High-strength magnesium alloy and process for production thereof

A manufacturing method and technology for magnesium alloys, applied in the field of high-strength magnesium alloys, can solve problems such as cost increase, and achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the present invention, the final composition of the whole alloy is Mg-Zn-Zr magnesium alloy with the composition shown in Table 1, and the metal structure observation and tensile test are carried out.

[0040] (1) Fabrication of quasicrystals

[0041] Weigh out pure Mg (99.9%), pure Zn (99.99%), pure Zr (99.5%) each metal (the numerical value in parentheses represents purity), so that form Mg by at% ratio 11 Zn 83 Zr 6 The quasi-crystal composition, the total amount is 5g, put into a Taman tube (Ф12mm×10mm) made of alumina, and then seal it in a quartz tube. The interior of the quartz tube is replaced with high-purity argon.

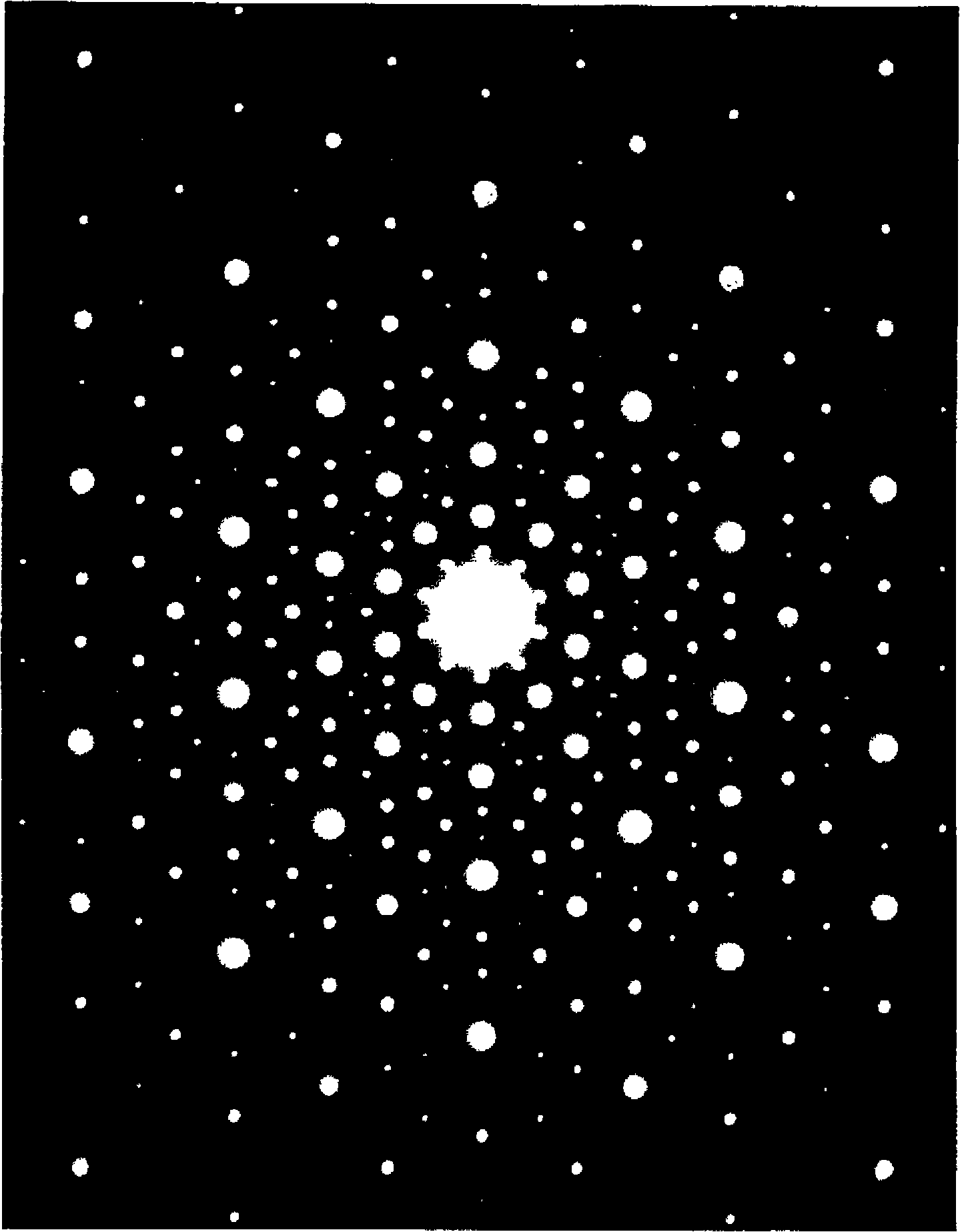

[0042] The temperature was raised from room temperature to 700° C. over 5 hours, kept for 12 hours, then lowered to 500° C. and kept for 48 hours. Thus, the Mg 11 Zn 83 Zr 6 quasicrystal. Such as figure 1 As shown in the electron diffraction pattern of , the typical 5-fold symmetry can be confirmed.

[0043] The resulting ma...

Embodiment 2

[0059] According to the present invention, the final composition of the alloy as a whole is made as a Mg-Zn-Ti magnesium alloy with the composition shown in Table 1, and the alloy metal structure observation and tensile test are carried out.

[0060] In addition to making Mg 11 Zn 83 Ti 6 As a quasi-crystal and added to the pure Mg melt, the rest are produced in the same order as in Example 1.

[0061] After heat treatment, fine precipitates of tens of nanometers were observed in the α-Mg crystal grains in the form of white dots through a transmission electron microscope. Confirm that the precipitate is Mg 11 Zn 83 Ti 6 Quasicrystals and their near crystals.

[0062] Tensile tests were performed under the same conditions as in Example 1 for the samples after the heat treatment and the samples extruded under the same conditions as in Example 1.

[0063] In addition, the tensile test was similarly performed on the comparative material whose composition was outside the sco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com