Preparation and application of supported cobalt sulfide catalyst for selectively synthesizing carbon nanotubes

A technology of carbon nanotubes and single-walled carbon nanotubes, which is used in the preparation and application of supported cobalt sulfide catalysts for selective synthesis of carbon nanotubes, and can solve problems such as easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use a certain amount of deionized water to wet the fumed silica carrier first, and place it on a magnetic stirrer to stir for 10 minutes; add cobalt sulfide to the above silica mixture, and stir for 0.5 hours at room temperature; place the stirred mixture in an ultrasonic cleaner Ultrasonic dispersion for 2 hours; transfer the ultrasonicated mixture to a cell pulverizer for further dispersion for 2 hours; continue to stir on a magnetic stirrer at room temperature for 12 hours; then raise the temperature of the stirrer to 100°C to evaporate excess water, and place it in an oven at 100°C for drying Dry overnight; finally the dried sample is ground into a powder. Silica-supported cobalt sulfide catalysts with cobalt content of 1 wt%, 3 wt%, 5 wt%, 7 wt% and 10 wt% were respectively prepared according to the above steps.

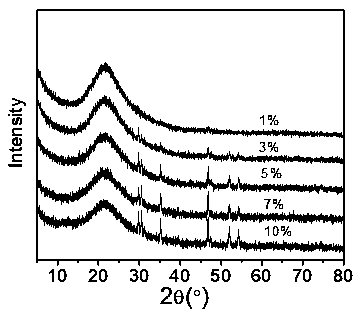

[0032] figure 1 It is the X-ray diffraction pattern of the silica-supported cobalt sulfide catalysts with different cobalt contents prepared as describe...

Embodiment 2

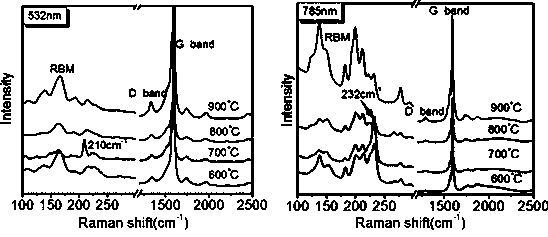

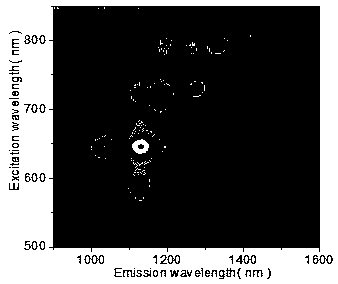

[0034] The silica-loaded cobalt sulfide catalyst prepared in Example 1 with a cobalt content of 1 wt% is used for chemical vapor deposition to synthesize single-walled carbon nanotubes: 200 mg of the catalyst sample is spread in a porcelain boat, and the porcelain boat is sent into a tube furnace In the middle constant temperature zone, the catalyst is raised from room temperature to 600°C at a rate of 10°C / min in hydrogen, and then the hydrogen is replaced by argon immediately, and the temperature is kept at this rate; when the temperature rises to 900°C, the argon Air (200 sccm) was used to bubble absolute ethanol, and the steam entered the reactor for 30 minutes; the sample was naturally cooled to room temperature in an argon atmosphere to obtain single-walled carbon nanotubes.

Embodiment 3

[0036] The preparation described in Example 1 with a cobalt content of 1 wt% is used for the step of synthesizing carbon nanotubes by chemical vapor deposition using the silicon oxide-supported cobalt sulfide catalyst. Min heating rate from room temperature to 700°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com