Squeeze casting method for mixed-particle-reinforced type aluminum matrix composite

An aluminum matrix composite material and particle reinforcement technology, which is applied in the field of metal matrix composite material preparation, can solve the problems of thermal expansion mismatch between particles and aluminum matrix, low oxidation resistance and friction coefficient, non-wetting of particles and aluminum matrix, etc. Advanced, accurate and detailed data, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

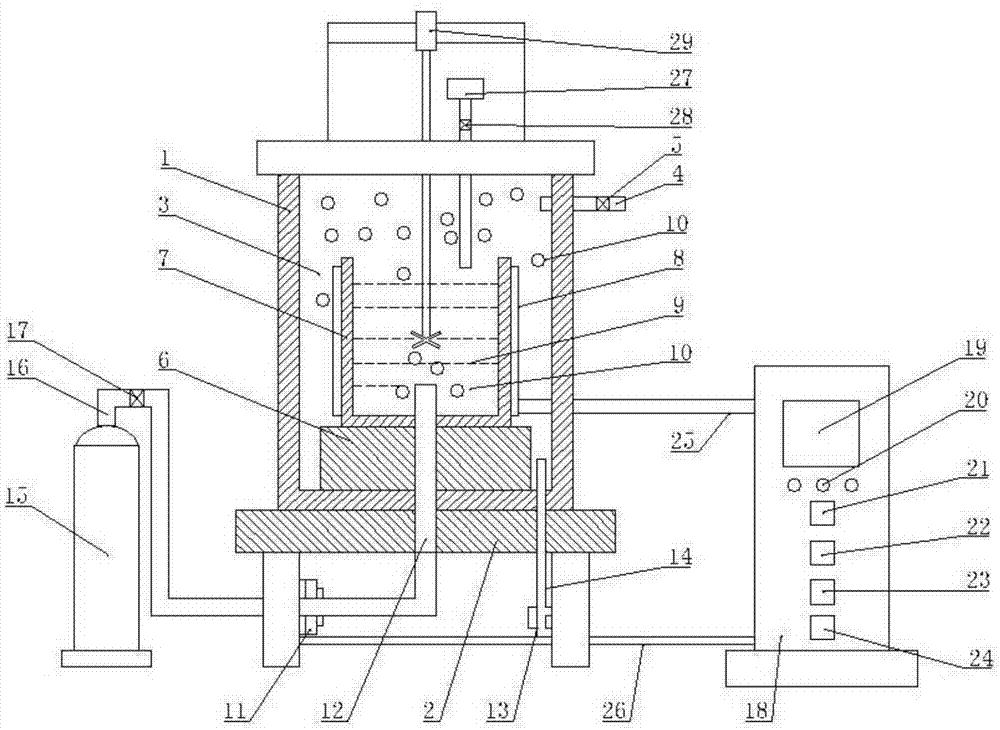

[0060] The principle of squeeze casting of mixed particle reinforced aluminum matrix composites is as follows:

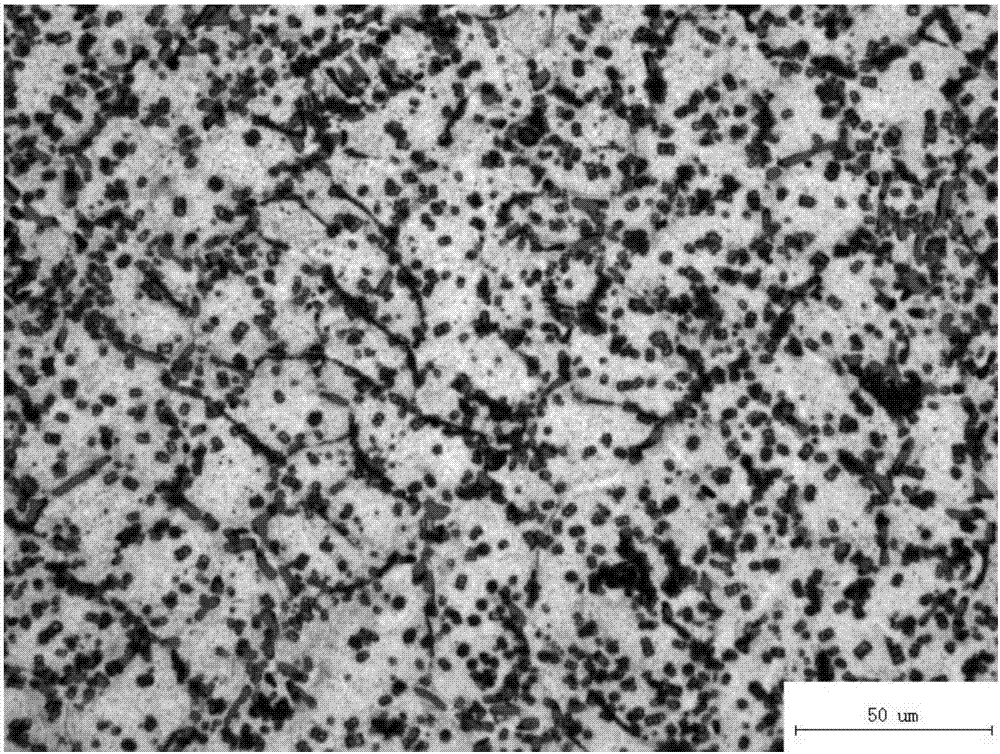

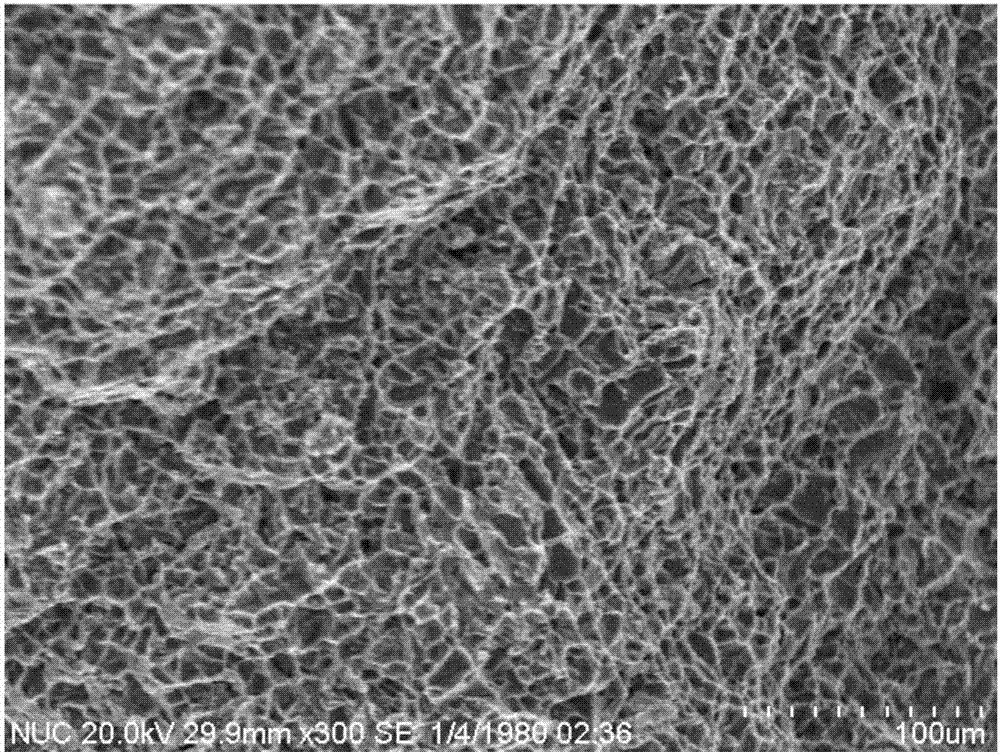

[0061] During the squeeze casting process of composite materials, there are alumina, zirconium aluminide and aluminum-copper-iron-beryllium quasicrystal reinforcement phases in the alloy melt, the alloy melt is cast into the cavity of the extrusion mold, the squeeze casting machine is turned on, and the extrusion Molded into the molten metal, the extrusion pressure is 230MPa, and the holding time is 20s, so that the metal melt is crystallized under this pressure, the grain structure of the casting is refined, the distribution of the reinforcing phase is improved, and the uniformity of the alloy structure is improved. , so as to obtain the mixed particle reinforced aluminum matrix composite with dense structure and excellent performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com