Rare-earth oxide modified high-selectivity catalyst for adiponitrile hydrogenation and hexylenediamine production, preparation method and application thereof

A rare earth metal, high-selectivity technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, preparation of organic compounds, preparation of amino compounds, etc. High mechanical strength, reduced environmental pollution, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

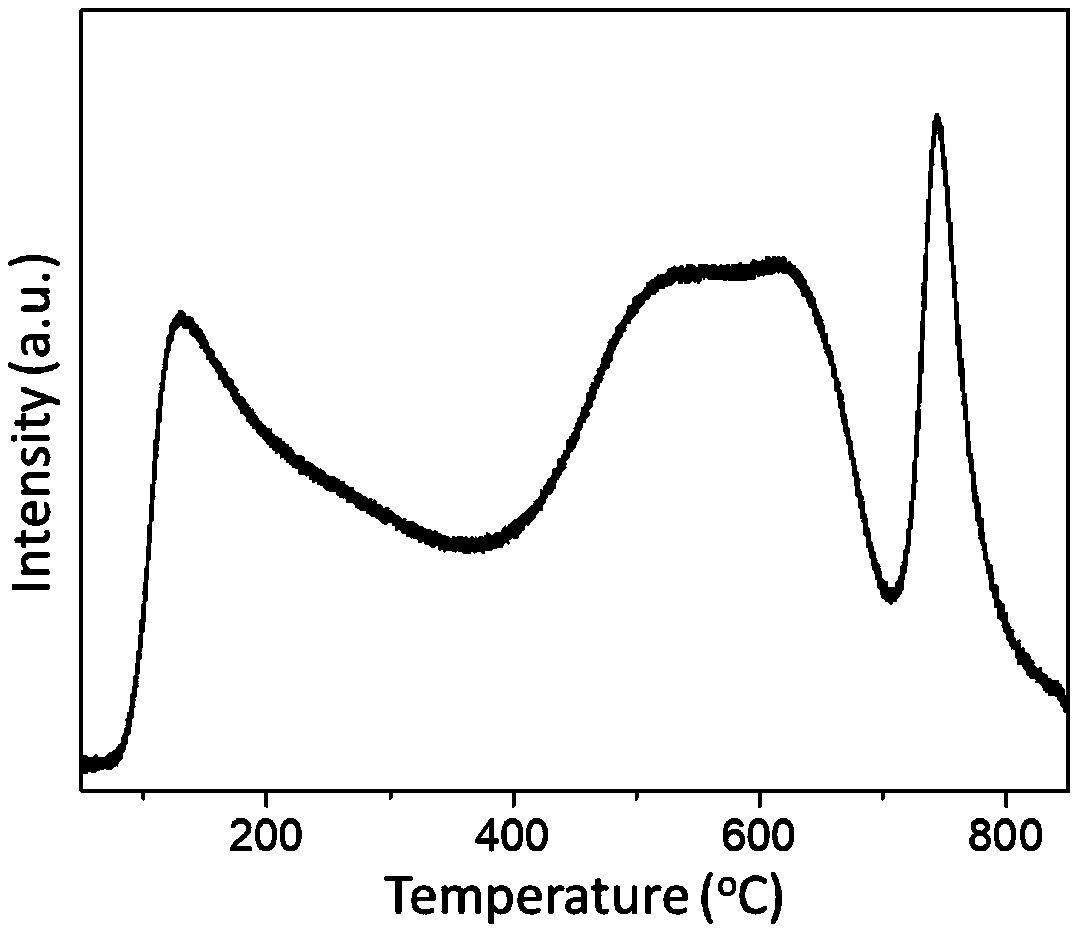

[0030] Prepare a certain concentration of nickel nitrate, aluminum nitrate and cerium nitrate metal salt precursors, and mix them uniformly by ultrasonic to form a mixed solution A. Sodium carbonate solution B with pH = 11 was prepared in deionized water. Under constant temperature and stirring conditions of 45°C, the above two clear solutions A and B were dripped into deionized water side by side, and the dropping speed was controlled to be 3 s / drop. Continue to adjust with sodium carbonate solution until pH=10. After aging for 8 hours, filter, wash, and dry at 110°C for 10 hours with deionized water and methanol, and roast the ground powder in a tube furnace at 400°C for 4 hours to obtain a catalyst precursor. Catalyst precursor in H 2 / Ar mixed gas at 400°C for 6 h to obtain catalyst powder. figure 1 Exhibit 2wt% CeO 2 X-ray diffraction (XRD) pattern of the modified nickel-based catalyst. figure 2 Exhibit 2wt% CeO 2 Modified Ni-based catalyst samples (2%) in NH 3 Te...

Embodiment 2

[0032] 2.5g of adiponitrile, 25ml of absolute ethanol and reduction pretreated 0.5g of CeO 2 The mass percentage is 2wt% Ni / CeO 2 / Al 2 o 3 Add the catalyst into a 50ml high-pressure closed reaction kettle, and replace the air in the kettle with hydrogen for 2-3 times. The stirring speed is 800rpm, and the reaction time is 3h. image 3 and Figure 4 Demonstration of 2wt% CeO after pretreatment 2 Modified Ni / CeO 2 / Al 2 o 3 Transmission electron micrograph of the catalyst. See Table 1 below for Ni / CeO under different reaction conditions 2 / Al 2 o 3 Test results for liquid-phase catalytic hydrogenation of adiponitrile.

[0033] Table 1 2wt% CeO at different reaction temperatures 2 Modified Ni / CeO 2 / Al 2 o 3 Test results of liquid-phase catalytic hydrogenation of adiponitrile

[0034]

Embodiment 3

[0036] 2.5g of adiponitrile, 25ml of absolute ethanol and reduction pretreated 0.5g of CeO 2 The mass percentage is 1wt% Ni / CeO 2 / Al 2 o 3 Catalyst The catalyst is added to a 50ml high-pressure reaction kettle, and the air in the kettle is replaced with hydrogen for 2-3 times. The stirring speed is 800 rpm, the reaction time is 3 h, the reaction temperature is 90° C., the hydrogen pressure is 7 MPa, the conversion rate of adiponitrile is 100%, and the selectivity of hexamethylenediamine is 70%. High-purity hexamethylenediamine can be obtained after distillation and purification under reduced pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com