Solar cell conductive slurry and preparation method thereof

A technology of solar cells and conductive paste, which is applied to conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials, and can solve problems such as leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

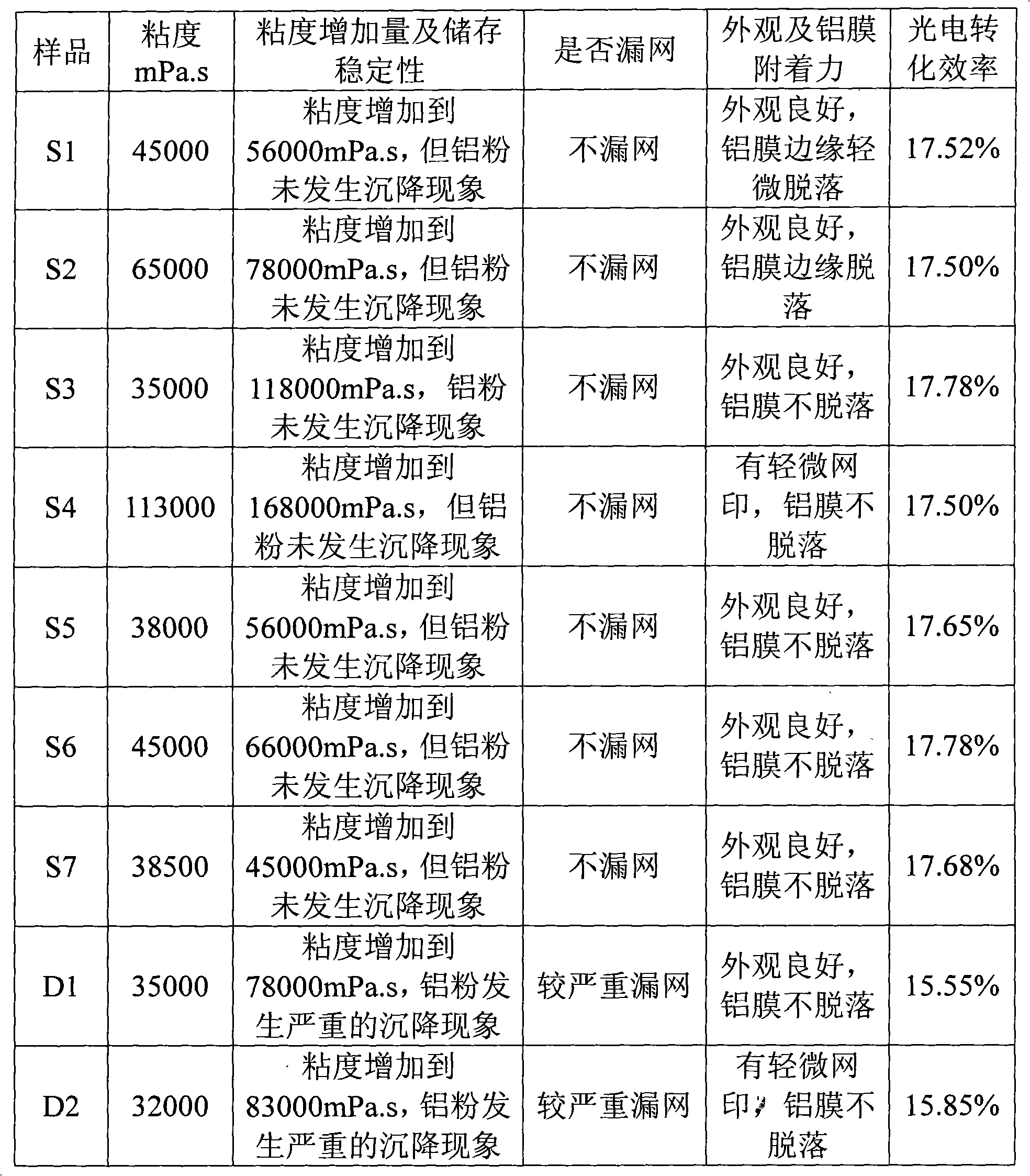

Examples

preparation example Construction

[0026] The invention also discloses a preparation method of the solar battery conductive paste, comprising: mixing the above-mentioned primary aluminum powder, secondary aluminum powder, glass powder and an organic carrier, and ball milling.

[0027] Preferably, the specific steps can be as follows: first mix the primary aluminum powder and secondary aluminum powder to obtain mixed aluminum powder; then mix the mixed aluminum powder with glass powder and organic carrier, and ball mill.

[0028] More specifically, the above-mentioned mixing of the mixed aluminum powder, glass powder and organic carrier is as follows: the organic carrier is placed in the stainless steel tank of the high-speed disperser, and the glass powder is added while stirring, and stirred well; then the mixed aluminum powder is divided into 2- 3 times into the mixture of glass powder and organic vehicle. Stir well after each addition, and then add the next time; after all the addition, stir well at high spe...

Embodiment 1

[0033] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0034] 1. Configuration of organic carrier

[0035] Based on the total weight of the organic vehicle to be prepared, get 39 parts by weight of terpineol, 45 parts by weight of dibutyl phthalate (DBP), mix uniformly, and dissolve 16 parts by weight of ethyl cellulose In the above mixed solvent, heat to 45°C to fully dissolve it, and stir evenly to obtain a uniform and clear organic vehicle A1.

[0036] 2. Preparation of solar cell conductive paste

[0037] Taking the total weight of the solar cell conductive paste required to be prepared as a benchmark, get 30 parts by weight of the organic carrier A1 and place it in the stainless steel tank of the high-speed disperser, add 4 parts by weight of glass powder (Southern Foshan, Guangdong) under the condition of stirring Glass powder produced by Glaze Co., Ltd., median particle size D 50 5um,...

Embodiment 2

[0041] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0042] 1. Configuration of organic carrier

[0043] Based on the total weight of the organic vehicle to be prepared, 42 parts by weight of butyl carbitol and 40 parts by weight of butyl glycol ether are mixed uniformly, and 12 parts by weight of ethyl cellulose, 6 parts by weight of P-tert-butylphenol formaldehyde resin (2402 resin produced by Shanghai Nanda Chemical Factory) was dissolved in the above mixed solvent, heated to 45° C. to fully dissolve, and stirred evenly to obtain a uniform and clear organic carrier A2.

[0044] 2. Preparation of solar cell conductive paste

[0045] Based on the total weight of the solar cell conductive paste required to be prepared, get 20 parts by weight of the organic carrier A2 and place it in the stainless steel tank of the high-speed disperser, and add 10 parts by weight of glass powder (Southern Fos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com