Magnesium-based spherical quasicrystal master alloy and preparation method thereof

An intermediate alloy and spherical technology, applied in the field of magnesium-based alloys, can solve the problems of waste of energy consumption, difficult industrialized production, complicated control, etc., and achieve the effects of improving mechanical properties, simplifying production steps, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

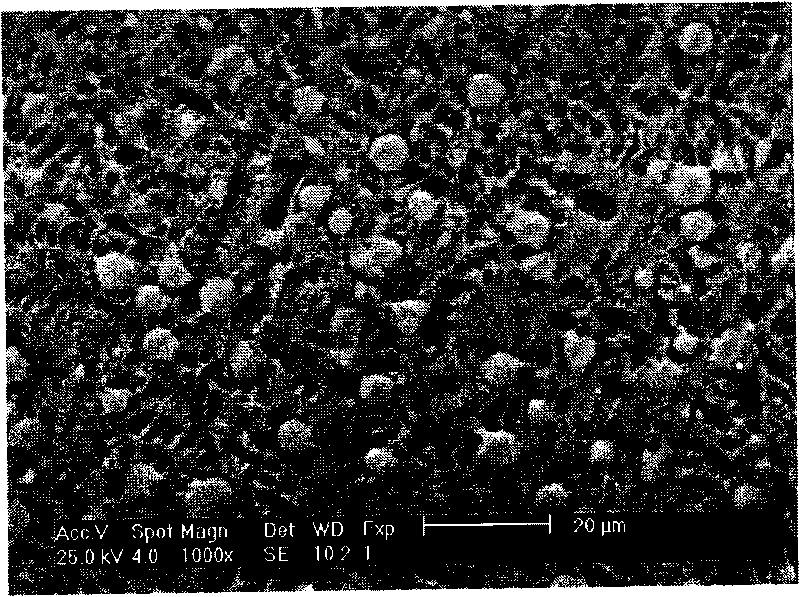

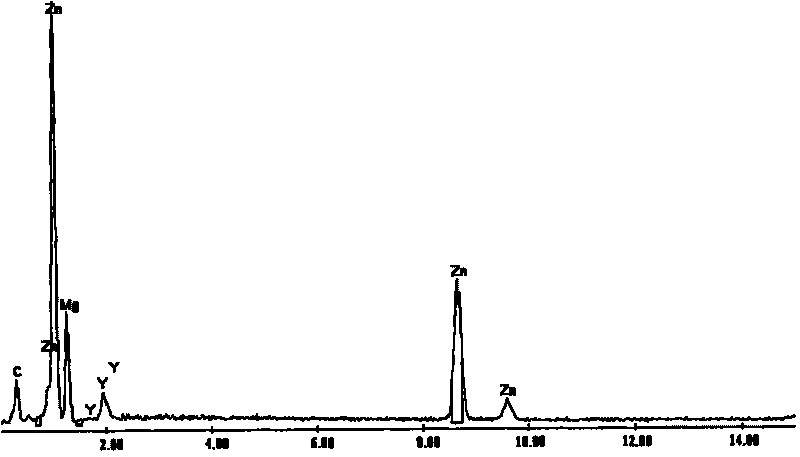

Image

Examples

Embodiment 1

[0026] The first step is to smelt the raw material melt of magnesium-based spherical quasicrystal master alloy

[0027] Set the heating temperature of the crucible resistance furnace to be 790°C. When the crucible temperature rose to 380°C, add magnesium ingots accounting for 60.5% of the total raw material mass percent and zinc ingots accounting for 35.5% of the total raw material mass percent to the crucible. And start to pass CO with a volume ratio of 100:1 2 / SF 6 The mixed gas is used as a protective gas, and the temperature continues to rise. After the magnesium ingot and the zinc ingot in the crucible are completely melted, add 3.7% yttrium ingot accounting for the mass percentage of the total amount of raw materials, and stir for 1 minute after the yttrium ingot is completely melted. In the Mg-Zn-Y alloy melt, add the carbon powder that accounts for 0.3% of the mass percentage of the total amount of raw materials with a particle size of 200 mesh carbon powder, and the...

Embodiment 2

[0033] The first step is to smelt the raw material melt of magnesium-based spherical quasicrystal master alloy

[0034] Set the heating temperature of the crucible resistance furnace to be 780°C, and when the crucible temperature rises to 350°C, add magnesium ingots accounting for 65.0% of the total mass percentage of raw materials and zinc ingots accounting for 30.0% of the total mass percentage of raw materials to the crucible, And start to pass CO with a volume ratio of 100:1 2 / SF 6 The mixed gas is used as a protective gas, and the temperature continues to rise. After the magnesium ingot and zinc ingot in the crucible are completely melted, add yttrium ingot accounting for 4.5% of the total mass percentage of raw materials, and stir for 1 minute after the yttrium ingot is completely melted. In the Mg-Zn-Y alloy melt, add the carbon powder that accounts for 0.5% of the mass percentage of the total amount of raw materials with a particle size of 200 mesh carbon powder, and...

Embodiment 3

[0038] The first step is to smelt the raw material melt of magnesium-based spherical quasicrystal master alloy

[0039] Set the heating temperature of the crucible resistance furnace to be 800°C. When the crucible temperature rose to 400°C, add magnesium ingots accounting for 55.0% of the total mass percentage of raw materials and zinc ingots accounting for 40.0% of the total mass percentage of raw materials to the crucible. And start to pass CO with a volume ratio of 100:1 2 / SF 6 The mixed gas is used as a shielding gas, and the temperature continues to rise. After the magnesium ingot and the zinc ingot in the crucible are completely melted, add yttrium ingot accounting for 4.9% of the total mass percentage of raw materials, and stir for 2 minutes after the yttrium ingot is completely melted. In the Mg-Zn-Y alloy melt, add the carbon powder that accounts for 0.1% of the mass percentage of the total amount of raw materials and be 200 mesh carbon powder, and the raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com