Abrasive particle abrasion pretreatment method for preparing compact passivation film on stainless steel surface

A technology of abrasive wear and stainless steel, applied in the direction of surface polishing machine tools, abrasives, manufacturing tools, etc., can solve problems affecting the integrity of the surface passivation film, secondary scratches, surface wear, etc., to achieve good processing sharpness, Prevents scratches and improves corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

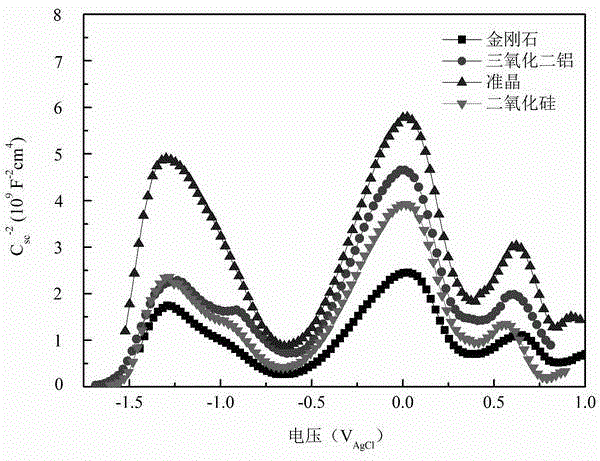

[0018] Example 1: AlCuFe Quasicrystalline Abrasive Wear Pretreatment

[0019] Step 1. Preparation of Alloy

[0020] According to Al 62 Cu 25.5 Fe 12.5 The atomic percentage is used for batching, and the raw materials are placed in a water-cooled copper mold for repeated melting by a non-consumable arc to prepare an alloy ingot with a uniform composition;

[0021] Step 2, preparation of quasicrystals with a purity greater than 50%

[0022] The alloy ingot in step 1 was annealed in vacuum at 800°C for 8 hours, and then air-cooled to obtain a high-purity icosahedral quasicrystalline single-phase alloy. The quasicrystalline characteristic peak and its quasicrystalline phase content were determined to be greater than 75% by X-ray diffraction testing technology;

[0023] Step 3. Flour making

[0024] Put the high-purity quasi-crystalline ingot in step 2 into a planetary ball mill, under the protection of argon, set the speed at 250r / min, ball mill for 8 hours, and then sieve wi...

Embodiment 2

[0036] Example 2: AlCuCo Quasicrystalline Abrasive Wear Pretreatment

[0037] Step 1. Preparation of Alloy

[0038] According to Al 65 Cu 20 co 15The atomic percentage is used for batching, and the raw materials are placed in a water-cooled copper mold for repeated melting by a non-consumable arc to prepare an alloy ingot with a uniform composition;

[0039] Step 2, preparation of quasicrystals with a purity greater than 50%

[0040] The alloy ingot in step 1 was annealed in vacuum at 850°C for 12 hours, and then air-cooled to obtain a high-purity icosahedral quasicrystalline single-phase alloy. The quasicrystalline characteristic peak and its quasicrystalline phase content were determined to be greater than 90% by X-ray diffraction testing technology;

[0041] Step 3. Flour making

[0042] Put the high-purity quasi-crystalline ingot in step 2 into a planetary ball mill, under the protection of argon, set the speed at 350r / min, ball mill for 18 hours, and then sieve with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com