Method for directly growing graphene on insulating substrate through remote catalysis of copper particle

A technology of copper particles on an insulating substrate, applied in nanotechnology, coating, nanotechnology, etc. for materials and surface science, can solve complex transfer, graphene cannot be directly applied to electronic devices, etc., to avoid transfer Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

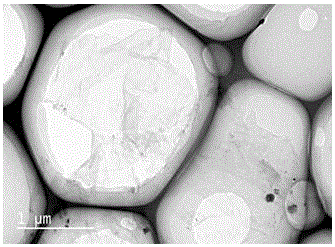

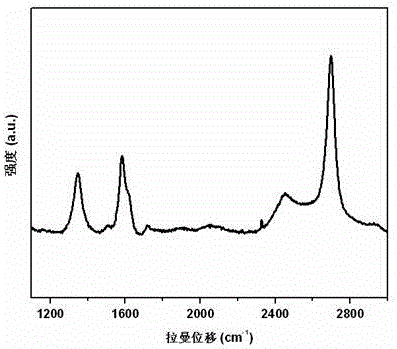

[0026] Cut commercially available quartz wafers into 1cm*1cm quartz wafer substrates, wash them with detergent and deionized water first, then clean the quartz substrates with ethanol and acetone solvents by ultrasonic waves for 30 minutes, and then wash them with deionized water Rinse and dry at 60°C, then anneal at 1000°C for 20 minutes. Immerse the treated quartz substrate in 0.1M copper acetate solution for 10 minutes, take it out and put it into a chemical vapor deposition (CVD) reaction furnace after drying. The high-temperature furnace is kept sealed, and 230 sccm of argon and 15 sccm of hydrogen are introduced Remove the air in the tube for 30 minutes, then keep the flow rate of argon and hydrogen constant and raise the temperature to 1000°C at a rate of 20°C / min. After holding for 30 minutes, feed 15sccm of methane, adjust the flow rate of hydrogen to 5sccm, and the reaction time is 20 minutes. Stop feeding methane after the reaction is finished, keep the flow of argo...

Embodiment 2

[0028] Cut commercially available quartz wafers into 1cm*1cm quartz wafer substrates, wash them with detergent and deionized water first, then clean the quartz substrates with ethanol and acetone solvents by ultrasonic waves for 30 minutes, and then wash them with deionized water Rinse and dry at 60°C, then anneal at 1000°C for 20 minutes. Immerse the treated quartz substrate in 0.1M copper acetate solution for 10 minutes, take it out and put it into a chemical vapor deposition (CVD) reaction furnace after drying. The high-temperature furnace is kept sealed, and 230 sccm of argon and 15 sccm of hydrogen are introduced Remove the air in the tube for 30 minutes, then keep the flow rate of argon and hydrogen constant and raise the temperature to 1000°C at a rate of 20°C / min. After holding for 30 minutes, feed 15sccm of methane, adjust the flow rate of hydrogen to 5sccm, and the reaction time is 10 minutes. Stop feeding methane after the reaction is finished, keep the flow of argo...

Embodiment 3

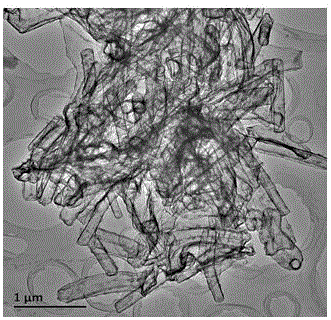

[0030] A single-layer monodisperse silica nanosphere-coated substrate was prepared, and the silica nanosphere substrate was annealed at 1000° C. for 20 minutes. Immerse the treated silica nanosphere substrate in 0.1M copper acetate solution for 10 minutes, take it out and put it into a chemical vapor deposition (CVD) reaction furnace after drying. Remove the air in the tube with 15 sccm of hydrogen for 30 minutes, then keep the flow rate of argon and hydrogen constant and raise the temperature to 1000 °C at a rate of 20 °C / min. for 20 minutes. After the reaction, the feeding of methane was stopped, the flows of argon and hydrogen were kept constant, and the mixture was naturally cooled to room temperature to obtain a graphene / silicon dioxide nanosphere composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com