A kind of conductive paste for solar cell and preparation method thereof

A solar cell and conductive paste technology, applied in the field of solar cells, can solve problems such as unsatisfactory photoelectric conversion efficiency of cells, difficulty in agglomeration and settlement, and unstable paste, so as to achieve good appearance and inhibit the adhesion of aluminum film and electrodes Reduced and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

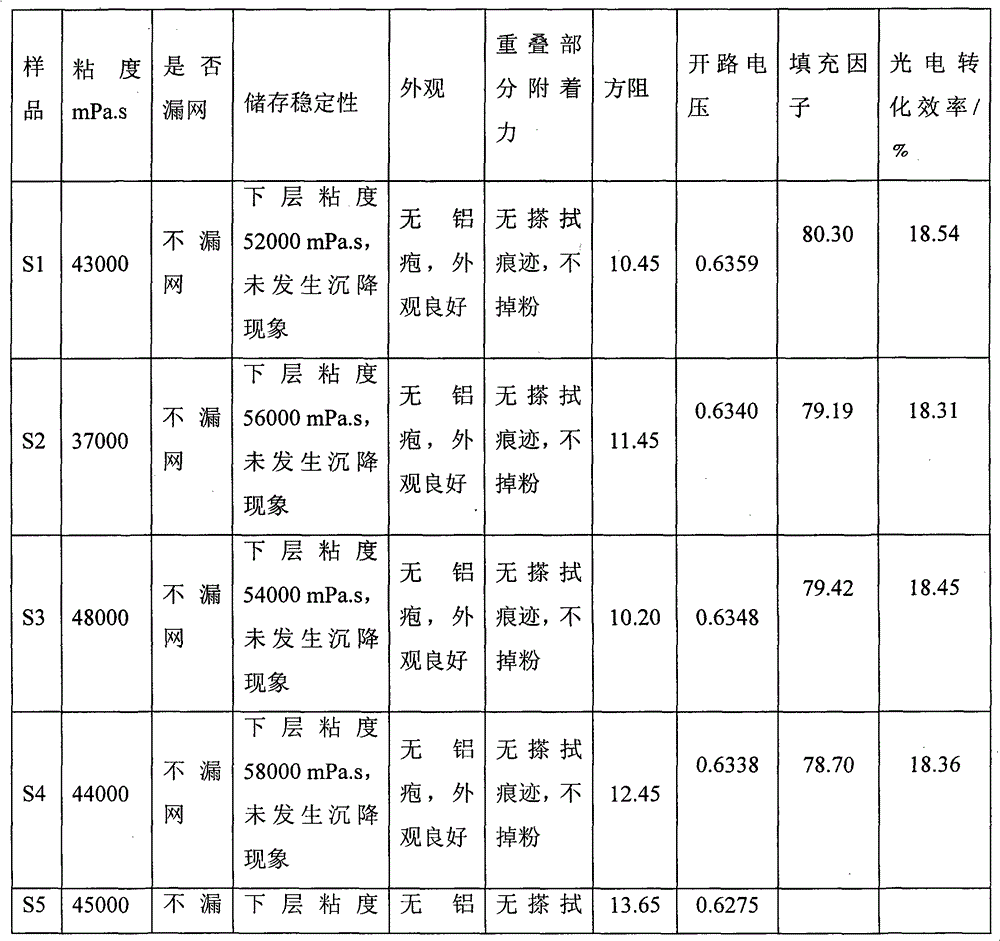

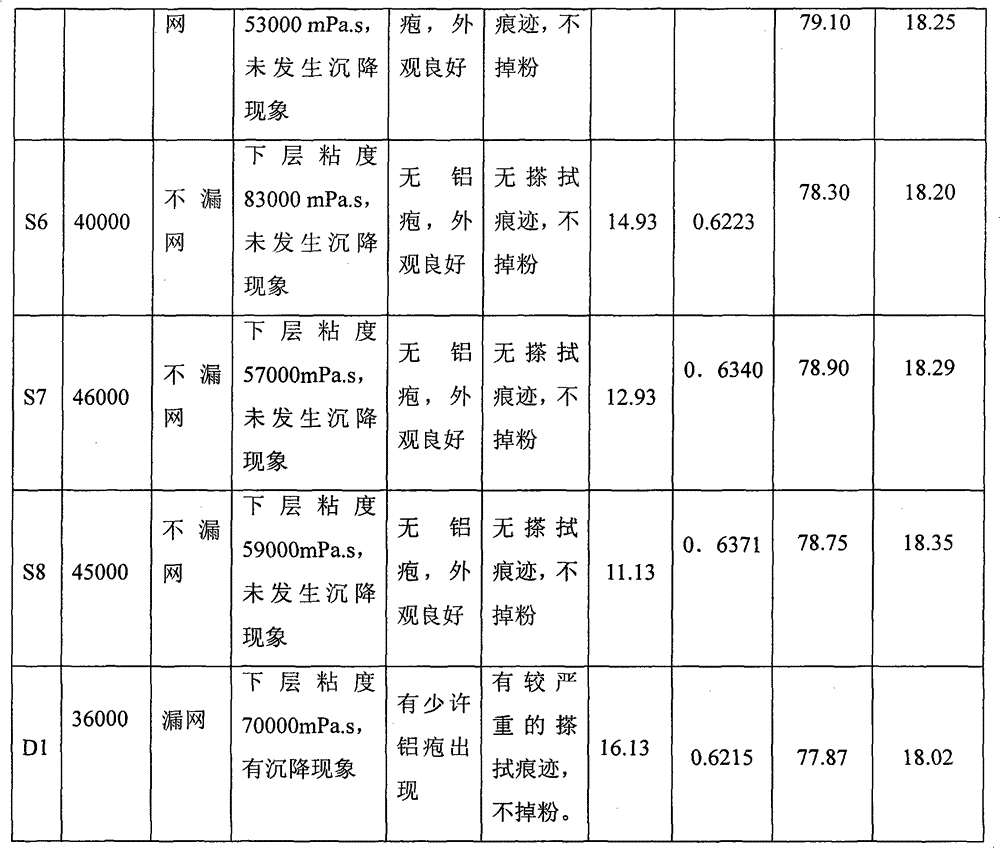

Examples

preparation example Construction

[0023] The present invention simultaneously provides a method for preparing a conductive paste for solar cells, the steps comprising:

[0024] A, adopting the chemical reduction deposition method to prepare the core material is a glass powder, and the shell material is a nano-metal-glass composite powder of metal;

[0025] B. Add the nanometer metal-glass composite powder obtained in step A, inorganic binder and aluminum powder into the organic carrier and mix well. The method is simple and easy to implement, and can prepare nanometer metal-glass composite powder with uniform particles. At the same time, the prepared conductive paste is stable and easy to store, is not easy to slip through the net, is conducive to transportation, storage and use, and is easy to process.

[0026] The step of the chemical reduction deposition method of step A of the present invention can comprise:

[0027] S1, mixing the glass powder with the metal compound solution;

[0028] S2. After slowly ad...

Embodiment 1

[0046] A. Preparation of nanometer metal-glass composite powder:

[0047] (1) Take 85 grams of AgNO 3 1 liter of solution prepared with deionized water, and 85 grams of complexing agent citric acid and 2.55 grams of dispersing agent polyvinylpyrrolidone (PVP) were added thereto to form an oxidation solution of silver element.

[0048] (2) Get lead-free nano-glass powder (produced by South Korean SEG company, median diameter D) composed of Bi-Zn-Si system 50 Mix 85 grams of 80nm) and 850 grams of deionized water in a reaction kettle, ultrasonically disperse for 10 minutes, heat in a water bath to 80°C while stirring rapidly, and add silver element oxidation solution to the reaction system to form a silver oxidation system containing glass powder.

[0049] (3) Add the hydrazine hydrate solution with a concentration of 50% by weight dropwise in the oxidation system of the reaction kettle, perform high-shear dispersion and ultrasonic emulsification for 2 hours, age to make the na...

Embodiment 2

[0058] The same method as in Example 1 was used to prepare nanometer metal-glass composite powder and conductive paste. The difference is that the reducing agent solution used in step A (3) is a glucose solution with a concentration of 50% by weight, and simultaneously contains 3.0 grams of polyvinylpyrrolidone (PVP) dispersant. Prepare solar cell back field aluminum conductive paste S2.

[0059] Adopt the method identical with embodiment 1 to measure the median diameter D of nanometer silver-glass composite powder 50 is 450.8nm, and the BET specific surface area is 184.4m 2 / g, the silver content is 26.8wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com