Preparation method of large-area graphene and hexagonal boron nitride heterojunction with controllable number of layers

A technology of hexagonal boron nitride and graphene, applied in the field of materials, can solve the problems of multiple impurities, low output, and unfavorable industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, the method that utilizes nickel foam and copper foil substrate to prepare graphene and hexagonal boron nitride heterojunction

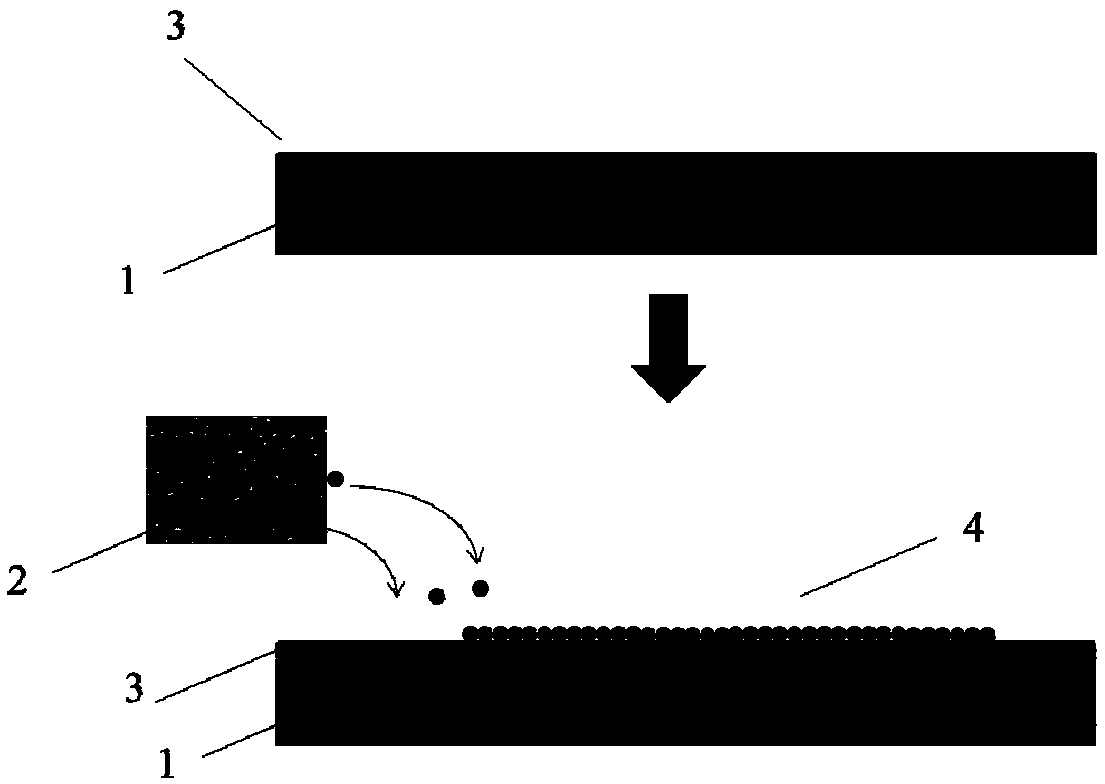

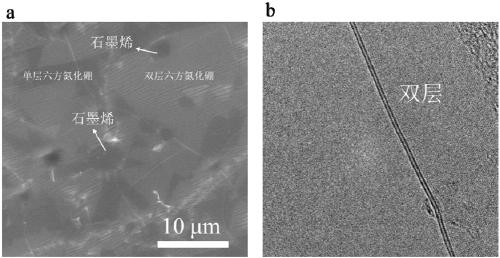

[0051] according to Figure 1-Figure 2 In principle, the method for preparing graphene and hexagonal boron nitride heterojunction specifically includes the following steps:

[0052](1) Soak nickel foam (specific specifications, thickness 3mm, pore diameter 0.1mm, 100 holes per inch) and copper foil (thickness 25 microns, size 3cm*4cm) with ammonium persulfate solution for 2-3 minutes , to remove surface oxides, and then rinse with deionized water.

[0053] (2) Wrap the copper foil into a box shape, cut the nickel foam into 2cm*2cm and wrap it into one end of the copper (substrate) box, then use a balance to weigh 20 mg of ammonia borane as the growth material, and put it into the quartz boat. Put the quartz boat containing the raw materials into the tube furnace together with the copper box, wherein the copper box is located in ...

Embodiment 2

[0061] Embodiment 2, the method that utilizes cobalt nanopowder and copper foil substrate to prepare graphene and hexagonal boron nitride heterojunction

[0062] (1) Copper foil (thickness 25 microns, size 3cm*4cm) is soaked in ammonium persulfate solution for 2-3 minutes to remove surface oxides, and then cleaned with deionized water.

[0063] (2) Use a balance to weigh 3mg of cobalt nanopowder (2nm) for use, then wrap the copper foil into a box shape, and sprinkle the weighed nanopowder evenly on the folded part of the copper box before sealing. Then use a balance to weigh 20 mg of ammonium borane as a growth material, and put it into a quartz boat. Put the quartz boat containing the raw materials into the tube furnace together with the copper box, where the copper box is located in the middle of the high temperature zone, and the half-folded treatment with cobalt nano powder is placed at the upstream of the air flow, and the quartz boat is placed at the source area, closed ...

Embodiment 3

[0071] Embodiment 3, using copper sheet and copper foam respectively as the comparative experiment of additional metal catalytic material

[0072] (1) Process copper sheet (thickness is 50 μm, size is 2cm*2cm), foam copper (specific specification, thickness is 3mm, aperture is 0.1mm, number of holes per inch is 100, size is 2cm*2cm) according to previous embodiment And two pieces of copper foil (thickness 25μm, size 3cm*4cm);

[0073] (2) Wrap two pieces of copper foil into a box shape, wrap the treated foam copper and copper sheet into one end of the copper (substrate) box, then use a balance to weigh 20 mg of ammonia borane as a growth material, and put it into a quartz boat Inside. Put the quartz boat containing the raw materials into the tube furnace together with the copper box, where the copper box is located in the middle of the high temperature zone (reaction zone), and place the section wrapped with foamed copper and copper sheet at the upstream of the air flow, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com