Device and process for realizing denitration reaction and regeneration of SCR catalyst

A SCR catalyst and denitrification technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of large consumption, time-consuming and labor-consuming, high investment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

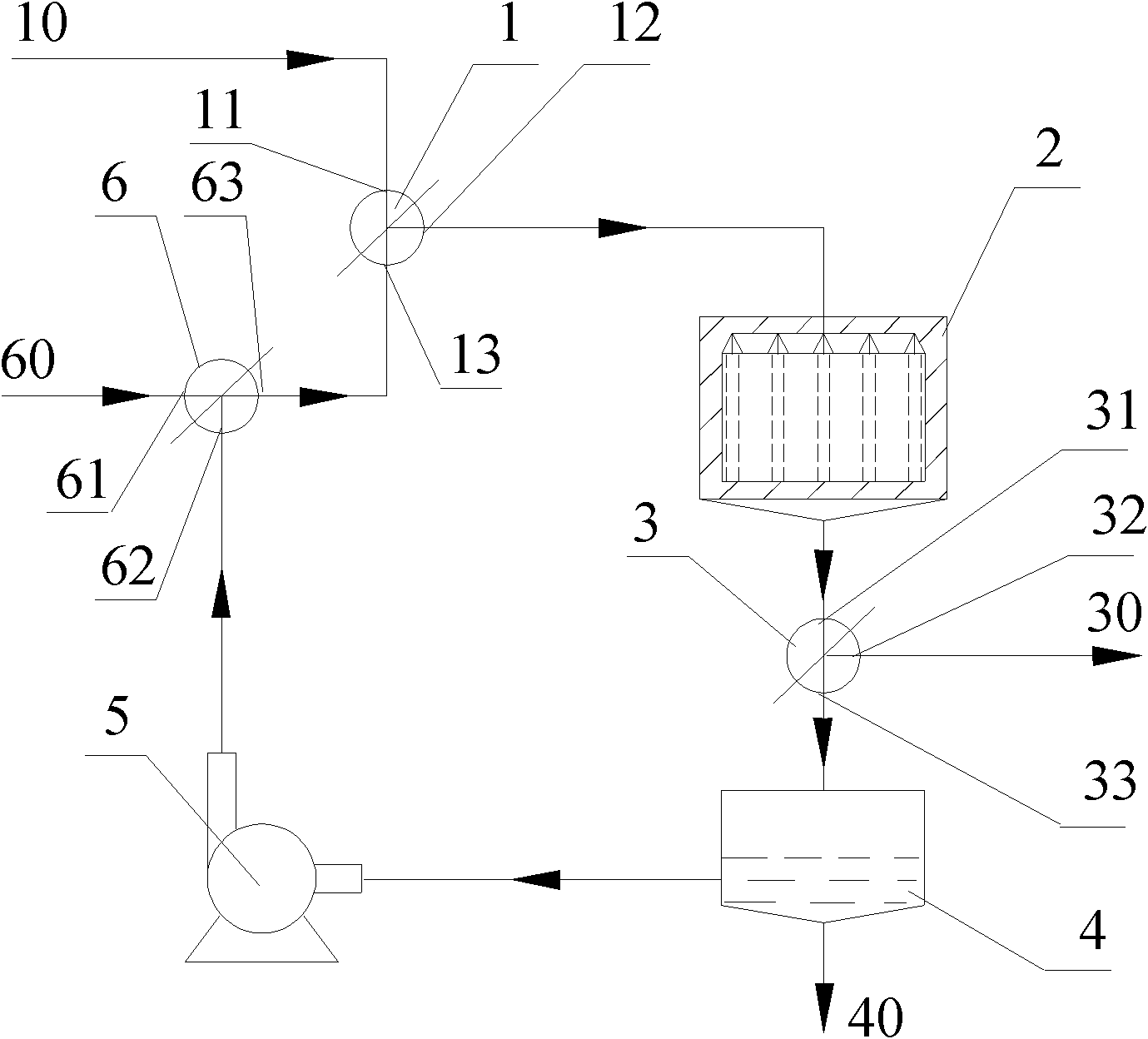

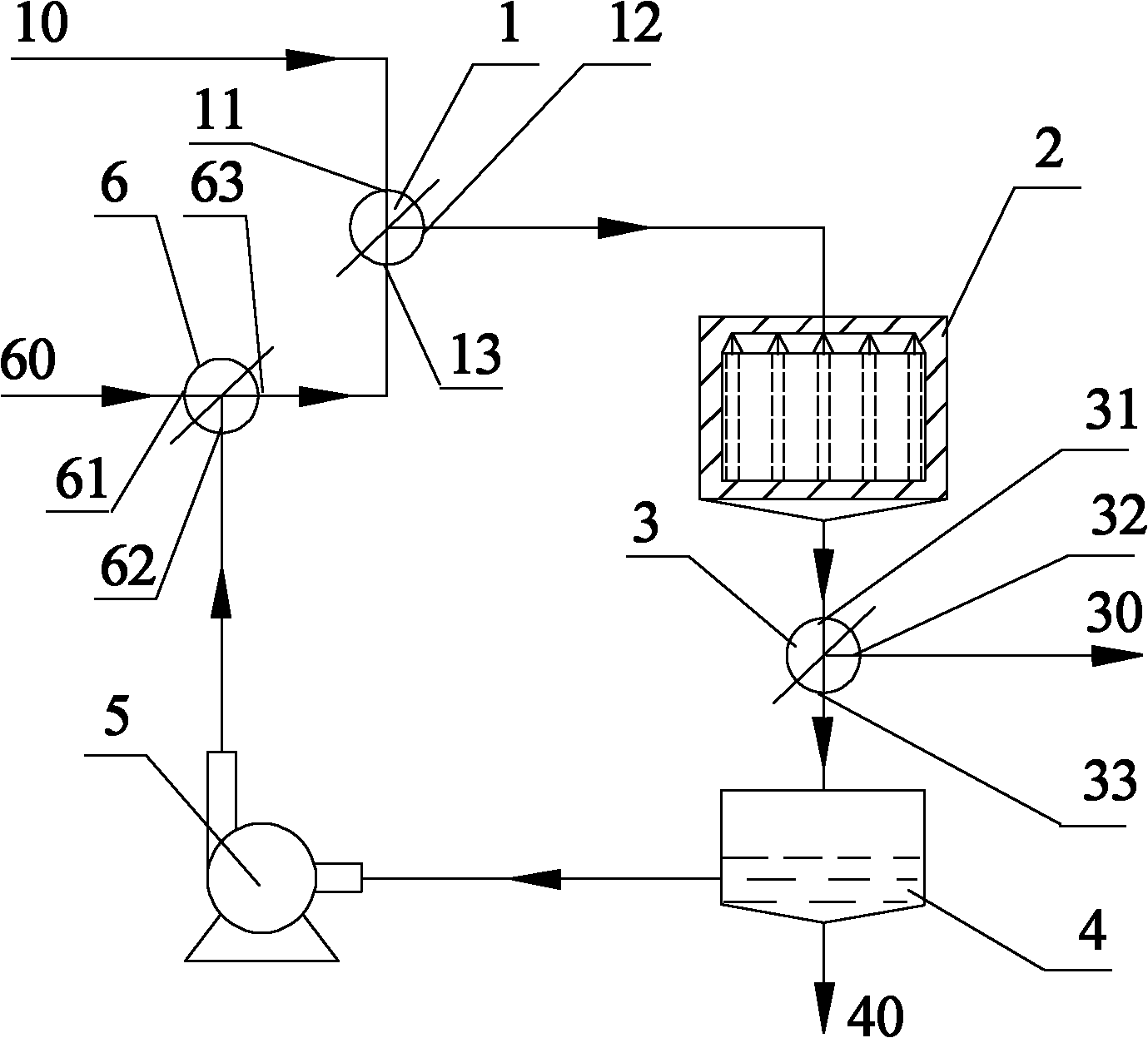

[0048] (1) SCR catalyst denitrification reaction

[0049] The flue gas is introduced from the flue gas input pipeline 10, and introduced into the SCR catalyst (V 2 o 5 -WO 3 / TiO 2 ) in the reactor 2, the denitrification reaction occurs, and the flue gas after denitrification is passed into the third three-way transfer valve 3, and the flue gas discharge pipeline 30 is used to achieve standard discharge.

[0050] SCR catalyst denitration reaction conditions: NH 3 / NO molar ratio 1.0, O 2 Concentration 5%, reaction temperature 330°C, gas space velocity 4000h -1 .

[0051] (2) SCR catalyst regeneration process

[0052] After the SCR catalyst is deactivated, it can be revived through the SCR catalyst regeneration process. The regeneration process is strictly operated according to the following process steps:

[0053] (I) Air purge

[0054] Oil-free dry compressed air (0.5MPa) is passed through the regeneration raw material input pipeline 60, the third three-way transfer ...

Embodiment 2

[0072] (1) SCR catalyst denitrification reaction

[0073] The flue gas is introduced through the flue gas input pipeline 10 and the first three-way transfer valve 1 into the 2 o 5 -MoO 3 / TiO 2 ) in the reactor, the denitrification reaction occurs, and the flue gas after denitrification is passed into the second three-way transfer valve 3, and the flue gas discharge pipeline 30 is used to achieve standard discharge.

[0074] SCR catalyst denitration reaction conditions: NH 3 / NO molar ratio 1.2, O 2 Concentration 8%, reaction temperature 380°C, gas space velocity 6000h -1 .

[0075] (2) SCR catalyst regeneration process

[0076] After the SCR catalyst is deactivated, it can be revived through the SCR catalyst regeneration process. The regeneration process is strictly operated according to the following process steps:

[0077] (I) Air purge

[0078] Same as Example 1, air purging time: 4h.

[0079] (II) pickling and alkali removal

[0080] Same as in Example 1, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com