Large-diameter flux-cored wire for revolving body or wear-resistant composite board overlaying welding

A technology of flux-cored welding wire and composite plate, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve problems such as easy moisture absorption, and achieve the effect of improving moisture absorption resistance, uniform distribution and productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

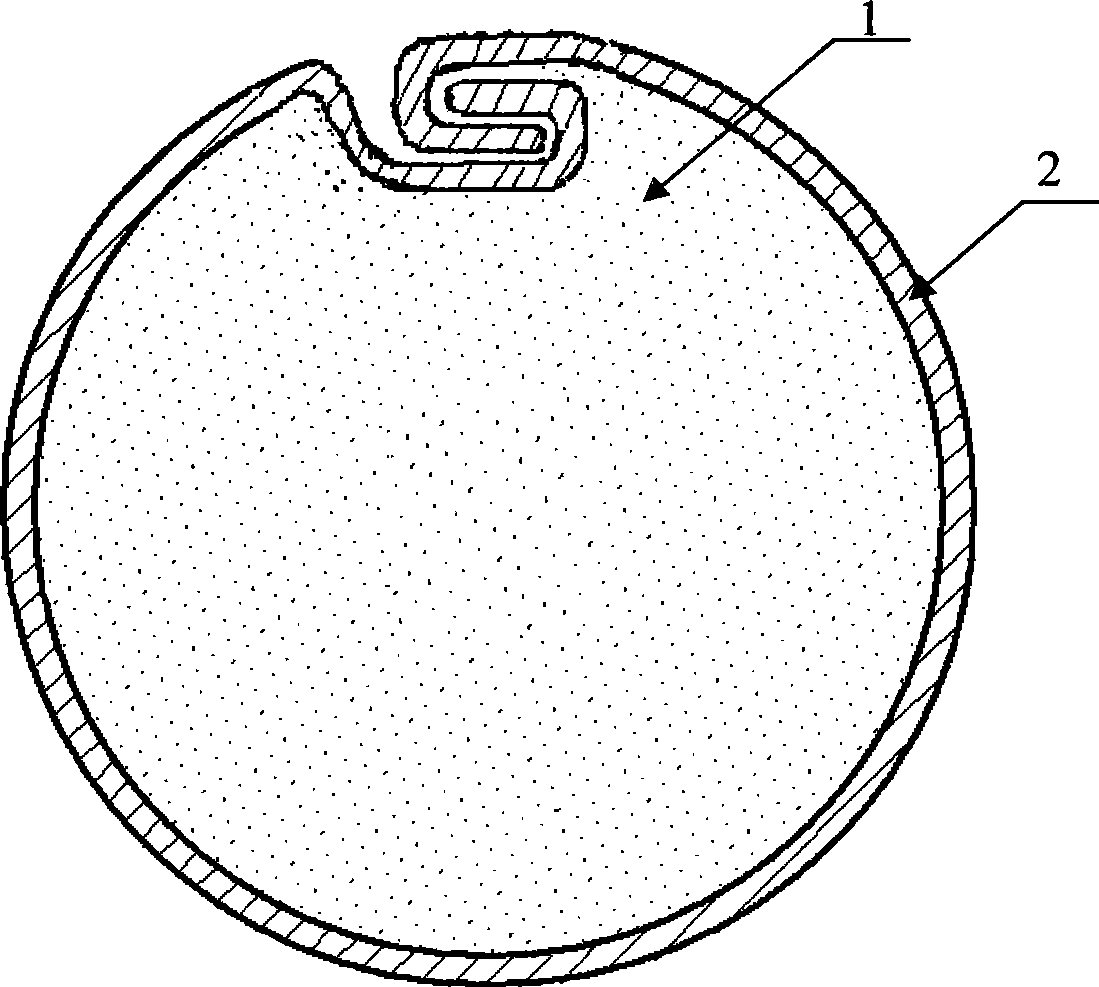

[0055] (1) Choose a commercially available H08A steel strip with a wall thickness of 0.4mm and a width of 35mm, and use conventional steel-making cored wire production equipment to roll it into a U-shaped cross-section along the length of the strip (longitudinal);

[0056] (2) Add medicinal powder to the above U-shaped grain with a filling rate of 50% (the filling rate is the ratio of the mass of the medicinal powder to the sum of the mass of the medicinal powder and the steel strip), wherein: the particle size of the medicinal powder is -50~+200 mesh, The powder composition is calculated in parts by weight, including 60 parts high-carbon ferrochromium, 9 parts ferro-vanadium, 4 parts 75# ferrosilicon, 1 part silicon-calcium alloy, 1 part high-carbon ferromanganese, 3 parts aluminum-magnesium alloy, 5 parts boron iron , 4 parts of ferro-titanium, 6 parts of ferromolybdenum, 1 soda ash, 2 rutile.

[0057] The above-mentioned medicinal powder is applied after mixing the powder with ...

Embodiment 2

[0065] (1) Choose a commercially available H08A steel strip with a wall thickness of 0.45mm and a width of 32mm, and use conventional steel-making cored wire production equipment to roll it into a U-shaped cross-section along the length of the strip (longitudinal);

[0066] (2) Add medicinal powder to the above U-shaped grain with a filling rate of 52% (the filling rate is the ratio of the mass of the medicinal powder to the sum of the mass of the medicinal powder and the steel strip), wherein: the particle size of the medicinal powder is -50~+200 mesh, The powder composition is calculated in parts by weight, including 68 parts of high-carbon ferrochromium, 10 parts of ferro-vanadium, 2 parts of 75# ferrosilicon, 2 parts of silicon-calcium alloy, 1 part of high-carbon ferromanganese, 2 parts of aluminum-magnesium alloy, 12 parts of boron iron , 3 parts of ferro-titanium, 3 parts of ferromolybdenum, 4 parts of graphite, 1 part of rutile.

[0067] The above medicinal powder is appli...

Embodiment 3

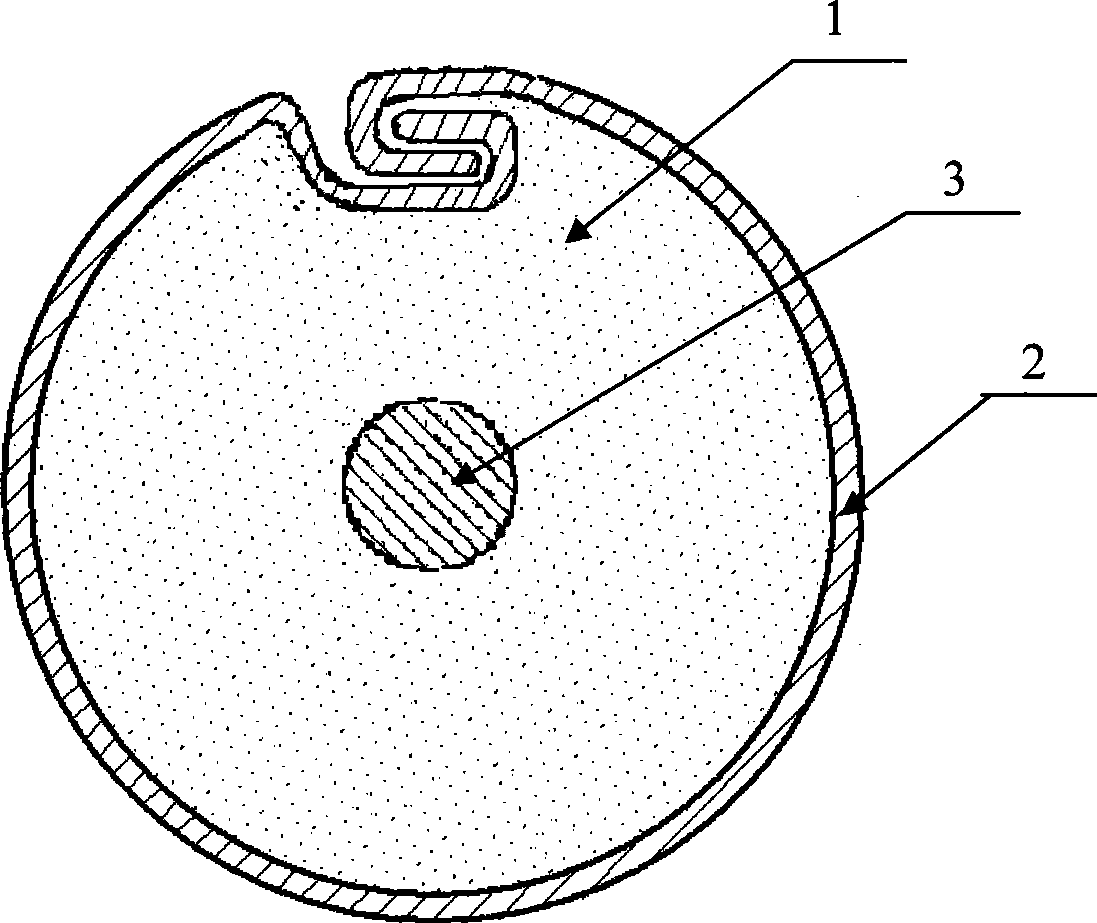

[0074] (1) Choose a commercially available H08A steel strip with a wall thickness of 0.45mm and a width of 35mm, and use conventional steel-making cored wire production equipment to roll it into a U-shaped cross-section along the length of the strip (longitudinal);

[0075] (2) Add medicinal powder to the above U-shaped grain with a filling rate of 45% (the filling rate is the ratio of the mass of the medicinal powder to the sum of the mass of the medicinal powder, steel strip and steel wire), wherein: the particle size of the medicinal powder is -50~ +200 mesh, the powder composition is calculated in parts by weight, including 2 parts high-carbon ferrochrome, 15 parts metallic chromium, 5 parts ferro-vanadium, 1 part 75# ferrosilicon, 2 parts high-carbon ferromanganese, 2 parts aluminum-magnesium alloy, 1 part Parts of ferro-titanium, 1 part of ferromolybdenum, 1 part of metallic nickel, 30 parts of iron powder, 2 parts of rutile.

[0076] The above-mentioned medicinal powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com