Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150results about How to "Long term" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

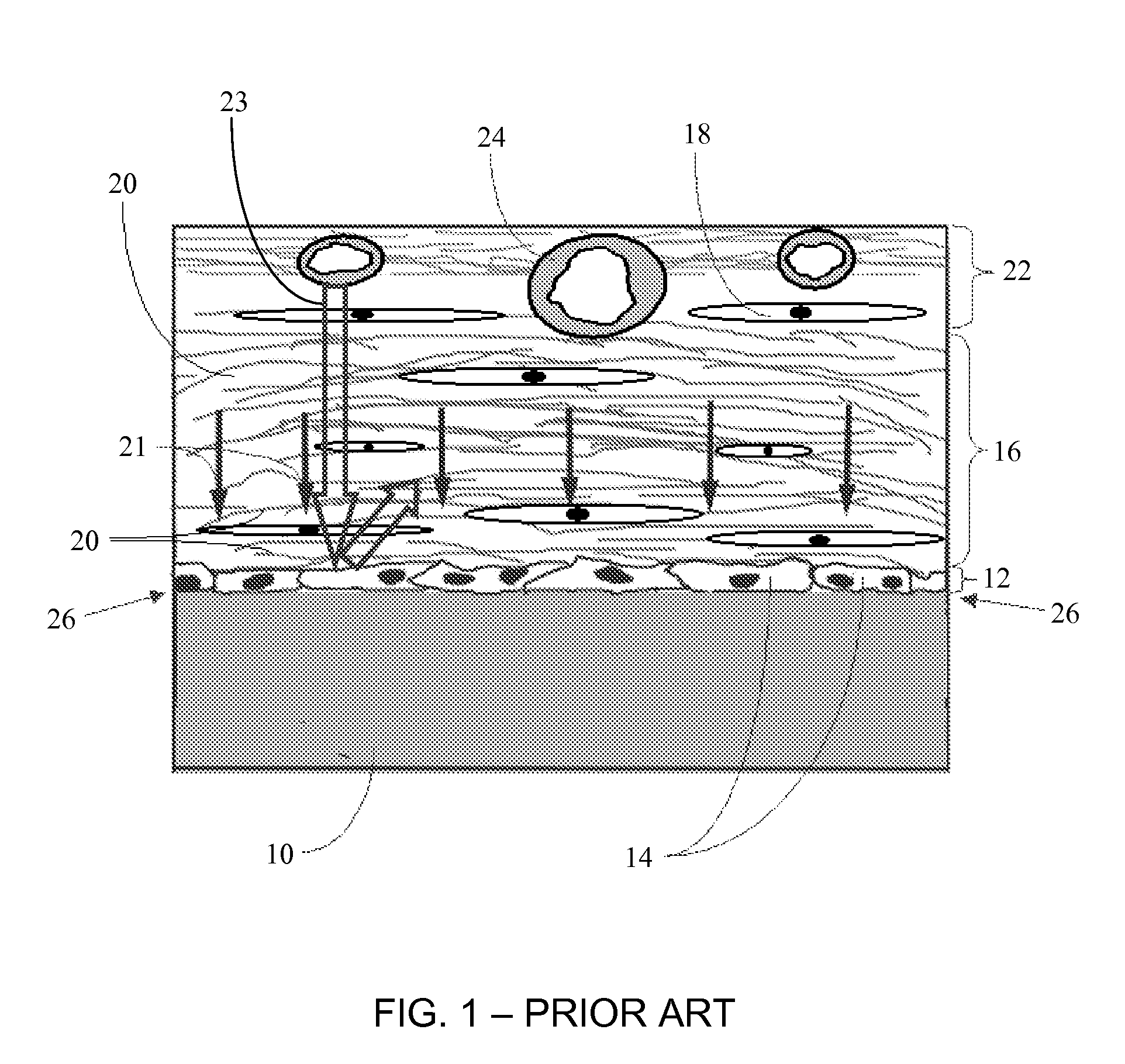

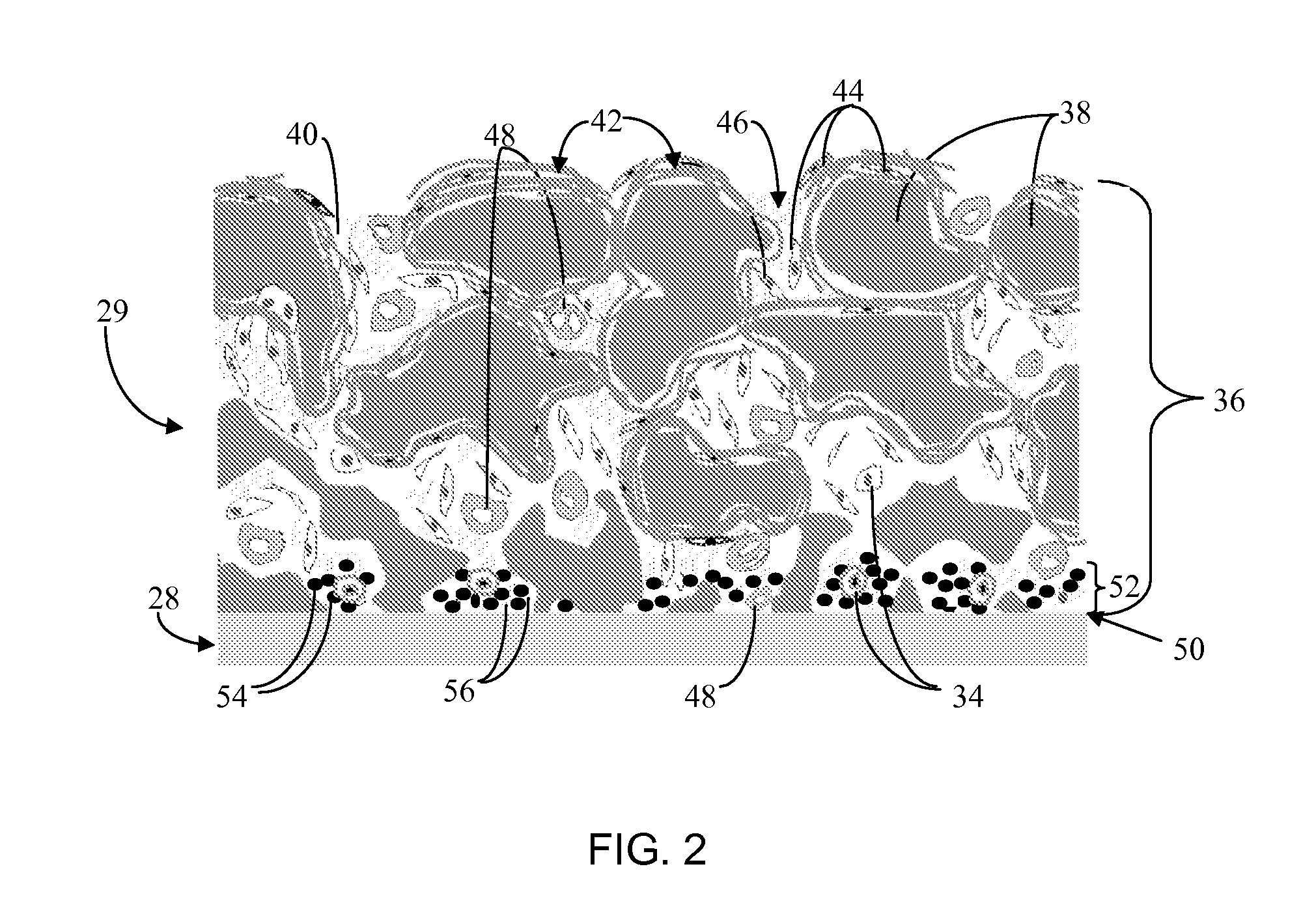

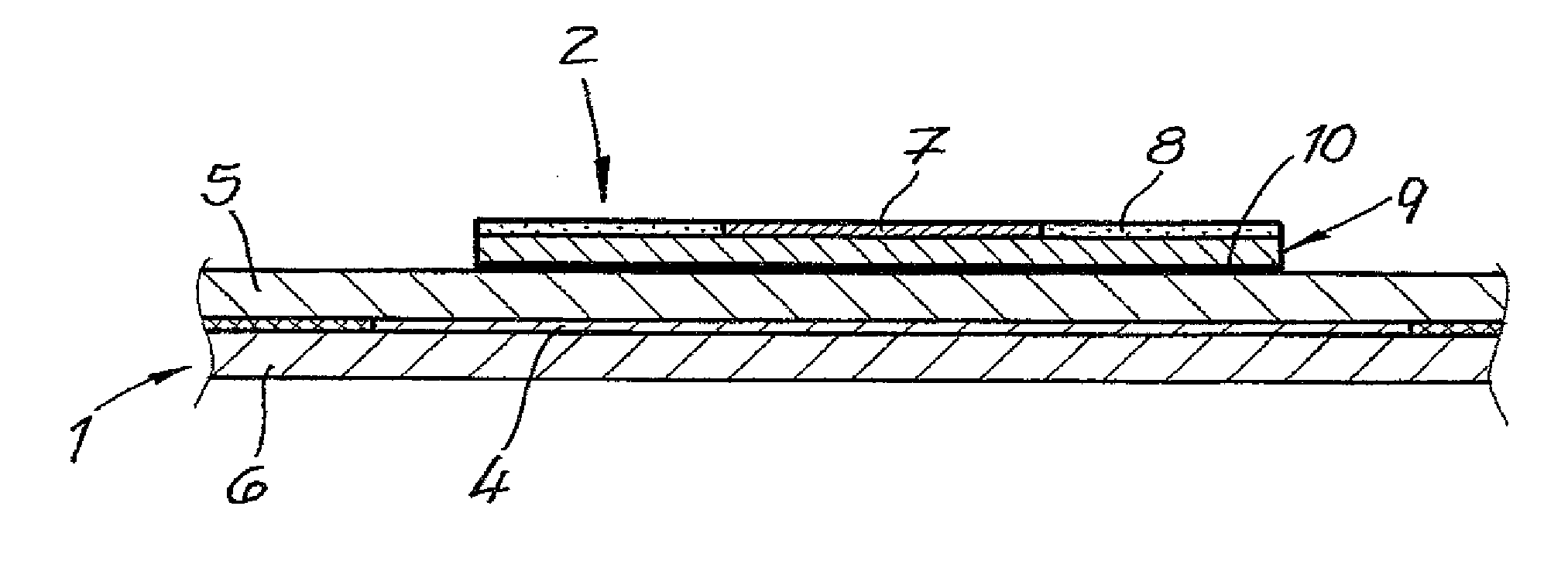

Biointerface membrane with macro-and micro-architecture

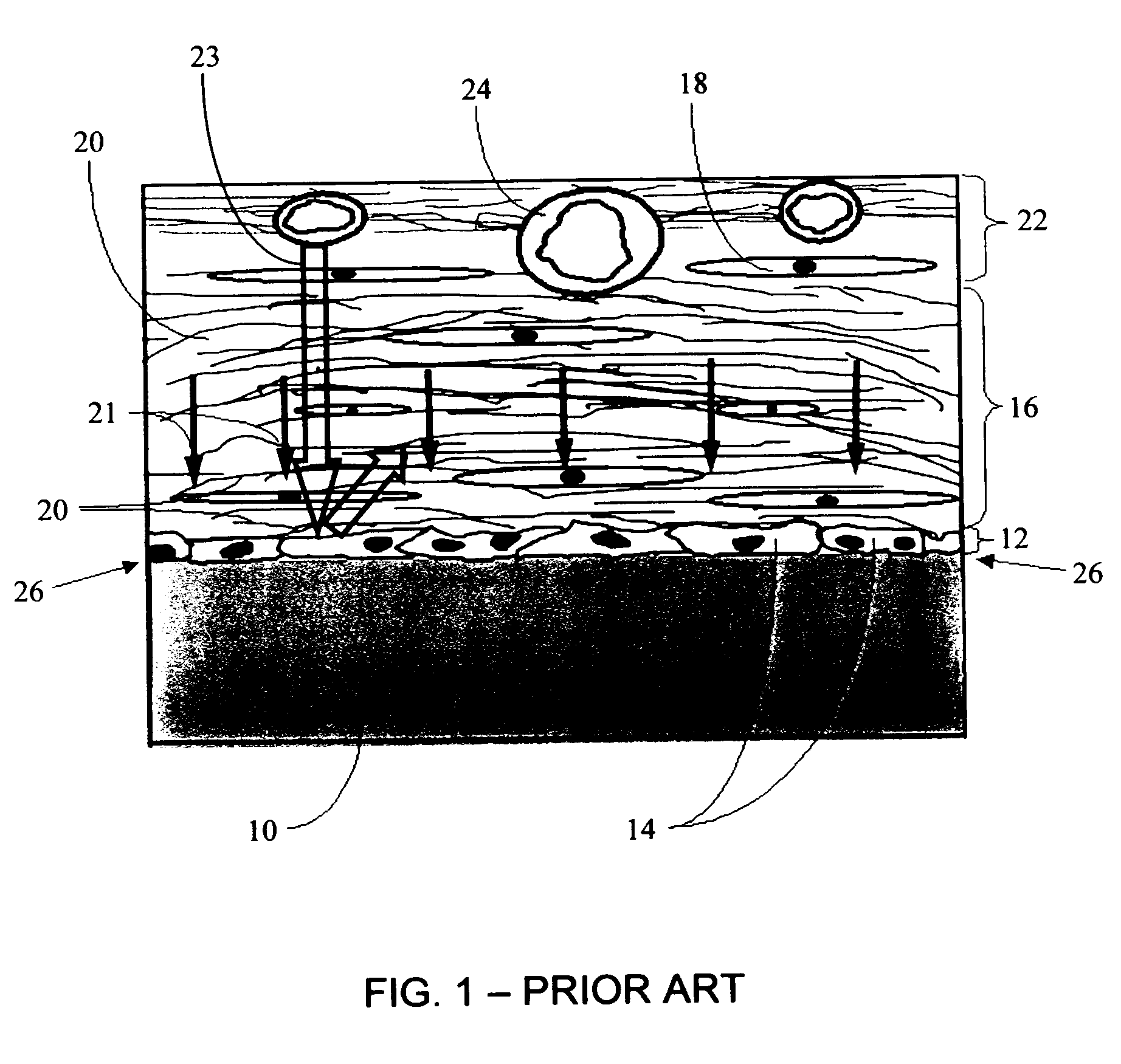

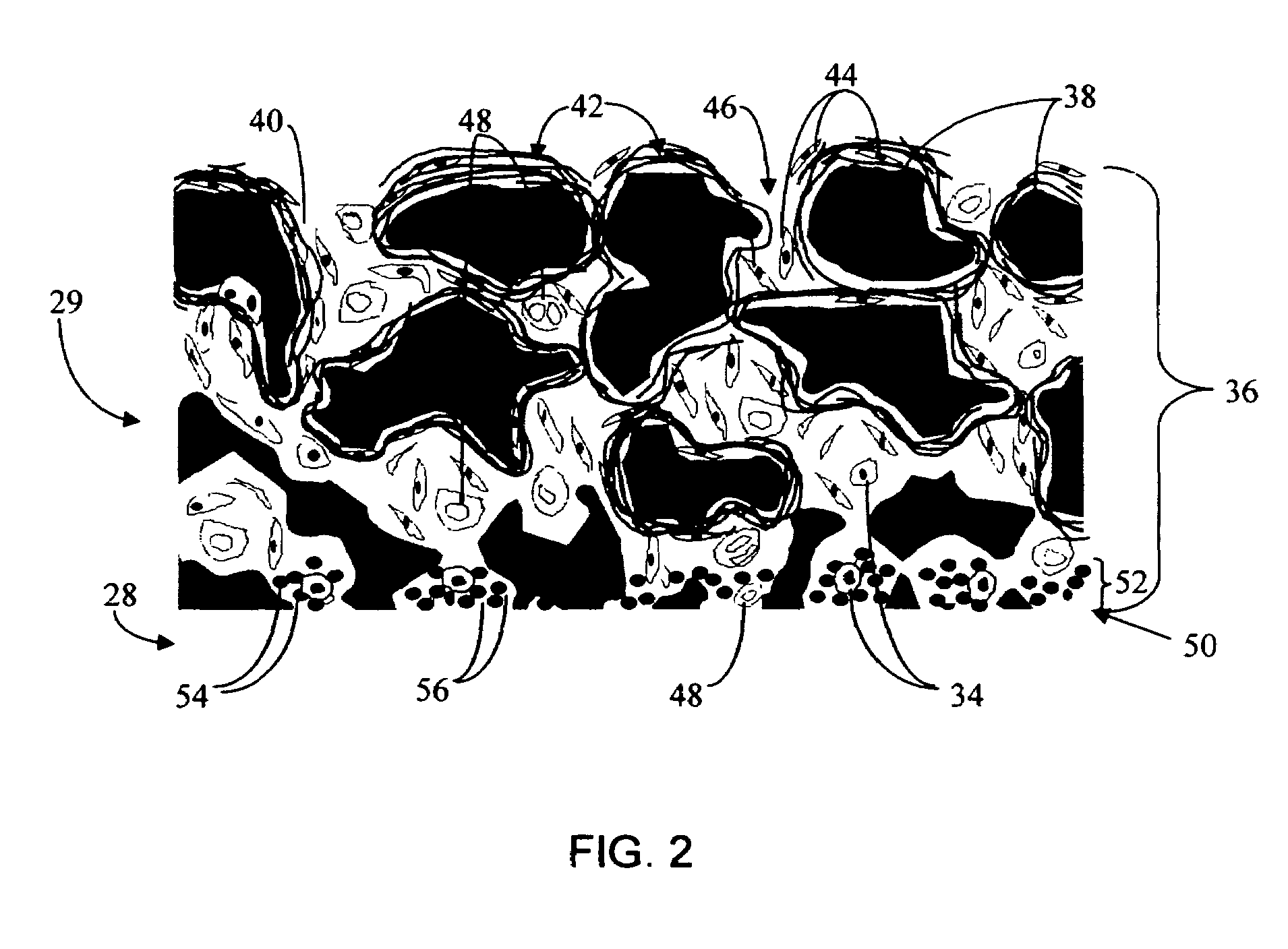

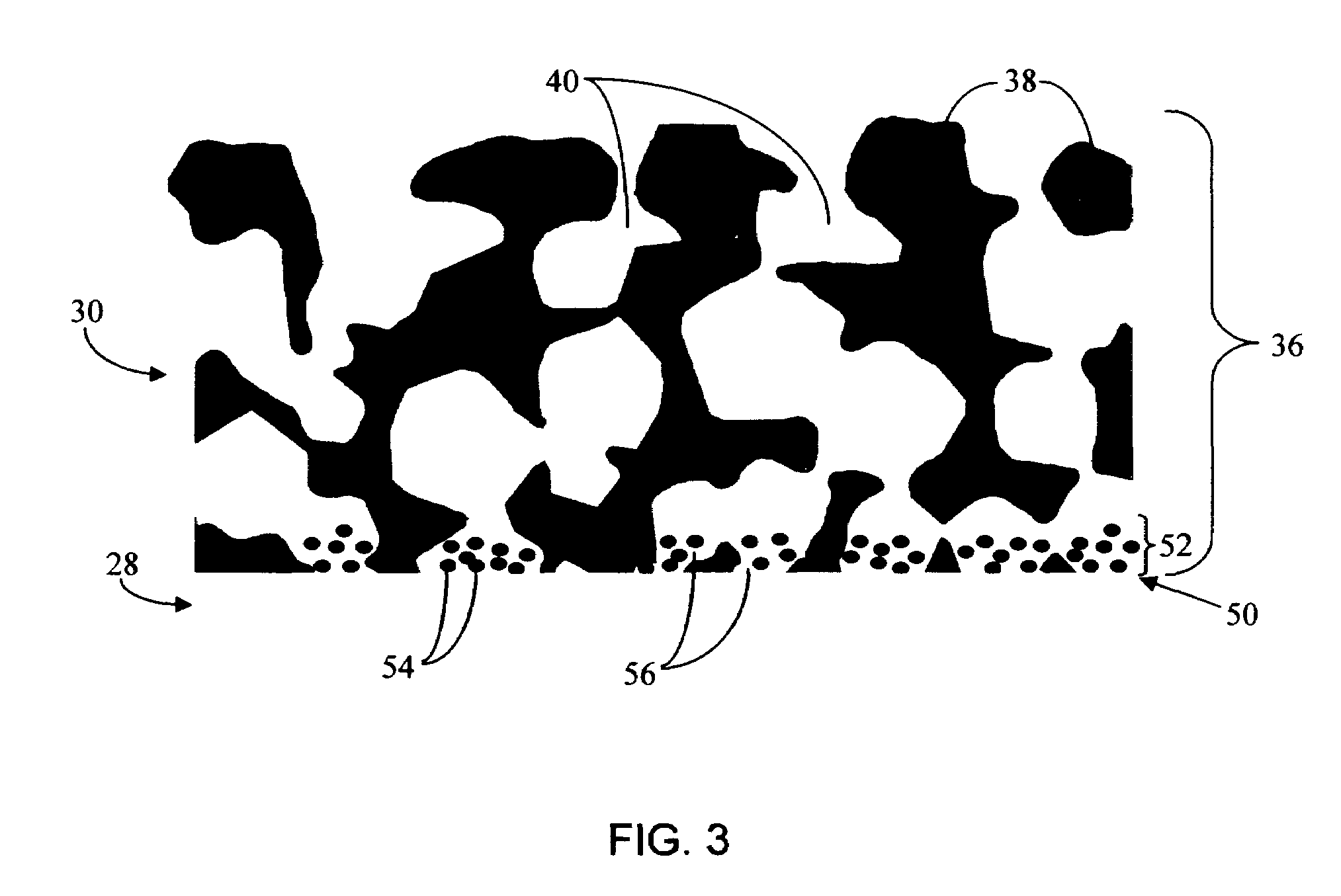

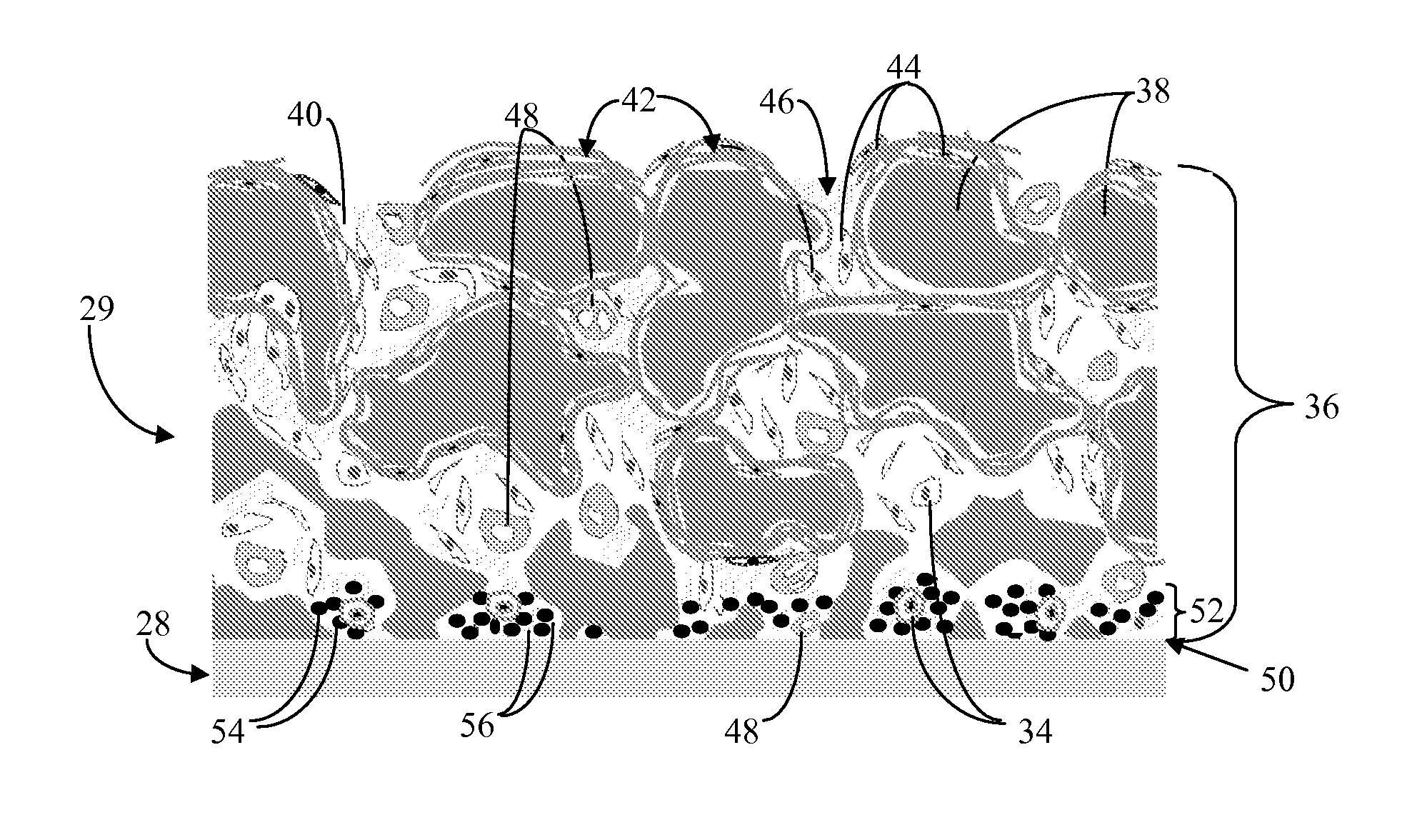

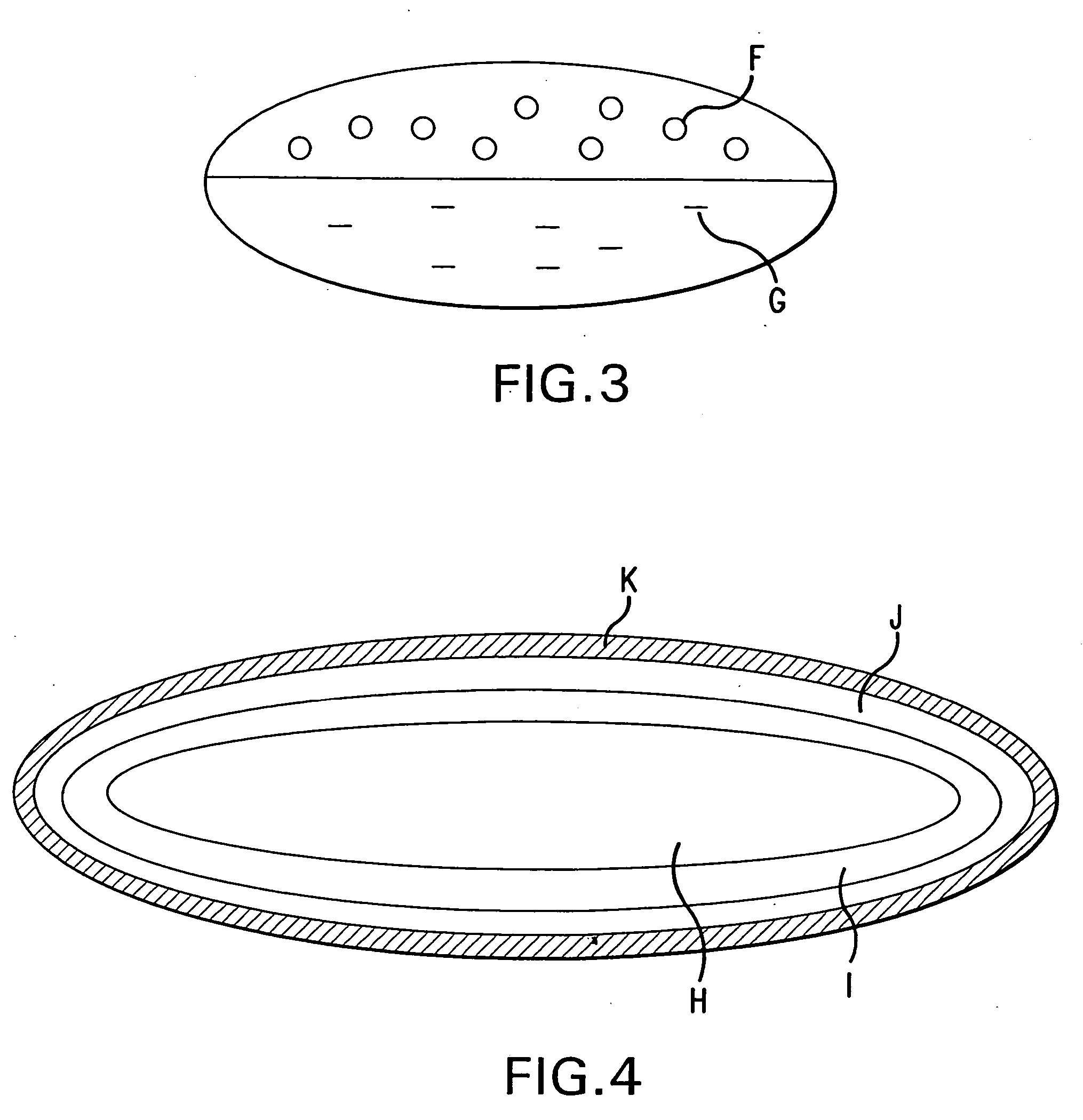

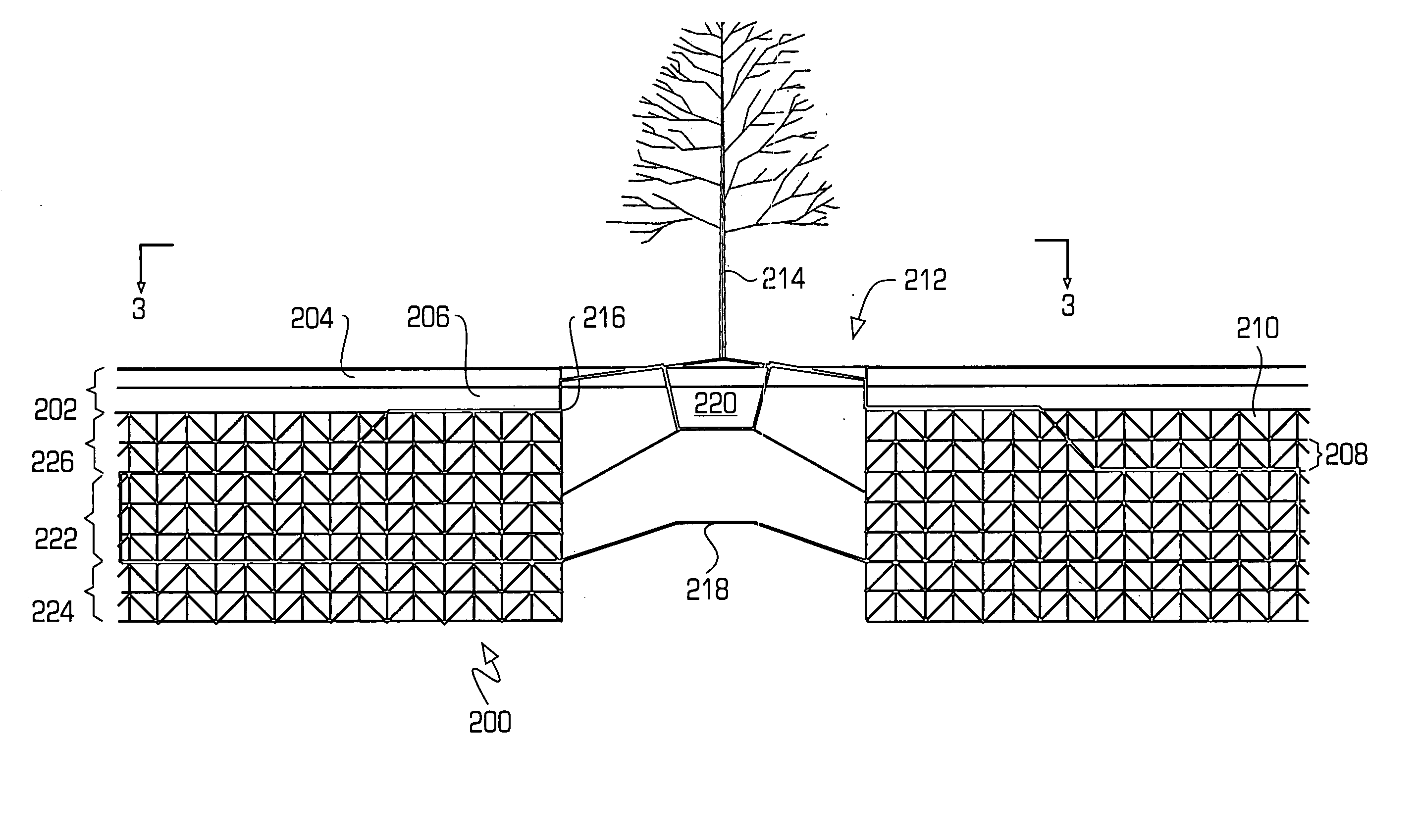

Disclosed herein are biointerface membranes including a macro-architecture and a micro-architecture co-continuous with and bonded to and / or located within at least a portion of the macro-architecture. The macro- and micro-architectures work together to manage and manipulate the high-level tissue organization and the low-level cellular organization of the foreign body response in vivo, thereby increasing neovascularization close to a device-tissue interface, interfering with barrier cell layer formation, and providing good tissue anchoring, while reducing the effects of motion artifact, and disrupting the organization and / or contracture of the FBC. The biointerface membranes of the preferred embodiments can be utilized with implantable devices such as devices for the detection of analyte concentrations in a biological sample (for example, from a body), cell transplantation devices, drug delivery devices, electrical signal delivering or measuring devices, and / or combinations thereof.

Owner:DEXCOM

Biointerface with macro- and micro-architecture

Owner:DEXCOM INC

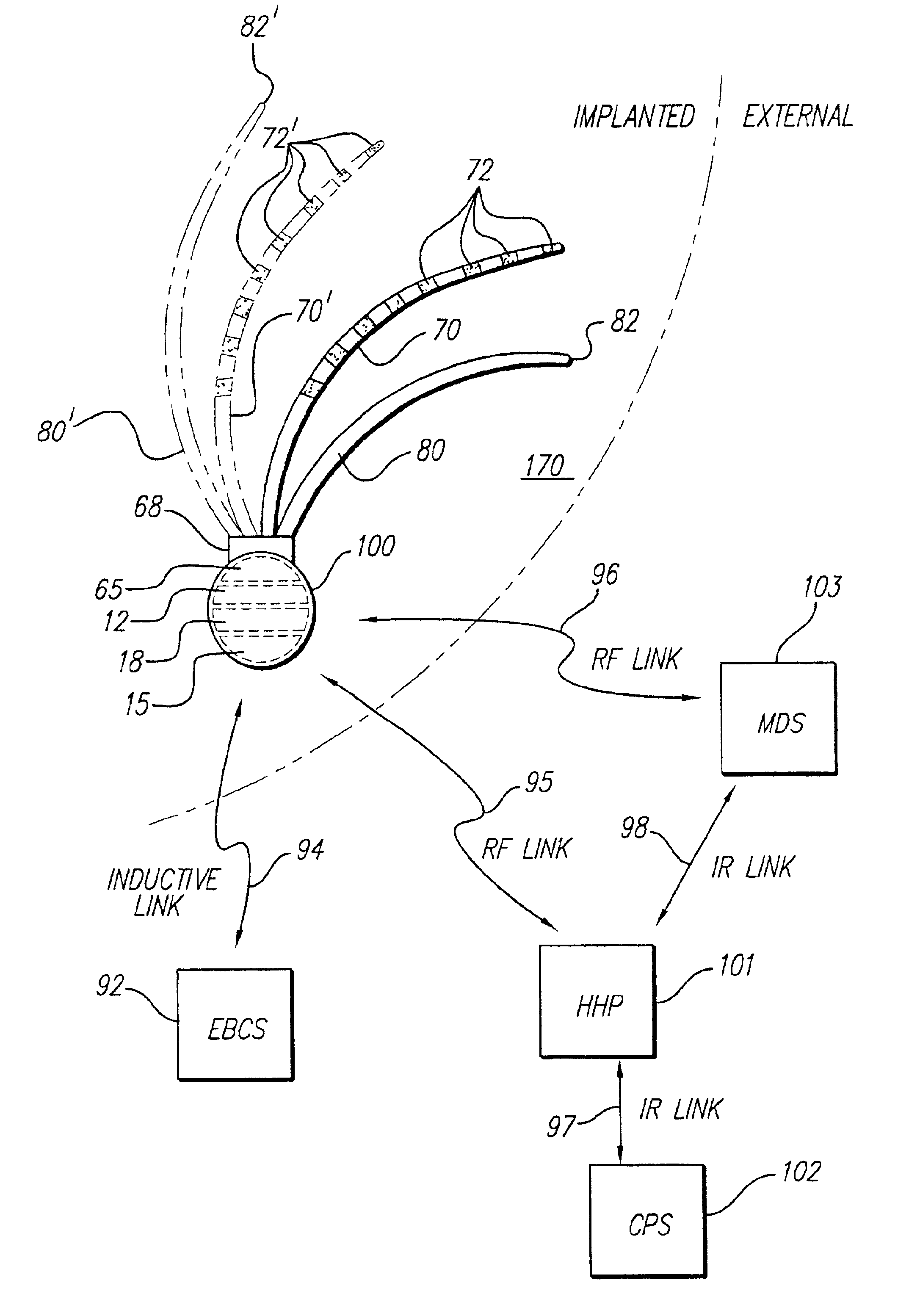

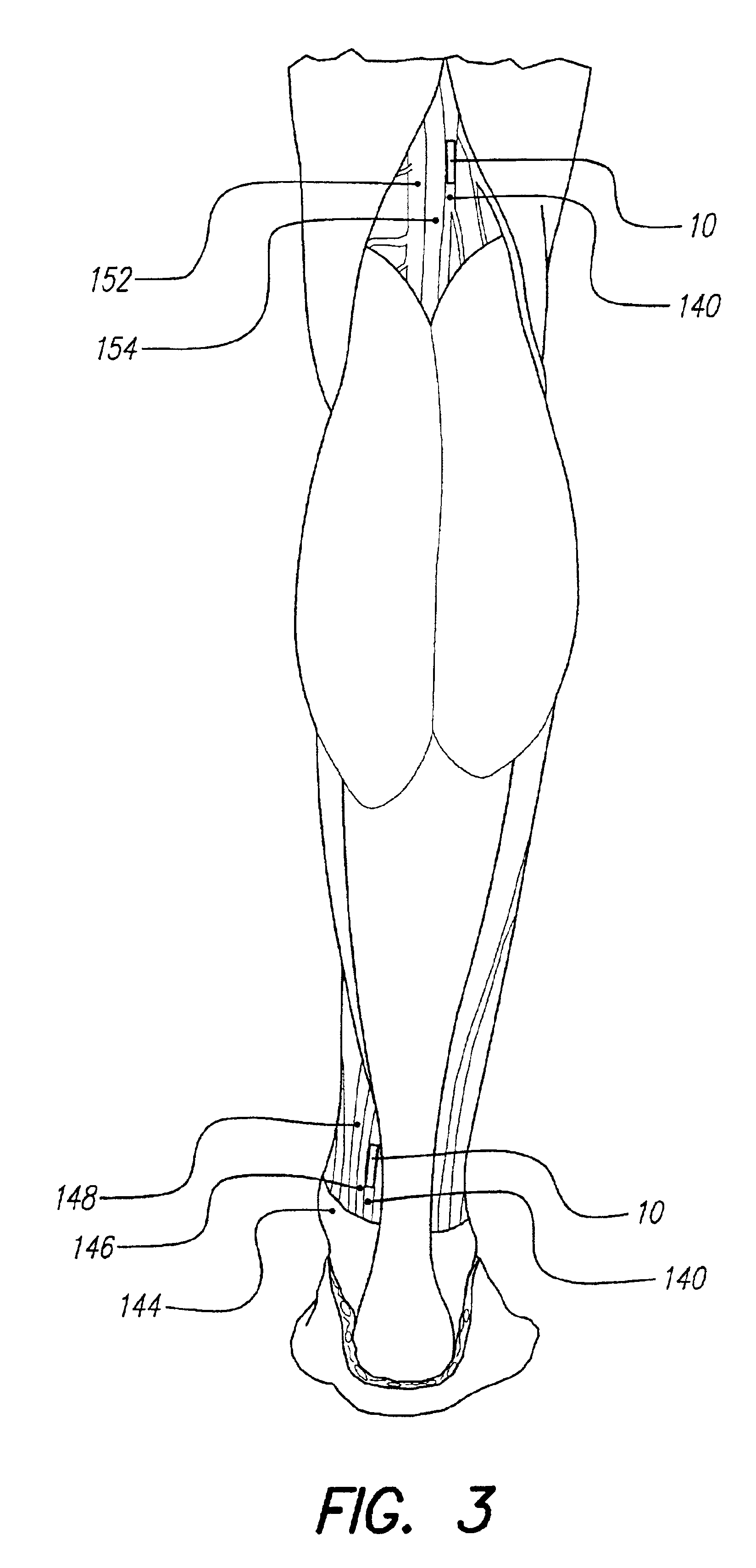

Implantable stimulator methods for treatment of incontinence and pain

InactiveUS6941171B2Improve closureReduce and eliminate incidenceElectrotherapyDiagnosticsBladder emptyingBladder outlet

A method and system for treatment of incontinence, urgency, frequency, and / or pelvic pain includes implantation of electrodes on a lead or the discharge portion of a catheter adjacent the perineal nerve(s) or tissue(s) to be stimulated. Stimulation pulses, either electrical or drug infusion pulses, are supplied by a stimulator implanted remotely, and through the lead or catheter, which is tunneled subcutaneously between the stimulator and stimulation site. For instance, the system and method reduce or eliminate the incidence of unintentional episodes of bladder emptying by stimulating nerve pathways that diminish involuntary bladder contractions, improve closure of the bladder outlet, and / or improve the long-term health of the urinary system by increasing bladder capacity and period between emptying. Moreover, the system and method allow a patient to be taught to receive one or more patterns of neural stimulation that can be prescribed by a physician and administered without continuous oversight by a clinical practitioner.

Owner:BOSTON SCI NEUROMODULATION CORP

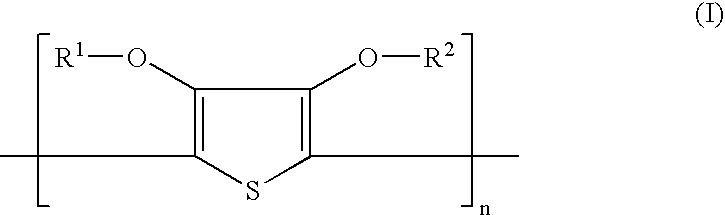

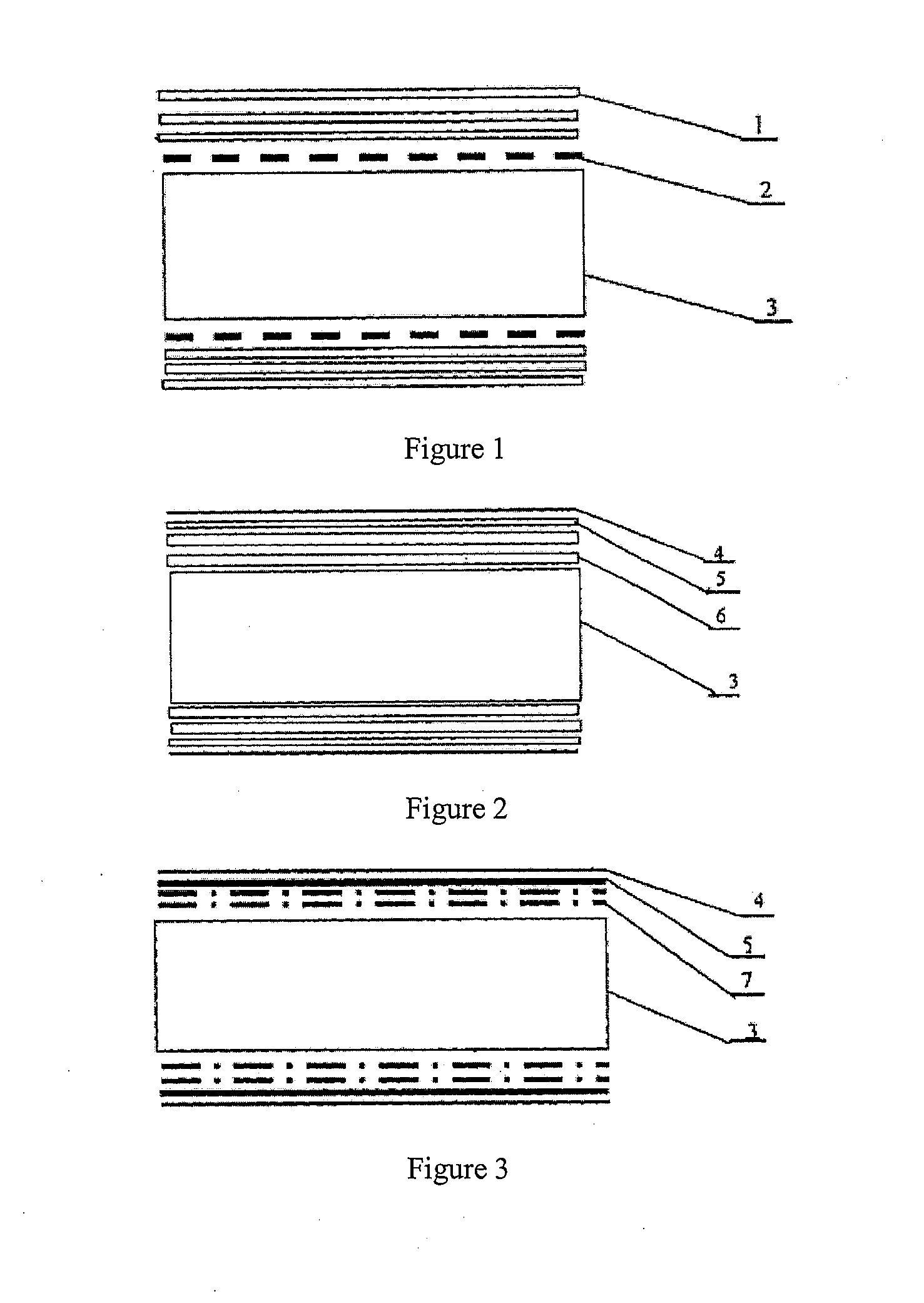

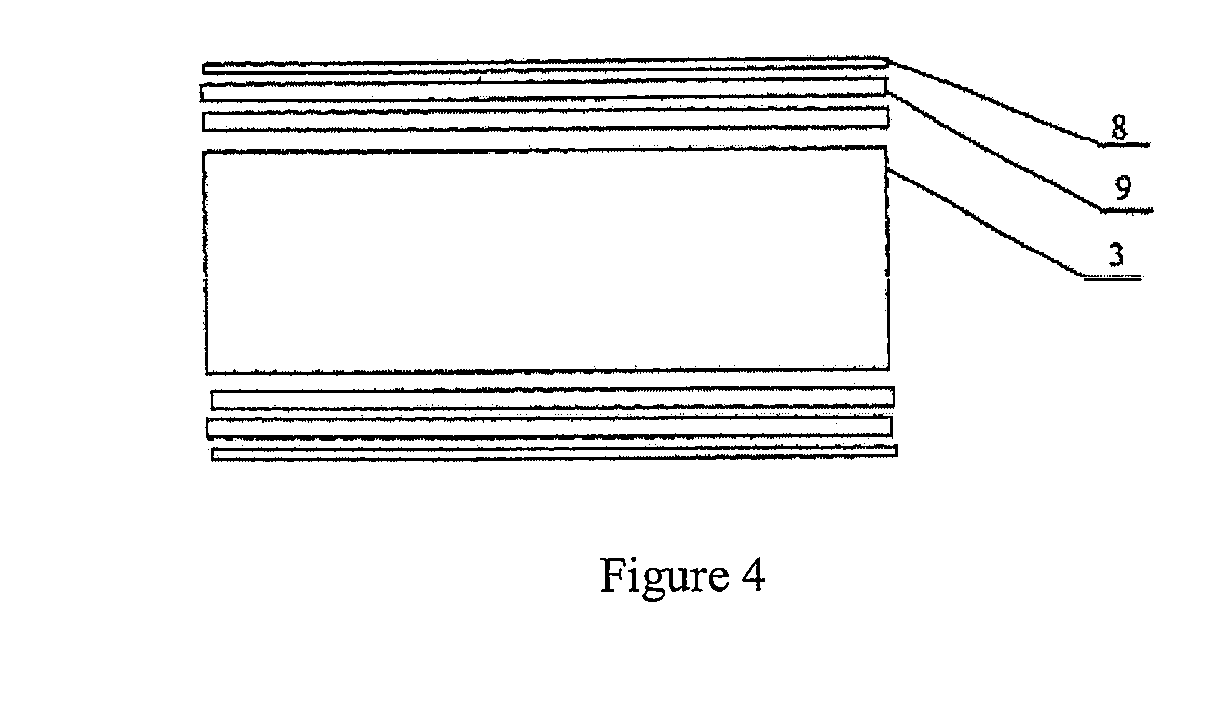

Process for preparing a substantially transparent conductive layer configuration

InactiveUS20040149962A1Improve flatnessPrevent ion migrationPhotosensitive materialsHybrid capacitor electrodesHydrogenConductive polymer

A substantially transparent conductive layer on a support, the layer comprising an intrinsically conductive polymer e.g. containing an intrinsically conductive polymer optionally containing structural units represented by formula (I): wherein n is larger than 1 and each of R<1 >and R<2 >independently represents hydrogen or an optionally substituted C1-4 alkyl group or together represent an optionally substituted C1-4 alkylene group or an optionally substituted cycloalkylene group, preferably an ethylene group, an optionally alkyl-substituted methylene group, an optionally C1-12 alkyl- or phenyl-substituted ethylene group, a 1,3-propylene group or a 1,2-cyclohexylene group; and a conductive metal non-uniformly distributed therein and forming of itself a conductive entity; a process for preparing the transparently conductive layer; and light emitting diodes, photovoltaic devices, transistors and electroluminescent devices comprising the above-described conductive layer.

Owner:AGFA GEVAERT AG

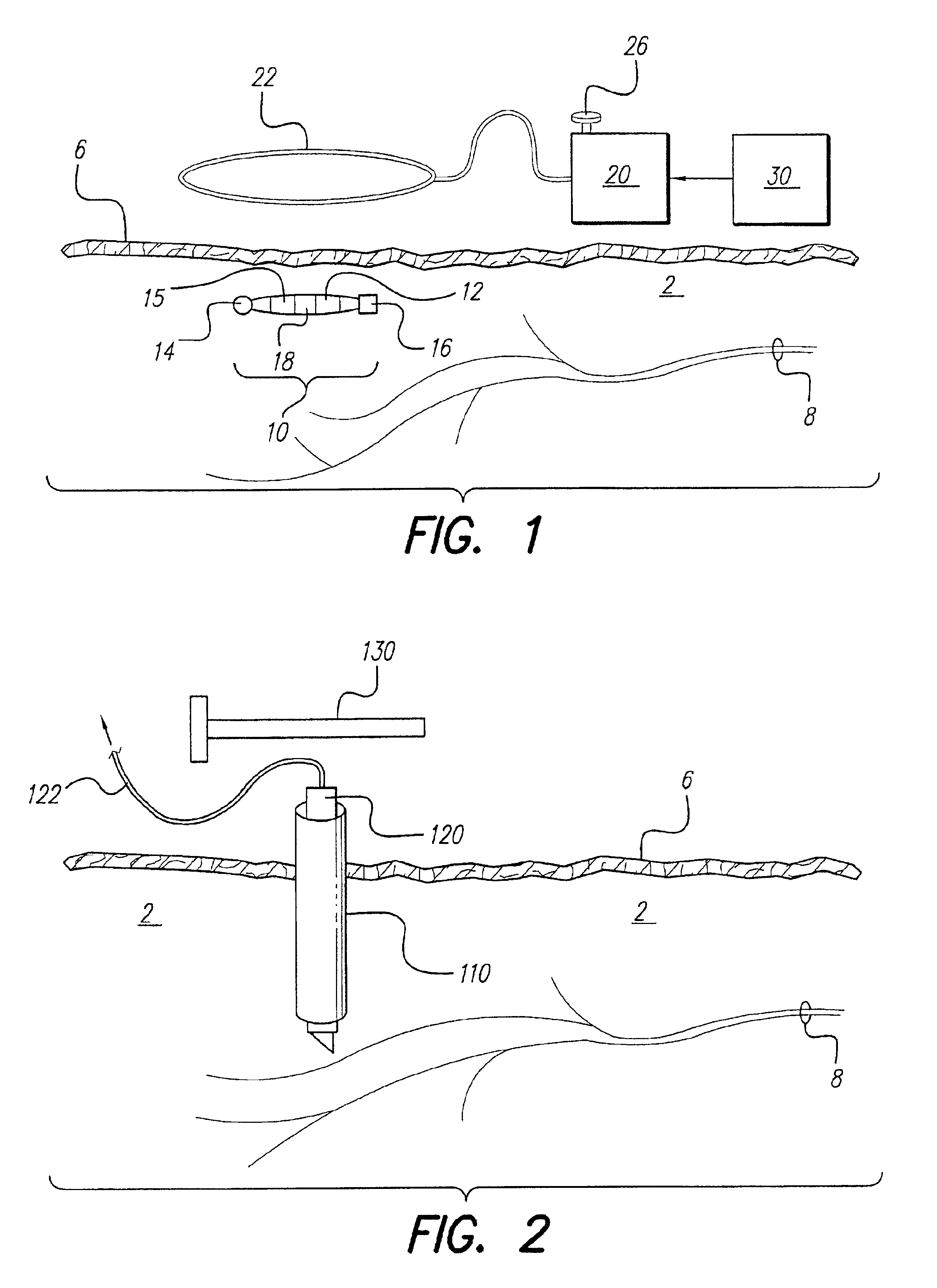

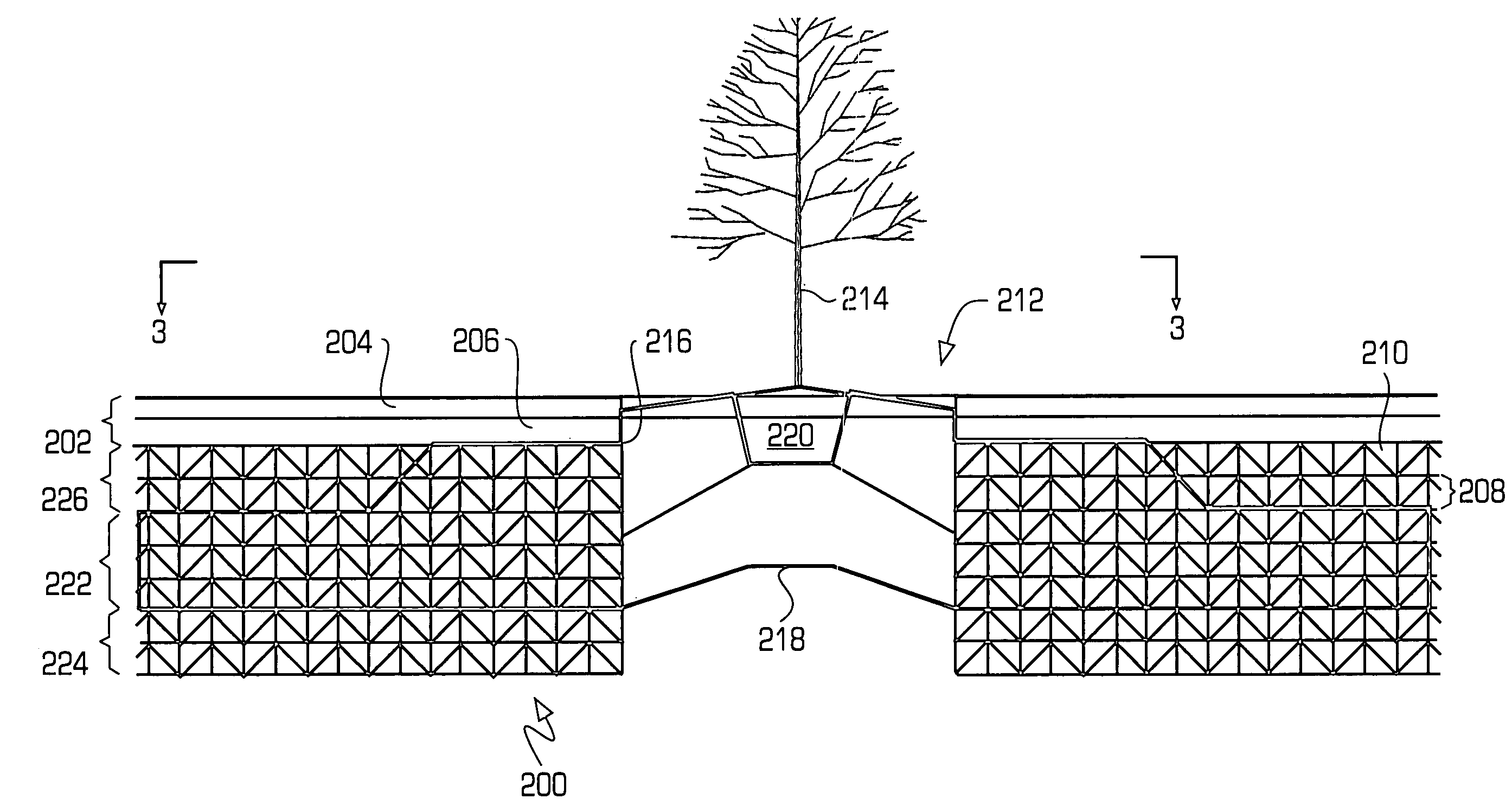

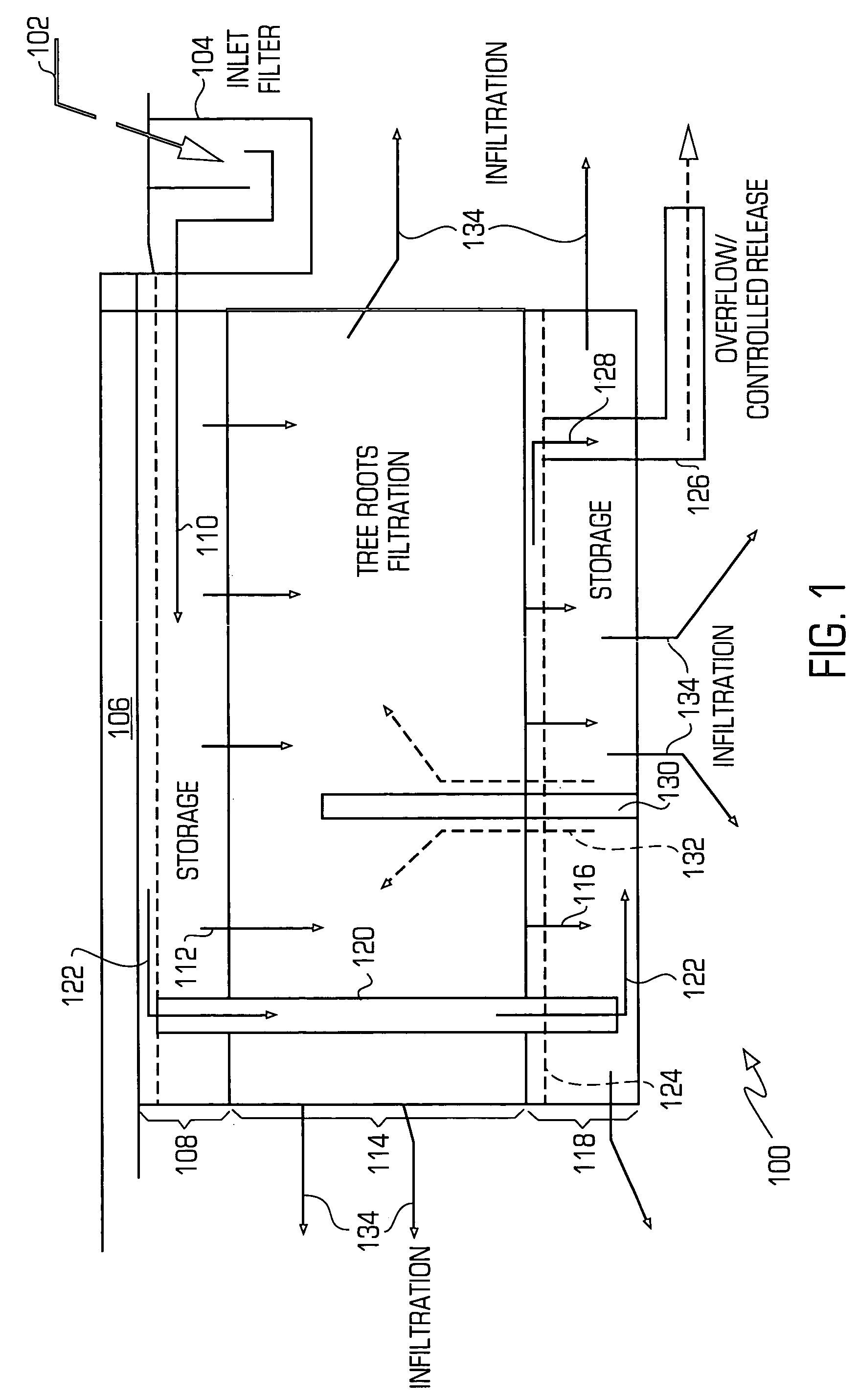

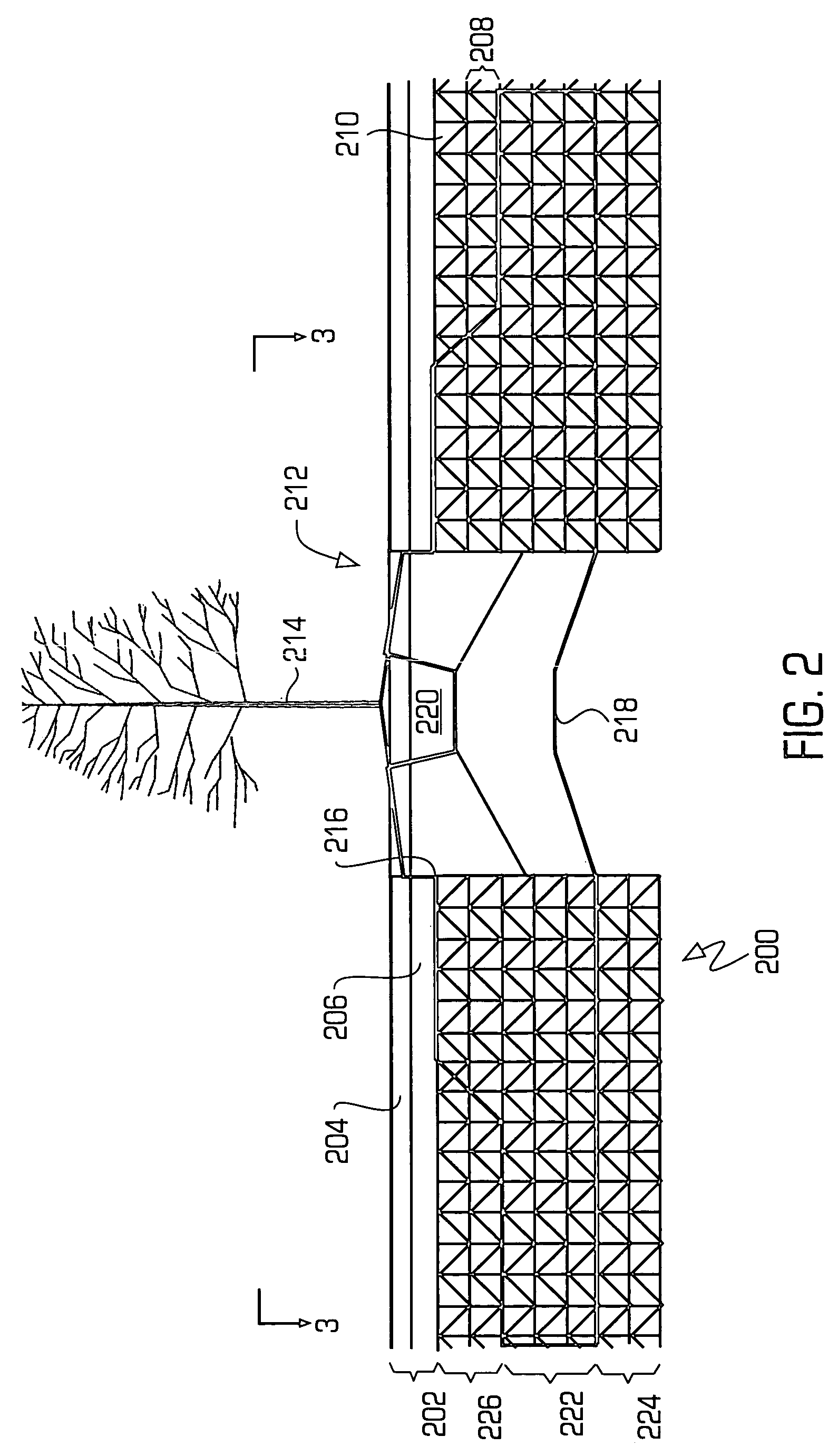

Integrated tree root and storm water system

Owner:DEEPROOT GREEN INFRASTRUCTURE

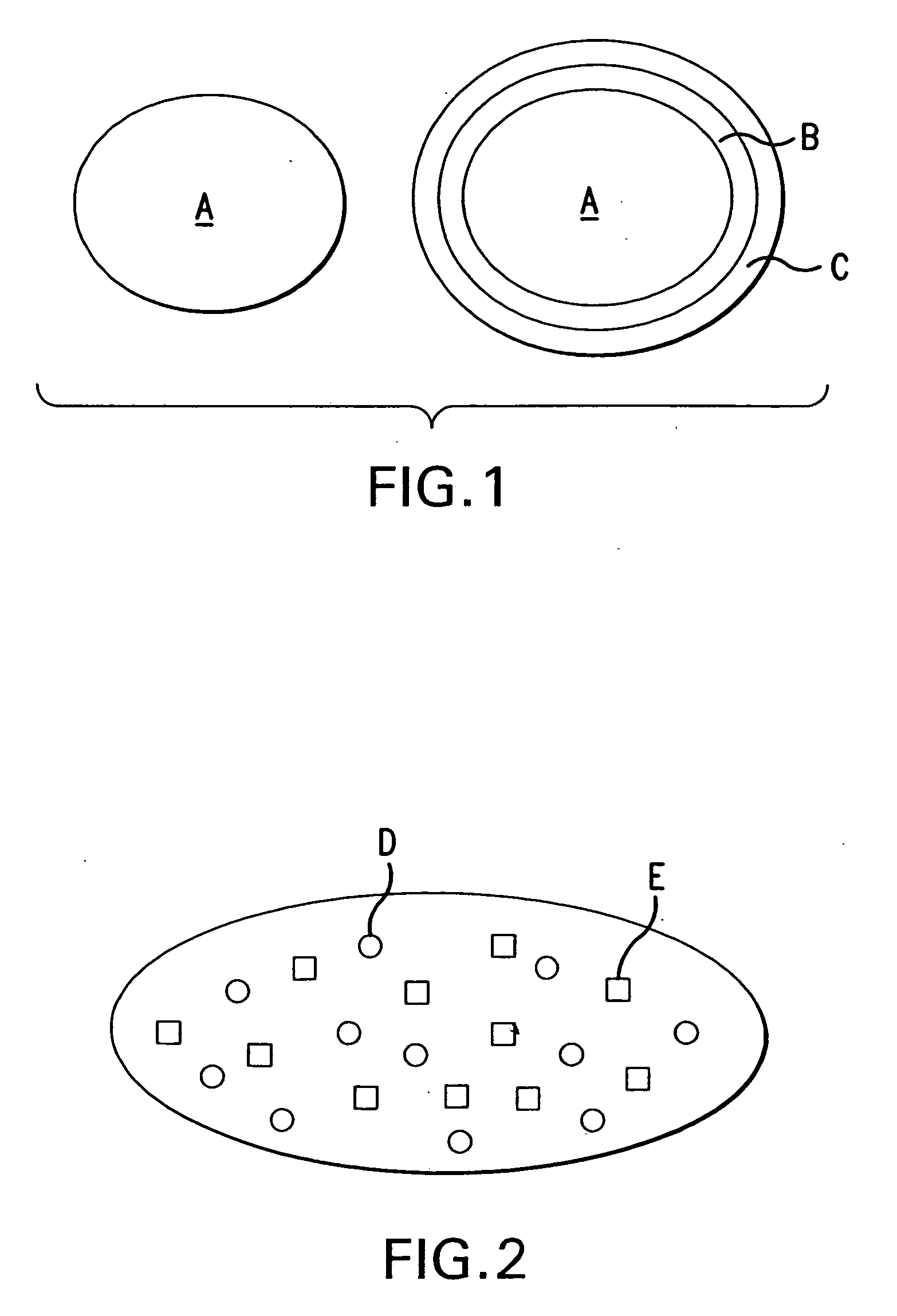

Dosage form for treating gastrointestinal disorders

InactiveUS20060165797A1Quick reliefPrevent relapseBiocideDigestive systemGastrointestinal disorderSecreted substance

The present invention is directed to drug dosage forms that can be used to treat diseases characterized by abnormal gastric acid secretion. The dosage forms have a core containing a proton pump inhibitor surrounded by an enteric coating or multiple particles containing proton pump inhibitor, each particle being surrounded by an enteric coating. The enteric coating delays the release of drug until the surrounding pH has risen. The tablets also include an outer coating that contains either a proton pump inhibitor or an H2 blocker. The outer coating is designed to rapidly dissolve in a patient's stomach.

Owner:POZEN INC

Integrated tree root and storm water system

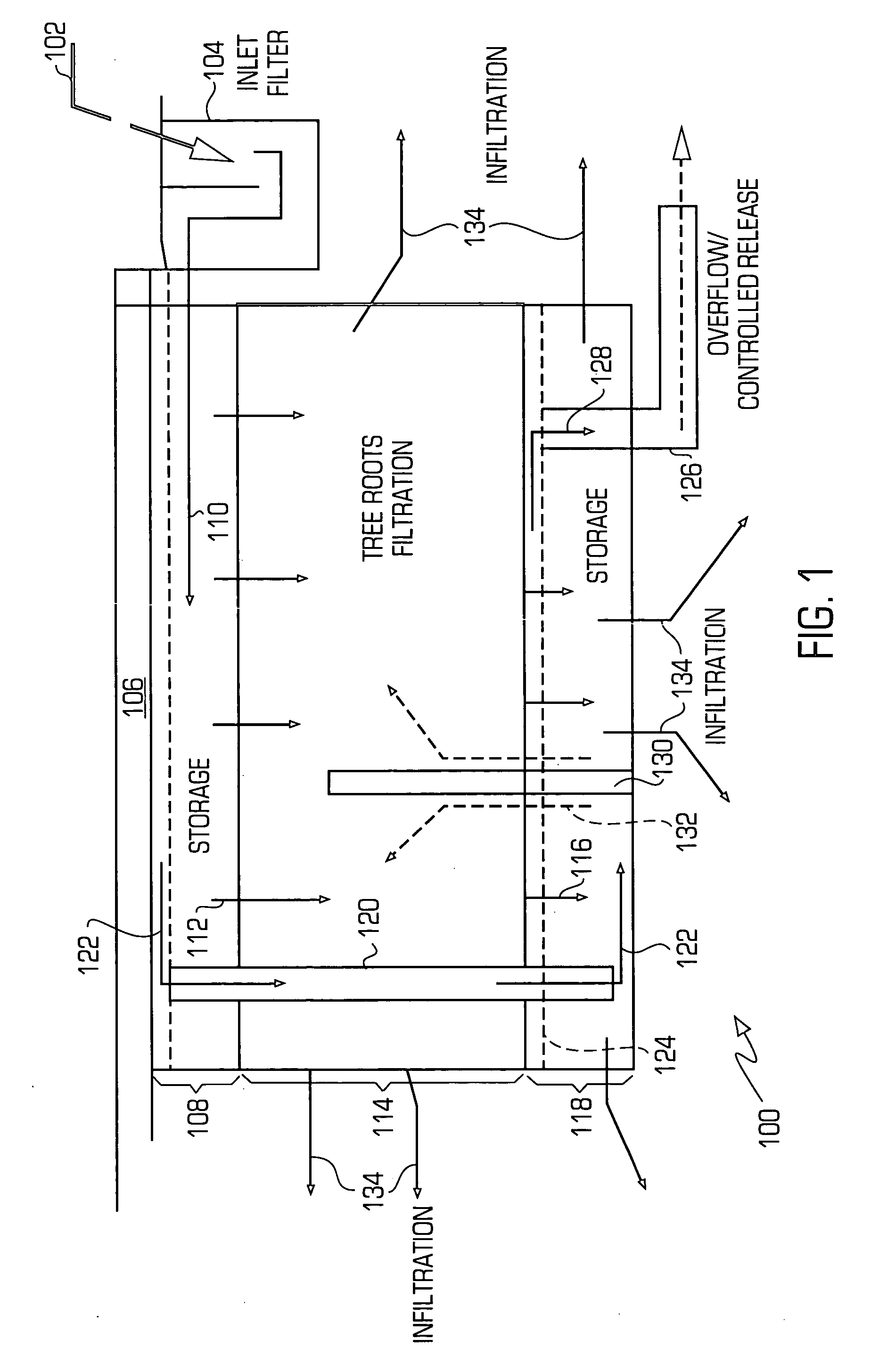

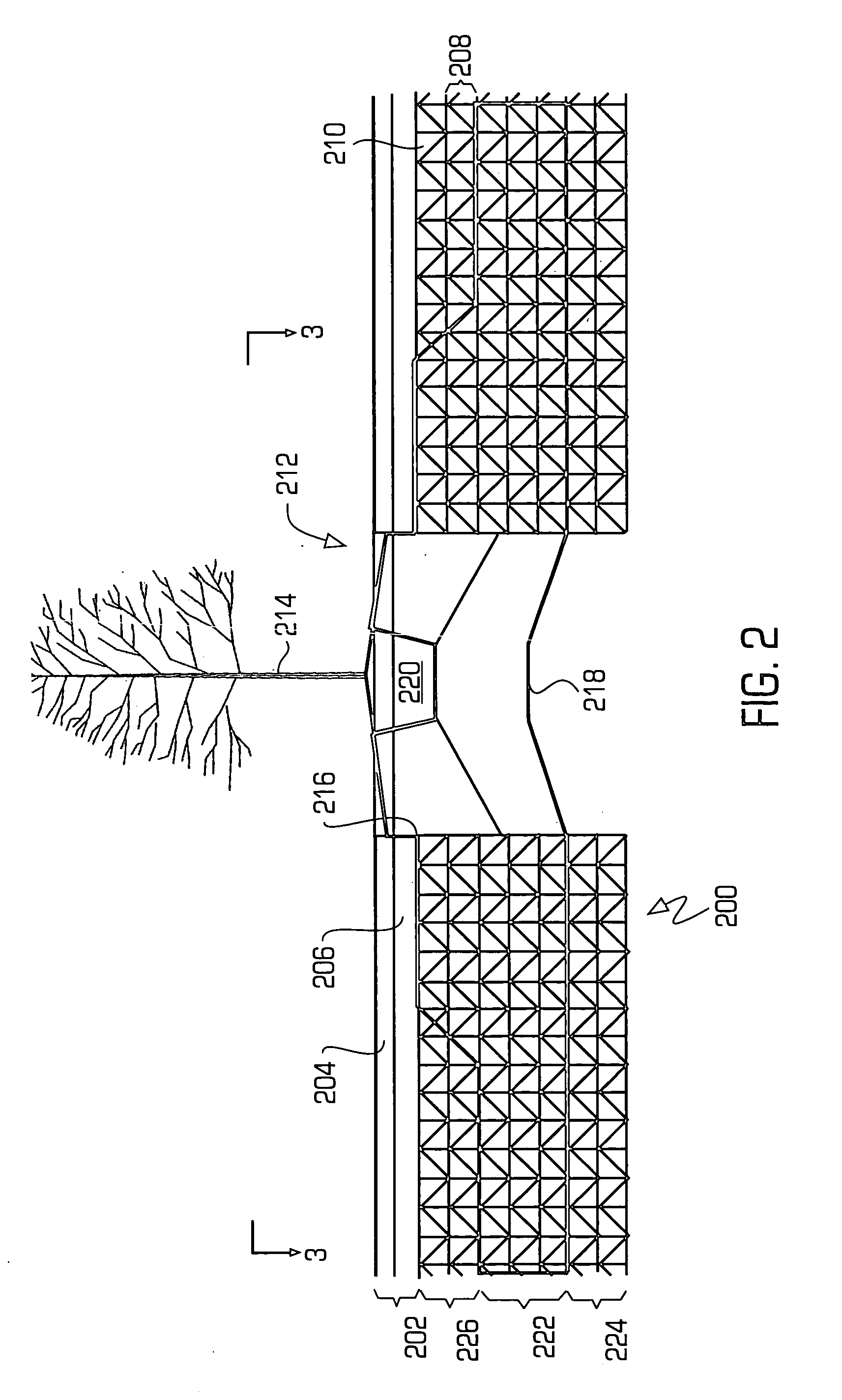

A structural cell system is disclosed for supporting hardscape areas in a way that enables tree root growth and accommodates filtering, retention, storage and infiltration of storm water while preventing hardscape damage. The system includes a plurality of structural cells capable of being positioned below a hardscape. The structural cells are designed to have openings that are sized to accept tree roots. The system has one or more permeable barriers around the structural cells with a way for water to flow into the plurality of structural cells flow out of the structural cells.

Owner:DEEPROOT GREEN INFRASTRUCTURE

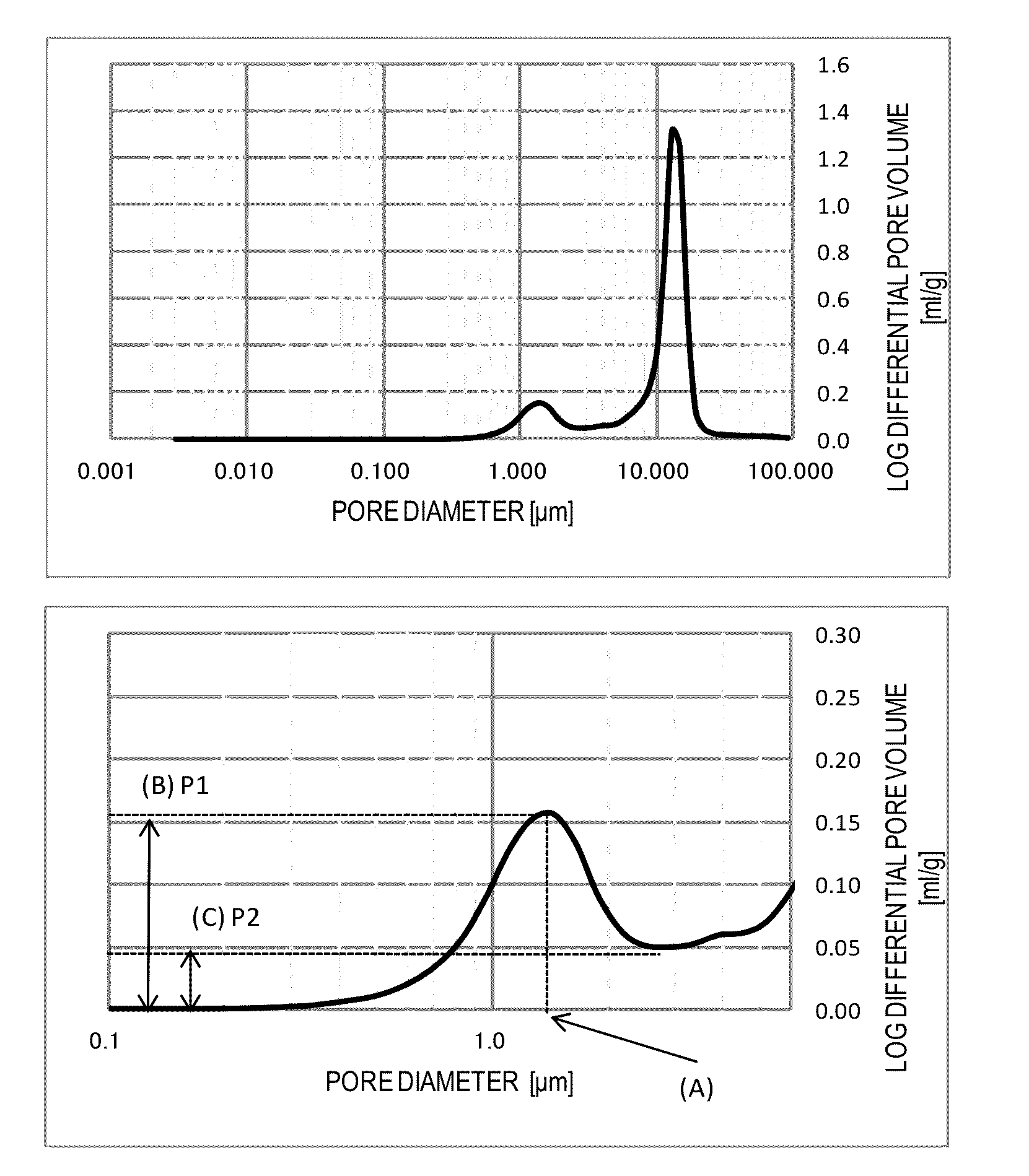

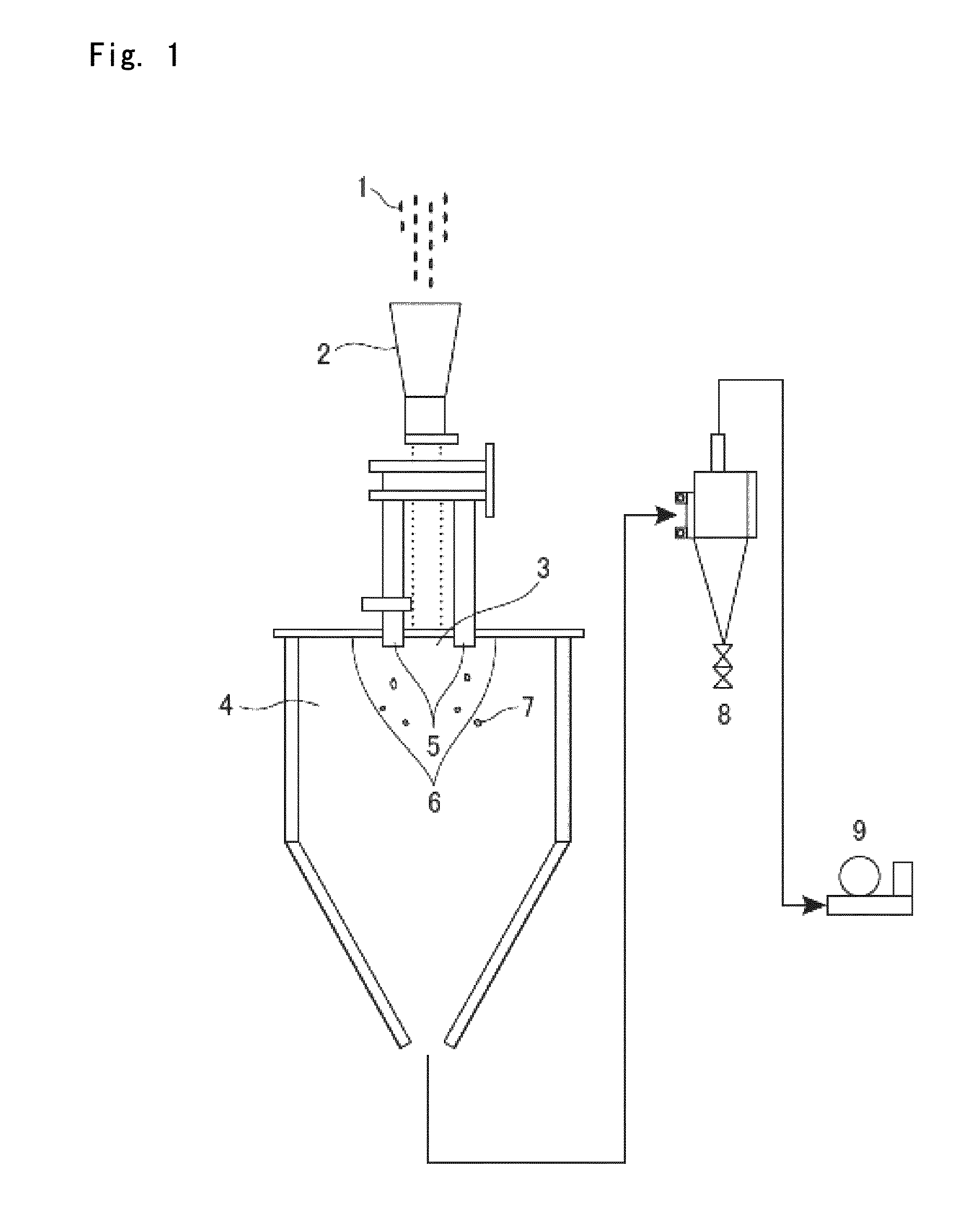

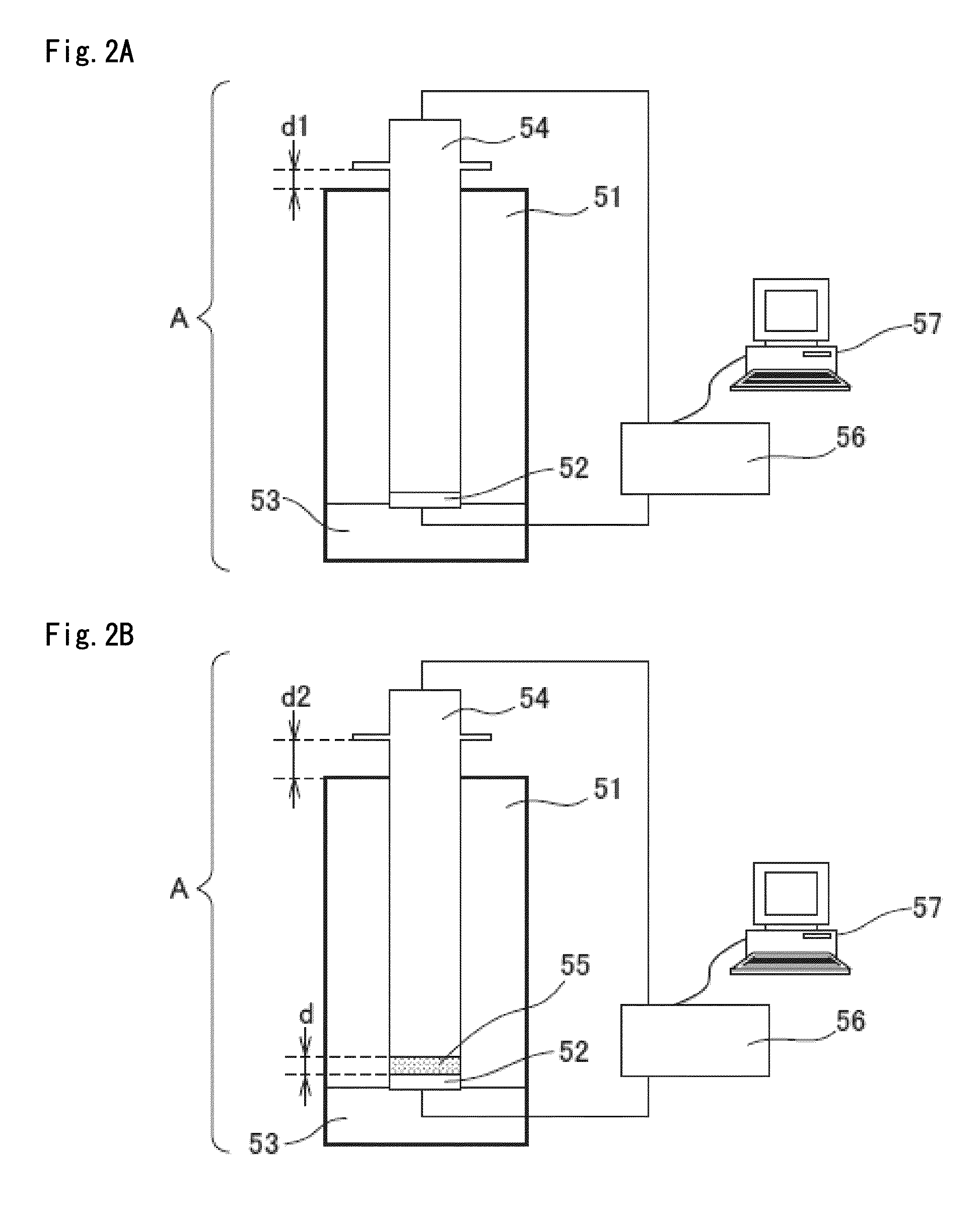

Magnetic carrier and two-component developer

ActiveUS9058924B2Improve charging effectAvoid it happening againInorganic material magnetismDevelopersPore diameterMetal

A magnetic carrier having a resin-containing ferrite particles each containing a porous ferrite core and a resin in pores of the porous ferrite core, wherein the porous ferrite core has a particular pore diameter corresponding to the maximum logarithmic differential pore volume in a pore diameter range from at least 0.10 μm to not more than 3.00 μm, the resistivity of the porous ferrite core is in a particular range, and the porous ferrite core contains an oxide of Mg in a particular amount and contains a particular amount of a oxide of at least one metal selected from the group consisting of Mn, Sr, and Ca.

Owner:CANON KK

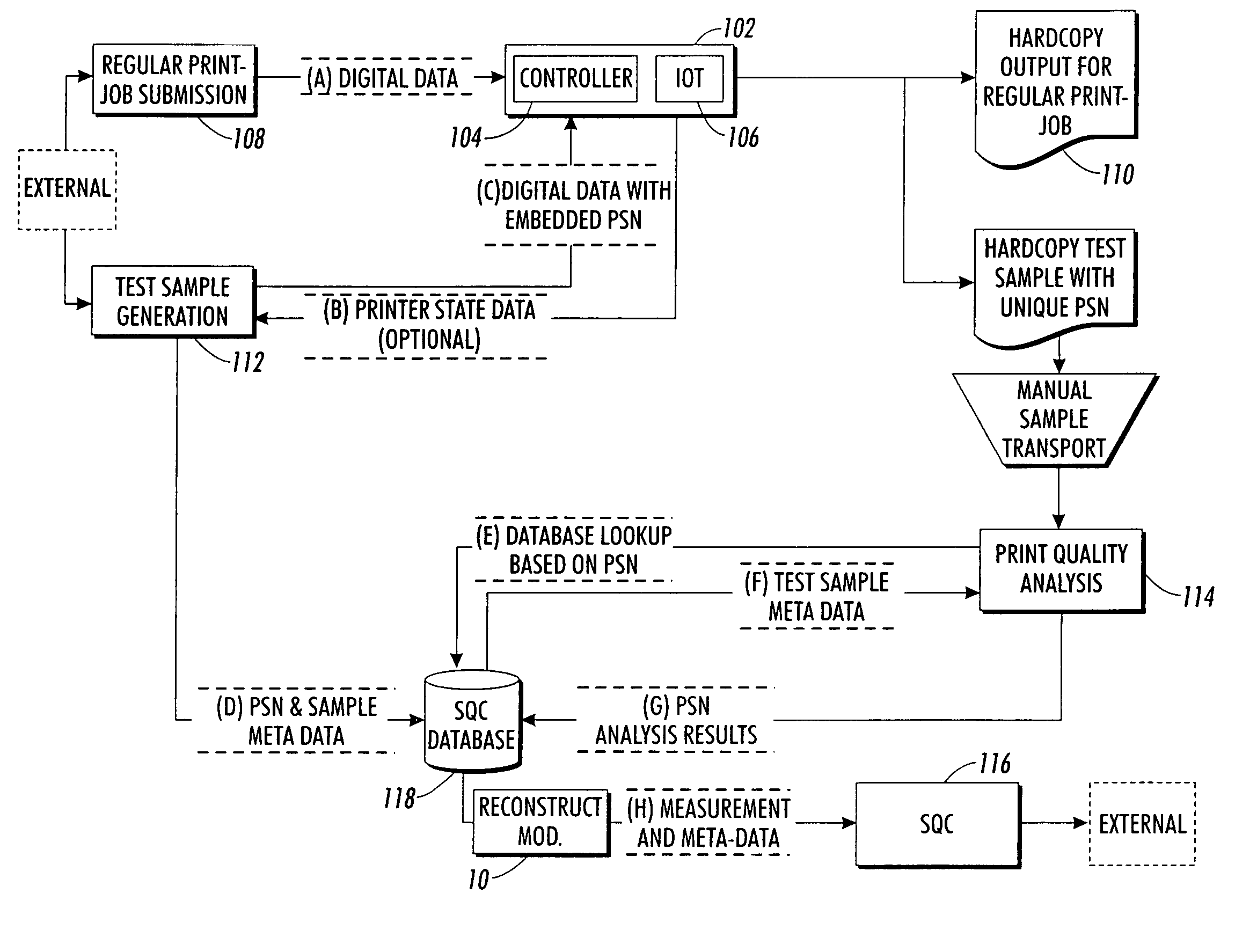

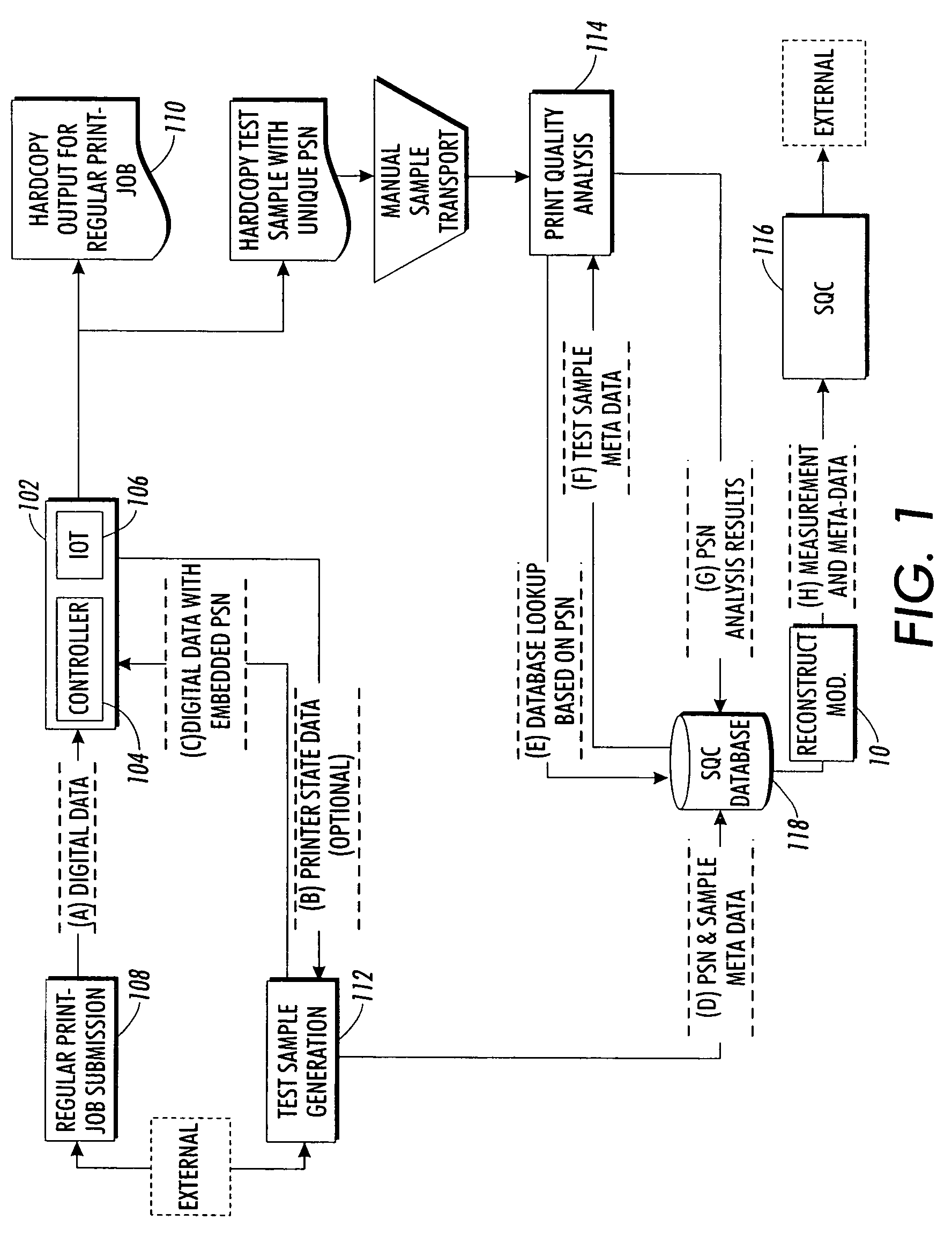

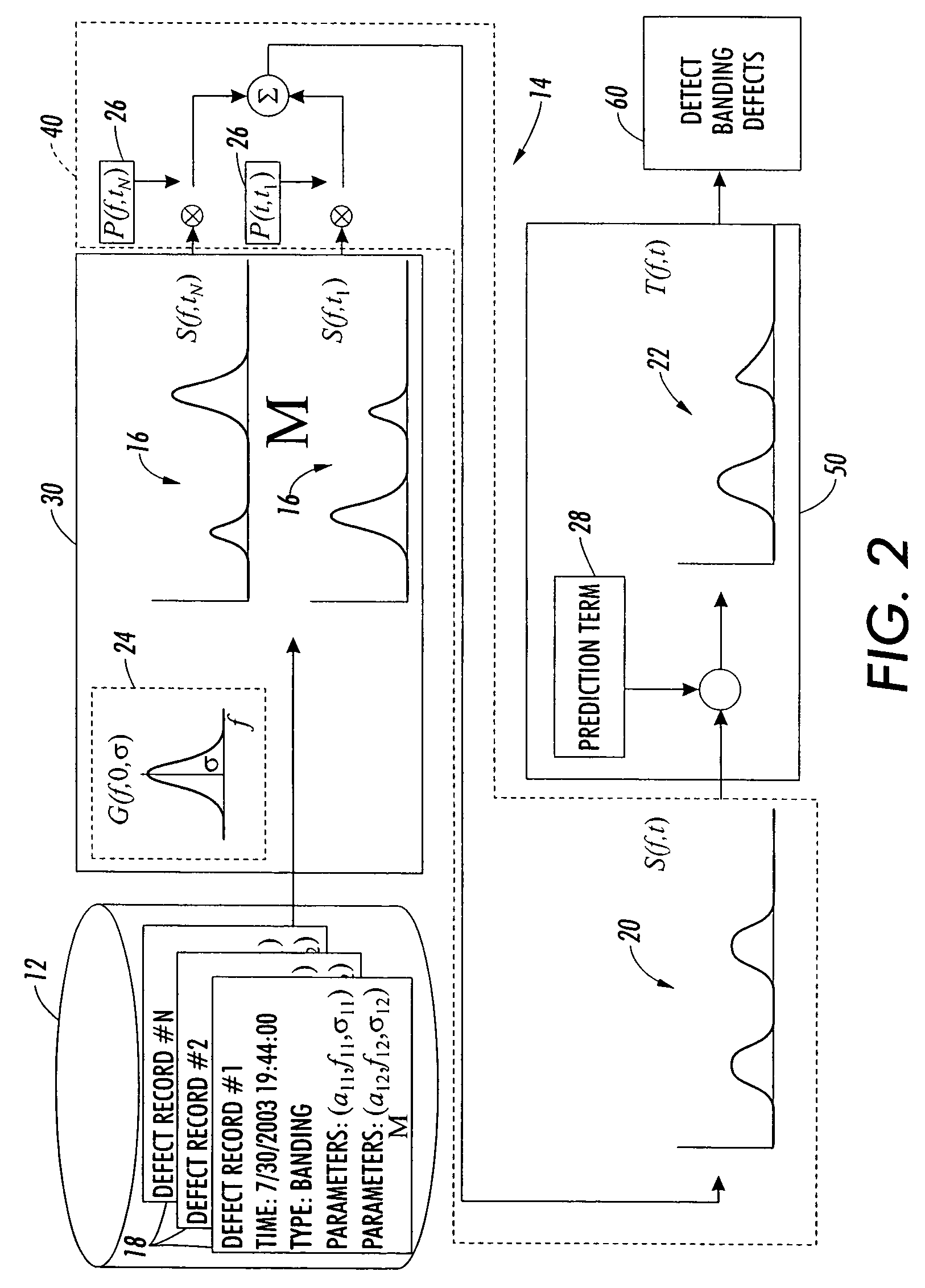

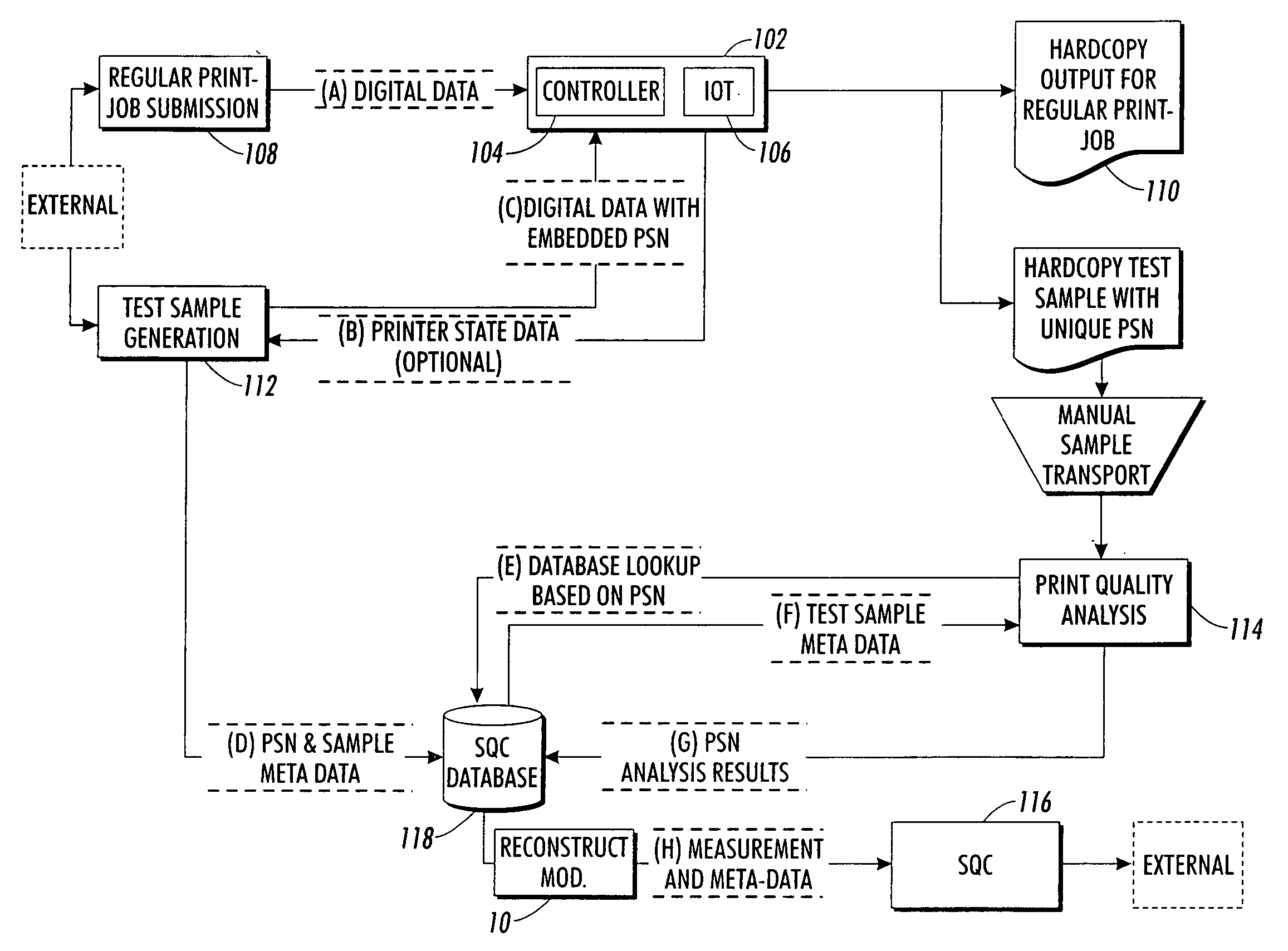

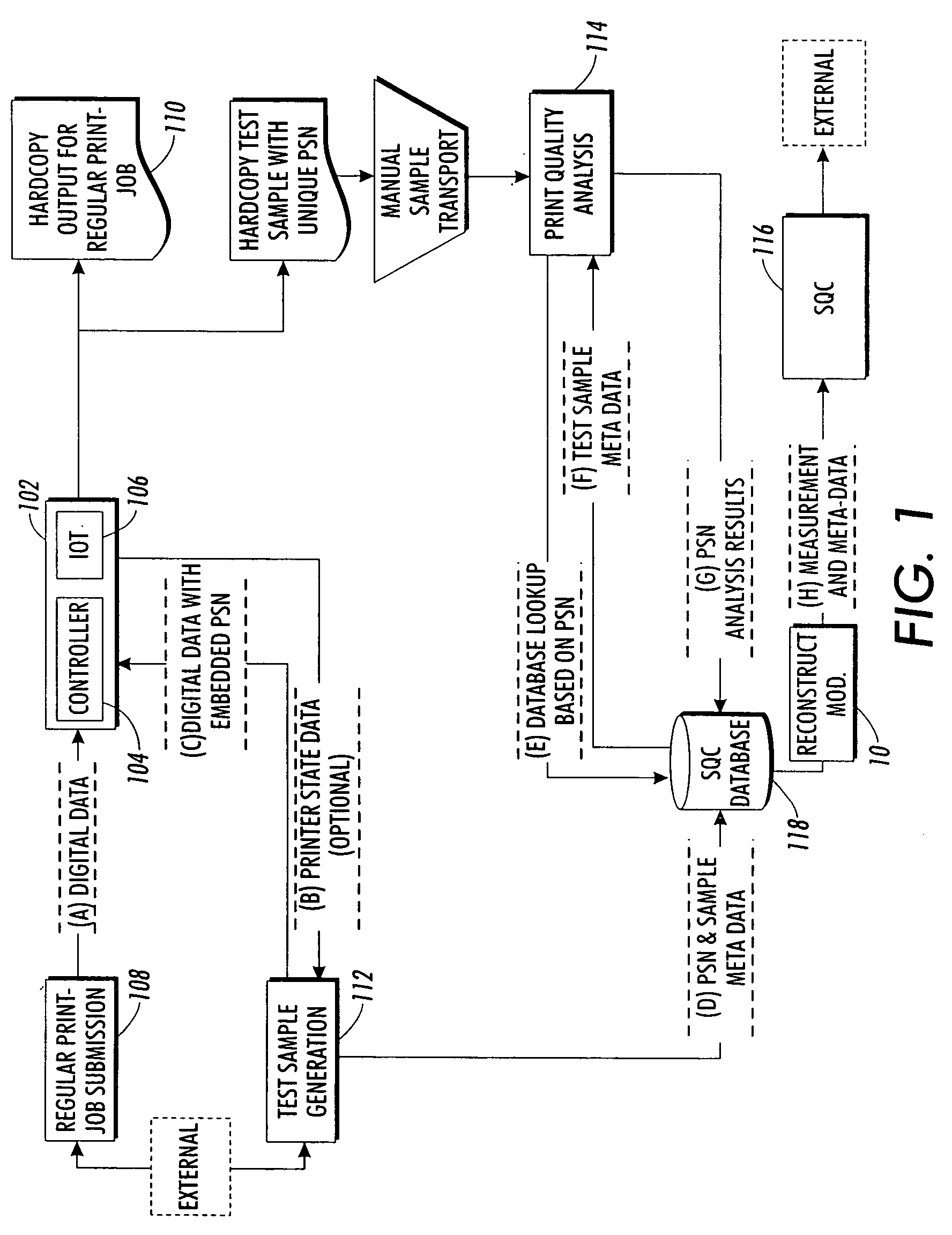

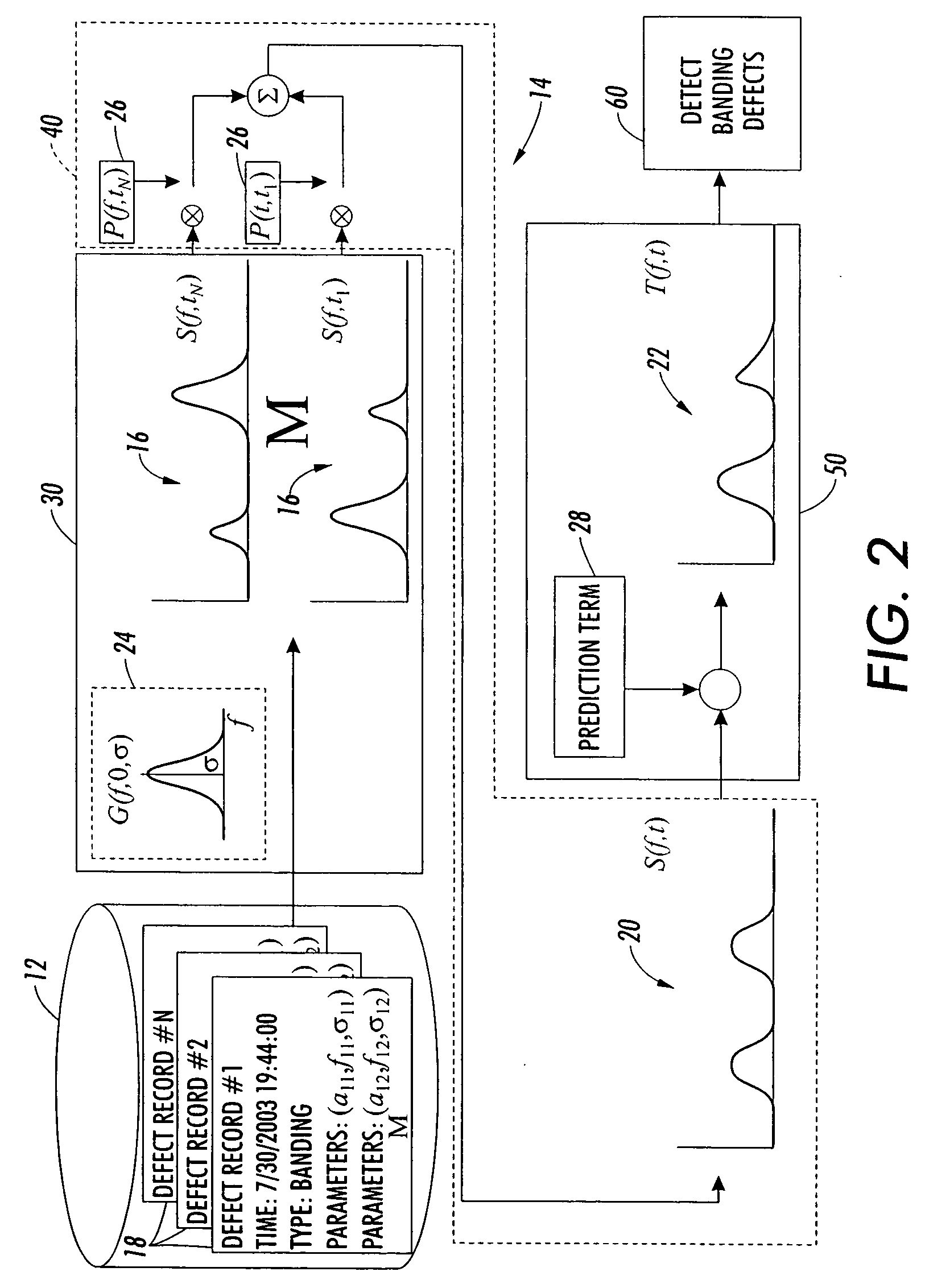

Image quality defect detection from image quality database

ActiveUS7382507B2Facilitates diagnostics on the print engineReduce dependenceImage enhancementDigitally marking record carriersPattern recognitionImaging quality

A method of detecting image quality defects in the output of an image output device includes the steps of generating a test pattern at a known time, analyzing the test pattern to generate image quality defect records, storing the image quality defect records in memory linked to a time stamp indicating known time when the test pattern was generated, repeating the generating, analyzing and storing steps at a plurality of different known times to generate a database of time stamped image quality defect records, reconstructing isolated defect data from each of a plurality of image quality defect records in the database, constructing cumulative defect data by probabilistic summation of the isolated defect data and analyzing the cumulative defect data using an image quality assessment / analysis engine.

Owner:XEROX CORP

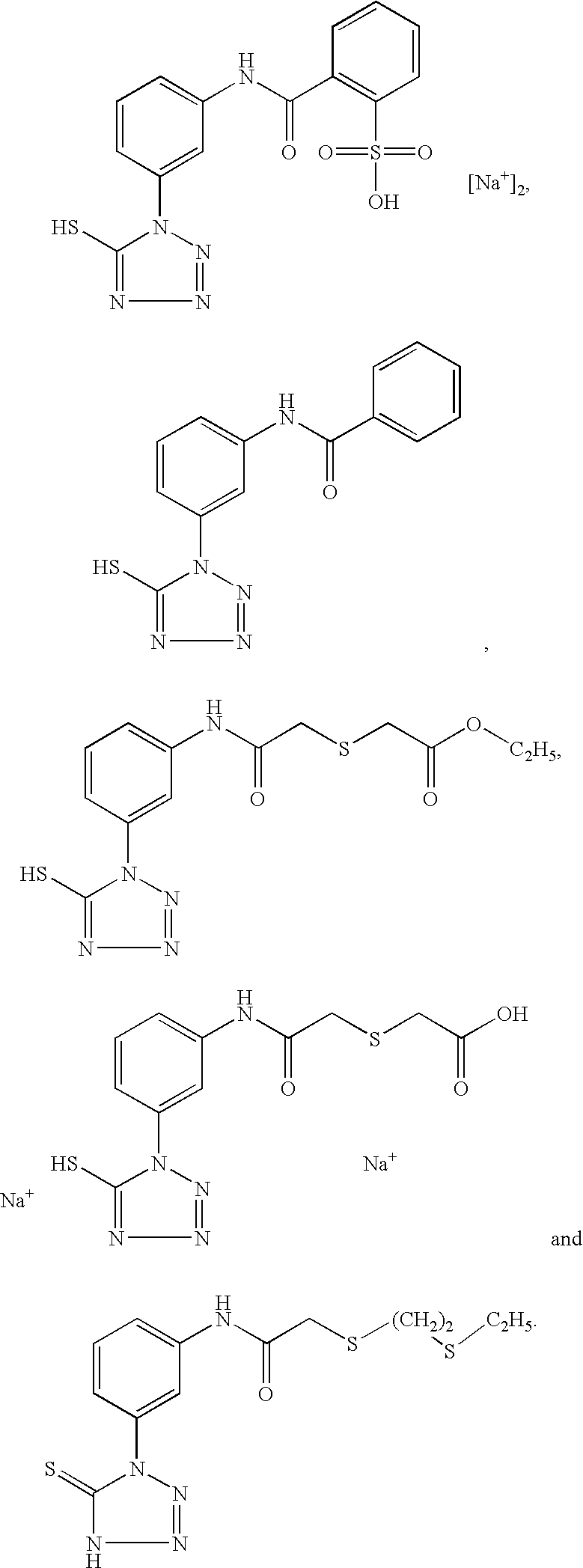

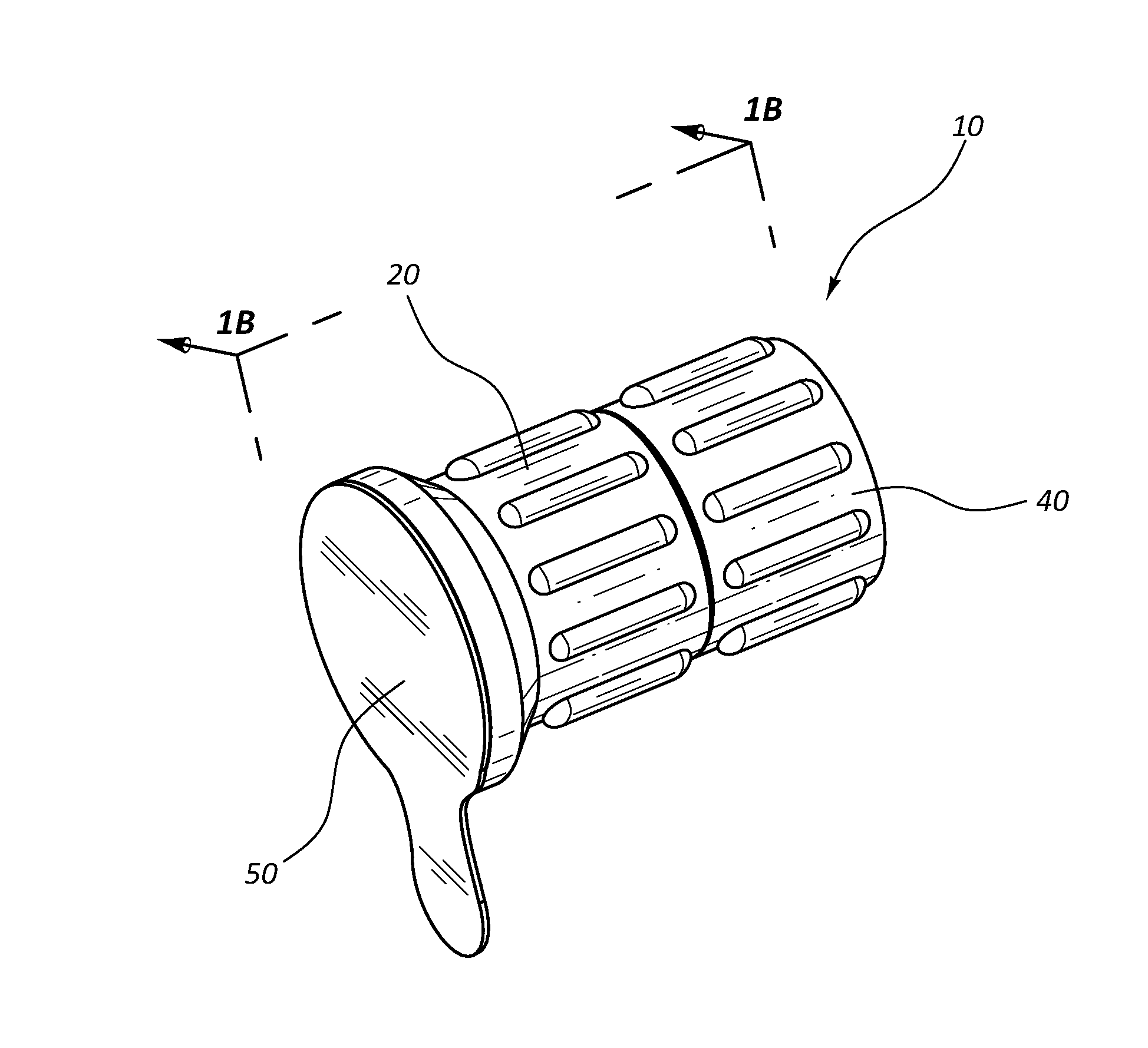

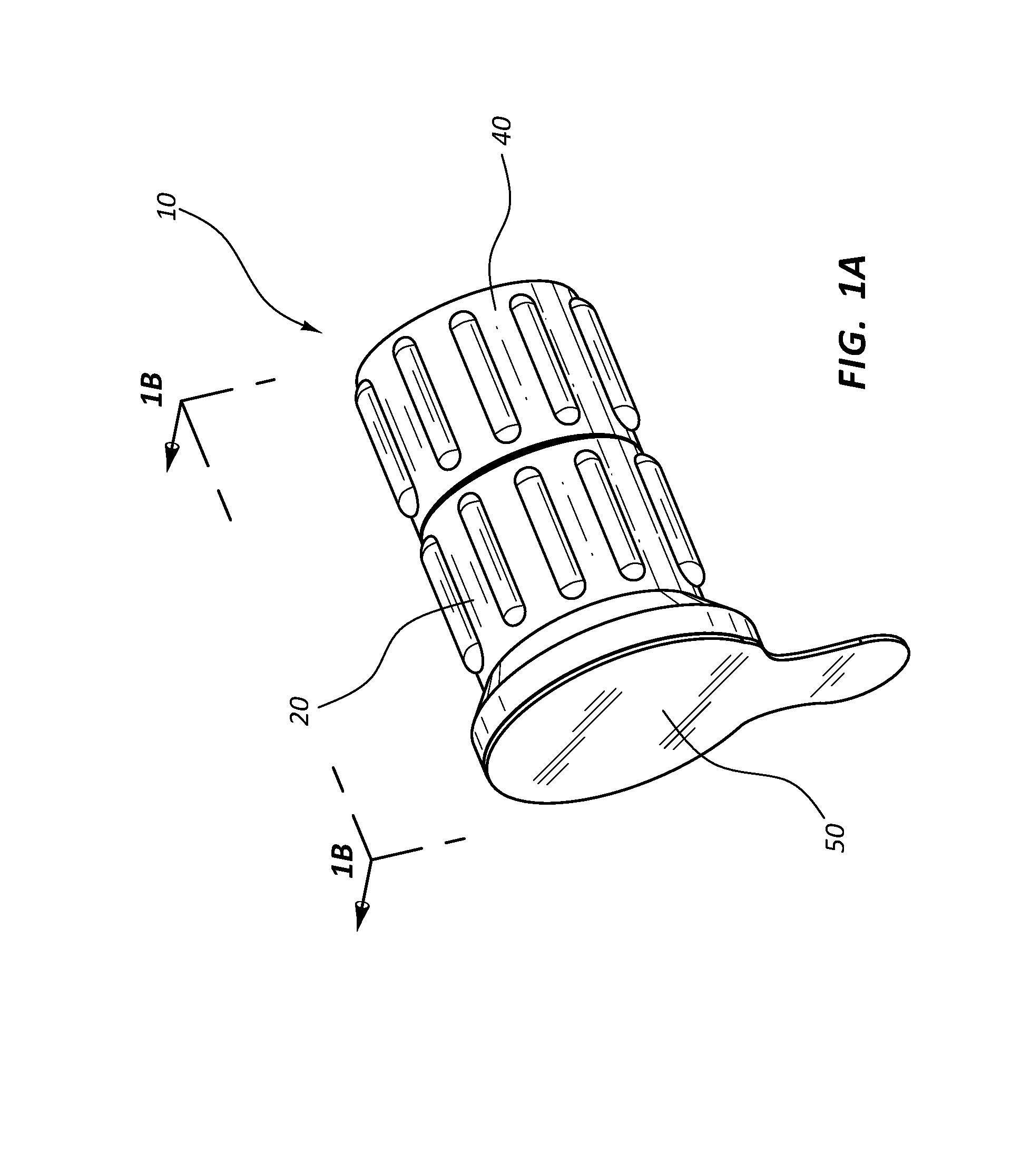

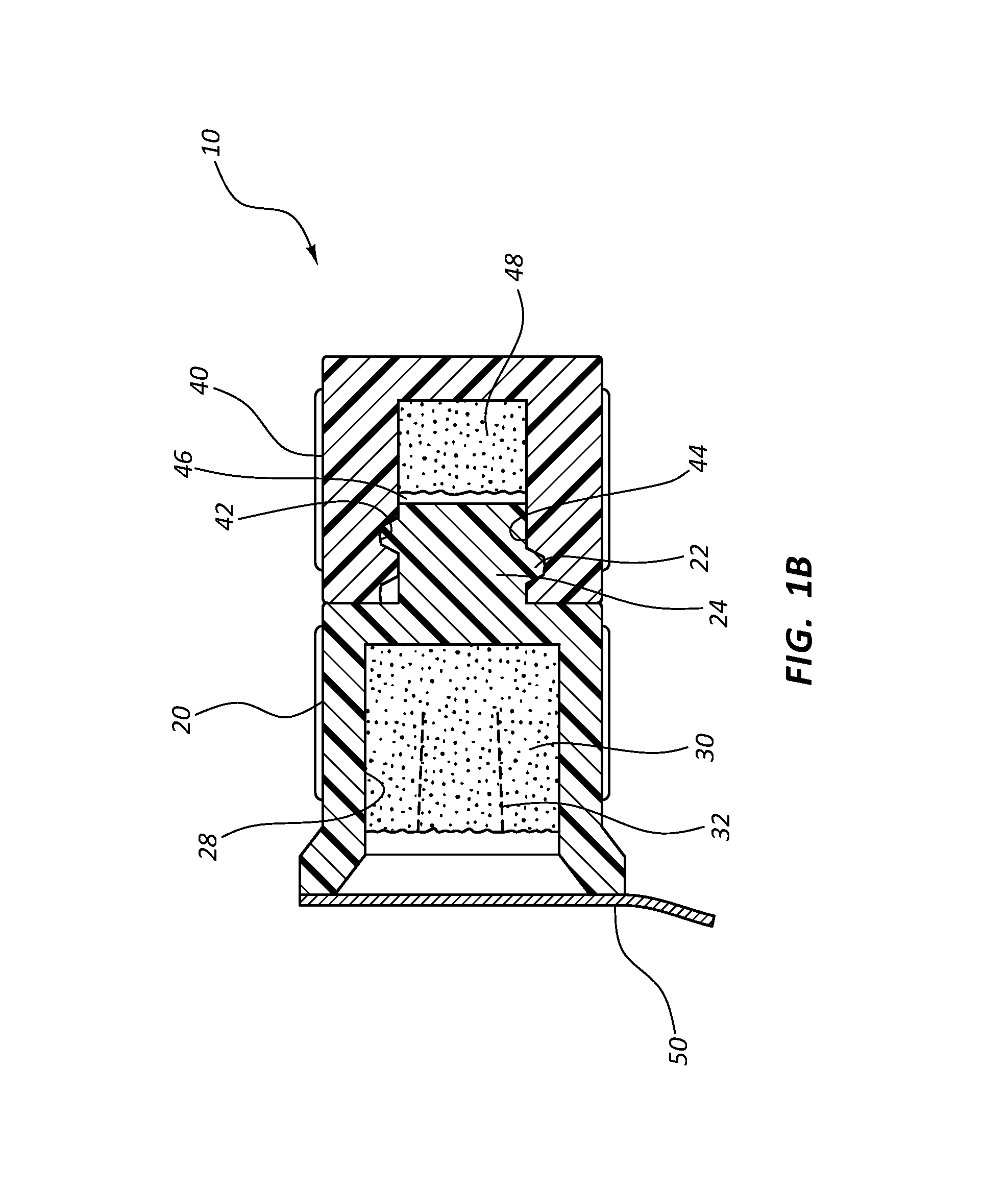

Needleless connector and access port disinfection cleaner and antimicrobial protection cap

ActiveUS20140228773A1Avoid contaminationAvoid pollutionInfusion syringesCatheterEngineeringShort terms

A protective cap having a first cap and a second cap that are removably coupled together for use in short-term and long-term antimicrobial treatment of needleless connectors and access ports of an infusion system. The instant invention further provides a protective cap having a first cap and a second cap that each coupled to a different surface of a component of an infusion system, such as a syringe. The instant invention further provides a strip containing a plurality of disposable protective caps.

Owner:BECTON DICKINSON & CO

Heat resistant semi-aromatic polyamide composite structures and processes for their preparation

InactiveUS20110028060A1Easily and rapidly and efficiently impregnatedLong-termSynthetic resin layered productsFilament/thread formingFiberAlcohol

Owner:EI DU PONT DE NEMOURS & CO

Image quality defect detection from image quality database

ActiveUS20060103899A1Facilitates diagnostics on the print engineReduce dependenceImage enhancementDigitally marking record carriersPattern recognitionImaging quality

A method of detecting image quality defects in the output of an image output device includes the steps of generating a test pattern at a known time, analyzing the test pattern to generate image quality defect records, storing the image quality defect records in memory linked to a time stamp indicating known time when the test pattern was generated, repeating the generating, analyzing and storing steps at a plurality of different known times to generate a database of time stamped image quality defect records, reconstructing isolated defect data from each of a plurality of image quality defect records in the database, constructing cumulative defect data by probabilistic summation of the isolated defect data and analyzing the cumulative defect data using an image quality assessment / analysis engine.

Owner:XEROX CORP

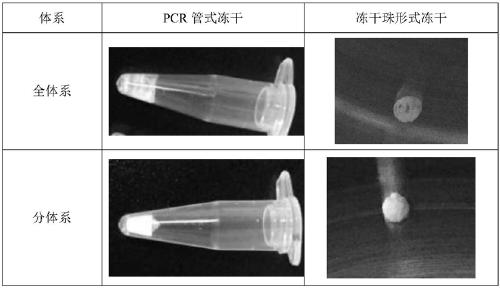

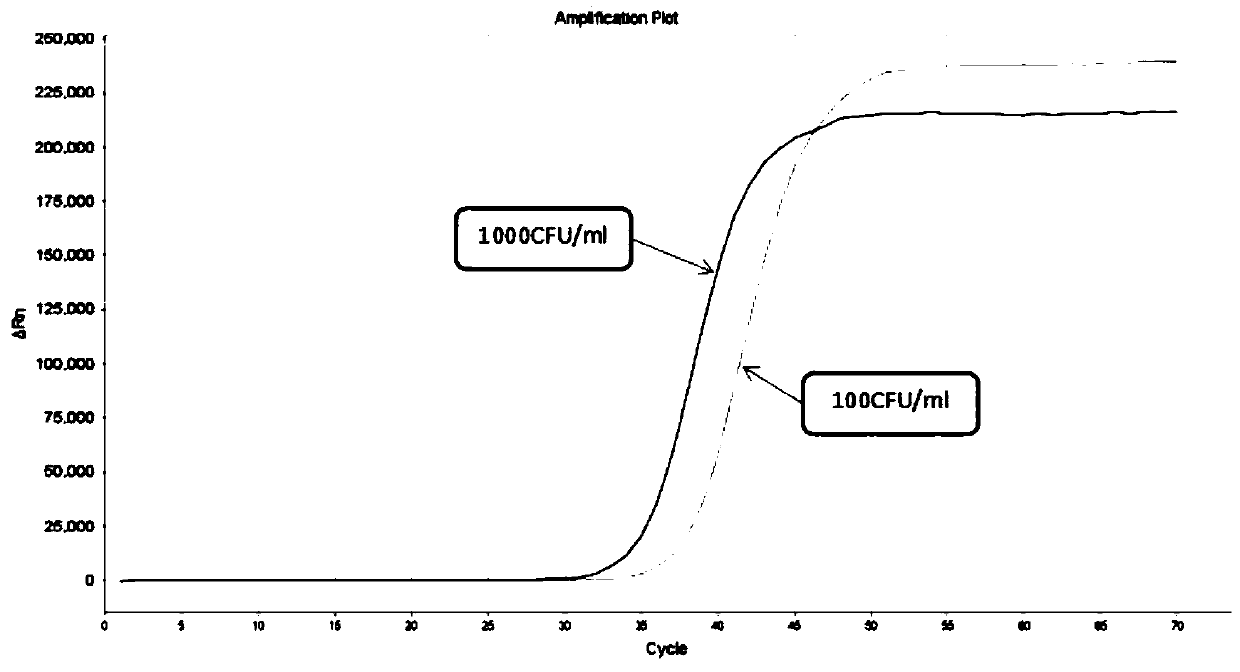

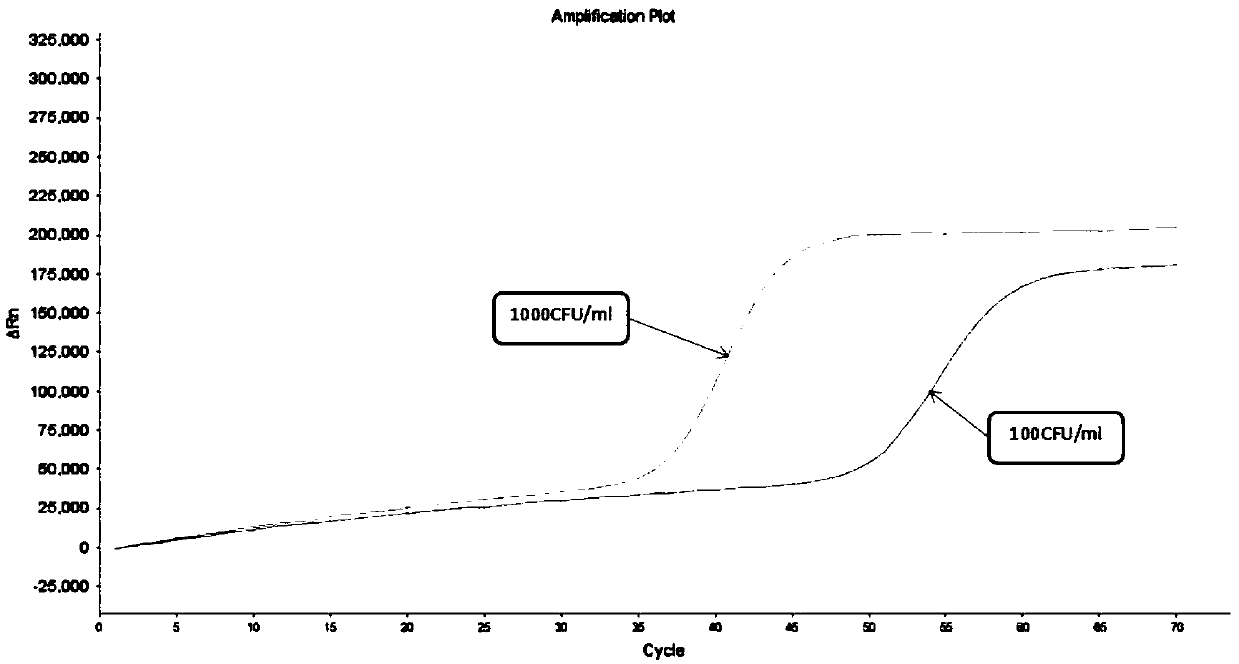

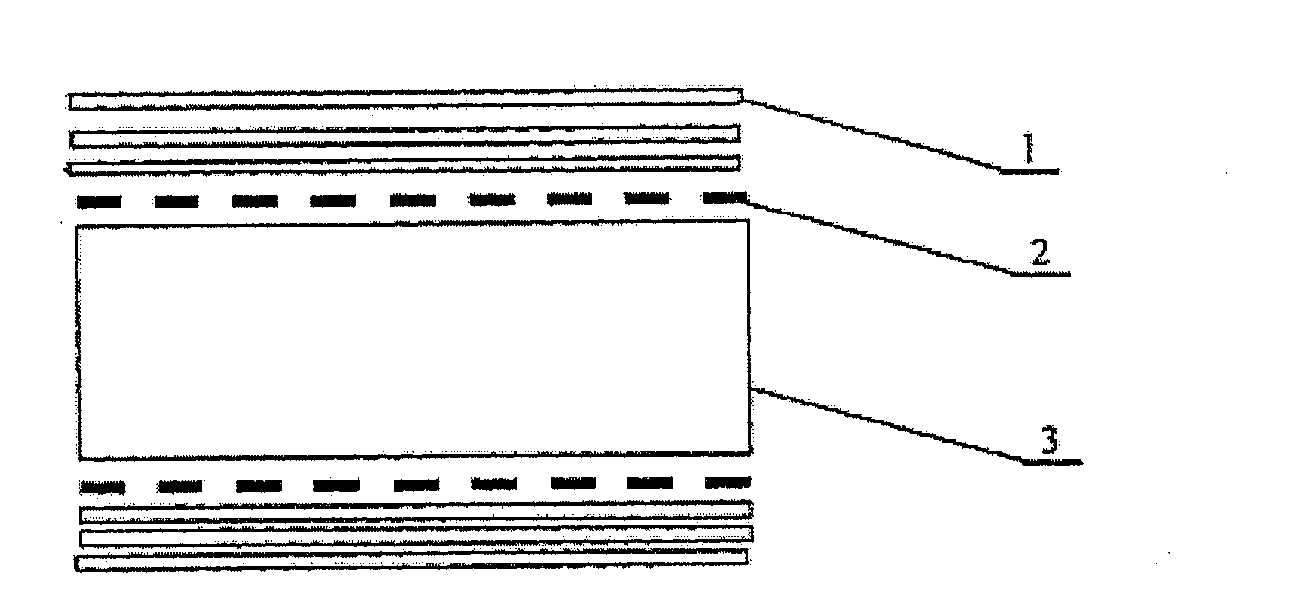

Freeze-drying protection system required for nucleic acid amplification reagent and preparation method of freeze-drying protection system

InactiveCN109593834AKeep aliveNo biohazardMicrobiological testing/measurementFreeze thawingFreeze-drying

The invention belongs to the technical field of medicine preparation, and particularly relates to a freeze-drying protection system required for a nucleic acid amplification reagent and a preparationmethod of the freeze-drying protection system. The freeze-drying protection system comprises the nucleic acid amplification reagent and a freeze-drying protection additive, wherein the nucleic acid amplification reagent is a reagent used for LAMP reaction amplification, the freeze-drying protection additive is one or a compound of the following reagents: polyethylene glycol, mannitol, polyvinylpyrrolidone, glucan, trehalose, sucrose, bovine serum albumin, collagen, threonine and glycine, and the concentration of the weight-to-volume ratio of the freeze-drying protection additive and the amplification reaction reagent is 3% to 25%. The freeze-drying protection additive used in the invention has the advantages of small volume, short freeze-drying time, high efficiency and low energy consumption, and the freeze-drying protection system can be directly used for gene chip experiments, does not cause repeated freeze-thaw and waste of reagents, and can effectively ensure the activity of active substances in the freeze-drying process.

Owner:百康芯(天津)生物科技有限公司

Container flooring material and method of manufacture

InactiveUS20100015389A1Efficient use ofOvercome shortageLamination ancillary operationsLayered product treatmentSoutheast asiaResin coating

The present invention relates to a composite container floorboard having a structural strand-based board as the core material and its fabrication method thereof. It is characterized wherein the composite container floorboard, using a structural strand-based board as a core material, comprises 2 to 4 layers of wooden veneers coated or impregnated with resin, respectively, on a top and a bottom of the surface overlay materials; or comprises one piece of impregnated paper, one piece of resin-impregnated bamboo-woven mat, and 1 to 3 pieces of double-side resin-coated or resin-impregnated wooden veneers, respectively, from an exterior to an interior of the surface overlay materials; or comprises one Keruing or Apitong wooden veneer of Southeast Asia, or other wooden veneer with similar properties and 1 to 3 pieces of double-side resin-coated or resin-impregnated wooden veneers [or partially or entirely replacing wooden veneer(s) with resin-impregnated bamboo curtain(s) or bamboo-woven mat(s)], respectively, from an exterior to an interior of the surface overlay materials.

Owner:ALBERTA INNOVATES TECH FUTURES

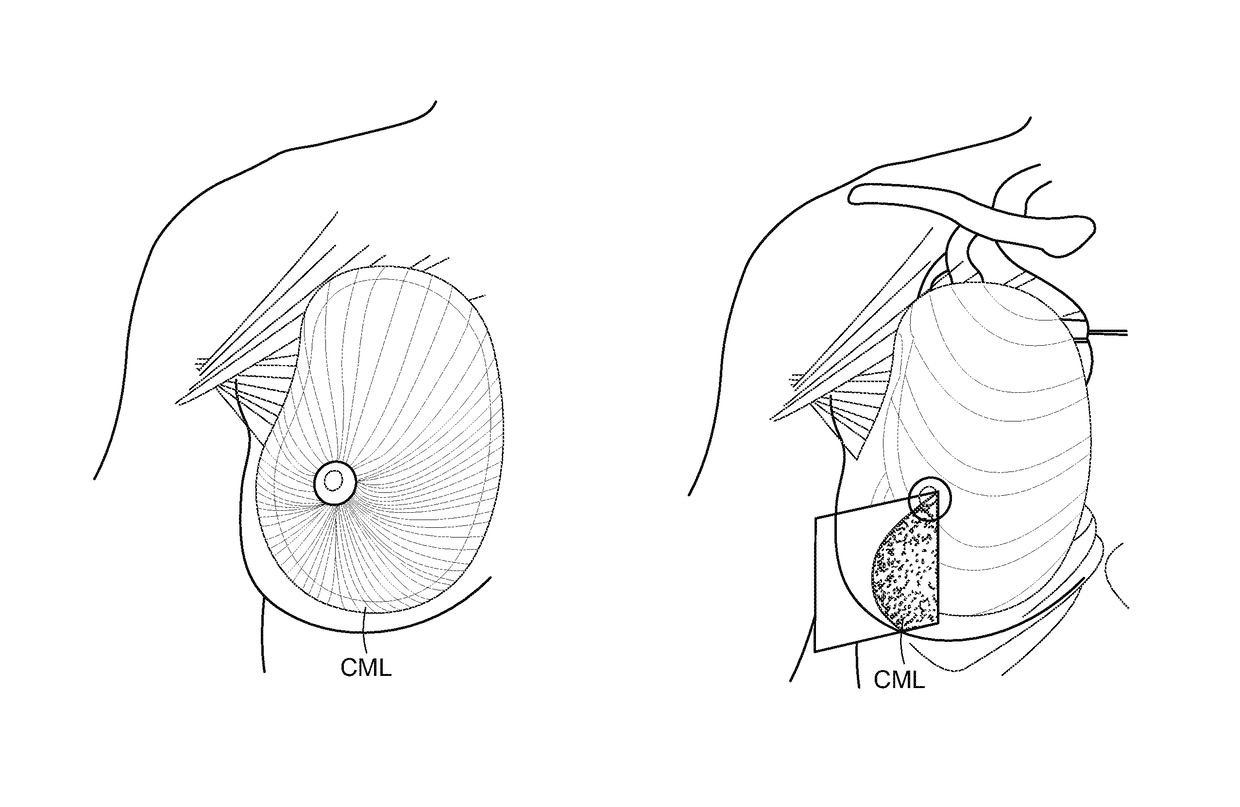

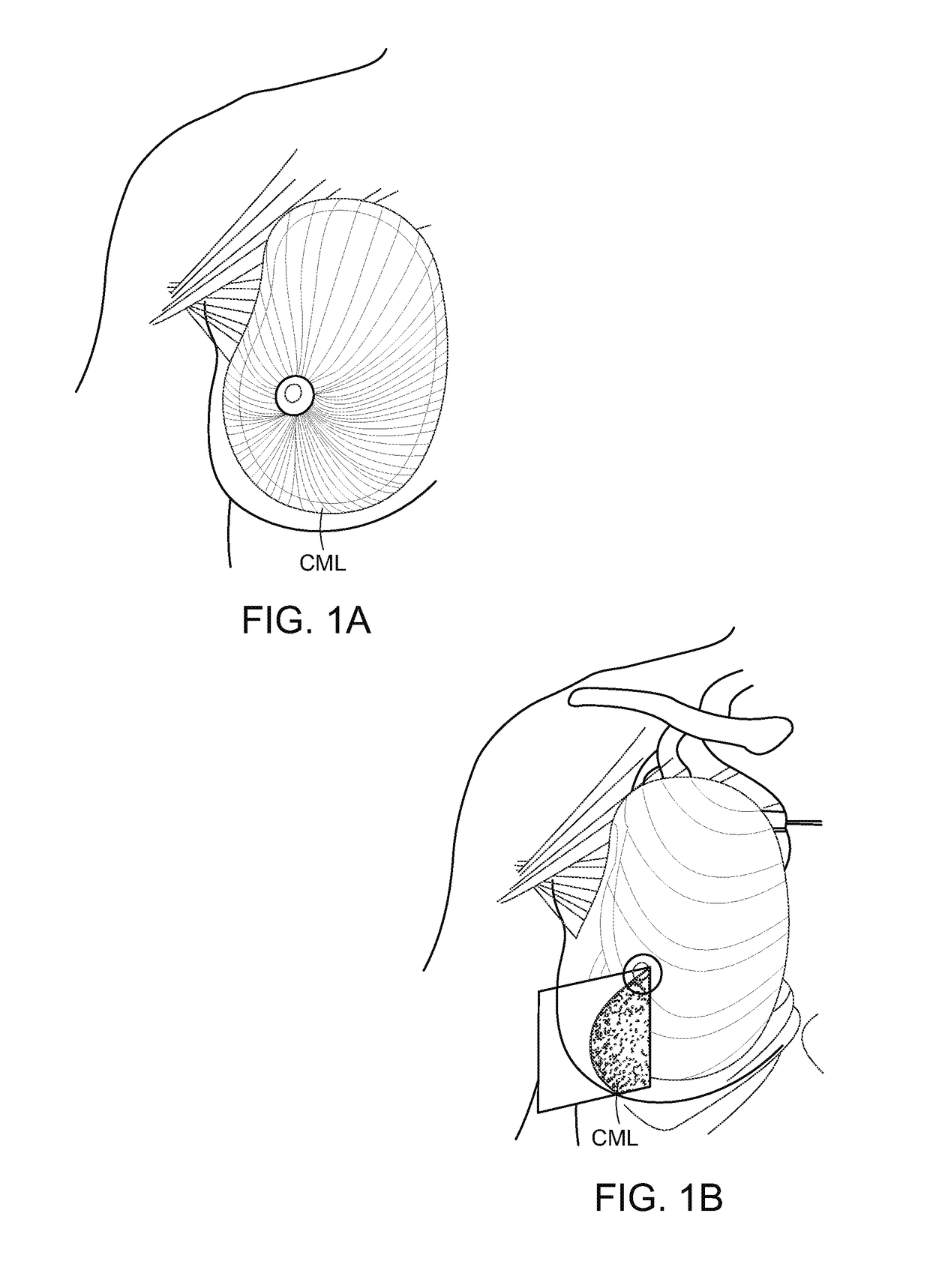

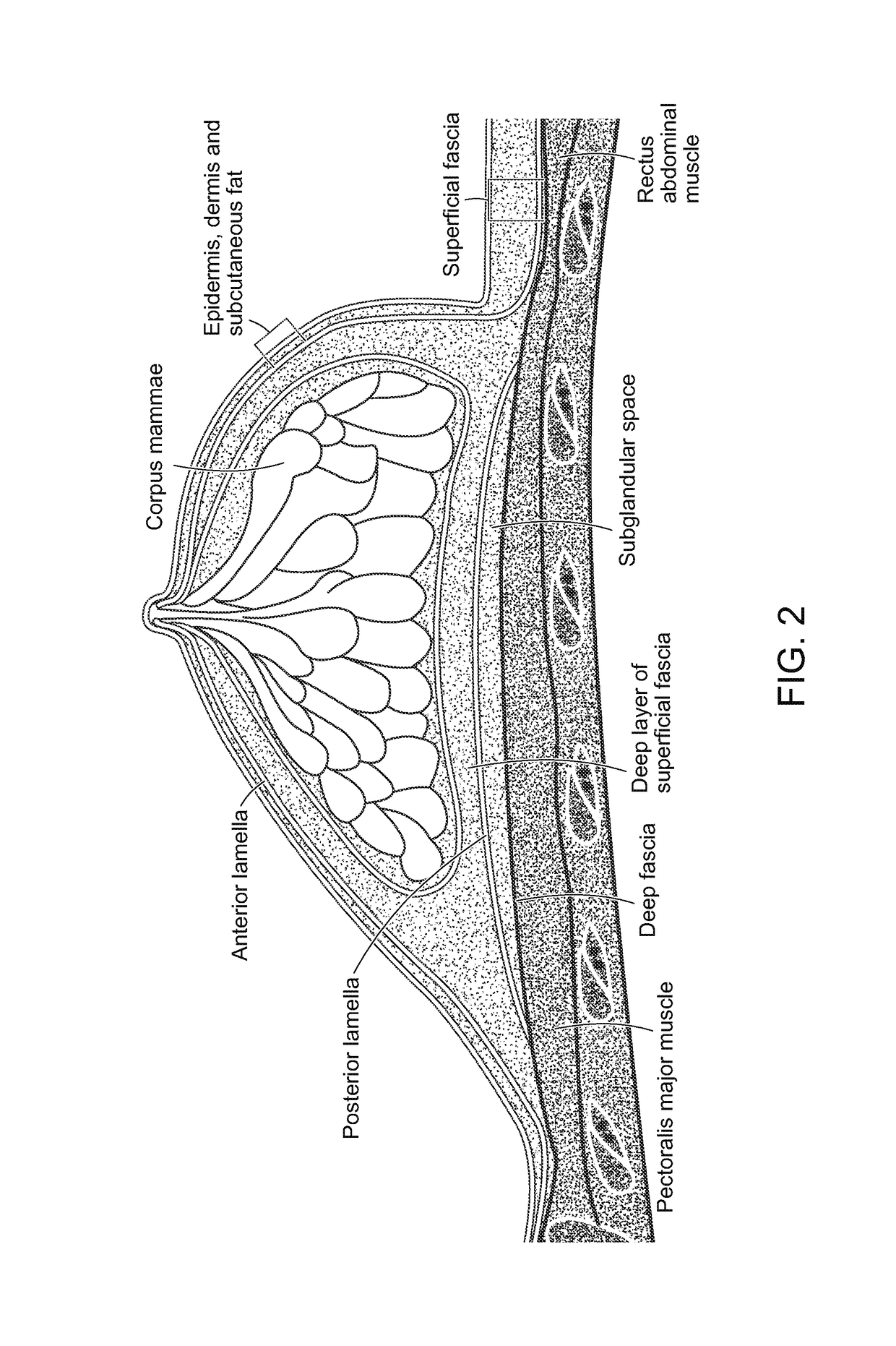

Internal Long Term Absorbable Matrix Brassiere

Owner:BARD SHANNON LTD

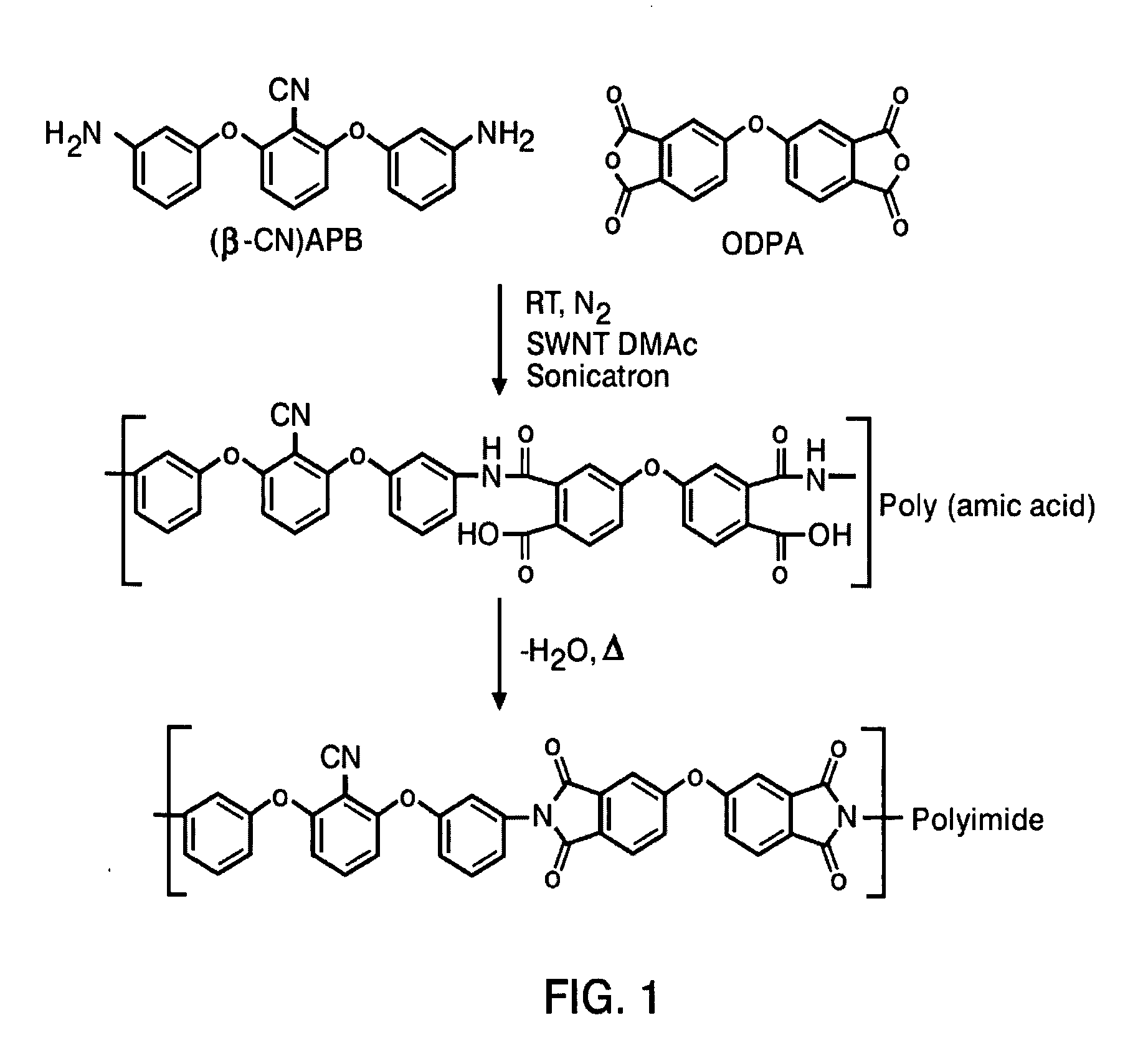

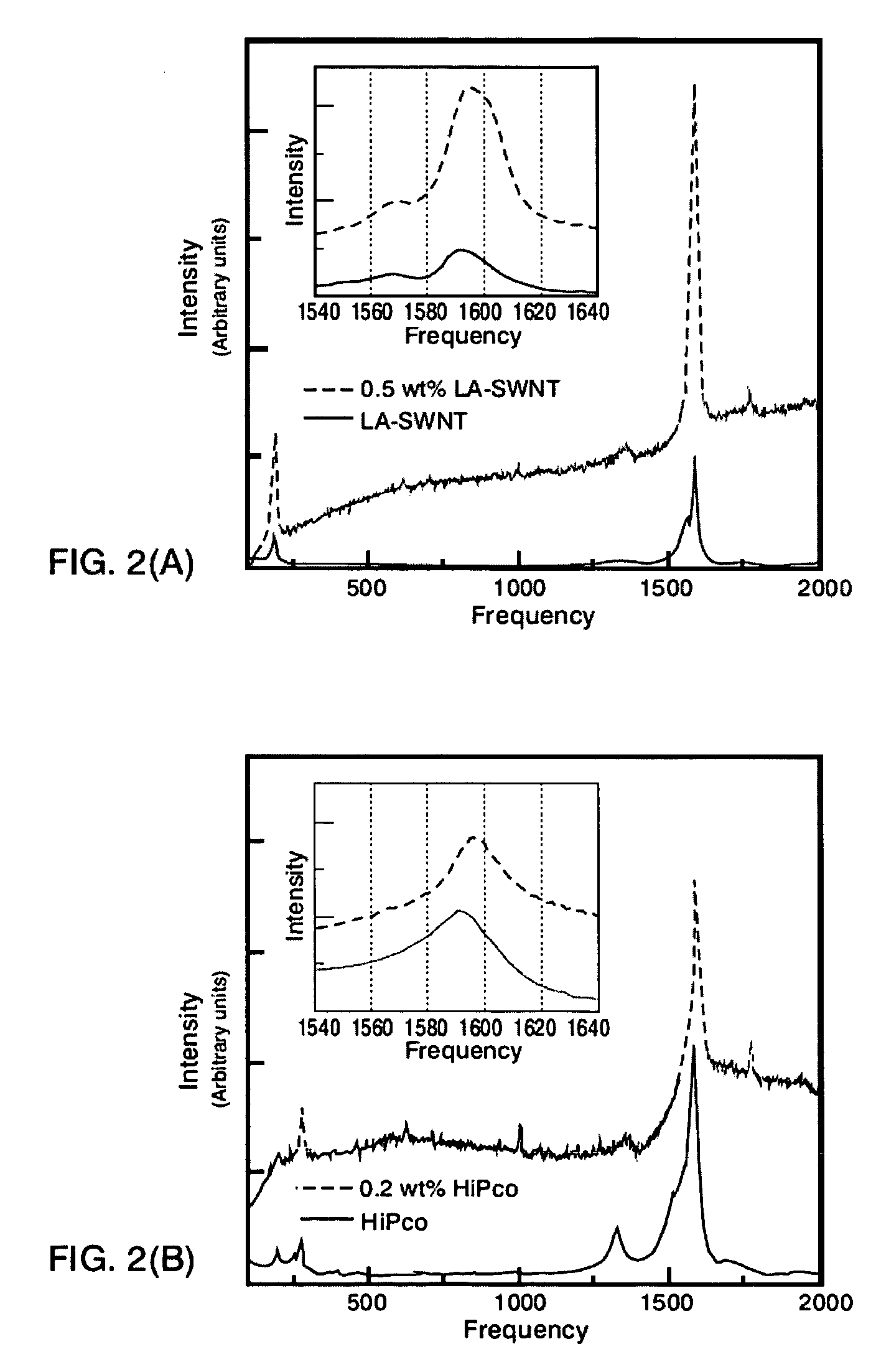

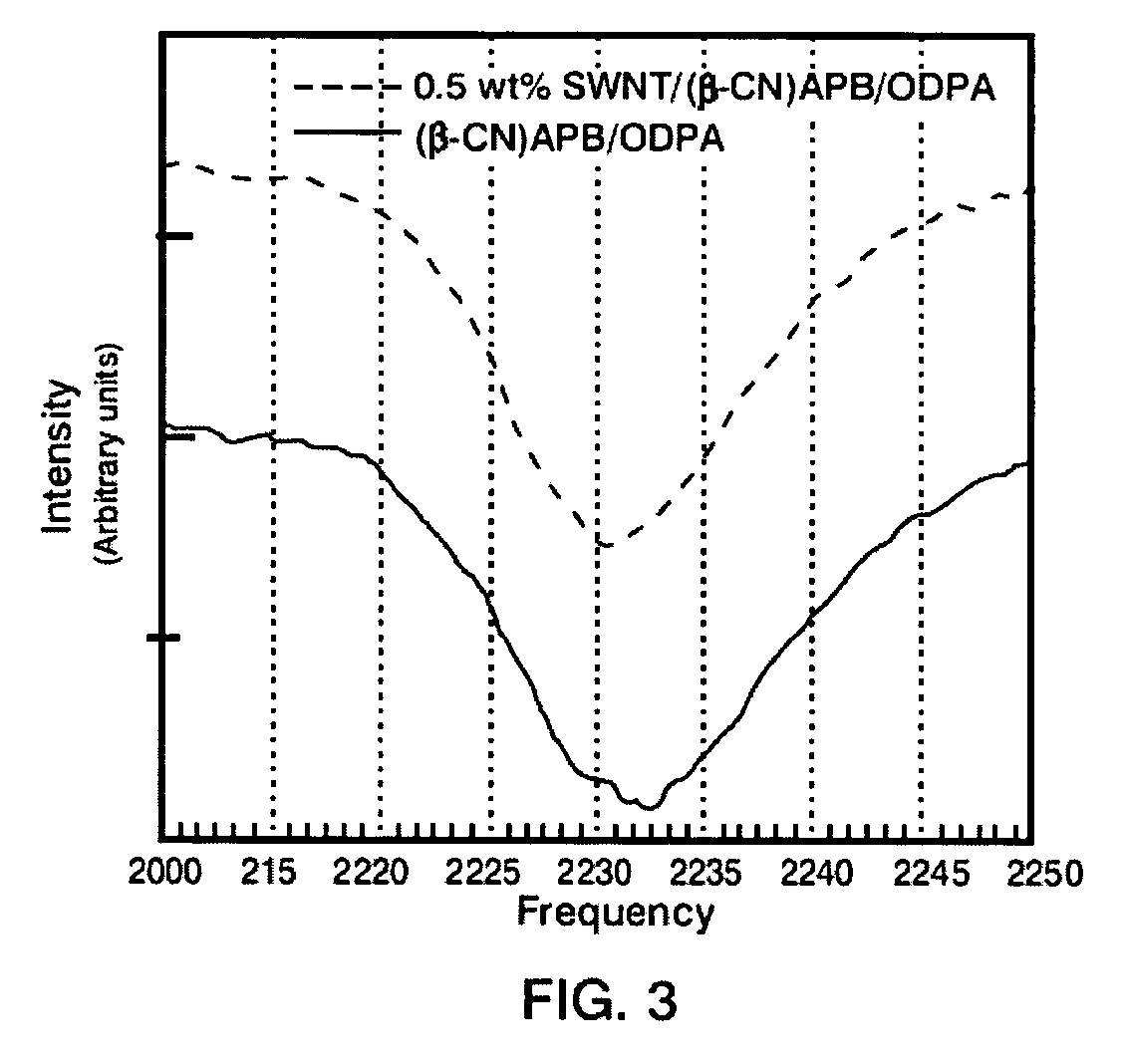

Dispersions of carbon nanotubes in polymer matrices

Dispersions of carbon nanotubes exhibiting long term stability are based on a polymer matrix having moieties therein which are capable of a donor-acceptor complexation with carbon nanotubes. The carbon nanotubes are introduced into the polymer matrix and separated therein by standard means. Nanocomposites produced from these dispersions are useful in the fabrication of structures, e.g., lightweight aerospace structures.

Owner:NAT INST AEROSPACE ASSOC +1

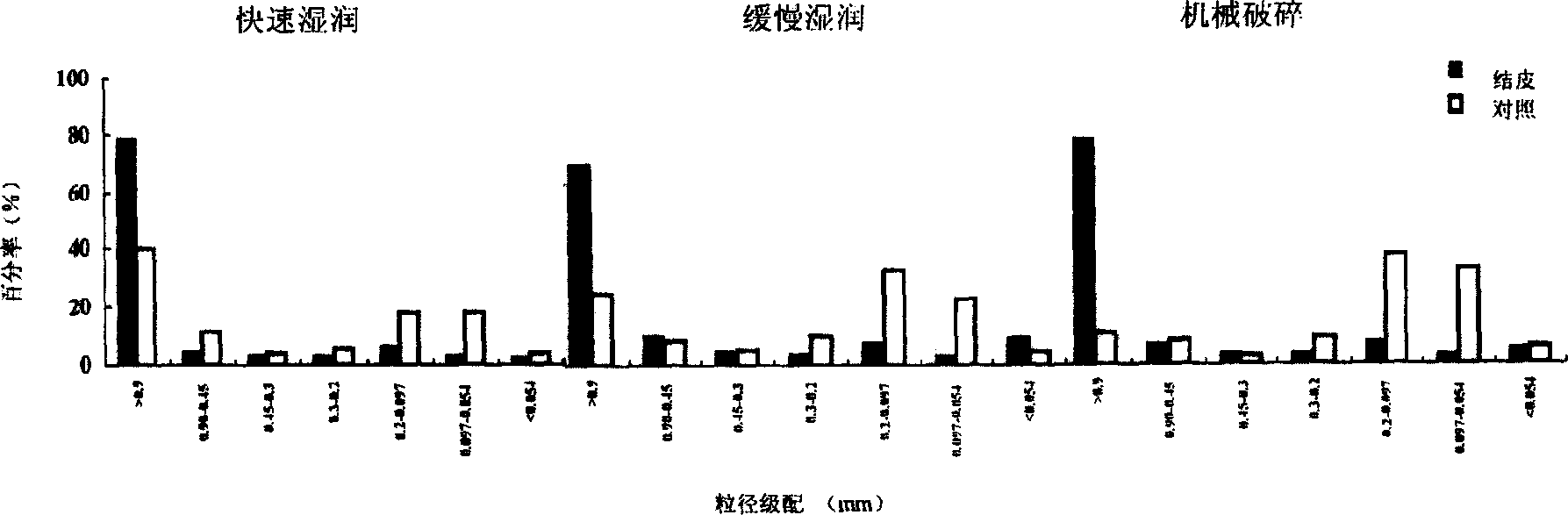

Method for improving desert and semi-desert soil by soil algae

InactiveCN1654596ARestore physiological activityGet biomassOrganic fertilisersSoil conditioning compositionsSheet mulchingPlastic mulch

The process of improving desert soil and semi-desert soil with soil algae includes the steps of: 1. separating algae from soil crust and performing solid plate culture for purifying; 2. inoculating algae seed to liquid and ventilating to culture, selecting algae seed with practical value, centrifugally collecting and drying for storage; 3. re-compounding dried algae with water to restore activity for spread culture; 4. exercising via simulating field environment to make algae suit to varying environment; 5. inoculating the algae to desert soil and semi-desert soil, covering with mulching and spraying nutritious liquid for culture; and 6. field management. By means of the growth, propagation and cell secretion of algae in soil surface, the present invention raises the organic matter content in soil and water content in soil, promotes soil structure stability and improves the physical, chemical and biological characteristics of soil effectively.

Owner:INST OF AQUATIC LIFE ACAD SINICA

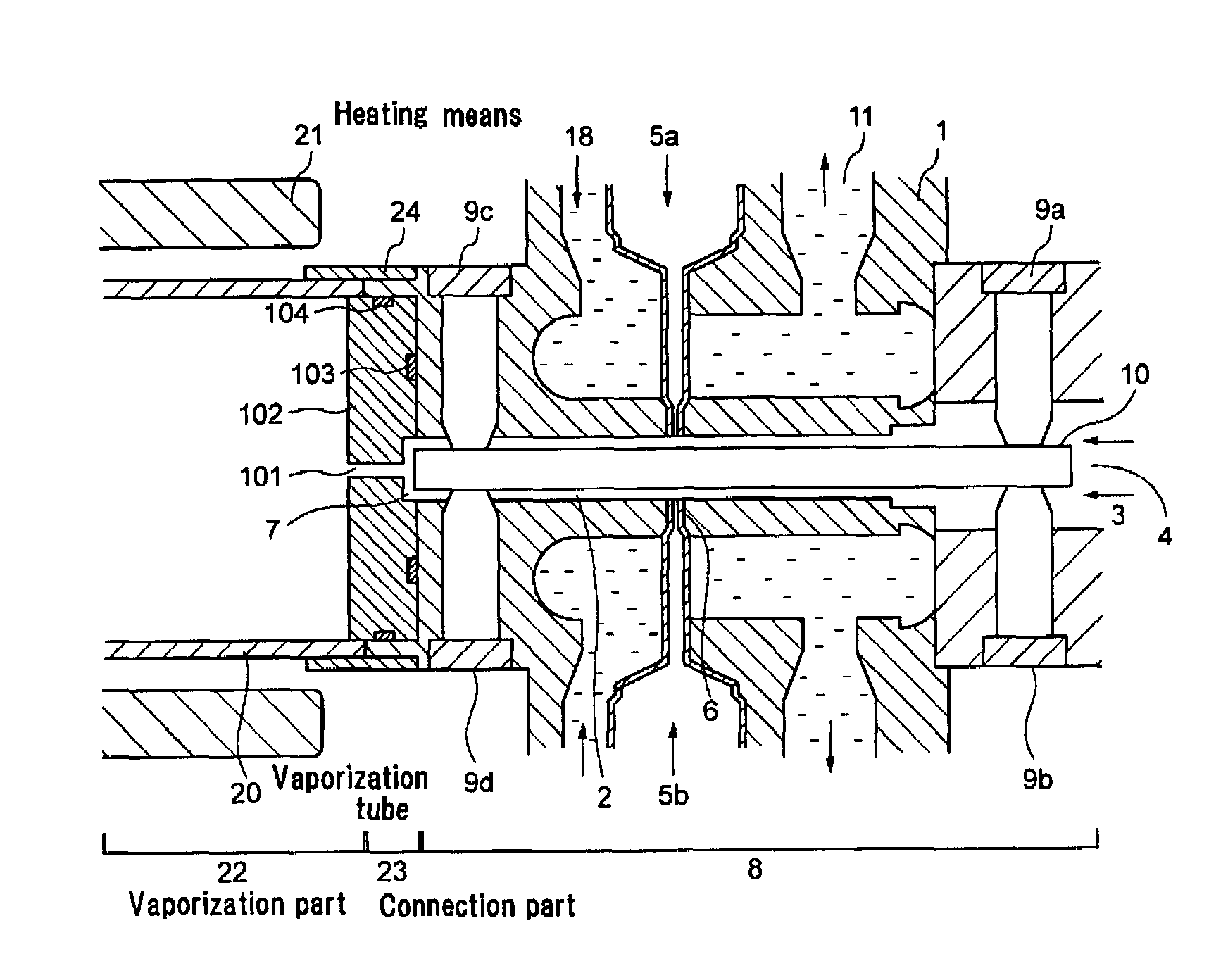

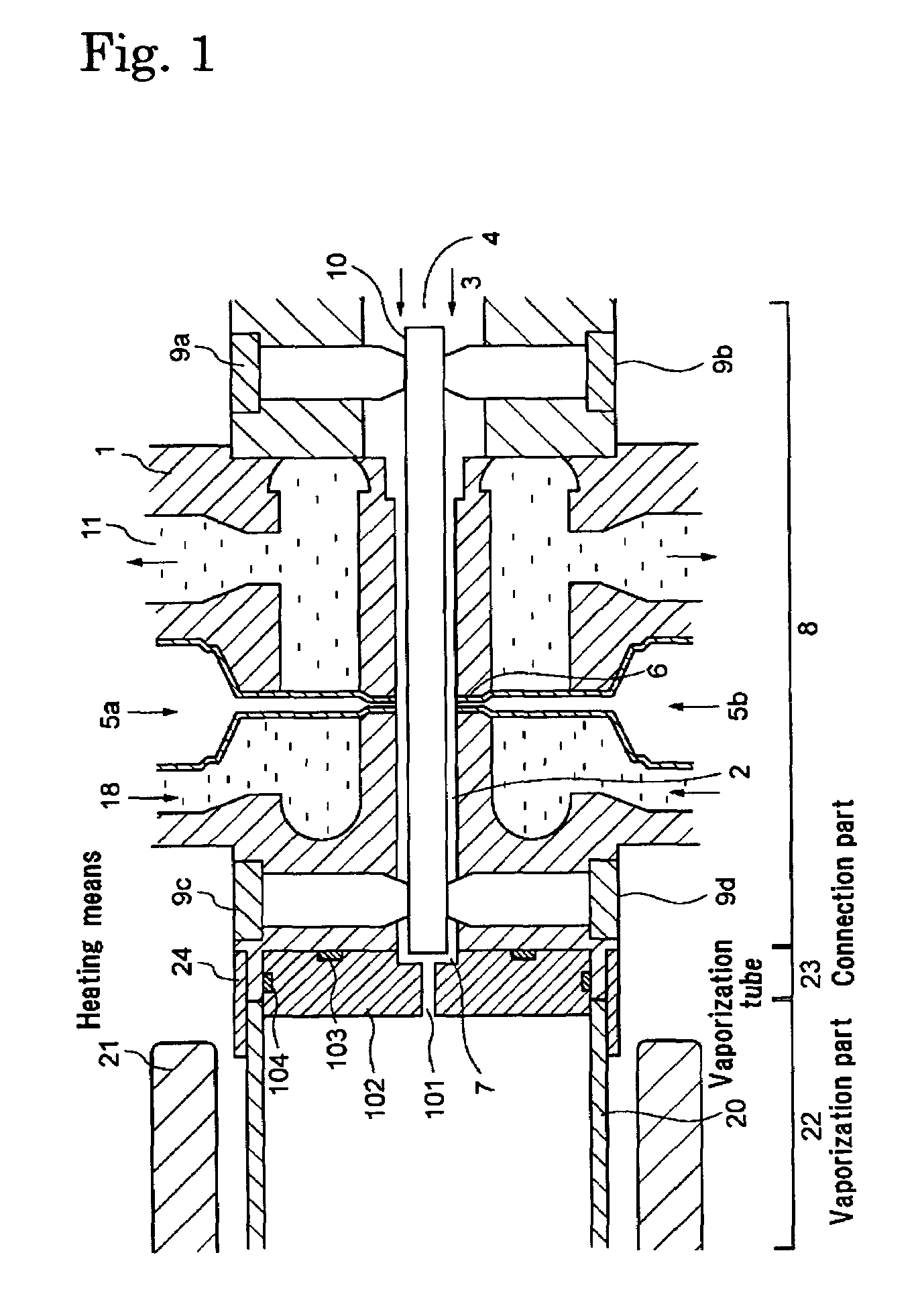

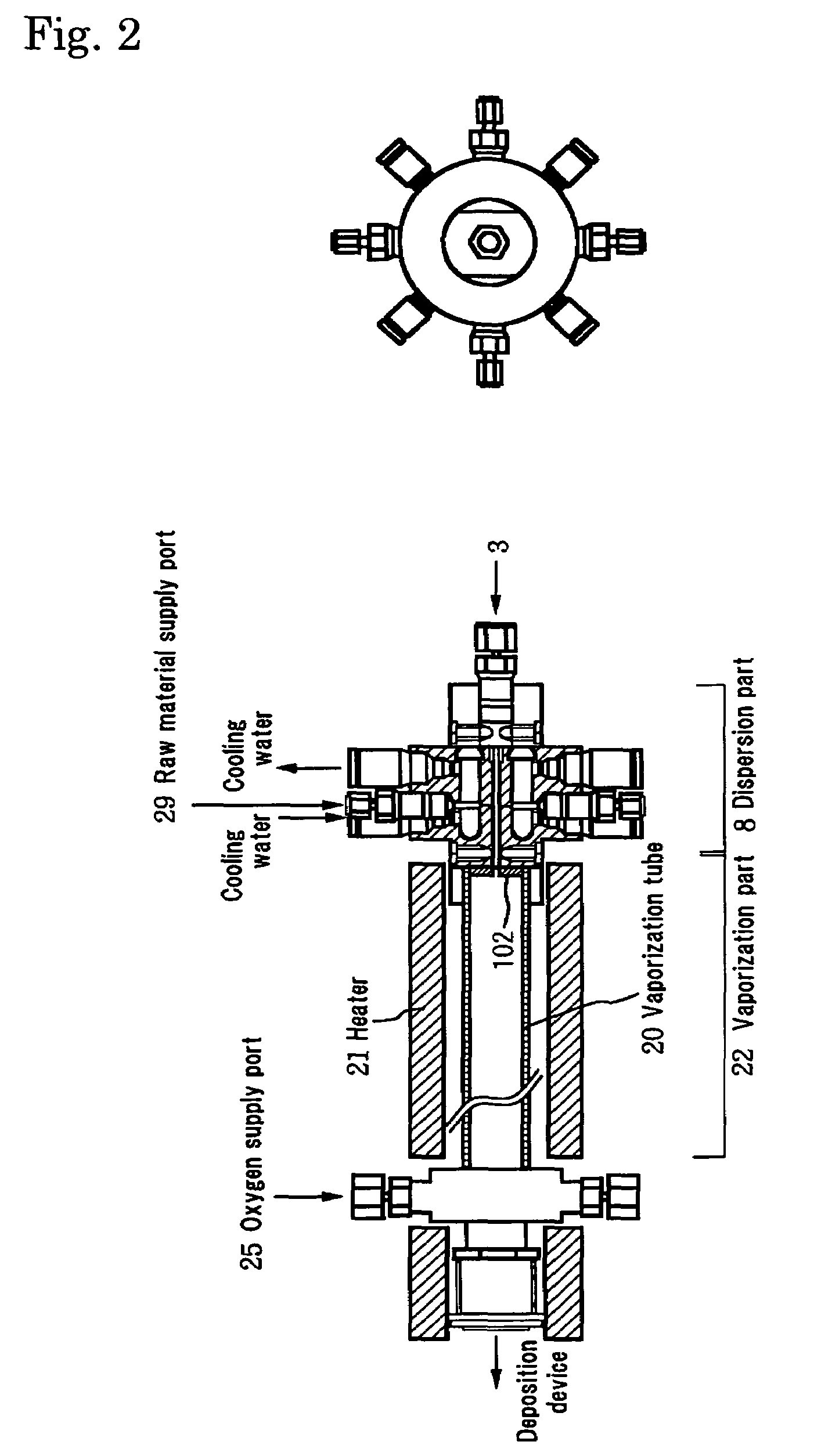

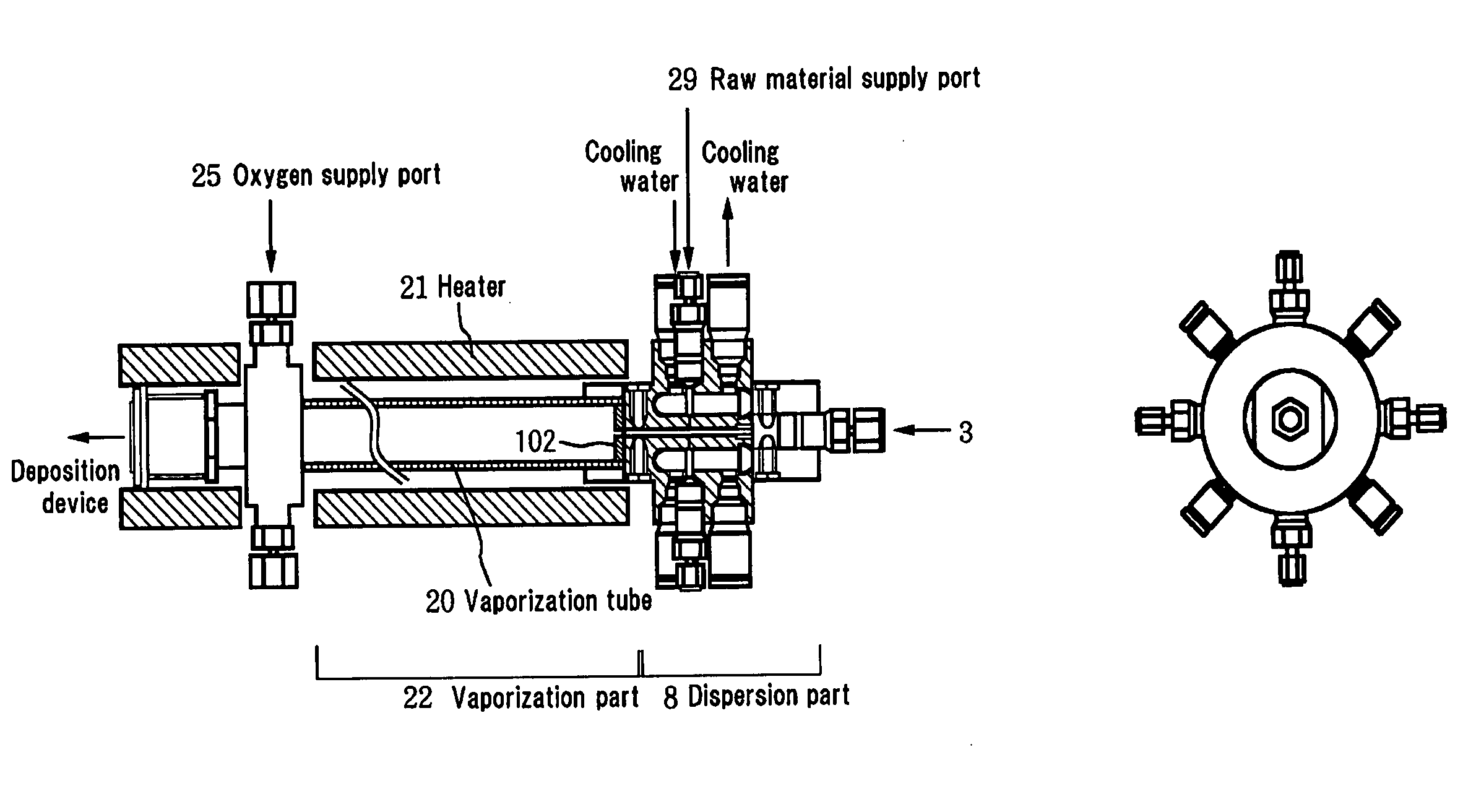

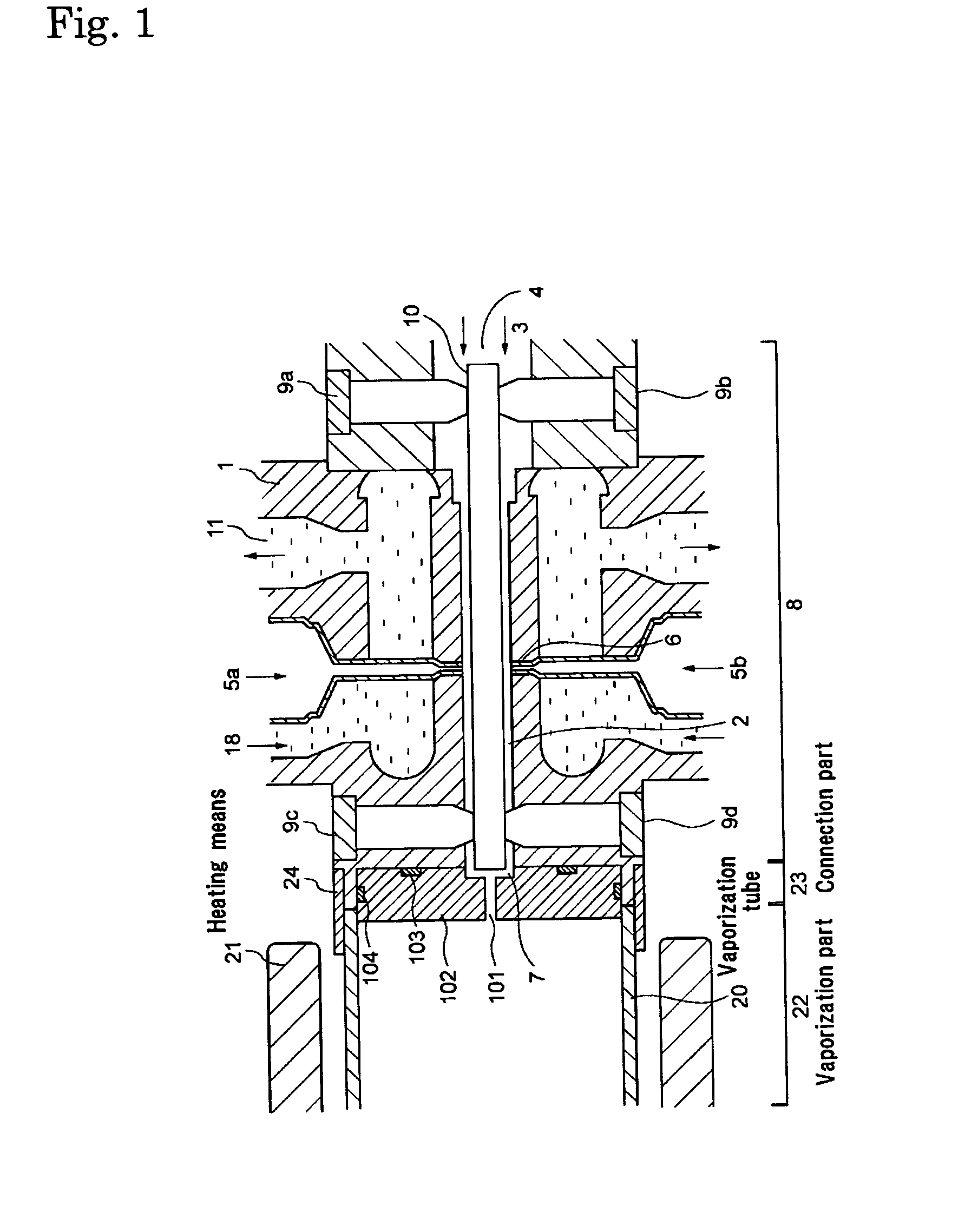

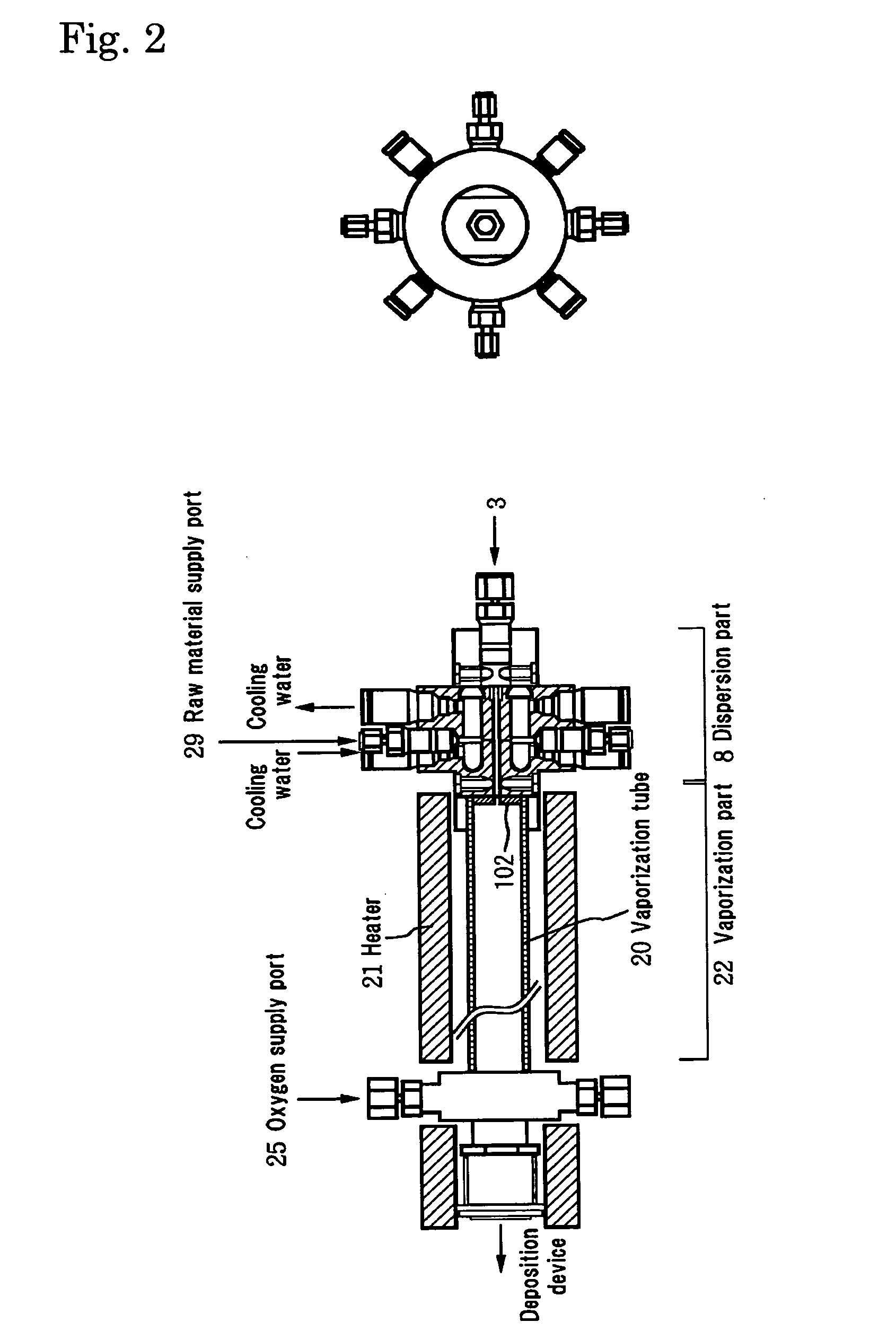

Vaporizer and various devices using the same and an associated vaporizing method

InactiveUS7673856B2Stable supplyLong termFlow mixersUsing liquid separation agentGas passingVaporization

A vaporizer has gas passage formed inside of main body of a dispersion part, a gas inlet opening to introduce pressurized carrier gas into gas passage, a part to supply raw materials solution to carrier gas passing gas passage, a gas outlet to send carrier gas including dispersed raw material solution to vaporization part, a dispersion part to flow through gas passage having a part to cool, a vaporization pipe connected with a reaction part and gas outlet of dispersion part of the device, and a heater to heat vaporization pipe is provided, a vaporization part to heat and vaporizes the carrier gas where raw materials solution is dispersed is provided, and a radiation prevention portion having small hole for the outside of gas outlet is provided.

Owner:M WATANABE CO LTD

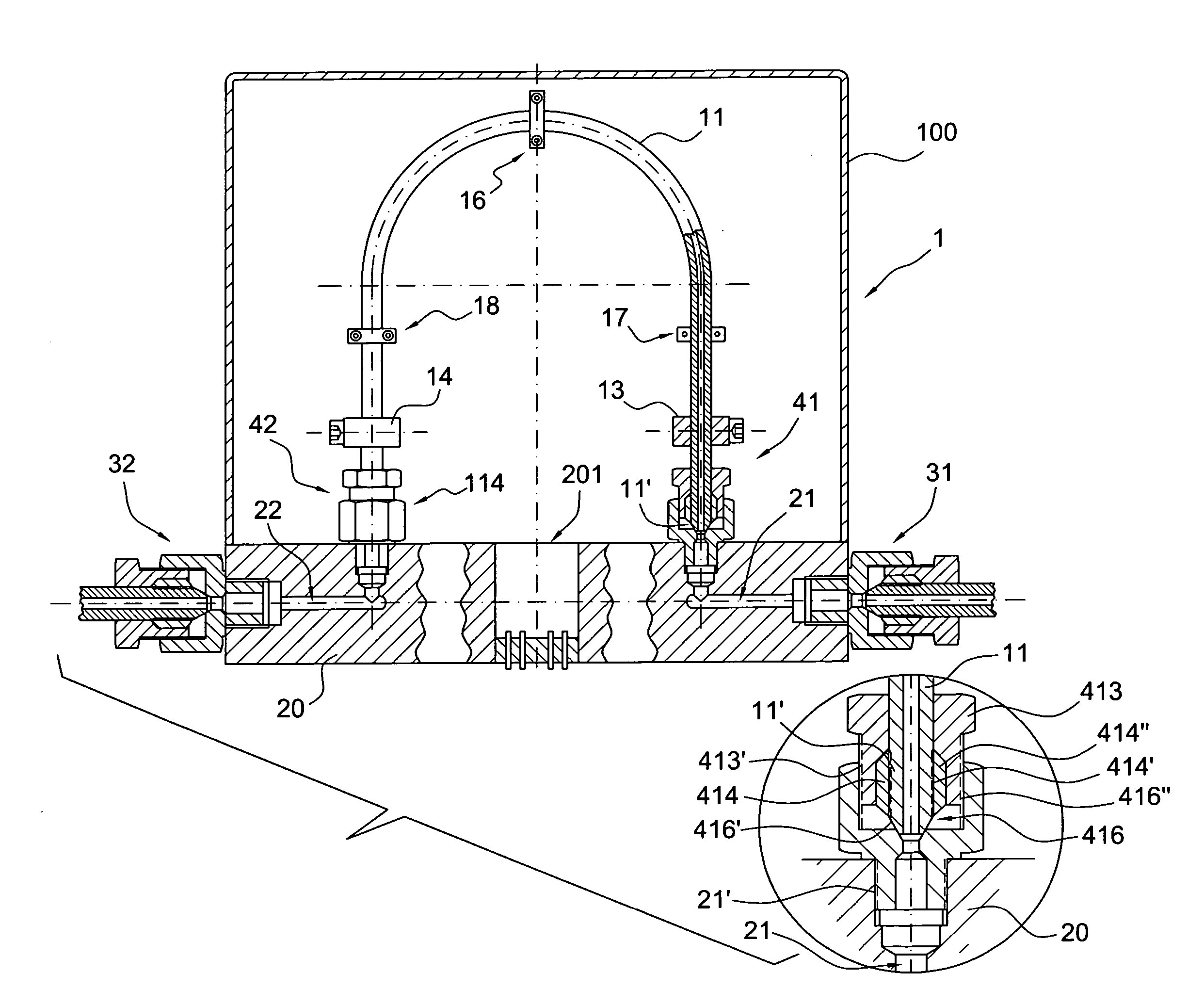

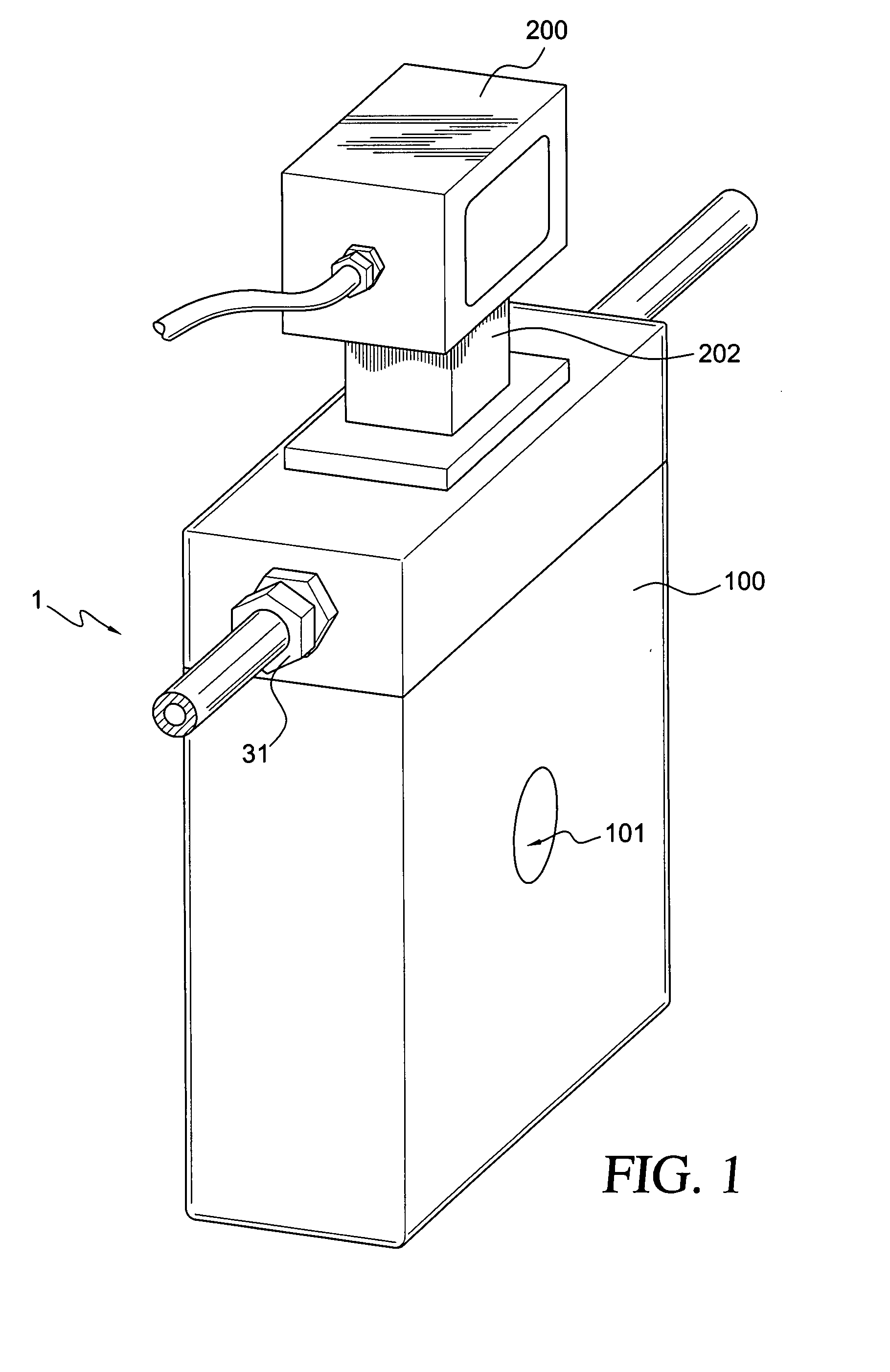

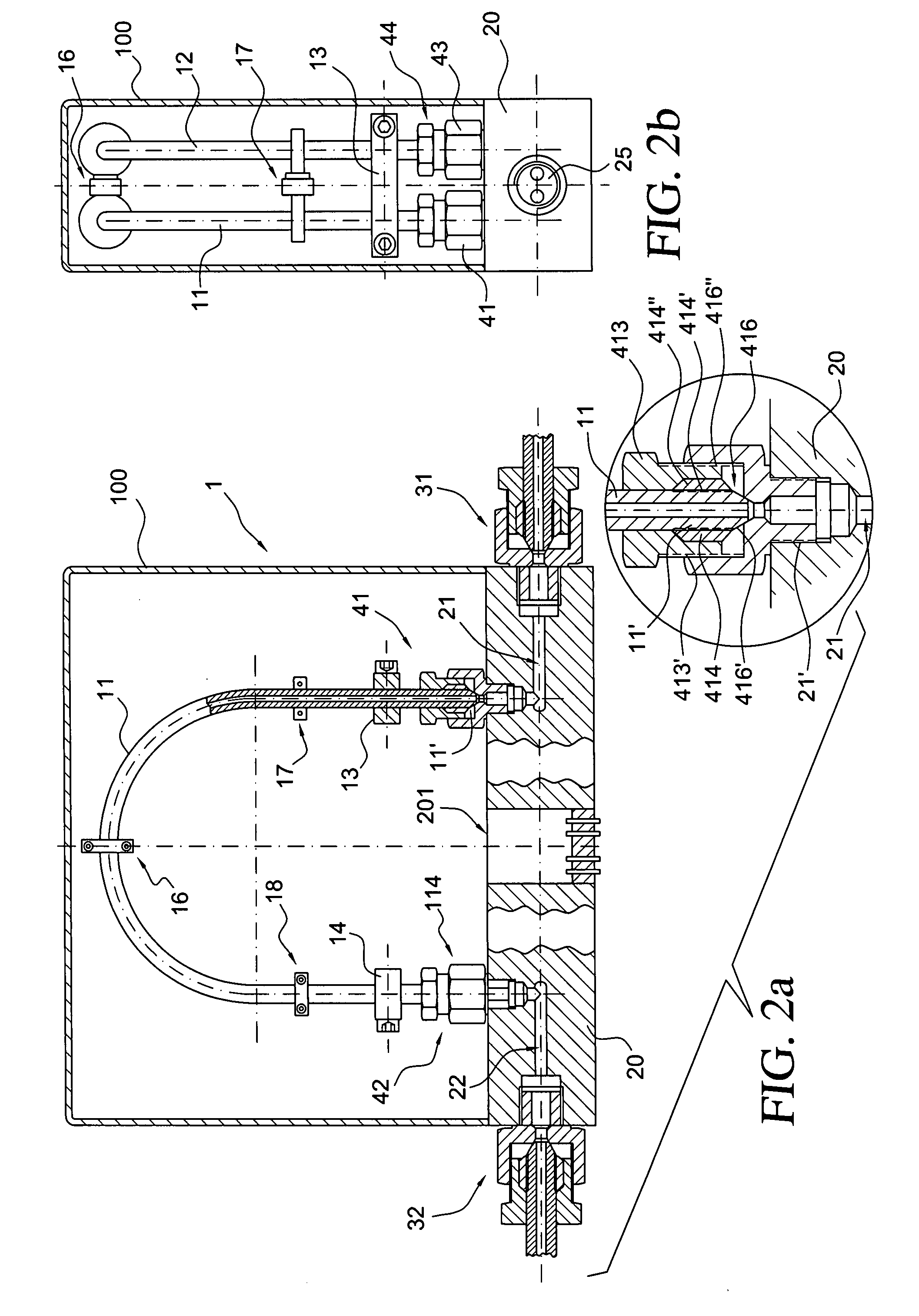

Measuring transducer of vibration-type

ActiveUS20070234822A1High sensitivityEasy constructionVolume meteringDirect mass flowmetersTransducerEngineering

The measuring transducer includes at least one measuring tube communicating with a line connected during operation for conveying a medium to be measured, and a support element oscillatably holding the at least one measuring tube. Additionally, it is provided that the support element contains at least two passageways, via which the at least one measuring tube communicates with the line, and that the at least one measuring tube is affixed, especially releasably, at at least one end to the support element by means of a screwed-fitting at one of the passageways. Alternatively or in supplementation thereof, it is further provided that the at least one measuring tube is, at least in part, made of cold-strengthened, for instance cold-stretched or autofrettaged, material. As required, the measuring transducer can further include at least two measuring tubes communicating with the line for conveying the medium; each of these two measuring tubes is to be connected to an inlet-side distributor element and an outlet-side distributor element. In such case, at least one of the two distributor elements can be embodied as an integral component of the support element, so that the support element can be kept, at least in the area of this at least one distributor element, free of materially bonded, joined locations, especially free of solder, braze or weld connections. The measuring transducer of the invention is especially provided also for applications in which the medium to be measured acts with a pressure of more than 500 bar, especially over 700 bar, on the measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

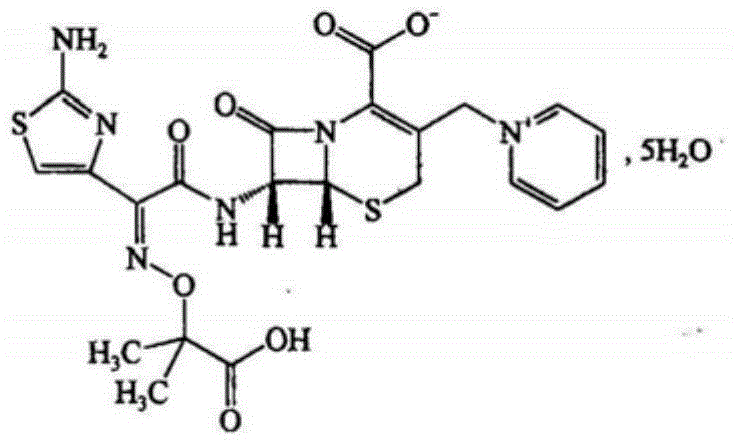

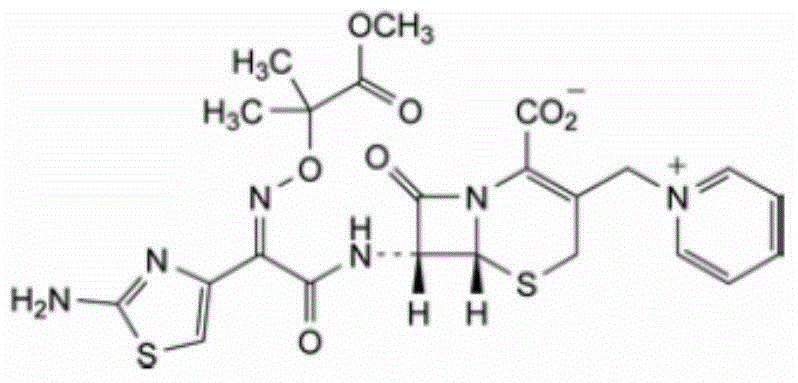

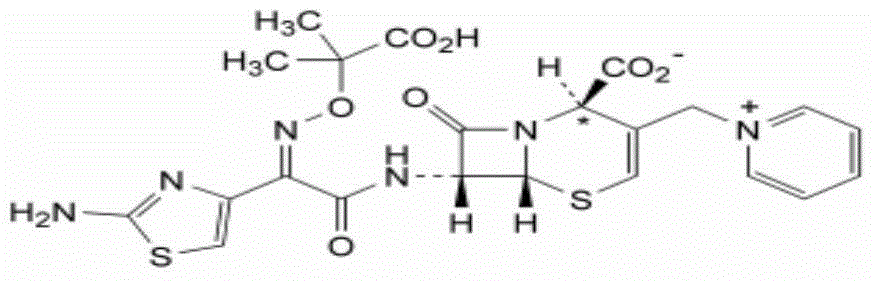

High-purity ceftazidime powder injection and preparation method thereof

ActiveCN105560194AHigh antibacterial activityImprove stabilityAntibacterial agentsPowder deliveryCeftazidimeAntibacterial activity

The invention belongs to the field of medicinal chemistry, and particularly relates to a high-purity ceftazidime powder injection and a preparation method thereof. The high-purity ceftazidime powder injection can have the dosage of 0.5g, 1g or 2g, and contains ceftazidime crude drug, wherein in the ceftazidime crude drug, the content of ceftazidime with the structural formula (I) is 99.70-99.95wt%, the content of impurity pyridine is 0.001-0.05wt%, the content of impurity ceftazidime polymer is 0.001-0.05wt%, the content of impurity ceftazidime methyl ester is lower than 0.05wt%, and the total content of other impurities is 0.03-0.30wt%. The high-purity ceftazidime powder injection has extremely high stability, high safety and high antibacterial activity, and the lifetime thereof is longer than that of existing ceftazidime powder injection by 50% or above. Furthermore, the preparation method of the high-purity ceftazidime powder injection, provided by the invention, is easy and convenient to operate, low in cost and high in safety.

Owner:GUANGZHOU HC PHARM CO LTD

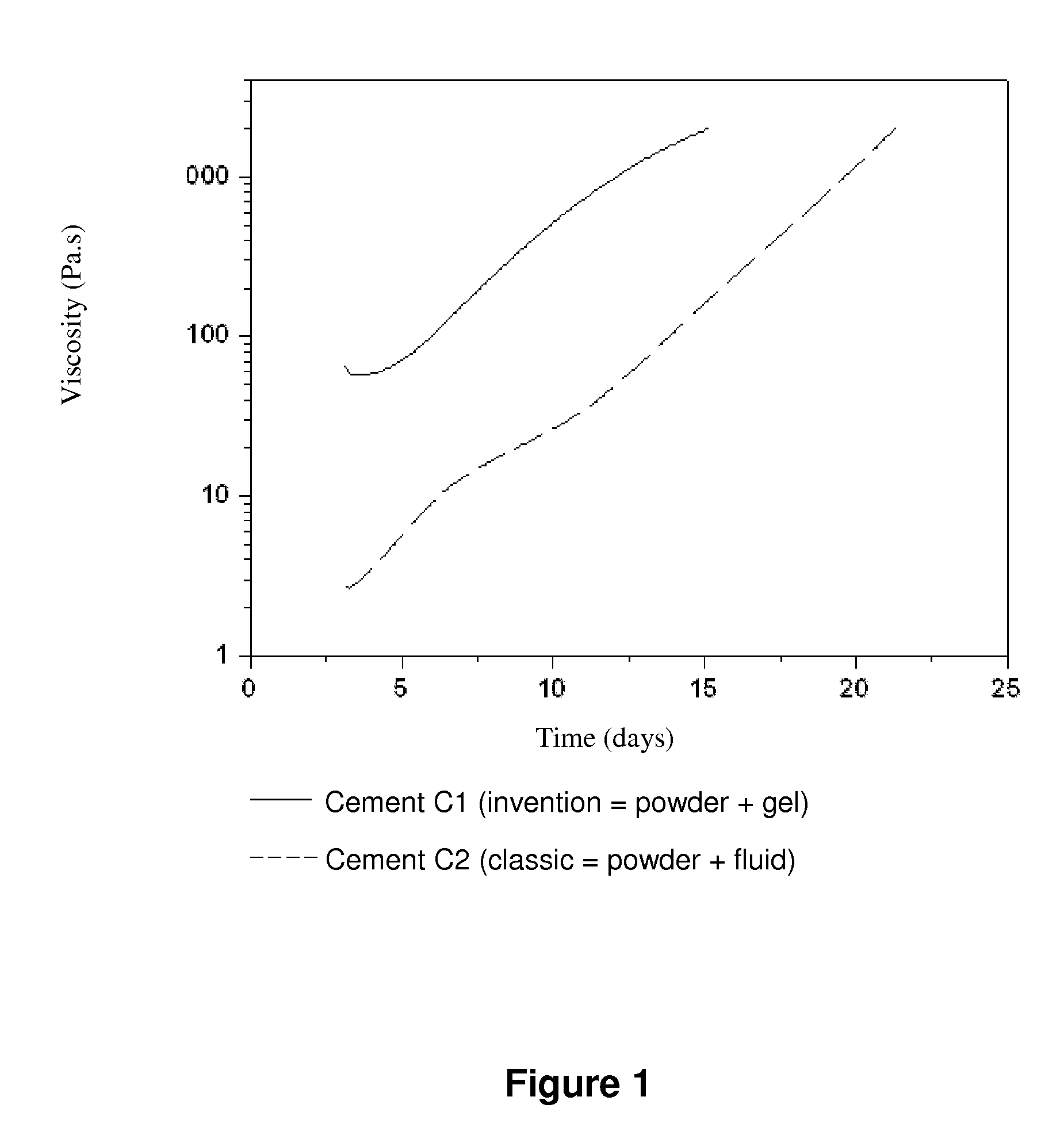

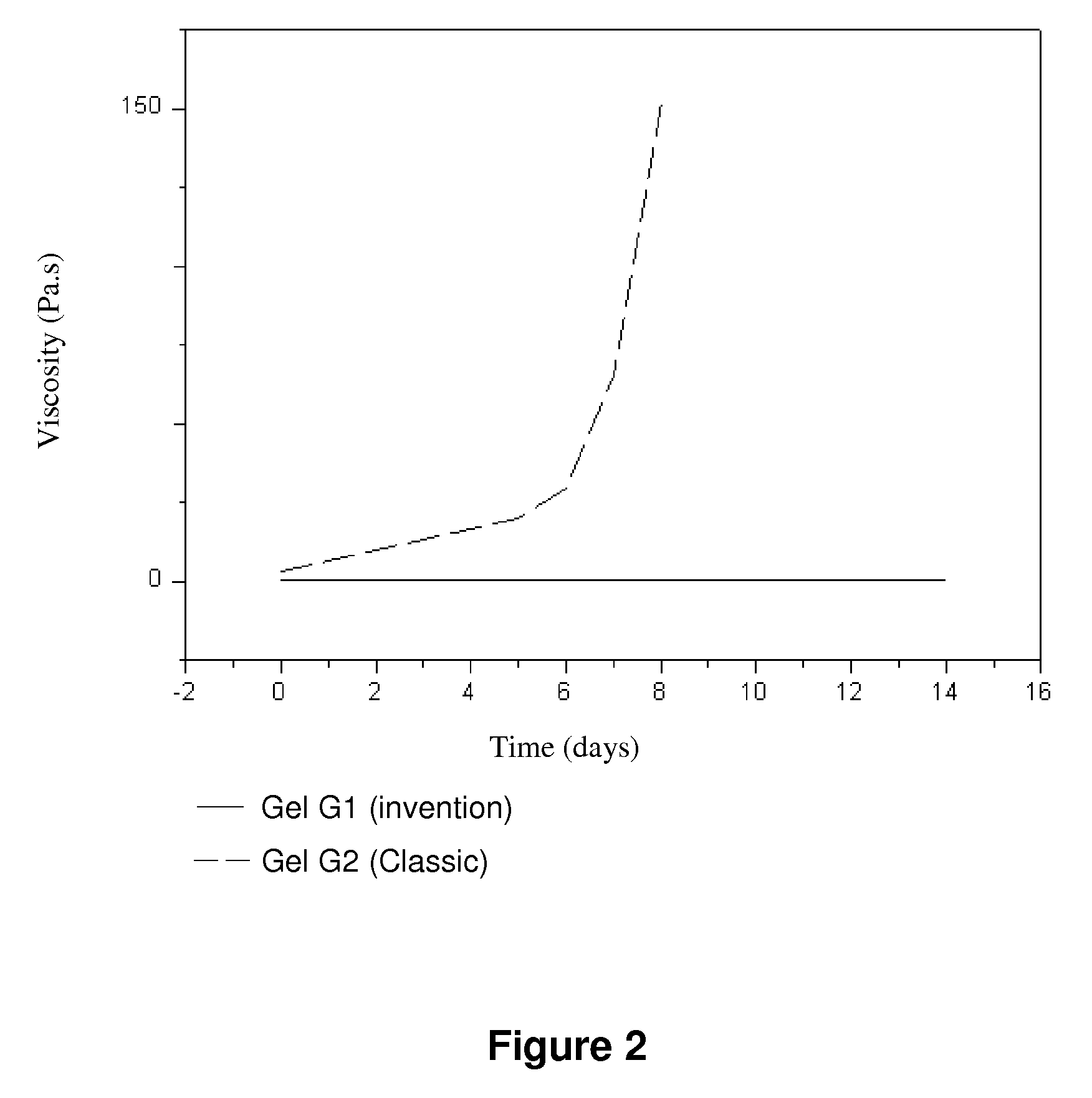

Two-component system for bone cement

InactiveUS8536243B2Eliminate waiting timeReduce riskCosmetic preparationsImpression capsPolymer scienceBone cement

The invention relates to a system for preparing a polymerized bone cement, including two components reacting with each other when they are mixed to form a solid polymer material. The first component may include a biocompatible acrylic polymer and an initiator capable of initiating a polymerization reaction. The second component may include a monomer capable of dissolving an acrylic polymer, a polymerization activator and a polymerization inhibitor, system in which the second component also includes a biocompatible acrylic polymer dissolved in said monomer, identical or different from the polymer of the first component with an average molar mass greater than 1,000,000 g / mol and a residual initiator content of less than 0.1% to form a gel with determined viscosity. Another object of the invention is a composition designed to constitute the second component of as system used to prepare such cement.

Owner:TEKNIMED SAS

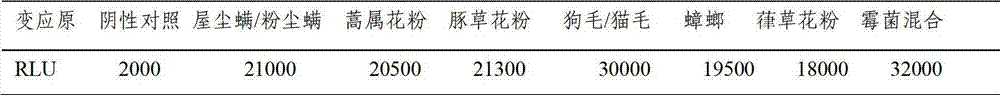

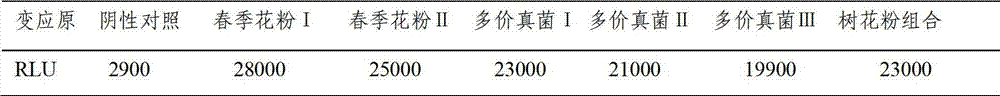

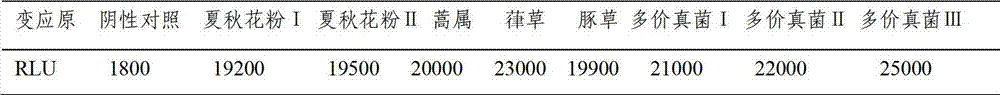

Chemiluminiscence diagnostic kit for sensitization allergens and preparation method thereof

InactiveCN103033611AHigh sensitivityGood repeatabilityChemiluminescene/bioluminescenceSorbentWestern blot

The invention provides a chemiluminiscence diagnostic kit for sensitization allergens and a preparation method thereof. The diagnostic kit comprises a microporous plate coated with the sensitization allergens, a horseradish peroxidase-labeled anti-human IgE (immunoglobulin e) antibody, chemiluminiscence substrate solutions A and B, and a washing solution, wherein the sensitization allergens comprise one or more of an insect allergen, a pollen allergen, a fungus allergen and a food allergen. According to the diagnostic kit, the difference of the sensitivities of different proteins in one diagnostic kit is overcome, and the detection sensitivity of each allergen is enhanced to the maximum extent by repeatedly testing and adjusting the coating amount of the allergens, the concentration of the enzyme-labeled antibody and the formulae and the concentrations of the chemiluminiscence substrate solutions. The chemiluminiscence diagnostic kit is higher in detection sensitivity, safe, reliable, simple and convenient to operate and low in cost in comparison with the ELISA (enzyme linked immunosorbent assay), western-blot and RAST (radioallergo-sorbent test) diagnostic kits for the allergens.

Owner:北京新华联协和药业有限责任公司

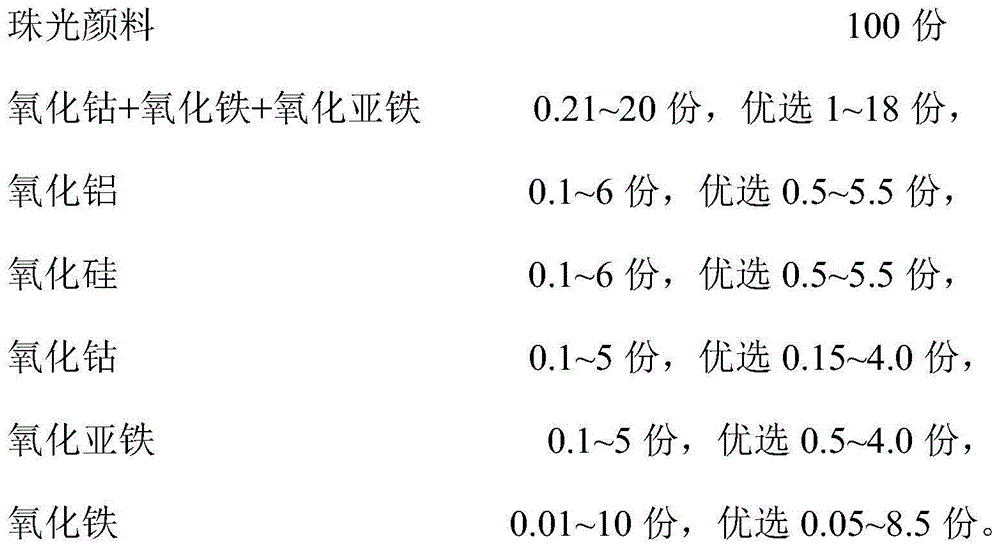

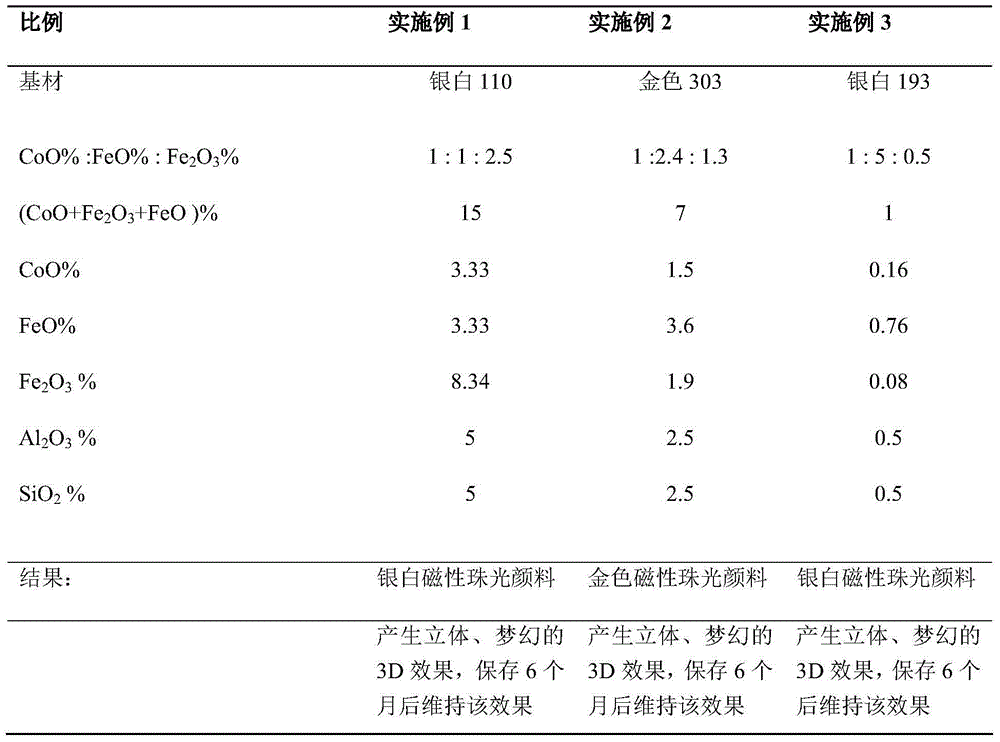

Magnetic pearlescent pigment with 3D (three-dimensional) effect and preparation method of magnetic pearlescent pigment

ActiveCN104893366AReduce the loss of ferroferric oxideReduce magnetic lossInorganic pigment treatmentCobalt oxideChemistry

The invention discloses magnetic pearlescent pigment with a 3D (three-dimensional) effect and a preparation method of the magnetic pearlescent pigment. The magnetic pearlescent pigment comprises pearlescent pigment, a magnetic coating and a protecting layer, wherein the magnetic coating is located on one or more pearlescent pigment layers and comprises cobalt oxide, iron oxide and iron protoxide; the protecting layer is located on the magnetic coating; the pearlescent pigment comprises a base material and one or more pearlescent pigment layers. The prepared magnetic pearlescent pigment with the 3D effect can have a stereoscopic and dreamlike 3D effect by utilizing the magnetic tracking phenomenon of a surface magnetism material. By means of the preparation method of the magnetic pearlescent pigment with the 3D effect, the problem that ferrous iron is easily oxidized in the prior art can be solved, loss of ferroferric oxide is reduced, magnetic loss is reduced, part of produced iron cobaltate is stable and not prone to oxidation, and long-time storage of the pigment is guaranteed.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

Multi-layer high moisture barrier polylactic acid film

ActiveUS20130143057A1Excellent gas barrier performanceImprove barrier propertiesLiquid surface applicatorsPig casting plantsEmulsionMoisture barrier

Owner:TORAY PLASTICS (AMERICA) INC

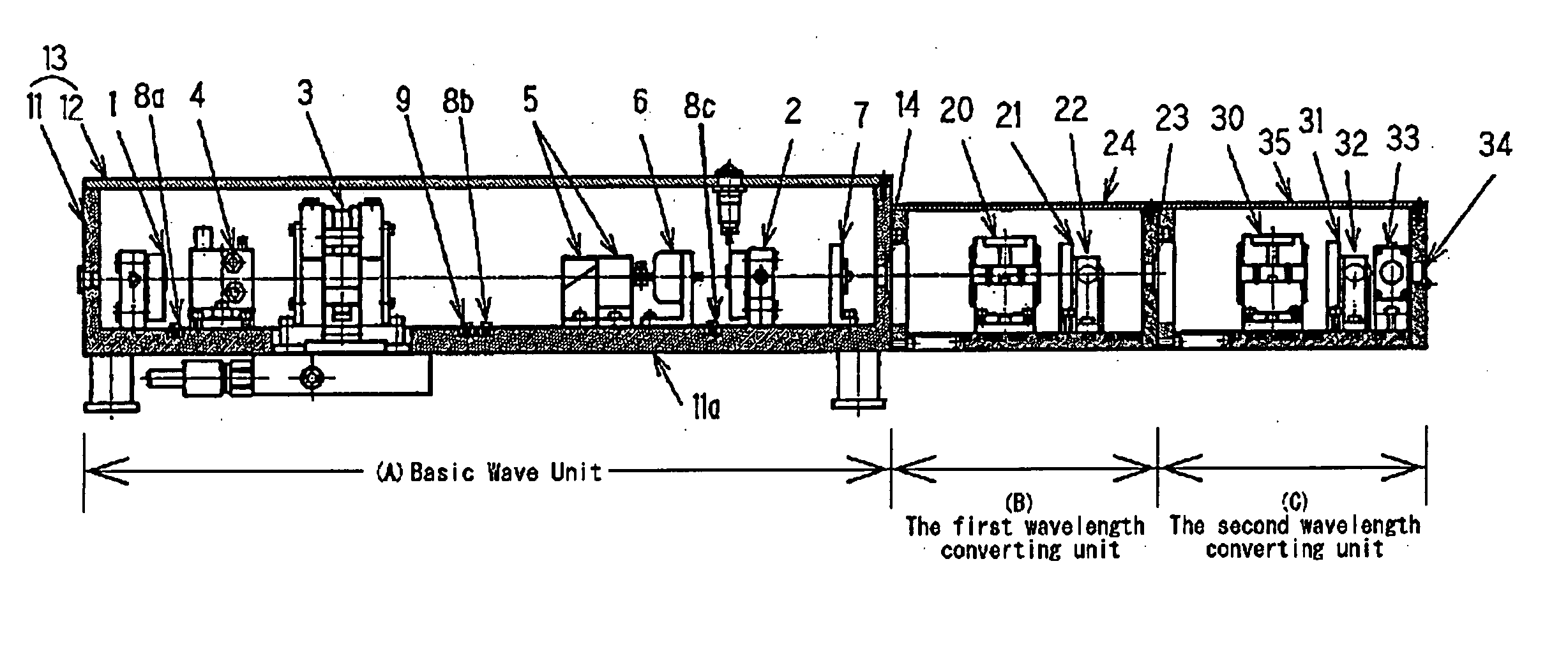

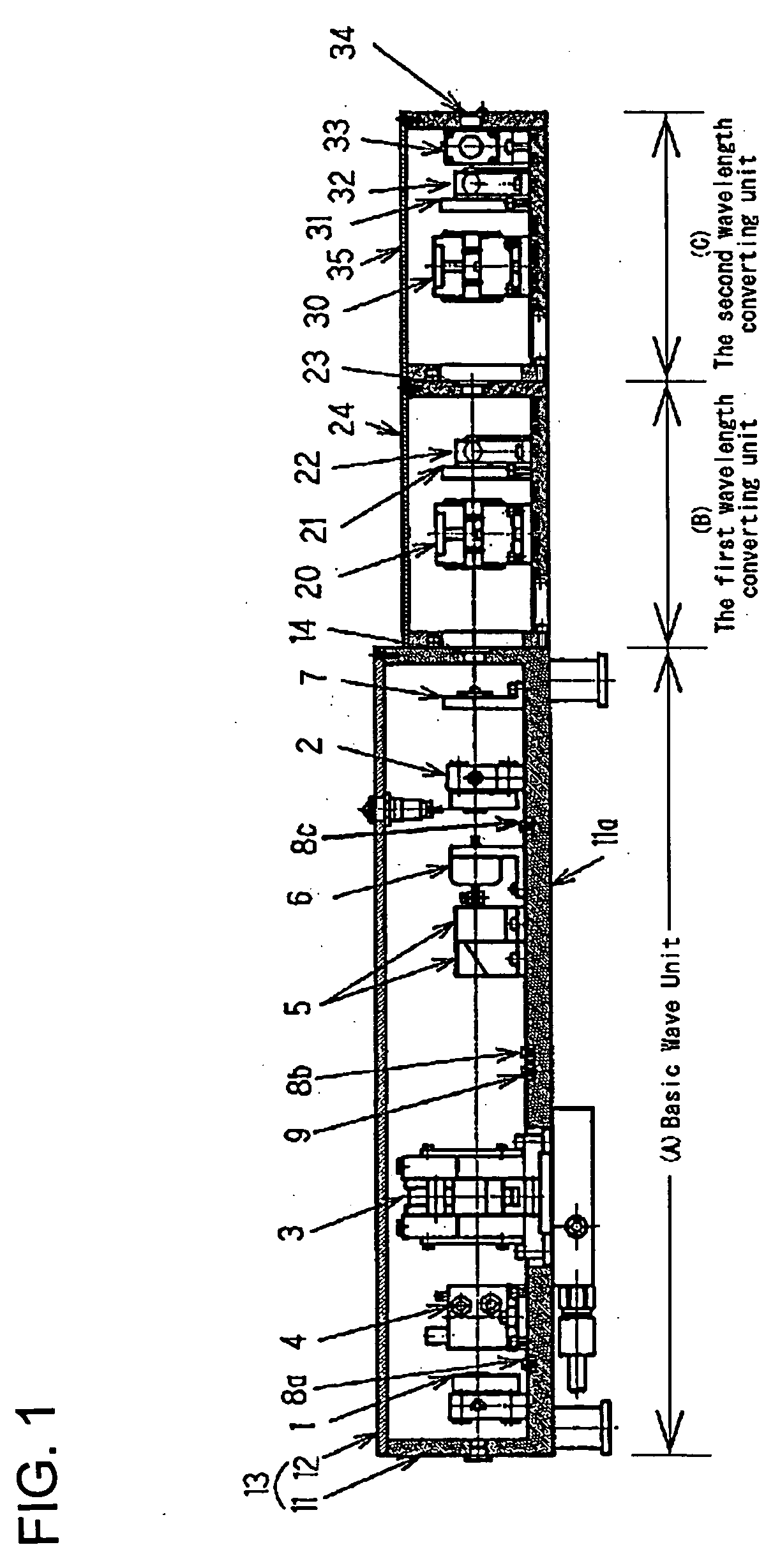

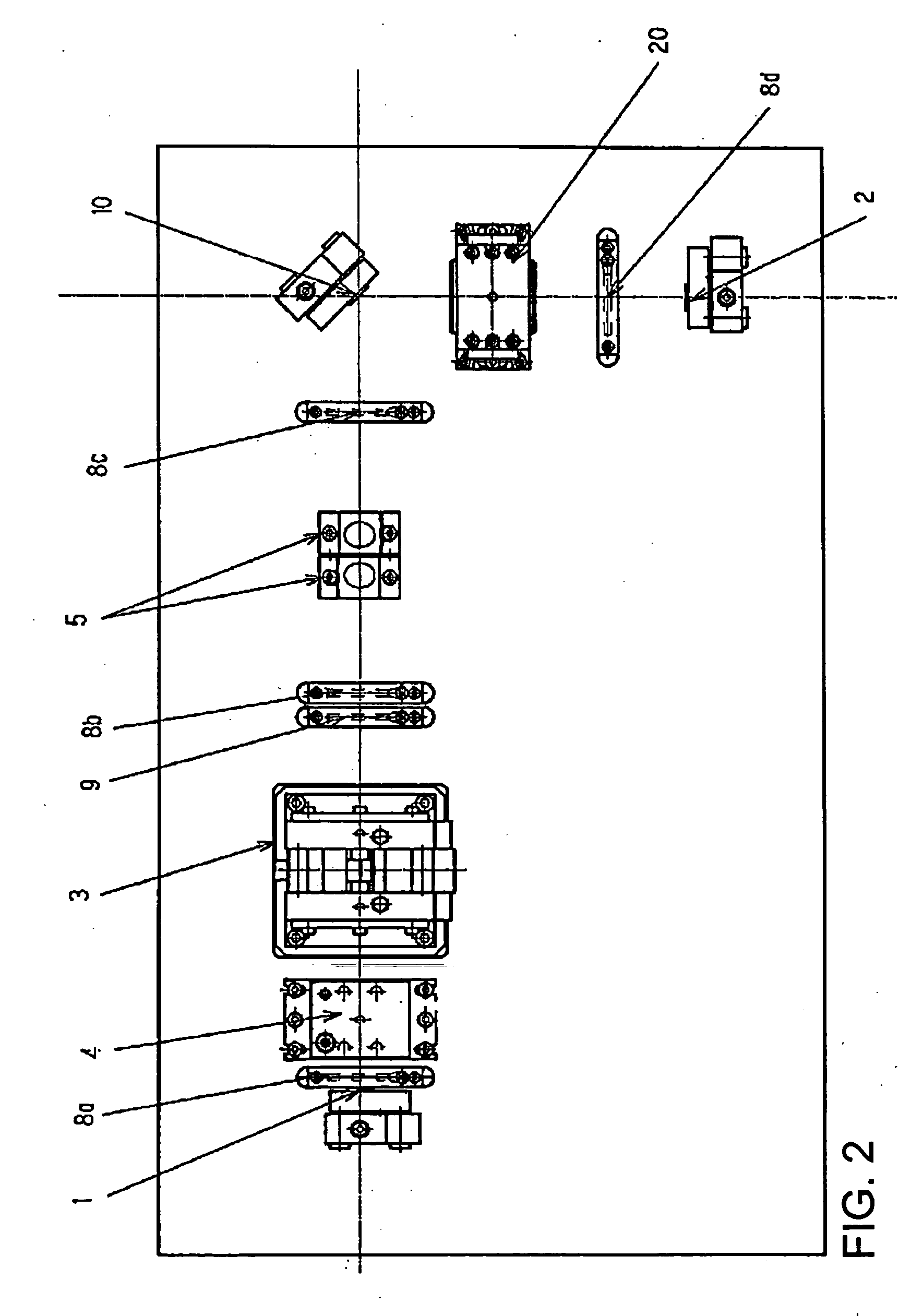

Laser system and laser wavelength conversion

InactiveUS20050008047A1Long-termPrevent rotOptical devices for laserNon-linear opticsNonlinear optical crystalComing out

A laser system is enabled to generate laser beam stably for a long term by avoiding the decay of nonlinear optical crystals due to moisture. The fundamental laser wave at a wavelength of 1064 nm is emitted from the pumping chamber unit of the solid-state laser device. The fundamental laser wave enters the first nonlinear optical crystal unit (20). The wavelength of the laser beam is converted into a half by the first nonlinear optical crystal unit (20). The converted laser beam emanates out of the unit. The fundamental laser wave and the second harmonic laser wave are introduced into the second nonlinear optical crystal unit. Each of the laser beams is converted into the third harmonic laser wave (three-time fundamental frequency) or the fourth harmonic laser beam (four-time fundamental frequency) and the laser beam comes out of the exit-window (34). The nonlinear optical crystal units (20), (30) are held in a hermetically sealed cell whose inner surface is treated to be water-repellent. As the dry atmosphere is kept by means of isolating the nonlinear optical crystal from the outer air, the crystals can avoid decay due to moisture and the damage on the crystals can be reduced.

Owner:ORC MFG

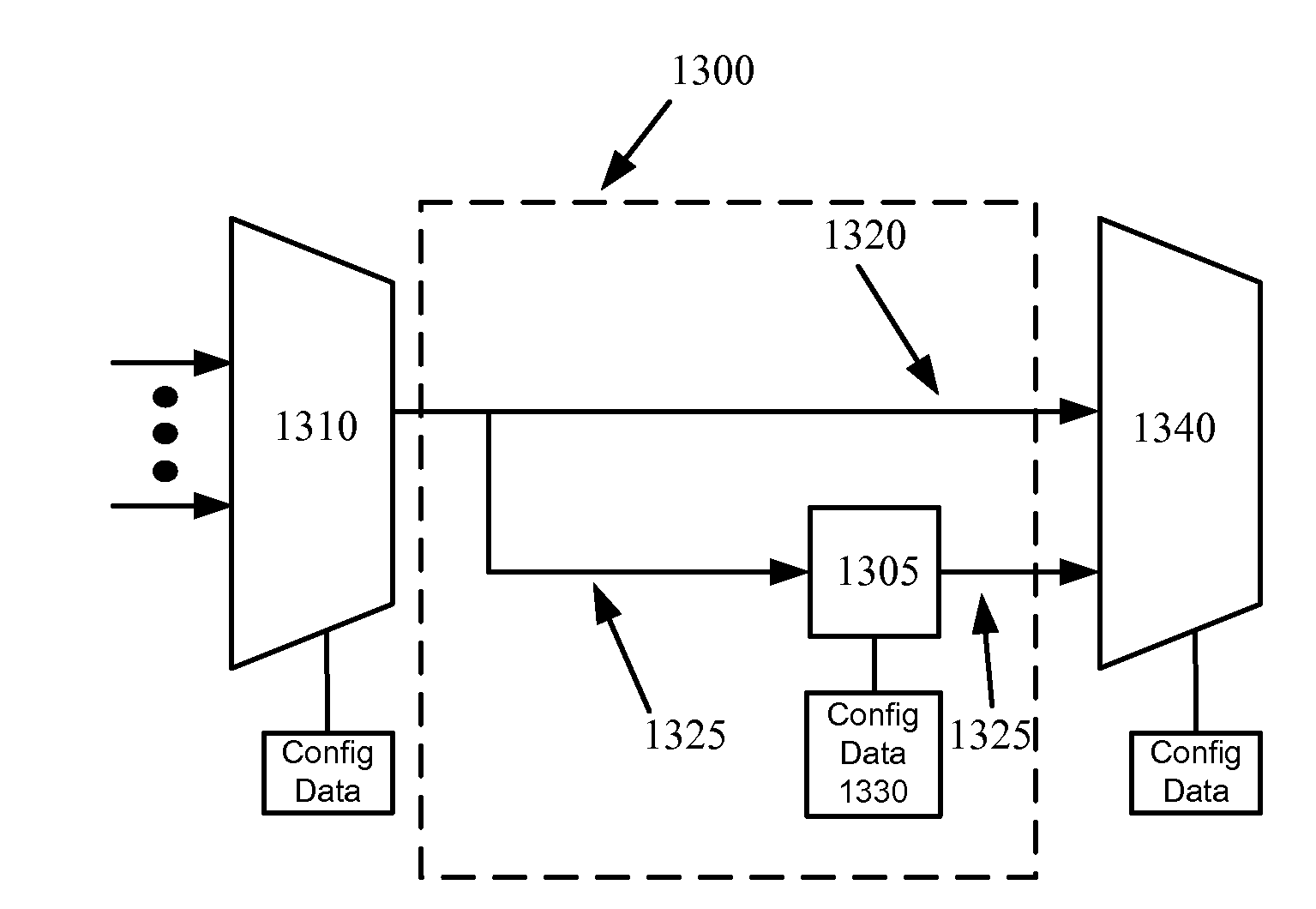

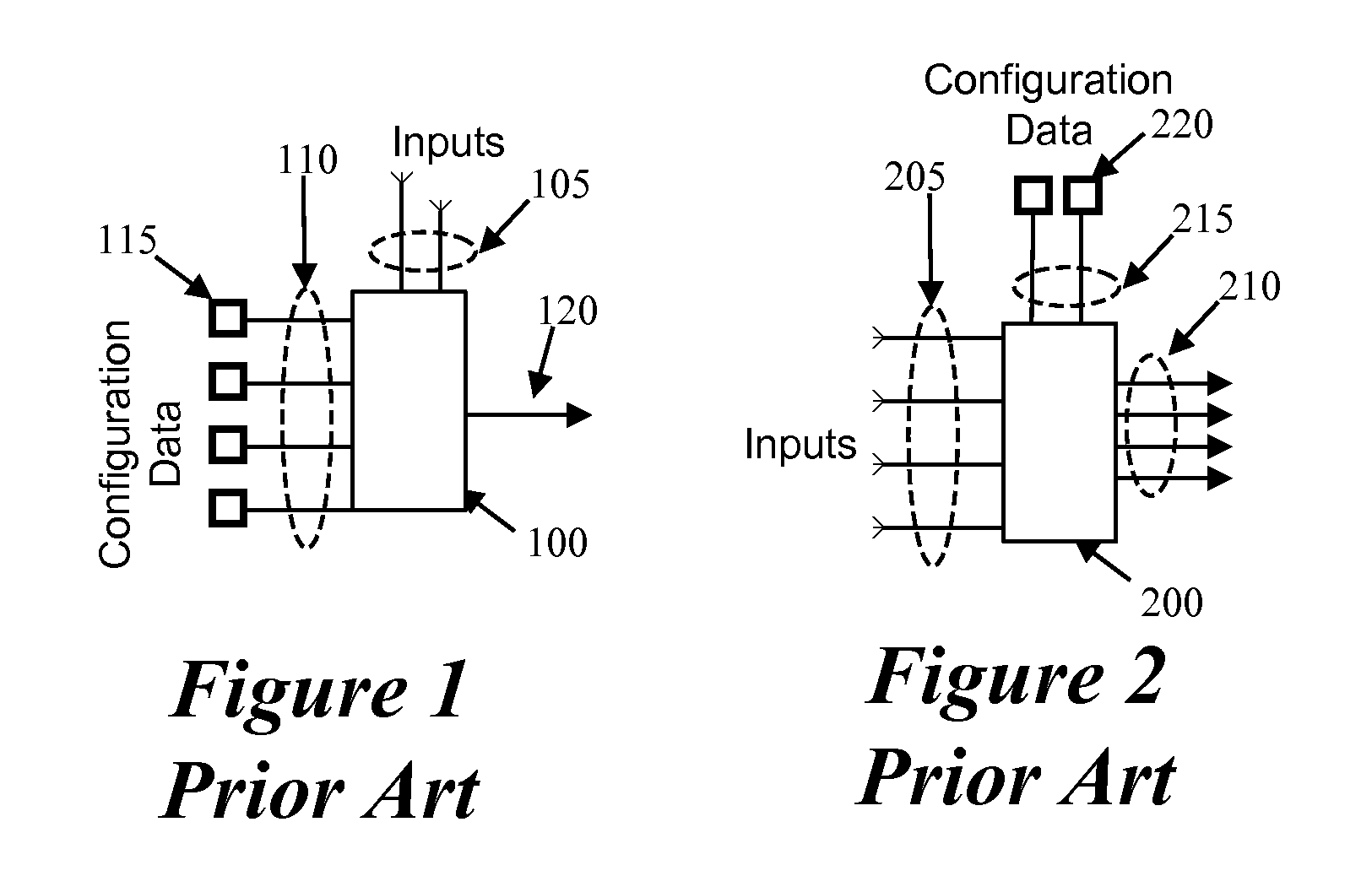

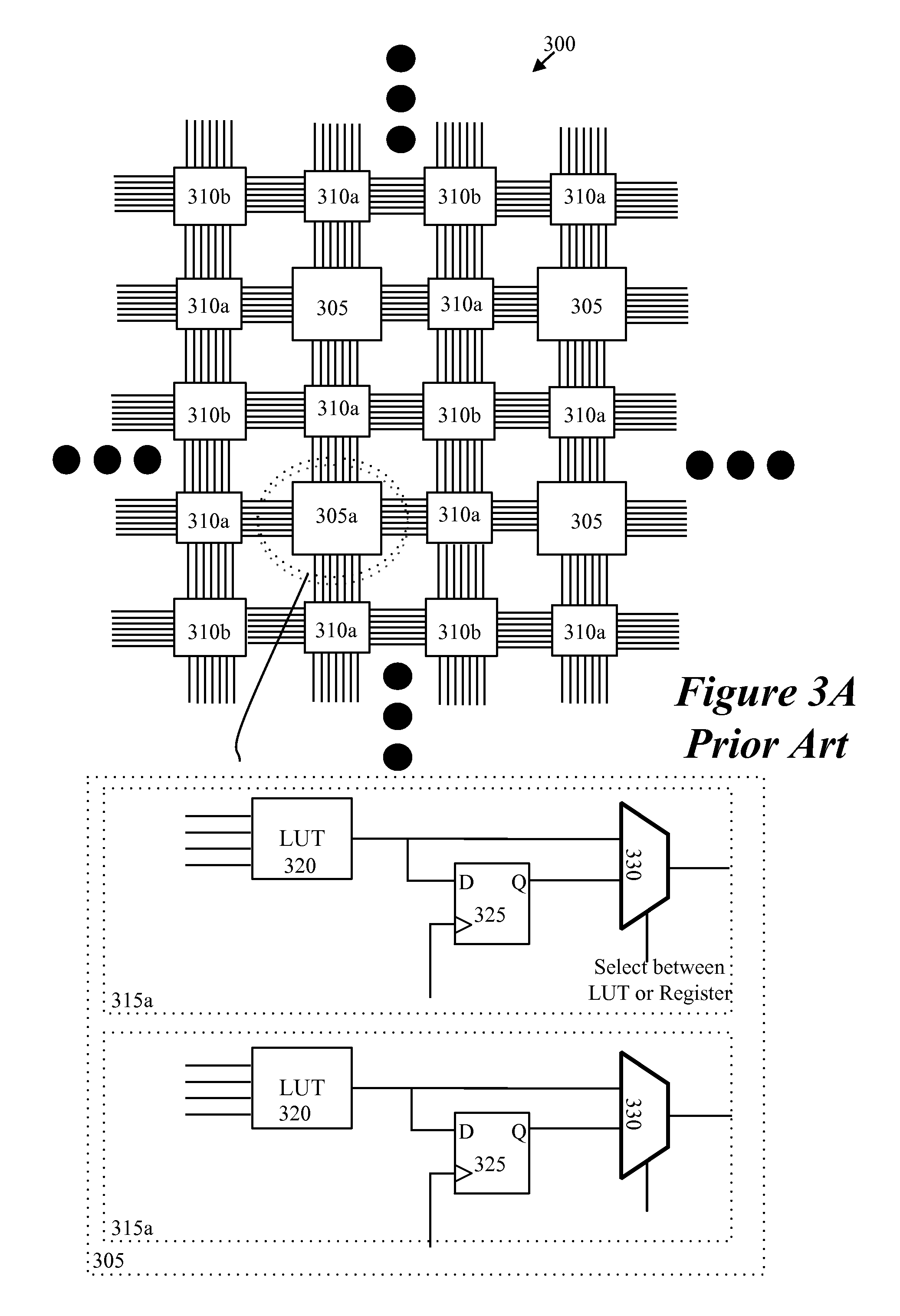

Configurable IC Having A Routing Fabric With Storage Elements

InactiveUS20080231314A1Long-termSolid-state devicesLogic circuits using elementary logic circuit componentsSignal routingComputer science

Some embodiments provide a configurable IC that includes a configurable routing fabric with storage elements. In some embodiments, the routing fabric provides a communication pathway that routes signals to and from source and destination components. The routing fabric of some embodiments provides the ability to selectively store the signals passing through the routing fabric within the storage elements of the routing fabric. In this manner, a source or destination component continually performs operations (e.g., computational or routing) irrespective of whether a previous signal from or to such a component is stored within the routing fabric. The source and destination components include configurable logic circuits, configurable interconnect circuits, and various other circuits that receive or distribute signals throughout the configurable IC.

Owner:ALTERA CORP

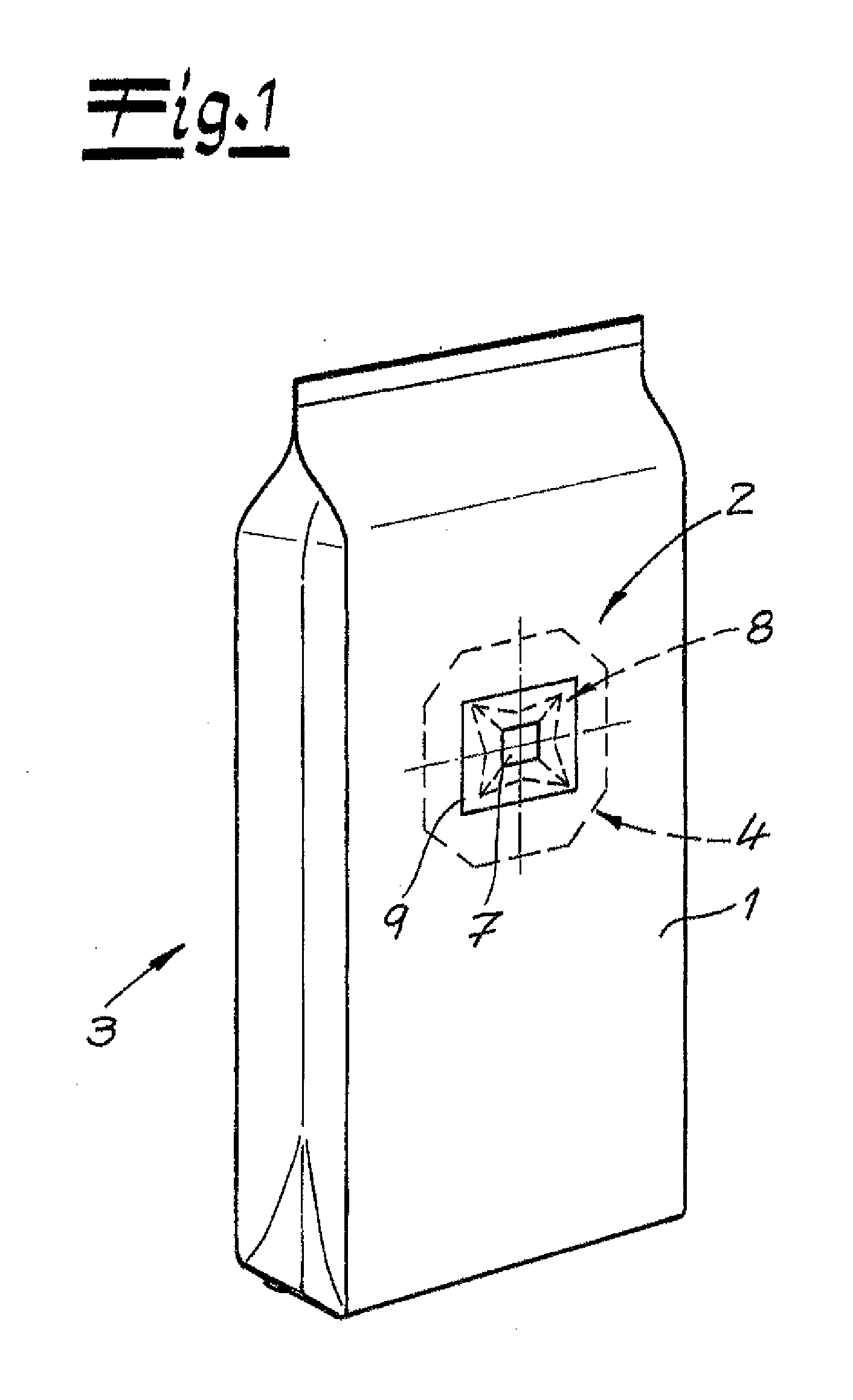

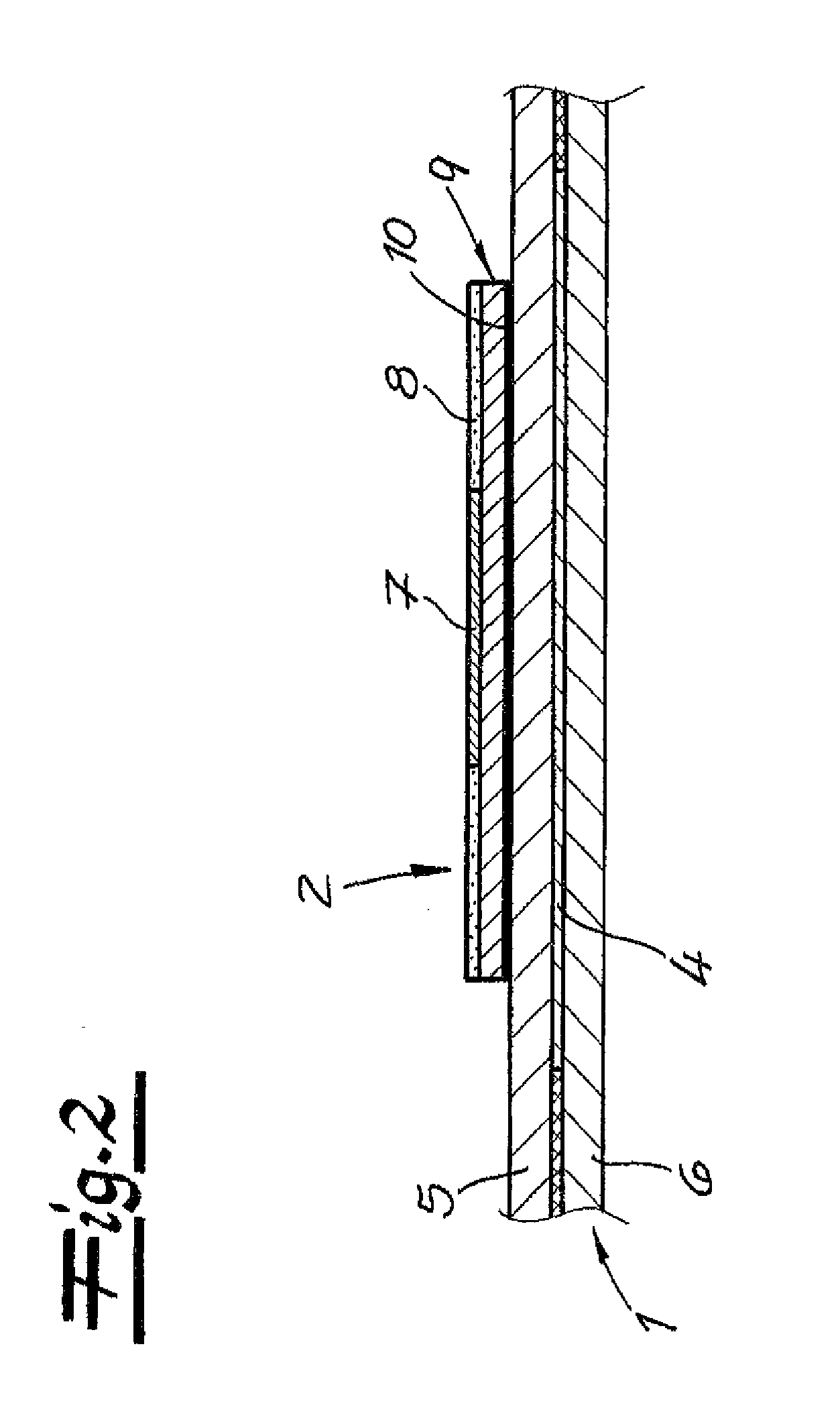

Body in the form of a packaging or of a molded part

InactiveUS20120267434A1Improve protectionPossible to easilyRecord carriers used with machinesEngineeringRadio frequency

A body in the form of a packaging or of a molded part has an outer layer composed of a film, on which a radio-frequency identification (RFID) arrangement is provided. An antenna of the RFID arrangement is printed directly on a layer of the film, wherein an RFID chip of the RFID arrangement is disposed on a support section, and wherein the support section with the RFID chip is set onto the film in the region of the RFID antenna.

Owner:NORDENIA TECH

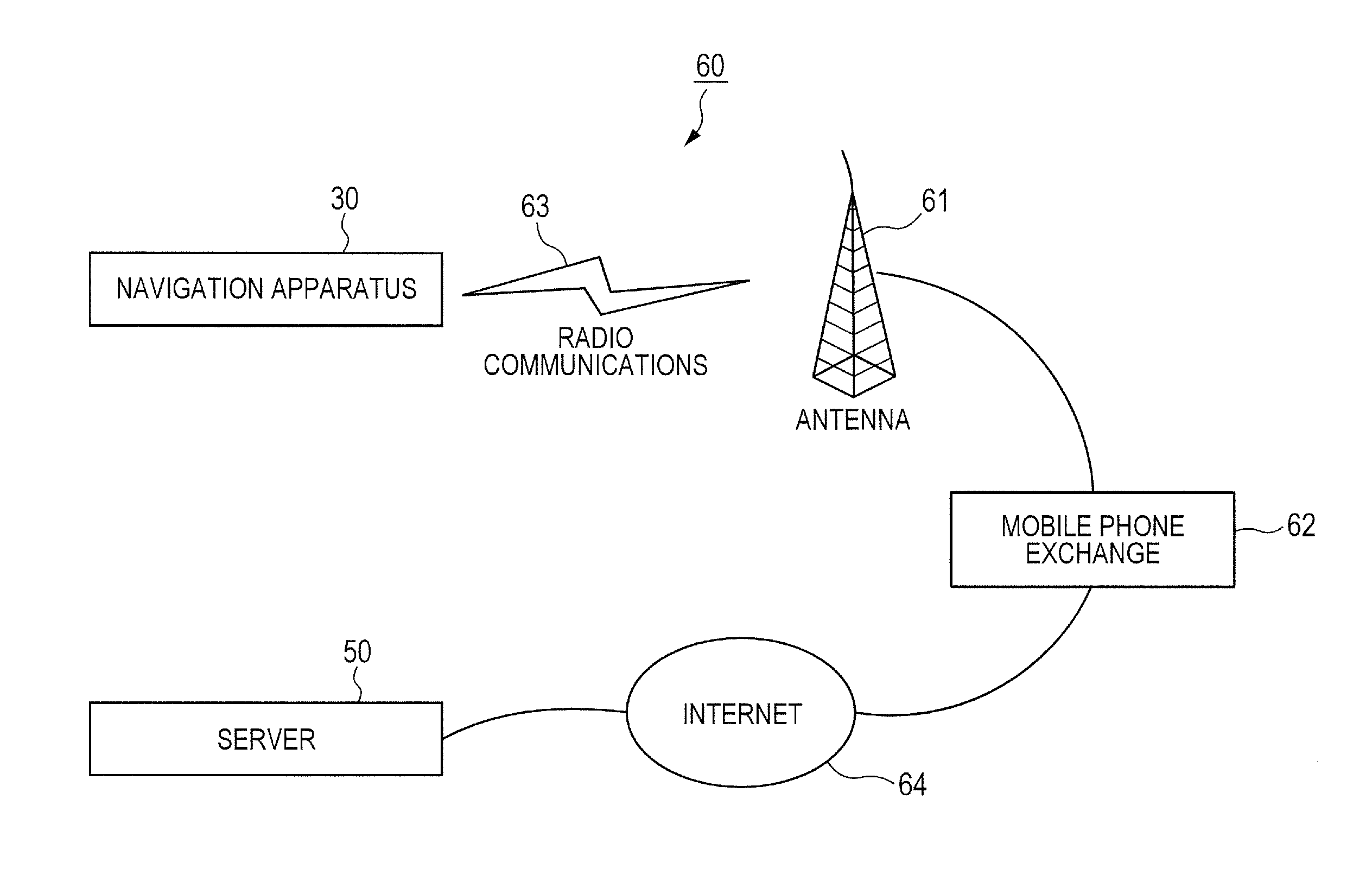

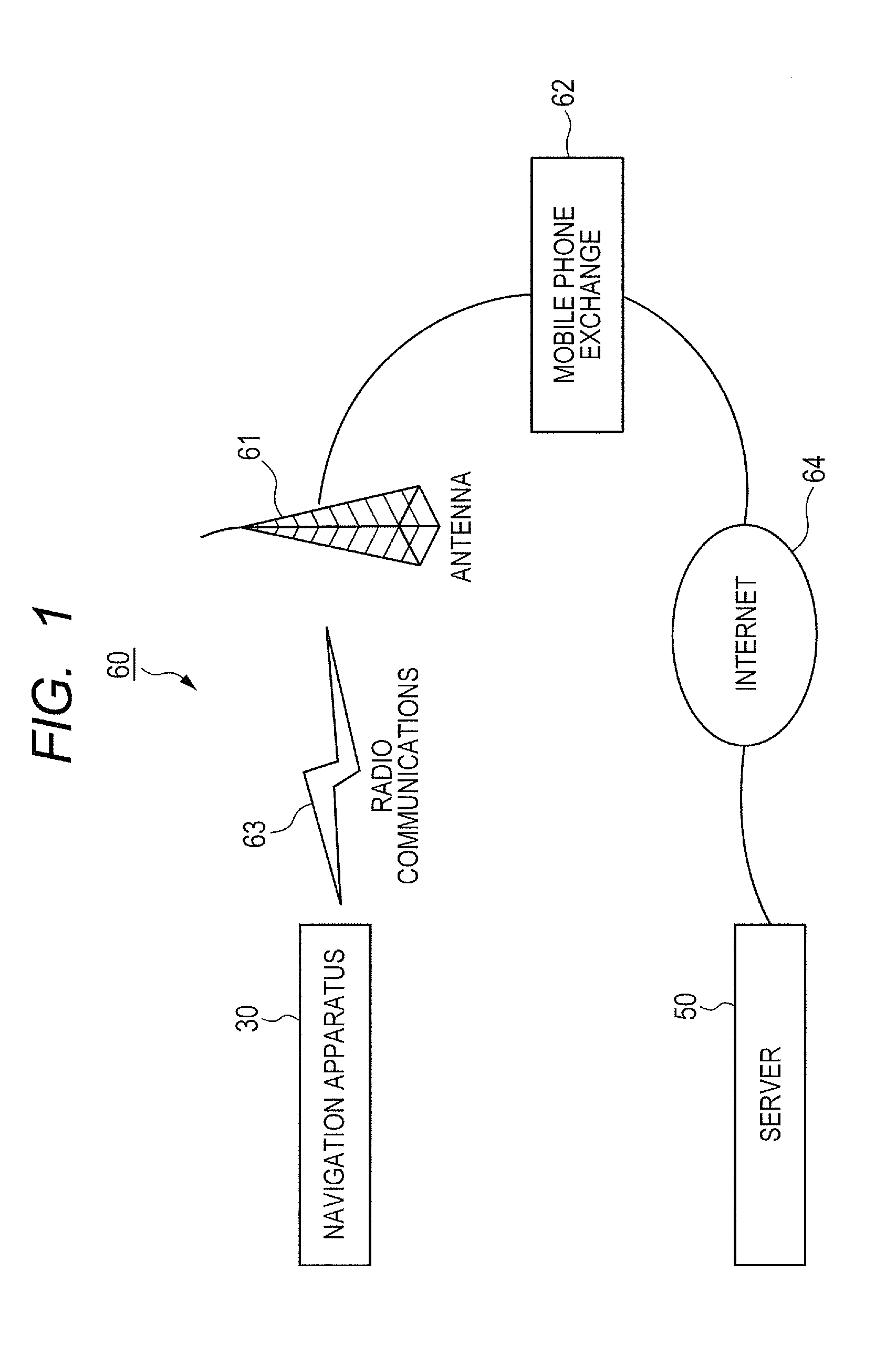

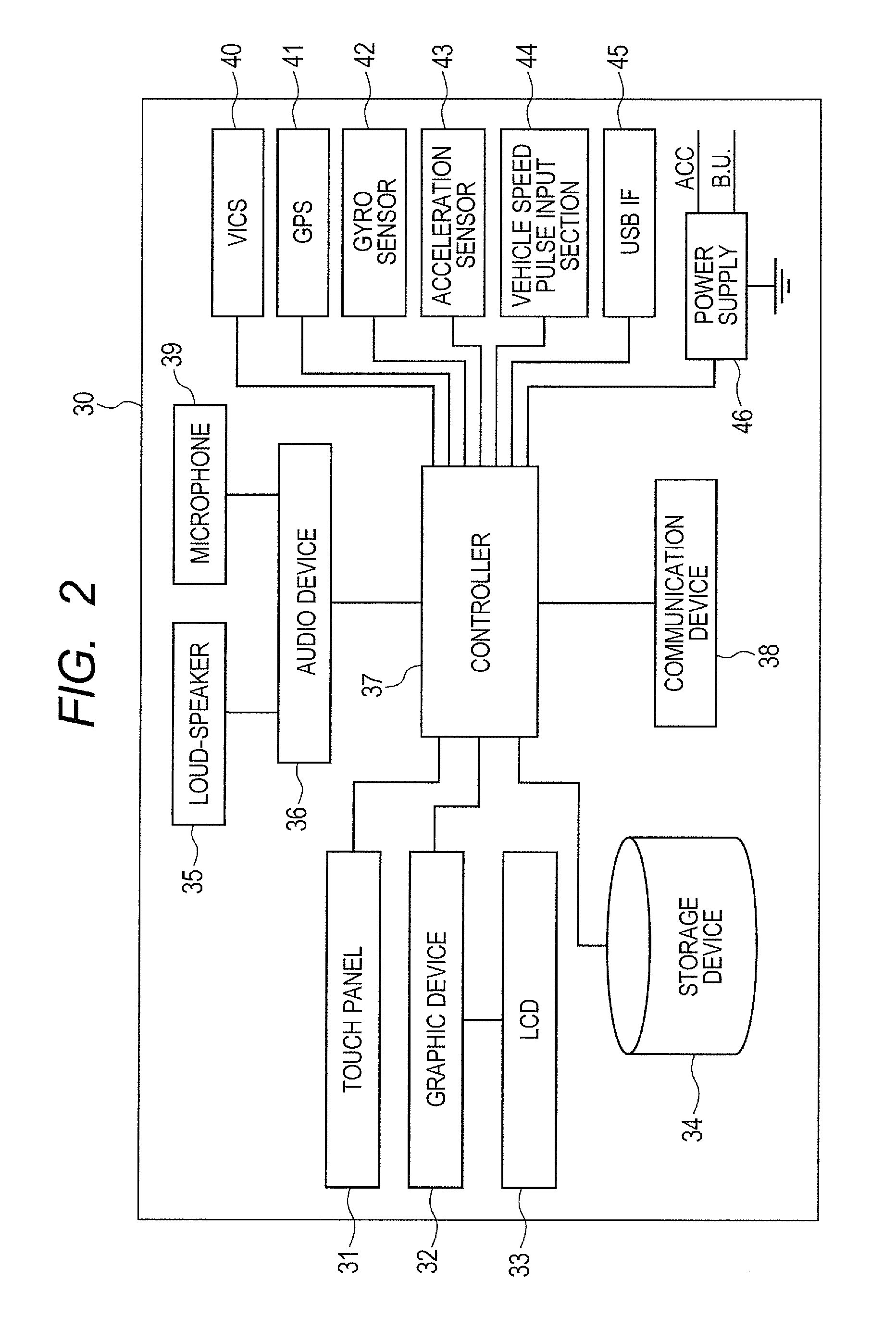

On-Vehicle Apparatus, And Method And Computer Program For Transmitting Positional Information

ActiveUS20130173879A1Long-termInhibition of Accuracy DecreaseInstruments for road network navigationRoad vehicles traffic controlComputer programStorage area

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Heat resistant polyamide composite structures and processes for their preparation

InactiveUS20110027571A1Easily and rapidly and efficiently impregnatedLong-termCeramic shaping apparatusFurniture partsPolyamideComposite structure

Owner:EI DU PONT DE NEMOURS & CO

Vaporizer and various devices using the same and an associated vaporizing method

InactiveUS20080193645A1Stable supplyLong termFlow mixersTransportation and packagingGas passingProcess engineering

A vaporizer has gas passage formed inside of main body of a dispersion part, a gas inlet opening to introduce pressurized carrier gas into gas passage, a part to supply raw materials solution to carrier gas passing gas passage, a gas outlet to send carrier gas including dispersed raw material solution to vaporization part, a dispersion part to flow through gas passage having a part to cool, a vaporization pipe connected with a reaction part and gas outlet of dispersion part of the device, and a heater to heat vaporization pipe is provided, a vaporization part to heat and vaporizes the carrier gas where raw materials solution is dispersed is provided, and a radiation prevention portion having small hole for the outside of gas outlet is provided.

Owner:M WATANABE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com