Method for preparing FeNi alloy catalytic growth carbon nanotube material through electromagnetic induction heating method

A technology of electromagnetic induction heating and carbon nanotubes, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of selenium fixation difficulties, selenium difficulties, small tube diameters, etc., and achieve excellent sodium The effect of ion storage performance, reduction of agglomeration, and enhancement of load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: fully grind 0.1g iron oxalate, 0.9g nickel nitrate, and 2g melamine in a mortar;

[0025] Step 2: Put the ground solid powder in a crucible in a sealed glove box under an argon atmosphere. Under an induction alternating magnetic field environment, the material in the crucible cuts the magnetic induction line to generate an induced current, so that the material in the crucible is Heating, the temperature is controlled at 700°C, and the product is naturally cooled to collect the product;

[0026] Step 3: Stand the obtained product in nitric acid with a concentration of 3M, corrode for 12 hours, separate the remaining solid, and dry;

[0027] Step 4: Mix the product obtained in Step 3 with selenium powder at a ratio of 2:3, place it in a reaction kettle under an argon atmosphere in a sealed glove box, heat it to 260°C in a homogeneous reactor, and keep it warm for 12 hours to obtain FeNi@ Se / C.

Embodiment 2

[0029] Step 1: fully grind 0.05g iron oxalate, 0.95g nickel nitrate, and 2g urea in a mortar;

[0030] Step 2: Put the ground solid powder in a crucible in a sealed glove box under an argon atmosphere. Under an induction alternating magnetic field environment, the material in the crucible cuts the magnetic induction line to generate an induced current, so that the material in the crucible is Heating, the temperature is controlled at 600°C, and the product is collected after natural cooling to obtain the product;

[0031] Step 3: Stand the obtained product in nitric acid with a concentration of 1M, corrode for 12 hours, separate the remaining solid, and dry;

[0032] Step 4: Mix the product obtained in Step 3 with selenium powder at a ratio of 1:4, place it in a reaction kettle under an argon atmosphere in a sealed glove box, heat it to 260° C. in a homogeneous reactor, and keep it warm for 12 hours to obtain FeNi@ Se / C.

Embodiment 3

[0034] Step 1: Fully grind 0.3g iron oxalate, 0.2g nickel nitrate, and 2g urea in a mortar,

[0035] Step 2: Put the ground solid powder in a crucible in a sealed glove box under an argon atmosphere. Under an induction alternating magnetic field environment, the material in the crucible cuts the magnetic induction line to generate an induced current, so that the material in the crucible is Heating, the temperature is controlled at 300°C, and the product is collected after natural cooling to obtain the product;

[0036] Step 3: Stand the obtained product in nitric acid with a concentration of 0.5M, corrode for 12 hours, separate the remaining solid, and dry;

[0037] Step 4: Mix the product obtained in Step 3 with selenium powder at a ratio of 1:4, place it in a reaction kettle under an argon atmosphere in a sealed glove box, heat it to 260°C in a homogeneous reactor, and keep it warm for 10 hours to obtain FeNi@ Se / C.

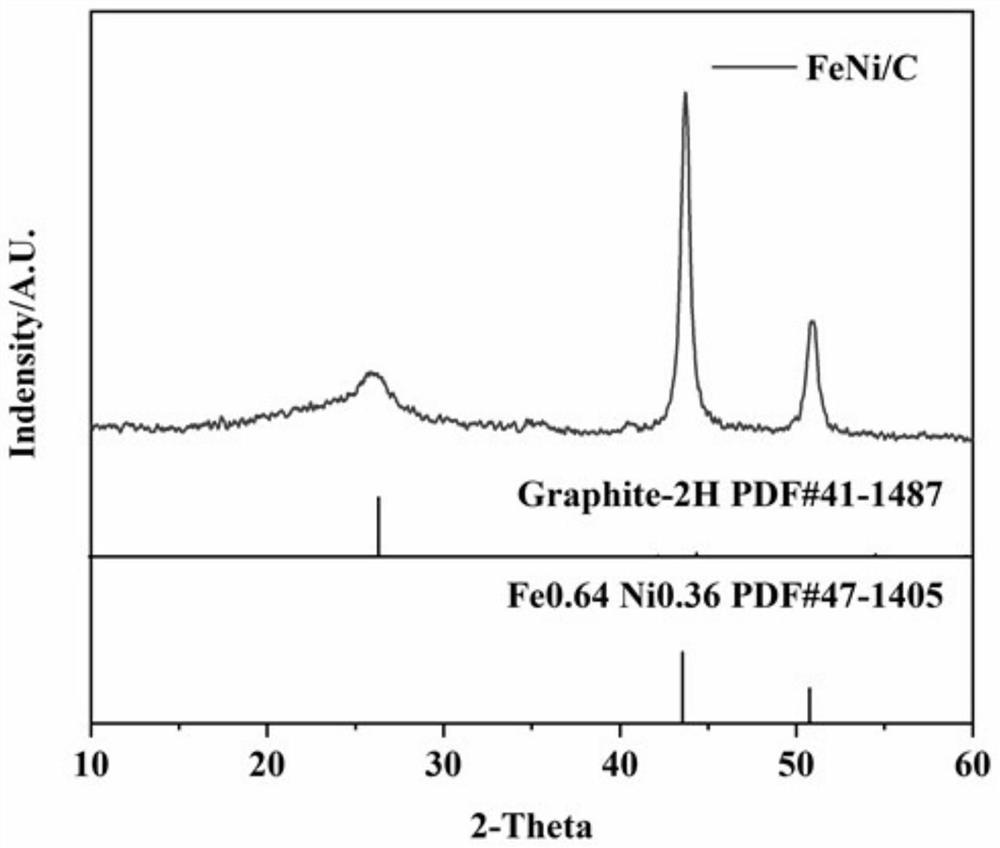

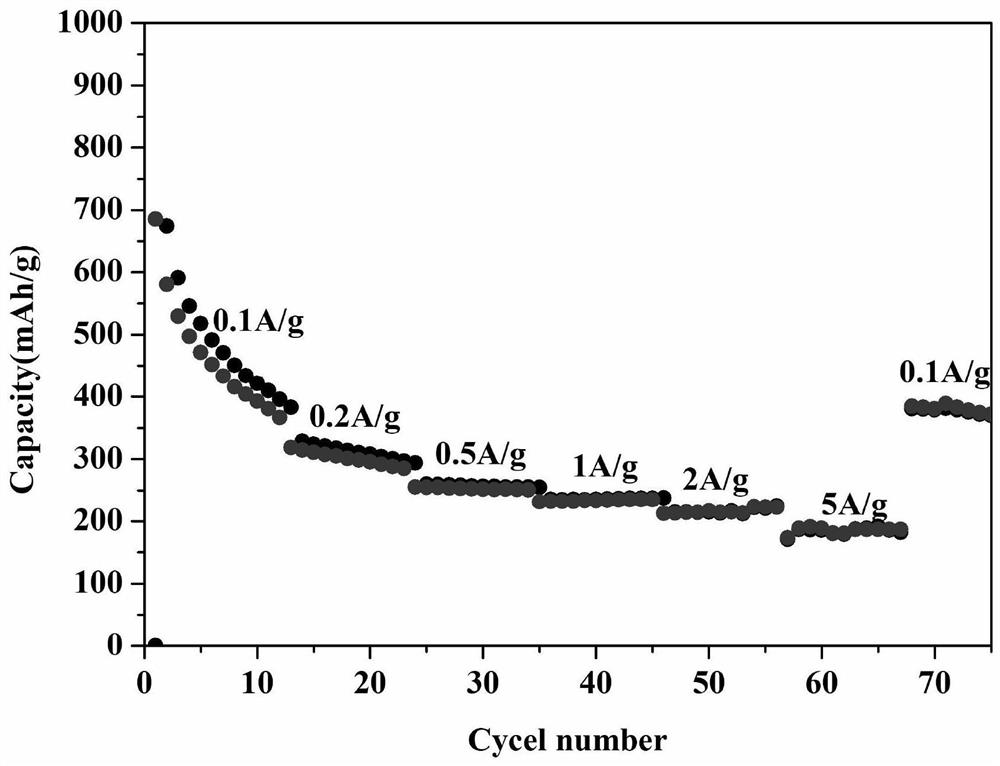

[0038] The sample that embodiment 1 is made observes un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com