high charge-discharge capacity and good rate capability; the conductivity and the structural stability of the material in the charging and discharging process can be obviously improved.

Owner:SHAANXI UNIV OF SCI & TECH

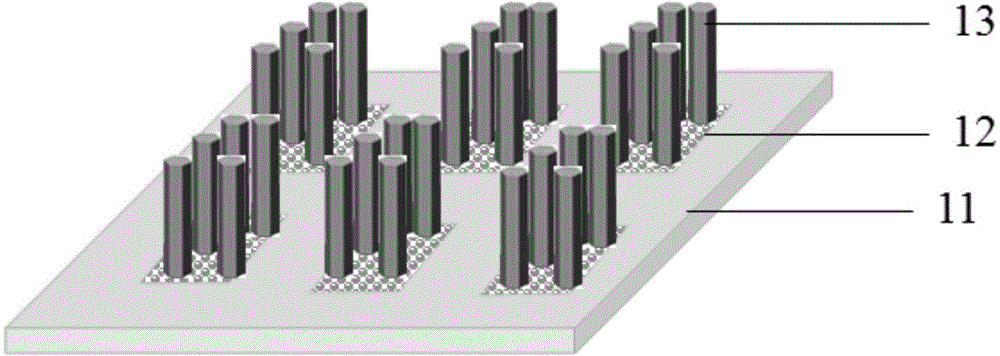

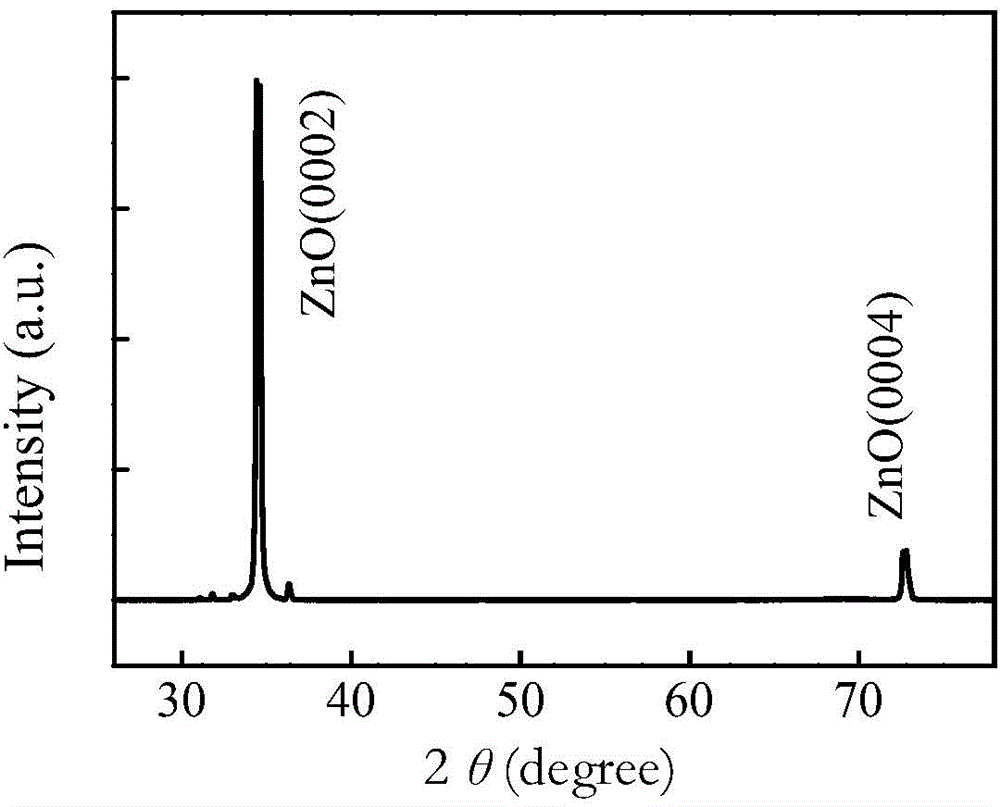

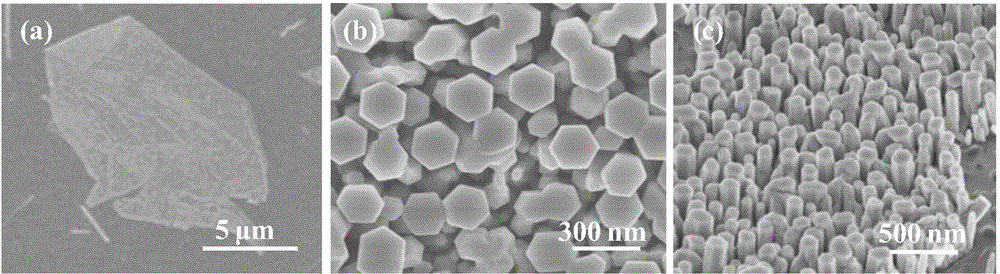

ZnO grading nanoarray on graphene substrate and preparation method and application thereof

InactiveCN104894640AIncrease nucleation rateIncrease nucleation pointPolycrystalline material growthFinal product manufactureCvd grapheneThermal conductivity

The invention discloses a ZnO grading nanoarray on a graphene substrate and a preparation method and application thereof. A graphene nanosheet substrate and grading ZnO nanoarray on the graphene nanosheet substrate area included. The grading ZnO nanoarray on the graphene nanosheet substrate is grown without catalytic CVD graphene. The invention also discloses the preparation method and application of the grading ZnO nanoarray. Compared with the prior art, the invention has the advantages of no need of deposition metal catalyst and deposition of other nucleation layer; and the prepared ZnO nanoarray can be transferred to a flexible substrate as well as to a high thermal conductivity substrate, and is conducive to the preparation of efficient, flexible, high-performance ZnO-based devices.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for removing perfluorooctanoic acid in water body by utilizing lignin-based carbon nanotubes

ActiveCN111170402ABreakthrough preparation technologyImprove adsorption capacitySpecific water treatment objectivesWater contaminantsPerfluorooctanoic acidMaterials science

The invention belongs to the field of water body perfluorooctanoic acid purification treatment. The invention discloses a method for removing perfluorooctanoic acid in a water body by utilizing lignin-based carbon nanotubes. The preparation method comprises the following steps: dissolving a mixture of lignin, dicyclopentadiene nickel and dicyclopentadiene iron and thiophene into a methanol solution; under the protection of inert gas, feeding the lignin to a porous cracking tube in a first high-temperature area, to pyrolyze the lignin into low-molecular light polyphenol gas; then releasing thegas into a second high-temperature area through backflow of the porous cracking tube, and further performing cracking catalytic growth is performed to form a carbon nanotube aggregate with the diameter of 10-37 nm; and then processing the carbon nanotube aggregate into the carbon nanotube filter membrane. The method is used for removing the perfluorooctanoic acid in the water body, wherein the lignin is used for preparing the carbon nano tube aggregate, and the carbon nano tube aggregate is prepared into the carbon nano tube filter membrane, so that after adsorption of the perfluorooctanoic acid is completed, the perfluorooctanoic acid can be rapidly regenerated in a high-temperature environment.

Owner:DONGHUA UNIV

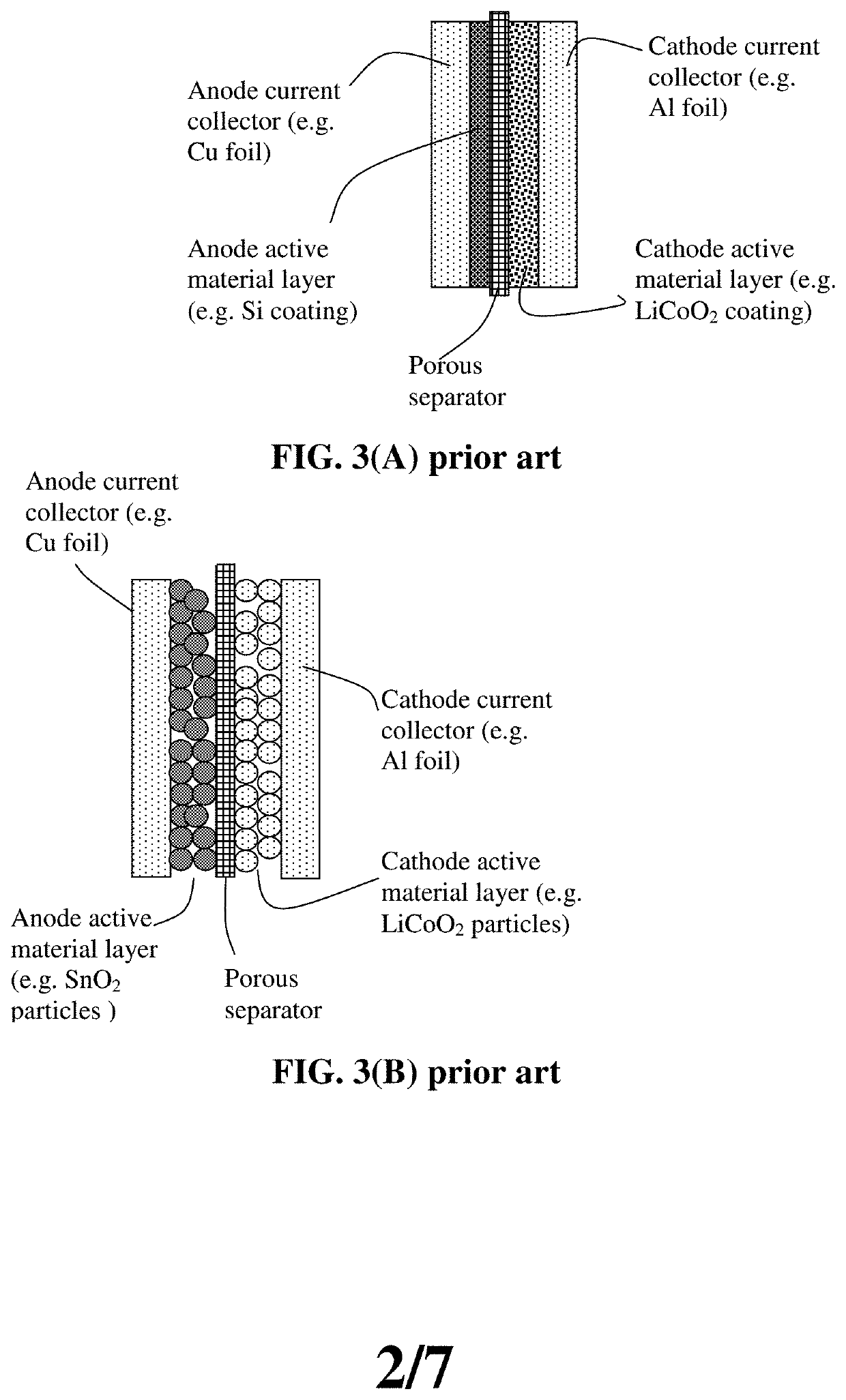

Lithium Ion Battery Anode Containing Silicon Nanowires Grown in situ in Pores of Graphene Foam and Production Process

ActiveUS20180261847A1Improve conductivitySolve the lack of spaceElectrode thermal treatmentElectrode carriers/collectorsLiquid mediumSilicon nanowires

A process for producing an anode layer, comprising: (a) dispersing catalyst metal-coated Si particles, graphene sheets, and an optional blowing agent in a liquid medium to form a graphene / Si dispersion; (b) dispensing and depositing the dispersion onto a supporting substrate to form a wet layer and removing the liquid medium from the wet layer to form a dried layer of graphene / Si mixture material; and (c) exposing the dried layer to a high temperature environment, from 300° C. to 2,000° C., to induce volatile gas molecules from graphene sheets or to activate the blowing agent for producing the graphene foam and, concurrently, to enable a catalyst metal-catalyzed growth of multiple Si nanowires emanated from Si particles as a feed material in pores of the foam to form the anode layer; wherein the Si nanowires have a diameter of 5-100 nm and a length-to-diameter aspect ratio of at least 5.

Owner:GLOBAL GRAPHENE GRP INC

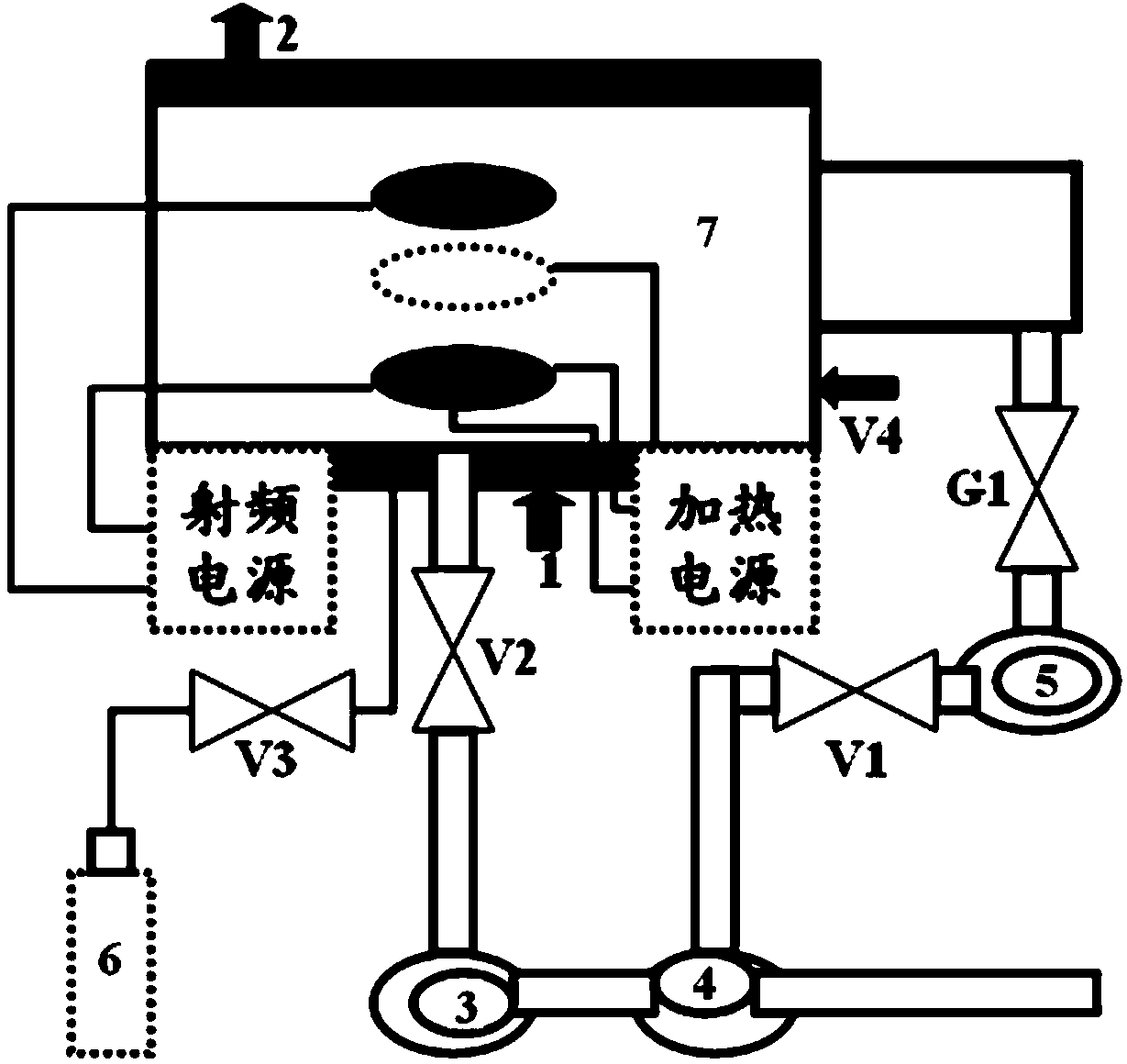

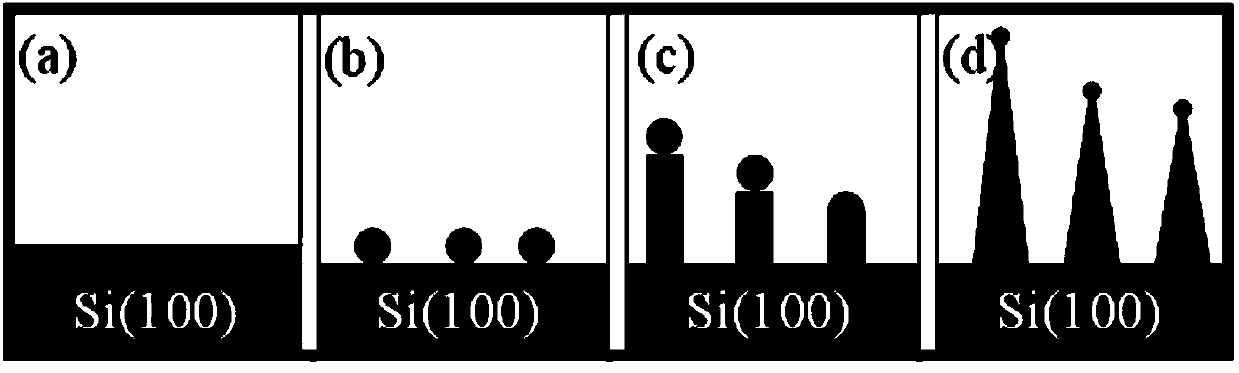

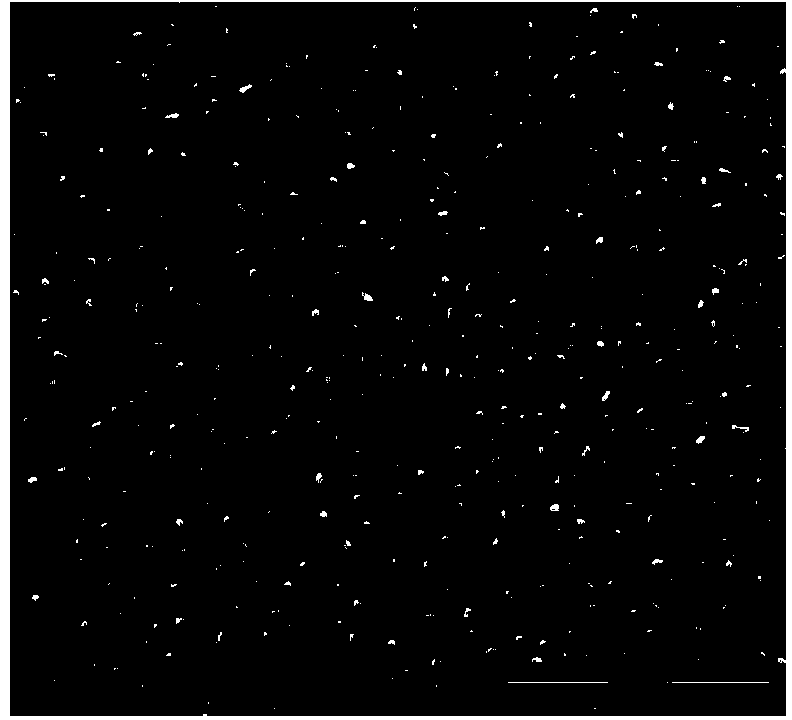

Preparation method for needle point type silicon nanowire

ActiveCN103787335AFast growthHigh densityMaterial nanotechnologyChemical vapor deposition coatingPtru catalystSilicon alloy

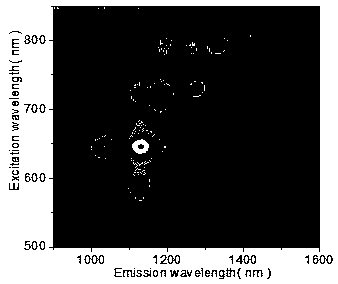

The invention provides a preparation method for a needle point type silicon nanowire. The preparation method comprises the following steps: depositing an Au thin film with the thickness of 5-10nm on a cleanly-washed substrate; transferring the substrate deposited with the Au film to a PECVD (Plasma Enhanced Chemical Vapor Deposition) reaction cavity; heating to 800 DEG C within 30 minutes and annealing for 40 minutes; introducing 40sccm of silane and maintaining a reaction pressure to 32pa so as to carry out a luminance build-up reaction; continuously reacting for 1 hour at 600-800 DEG C; annealing the Au film which is sputtered and deposited on the substrate to form silicon alloy liquid drops which are used as a growth catalyst of the needle point type silicon nanowire; after a silicon source in a gas phase is saturated in the alloy liquid drops, gradually separating out the silicon nanowire to grow. The dispersion of gold in the alloy liquid drops enables the volume to be gradually reduced so that the diameter of the catalytically-growing nanowire is reduced along the length direction to form a needle point shape. The preparation method is simple in process and is convenient for large-area growth; the prepared needle point type silicon nanowire can be widely applied to fields of SERS (Surface Enhanced Raman Scattering) and the like.

Owner:西安艾斯达特新材料科技有限公司

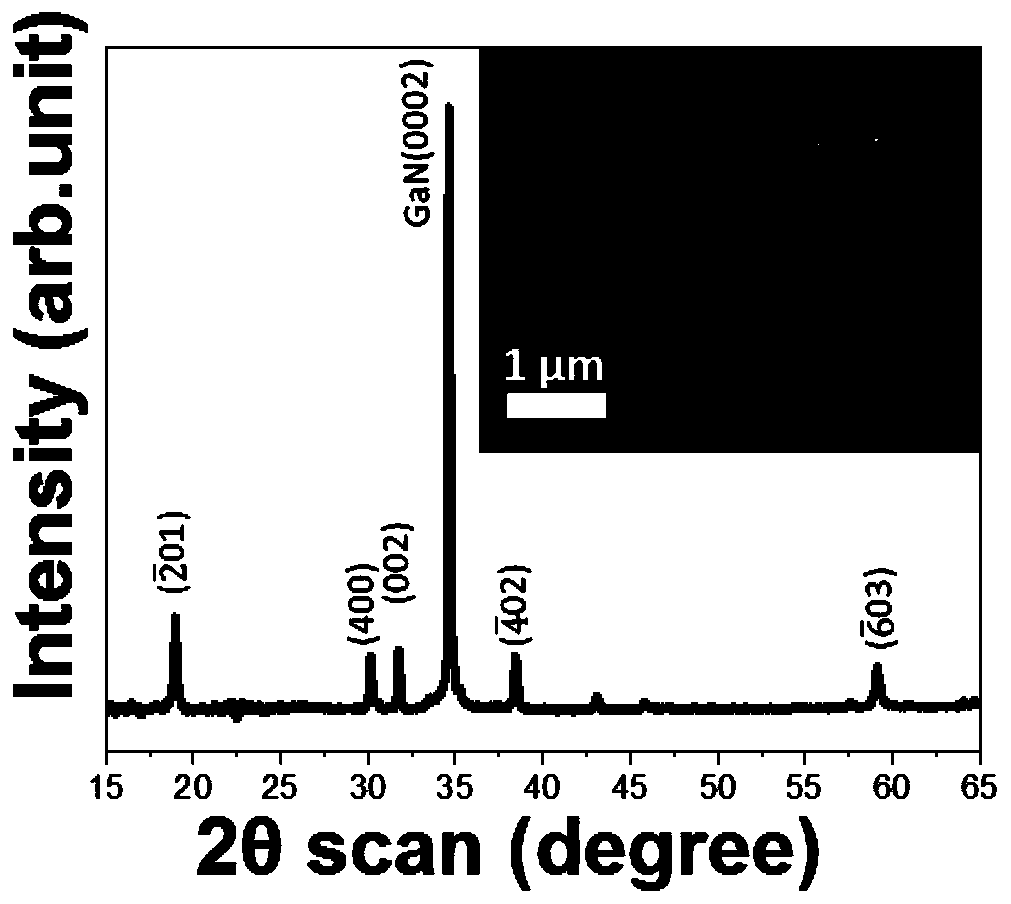

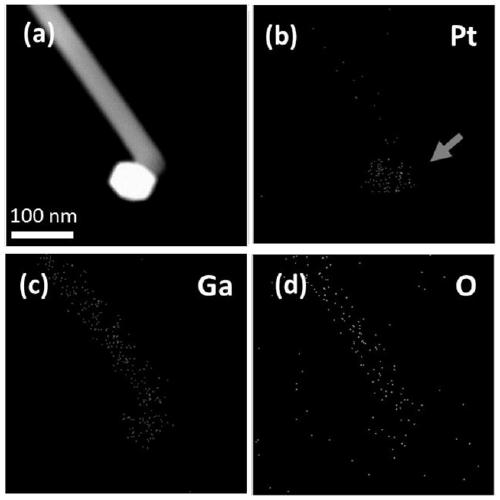

Preparation method of large-size single crystal beta-gallium oxide nanobelt structure

ActiveCN109881246ASmall sizeQuality improvementMaterial nanotechnologyPolycrystalline material growthSemiconductor materialsNanowire

The invention belongs to the technical field of semiconductor materials, and particularly relates to a large-size single crystal beta-gallium oxide nanobelt structure and a preparation method thereof.The preparation method comprises: firstly plating a catalytic thin layer on the surface of a gallium nitride film; placing into a chemical vapor deposition device, and thermally annealing the galliumnitride thin film covered with the catalytic thin layer; growing a {-201} single crystal gallium oxide nanowire on the gallium nitride film under a less oxygen condition by a thermal oxidation growthmethod; by utilizing the growth condition of rich gallium / less oxygen, selectively growing in a side direction on the side face of the nanowire to obtain the large-sized single crystal beta-gallium oxide nanobelt. The preparation method has the advantages of simple process and good universality and repeatability, can overcome the disadvantage of different crystal phases of a catalytically grown gallium oxide nano material, the grown gallium oxide nanobelt controllable in thickness, is high in yield, and the can be stably transferred on various substrates for the preparation of various novel gallium oxide based devices.

Owner:纳微朗科技(深圳)有限公司

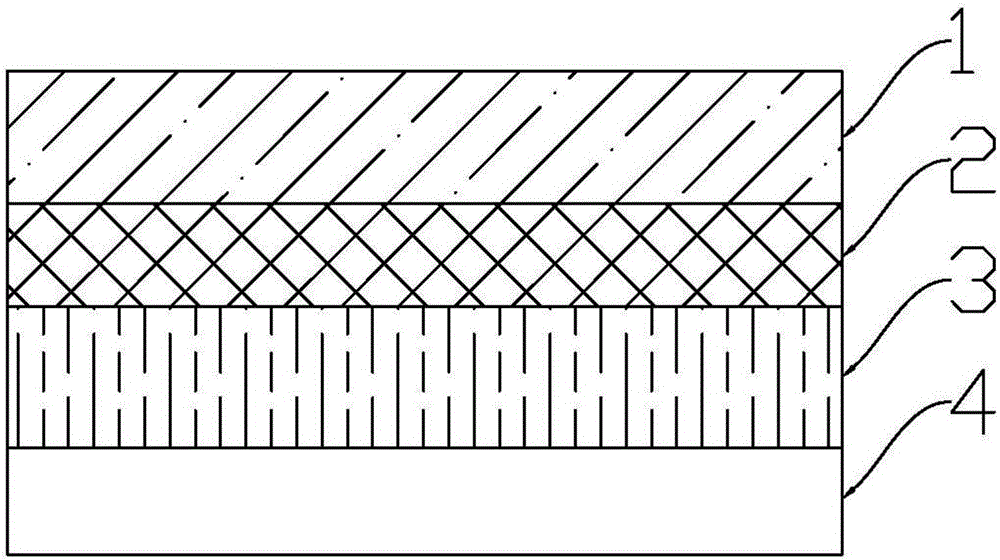

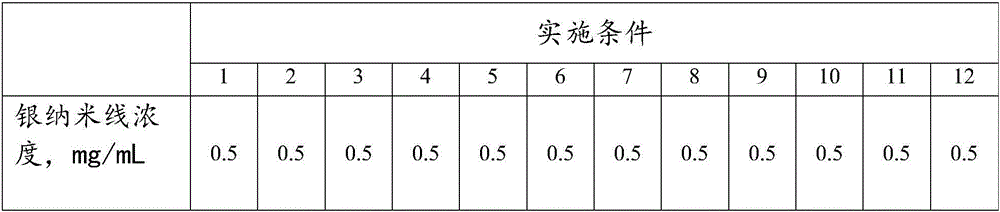

Composite transparent conductive film and preparation method thereof

InactiveCN106297964AImprove stabilityImproved surface chemical inertnessConductive layers on insulating-supportsMetal/alloy conductorsSingle crystalIrradiation

The invention relates to a composite transparent conductive film and a preparation method thereof. The preparation method comprises the following steps of S1, performing catalytic growth of a single-crystal-layer graphene film on the surface of a metal substrate, and obtaining a structure I; S2, plating a silver nanometer wire on the surface of the graphene film of the structure I, thereby obtaining a composite structure II; S3, uniformly plating a liquid photo-curable material on a flexible transparent substrate, thereby obtaining a composite structure III; S4, performing aligned pressing on the liquid photo-curable coating in the composite structure III and the silver nano-wire coating in the composite structure II, thereby obtaining a composite structure IV; S5, performing irradiation on the composite structure IV so that the liquid photo-curable coating is converted to solid, thereby obtaining a composite structure V; and S6, through an electrochemical stripping method, separating a metal substrate in the composite structure V, thereby obtaining a composite conductive flexible film. The preparation method has advantages of simple operation, high reliability and high suitability for large-scale production. The prepared composite transparent conductive film has advantages of excellent conductivity, high transmittance and reliable performance.

Owner:CHONGQING GRAPHENE TECH

Method for eliminating the metal catalyst residues on the surface of wires produced by catalytic growth

InactiveUS20120070964A1Individual molecule manipulationSemiconductor/solid-state device manufacturingMetal catalystCatalytic growth

This method for eliminating the catalyst residues present on the surface of solid structures made from a first material and obtained by catalytic growth, includes the following steps:catalytic growth, from the catalyst residues, of solid structures made from a second material;selective elimination of said solid structures made from a second material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

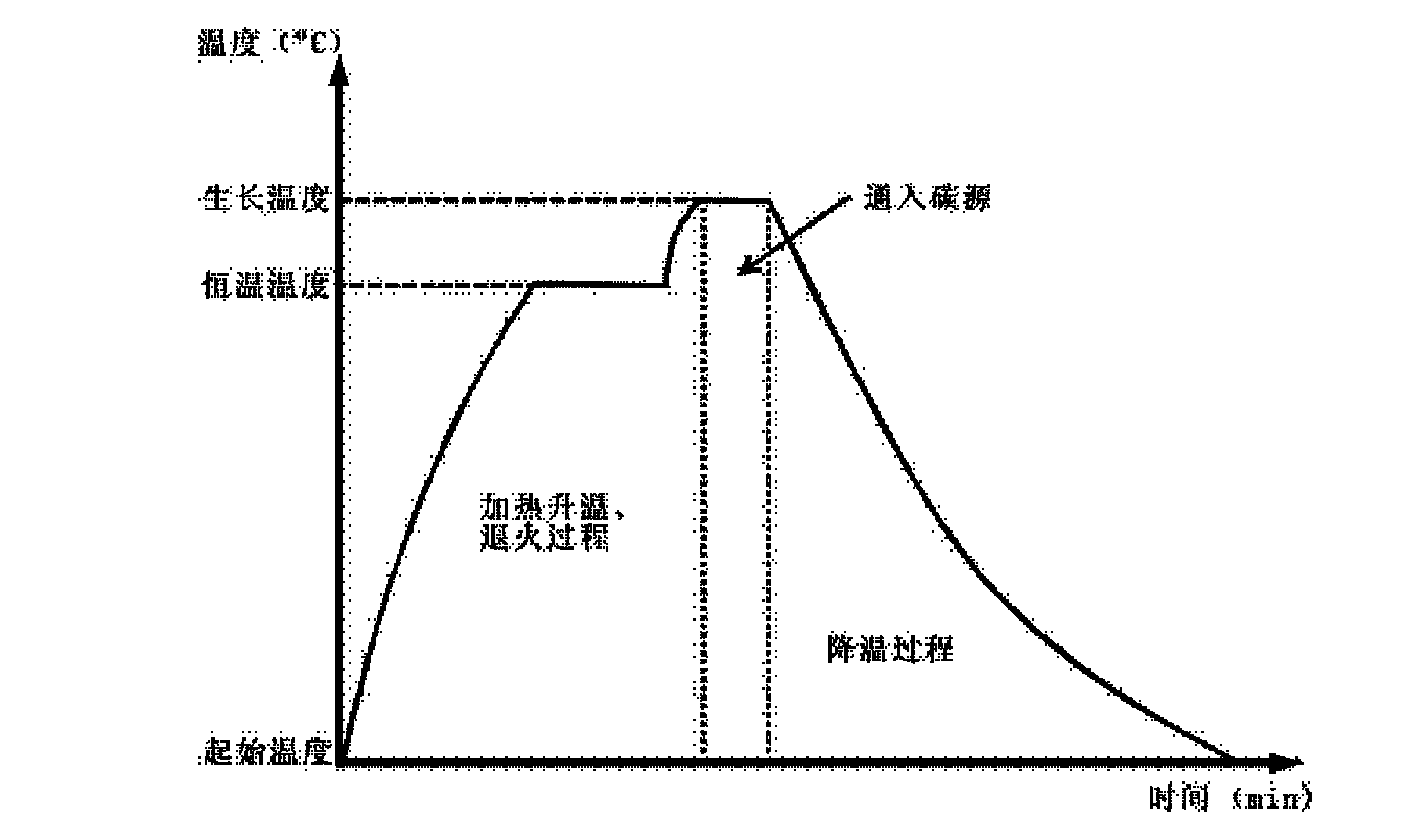

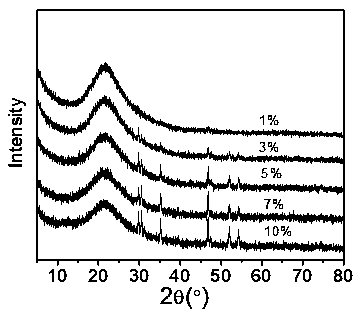

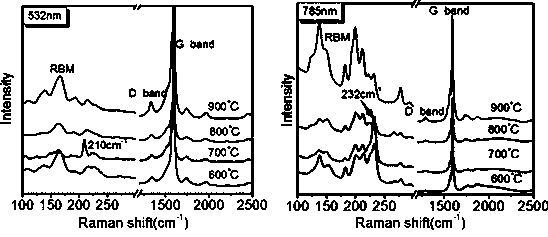

Preparation and application of supported cobalt sulfide catalyst for selectively synthesizing carbon nanotubes

The invention provides preparation and application of a supported cobalt sulfide catalyst for selectively synthesizing carbon nanotubes. The experimental process comprises the following steps: (1) preparing a silicon dioxide loaded cobalt sulfide catalyst, namely preparing the silicon dioxide loaded cobalt sulfide catalyst from pure cobalt sulfide and a silicon dioxide carrier through the treatment modes of infiltration, dispersion, heating and stirring, drying, grinding and the like; and (2) researching the condition that the silicon dioxide loaded cobalt sulfide catalyst which takes ethanolas a carbon source and has the cobalt content of 1-10 wt% catalyzes the growth of the carbon nanotubes by adopting a chemical vapor deposition method under the conditions that the reduction temperature is 600-900 DEG C, the growth temperature is 900 DEG C and the temperature rises at the heating rate of 10 DEG C / min. The silicon dioxide loaded cobalt sulfide catalyst prepared by the method can beused for selectively synthesizing single-walled carbon nanotubes and multi-walled carbon nanotubes with narrower tube diameter distribution by a chemical vapor deposition method.

Owner:SOUTHWEST PETROLEUM UNIV

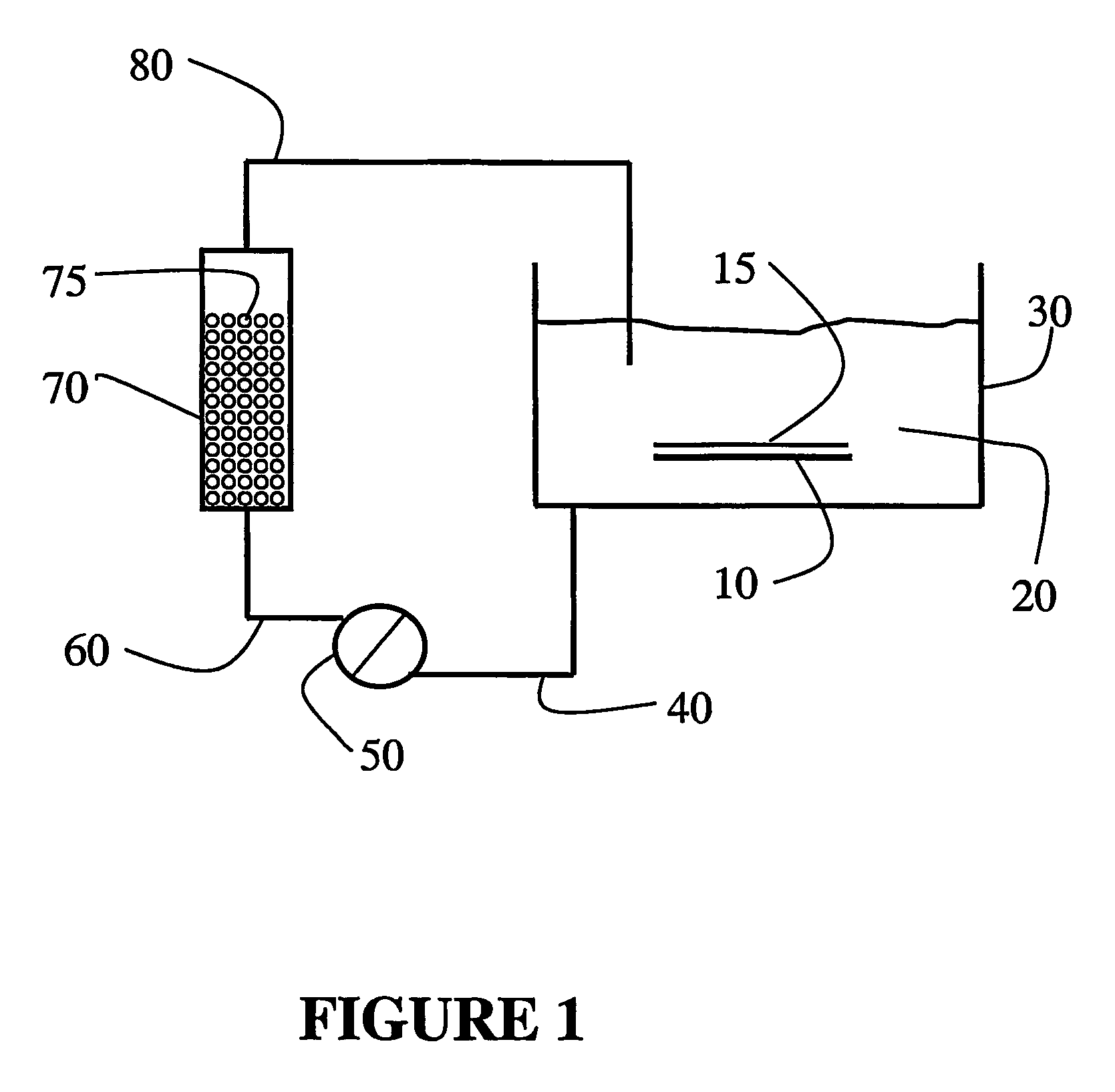

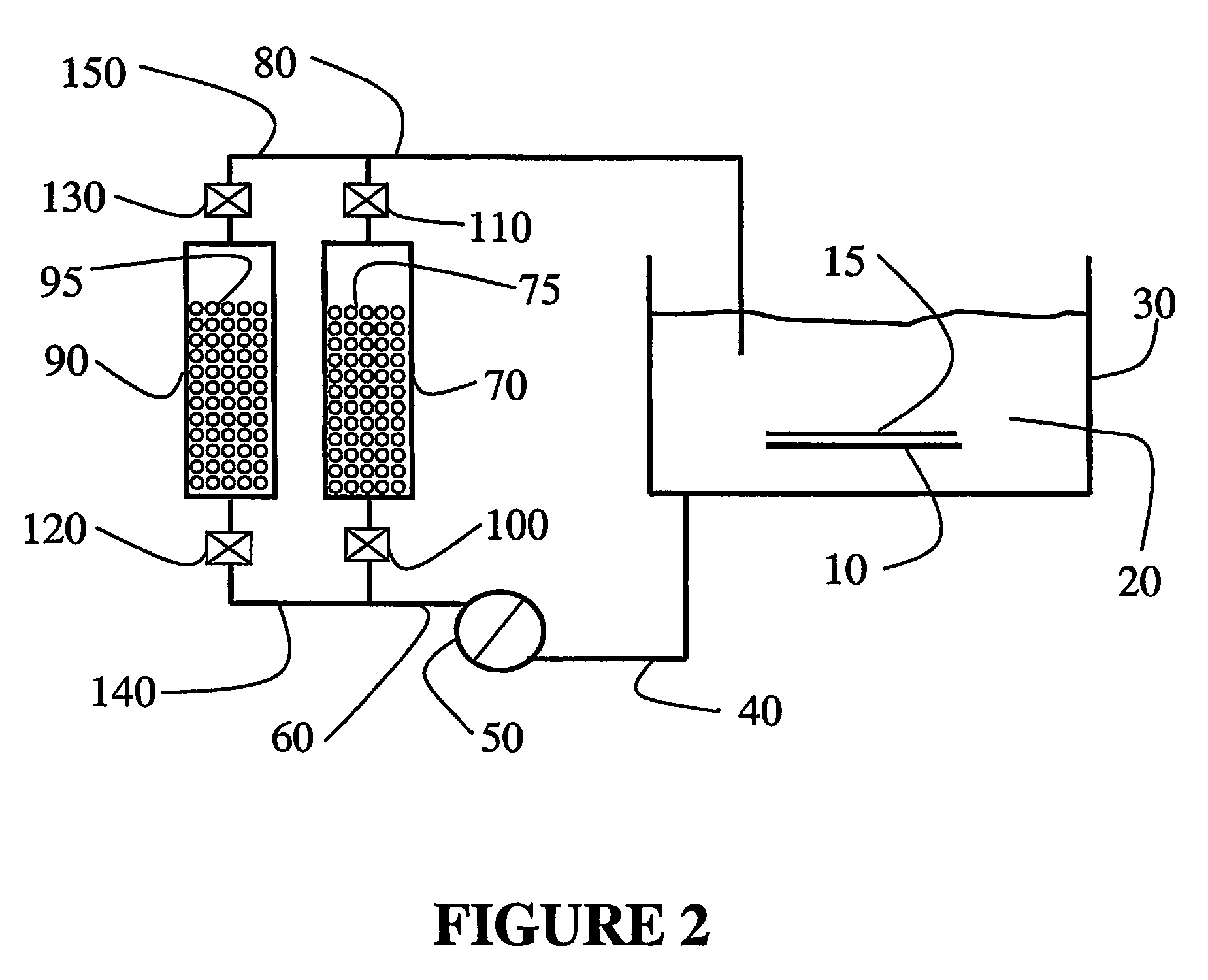

Method for low temperature growth of inorganic materials from solution using catalyzed growth and re-growth

ActiveUS7718550B2Semiconductor/solid-state device manufacturingSolid state diffusion coatingChemical treatmentSilicon oxide

The present invention involves a method and apparatus for depositing a silicon oxide onto a substrate from solution at low temperatures in a manner that produces homogeneous growth of the silicon oxide. The method generally comprises the following steps: (a) Chemically treating a substrate to activate it for growth of the silicon oxide. (b) Immersing the treated substrate into a bath with a reactive solution. (c) Regenerating the reactive solution to allow for continued growth of the silicon oxide. In another embodiment of the present invention, the apparatus includes a first container holding a reactive solution, a substrate on which the silicon oxide is deposited, a second container holding silica, and a means for adding silica to the reactive solution.

Owner:RICE UNIV

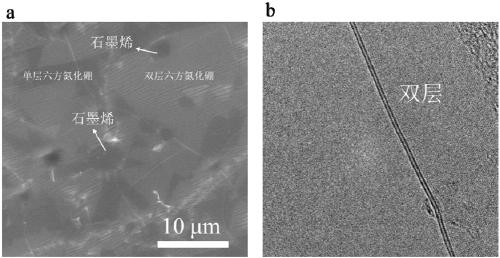

Preparation method of large-area graphene and hexagonal boron nitride heterojunction with controllable number of layers

InactiveCN109402605AHigh boron or nitrogen solubilityLarge specific surface areaChemical vapor deposition coatingHeterojunctionSolubility

The invention provides a method for preparing a graphene and hexagonal boron nitride heterojunction with a controllable number of layers. The method comprises the steps that hexagonal boron nitride isprepared on the surface of a metal thin film substrate by a chemical vapor deposition method under the catalysis of the metal thin film substrate, and graphene is formed on the surface of the prepared hexagonal boron nitride by the chemical vapor deposition method under the remote catalysis of another metal material placed on the upstream of a gas stream. The metal material has higher boron and nitrogen solubility or a higher specific surface area than the material of the metal thin film substrate. In the preparation method, the metal material is placed in the vicinity of the growth substrate, and the large-area graphene and hexagonal boron nitride heterojunction with the controllable number of layers can be prepared in situ. After the surface of the metal substrate is covered with a certain number of layers of hexagonal boron nitride, the graphene cannot continue to be catalyzed and grown on the surface of the metal substrate after the chemical catalytic activity is lost; and at thetime, the pre-placed metal material can continuously provide catalysis to grow the graphene on the surface of the hexagonal boron nitride.

Owner:RENMIN UNIVERSITY OF CHINA

Method for preparing blocky carbon nano ¬ fibers composite

The invention discloses a preparation method of block carbon nanofiber composite material which is characterized by putting a catalyst into a mould and raising the temperature until 400 to 700 DEG C in the He air stream containing H2 for 0.5 to 8 hours and then the air stream is switched and is conducted with gas containing carbon to carry out catalytic growth reaction of the block carbon nanofiber to obtain the block carbon nanofiber. The obtained block carbon nanofiber is infused into the solution of phenolic resin-ethanol, then is taken out, and the redundant solution is removed for drying in vacuum at the temperature of 40 to 70 DEG C, then is carbonized in the N2 air stream at the temperature of 700 to 1100 DEG C and finally the block carbon nanofiber composite material is obtained. The material of the invention shows high conductivity and high thermal conductivity, high mechanical strength and low density.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com